Mechanical Properties and Deformation Behavior of Superhard Lightweight Nanocrystalline Ceramics

Abstract

1. Introduction

2. Effect of Grain Size on the Mechanical Properties of B4C and Sic

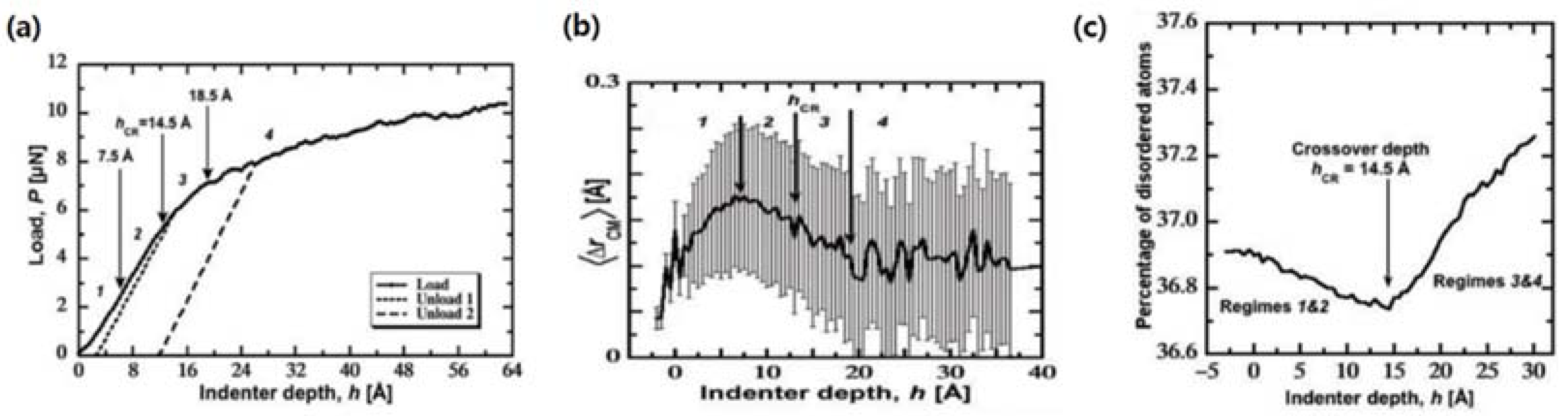

2.1. Mechanical Properties in the Crossover Region and Inverse Hall–Petch Region of Nanocrystalline B4C

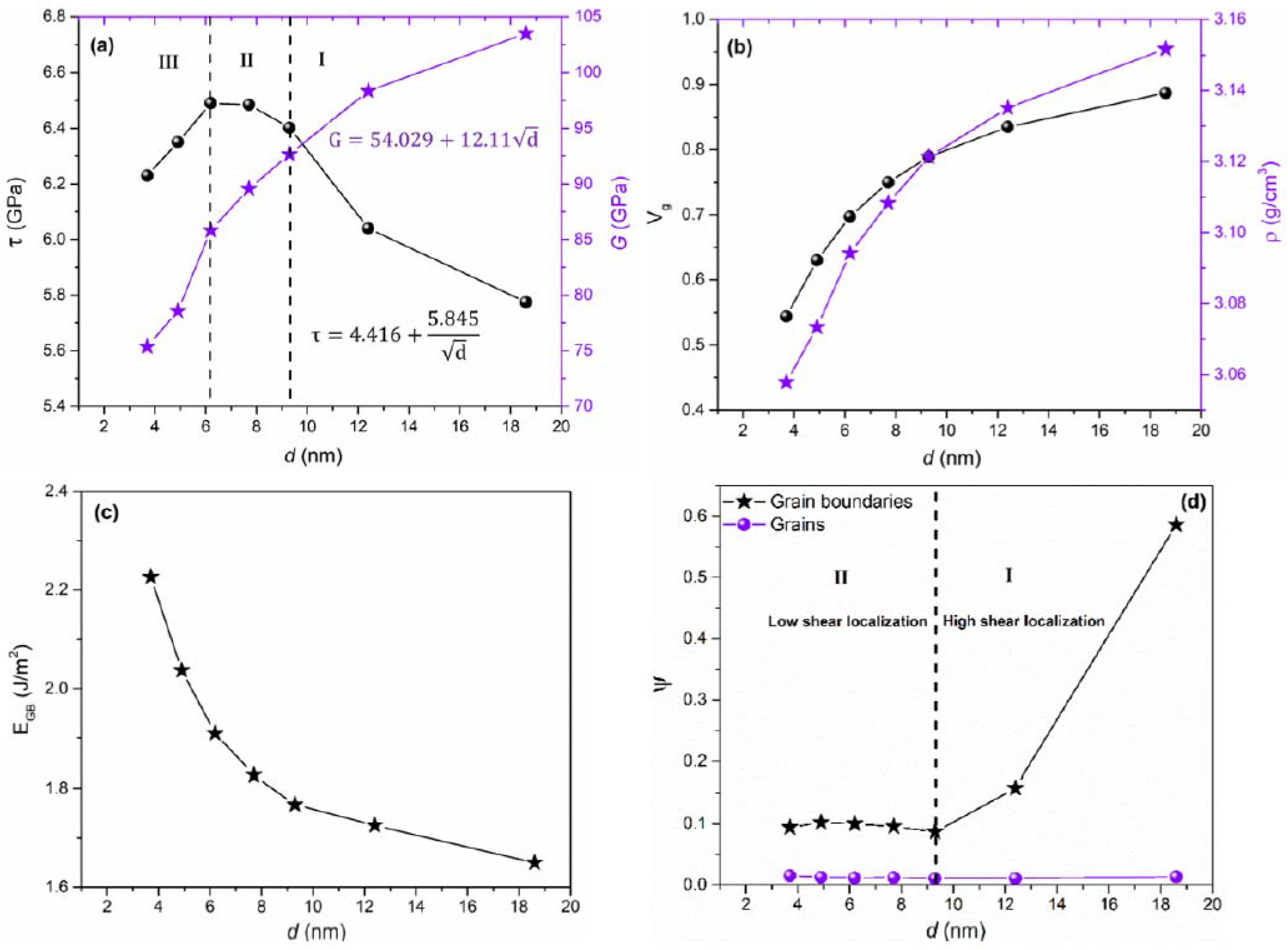

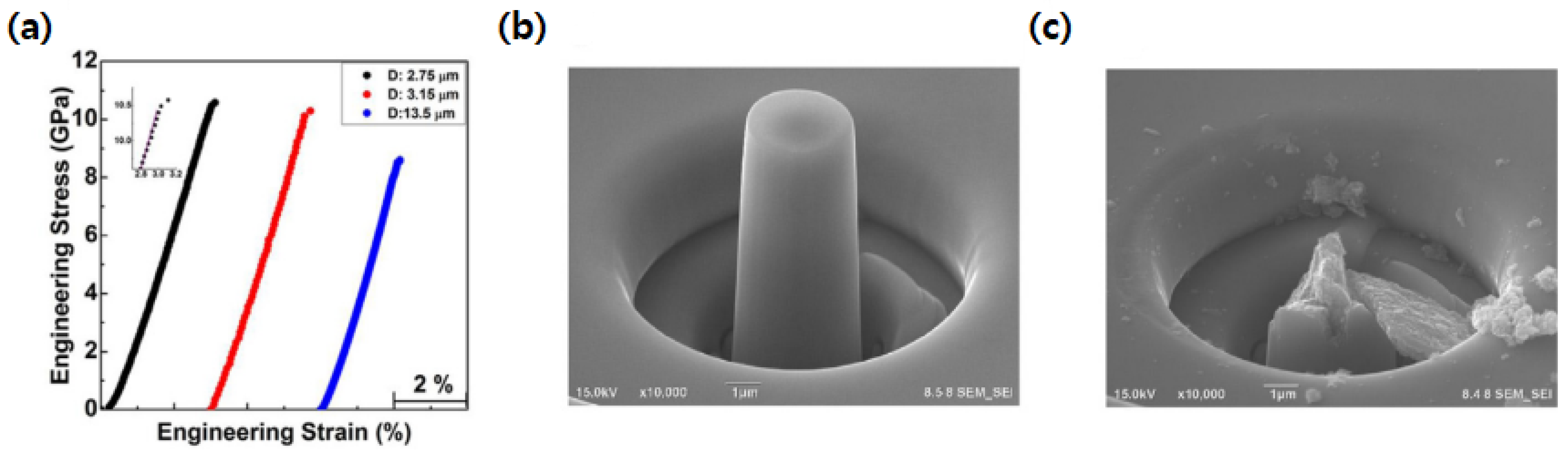

2.2. Mechanical Properties in the Crossover Region and Inverse Hall–Petch Region of Nanocrystalline Sic

3. Deformation Behavior in Nanocrystalline B4C and β-SiC

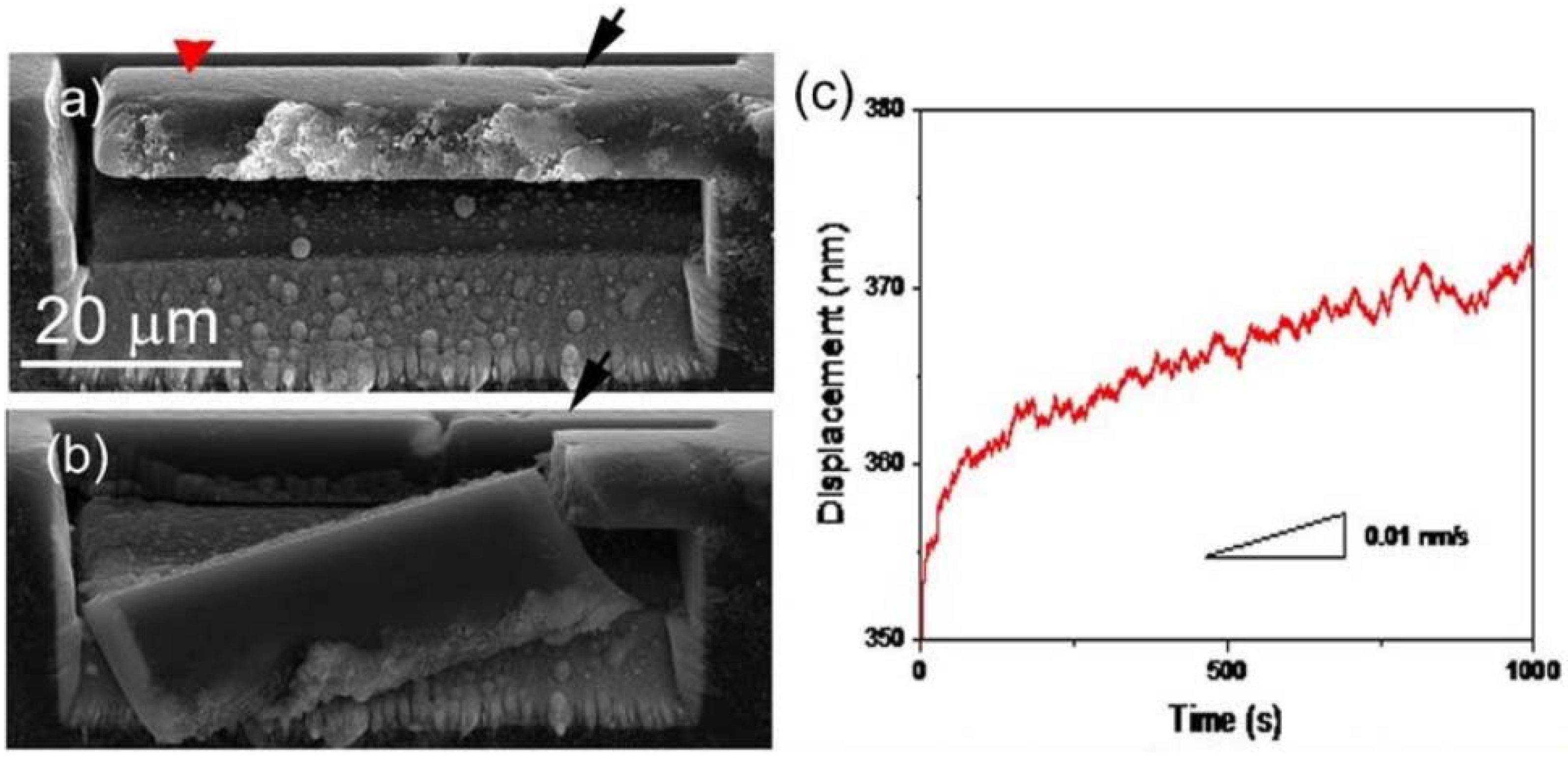

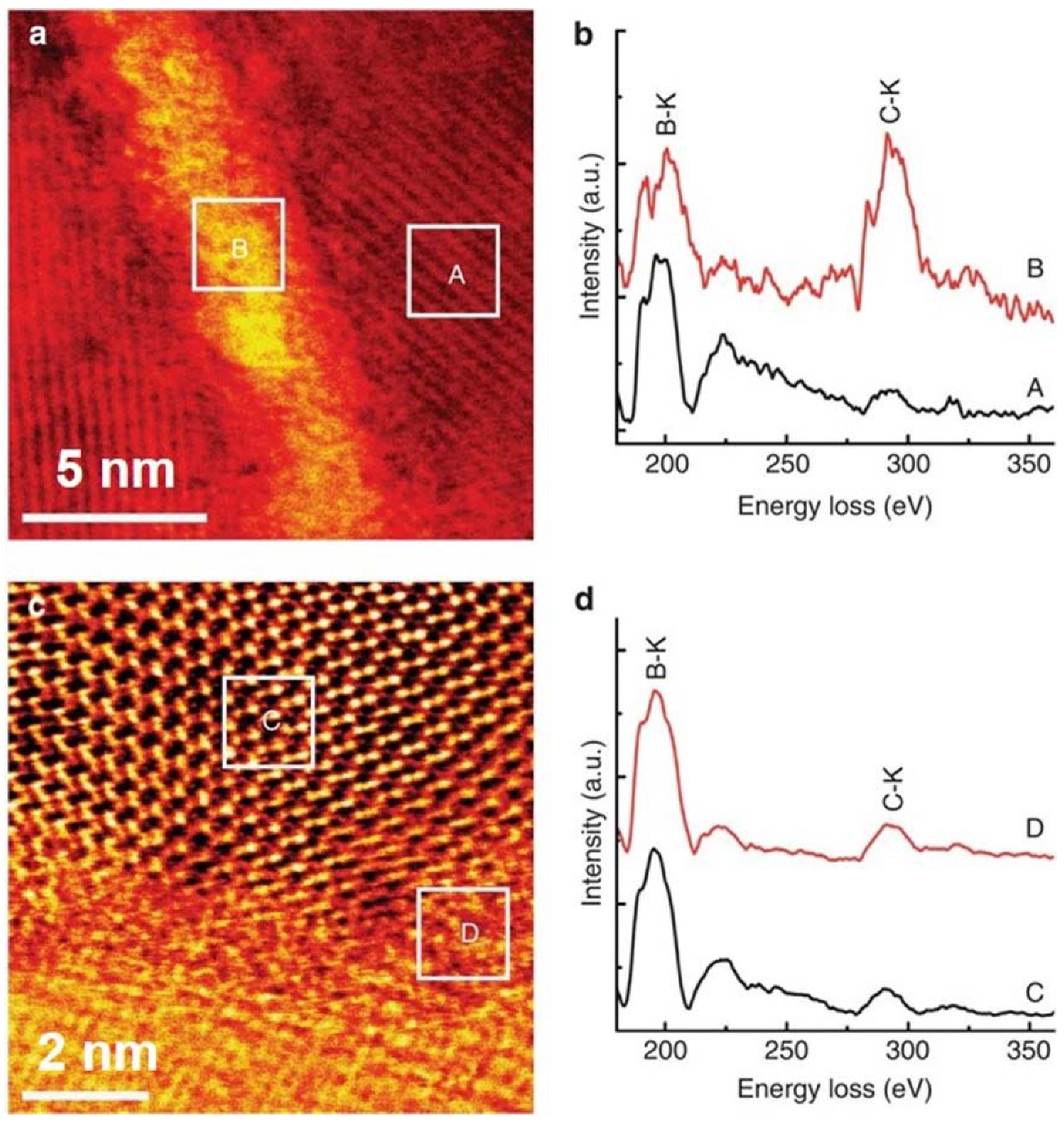

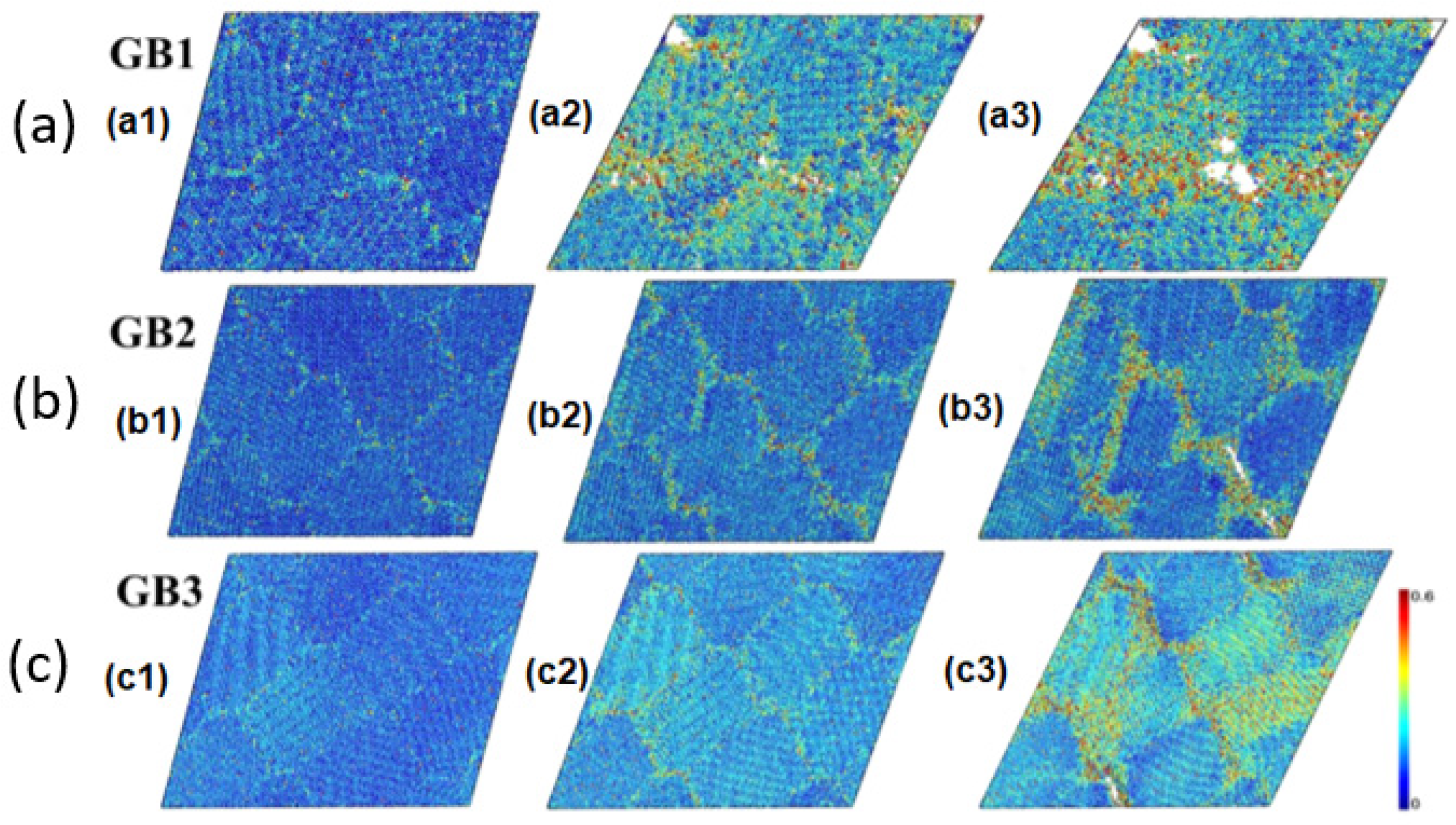

3.1. Nanocrystalline B4C

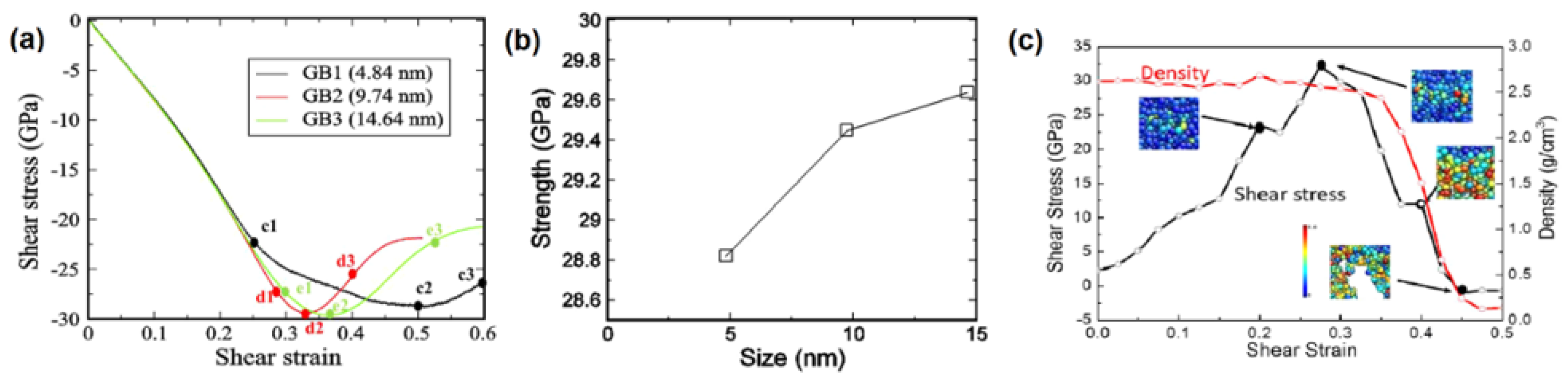

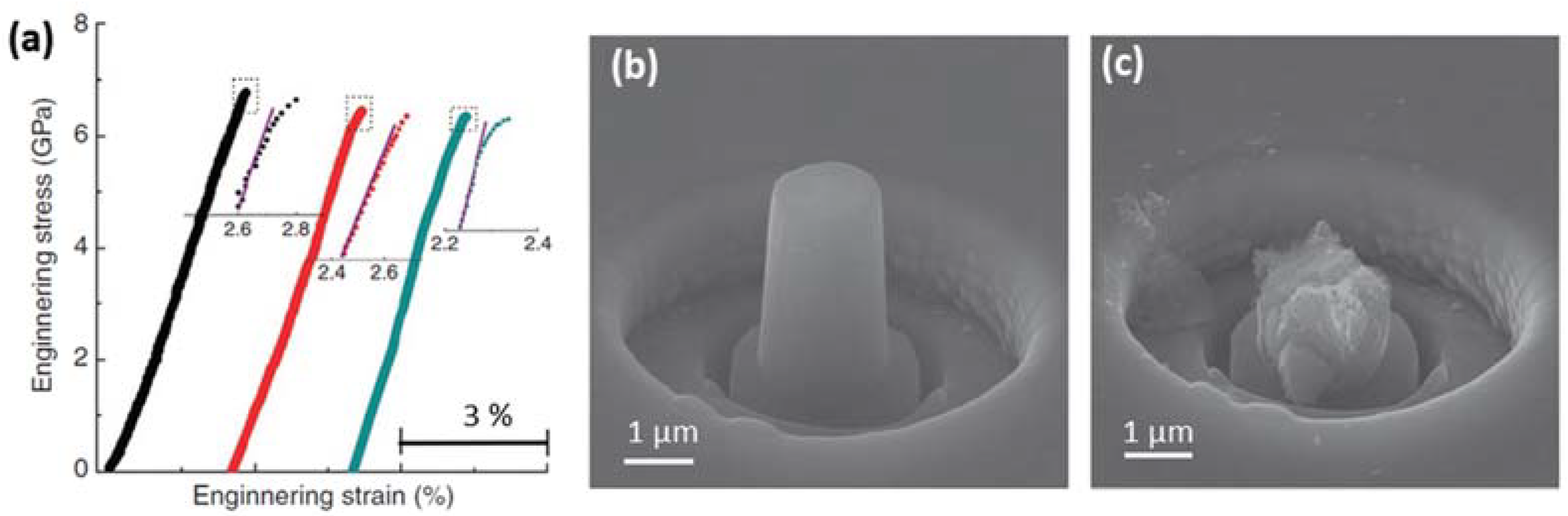

3.2. Nanocrystalline β-SiC

4. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bundy, F.P.; Hall, H.T.; Strong, H.M.; Wentorfjun, R.H. Man-Made Diamonds. Nature 1955, 176, 51–55. [Google Scholar] [CrossRef]

- Wentorf, R.H., Jr. Cubic Form of Boron Nitride. J. Chem. Phys. 1957, 26, 956. [Google Scholar] [CrossRef]

- Wentorf, R.H.; DeVries, R.C.; Bundy, F.P. Sintered Superhard Materials. Science 1980, 208, 873–880. [Google Scholar] [CrossRef] [PubMed]

- Liew, W.Y.H.; Yuan, S.; Ngoi, B.K.A. Evaluation of machining performance of STAVAX with PCBN tools. Int. J. Adv. Manuf. Technol. 2004, 23, 11–19. [Google Scholar] [CrossRef]

- Solozhenko, V.L.; Kurakevych, O.O.; le Godec, Y. Creation of Nanostuctures by Extreme Conditions: High-Pressure Synthesis of Ultrahard Nanocrystalline Cubic Boron Nitride. Adv. Mater. 2012, 24, 1540–1544. [Google Scholar] [CrossRef]

- Tian, Y.; Xu, B.; Yu, D.; Ma, Y.; Wang, Y.; Jiang, Y.; Hu, W.; Tang, C.; Gao, Y.; Luo, K.; et al. Ultrahard nanotwinned cubic boron nitride. Nature 2013, 493, 385–388. [Google Scholar] [CrossRef]

- Krauss, A.R.; Auciello, O.; Gruen, D.M.; Jayatissa, A.; Sumant, A.; Tucek, J.; Mancini, D.C.; Moldovan, N.; Erdemir, A.; Ersoy, D.; et al. Ultrananocrystalline diamond thin films for MEMS and moving mechanical assembly devices. Diam. Relat. Mater. 2001, 10, 1952–1961. [Google Scholar] [CrossRef]

- Ghosh, D.; Subhash, G.; Sudarshan, T.S.; Radhakrishnan, R.; Gao, X.-L. Dynamic Indentation Response of Fine-Grained Boron Carbide. J. Am. Ceram. Soc. 2007, 90, 1850–1857. [Google Scholar] [CrossRef]

- Rendtel, A.; Moessner, B.; Schwetz, K.A. Hardness and Hardness Determination in Silicon Carbide Materials. In Advances in Ceramic Armor: A Collection of Papers Presented at the 29th International Conference on Advanced Ceramics and Composites, January 23–28, 2005, Cocoa Beach, Florida, Ceramic Engineering and Science Proceedings; American Ceramic Society: Columbus, OH, USA, 2005; pp. 161–168. [Google Scholar]

- Rao, X.; Zhang, F.; Luo, X.; Ding, F. Characterization of hardness, elastic modulus and fracture toughness of RB-SiC ceramics at elevated temperature by Vickers test. Mater. Sci. Eng. A 2019, 744, 426–435. [Google Scholar] [CrossRef]

- Rahman, A.; Singh, A.; Harimkar, S.P.; Singh, R.P. Mechanical characterization of fine grained silicon carbide consolidated using polymer pyrolysis and spark plasma sintering. Ceram. Int. 2014, 40(Pt A), 12081–12091. [Google Scholar] [CrossRef]

- Han, Z.; Li, G.; Tian, J.; Gu, M. Microstructure and mechanical properties of boron carbide thin films. Mater. Lett. 2002, 57, 899–903. [Google Scholar] [CrossRef]

- Liao, F.; Girshick, S.L.; Mook, W.M.; Gerberich, W.W.; Zachariah, M.R. Superhard nanocrystalline silicon carbide films. Appl. Phys. Lett. 2005, 86, 171913. [Google Scholar] [CrossRef]

- Thévenot, F. Boron carbide—A comprehensive review. J. Eur. Ceram. Soc. 1990, 6, 205–225. [Google Scholar] [CrossRef]

- Maboudian, R.; Carraro, C.; Senesky, D.G.; Roper, C.S. Advances in silicon carbide science and technology at the micro- and nanoscales. J. Vac. Sci. Technol. A 2013, 31, 050805. [Google Scholar] [CrossRef]

- Koyanagi, T.; Katoh, Y.; Nozawa, T. Design and strategy for next-generation silicon carbide composites for nuclear energy. J. Nucl. Mater. 2020, 540, 152375. [Google Scholar] [CrossRef]

- An, Q.; Goddard, W.A.; Cheng, T. Atomistic Explanation of Shear-Induced Amorphous Band Formation in Boron Carbide. Phys. Rev. Lett. 2014, 113, 095501. [Google Scholar] [CrossRef] [PubMed]

- Reddy, K.M.; Liu, P.; Hirata, A.; Fujita, T.; Chen, M.W. Atomic structure of amorphous shear bands in boron carbide. Nat. Commun. 2013, 4, 2483. [Google Scholar] [CrossRef]

- Chen, M.; McCauley, J.W.; Hemker, K.J. Shock-Induced Localized Amorphization in Boron Carbide. Science 2003, 299, 1563–1566. [Google Scholar] [CrossRef]

- Grady, D.E. Shock-wave compression of brittle solids. Mech. Mater. 1998, 29, 181–203. [Google Scholar] [CrossRef]

- Vogler, T.J.; Reinhart, W.D.; Chhabildas, L.C. Dynamic behavior of boron carbide. J. Appl. Phys. 2004, 95, 4173–4183. [Google Scholar] [CrossRef]

- Evans, A.G. Perspective on the Development of High-Toughness Ceramics. J. Am. Ceram. Soc. 1990, 73, 187–206. [Google Scholar] [CrossRef]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef] [PubMed]

- Reddy, K.M.; Guo, D.; Song, S.; Cheng, C.; Han, J.; Wang, X.; An, Q.; Chen, M. Dislocation-mediated shear amorphization in boron carbide. Sci. Adv. 2021, 7, eabc6714. [Google Scholar] [CrossRef] [PubMed]

- Szlufarska, I.; Kalia, R.K.; Nakano, A.; Vashishta, P. Atomistic processes during nanoindentation of amorphous silicon carbide. Appl. Phys. Lett. 2005, 86, 021915. [Google Scholar] [CrossRef]

- Szlufarska, I.; Kalia, R.K.; Nakano, A.; Vashishta, P. Nanoindentation-induced amorphization in silicon carbide. Appl. Phys. Lett. 2004, 85, 378–380. [Google Scholar] [CrossRef]

- Meyersm, M.A.; Ashworth, E. A model for the effect of grain size on the yield stress of metals. Philos. Mag. A 1982, 46, 737–759. [Google Scholar] [CrossRef]

- Würschum, R.; Herth, S.; Brossmann, U. Diffusion in Nanocrystalline Metals and Alloys—A Status Report. Adv. Eng. Mater. 2003, 5, 365–372. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Birringer, R. Nanocrystalline materials. Mater. Sci. Eng. A 1989, 117, 33–43. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Petch, N. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Shimokawa, T.; Nakatani, A.; Kitagawa, H. Grain-size dependence of the relationship between intergranular and intragranular deformation of nanocrystalline Al by molecular dynamics simulations. Phys. Rev. B 2005, 71, 224110. [Google Scholar] [CrossRef]

- Shan, Z.; Stach, E.A.; Wiezorek, J.M.K.; Knapp, J.A.; Follstaedt, D.M.; Mao, S.X. Grain Boundary-Mediated Plasticity in Nanocrystalline Nickel. Science 2004, 305, 654–657. [Google Scholar] [CrossRef] [PubMed]

- Schiøtz, J.; di Tolla, F.D.; Jacobsen, K.W. Softening of nanocrystalline metals at very small grain sizes. Nature 1998, 391, 561–563. [Google Scholar] [CrossRef]

- Swygenhoven, H.V. Grain Boundaries and Dislocations. Science 2002, 296, 66–67. [Google Scholar] [CrossRef] [PubMed]

- Ryou, H.; Drazin, J.W.; Wahl, K.J.; Qadri, S.B.; Gorzkowski, E.P.; Feigelson, B.N.; Wollmershauser, J.A. Below the Hall–Petch Limit in Nanocrystalline Ceramics. ACS Nano 2018, 12, 3083–3094. [Google Scholar] [CrossRef]

- Schneibel, J.H.; White, C.L.; Padgett, R.A. The Influence of Traces of Sb and Zr on Creep and Creep Fracture of Ni-20% Cr. In Strength of Metals and Alloys (ICSMA 6); Gifkins, R.C., Ed.; Pergamon: Oxford, UK, 1982; pp. 649–654. [Google Scholar]

- Masuda, H.; Tobe, H.; Sato, E.; Sugino, Y.; Ukai, S. Two-dimensional grain boundary sliding and mantle dislocation accommodation in ODS ferritic steel. Acta Mater. 2016, 120, 205–215. [Google Scholar] [CrossRef]

- Dupas-Bruzek, C.; Tingle, T.N.; Green Ii, H.W.; Doukhan, N.; Doukhan, J.-C. The rheology of olivine and spinel magnesium germanate (Mg2GeO4): TEM study of the defect microstructures. Phys. Chem. Miner. 1998, 25, 501–514. [Google Scholar] [CrossRef]

- Samae, V.; Cordier, P.; Demouchy, S.; Bollinger, C.; Gasc, J.; Koizumi, S.; Mussi, A.; Schryvers, D.; Idrissi, H. Stress-induced amorphization triggers deformation in the lithospheric mantle. Nature 2021, 591, 82–86. [Google Scholar] [CrossRef]

- Han, Y.; Li, S.; Zhu, T.; Wu, W.; An, D.; Xie, Z. Enhanced properties of pure alumina ceramics by oscillatory pressure sintering. Ceram. Int. 2018, 44, 5238–5241. [Google Scholar] [CrossRef]

- Gosset, D.; Colin, M. Boron carbides of various compositions: An improved method for X-rays characterisation. J. Nucl. Mater. 1991, 183, 161–173. [Google Scholar] [CrossRef]

- Domnich, V.; Gogotsi, Y.; Trenary, M.; Tanaka, T. Nanoindentation and Raman spectroscopy studies of boron carbide single crystals. Appl. Phys. Lett. 2002, 81, 3783–3785. [Google Scholar] [CrossRef]

- Zare, A.; He, M.-R.; Straker, M.; Chandrashekhare, M.V.S.; Spencer, M.; Hemker, K.J.; McCauley, J.W.; Ramesh, K.T. Mechanical characterization of boron carbide single crystals. J. Am. Ceram. Soc. 2022, 105, 3030–3042. [Google Scholar] [CrossRef]

- Goel, S.; Stukowski, A.; Luo, X.; Agrawal, A.; Reuben, R.L. Anisotropy of single-crystal 3C–SiC during nanometric cutting. Model. Simul. Mater. Sci. Eng. 2013, 21, 065004. [Google Scholar] [CrossRef]

- Rajamallu, K.; Reddy, K. Mechanical properties and deformation mechanism in nanocrystalline boron carbide. In Boron Carbide: Structure, Processing, Properties and Applications; Reddy, K.M., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2020; pp. 219–254. [Google Scholar]

- Vassen, R.; Stöver, D. Processing and Properties of Nanograin Silicon Carbide. J. Am. Ceram. Soc. 1999, 82, 2585–2593. [Google Scholar] [CrossRef]

- Carnahan, R.D. Elastic Properties of Silicon Carbide. J. Am. Ceram. Soc. 1968, 51, 223–224. [Google Scholar] [CrossRef]

- Moshtaghioun, B.M.; Gomez-Garcia, D.; Dominguez-Rodriguez, A.; Todd, R.I. Grain size dependence of hardness and fracture toughness in pure near fully-dense boron carbide ceramics. J. Eur. Ceram. Soc. 2016, 36, 1829–1834. [Google Scholar] [CrossRef]

- Angers, R.; Beauvy, M. Hot-pressing of boron carbide. Ceram. Int. 1984, 10, 49–55. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Mitomo, M.; Hirotsuru, H. Grain Growth and Fracture Toughness of Fine-Grained Silicon Carbide Ceramics. J. Am. Ceram. Soc. 1995, 78, 3145–3148. [Google Scholar] [CrossRef]

- Suri, A.K.; Subramanian, C.; Sonber, J.K.; Murthy, T.S.R.C. Synthesis and consolidation of boron carbide: A review. Int. Mater. Rev. 2010, 55, 4–40. [Google Scholar] [CrossRef]

- Belon, R.; Antou, G.; Pradeilles, N.; Maître, A.; Gosset, D. Mechanical behaviour at high temperature of spark plasma sintered boron carbide ceramics. Ceram. Int. 2017, 43, 6631–6635. [Google Scholar] [CrossRef]

- Hayun, S.; Paris, V.; Dariel, M.P.; Frage, N.; Zaretzky, E. Static and dynamic mechanical properties of boron carbide processed by spark plasma sintering. J. Eur. Ceram. Soc. 2009, 29, 3395–3400. [Google Scholar] [CrossRef]

- Kim, K.-H.; Chae, J.-H.; Park, J.-S.; Kim, D.-K.; Shim, K.-B.; Lee, B.-H. Sintering Behavior and Mechanical Property of B4C Ceramics Fabricated by Spark Plasma Sintering. J. Korean Ceram. Soc. 2008, 45, 60–64. [Google Scholar] [CrossRef]

- Li, X.; Jiang, D.; Zhang, J.; Lin, Q.; Chen, Z.; Huang, Z. Densification behavior and related phenomena of spark plasma sintered boron carbide. Ceram. Int. 2014, 40, 4359–4366. [Google Scholar] [CrossRef]

- Madhav Reddy, K.; Guo, J.J.; Shinoda, Y.; Fujita, T.; Hirata, A.; Singh, J.P.; McCauley, J.W.; Chen, M.W. Enhanced mechanical properties of nanocrystalline boron carbide by nanoporosity and interface phases. Nat. Commun. 2012, 3, 1052. [Google Scholar] [CrossRef]

- Moshtaghioun, B.M.; Cumbrera, F.L.; Ortiz, A.L.; Castillo-Rodríguez, M.; Gómez-García, D. Additive-free superhard B4C with ultrafine-grained dense microstructures. J. Eur. Ceram. Soc. 2014, 34, 841–848. [Google Scholar] [CrossRef]

- Moshtaghioun, B.M.; Cumbrera-Hernández, F.L.; Gómez-García, D.; de Bernardi-Martín, S.; Domínguez-Rodríguez, A.; Monshi, A.; Abbasi, M.H. Effect of spark plasma sintering parameters on microstructure and room-temperature hardness and toughness of fine-grained boron carbide (B4C). J. Eur. Ceram. Soc. 2013, 33, 361–369. [Google Scholar] [CrossRef]

- Moshtaghioun, B.M.; Gómez-García, D.; Domínguez-Rodríguez, A.; Ortiz, A.L. Enhancing the spark-plasma sinterability of B4C nanopowders via room-temperature methylation induced purification. J. Eur. Ceram. Soc. 2016, 36, 2843–2848. [Google Scholar] [CrossRef]

- Moshtaghioun, B.M.; Ortiz, A.L.; Gómez-García, D.; Domínguez-Rodríguez, A. Densification of B4C nanopowder with nanograin retention by spark-plasma sintering. J. Eur. Ceram. Soc. 2015, 35, 1991–1998. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, H.; Zhang, Z.; Wen, R.; Wang, G.; Mu, J.; Che, H.; Zhang, X. Effects of pressure on densification behaviour, microstructures and mechanical properties of boron carbide ceramics fabricated by hot pressing. Ceram. Int. 2017, 43, 6345–6352. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Nie, B.; Chen, H.; Wang, G.; Mu, J.; Zhang, X.; Che, H.; Wang, W. Ultrafine-grained boron carbide ceramics fabricated via ultrafast sintering assisted by high-energy ball milling. Ceram. Int. 2018, 44, 7291–7295. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Nie, B.; Chen, H.; Wang, Y.; Zheng, L.; Bai, Y.; Wang, W. Microstructure and mechanical properties of fine-grained boron carbide ceramics fabricated by high-pressure hot pressing combined with high-energy ball milling. Ceram. Int. 2018, 44, 10766–10772. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Sun, Y.; Xiang, M.; Wang, G.; Bai, Y.; Mu, J.; Che, H.; Wang, W. Preparation, microstructure and toughening mechanism of superhard ultrafine-grained boron carbide ceramics with outstanding fracture toughness. J. Alloy. Compd. 2018, 762, 125–132. [Google Scholar] [CrossRef]

- Pittari, J.; Subhash, G.; Zheng, J.; Halls, V.; Jannotti, P. The rate-dependent fracture toughness of silicon carbide- and boron carbide-based ceramics. J. Eur. Ceram. Soc. 2015, 35, 4411–4422. [Google Scholar] [CrossRef]

- Pan, C.; Zhang, L.; Jiang, W.; Setyawan, W.; Chen, L.; Li, Z.; Liu, N.; Wang, T. Grain size dependence of hardness in nanocrystalline silicon carbide. J. Eur. Ceram. Soc. 2020, 40, 4396–4402. [Google Scholar] [CrossRef]

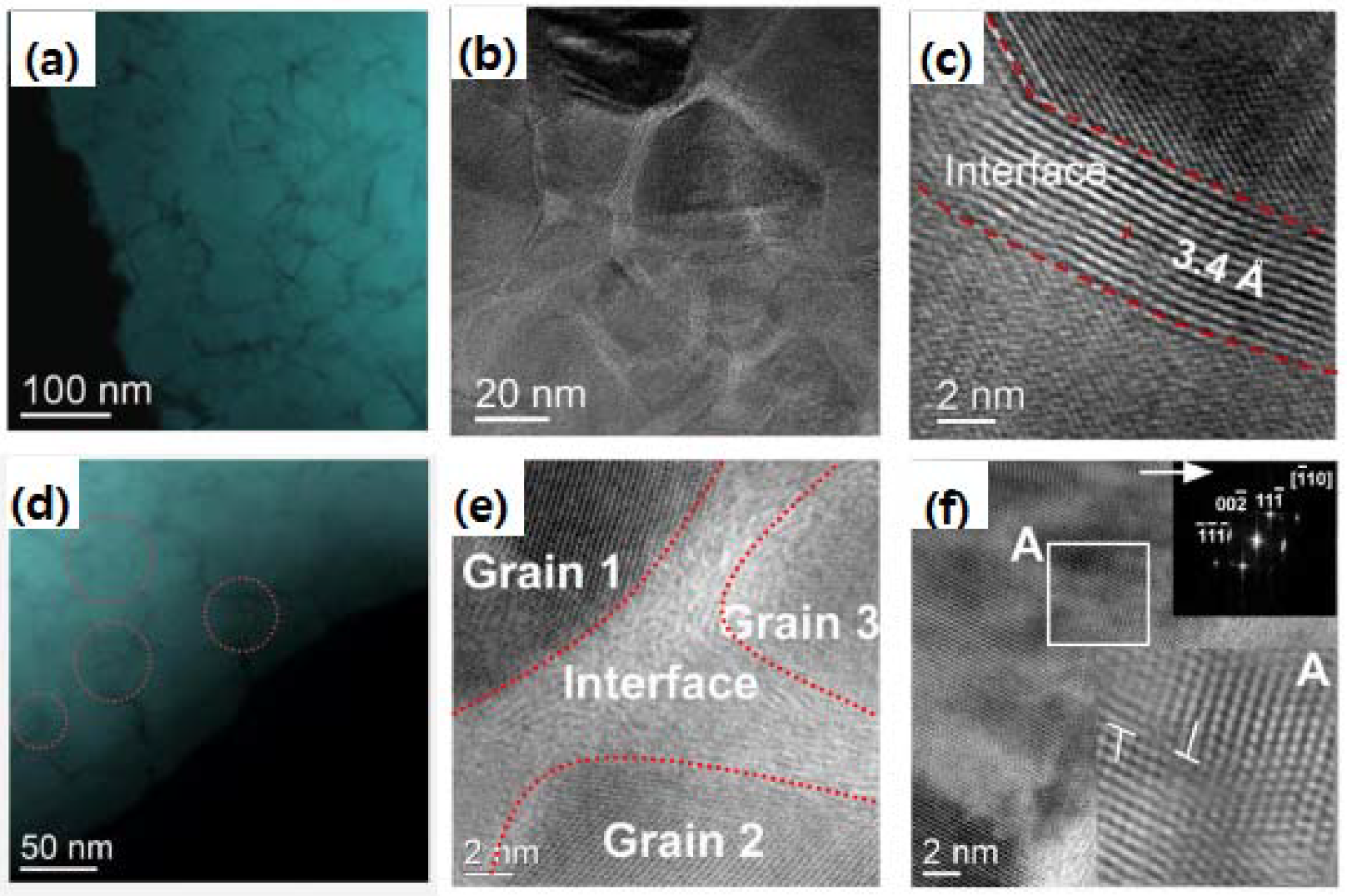

- Madhav Reddy, K.; Guo, D.; Lahkar, S.; Cheng, C.; Shinoda, Y.; An, Q.; Wang, X. Graphite interface mediated grain-boundary sliding leads to enhanced mechanical properties of nanocrystalline silicon carbide. Materialia 2019, 7, 100394. [Google Scholar] [CrossRef]

- Cao, J.J.; MoberlyChan, W.J.; De Jonghe, L.C.; Gilbert, C.J.; Ritchie, R.O. In Situ Toughened Silicon Carbide with Al-B-C Additions. J. Am. Ceram. Soc. 1996, 79, 461–469. [Google Scholar] [CrossRef]

- Sun, R.; Wei, X.; Hu, W.; Ying, P.; Wu, Y.; Wang, L.; Chen, S.; Zhang, X.; Ma, M.; Yu, D.; et al. Nanocrystalline Cubic Silicon Carbide: A Route to Superhardness. Small 2022, 18, 2201212. [Google Scholar] [CrossRef]

- Chakraborti, A.; Vast, N.; Le Godec, Y. Synthesis of boron carbide from its elements at high pressures and high temperatures. Solid State Sci. 2020, 104, 106265. [Google Scholar] [CrossRef]

- Chen, S.; Wang, D.Z.; Huang, J.Y.; Ren, Z.F. Synthesis and characterization of boron carbide nanoparticles. Appl. Phys. A 2004, 79, 1757–1759. [Google Scholar] [CrossRef]

- Chakraborti, A.; Guignot, N.; Vast, N.; Le Godec, Y. Synthesis of boron carbide from its elements up to 13 GPa. J. Phys. Chem. Solids 2021, 159, 110253. [Google Scholar] [CrossRef]

- Xie, K.Y.; Kuwelkar, K.; Haber, R.A.; LaSalvia, J.C.; Hemker, K.J. Microstructural Characterization of a Commercial Hot-Pressed Boron Carbide Armor Plate. J. Am. Ceram. Soc. 2016, 99, 2834–2841. [Google Scholar] [CrossRef]

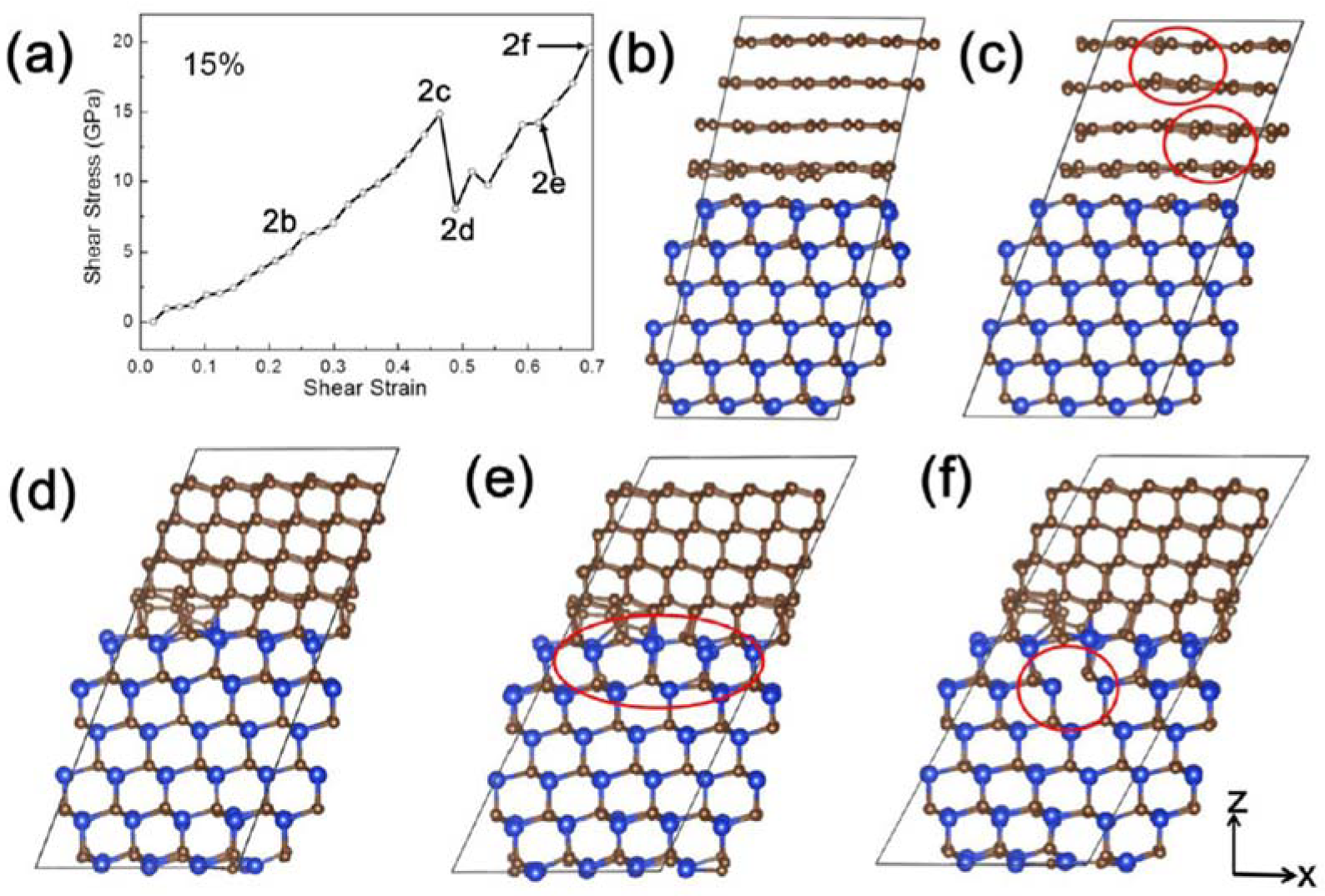

- Guo, D.; Song, S.; Luo, R.; Goddard, W.A.; Chen, M.; Reddy, K.M.; An, Q. Grain Boundary Sliding and Amorphization are Responsible for the Reverse Hall-Petch Relation in Superhard Nanocrystalline Boron Carbide. Phys. Rev. Lett. 2018, 121, 145504. [Google Scholar] [CrossRef] [PubMed]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Erhart, P.; Albe, K. Analytical potential for atomistic simulations of silicon, carbon, and silicon carbide. Phys. Rev. B 2005, 71, 035211. [Google Scholar] [CrossRef]

- Vashishta, P.; Kalia, R.K.; Nakano, A.; Rino, J.P. Interaction potential for silicon carbide: A molecular dynamics study of elastic constants and vibrational density of states for crystalline and amorphous silicon carbide. J. Appl. Phys. 2007, 101, 103515. [Google Scholar] [CrossRef]

- Devanathan, R.; de la Rubia, T.D.; Weber, W.J. Displacement threshold energies in β-SiC. J. Nucl. Mater. 1998, 253, 47–52. [Google Scholar] [CrossRef]

- Gao, F.; Weber, W.J. Empirical potential approach for defect properties in 3C-SiC. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2002, 191, 504–508. [Google Scholar] [CrossRef]

- Baskes, M.I. Modified embedded-atom potentials for cubic materials and impurities. Phys. Rev. B 1992, 46, 2727. [Google Scholar] [CrossRef]

- Tersoff, J. Modeling solid-state chemistry: Interatomic potentials for multicomponent systems. Phys. Rev. B 1989, 39, 5566. [Google Scholar] [CrossRef]

- Lambrecht, W.; Segall, B.; Methfessel, M.; Van Schilfgaarde, M. Calculated elastic constants and deformation potentials of cubic SiC. Phys. Rev. B 1991, 44, 3685. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Alam, M.; Zhang, J.; Janisch, R.; Hartmaier, A. Amorphization-governed elasto-plastic deformation under nanoindentation in cubic (3C) silicon carbide. Ceram. Int. 2020, 46 (Pt B), 12470–12479. [Google Scholar] [CrossRef]

- Zare Chavoshi, S.; Branicio, P.S.; An, Q. Transition between Hall-Petch and inverse Hall-Petch behavior in nanocrystalline silicon carbide. Phys. Rev. Mater. 2021, 5, 073606. [Google Scholar] [CrossRef]

- Voronoi, G. New applications of continuous parameters to the theory of quadratic forms. Z. Reine Angew. Math. 1908, 134, 198. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Sha, Z.D.; Branicio, P.S.; Zhang, Y.W.; Sorkin, V.; Pei, Q.X.; Srolovitz, D.J. Superplastic nanocrystalline ceramics at room temperature and high strain rates. Scr. Mater. 2013, 69, 525–528. [Google Scholar] [CrossRef]

- Shimizu, F.; Ogata, S.; Li, J. Theory of Shear Banding in Metallic Glasses and Molecular Dynamics Calculations. Mater. Trans. 2007, 48, 2923–2927. [Google Scholar] [CrossRef]

- Zhao, S.; Flanagan, R.; Hahn, E.N.; Kad, B.; Remington, B.A.; Wehrenberg, C.E.; Cauble, R.; More, K.; Meyers, M.A. Shock-induced amorphization in silicon carbide. Acta Mater. 2018, 158, 206–213. [Google Scholar] [CrossRef]

- Hill, R. The Elastic Behaviour of a Crystalline Aggregate. Proc. Phys. Soc. Sect. A 1952, 65, 349–354. [Google Scholar] [CrossRef]

- Szlufarska, I.; Nakano, A.; Vashishta, P. A Crossover in the Mechanical Response of Nanocrystalline Ceramics. Science 2005, 309, 911–914. [Google Scholar] [CrossRef]

- Sarva, S.; Nemat-Nasser, S. Dynamic compressive strength of silicon carbide under uniaxial compression. Mater. Sci. Eng. A 2001, 317, 140–144. [Google Scholar] [CrossRef]

- Shackelford, J.F.; Han, Y.-H.; Kim, S.; Kwon, S.-H. CRC Materials Science and Engineering Handbook; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Tamari, N.; Tanaka, T.; Tanaka, K.; Kondoh, I.; Kawahara, M.; Tokita, M. Effect of Spark Plasma Sintering on Densification and Mechanical Properties of Silicon Carbide. J. Ceram. Soc. Jpn. 1995, 103, 740–742. [Google Scholar] [CrossRef]

- Cho, N.; Bao, Z.; Speyer, R.F. Density- and hardness-optimized pressureless sintered and post-hot isostatic pressed B4C. J. Mater. Res. 2005, 20, 2110–2116. [Google Scholar] [CrossRef]

- Ge, D.; Domnich, V.; Juliano, T.; Stach, E.A.; Gogotsi, Y. Structural damage in boron carbide under contact loading. Acta Mater. 2004, 52, 3921–3927. [Google Scholar] [CrossRef]

- Harmer, M.P. The Phase Behavior of Interfaces. Science 2011, 332, 182–183. [Google Scholar] [CrossRef] [PubMed]

- Shih, C.J.; Meyers, M.A.; Nesterenko, V.F.; Chen, S.J. Damage evolution in dynamic deformation of silicon carbide. Acta Mater. 2000, 48, 2399–2420. [Google Scholar] [CrossRef]

- Giannuzzi, L.A. Introduction to Focused Ion Beams: Instrumentation, Theory, Techniques and Practice; Springer Science & Business Media: New York, NY, USA, 2004. [Google Scholar]

- Wang, H.; Ramesh, K.T. Dynamic strength and fragmentation of hot-pressed silicon carbide under uniaxial compression. Acta Mater. 2004, 52, 355–367. [Google Scholar] [CrossRef]

- Sharpe, W.N.; Jadaan, O.; Beheim, G.M.; Quinn, G.D.; Nemeth, N.N. Fracture strength of silicon carbide microspecimens. J. Microelectromechanical Syst. 2005, 14, 903–913. [Google Scholar] [CrossRef]

- Orange, G.; Tanaka, H.; Fantozzi, G. Fracture toughness of pressureless sintered silicon carbide: A comparison of Klc measurement methods. Ceram. Int. 1987, 13, 159–165. [Google Scholar] [CrossRef]

- Gao, Y.; Ma, Y.; An, Q.; Levitas, V.; Zhang, Y.; Feng, B.; Chaudhuri, J.; Goddard, W.A. Shear driven formation of nano-diamonds at sub-gigapascals and 300 K. Carbon 2019, 146, 364–368. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, B.; Lahkar, S.; An, Q.; Reddy, K.M. Mechanical Properties and Deformation Behavior of Superhard Lightweight Nanocrystalline Ceramics. Nanomaterials 2022, 12, 3228. https://doi.org/10.3390/nano12183228

Jeong B, Lahkar S, An Q, Reddy KM. Mechanical Properties and Deformation Behavior of Superhard Lightweight Nanocrystalline Ceramics. Nanomaterials. 2022; 12(18):3228. https://doi.org/10.3390/nano12183228

Chicago/Turabian StyleJeong, Byeongyun, Simanta Lahkar, Qi An, and Kolan Madhav Reddy. 2022. "Mechanical Properties and Deformation Behavior of Superhard Lightweight Nanocrystalline Ceramics" Nanomaterials 12, no. 18: 3228. https://doi.org/10.3390/nano12183228

APA StyleJeong, B., Lahkar, S., An, Q., & Reddy, K. M. (2022). Mechanical Properties and Deformation Behavior of Superhard Lightweight Nanocrystalline Ceramics. Nanomaterials, 12(18), 3228. https://doi.org/10.3390/nano12183228