Nanoscale Doping and Its Impact on the Ferroelectric and Piezoelectric Properties of Hf0.5Zr0.5O2

Abstract

:1. Introduction

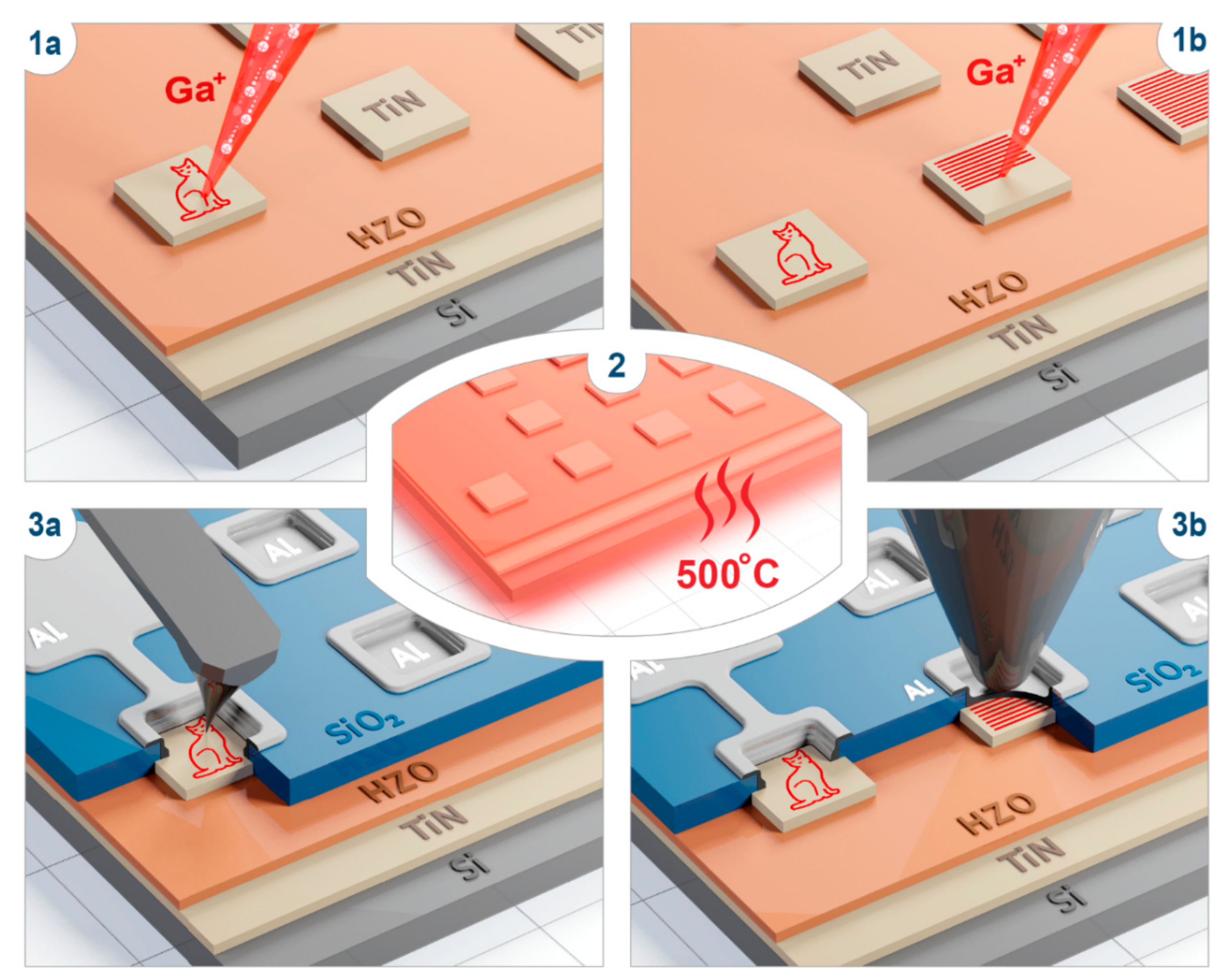

2. Materials and Methods

3. Results and Discussion

3.1. Ferroelectric Properties of Ga-Doped HZO Capacitors

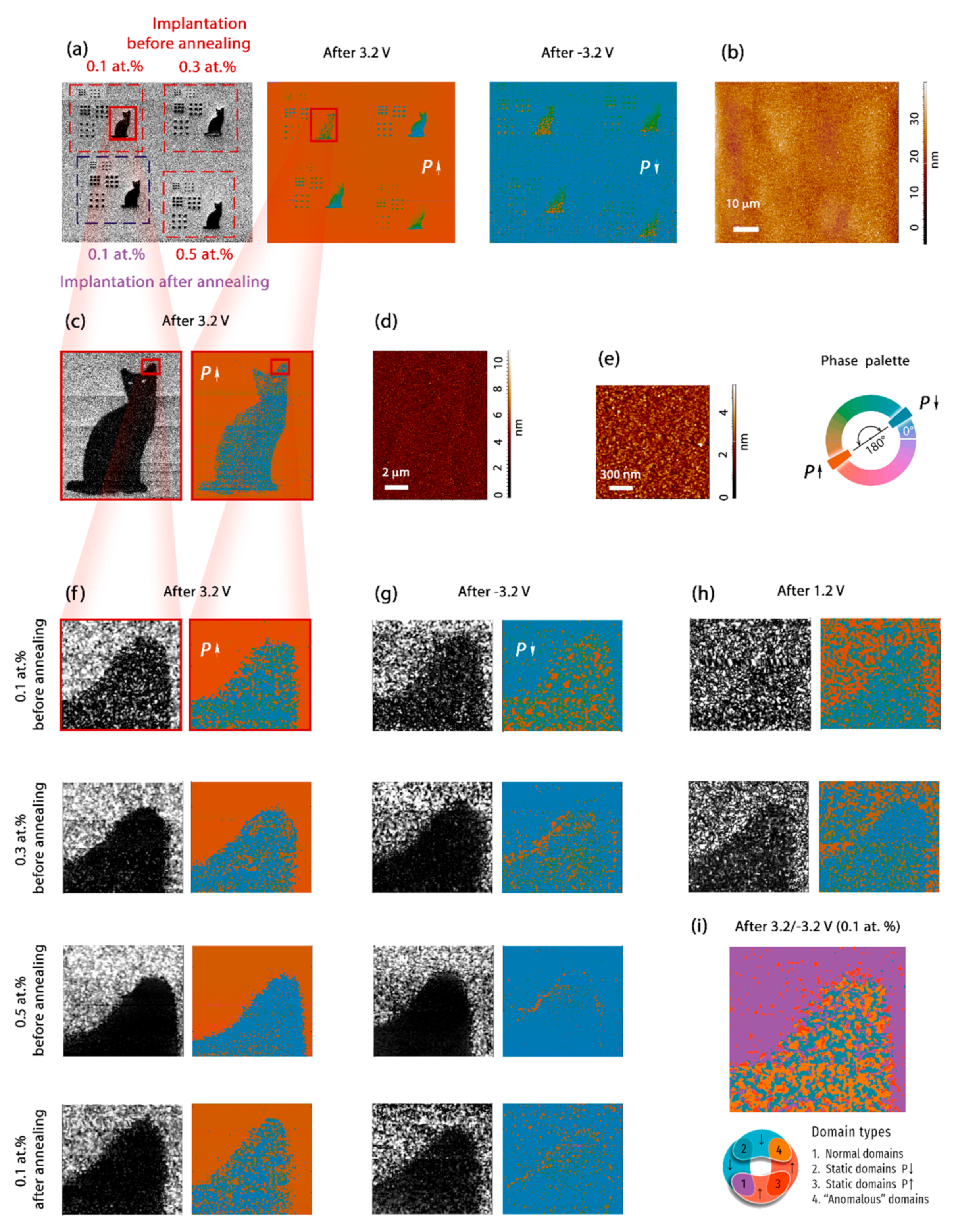

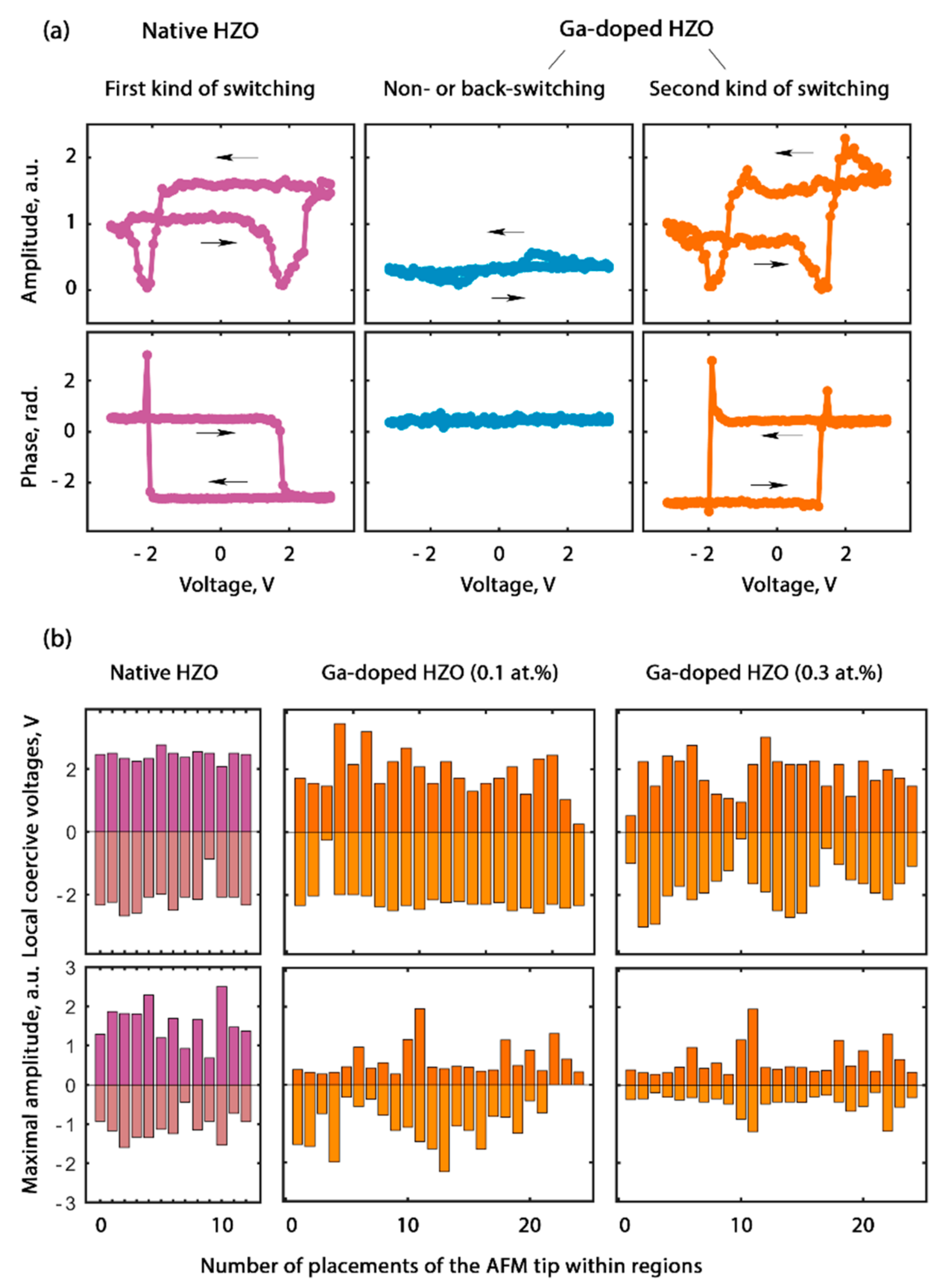

3.2. Local Ferroelectric and Piezoelectric Properties of Native and Doped HZO

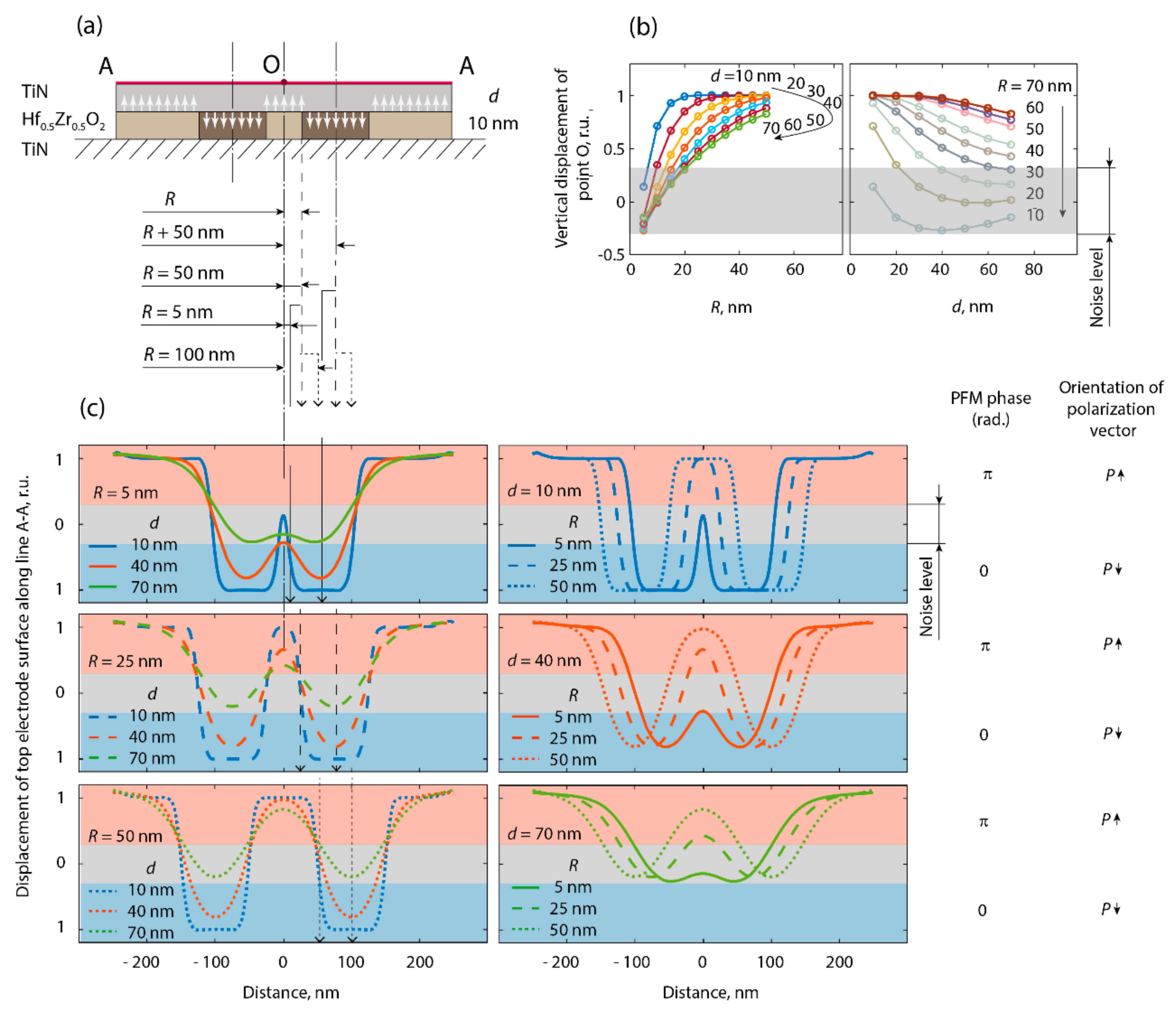

3.2.1. Qualitative Analysis of the Magnitude of the Piezoresponse Determined by the Local Piezoelectric Coefficient

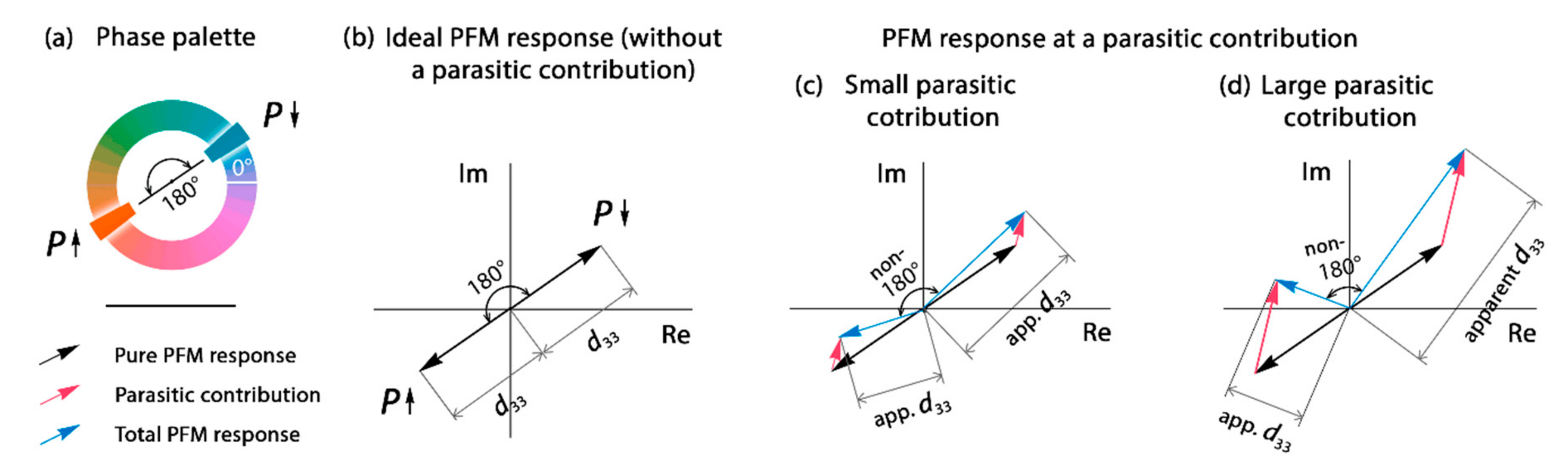

3.2.2. Sign of the Piezoresponse Determined either by the Orientation of the Vertical Component of the Polarization Vector or the Sign of the Piezoelectric Coefficient

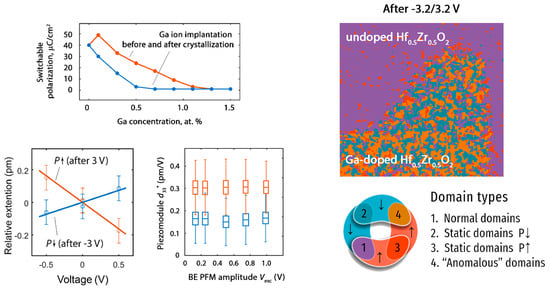

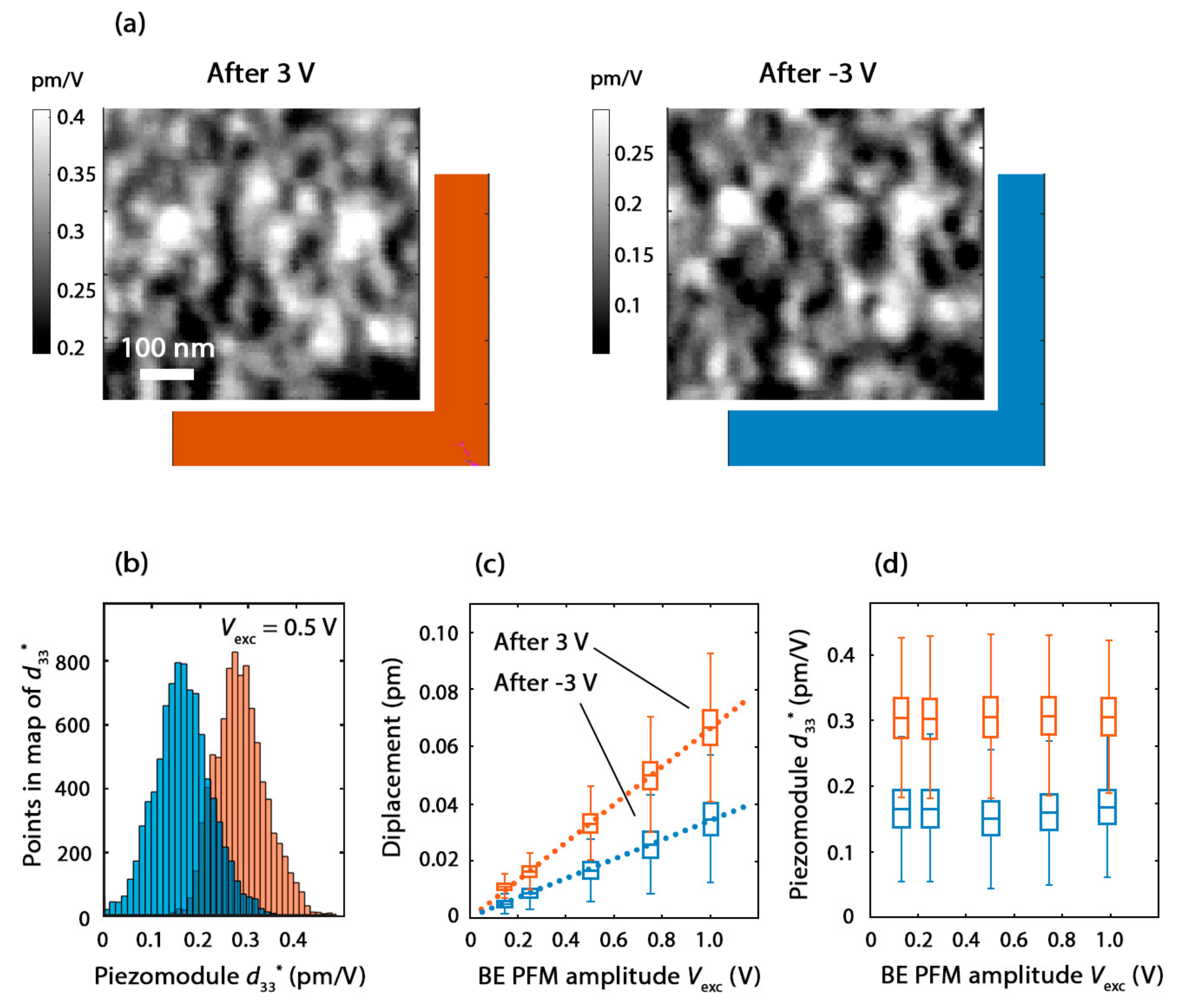

3.3. Quantitative Measurement of the Magnitude and Sign of the Piezoelectric Coefficient

3.3.1. The Piezoelectric Coefficient Measured by Means of In Situ Synchrotron X-ray Microdiffractometry

3.3.2. The Piezoelectric Coefficient Measured by Means of BE PFM

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Böscke, T.S.; Müller, J.; Brauhaus, D.; Schröder, U.; Böttger, U. Ferroelectricity in Hafnium Oxide Thin Films. Appl. Phys. Lett. 2011, 99, 102903. [Google Scholar] [CrossRef]

- Chouprik, A.; Negrov, D.; Tsymbal, Y.; Zenkevich, A. Defects in ferroelectric HfO2. Nanoscale 2021, 13, 11635–11678. [Google Scholar] [CrossRef] [PubMed]

- Ghatge, M.; Walters, G.; Nishida, T.; Tabrizian, R. A Nano-Mechanical Resonator with 10 nm Hafnium-Zirconium Oxide Ferroelectric Transducer. In Proceedings of the 2018 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018. [Google Scholar]

- Ghatge, M.; Walters, G.; Nishida, T.; Tabrizian, R. A 30-nm Thick Integrated Hafnium Zirconium Oxide Nano-Electro-Mechanical Membrane Resonator. Appl. Phys. Lett. 2020, 116, 043501. [Google Scholar] [CrossRef]

- Celano, U.; Gomez, U.; Piedimonte, P.; Neumayer, S.; Collins, L.; Popovici, M.; Florent, K.; McMitchell, S.R.C.; Favia, P.; Drijbooms, C.; et al. Ferroelectricity in Si-Doped Hafnia: Probing Challenges in Absence of Screening Charges. Nanomaterials 2020, 10, 1576. [Google Scholar] [CrossRef] [PubMed]

- Starschich, S.; Schenk, T.; Schroeder, U.; Boettger, U. Ferroelectric and Piezoelectric Properties of Hf1−xZrxO2 and Pure ZrO2 Films. Appl. Phys. Lett. 2017, 110, 182905. [Google Scholar] [CrossRef]

- Kirbach, S.; Lederer, M.; Eßlinger, S.; Mart, C.; Czernohorsky, M.; Weinreich, W.; Wallmersperger, T. Doping Concentration Dependent Piezoelectric Behavior of Si:HfO2 Thin-Films. Appl. Phys. Lett. 2021, 118, 012904. [Google Scholar] [CrossRef]

- Mart, C.; Kämpfe, T.; Hoffmann, R.; Eßlinger, S.; Kirbach, S.; Kühnel, K.; Czernohorsky, M.; Eng, L.M.; Weinreich, W. Piezoelectric Response of Polycrystalline Silicon-Doped Hafnium Oxide Thin Films Determined by Rapid Temperature Cycles. Adv. Electron. Mater. 2020, 6, 1901015. [Google Scholar] [CrossRef]

- Falkowski, M.; Kersch, A. Optimizing the Piezoelectric Strain in ZrO2- and HfO2-Based Incipient Ferroelectrics for Thin-Film Applications: An Ab Initio Dopant Screening Study. ACS Appl. Mater. Interfaces 2020, 12, 32915. [Google Scholar] [CrossRef]

- Glinchuk, M.D.; Morozovska, A.N.; Lukowiak, A.; Stręk, W.; Silibin, M.V.; Karpinsky, D.V.; Kim, Y.; Kalinin, S.V. Possible Electrochemical Origin of Ferroelectricity in HfO2 Thin Films. J. Alloys Compd. 2020, 830, 153628. [Google Scholar] [CrossRef] [Green Version]

- Nukala, P.; Ahmadi, M.; Wei, Y.; de Graaf, S.; Stylianidis, E.; Chakrabortty, T.; Matzen, S.; Zandbergen, H.W.; Björling, A.; Mannix, D.; et al. Reversible Oxygen Migration and Phase Transitions in Hafnia-Based Ferroelectric Devices. Science 2021, 372, 630. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, B.; Sun, B.; Chen, G.; Zeng, L.; Liu, L.; Liu, X.; Lu, J.; Han, R.; Kang, J.; et al. Ionic Doping Effect in ZrO2 Resistive Switching Memory. Appl. Phys. Lett. 2010, 96, 123502. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, B.L.; Wang, S.Y.; Lu, H.B.; Zhou, Y.L.; Chen, Z.H.; Yang, G.H. Effects of oxygen pressure on lattice parameter, orientation, surface morphology and deposition rate of (Ba0.02Sr0.98)TiO3 thin films grown on MgO substrate by pulsed laser deposition. Thin Solid Films 2005, 485, 82–89. [Google Scholar] [CrossRef]

- Lee, D.; Yoon, A.; Jang, S.Y.; Yoon, J.-G.; Chung, J.-S.; Kim, M.; Scott, J.F.; Noh, T.W. Giant Flexoelectric Effect in Ferroelectric Epitaxial Thin Films. Phys. Rev. Lett. 2011, 107, 057602. [Google Scholar] [CrossRef] [PubMed]

- Dutta, S.; Buragohain, P.; Glinsek, S.; Richter, C.; Aramberri, H.; Lu, H.; Schroeder, U.; Defay, E.; Gruverman, A.; Íñiguez, J. Piezoelectricity in hafnia. Nat. Commun. 2021, 12, 7301. [Google Scholar] [CrossRef] [PubMed]

- Kunneth, C.; Batra, R.; Rossetti, G.A., Jr.; Ramprasad, R.; Kersch, A. Chapter 6—Thermodynamics of Phase Stability and Ferroelectricity from First Principles. In Ferroelectricity in Doped Hafnium Oxide: Materials, Properties and Devices; Woodhead Publishing: Cambridge, UK, 2019; p. 245. [Google Scholar]

- Chouprik, A.; Kirtaev, R.; Spiridonov, M.; Markeev, A.M.; Negrov, D. Nanoscale Tailoring of Ferroelectricity in a Thin Dielectric Film. ACS Appl. Mat. Interfaces 2020, 12, 56195. [Google Scholar] [CrossRef]

- Guberna, E.; Chouprik, A.; Kirtaev, R.; Zarubin, S.; Spiridonov, M.; Margolin, I.; Negrov, D. Local Ga Ion Implantation as a Source of Diverse Ferroelectric Properties of Hafnium Oxide. Phys. Status Solidi RRL 2022, 16, 2100485. [Google Scholar] [CrossRef]

- Kozodaev, M.G.; Chernikova, A.G.; Korostylev, E.V.; Park, M.H.; Khakimov, R.R.; Hwang, C.S.; Markeev, A.M. Mitigating wakeup effect and improving endurance of ferroelectric HfO2-ZrO2 thin films by careful La-doping. J. Appl. Phys. 2019, 125, 034101. [Google Scholar] [CrossRef]

- Shimizu, T.; Mimura, T.; Kiguchi, T.; Shiraishi, T.; Konno, T.J.; Katsuya, Y.; Sakata, O.; Funakubo, H. Ferroelectricity Mediated by Ferroelastic Domain Switching in HfO2-based Epitaxial Thin Films. Appl. Phys. Lett. 2018, 113, 212901. [Google Scholar] [CrossRef]

- Spiridonov, M.; Chouprik, A.; Mikheev, V.; Markeev, A.M.; Negrov, D. Band Excitation Piezoresponse Force Microscopy Adapted for Weak Ferroelectrics: On-the-Fly Tuning of the Central Band Frequency. Microsc. Microanal. 2021, 27, 326–336. [Google Scholar] [CrossRef]

- Balke, N.; Maksymovych, P.; Jesse, S.; Herklotz, A.; Tselev, A.; Eom, C.-B.; Kravchenko, I.I.; Yu, P.; Kalinin, S.V. Differentiating Ferroelectric and Nonferroelectric Electromechanical Effects with Scanning Probe Microscopy. ACS Nano 2015, 9, 6484–6492. [Google Scholar] [CrossRef]

- Chouprik, A.; Spiridonov, M.; Zarubin, S.; Kirtaev, R.; Mikheev, V.; Lebedinskii, Y.; Zakharchenko, S.; Negrov, D. Wake-Up in a HZO: A Cycle-By-Cycle Emergence of the Remnant Polarization via The Domain Depinning and the Vanishing of the Anomalous Polarization Switching. ACS Appl. Electron. Mater. 2019, 1, 275–287. [Google Scholar] [CrossRef]

- Schenk, T.; Hoffmann, M.; Ocker, J.; Peŝić, M.; Mikolajick, T.; Schroeder, U. Complex Internal Bias Fields in Ferroelectric Hafnium Oxide. ACS Appl. Mater. Interfaces 2015, 7, 20224. [Google Scholar] [CrossRef] [PubMed]

- Grimley, E.D.; Schenk, T.; Sang, X.; Pešić, M.; Schroeder, U.; Mikolajick, T.; LeBeau, J.M. Structural Changes Underlying Field Cycling Phenomena in Ferroelectric HfO2 Thin Films. Adv. Electron. Mater. 2016, 2, 1600173. [Google Scholar] [CrossRef]

- McGilly, L.J.; Sandu, C.S.; Feigl, L.; Damjanovic, D.; Setter, N. Nanoscale Defect Engineering and The Resulting Effects on Domain Wall Dynamics in Ferroelectric Thin Films. Adv. Funct. Mater. 2017, 27, 1605196. [Google Scholar] [CrossRef]

- Chouprik, A.; Zakharchenko, S.; Spiridonov, M.; Zarubin, S.; Chernikova, A.; Kirtaev, R.; Buragohain, P.; Gruverman, A.; Zenkevich, A.; Negrov, D. Ferroelectricity in Hf0.5Zr0.5O2 Thin Films: A Microscopic Study of the Polarization Switching Phenomenon and Field-Induced Phase Transformations. ACS Appl. Mater. Interfaces 2018, 10, 8818–8826. [Google Scholar] [CrossRef]

- Lederer, M.; Olivo, R.; Lehninger, D.; Abdulazhanov, S.; Kämpfe, T.; Kirbach, S.; Mart, C.; Seidel, K.; Eng, L.M. On the Origin of Wake-Up and Antiferroelectric-Like Behavior in Ferroelectric Hafnium Oxide. Phys. Status Solidi RRL 2021, 15, 2100086. [Google Scholar] [CrossRef]

- Chouprik, A.; Kondratyuk, E.; Mikheev, V.; Matveyev, Y.; Spiridonov, M.; Chernikova, A.; Kozodaev, M.G.; Markeev, A.M.; Zenkevich, A.; Negrov, D. Origin of the retention loss in ferroelectric Hf0.5Zr0.5O2-based memory devices. Acta Mater. 2021, 204, 116515. [Google Scholar] [CrossRef]

- Abplanalp, M.; Fousek, J.; Günter, P. Higher Order Ferroic Switching Induced by Scanning Force Microscopy. Phys. Rev. Lett. 2001, 86, 5799. [Google Scholar] [CrossRef]

- Edwards, D.; Brewer, S.; Cao, Y.; Jesse, S.; Chen, L.-Q.; Kalinin, S.V.; Kumar, A.; Bassiri-Gharb, N. Local Probing of Ferroelectric and Ferroelastic Switching through Stress-Mediated Piezoelectric Spectroscopy. Adv. Mater. Interfaces 2016, 3, 1500470. [Google Scholar] [CrossRef] [Green Version]

- de Jong, M.; Chen, W.; Geerlings, H.; Asta, M.; Aslaug Persson, K. A Database to Enable Discovery and Design of Piezoelectric Materials. Sci. Data 2015, 2, 150053. [Google Scholar] [CrossRef] [Green Version]

- Tan, G.; Maruyama, K.; Kanamitsu, Y.; Nishioka, S.; Ozaki, T.; Umegaki, T.; Hida, H.; Kanno, I. Crystallographic Contributions to Piezoelectric Properties in PZT Thin Films. Sci. Rep. 2019, 9, 7309. [Google Scholar] [CrossRef] [PubMed]

- Lübbe, J.; Temmen, M.; Rode, S.; Rahe, P.; Kühnle, A.; Reichling, M. Thermal noise Limit for Ultra-High Vacuum Noncontact Atomic Force Microscopy. Beilstein J. Nanotechnol. 2013, 4, 32–44. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vargas, A.L.M.; de Araújo Ribeiro, F.; Hübler, R. Changes in the Young Modulus of Hafnium Oxide Thin Films. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 365, 362–366. [Google Scholar] [CrossRef]

- Jesse, S.; Kalinin, S.V.; Proksch, R.; Baddorf, A.P.; Rodriguez, B.J. The Band Excitation Method in Scanning Probe Microscopy for Rapid Mapping of Energy Dissipation on the Nanoscale. Nanotechnology 2007, 18, 435503. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chouprik, A.; Kirtaev, R.; Korostylev, E.; Mikheev, V.; Spiridonov, M.; Negrov, D. Nanoscale Doping and Its Impact on the Ferroelectric and Piezoelectric Properties of Hf0.5Zr0.5O2. Nanomaterials 2022, 12, 1483. https://doi.org/10.3390/nano12091483

Chouprik A, Kirtaev R, Korostylev E, Mikheev V, Spiridonov M, Negrov D. Nanoscale Doping and Its Impact on the Ferroelectric and Piezoelectric Properties of Hf0.5Zr0.5O2. Nanomaterials. 2022; 12(9):1483. https://doi.org/10.3390/nano12091483

Chicago/Turabian StyleChouprik, Anastasia, Roman Kirtaev, Evgeny Korostylev, Vitalii Mikheev, Maxim Spiridonov, and Dmitrii Negrov. 2022. "Nanoscale Doping and Its Impact on the Ferroelectric and Piezoelectric Properties of Hf0.5Zr0.5O2" Nanomaterials 12, no. 9: 1483. https://doi.org/10.3390/nano12091483

APA StyleChouprik, A., Kirtaev, R., Korostylev, E., Mikheev, V., Spiridonov, M., & Negrov, D. (2022). Nanoscale Doping and Its Impact on the Ferroelectric and Piezoelectric Properties of Hf0.5Zr0.5O2. Nanomaterials, 12(9), 1483. https://doi.org/10.3390/nano12091483