Gain Enhancement of the Optical Waveguide Amplifier Based on NaYF4/NaLuF4: Yb, Er NPs-PMMA Integrated with a Si3N4 Slot

Abstract

1. Introduction

2. Experiments Details

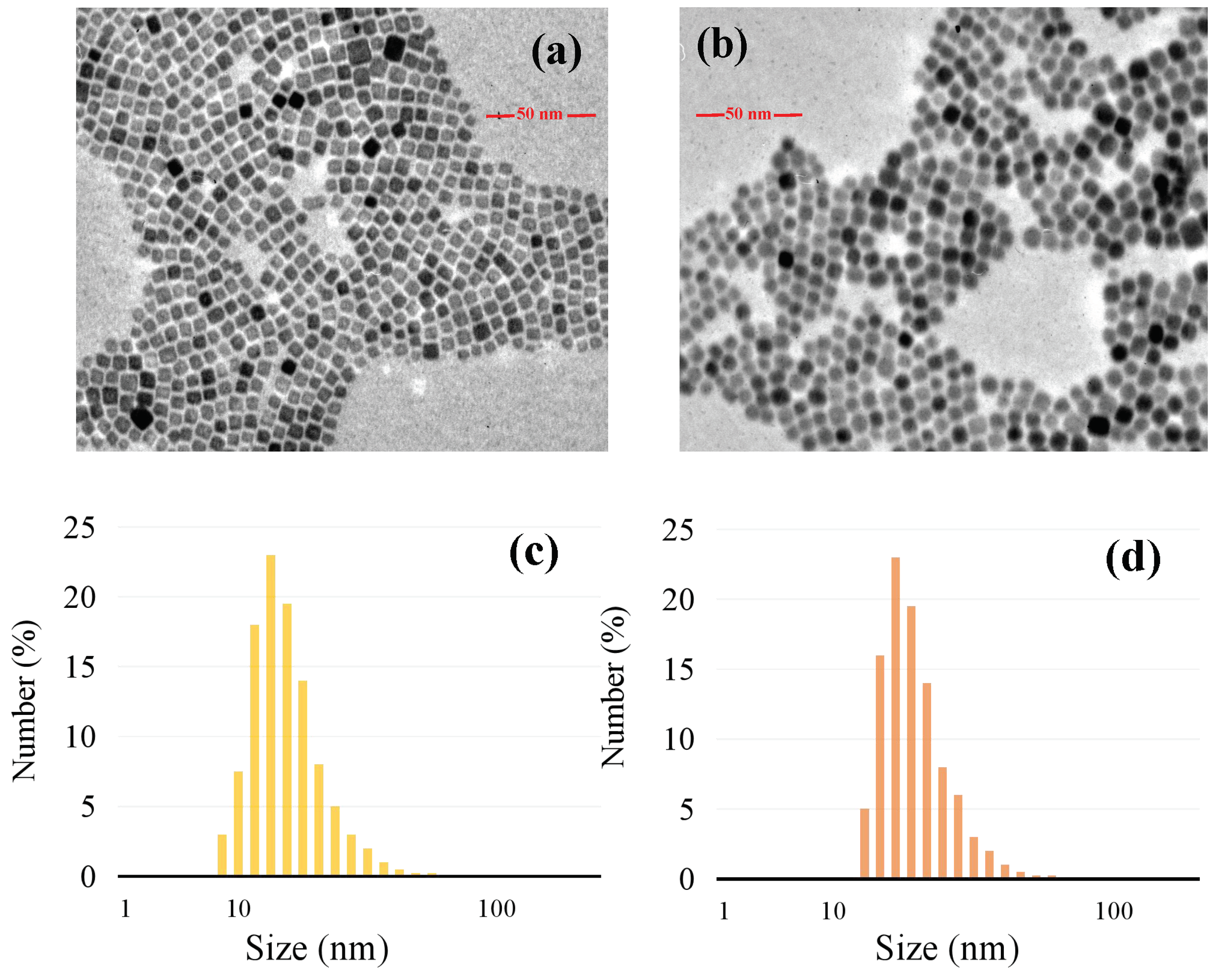

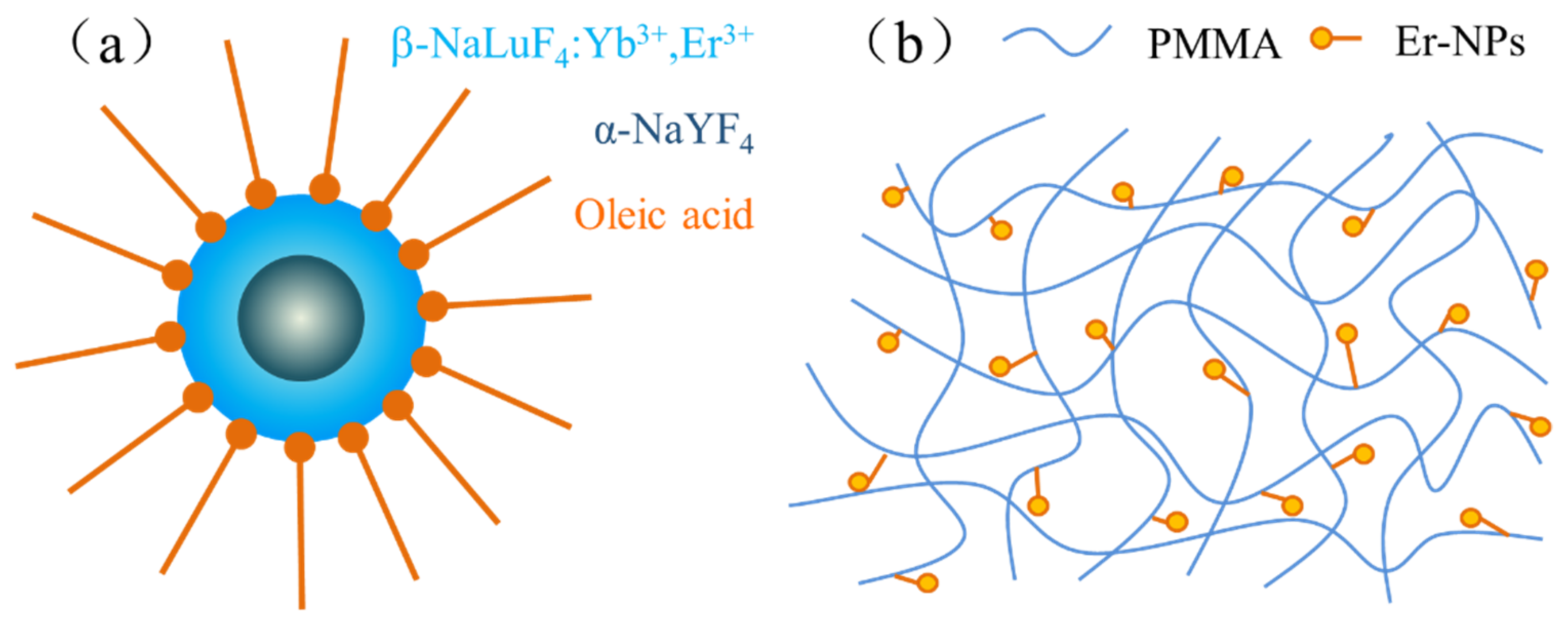

2.1. Preparation of NaYF4/NaLuF4: Yb, Er NPs-PMMA

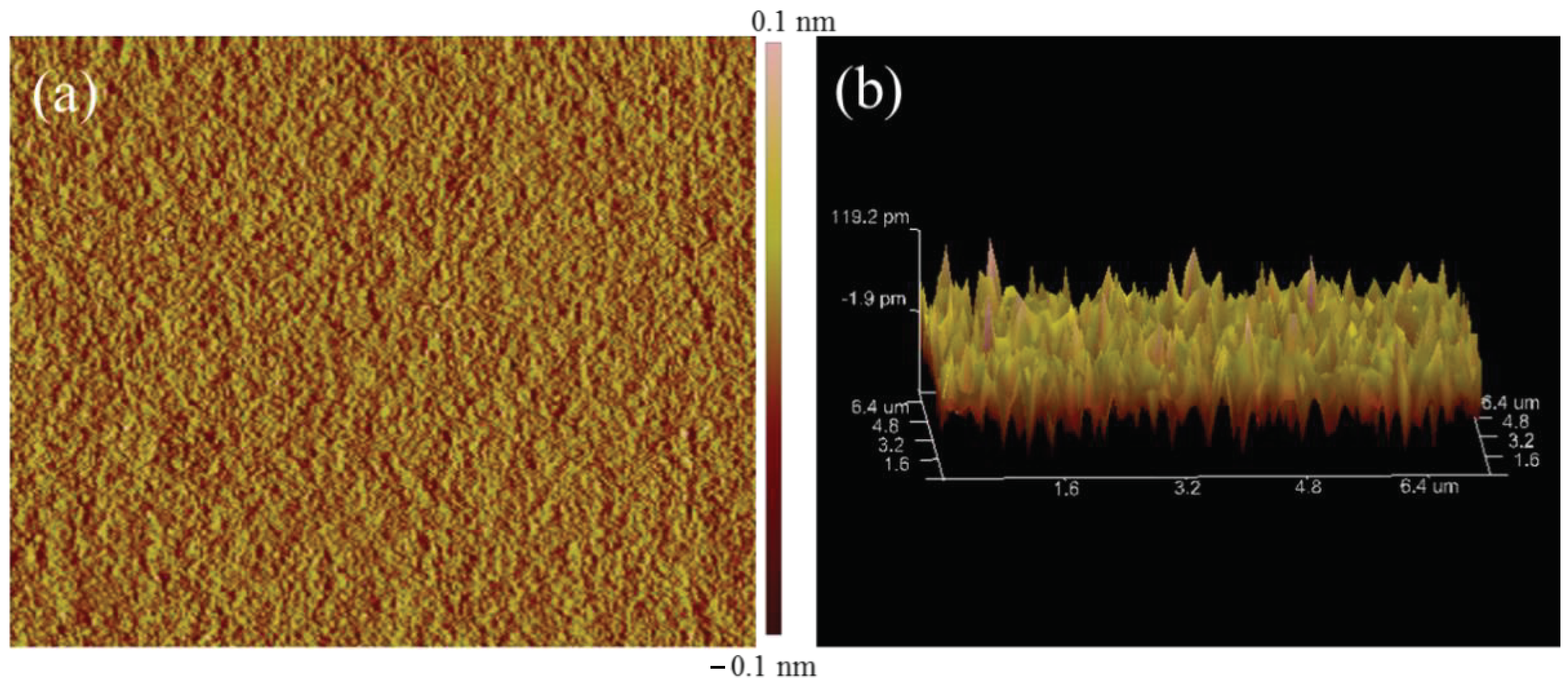

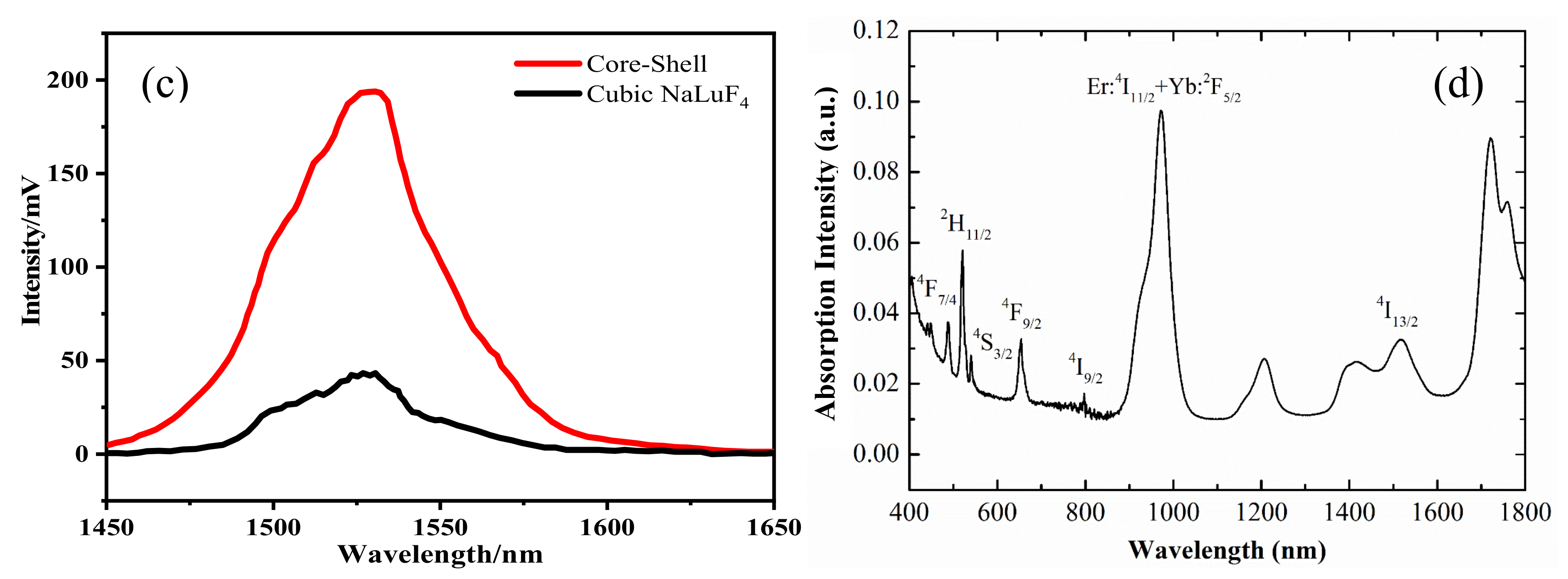

2.2. Characterization of NaYF4/NaLuF4: Yb, Er NPs-PMMA

2.3. Optimization of the Slot Waveguide

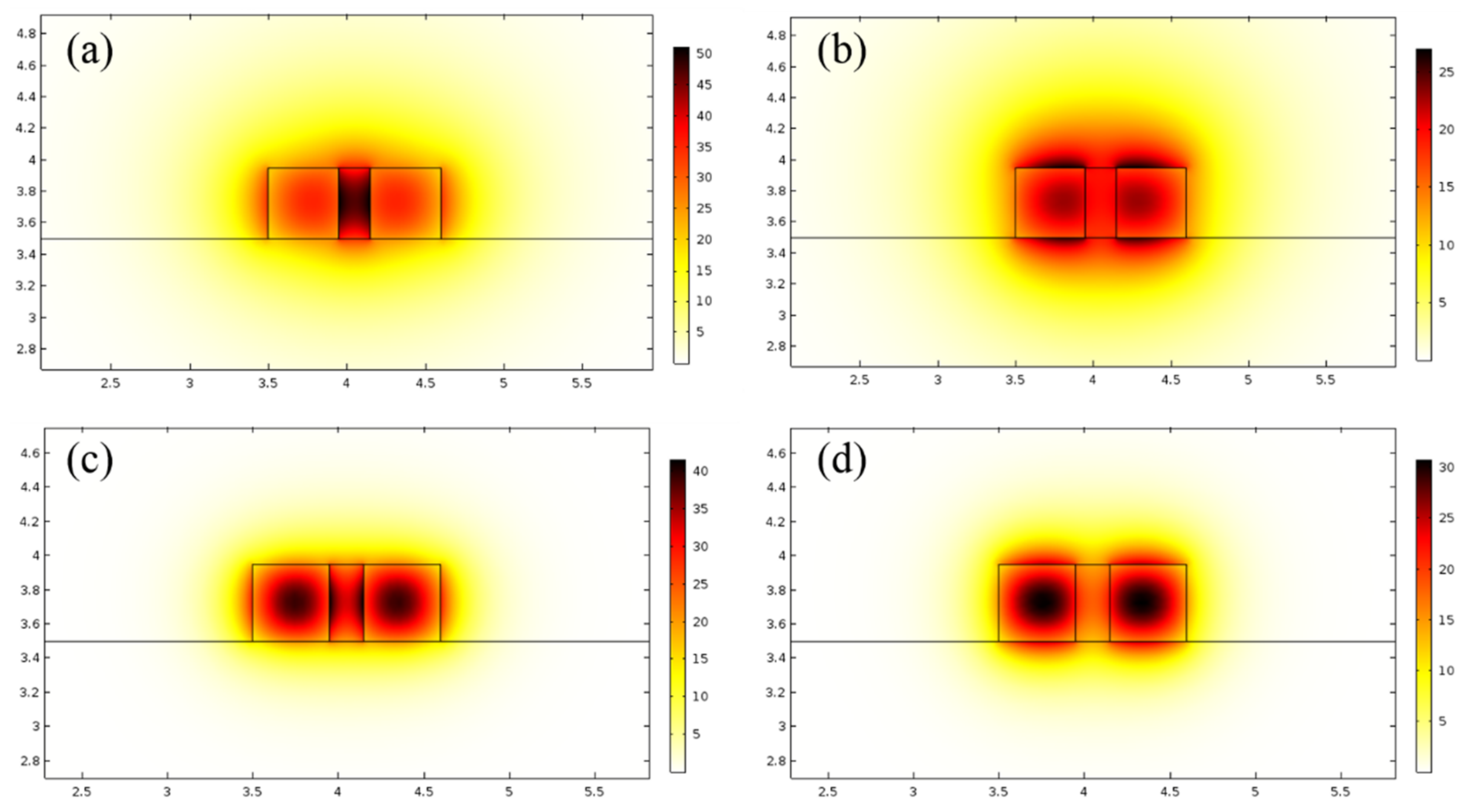

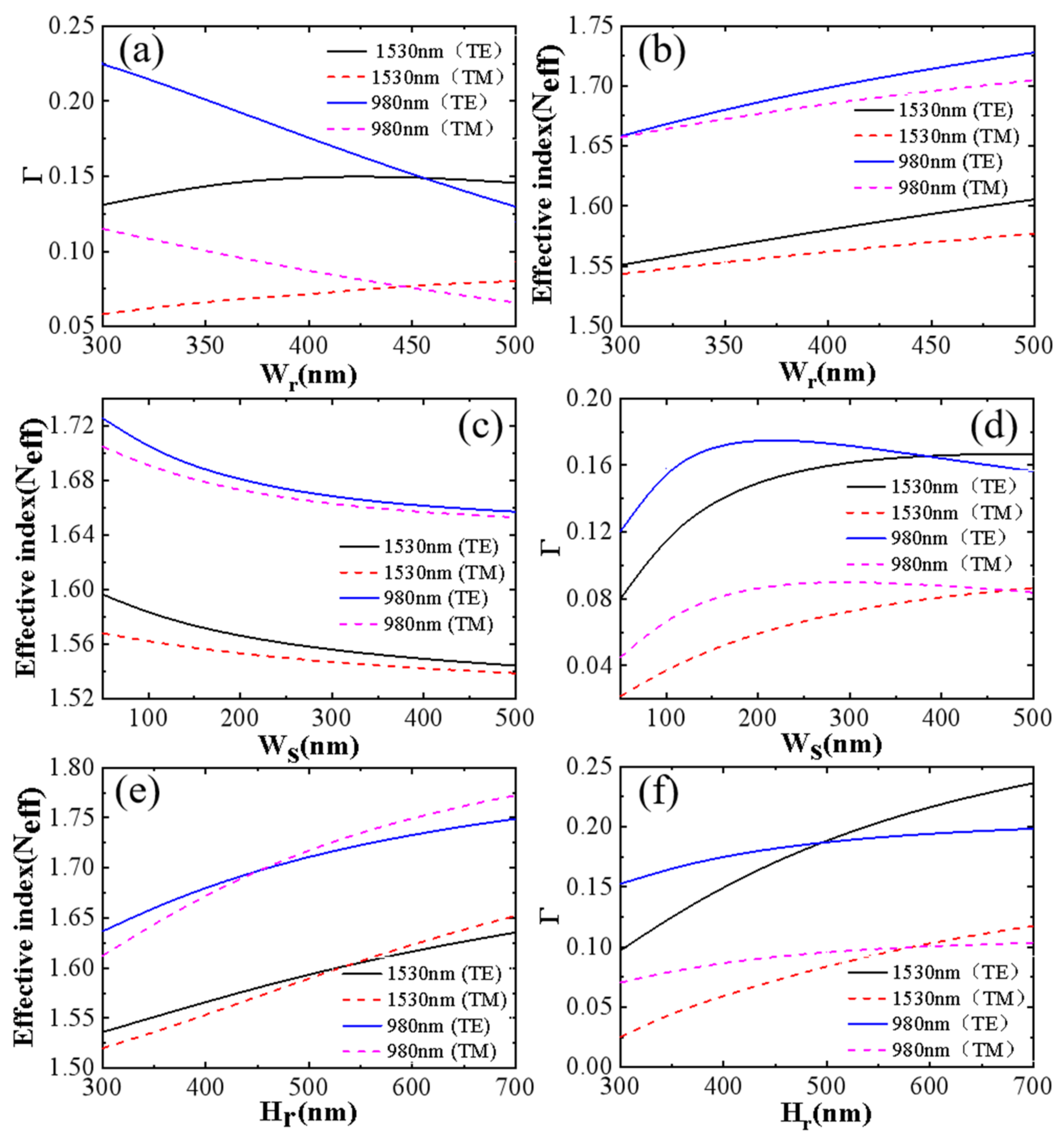

2.3.1. Optimization of Slot Waveguides Combined with Maximum Confinement Factors

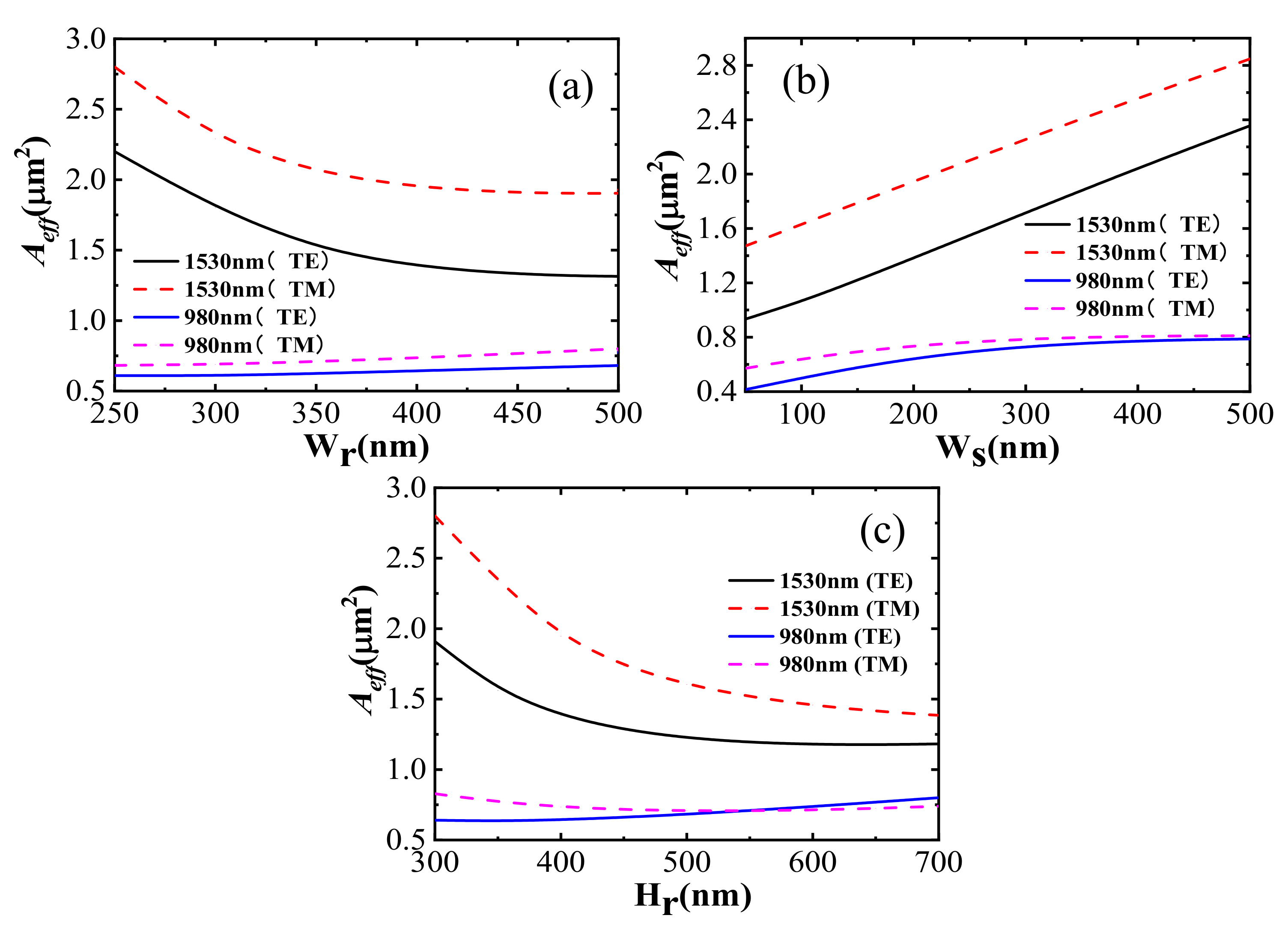

2.3.2. Optimization of Slot Waveguide Combined with Minimum Effective Mode Area

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ye, W.N.; Xiong, Y. Review of silicon photonics: History and recent advances. J. Mod. Opt. 2013, 60, 1299–1320. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.; Tsang, H.K. Device engineering for silicon photonics. NPG Asia Mater. 2011, 3, 34–40. [Google Scholar] [CrossRef]

- Lim, A.E.-J.; Song, J.; Fang, Q.; Li, C.; Tu, X.; Duan, N.; Chen, K.K.; Tern, R.P.-C.; Liow, T.-Y. Review of Silicon Photonics Foundry Efforts. IEEE J. Sel. Top Quantum Electron. 2014, 20, 8300112. [Google Scholar] [CrossRef]

- Shiramin, L.A.; Van, D. Graphene Modulators and Switches Integrated on Silicon and Silicon Nitride Waveguide. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 3600107. [Google Scholar]

- Lacava, C.; Cardea, I.; Demirtzioglou, I.; Khoja, A.E.; Ke, L.; Thomson, D.; Ruan, J.X.; Zhang, F.; Reed, G.T.; Richardson, D.J.; et al. 49.6 Gb/s direct detection DMT transmission over 40 km single mode fibre using an electrically packaged silicon photonic modulator. Opt. Express 2017, 25, 29798–29811. [Google Scholar] [CrossRef]

- Dai, T.; Shen, A.; Wang, G.; Wang, Y.; Li, Y.; Jiang, X.; Yang, J. Bandwidth and wavelength tunable optical passband filter based on silicon multiple microring resonators. Opt. Lett. 2016, 41, 4807–4810. [Google Scholar] [CrossRef]

- Qiu, H.; Jiang, J.; Yu, P.; Dai, T.; Yang, J.; Yu, H.; Jiang, X. Silicon band-rejection and band-pass filter based on asymmetric Bragg sidewall gratings in a multimode waveguide. Opt. Lett. 2016, 41, 2450–2453. [Google Scholar] [CrossRef]

- Bucio, T.D.; Khokhar, A.Z.; Mashanovich, G.Z.; Gardes, F.Y. Athermal silicon nitride angled MMI wavelength division (de) multiplexers for the near-infrared. Opt. Express 2017, 25, 27310–27320. [Google Scholar] [CrossRef]

- Dai, D.; Wang, J.; Chen, S.; Wang, S.; He, S. Monolithically integrated 64-channel silicon hybrid demultiplexer enabling simultaneous wavelength- and mode-division-multiplexing. Laser Photonics Rev. 2015, 9, 339–344. [Google Scholar] [CrossRef]

- Alloatti, L.; Ram, R.J. Resonance-enhanced waveguide-coupled silicon-germanium detector. Appl. Phys. Lett. 2016, 108, 071105. [Google Scholar] [CrossRef]

- Chen, H.T.; Verheyen, P.; De Heyn, P.; Lepage, G.; De Coster, J.; Absil, P.; Roelkens, G.; Van Campenhout, J. High-Responsivity Low-Voltage 28-Gb/s Ge p-i-n Photodetector With Silicon Contacts. J. Lightwave Technol. 2015, 33, 820–824. [Google Scholar] [CrossRef]

- Suntsov, S.; Rüter, C.E.; Kip, D. Er:Ti:LiNbO3 ridge waveguide optical amplifiers by optical grade dicing and three-side Er and Ti in-diffusion. Appl. Phys. B 2017, 123, 118. [Google Scholar] [CrossRef]

- Belt, M.; Davenport, M.L.; Bowers, J.E.; Blumenthal, D. Ultra-low-loss Ta2O5-core/SiO2-clad planar waveguides on Si substrates. Optica 2017, 4, 532–537. [Google Scholar] [CrossRef]

- Bradley, J.D.; Pollnau, M. Erbium-doped integrated waveguide amplififiers and lasers. Laser Photonics Rev. 2011, 5, 368–403. [Google Scholar] [CrossRef]

- Vázquez-Córdova, S.A.; Dijkstra, M.; Bernhardi, E.H.; Ay, F.; Worhoff, K.; Herek, J.L.; García-Blanco, S.M.; Pollnauet, M. Erbium-doped spiral amplififiers with 20 dB of net gain on silicon. Opt. Express 2014, 22, 25993–26004. [Google Scholar] [CrossRef]

- Korn, D.; Lauermann, M.; Koeber, S.; Appel, P.; Alloatti, L.; Palmer, R.; Dumon, P.; Freude, W.; Leuthold, J.; Koos, C. Lasing in silicon–organic hybrid waveguides. Nat. Commun. 2016, 7, 10864. [Google Scholar] [CrossRef]

- Bradley, J.D.; Hosseini, E.S.; Purnawirman; Su, Z.; Adam, T.N.; Leake, G.; Coolbaugh, D.; Watts, M.R. Monolithic erbium- and ytterbium-doped microring lasers on silicon chips. Opt. Express 2014, 22, 12226–12237. [Google Scholar] [CrossRef]

- Koos, C.; Vorreau, P.; Vallaitis, T.; Dumon, P.; Bogaerts, W.; Baets, R.; Esembeson, B.; Biaggio, I.; Michinobu, T.; Diederich, F.; et al. All-optical high-speed signal processing with silicon–organic hybrid slot waveguides. Nat. Photonics 2009, 3, 216–219. [Google Scholar] [CrossRef]

- Säynätjoki, A.; Karvonen, L.; Alasaarela, T.; Tu, X.; Liow, T.Y.; Hiltunen, M.; Tervonen, A.; Lo, G.Q.; Honkanenet, S. Low-loss silicon slot waveguides and couplers fabricated with optical lithography and atomic layer deposition. Opt. Express 2011, 19, 26275–26282. [Google Scholar] [CrossRef]

- Alasaarela, T.; Säynätjoki, A.; Hakkarinen, T.; Honkanen, S. Feature size reduction of silicon slot waveguides by partial fifilling using atomic layer deposition. Opt. Eng. 2009, 48, 080502. [Google Scholar] [CrossRef][Green Version]

- Guo, R.M.; Wang, B.; Wang, X.J.; Wang, L.; Jiang, L.J.; Zhou, Z.P. Optical amplification in Er/Yb silicate slot waveguide. Opt. Lett. 2012, 37, 1427–1429. [Google Scholar] [CrossRef]

- Yu, C.; Hu, G.J.; Wang, F.; Li, J.Y.; Zhao, D.; Zhang, M.L. Few-mode polymer optical waveguide amplifier for mode-division multiplexed transmission. Opt. Lett. 2021, 46, 5509–5512. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.B.; Zhang, M.L.; Jiang, M.H.; Lian, T.H.; Wang, F.; Zhang, D.M. Monolithic integrated waveguide device with dual functions of electro-optic modulation and optical amplification. Opt. Lett. 2021, 46, 3536–3539. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Zhang, B.P.; Wang, C.; Ying, L.Y.; Yang, X.C.; Zhou, Z.Q.; Zhang, D. Demonstration of optical gain at 1550 nm in an Er3+ -Yb3+ co-doped phosphate planar waveguide under commercial and convenient LED pumping. Opt. Express 2021, 29, 11372–11385. [Google Scholar]

- Zhao, P.C.; Zhang, M.L.; Wang, T.J.; Liu, X.Y.; Zhai, X.S.; Qin, G.S.; Qin, W.P.; Wang, F.; Zhang, D.M. Optical Amplification at 1525 nm in BaYF5: 20% Yb3+, 2% Er3+ Nanocrystals Doped SU-8 Polymer Waveguide. J. Nanomater. 2014, 2014, 153028. [Google Scholar] [CrossRef]

- Serna, S.; Zhang, W.W.; Leroux, X.; Gao, D.S.; Cassan, E. Potential for large optical gain improvement of erbium doped slot waveguide amplifiers in silicon photonics. J. Opt. Soc. Am. B 2014, 31, 2021–2027. [Google Scholar] [CrossRef]

- Zhang, M.L.; Hu, G.J.; Zhang, S.R.; Gao, D.S.; Sun, Y.D.; Wang, F. Gain characteristic of the hybrid slot waveguide amplifiers integrated with NaYF4:Er3+ NPs-PMMA covalently linked nanocomposites. RSC Adv. 2020, 10, 11148–11155. [Google Scholar] [CrossRef]

- Pascual, M.; Gloria, M.; Luis, B.; Daniel, P.; Daniel, P.; José, D.; Juan, F.; Rocío, B.; Bernardo, G.; Rubén, A.; et al. Silicon nitride photonic integration platforms for visible, near-infrared and mid-infrared applications. Sensors 2017, 17, 2088. [Google Scholar]

- Rönn, J.; Zhang, W.W.; Autere, A.; Leroux, X.; Lasse, P.; Alonso-Ramos, C.; Säynätjoki, A.; Lipsanen, H.; Vivien, L.; Cassan, E.; et al. Ultra-high on-chip optical gain in erbium-based hybrid slot waveguides. Nat. Commun. 2019, 10, 432. [Google Scholar] [CrossRef]

- Yi, Y.J.; Wang, H.R.; Liu, Y.; Jiang, M.H.; Wang, X.; Wang, F.; Zhang, D.M. Multilayer Hybrid Waveguide Amplifier for Three-Dimension Photonic Integrated Circuit. IEEE Photonics Technol. Lett. 2015, 27, 2411–2413. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhang, M.; Hu, G. Gain Enhancement of the Optical Waveguide Amplifier Based on NaYF4/NaLuF4: Yb, Er NPs-PMMA Integrated with a Si3N4 Slot. Nanomaterials 2022, 12, 2937. https://doi.org/10.3390/nano12172937

Liu X, Zhang M, Hu G. Gain Enhancement of the Optical Waveguide Amplifier Based on NaYF4/NaLuF4: Yb, Er NPs-PMMA Integrated with a Si3N4 Slot. Nanomaterials. 2022; 12(17):2937. https://doi.org/10.3390/nano12172937

Chicago/Turabian StyleLiu, Xiao, Meiling Zhang, and Guijun Hu. 2022. "Gain Enhancement of the Optical Waveguide Amplifier Based on NaYF4/NaLuF4: Yb, Er NPs-PMMA Integrated with a Si3N4 Slot" Nanomaterials 12, no. 17: 2937. https://doi.org/10.3390/nano12172937

APA StyleLiu, X., Zhang, M., & Hu, G. (2022). Gain Enhancement of the Optical Waveguide Amplifier Based on NaYF4/NaLuF4: Yb, Er NPs-PMMA Integrated with a Si3N4 Slot. Nanomaterials, 12(17), 2937. https://doi.org/10.3390/nano12172937