Large-Scale MoS2 Pixel Array for Imaging Sensor

Abstract

1. Introduction

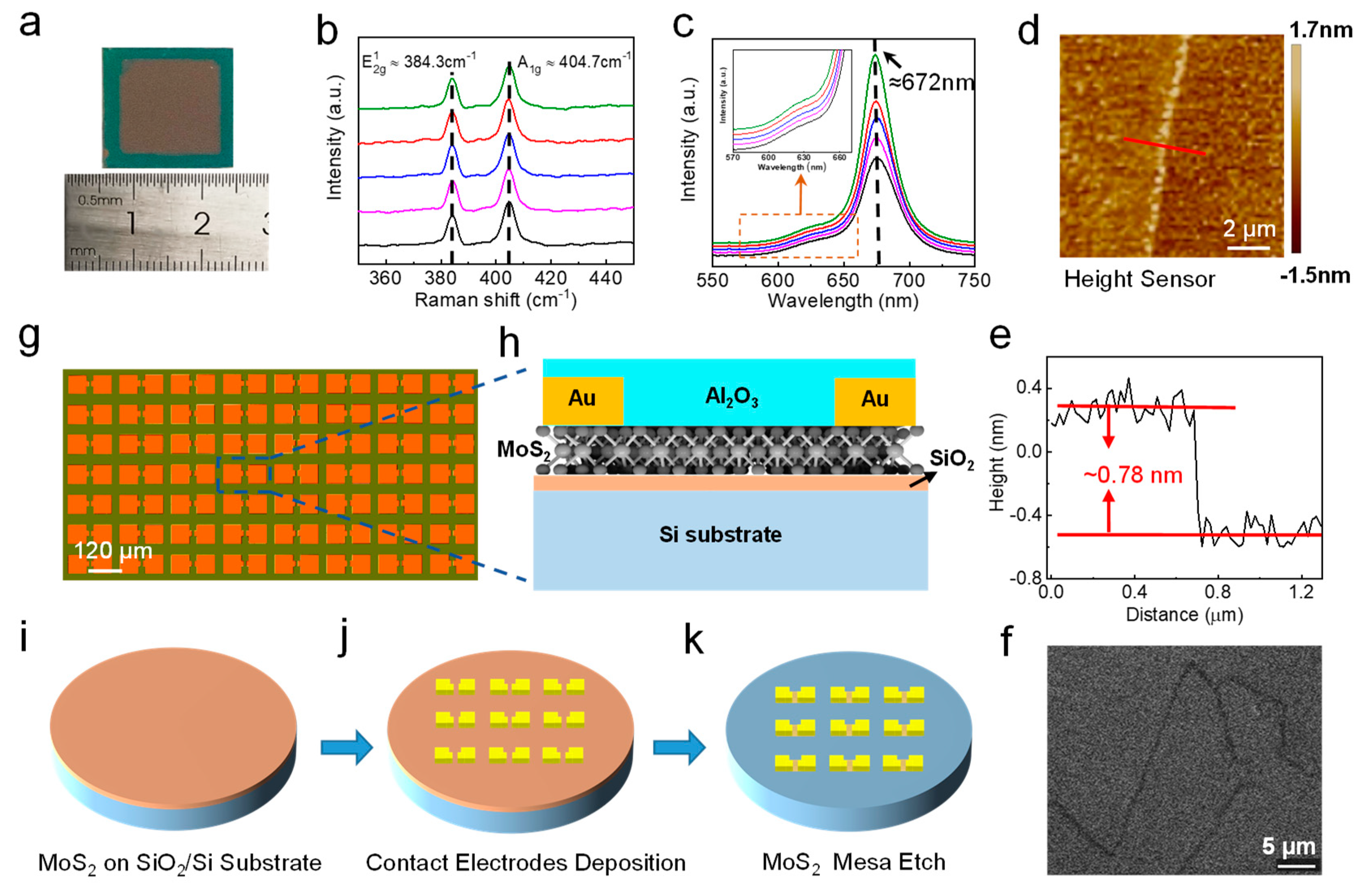

2. Materials Synthesis and Characterizations

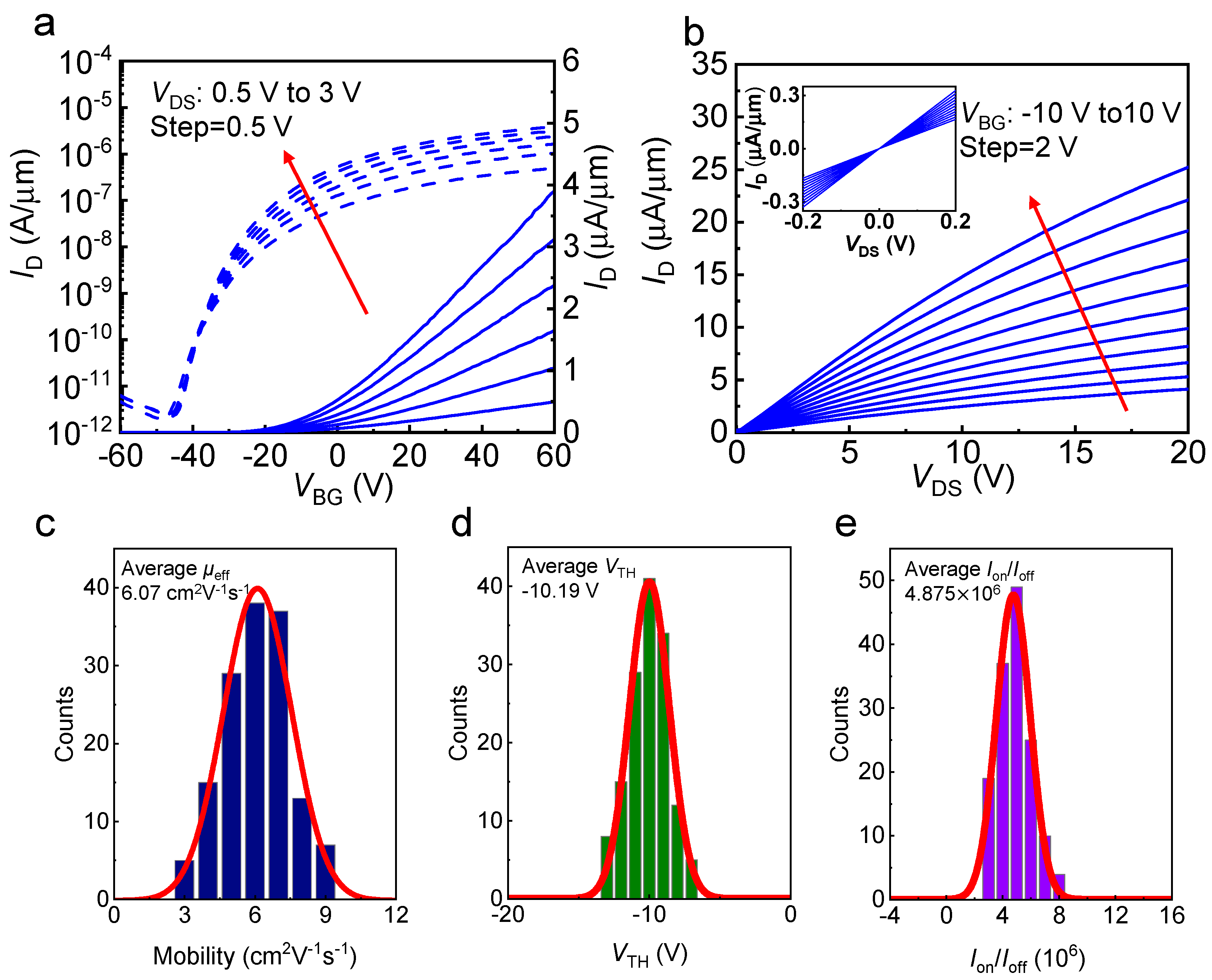

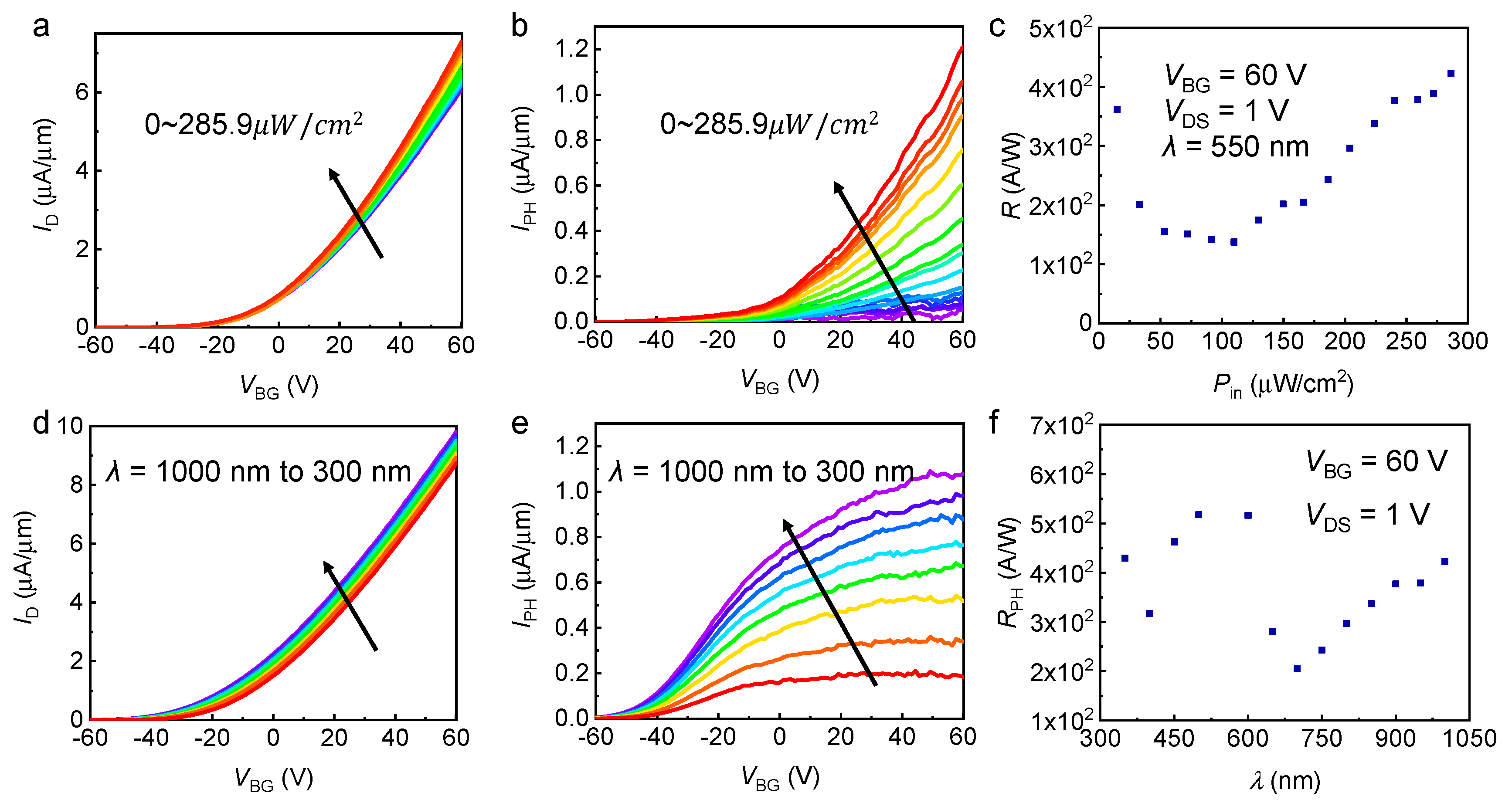

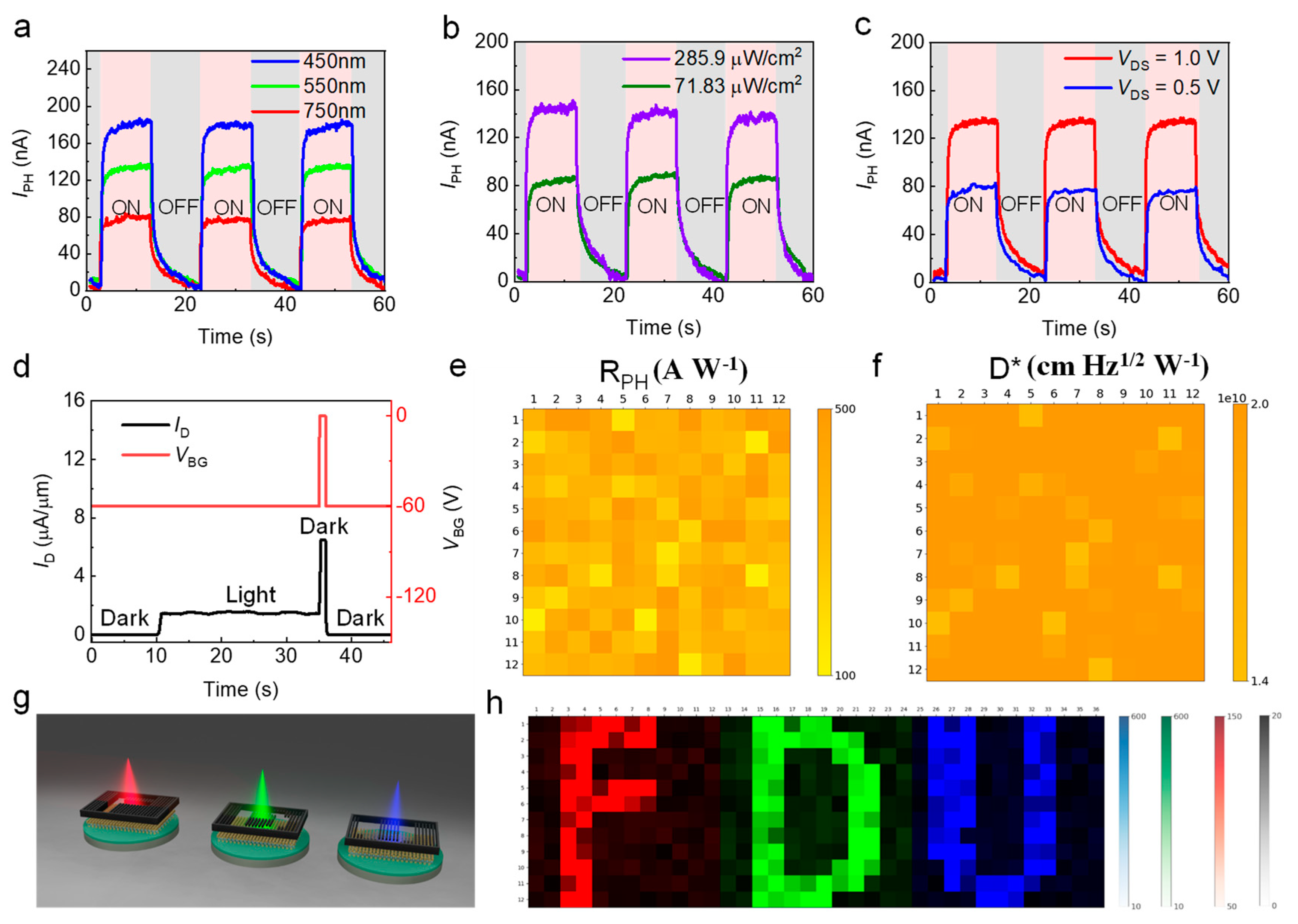

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, X.; Pan, Y.; Liu, S.; Han, B. Seeded 2D epitaxy of large-area single-crystal films of the van der Waals semiconductor 2H MoTe2. Science 2021, 372, 195–200. [Google Scholar] [CrossRef] [PubMed]

- Michailow, W.; Spencer, P.; Almond, N.W.; Kindness, S.J.; Wallis, R.; Mitchell, T.A.; Degl’Innocenti, R.; Mikhailov, S.A.; Beere, H.E.; Ritchie, D.A. An in-plane photoelectric effect in two-dimensional electron systems for terahertz detection. Sci. Adv. 2022, 8, eabi8398. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef] [PubMed]

- Xia, F.; Wang, H.; Xiao, D.; Dubey, M.; Ramasubramaniam, A. Two-dimensional material nanophotonics. Nat. Photonics 2014, 8, 899–907. [Google Scholar] [CrossRef]

- Koppens, F.H.; Mueller, T.; Avouris, P.; Ferrari, A.C.; Vitiello, M.S.; Polini, M. Photodetectors based on graphene, other two-dimensional materials and hybrid systems. Nat. Nanotechnol. 2014, 9, 780–793. [Google Scholar] [CrossRef]

- Mennel, L.; Symonowicz, J.; Wachter, S.; Polyushkin, D.K.; Molina-Mendoza, A.J.; Mueller, T. Ultrafast machine vision with 2D material neural network image sensors. Nature 2020, 579, 62–66. [Google Scholar] [CrossRef]

- Liao, F.; Zhou, Z.; Kim, B.; Chen, J.; Wang, J.; Wan, T.; Zhou, Y.; Hoang, A.; Wang, C.; Kang, J.; et al. Bioinspired in-sensor visual adaptation for accurate perception. Nat. Electron. 2022, 5, 84–91. [Google Scholar] [CrossRef]

- Yu, J.; Yang, X.; Gao, G.; Xiong, Y.; Wang, Y.; Han, J.; Chen, Y.; Zhang, H.; Sun, Q.; Wang, Z.L. Bioinspired mechano-photonic artificial synapse based on graphene/MoS2 heterostructure. Sci. Adv. 2021, 7, eabd9117. [Google Scholar] [CrossRef]

- Hu, Y.; Dai, M.; Feng, W.; Zhang, X.; Gao, F.; Zhang, S.; Tan, B.; Zhang, J.; Shuai, Y.; Fu, Y.; et al. Ultralow Power Optical Synapses Based on MoS2 Layers by Indium-Induced Surface Charge Doping for Biomimetic Eyes. Adv. Mater. 2021, 33, 2104960. [Google Scholar] [CrossRef]

- Liu, L.; Li, T.; Ma, L.; Li, W.; Gao, S.; Sun, W.; Dong, R.; Zou, X.; Fan, D.; Shao, L.; et al. Uniform nucleation and epitaxy of bilayer molybdenum disulfide on sapphire. Nature 2022, 605, 69–75. [Google Scholar] [CrossRef]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef] [PubMed]

- Yoon, Y.; Ganapathi, K.; Salahuddin, S. How good can monolayer MoS2 transistors be? Nano Lett. 2011, 11, 3768–3773. [Google Scholar] [CrossRef] [PubMed]

- Mak, K.F.; Lee, C.; Hone, J.; Shan, J.; Heinz, T.F. Atomically thin MoS2: A new direct-gap semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef]

- Dodda, A.; Trainor, N.; Redwing, J.M.; Das, S. All-in-one, bio-inspired, and low-power crypto engines for near-sensor security based on two-dimensional memtransistors. Nat. Commun. 2022, 13, 3587. [Google Scholar] [CrossRef] [PubMed]

- Waltl, M.; Knobloch, T.; Tselios, K.; Filipovic, L.; Stampfer, B.; Hernandez, Y.; Waldhor, D.; Illarionov, Y.; Kaczer, B.; Grasser, T. Perspective of 2D Integrated Electronic Circuits: Scientific Pipe Dream or Disruptive Technology? Adv. Mater. 2022, 2201082. [Google Scholar] [CrossRef]

- Zhu, K.; Wen, C.; Aljarb, A.; Xue, F.; Xu, X.; Tung, V.; Zhang, X.; Alshareef, H.; Lanza, M. The development of integrated circuits based on two-dimensional materials. Nat. Electron. 2021, 4, 775–785. [Google Scholar] [CrossRef]

- Long, M.; Wang, P.; Fang, H.; Hu, W. Progress, challenges, and opportunities for 2D material based photodetectors. Adv. Funct. Mater. 2019, 29, 1803807. [Google Scholar] [CrossRef]

- Lee, C.; Yan, H.; Brus, L.; Heinz, T.; Hone, J.; Ryu, S. Anomalous lattice vibrations of single-and few-layer MoS2. ACS Nano 2010, 4, 2695–2700. [Google Scholar] [CrossRef]

- Ermolaev, G.A.; El-Sayed, M.A.; Yakubovsky, D.I.; Voronin, K.V.; Romanov, R.I.; Tatmyshevskiy, M.K.; Doroshina, N.V.; Nemtsov, A.B.; Voronov, A.A.; Novikov, S.M. Optical Constants and Structural Properties of Epitaxial MoS2 Monolayers. Nanomaterials 2021, 11, 1411. [Google Scholar] [CrossRef]

- Coleman, J.N.; Lotya, M.; O’Neill, A.; Bergin, S.D.; King, P.J.; Khan, U.; Young, K.; Gaucher, A.; De, S.; Smith, R.J. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 2011, 331, 568–571. [Google Scholar] [CrossRef]

- Peng, M.; Xie, R.; Wang, Z.; Wang, P.; Wang, F.; Ge, H.; Wang, Y.; Zhong, F.; Wu, P.; Ye, J.; et al. Blackbody-sensitive room-temperature infrared photodetectors based on low-dimensional tellurium grown by chemical vapor deposition. Sci. Adv. 2021, 7, eabf7358. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Liu, C.; Zhu, Q.; Su, X.; Qian, W.; Sun, Y.; Wang, C.; Li, B.; Chen, M.; Chen, L. An ultrasensitive molybdenum-based double-heterojunction phototransistor. Nat. Commun. 2021, 12, 4094. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Chen, H.; Bian, J.; Liao, F.; Ma, J.; Zhang, S.; Zhang, X.; Zhu, J.; Luo, C.; Zhang, Z.; et al. Stacking monolayers at will: A scalable device optimization strategy for two-dimensional semiconductors. Nano Res. 2022, 15, 6620–6627. [Google Scholar] [CrossRef]

- Chen, C.; Feng, Z.; Feng, Y.; Yue, Y.; Qin, C.; Zhang, D.; Feng, W. Large-scale synthesis of a uniform film of bilayer MoS2 on graphene for 2D heterostructure phototransistors. ACS Appl. Mater. Interfaces 2016, 8, 19004–19011. [Google Scholar] [CrossRef]

- Jeong, M.H.; Ra, H.S.; Lee, S.H.; Kwak, D.H.; Ahn, J.; Yun, W.S. Multilayer WSe2/MoS2 Heterojunction Phototransistors through Periodically Arrayed Nanopore Structures for Bandgap Engineering. Adv. Mater. 2022, 34, e2108412. [Google Scholar] [CrossRef]

- Park, H.; Liu, N.; Kim, B.H.; Kwon, S.H.; Baek, S.; Kim, S.; Lee, H.; Yoon, Y.J.; Kim, S. Exceptionally uniform and scalable multilayer MoS2 phototransistor array based on large-scale MoS2 grown by RF sputtering, electron beam irradiation, and sulfurization. ACS Appl. Mater. Interfaces 2020, 12, 20645–20652. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Liu, N.; Kim, B.H.; Kwon, S.H.; Baek, S.; Kim, S.; Lee, H.K.; Yoon, Y.J.; Kim, S. Highly sensitive active pixel image sensor array driven by large-area bilayer MoS2 transistor circuitry. Nat. Commun. 2021, 12, 3559. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, H.; Guo, Z.; Shan, Y.; Wu, S.; Wang, J. High-performance wafer-scale MoS2 transistors toward practical application. Small 2018, 14, 1803465. [Google Scholar] [CrossRef]

- Yin, X.; Ye, Z.; Chenet, D.A.; Ye, Y.; O’Brien, K.; Hone, J.C.; Zhang, X. Edge nonlinear optics on a MoS2 atomic monolayer. Science 2014, 344, 488–490. [Google Scholar] [CrossRef]

- Li, D.; Xiao, Z.; Mu, S.; Wang, F.; Liu, Y.; Song, J. A facile space-confined solid-phase sulfurization strategy for growth of high-quality ultrathin molybdenum disulfide single crystals. Nano Lett. 2018, 18, 2021–2032. [Google Scholar] [CrossRef]

- Choi, M.; Bae, S.R.; Hu, L.; Hoang, A.T.; Kim, S.Y.; Ahn, J.H. Full-color active-matrix organic light-emitting diode display on human skin based on a large-area MoS2 backplane. Sci. Adv. 2020, 6, eabb5898. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Chen, H.Y.; Penumatcha, A.V.; Appenzeller, J. High performance multilayer MoS2 transistors with scandium contacts. Nano Lett. 2013, 13, 100–105. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Calò, A.; Albisetti, E.; Liu, X.; Alharbi, A.; Arefe, G.; Liu, X.; Spieser, M.; Yoo, W.; Taniguchi, T.; et al. Patterning metal contacts on monolayer MoS2 with vanishing Schottky barriers using thermal nanolithography. Nat. Electron. 2019, 2, 17–25. [Google Scholar] [CrossRef]

- Buscema, M.; Island, J.O.; Groenendijk, D.J.; Blanter, S.I.; Steele, G.A.; van der Zant, H.S.; Castellanos-Gomez, A. Photocurrent generation with two-dimensional van der Waals semiconductors. Chem. Soc. Rev. 2015, 44, 3691–3718. [Google Scholar] [CrossRef] [PubMed]

- Butt, N.Z.; Sarker, B.K.; Chen, Y.P.; Alam, M. Substrate-induced photofield effect in graphene phototransistors. IEEE Trans. Electron Devices 2015, 62, 3734–3741. [Google Scholar] [CrossRef]

- Fang, H.; Hu, W. Photogating in low dimensional photodetectors. Adv. Sci. 2017, 4, 1700323. [Google Scholar] [CrossRef]

- Kim, S.; Maassen, J.; Lee, J.; Kim, S.M.; Han, G.; Kwon, J.; Hong, S.; Park, J.; Liu, N.; Park, Y.C.; et al. Interstitial Mo-assisted photovoltaic effect in multilayer MoSe2 phototransistors. Adv. Mater. 2018, 30, 1705542. [Google Scholar] [CrossRef]

- Lan, Z.; Lei, Y.; Chan WK, E.; Chen, S.; Luo, D.; Zhu, F. Near-infrared and visible light dual-mode organic photodetectors. Sci. Adv. 2020, 6, eaaw8065. [Google Scholar] [CrossRef]

- Lopez-Sanchez, O.; Lembke, D.; Kayci, M.; Radenovic, A.; Kis, A. Ultrasensitive photodetectors based on monolayer MoS2. Nat. Nanotechnol. 2013, 8, 497–501. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, B.; Nie, K.; Xu, J. Research on a pulse-based high-line-rate TDI CMOS image sensor. Microelectron. J. 2021, 111, 105021. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, W.; Xi, J.; He, L.; Hu, C. 14-Bit Fully Differential SAR ADC with PGA Used in Readout Circuit of CMOS Image Sensor. J. Sens. 2021, 2021, 6651642. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Liao, M.; Zhao, W.; Liu, G.; Zhou, X.J.; Wei, Z.; Xu, X.; Liu, K.; Hu, Z.; Deng, K.; et al. Wafer-Scale Growth and Transfer of Highly-Oriented Monolayer MoS2 Continuous Films. ACS Nano 2017, 11, 12001–12007. [Google Scholar] [CrossRef] [PubMed]

| Indicator | Park et al. [26] | Hong et al. [27] | Ours |

|---|---|---|---|

| Pixel size (width × height) | 4 × 4 | 8 × 8 | 12 × 12 |

| Layer of MoS2 film | 2 L | Multilayer | 1 L |

| Average responsivity (Unit: A W−1) | 0.503 | 119.16 | 364.00 |

| Std responsivity (Unit: percentage %) | 15 | -- | 27.2 |

| Average detectivity (Unit: cm Hz1/2 W−1) | 1.4 × 104 | 4.66 × 106 | 2.13 × 1010 |

| Std detectivity (Unit: percentage %) | 12 | -- | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Wang, X.; Su, H.; Chen, X.; Wang, D.; Guo, J.; Shao, L.; Bao, W.; Chen, H. Large-Scale MoS2 Pixel Array for Imaging Sensor. Nanomaterials 2022, 12, 4118. https://doi.org/10.3390/nano12234118

Liu K, Wang X, Su H, Chen X, Wang D, Guo J, Shao L, Bao W, Chen H. Large-Scale MoS2 Pixel Array for Imaging Sensor. Nanomaterials. 2022; 12(23):4118. https://doi.org/10.3390/nano12234118

Chicago/Turabian StyleLiu, Kang, Xinyu Wang, Hesheng Su, Xinyu Chen, Die Wang, Jing Guo, Lei Shao, Wenzhong Bao, and Honglei Chen. 2022. "Large-Scale MoS2 Pixel Array for Imaging Sensor" Nanomaterials 12, no. 23: 4118. https://doi.org/10.3390/nano12234118

APA StyleLiu, K., Wang, X., Su, H., Chen, X., Wang, D., Guo, J., Shao, L., Bao, W., & Chen, H. (2022). Large-Scale MoS2 Pixel Array for Imaging Sensor. Nanomaterials, 12(23), 4118. https://doi.org/10.3390/nano12234118