In Situ Measurements of Strain Evolution in Graphene/Boron Nitride Heterostructures Using a Non-Destructive Raman Spectroscopy Approach

Abstract

:1. Introduction

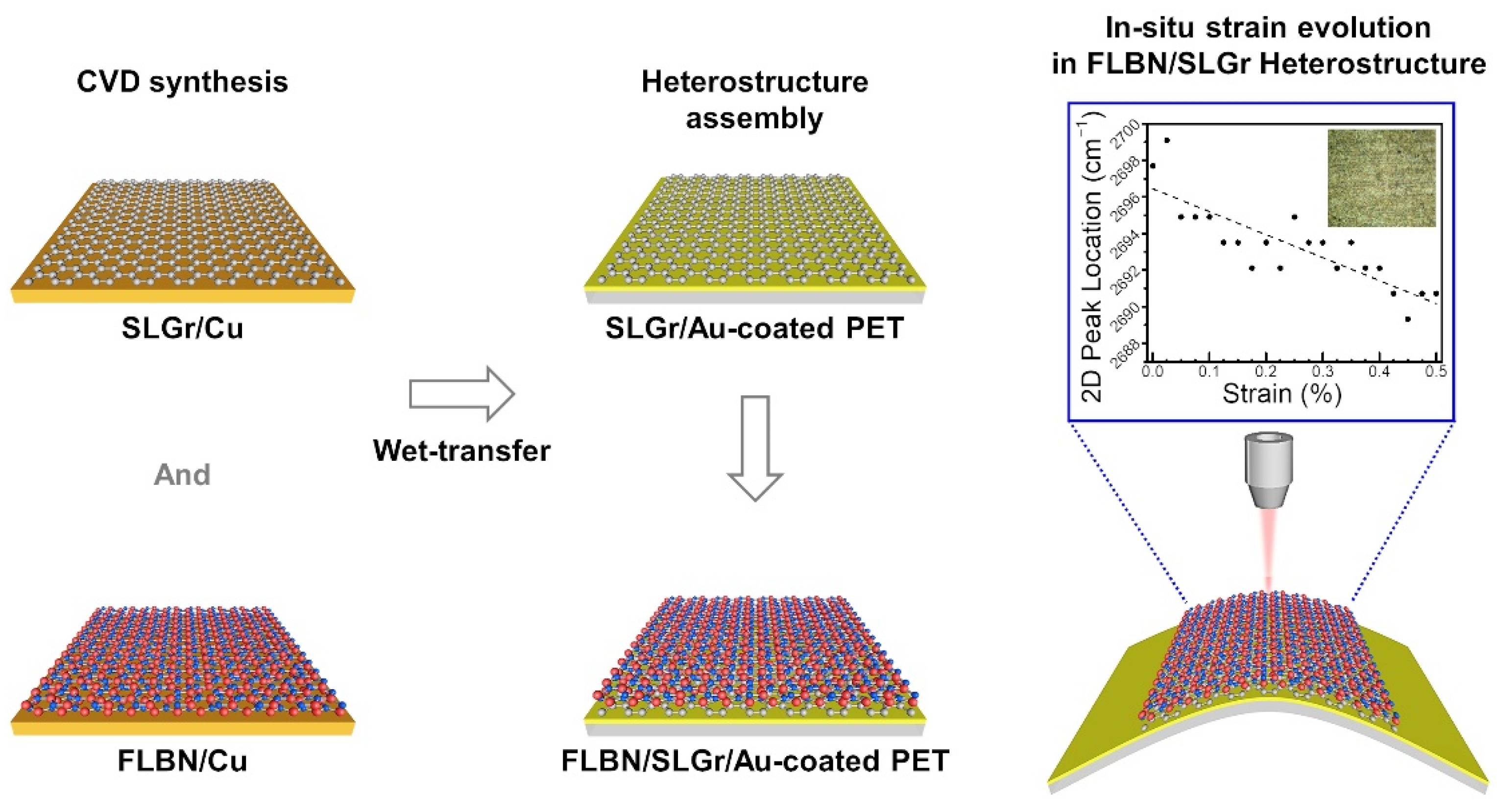

2. Materials and Methods

2.1. Graphene and Boron Nitride CVD Synthesis

2.2. Graphene and Boron Nitride Transfer

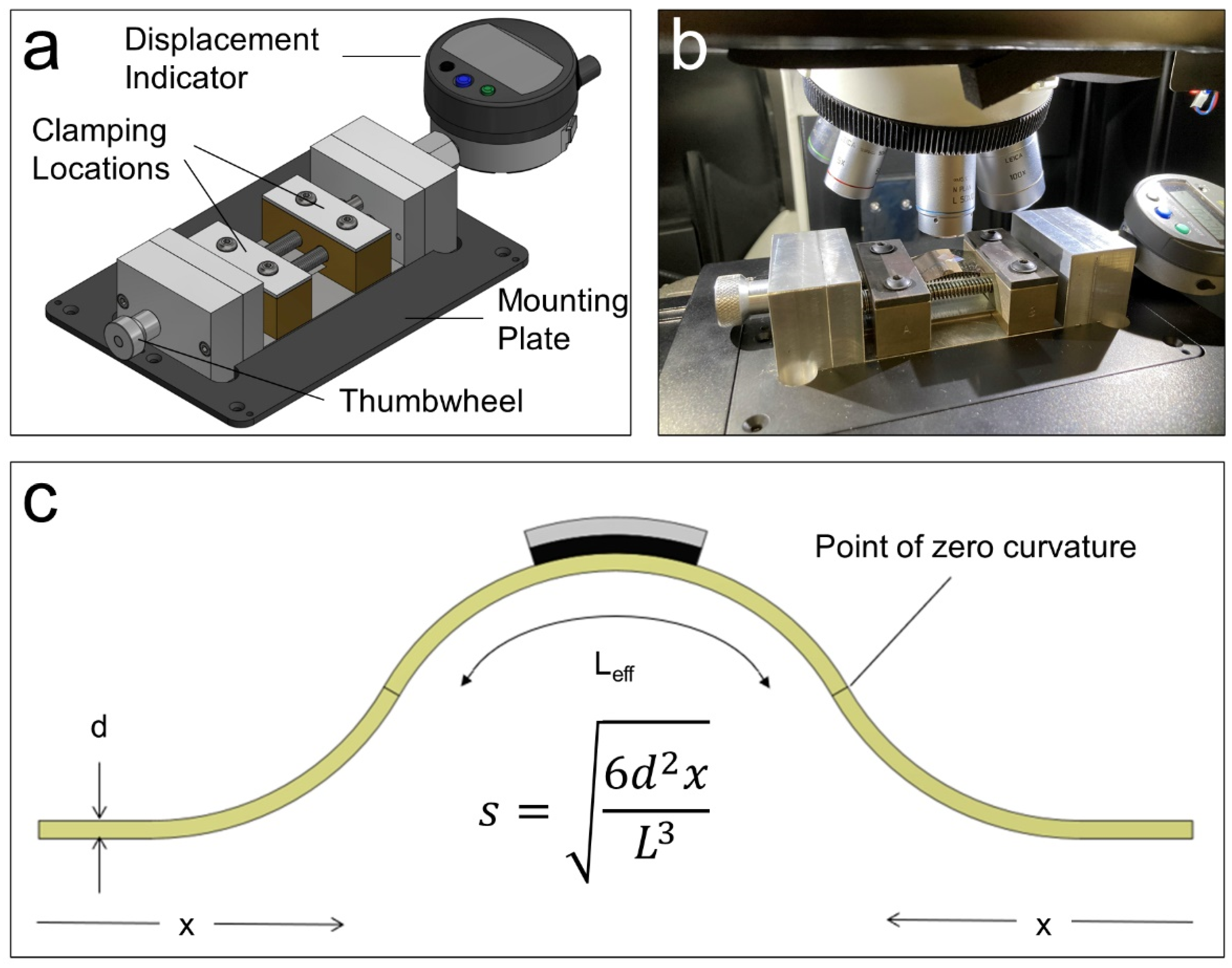

2.3. Mechanical Device (Jig) Characteristics

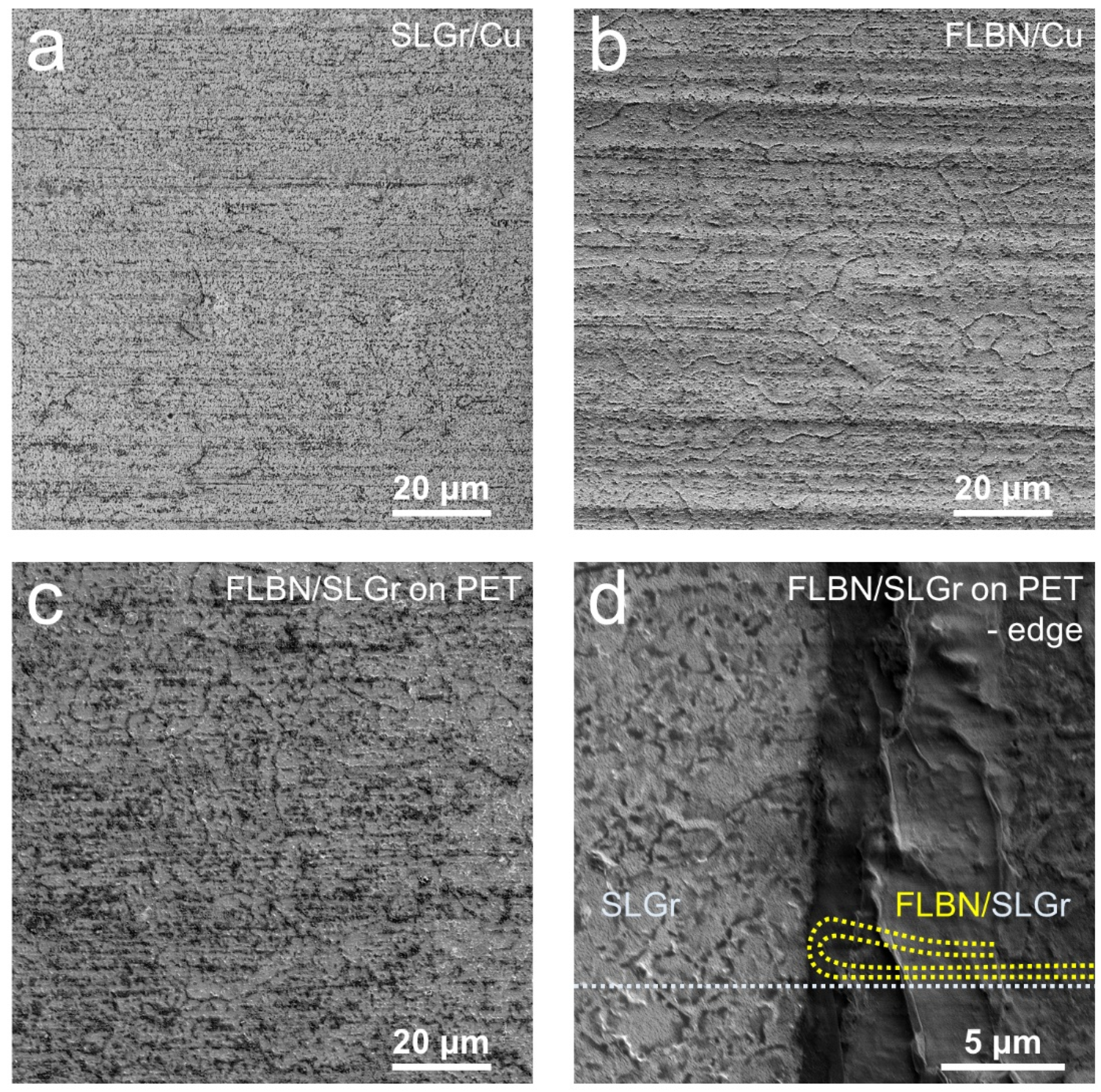

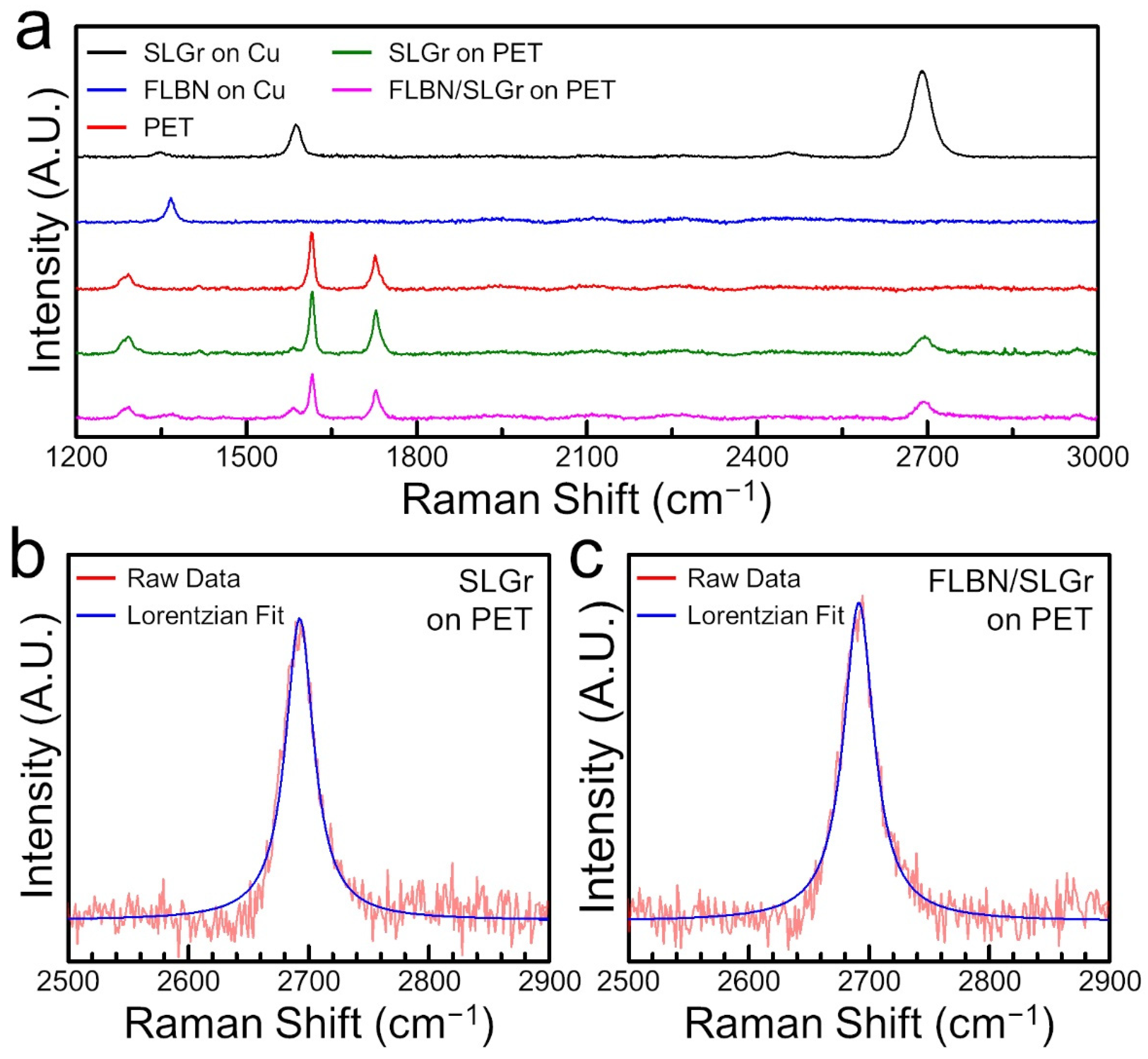

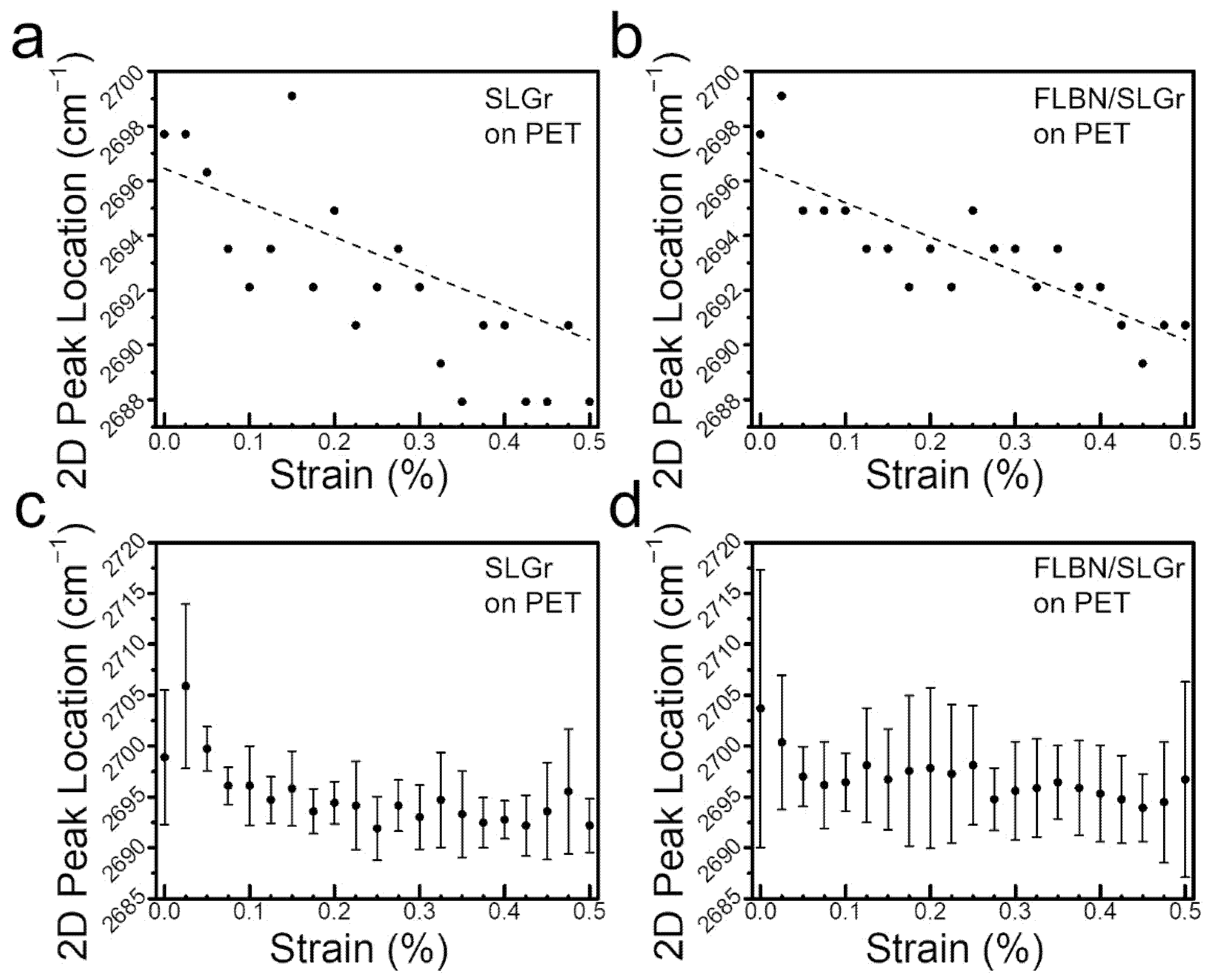

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, K.; Tareen, A.K.; Aslam, M.; Wang, R.; Zhang, Y.; Mahmood, A.; Ouyang, Z.; Zhang, H.; Guo, Z. Recent developments in emerging two-dimensional materials and their applications. J. Mater. Chem. C 2020, 8, 387–440. [Google Scholar] [CrossRef]

- Glavin, N.R.; Rao, R.; Varshney, V.; Bianco, E.; Apte, A.; Roy, A.; Ringe, E.; Ajayan, P.M. Emerging Applications of Elemental 2D Materials. Adv. Mater. 2020, 32, 1904302. [Google Scholar] [CrossRef] [PubMed]

- Alameri, D.; Nasr, J.R.; Karbach, D.; Liu, Y.; Divan, R.; Das, S.; Kuljanishvili, I. Mask-free patterning and selective CVD-growth of 2D-TMDCs semiconductors. Semicond. Sci. Technol. 2019, 34, 085010. [Google Scholar] [CrossRef]

- Alameri, D.; Ocola, L.E.; Kuljanishvili, I. Mask-free fabrication and chemical vapor deposition synthesis of ultrathin zinc oxide microribbons on Si/SiO2 and 2D substrates. J. Vac. Sci. Technol. A 2018, 36, 05G506. [Google Scholar] [CrossRef]

- Liang, S.-J.; Cheng, B.; Cui, X.; Miao, F. Van der Waals Heterostructures for High-Performance Device Applications: Challenges and Opportunities. Adv. Mater. 2020, 32, 1903800. [Google Scholar] [CrossRef]

- Choi, W.; Choudhary, N.; Han, G.H.; Park, J.; Akinwande, D.; Lee, Y.H. Recent development of two-dimensional transition metal dichalcogenides and their applications. Mater. Today 2017, 20, 116–130. [Google Scholar] [CrossRef]

- Ye, M.; Zhang, D.; Yap, Y.K. Recent Advances in Electronic and Optoelectronic Devices Based on Two-Dimensional Transition Metal Dichalcogenides. Electronics 2017, 6, 43. [Google Scholar] [CrossRef]

- Pang, Y.; Yang, Z.; Yang, Y.; Ren, T.-L. Wearable Electronics Based on 2D Materials for Human Physiological Information Detection. Small 2020, 16, 1901124. [Google Scholar] [CrossRef]

- Wang, J.; Ma, F.; Liang, W.; Wang, R.; Sun, M. Optical, photonic and optoelectronic properties of graphene, h-BN and their hybrid materials. Nanophotonics 2017, 6, 943–976. [Google Scholar] [CrossRef]

- Falin, A.; Cai, Q.; Santos, E.J.G.; Scullion, D.; Qian, D.; Zhang, R.; Yang, Z.; Huang, S.; Watanabe, K.; Taniguchi, T.; et al. Mechanical properties of atomically thin boron nitride and the role of interlayer interactions. Nat. Commun. 2017, 8, 15815. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Ma, F.; Liang, W.; Sun, M. Electrical properties and applications of graphene, hexagonal boron nitride (h-BN), and graphene/h-BN heterostructures. Mater. Today Phys. 2017, 2, 6–34. [Google Scholar] [CrossRef]

- De Sanctis, A.; Mehew, J.D.; Alkhalifa, S.; Withers, F.; Craciun, M.F.; Russo, S. Strain-Engineering of Twist-Angle in Graphene/hBN Superlattice Devices. Nano Lett. 2018, 18, 7919–7926. [Google Scholar] [CrossRef] [PubMed]

- Dresselhaus, M.S.; Dresselhaus, G.; Saito, R.; Jorio, A. Raman spectroscopy of carbon nanotubes. Phys. Rep. 2005, 409, 47–99. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Y.; Li, X.; Liu, N.; Cui, B.; Huang, X. Bending Effects in Graphene: Implication for Flexible Transparent Electronics. Phys. Status Solidi (b) 2019, 256, 1900095. [Google Scholar] [CrossRef]

- Sahalianov, I.Y.; Radchenko, T.M.; Tatarenko, V.A.; Cuniberti, G.; Prylutskyy, Y.I. Straintronics in graphene: Extra large electronic band gap induced by tensile and shear strains. J. Appl. Phys. 2019, 126, 054302. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Bilal, M.; Xu, W.; Wang, C.; Wen, H.; Zhao, X.; Song, D.; Ding, L. Optoelectronic Properties of Monolayer Hexagonal Boron Nitride on Different Substrates Measured by Terahertz Time-Domain Spectroscopy. Nanomaterials 2020, 10, 762. [Google Scholar] [CrossRef]

- Kostoglou, N.; Polychronopoulou, K.; Rebholz, C. Thermal and chemical stability of hexagonal boron nitride (h-BN) nanoplatelets. Vacuum 2015, 112, 42–45. [Google Scholar] [CrossRef]

- Han, Y.; Feng, S.; Cao, K.; Wang, Y.; Gao, L.; Xu, Z.; Lu, Y. Large Elastic Deformation and Defect Tolerance of Hexagonal Boron Nitride Monolayers. Cell Rep. Phys. Sci. 2020, 1, 100172. [Google Scholar] [CrossRef]

- Song, X.; Gao, T.; Nie, Y.; Zhuang, J.; Sun, J.; Ma, D.; Shi, J.; Lin, Y.; Ding, F.; Zhang, Y.; et al. Seed-Assisted Growth of Single-Crystalline Patterned Graphene Domains on Hexagonal Boron Nitride by Chemical Vapor Deposition. Nano Lett. 2016, 16, 6109–6116. [Google Scholar] [CrossRef]

- Aggoune, W.; Cocchi, C.; Nabok, D.; Rezouali, K.; Akli Belkhir, M.; Draxl, C. Enhanced Light–Matter Interaction in Graphene/h-BN van der Waals Heterostructures. J. Phys. Chem. Lett. 2017, 8, 1464–1471. [Google Scholar] [CrossRef] [PubMed]

- Maggini, L.; Ferreira, R.R. 2D material hybrid heterostructures: Achievements and challenges towards high throughput fabrication. J. Mater. Chem. C 2021, 9, 15721–15734. [Google Scholar] [CrossRef]

- Xu, H.Y.; Akbari, M.K.; Zhuiykov, S. 2D Semiconductor Nanomaterials and Heterostructures: Controlled Synthesis and Functional Applications. Nanoscale Res. Lett. 2021, 16, 94. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.Q.; Liu, J.L.; Kirchner, M.M.; Wang, H.; Ren, Y.L.; Lei, W. Two-dimensional heterostructures and their device applications: Progress, challenges and opportunities-review. J. Phys. D Appl. Phys. 2021, 54, 433001. [Google Scholar] [CrossRef]

- Pantano, M.F.; Kuljanishvili, I. Advances in mechanical characterization of 1D and 2D nanomaterials: Progress and prospects. Nano Express 2020, 1, 022001. [Google Scholar] [CrossRef]

- Suk, J.W.; Piner, R.D.; An, J.; Ruoff, R.S. Mechanical Properties of Monolayer Graphene Oxide. ACS Nano 2010, 4, 6557–6564. [Google Scholar] [CrossRef]

- Wang, C.; Frogley, M.D.; Cinque, G.; Liu, L.-Q.; Barber, A.H. Deformation and failure mechanisms in graphene oxide paper using in situ nanomechanical tensile testing. Carbon 2013, 63, 471–477. [Google Scholar] [CrossRef]

- Neumann, C.; Reichardt, S.; Venezuela, P.; Drögeler, M.; Banszerus, L.; Schmitz, M.; Watanabe, K.; Taniguchi, T.; Mauri, F.; Beschoten, B.; et al. Raman spectroscopy as probe of nanometre-scale strain variations in graphene. Nat. Commun. 2015, 6, 8429. [Google Scholar] [CrossRef]

- del Corro, E.; Taravillo, M.; Baonza, V.G. Nonlinear strain effects in double-resonance Raman bands of graphite, graphene, and related materials. Phys. Rev. B 2012, 85, 033407. [Google Scholar] [CrossRef]

- Li, Z.; Kinloch, I.A.; Young, R.J. The role of interlayer adhesion in graphene oxide upon its reinforcement of nanocomposites. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150283. [Google Scholar] [CrossRef] [Green Version]

- Androulidakis, C.; Koukaras, E.N.; Parthenios, J.; Kalosakas, G.; Papagelis, K.; Galiotis, C. Graphene flakes under controlled biaxial deformation. Sci. Rep. 2015, 5, 18219. [Google Scholar] [CrossRef] [PubMed]

- Ni, Z.H.; Yu, T.; Lu, Y.H.; Wang, Y.Y.; Feng, Y.P.; Shen, Z.X. Uniaxial Strain on Graphene: Raman Spectroscopy Study and Band-Gap Opening. ACS Nano 2008, 2, 2301–2305. [Google Scholar] [CrossRef] [PubMed]

- Mohiuddin, T.M.G.; Lombardo, A.; Nair, R.R.; Bonetti, A.; Savini, G.; Jalil, R.; Bonini, N.; Basko, D.M.; Galiotis, C.; Marzari, N.; et al. Uniaxial strain in graphene by Raman spectroscopy: $G$ peak splitting, Gr\"uneisen parameters, and sample orientation. Phys. Rev. B 2009, 79, 205433. [Google Scholar] [CrossRef]

- Chhikara, M.; Gaponenko, I.; Paruch, P.; Kuzmenko, A.B. Effect of uniaxial strain on the optical Drude scattering in graphene. 2D Mater. 2017, 4, 025081. [Google Scholar] [CrossRef]

- Malard, L.M.; Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S. Raman spectroscopy in graphene. Phys. Rep. 2009, 473, 51–87. [Google Scholar] [CrossRef]

- Cong, X.; Liu, X.L.; Lin, M.L.; Tan, P.H. Application of Raman spectroscopy to probe fundamental properties of two-dimensional materials. Npj 2D Mater. Appl. 2020, 4, 13. [Google Scholar] [CrossRef]

- Cancado, L.G.; Jorio, A.; Ferreira, E.H.M.; Stavale, F.; Achete, C.A.; Capaz, R.B.; Moutinho, M.V.O.; Lombardo, A.; Kulmala, T.S.; Ferrari, A.C. Quantifying Defects in Graphene via Raman Spectroscopy at Different Excitation Energies. Nano Lett. 2011, 11, 3190–3196. [Google Scholar] [CrossRef]

- Wang, J.; Ma, F.; Sun, M. Graphene, hexagonal boron nitride, and their heterostructures: Properties and applications. RSC Adv. 2017, 7, 16801–16822. [Google Scholar] [CrossRef]

- Androulidakis, C.; Zhang, K.; Robertson, M.; Tawfick, S. Tailoring the mechanical properties of 2D materials and heterostructures. 2D Mater. 2018, 5, 032005. [Google Scholar] [CrossRef]

- Dean, C.R.; Young, A.F.; Meric, I.; Lee, C.; Wang, L.; Sorgenfrei, S.; Watanabe, K.; Taniguchi, T.; Kim, P.; Shepard, K.L.; et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 2010, 5, 722–726. [Google Scholar] [CrossRef]

- Pizzocchero, F.; Gammelgaard, L.; Jessen, B.S.; Caridad, J.M.; Wang, L.; Hone, J.; Bøggild, P.; Booth, T.J. The hot pick-up technique for batch assembly of van der Waals heterostructures. Nat. Commun. 2016, 7, 11894. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Herlinger, P.; Taniguchi, T.; Watanabe, K.; Smet, J.H. Reliable Postprocessing Improvement of van der Waals Heterostructures. ACS Nano 2019, 13, 14182–14190. [Google Scholar] [CrossRef] [PubMed]

- Du, J.; Yu, H.; Liu, B.; Hong, M.; Liao, Q.; Zhang, Z.; Zhang, Y. Strain Engineering in 2D Material-Based Flexible Optoelectronics. Small Methods 2021, 5, 2000919. [Google Scholar] [CrossRef] [PubMed]

- Rouhi, S.; Pourmirzaagha, H.; Farzin, A. Predicting the mechanical properties of multi-layered silicene by molecular dynamics simulations. Mater. Res. Express 2019, 6, 085004. [Google Scholar] [CrossRef]

- Yang, Y.; Song, Z.; Lu, G.; Zhang, Q.; Zhang, B.; Ni, B.; Wang, C.; Li, X.; Gu, L.; Xie, X.; et al. Intrinsic toughening and stable crack propagation in hexagonal boron nitride. Nature 2021, 594, 57–61. [Google Scholar] [CrossRef] [PubMed]

- Qu, W.; Bagchi, S.; Chen, X.; Chew, H.B.; Ke, C. Bending and interlayer shear moduli of ultrathin boron nitride nanosheet. J. Phys. D Appl. Phys. 2019, 52, 465301. [Google Scholar] [CrossRef]

- Li, C.; Bando, Y.; Zhi, C.; Huang, Y.; Golberg, D. Thickness-dependent bending modulus of hexagonal boron nitride nanosheets. Nanotechnology 2009, 20, 385707. [Google Scholar] [CrossRef]

- Tsuneda, T.; Iwasa, T.; Taketsugu, T. Roles of silver nanoclusters in surface-enhanced Raman spectroscopy. J. Chem. Phys. 2019, 151, 094102. [Google Scholar] [CrossRef]

- Liu, K.; Wu, J. Mechanical properties of two-dimensional materials and heterostructures. J. Mater. Res. 2016, 31, 832–844. [Google Scholar] [CrossRef]

- Reich, S.; Ferrari, A.C.; Arenal, R.; Loiseau, A.; Bello, I.; Robertson, J. Resonant Raman scattering in cubic and hexagonal boron nitride. Phys. Rev. B 2005, 71, 205201. [Google Scholar] [CrossRef] [Green Version]

- Dresselhaus, M.S.; Jorio, A.; Hofmann, M.; Dresselhaus, G.; Saito, R. Perspectives on Carbon Nanotubes and Graphene Raman Spectroscopy. Nano Lett. 2010, 10, 751–758. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.Y.; Son, H.; Zhang, J.; Kong, J.; Liu, Z.F. Laser-heating effect on Raman spectra of individual suspended single-walled carbon nanotubes. J. Phys. Chem. C 2007, 111, 1988–1992. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman Spectrum of Graphene and Graphene Layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef]

- Tsoukleri, G.; Parthenios, J.; Galiotis, C.; Papagelis, K. Embedded trilayer graphene flakes under tensile and compressive loading. 2D Mater. 2015, 2, 024009. [Google Scholar] [CrossRef]

- Yankowitz, M.; Ma, Q.; Jarillo-Herrero, P.; LeRoy, B.J. van der Waals heterostructures combining graphene and hexagonal boron nitride. Nat. Rev. Phys. 2019, 1, 112–125. [Google Scholar] [CrossRef]

- Li, Q.C.; Liu, M.X.; Zhang, Y.F.; Liu, Z.F. Hexagonal Boron Nitride-Graphene Heterostructures: Synthesis and Interfacial Properties. Small 2016, 12, 32–50. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Neto, A.H.C. 2D materials and van der Waals heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef]

- Geim, A.K.; Grigorieva, I.V. Van der Waals heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef]

- Chakraborty, S.K.; Kundu, B.; Nayak, B.; Dash, S.P.; Sahoo, P.K. Challenges and opportunities in 2D heterostructures for electronic and optoelectronic devices. Iscience 2022, 25, 103942. [Google Scholar] [CrossRef]

- Zhong, T.; Li, J.B.; Zhang, K.W. A molecular dynamics study of Young’s modulus of multilayer graphene. J. Appl. Phys. 2019, 125, 175110. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, Y.C.; Yin, D.Q.; Song, S.F.; Lin, L.Y.; Zhang, M.X.; Qi, X.L.; Yao, J.Y. Mechanical properties and thickness-determined fracture mode of hexagonal boron nitride nanosheets under nanoindentation simulations. Comput. Mater. Sci. 2021, 186, 110047. [Google Scholar] [CrossRef]

- Wei, Y.J.; Wu, J.T.; Yin, H.Q.; Shi, X.H.; Yang, R.G.; Dresselhaus, M. The nature of strength enhancement and weakening by pentagon-heptagon defects in graphene. Nat. Mater. 2012, 11, 759–763. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Polin, G.; Gomez-Navarro, C.; Parente, V.; Guinea, F.; Katsnelson, M.I.; Perez-Murano, F.; Gomez-Herrero, J. Increasing the elastic modulus of graphene by controlled defect creation. Nat. Phys. 2015, 11, 26–31. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mezzacappa, M.; Alameri, D.; Thomas, B.; Kim, Y.; Lei, C.-H.; Kuljanishvili, I. In Situ Measurements of Strain Evolution in Graphene/Boron Nitride Heterostructures Using a Non-Destructive Raman Spectroscopy Approach. Nanomaterials 2022, 12, 3060. https://doi.org/10.3390/nano12173060

Mezzacappa M, Alameri D, Thomas B, Kim Y, Lei C-H, Kuljanishvili I. In Situ Measurements of Strain Evolution in Graphene/Boron Nitride Heterostructures Using a Non-Destructive Raman Spectroscopy Approach. Nanomaterials. 2022; 12(17):3060. https://doi.org/10.3390/nano12173060

Chicago/Turabian StyleMezzacappa, Marc, Dheyaa Alameri, Brian Thomas, Yoosuk Kim, Chi-Hou Lei, and Irma Kuljanishvili. 2022. "In Situ Measurements of Strain Evolution in Graphene/Boron Nitride Heterostructures Using a Non-Destructive Raman Spectroscopy Approach" Nanomaterials 12, no. 17: 3060. https://doi.org/10.3390/nano12173060

APA StyleMezzacappa, M., Alameri, D., Thomas, B., Kim, Y., Lei, C.-H., & Kuljanishvili, I. (2022). In Situ Measurements of Strain Evolution in Graphene/Boron Nitride Heterostructures Using a Non-Destructive Raman Spectroscopy Approach. Nanomaterials, 12(17), 3060. https://doi.org/10.3390/nano12173060