3.1. Structural Investigations

The ribbons, either in their as-cast state or annealed, were investigated using XRD and Mössbauer spectrometry.

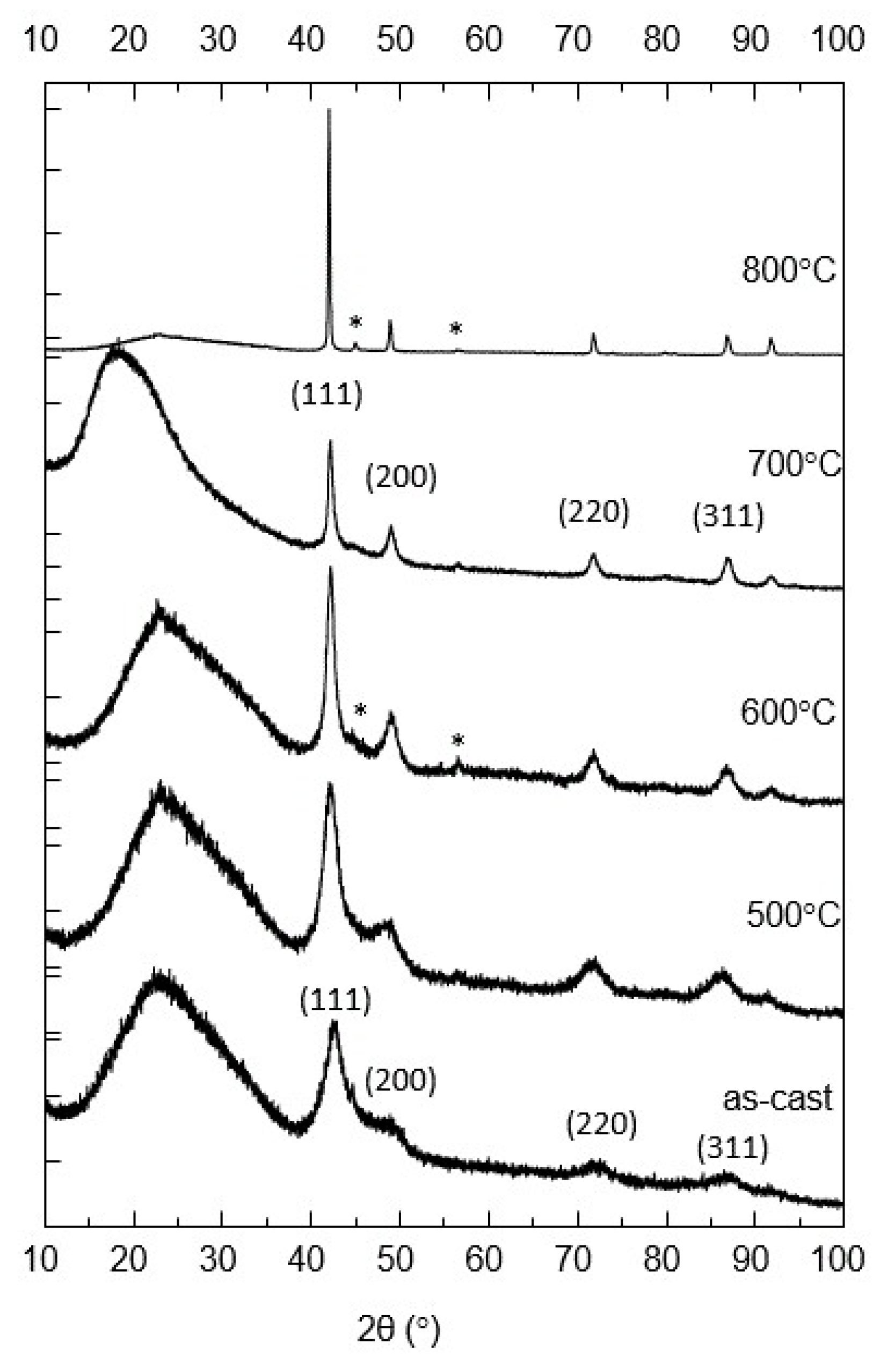

Figure 1 shows the X-ray diffractograms of the as-cast and annealed samples.

The diffractogram of the as-cast sample consists of several well-formed, very broad Bragg lines. These broad lines have been indexed as belonging to the face-centered cubic (fcc) A1 phase, their (hkl) assignation being shown on the graph. As proven by the lines broadening, the A1 fcc structure is quite disordered.

In order to correctly assess the observed Bragg reflections to the particular (hkl) planes of the A1 structure, full-profile analysis of the XRD patterns has been carried out using MAUD software (version 2.99, University of Trento, Italy). Bragg lines corresponding to the main reflections of the fcc phase were unambiguously identified thus proving that the structure of the as-cast sample has disordered fcc A1 symmetry. Based on the results of the MAUD fitting we have calculated, using the integral breadth approach [

16,

17,

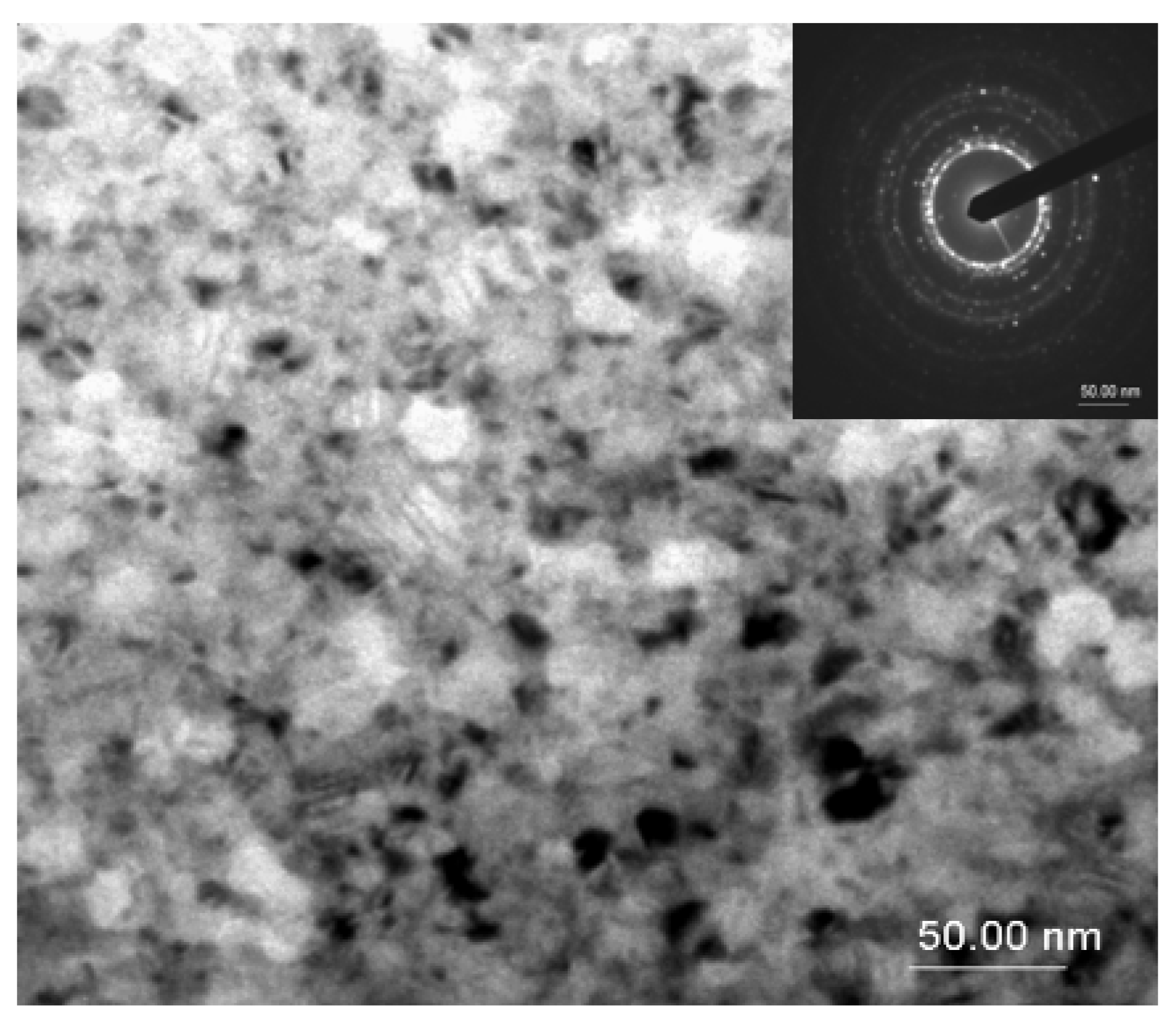

18], the crystallite size for all the Bragg peaks indexed in the fcc A1 system. Using the lattice parameters, FWHM, and mixing parameters of each Bragg reflection, the integral breadth method calculated the average crystallographically coherent domain size associated with the average size of the grains. Based on this approach, the mean grain size for the as-cast sample was found to be 3 ± 1 nm.

All the calculated lattice parameters as well as the average grain sizes for the as-cast and annealed samples are given in

Table 1.

For the sample annealed at 500 °C, the lines were narrower, the (200) reflection was better formed than in the case of the as-cast sample, but no additional Bragg peaks were observed. The broad line centered at around 25° is due to the glass sample holder and the glue used to hold the ribbons during measurements. This broad feature was preserved at all annealing temperatures, until 800 °C, where the intensity of the main Bragg peak was very high and the broad feature appears strongly diminished due to scaling. At 500 °C, the same A1 fcc broad line pattern was observed but line profiles were better formed with smaller linewidth than in the as-cast state.

At 600 °C the main lines of the fcc Fe3Pt phase were observed and the process of narrowing continued further, as expected. All the identified (hkl) reflections are shown on the graph. Starting at 600 °C, a small Bragg peak, attributed to the main Bragg reflection of the Fe2B tetragonal phase, began to be observed.

At 700 °C the lines of the fcc phase (the same fcc Fe3Pt and Fe2B phases being indexed in the XRD diagram) were even narrower, however, the intensities of the peaks attributed to the Fe2B phase were very weak. The XRD diagram at 800 °C shows a stronger narrowing of the Bragg reflections, corresponding to a sharp increase of the average grain size. The sample was completely crystallized and the fcc Fe3Pt and Fe2B are the only phases visible in the diagram.

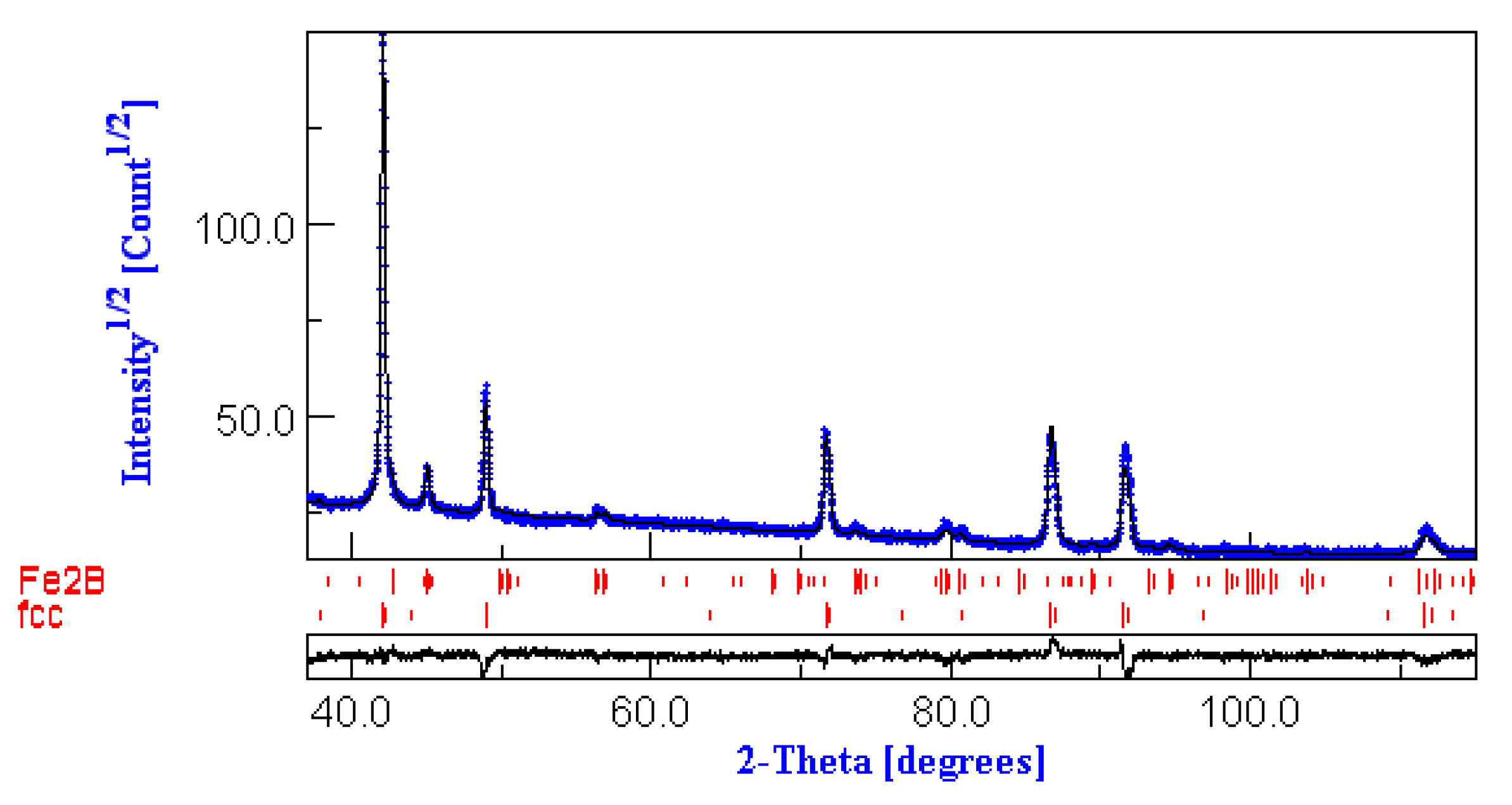

To prove the co-existence of the fcc Fe

3Pt and the fct Fe

2B in the sample annealed at 8000 °C and also to exemplify the goodness of the fit with the MAUD software, the fitting of the sample annealed at 800 °C is shown in

Figure 2. It can be seen that the experimental data in this diffractogram fits very well with the full-profile refinement fitting model. The analysis of the evolution of lattice parameters of the indexed phases and the average grain sizes derived from the fit of the XRD spectra, given in

Table 1, provide interesting insight into the phase evolution with annealing temperature.

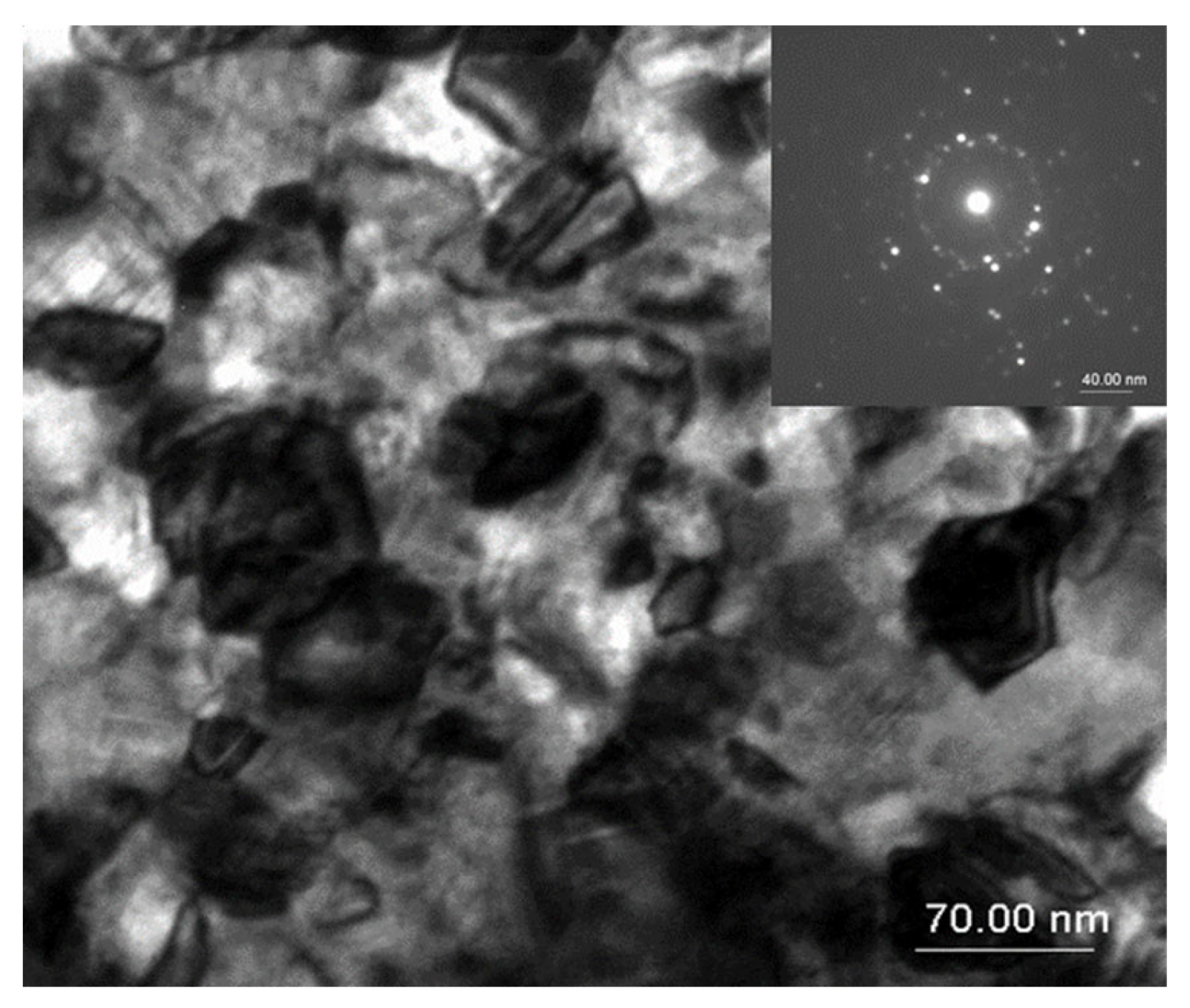

Firstly, it is worth mentioning the gradual crystallization of the sample, evidenced by the steady continuous increase of the grain size up to 700 °C. However, the average grain size at this annealing remained below 20 nm, proving a true nanocrystalline state. Then, at 800 °C the sample was fully crystallized, with large grain sizes of over 100 nm. There was thus a sharp increase of the average grain size from the case of 700 °C annealing (16 nm) to the case of 800 °C annealing (more than 100 nm). Such a drastic increase corroborates the fact that the mechanisms of crystallization may have switched from the primary crystallization (governed by nucleation) to the secondary crystallization (governed by the accelerated growth of the grains). It is obvious then that at 800 °C, annealing the crystallization process has been completed. Observing the evolution of the lattice parameter with the annealing temperature reveals another interesting aspect. It is seen that the lattice parameter of the fcc Fe3Pt phase increased slightly from the as-cast case, and above the annealing temperature of 600 °C, it remained constant up to the maximum annealing temperature of 800 °C. This proves a remarkable stability of the lattice which, associated with the grain growth observed during annealing, hints toward a grain microstructure that is homogeneous, with lesser crystal defects, even at the highest annealing temperature where the coarsening of the grain size becomes evident.

3.3. Mössbauer Analysis

The next structural investigation of the as-cast and annealed samples was performed using

57Fe Mössbauer spectrometry. All Mössbauer spectra were analyzed using Mosfit software [

19], a Lorentzian line-fitting program which allows the use of discrete distributions of hyperfine parameters corresponding to the different Fe chemical environments.

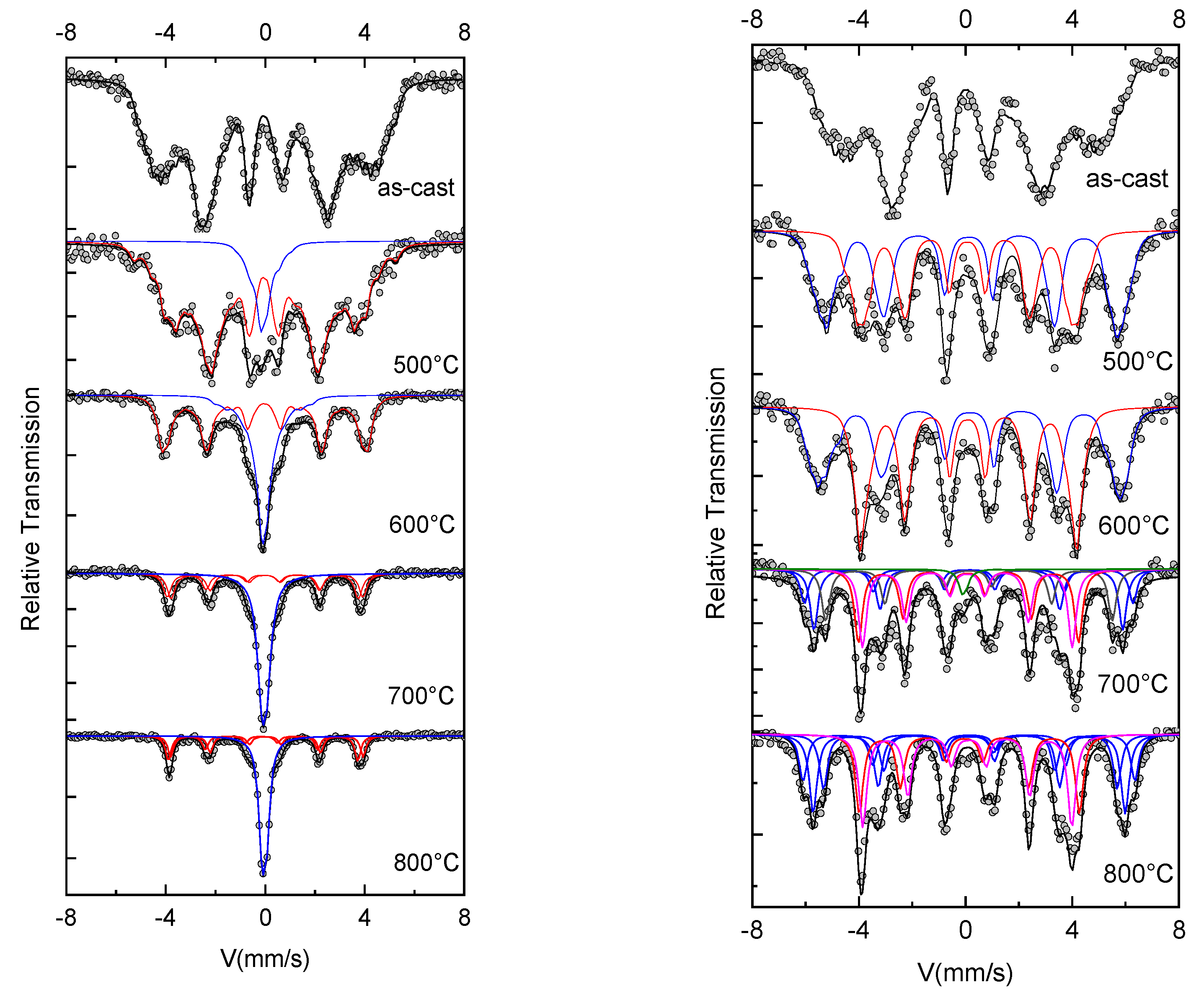

Figure 6 is showing all the 300 K and 77 K Mössbauer spectra together with their fitting, showing individual contributions. The results of the fitting, meaning the obtained hyperfine parameters, as well as the identification of each individual contribution to the Mössbauer spectra, are given in

Table 2.

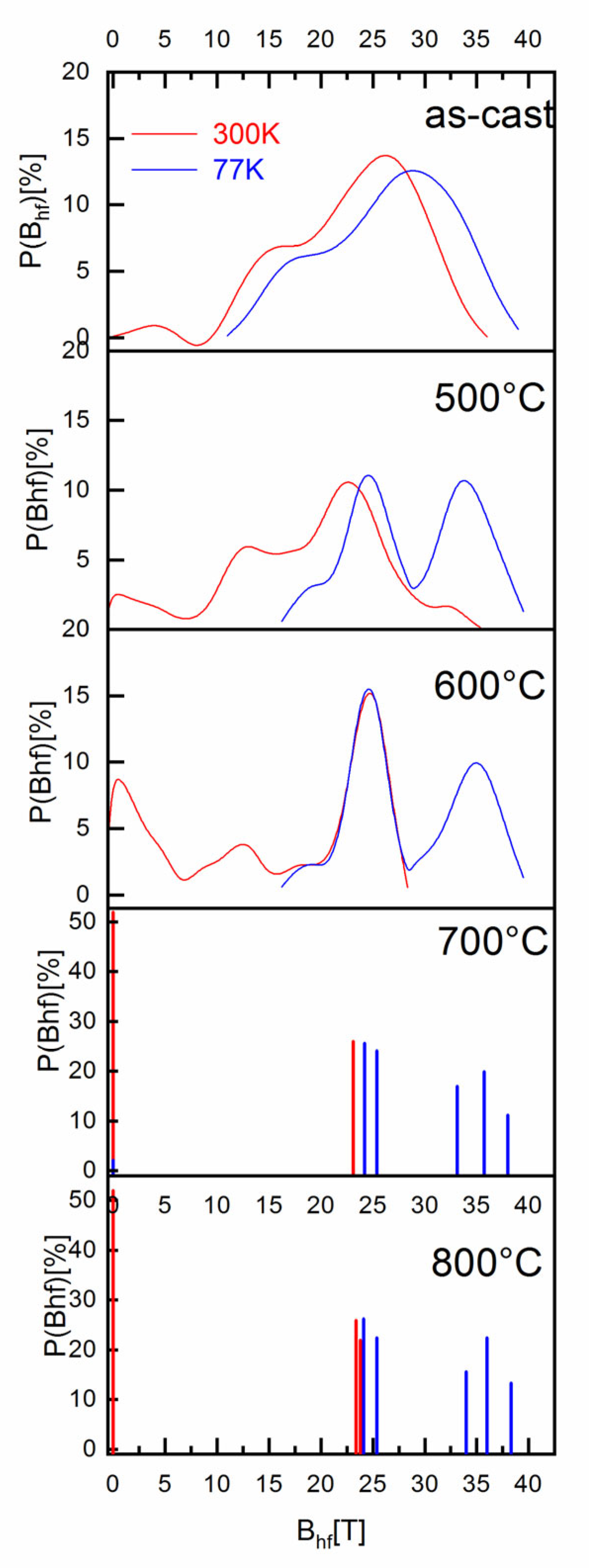

Figure 7 presents the as-obtained hyperfine field distributions for each of the Mössbauer spectra, as resulted from the fitting.

The Mössbauer spectrum for the as-cast sample (the top graphs) exhibits broad magnetic sextets, typical of distributed Fe environments encountered in Fe-rich amorphous ribbons. The shape of the spectra confirms the XRD results where an amorphous-like solid solution has been identified. The hyperfine field Bhf distributions derived from the fitting of the Mössbauer spectra show a bimodal-type large Gaussian profile distribution, which is characteristic for disordered Fe environment encountered in amorphous-like alloys, with two main chemical environments for Fe. From the numerical fitting of the size distribution with two Gaussian profiles, we have obtained for the low field mode an average Bhf of 14 T and 16 T for 300 K and 77 K, respectively, and for the high field mode an average Bhf of 26 T and 28 T for 300 K and 77 K. respectively. The relative proportion of the high-field to low-field relative contributions to the Bhf distributions is about 3:1. From the obtained Bhf values we can presume that the low field distribution corresponds to a disordered precursor phase, rich in boron, which would give rise upon annealing to a boride (possibly Fe2B) phase. On the contrary, the high field distribution is attributed to another disordered chemical environment, rich in iron, would supposedly promote, upon annealing, the formation of the fcc FePt grains. The observation of two different hyperfine field distributions hints to the potential formation of two different magnetic phases upon annealing.

The Mössbauer spectra of the annealed samples were also fitted with different discrete distributions of hyperfine parameters, corresponding to the different Fe chemical environments. A similar fitting model was used throughout the entire series of samples to ensure the reliability of the results. All the

Bhf distributions obtained for 300 K and 77 K spectra are plotted in

Figure 7.

As explained earlier, the shape of the hyperfine field distribution of the as-cast sample reveals the existence of two separate iron environments which can be considered as incipient “nuclei” of the phases that will develop under thermal processing. As the annealing temperature increases, the process of forming two separate phases starts to be observed.

The shape of the spectra recorded at 300 K, for the sample annealed at 500 °C, exhibits a low spectral resolution, similar to that of the as-cast sample. By reducing the measuring temperature to 77 K, the spectral resolution allows us to distinguish two magnetic phases. Nevertheless, the Zeeman sextet lines associated with each phase are large enough, signifying the presence of a poorly ordered crystalline state. This is consistent with the amorphous-like features, the broad Bragg lines, observed in

Figure 1. To take into account this crystalline state, the 77 K spectrum is refined using a discrete distribution of fields ranging from 5 to 40 T.

Table 2 shows the mean values for the hyperfine parameters, as obtained from the fit.

The 500 °C spectrum also shows a broad line sextet, a pattern that is typical for distributed Fe environments, but the Bhf distributions are narrower than in the as-cast state

At 77 K,

Figure 7 shows a bimodal result of the hyperfine field distribution centered around 25 T and 34 T, both having almost the same abundance. Data from the literature [

2,

20,

21,

22,

23] show that these hyperfine field values can be assigned to the iron boride Fe

2B phase and the fcc FePt (A1) phase, respectively. At 300 K, the

Bhf distributions exhibits a similar form as observed for the as-cast sample, the best fit was obtained with two subcomponents. One magnetic component (red line in

Figure 6) has large peaks, typical for disordered Fe environments, is predominant, and has a relative intensity of 89%. It is attributed to the Fe-B rich amorphous-like phase, but exhibits an average hyperfine field value lower than that of Fe

2B. The second, at low field (blue line in

Figure 6) of about 11% with an average

Bhf value of around 2 T, is attributed to a highly disordered fcc A1 phase having small sizes (estimated at 7 ± 2 nm, see

Table 1). The Fe

2B phase is reportedly stable at high temperatures [

24] and is characterized by two magnetic sextets with hyperfine fields of about 23.3 and 24.2 T at 300 K.

The appearance at 77 K of a second pic at around 34 T, identified as the fcc Fe3Pt phase, is the result of the effect of thermal energy on the magnetization dynamics. Indeed, the XRD results at ambient temperature clearly show the presence of the fcc Fe3Pt phase, however this was not evident on the Mössbauer spectra recorded at 300 K.

In fact, C.B. Rong et al. [

25] studied the dependence of Curie temperature on chemical composition of annealed Fe

xPt

100-x nanoparticles. They showed that for 70 < x < 80, T

C is between 600 K and 200 K. This may explain the differences between the magnetic features of the same fcc Fe

3Pt phase: sextet at 77 K and singlet at 300 K.

The shape of the Mössbauer spectra at 600 °C supports the emerging bimodal microstructure observed at 500 °C. In fact, the spectral width of the Mössbauer component lines is here narrower, marking a better crystalline state of the grains with increasing average size, under the influence of the thermal processing. This is consistent with XRD results displayed in

Figure 1 and

Table 1.

The 300 K spectrum clearly displays two phases: one magnetic phase with an average hyperfine field value of about 21 T, and a slightly magnetic central peak with a hyperfine field value of around 2 T. Compared with the 500 °C sample, changes in the abundance of the two sub-components show progressive growth of the fcc Fe3Pt phase to the detriment of the remaining Fe–B rich amorphous-like phase.

The spectrum and

Bhf distribution at 77 K confirm the previous indications of a paramagnetic behavior of fcc Fe

3Pt grains, about 10 nm in diameter (see

Table 1). This para-ferromagnetic transition of the fcc A1 Fe

3Pt is preserved also for the higher annealing temperatures.

The 300 K spectra for the samples annealed at 700 °C and 800 °C show features similar to the 600 °C spectrum. It consists of sextets attributed to the Fe

2B and paramagnetic component, assigned to the superparamagnetic fcc Fe

3Pt nanograins. The

Bhf distribution is narrower, as can be observed in

Figure 7, and the individual linewidths are also narrower (see

Table 2) than those of the 600 °C annealing. The fct Fe

2B contribution becomes here well deconvoluted into the two magnetic sextets, usually encountered in the literature for Fe

2B, with

Bhf of 24.2 T and 23.1 T, respectively. The paramagnetic blue component becomes predominant in the sample, reaching more than 50% relative abundance. It shall be noted that, in the diffraction studies, the Bragg lines of Fe

2B are of extremely small intensity, while in Mössbauer analysis the relative proportion of Fe

2B is found to be higher. This can be explained by the high structure factor of Pt that, in X-ray diffractograms, hinders the occurrence of Fe

2B Bragg lines.

The 77 K spectra for samples annealed at 700 °C and 800 °C are highly similar: the same fitting model is used and the same components are retrieved, as in the 600 °C case. This feature is also observed in the

Bhf distributions plotted in

Figure 7. The HF distributions are narrower, signaling the continuous process of structural refinement, as proven also by the XRD results. While at 700 °C annealing, Fe

2B and Fe

3Pt have almost the same relative abundance of 50%, at 800 °C annealing the Fe

3Pt predominates having a relative abundance of 52%. A small fraction of A1 fcc FePt remains still magnetically disordered as shown by the paramagnetic component of about 2% relative abundance, even after annealing at 800 °C.

The Mössbauer spectra confirm thus the XRD results where we have observed the formation of cubic Fe3Pt phases and Fe2B starting with the annealing at 700 °C. However, the gradual phase evolution shows various paths for achieving this two-phase magnetic structure, depending on the annealing temperature chosen.

To summarize the phase evolution that has been observed in the Fe

68Pt

13Nb

2B

17 sample, as documented by the XRD and Mössbauer results, the following sequences of crystallization, with main phases observed, may be depicted as in the scheme:

It is also shown that in the presence of additional magnetic phases, such as Fe2B, the fcc FePt undergo a chemical environment transition from magnetically ordered at 77 K to magnetically disordered at 300 K.

In the following we will undertake temperature dependent investigations in order to observe the dynamics of this chemical environment transition of the Fe3Pt phase, by measuring Mössbauer spectra at several temperatures, ranging from 300 K down to 4.2 K. This study will then be accompanied by extensive temperature-dependent magnetic measurements.

3.4. Magnetic Phase Evolution

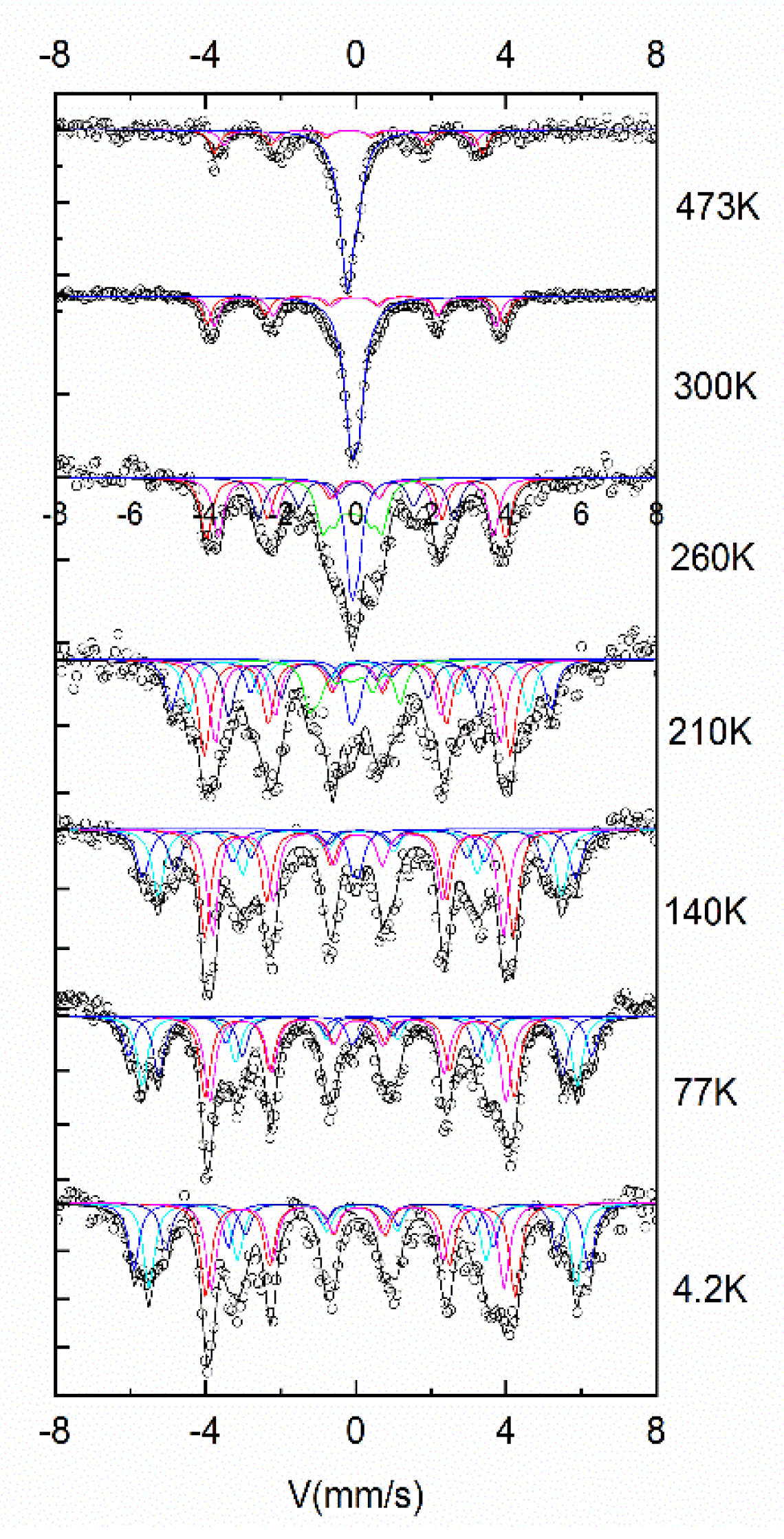

In order to properly monitor the evolution with temperature of the magnetic structure of the samples, we have undertaken two different experiments. In the first experiment, we have taken Mössbauer spectra at various temperatures, in an extended range, from 473 K (200 °C) down to 4.2 K.

Figure 8 presents the recorded Mössbauer spectra at various temperatures, together with the fitting of their constituent magnetic phases.

It can be observed that at 473 K and 300 K the spectra are quite similar, being composed of two main components: the paramagnetic (singlet) component, assigned to fcc FePt (blue color in the

Figure 8), and the ferromagnetic (sextet) component, assigned to tetragonal Fe

2B (red color in the

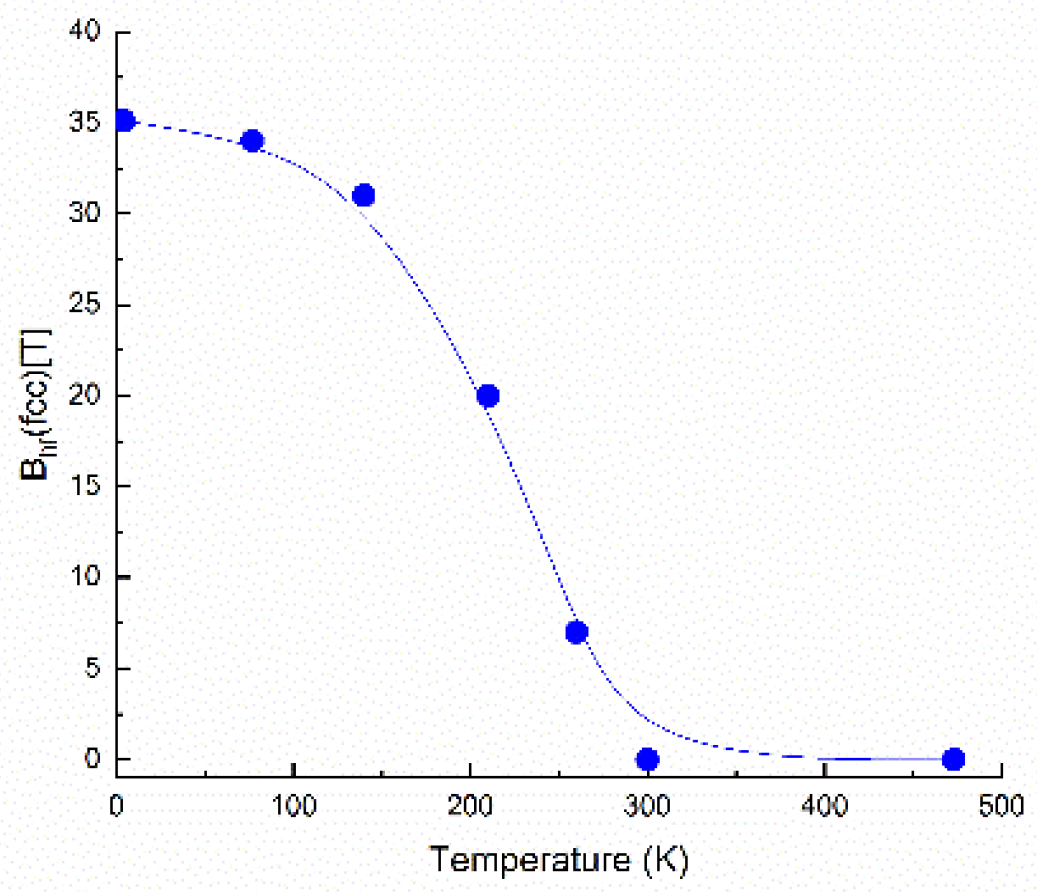

Figure 8). However, below room temperature, starting with 260 K, part of the paramagnetic component starts to become magnetically split, and the spectrum becomes multicomponent. The transformation from paramagnet to ferromagnet with the decrease in temperature is gradual, however at about 100 K, the transformation is almost complete. At 4.2 K the FePt phase appears fully ferromagnetic. This evolution with temperature is more visible if one plots (

Figure 9, top) the average hyperfine field, as resulted from the fitting of Mössbauer spectra in

Figure 8, as a function of temperature. It can be seen that going down in temperature below 300 K makes the average hyperfine field increase quite sharply, between 260 K and 77 K, and attaining saturation below 77 K, reaching up to about 35 T, value that is reached at 4.2 K. This value is consistent with hyperfine field values usually encountered in Fe-rich alloys.

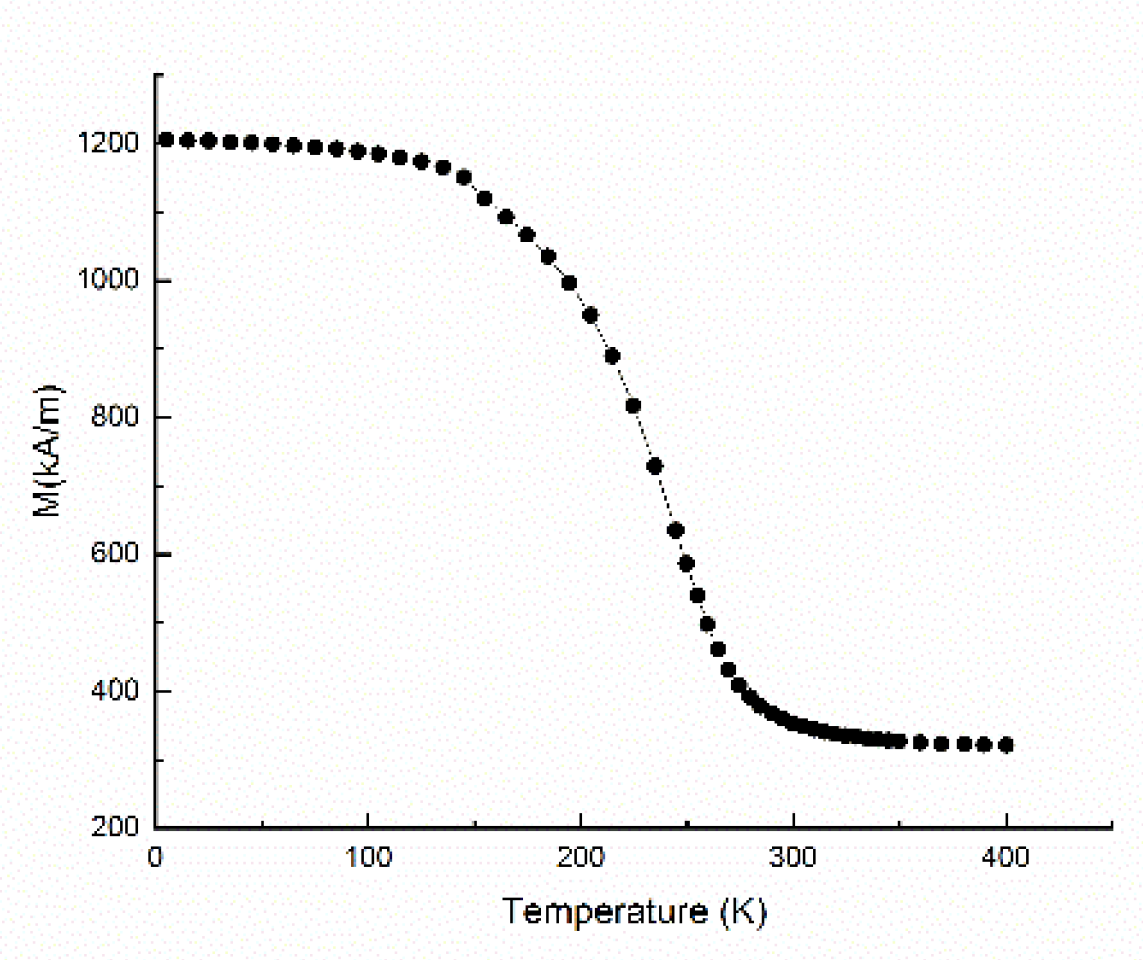

The second experiment, aiming at monitoring the evolution with temperature of the magnetic properties of the sample annealed at 700 °C, was made by recording the magnetization as a function of temperature in an experiment performed using the vibrating sample magnetometer in an applied field of 0.3 T. The graph depicting the magnetization vs. temperature M(T) is plotted in

Figure 9 (bottom). The measurement protocol employed consisted of heating the sample up to 400 K and starting measurement of the specific magnetization at 400 K while the system is steadily cooled down to 4.2 K with a continuous cooling rate of 2 K/min and under an applied field of 0.3 T. It can be observed that at 400 K the sample exhibits low specific magnetization (about 200 kA/m) and this value remains almost constant up to about 300 K where the magnetization starts to increase. Between 270 K and down to around 150 K there is a sharp and steady increase of the specific magnetization up to about 1100 kA/m. From about 120 K the magnetization stabilizes up to a saturation value of about 1200 kA/m. This situation is explainable by taking into account the phase structure at every temperature. At high temperatures, the fcc Fe

3Pt is in its paramagnetic state, as proven by the Mössbauer results, therefore its contribution to the total magnetization of the sample is null. The value recorded of around 200 kA/m represents only the contribution of the fct Fe

2B phase. Below 270 K, the magnetization starts to increase, as the Fe

3Pt phase starts having non-zero contributions to the total magnetization of the sample, due to the gradual transition para to ferro observed in

Figure 9. The sharp increase of the magnetization, upon decreasing the temperature from 270 K to 120 K, illustrates thus the para to ferro magnetic transition. This transition is proven to be gradual, as it happens over an interval of over 150 K. Since at lower temperatures, the total magnetization saturates at about 1200 kA/m, and at higher temperatures the minimum value (given only by the contribution of Fe

2B, Fe

3Pt being paramagnetic) is 200 kA/m, we can conclude that roughly the maximum contribution to the total magnetization at the lowest temperature investigated in the measurement is about 1000 kA/m, a value in very good agreement with the values reported in the literature for the Fe–Pt binary magnetic phases. This behavior is in very good agreement with the average hyperfine field dependence of temperature B

hf(T), where we have also seen a gradual increase of B

hf from 260 K down to about 100 K, exactly like in the case of M(T).

This temperature dependence of the magnetization measurement has allowed us to confirm once again the chemical environment transition of the fcc Fe

3Pt from the paramagnetic state at 300 K and above, to the ferromagnetic state at lower temperatures (120 K and below). Moreover, we have proven that this transition occurs gradually, over a large temperature interval of about 150 K. This transition was surprisingly observed only through Mössbauer studies. It is clear that the overall magnetic properties recorded at 300 K of the sample annealed at 700 °C where Fe

3Pt and Fe

2B co-exist, i.e., coercivity and saturation magnetization are actually dictated by the Fe

2B, as the Fe

3Pt is paramagnetic at 300 K. Moreover, the Curie temperature of Fe

3Pt [

25] was shown to decrease strongly from 550 K to 310 K when Fe content varied with only 3% around the stoichiometric value for Fe

3Pt. This strong deviation can be explained by changes in Fe

3Pt atom ordering, where lower Fe content may produce a tetragonal ordering of L1

0 type, with a higher T

C rather than an ordering of L1

2 type, typical for Fe

3Pt, which has a lower T

C. This temperature variability of the magnetic ordering has been also evidenced in some recent papers. A temperature-dependent study of the anisotropy field of L1

0 FePt near T

C [

13] showed that the scaling law (1 –

T/

Tc)

β holds experimentally only for β values close to 0.36 and thermally activated magnetization reversal at temperatures near T

c cannot be ignored, even at time scales smaller than 1 ns. Other kinds of incoherent magnetic switching have been evidenced in equiatomic L1

0 FePt grains [

14]. In addition, on thin films of FePt with variable concentrations oof Fe [

15], it was found that magnetic ordering was highly dependent on the actual composition and the temperature.

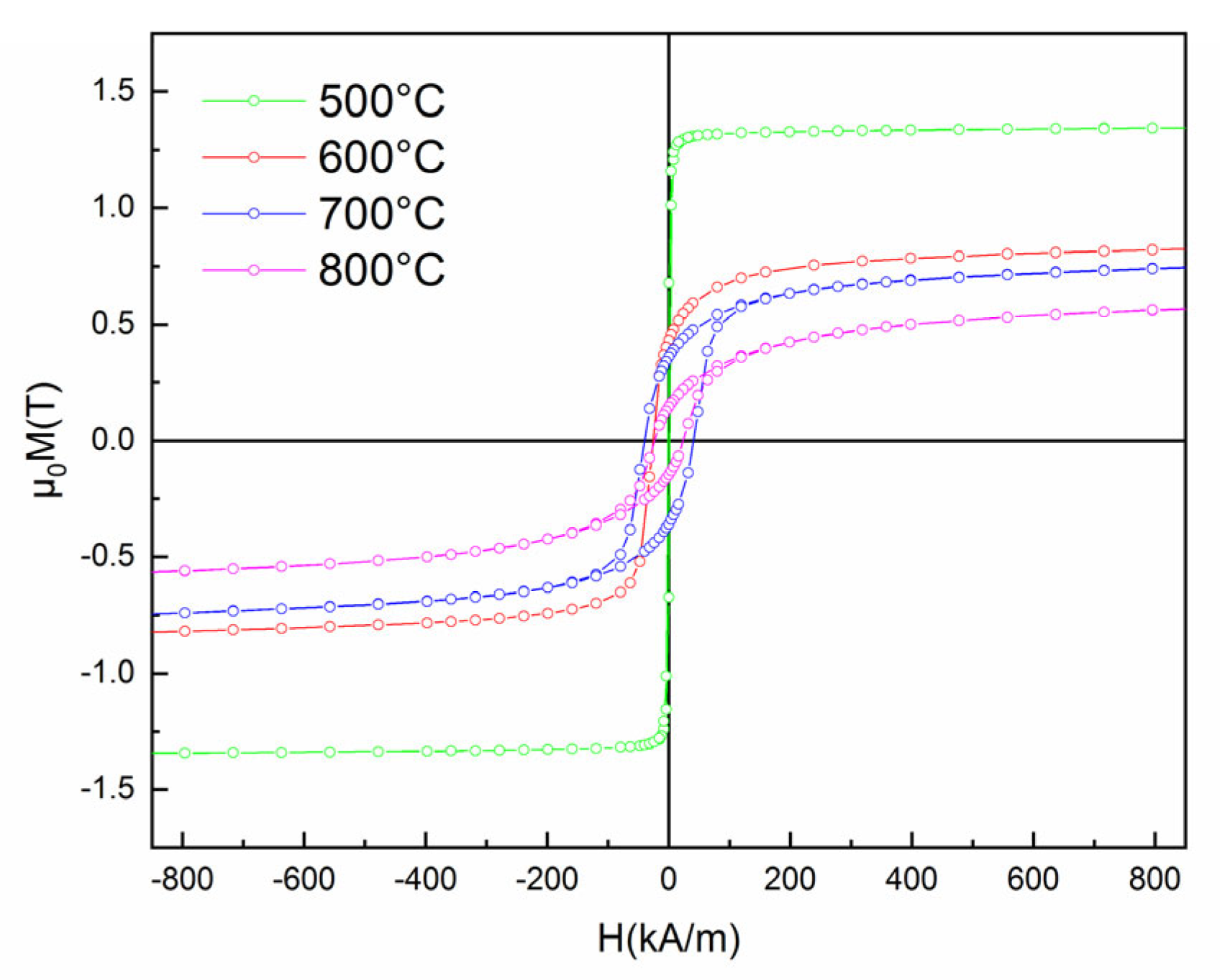

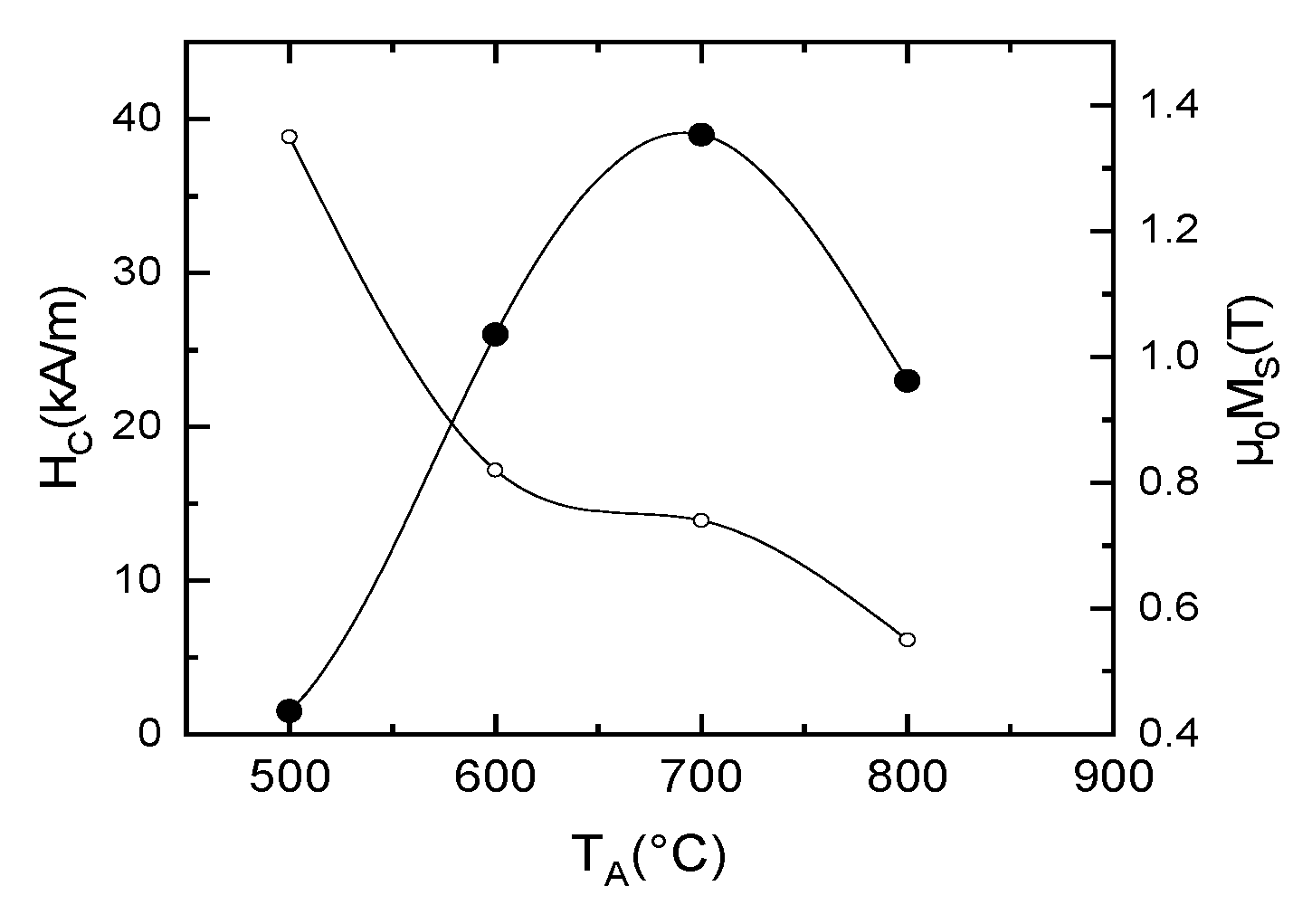

Further magnetic properties investigations of the samples annealed for 20 min at various temperatures were carried out by measuring the major hysteresis loops, which were recorded at 300 K using a VSM, under a parallel applied field of up to 1.5 T. The obtained hysteresis loops are presented in

Figure 10.

The curve for the sample annealed at 500 °C is typical for soft magnetic materials, with virtually no coercivity, a fast approach to saturation, and high saturation magnetization (cca. 1.3 T), but as the annealing temperature goes up, the saturation magnetization diminishes due to the continuous increase of the grain size and the steady increase of the paramagnetic contribution observed in the Mössbauer spectra. Most interesting is that a magnetic hardening occurs in the annealed sample, with non-negligible coercive fields recorded for the annealed samples. The coercivity reaches a maximum for the sample annealed at 700 °C. All the values of the coercive fields and of the saturation magnetization recorded in the hysteresis loops are plotted as a function of annealing temperature in

Figure 11. It can be observed that the coercivity reaches indeed a maximum for the annealing at 700 °C which is now confirmed to be the optimal annealing temperature for improving the magnetic properties of the alloy. As for the saturation magnetization, these values decrease slowly with an increase in the annealing temperature, from around 1.4 T for 500 °C annealing down to about 0.5 T for the 800 °C annealing. Such behavior of the coercivity is explainable by the phase evolution of the samples during annealing. As the metastable as-cast state is magnetically soft, upon annealing, the crystals nucleate and grow in a tridimensional model. The formed nanograins are initially monodomains, for intermediate stages of annealing 500 °C–600 °C. After annealing at 700 °C, the average grain size is only 16 nm. This refined microstructure is formed of grains from two magnetic phases and due to various reversal mechanisms, the coercive field increases up to the maximum. After 800 °C annealing, the grains have furthermore increased up to 100 nm (see

Table 1) and this leads to the decrease of the coercivity as observed in

Figure 11. This is hereafter interpreted in terms of a log H

c vs. log D dependence that resembles partly with a previously developed random anisotropy model.

The random anisotropy model, initially proposed by Alben et al. [

26] and reformulated by Herzer [

27,

28], proposes to explain the dependence of various grain size-dependent magnetic properties through the interplay of exchange coupling between grains and magnetic anisotropy energy. The distributed grain microstructure leads to a distribution of magnetic easy axes with various orientations over the scale of the structural correlation length which is here assimilated to the average grain size

D. The model of scaling these dependences, the random anisotropy model, is based on the exchange correlation length

L0, the length from which the exchange coupling overcomes the anisotropy energy barrier:

where

A is the exchange stiffness,

is the local magnetic anisotropy constant, and

ϕ is a proportionality factor, here assumed to be one. The random anisotropy model shows that for nanocrystalline materials with distributed grain size at the nanometric scale, there is a scaling formula linking the average anisotropy

to the local anisotropy

:

The coercive field is linked to the average magnetic anisotropy through the formula:

where p

c is a proportional constant and J

s is the saturation magnetization [

20].

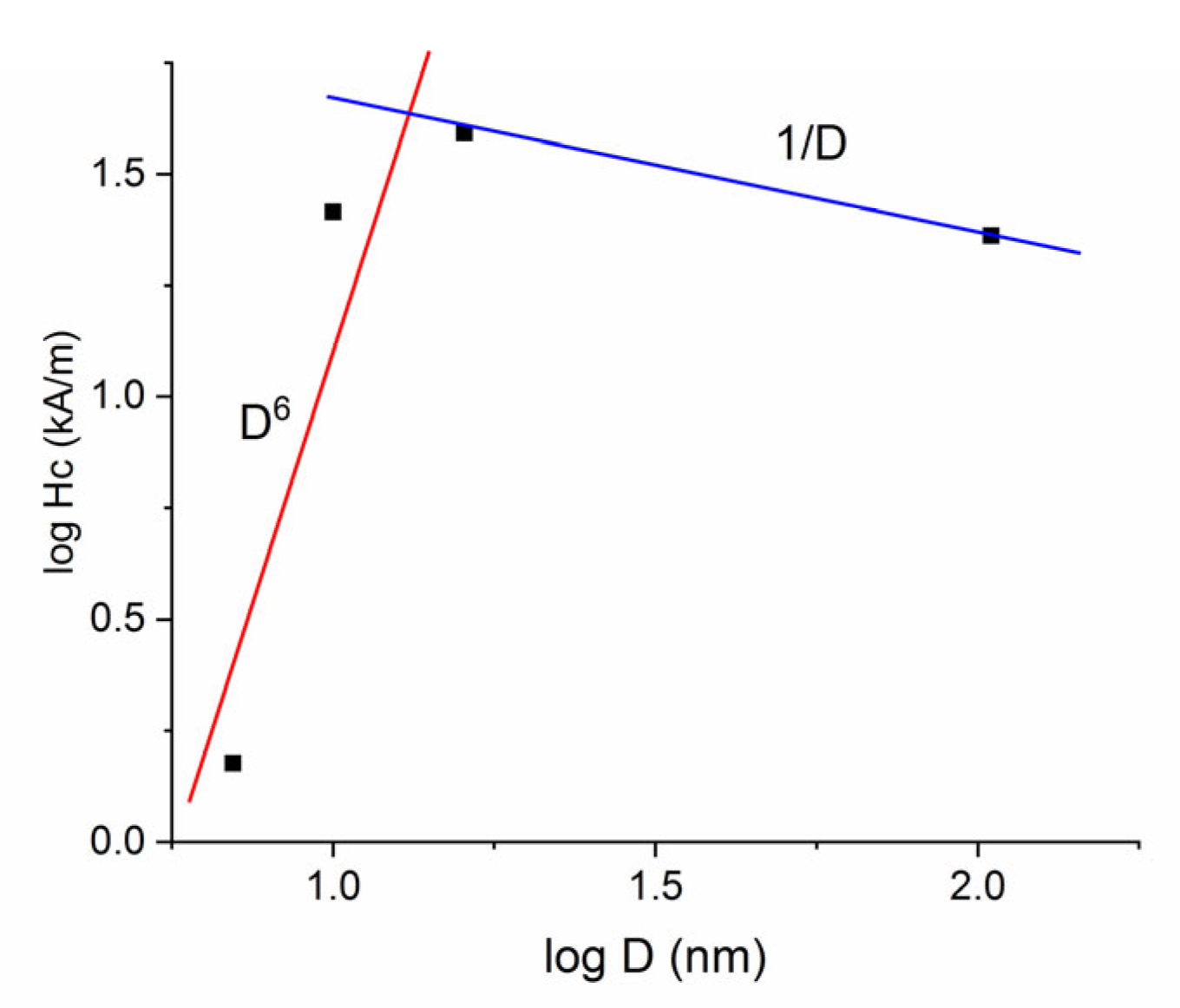

Some typical L0 values for Fe-based alloys are between 20–40 nm for Fe-based alloys. Therefore, for most amorphous and nanocrystalline materials, including our samples annealed at 500 °C until 700 °C, we are in the situation that D < L0. Combining Equations (2) and (3) we observe that the coercive field is scaling with D6, for D < L0 cases where the exchange anisotropy energy exceeds the exchange coupling.

The grain size dependence of the coercivity is displayed in

Figure 12, where we have plotted the coercive field values as revealed in

Figure 11 versus the average grain sizes D, as calculated in

Table 1. There are two dependences observed and linearly fitted in the graph. For the samples annealed between 500 °C and 700 °C the coercivity values follow a D

6 dependence (red line) while for annealed temperatures between 700 °C and 800 °C, due to the sharp increase of the grain sizes, the coercive field decreases and follows a 1/D dependence (blue line). This result presents similarities with the random anisotropy model for the samples annealed at 500 °C and shows good resemblance to other coercive field dependences on grain size, as reported previously in other papers [

29,

30,

31]. It must however be mentioned that the random anisotropy model is applicable mostly to amorphous and nanocrystalline alloys, having less relevance to multiple-phase polycrystalline systems, as is the case for instance for the sample annealed at 800 °C.

The magnetic behavior is consistent with a microstructure made of small grains of multiple magnetic phases with randomly distributed easy axes and with small coupling energy, as revealed in other materials with multiple magnetic phases [

32], pointing to a reduced exchange coupling between adjacent magnetic grains.