Study on the Electrical Conduction Mechanism of Unipolar Resistive Switching Prussian White Thin Films

Abstract

:1. Introduction

2. Experimental Section

2.1. Material Preparation

2.2. Characterization

3. Results and Discussion

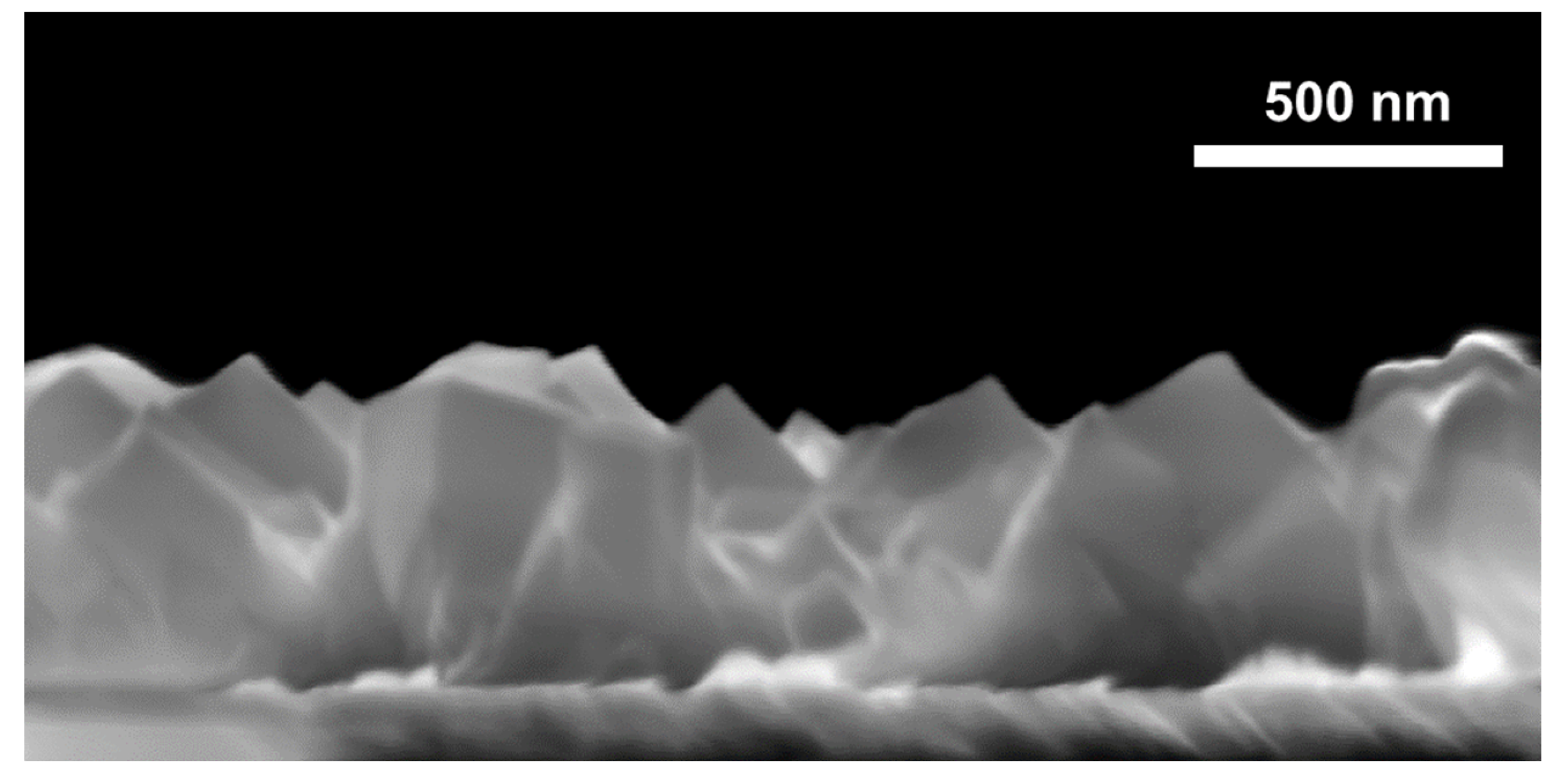

3.1. Morphological Characterization

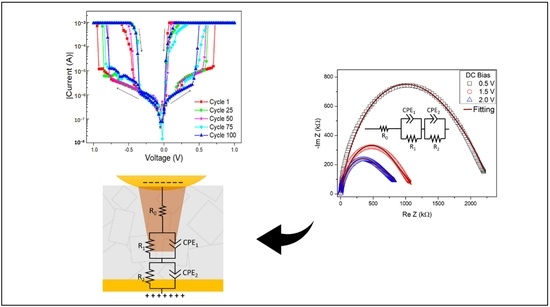

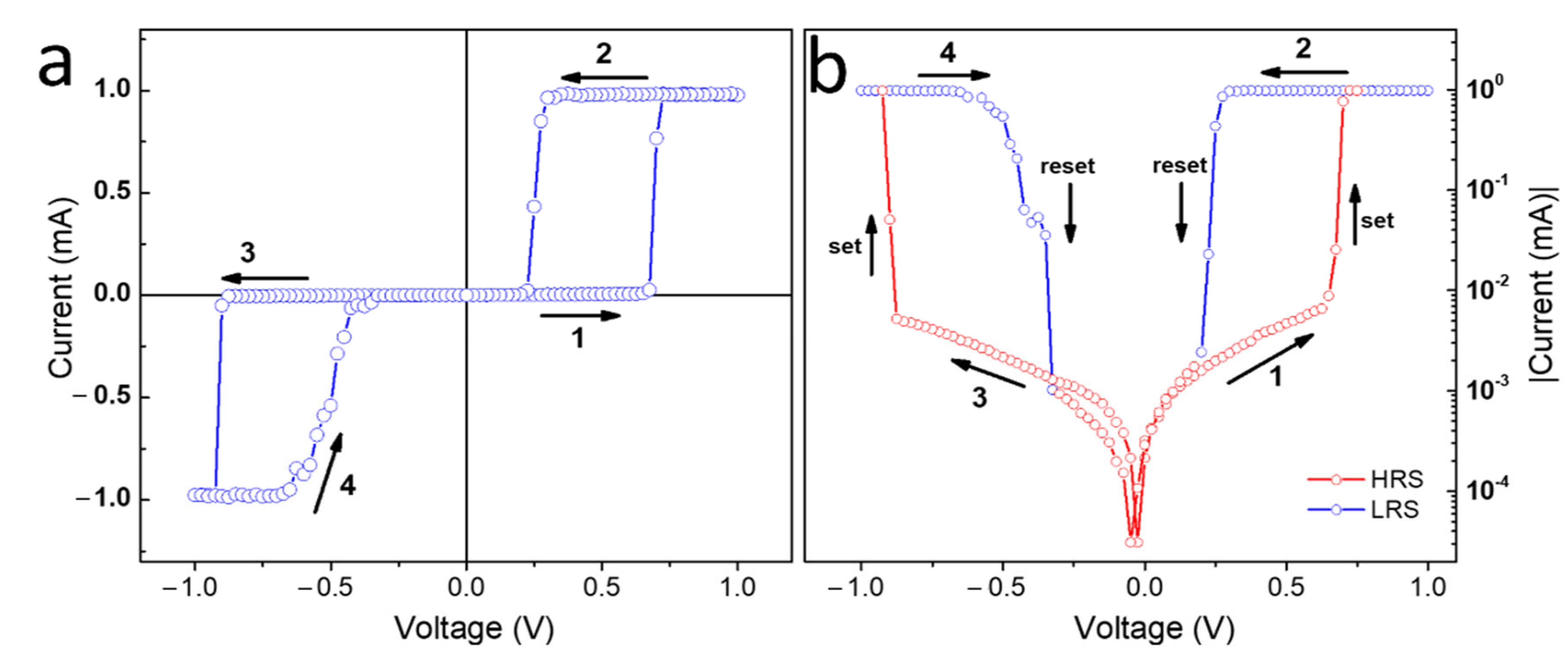

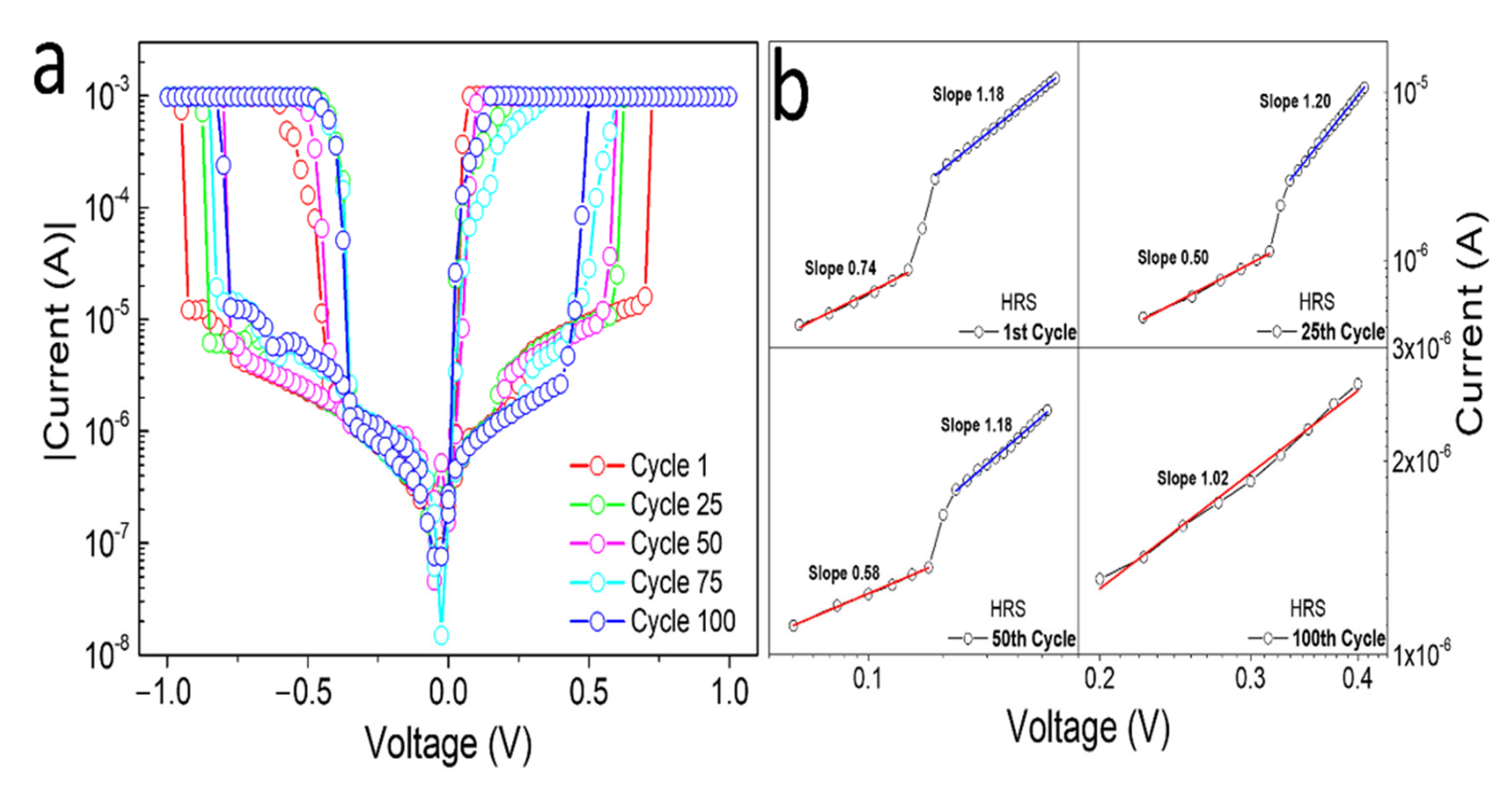

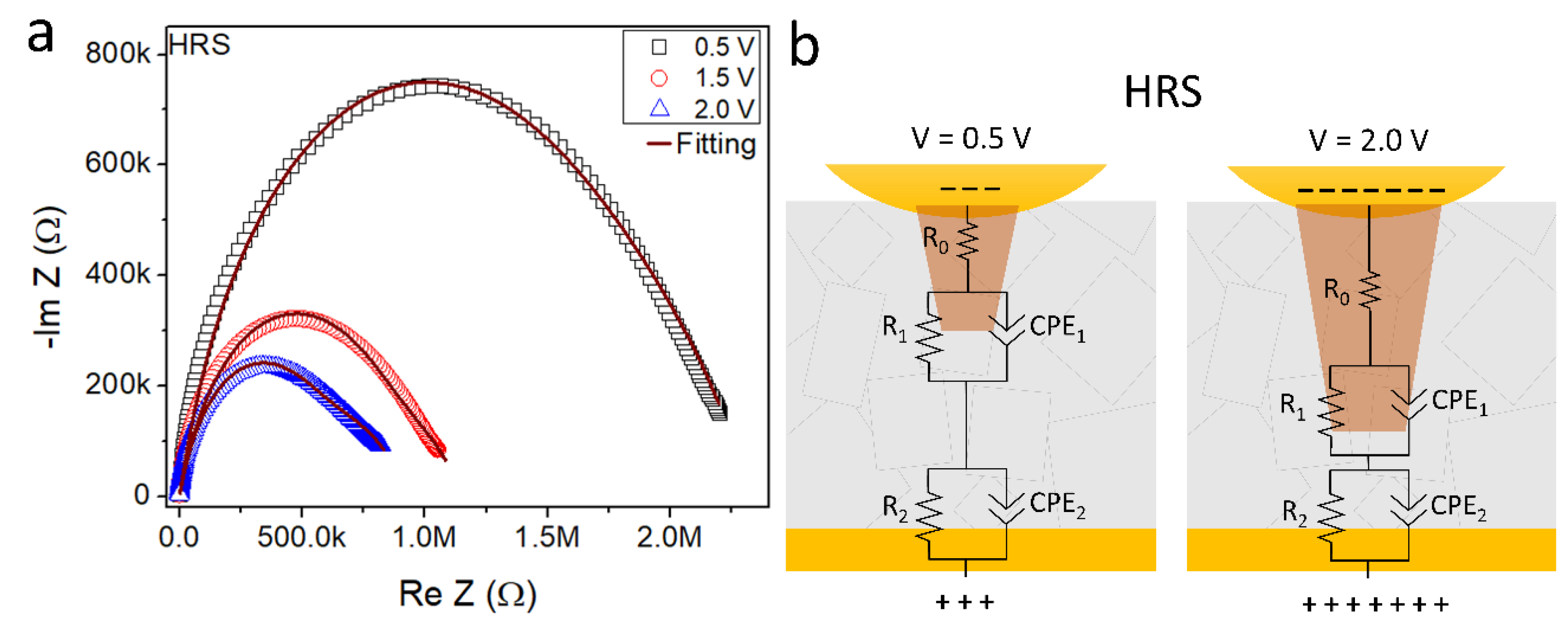

3.2. Electrical Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ling, Q.; Song, Y.; Ding, S.J.; Zhu, C.; Chan, D.S.H.; Kwong, D.-L.; Kang, E.-T.; Neoh, K.G. Non-Volatile Polymer Memory Device Based on a Novel Copolymer ofN-Vinylcarbazole and Eu-Complexed Vinylbenzoate. Adv. Mater. 2005, 17, 455–459. [Google Scholar] [CrossRef]

- Hamann, H.F.; O’Boyle, M.; Martin, Y.C.; Rooks, M.; Wickramasinghe, H.K. Wickramasinghe Ultra-high-density phase-change storage and memory. Nat. Mater. 2006, 5, 383–387. [Google Scholar] [CrossRef]

- Gaba, S.; Knag, P.; Zhang, Z.; Lu, W. Memristive devices for stochastic computing. In Proceedings of the 2014 IEEE International Symposium on Circuits and Systems (ISCAS), Melbourne, Australia, 1—5 June 2014; Volume 8, pp. 2592–2595. [Google Scholar] [CrossRef]

- Prezioso, M.; Hoskins, B.D.; Adam, G.C.; Likharev, K.K.; Strukov, D.B. Training and operation of an integrated neuromorphic network based on metal-oxide memristors. Nature 2015, 521, 61–64. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.S.; Park, B.H. Reproducible resistance switching in polycrystalline NiO films. Appl. Phys. Lett. 2006, 85, 5655–5657. [Google Scholar] [CrossRef]

- Choi, D.; Lee, D.; Sim, H.; Chang, M.; Hwang, H. Reversible resistive switching of thin films for nonvolatile memory applications. Appl. Phys. Lett. 2005, 88, 082904. [Google Scholar] [CrossRef]

- Song, S.J.; Kim, K.M.; Kim, G.H.; Lee, M.H.; Seok, J.Y.; Jung, R.; Hwang, C.S. Identification of the controlling parameter for the set-state resistance of a TiO2 resistive switching cell. Appl. Phys. Lett. 2010, 96, 112904. [Google Scholar] [CrossRef]

- Simmons, J.G.; Verderber, R.R. New Thin-film Resistive Memory. Radio Electron. Eng. 1967, 34, 81–89. [Google Scholar] [CrossRef]

- Hickmott, T.W. Low-Frequency Negative Resistance in Thin Anodic Oxide Films. J. Appl. Phys. 1962, 33, 2669–2682. [Google Scholar] [CrossRef]

- Chua, L. Memristor-The missing circuit element. IEEE Trans. Circuit Theory 1971, 18, 507–519. [Google Scholar] [CrossRef]

- Strukov, D.B.; Snider, G.S.; Stewart, D.R.; Williams, R.S. The missing memristor found. Nature 2008, 453, 80–83. [Google Scholar] [CrossRef]

- Luo, J.M.; Lin, S.P.; Zheng, Y.; Wang, B. Nonpolar resistive switching in Mn-doped BiFeO3 thin films by chemical solution deposition. Appl. Phys. Lett. 2012, 101, 062902. [Google Scholar] [CrossRef]

- Boratto, M.H.; Ramos, R.A.; Congiu, M.; Graeff, C.F.; Scalvi, L.V. Memristive behavior of the SnO2/TiO2 interface deposited by sol—gel. Appl. Surf. Sci. 2017, 410, 278–281. [Google Scholar] [CrossRef]

- Baggio, B.F.; Vicente, C.; Pelegrini, S.; Cid, C.C.P.; Brandt, I.S.; Tumelero, M.A.; Pasa, A.A. Morphology and Structure of Electrodeposited Prussian Blue and Prussian White Thin Films. Materials 2019, 12, 1103. [Google Scholar] [CrossRef] [Green Version]

- Lei, S.; Li, Q.-.Q.; Kang, Y.; Gu, Z.-.; Zhang, J. Epitaxial growth of oriented prussian blue analogue derived well-aligned CoFe2O4 thin film for efficient oxygen evolution reaction. Appl. Catal. B Environ. 2019, 245, 1–9. [Google Scholar] [CrossRef]

- Wang, Z.; Nminibapiel, D.; Shrestha, P.; Liu, J.; Guo, W.; Weidler, P.G.; Baumgart, H.; Wöll, C.; Redel, E. Resistive Switching Nanodevices Based on Metal—Organic Frameworks. ChemNanoMat 2016, 2, 67–73. [Google Scholar] [CrossRef]

- Tang, X.; Liu, H.; Su, D.; Notten, P.H.L.; Wang, G. Hierarchical sodium-rich Prussian blue hollow nanospheres as high-performance cathode for sodium-ion batteries. Nano Res. 2018, 11, 3979–3990. [Google Scholar] [CrossRef]

- Wu, X.; Wu, C.; Wei, C.; Hu, L.; Qian, J.; Cao, Y.; Ai, X.; Wang, J.; Yang, H. Highly Crystallized Na2CoFe(CN)6 with Suppressed Lattice Defects as Superior Cathode Material for Sodium-Ion Batteries. ACS Appl. Mater. Interfaces 2016, 8, 5393–5399. [Google Scholar] [CrossRef]

- Su, D.; Mcdonagh, A.; Qiao, S.; Wang, G. High-Capacity Aqueous Potassium-Ion Batteries for Large-Scale Energy Storage. Adv. Mater. 2017, 29, 1604007. [Google Scholar] [CrossRef]

- Moritomo, Y.; Takachi, M.; Moritomo, Y. A sodium manganese ferrocyanide thin film for Na-ion batteries. Chem. Commun. 2013, 49, 2750–2752. [Google Scholar] [CrossRef]

- Christensen, P.A.; Higgins, S.J. Analysis of Electrogenerated Films by Ellipsometry and Infrared Spectrometry. Analyst 1994, 119, 735–747. [Google Scholar] [CrossRef]

- Avila, L.B.; Müller, C.K.; Hildebrand, D.; Faita, F.L.; Baggio, B.F.; Cid, C.C.P.; Pasa, A.A. Resistive switching in electrodeposited Prussian blue layers. Materials 2020, 13, 5618. [Google Scholar] [CrossRef]

- Faita, F.L.; Avila, L.B.; Silva, J.P.; Boratto, M.H.; Cid, C.P.; Graeff, C.F.; Gomes, M.J.; Müller, C.K.; Pasa, A.A. Abnormal resistive switching in electrodeposited Prussian White thin films. J. Alloys Compd. 2022, 896, 162971. [Google Scholar] [CrossRef]

- Alamini, M.F.; da Silva, R.C.; Zoldan, V.C.; Isoppo, E.A.; Rodrigues Filho, U.P.; Reis, F.A.; Klein, A.N.; Pasa, A.A. Normal versus anomalous roughening in electrodeposited Prussian Blue layers. Electrochem. Commun. 2011, 13, 1455–1458. [Google Scholar] [CrossRef]

- Prakash, A.; Jana, D.; Maikap, S. TaO x -based resistive switching memories: Prospective and challenges. Nanoscale Res. Lett. 2013, 8, 418. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chiu, F. Resistance Switching Characteristics in ZnO-Based Nonvolatile Memory Devices. Adv. Mater. Sci. Eng. 2013, 2013, 362053. [Google Scholar] [CrossRef] [Green Version]

- Valov, I.; Linn, E.; Tappertzhofen, S.; Schmelzer, S.; van den Hurk, J.; Lentz, F.; Waser, R. Nanobatteries in redox-based resistive switches require extension of memristor theory. Nat. Commun. 2013, 4, 1771. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chang, W.-Y.; Lai, Y.-C.; Wu, T.-B.; Wang, S.-F.; Chen, F.; Tsai, M.-J. Unipolar resistive switching characteristics of ZnO thin films for nonvolatile memory applications for nonvolatile memory applications. Appl. Phys. Lett. 2017, 92, 022110. [Google Scholar] [CrossRef]

- Yu, X.; Shen, T.; Zhu, C.; Zeng, Q.; Yu, A.; Liu, S.; Yi, R.; Weng, Z.; Zhan, Y.; Hou, X.; et al. Memory Devices via Unipolar Resistive Switching in Symmetric Organic—Inorganic Perovskite Nanoscale Heterolayers. ACS Appl. Nano Mater. 2020, 3, 11889–11896. [Google Scholar] [CrossRef]

- Rehman, M.M.; Rheman, H.M.M.U.; Gul, J.Z.; Kim, W.Y.; Karimov, K.S.; Ahmed, N. Decade of 2D materials-based RRAM devices: A review. Sci. Technol. Adv. Mater. 2020, 21, 147–186. [Google Scholar] [CrossRef] [Green Version]

- Choi, B.J.; Jeong, D.S.; Kim, S.K.; Rohde, C.; Choi, S.; Oh, J.H.; Kim, H.J.; Hwang, C.S.; Szot, K.; Waser, R.; et al. Resistive switching mechanism of TiO2 thin films grown by atomic-layer deposition. J. Appl. Phys. 2005, 98, 033715. [Google Scholar] [CrossRef] [Green Version]

- Peng, H.Y.; Li, G.P.; Ye, J.Y.; Wei, Z.P.; Zhang, Z.; Wang, D.D.; Xing, G.Z.; Wu, T. Electrode dependence of resistive switching in Mn-doped ZnO: Filamentary versus interfacial mechanisms. Appl. Phys. Lett. 2010, 96, 192113. [Google Scholar] [CrossRef]

- Chiu, F.-C. A Review on Conduction Mechanisms in Dielectric Films. Adv. Mater. Sci. Eng. 2014, 2014, 578168. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Wang, Z.; Huang, X.; Kumari, N.; Davila, N.; Strachan, J.P.; Vine, D.; Kilcoyne, A.D.; Nishi, Y.; Williams, R.S. Conduction Channel Formation and Dissolution Due to Oxygen Thermophoresis/Diffusion in Hafnium Oxide Memristors. ACS Nano 2016, 10, 11205–11210. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chiu, F.-C. Conduction Mechanisms in Resistance Switching Memory Devices Using Transparent Boron Doped Zinc Oxide Films. Materials 2014, 7, 7339–7348. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chang, S.T.; Lee, Y.Y. Electrical conduction mechanism in high-dielectric-constant Ba0.5Sr0.5TiO3 thin films. Appl. Phys. Lett. 2002, 80, 655. [Google Scholar] [CrossRef] [Green Version]

- Koops, C.G. On the dispersion of resistivity and dielectric constant of some semiconductors at audiofrequencies. Phys. Rev. 1951, 83, 121–124. [Google Scholar] [CrossRef]

- Prokhorov, E.; Trapaga, G.; González-Hernández, J. Structural and electrical properties of Ge1Sb2Te4 face centered cubic phase. J. Appl. Phys. 2008, 104, 103712. [Google Scholar] [CrossRef]

- Tong, H.; Miao, X.S.; Yang, Z.; Cheng, X.M. Insulator-metal transition in GeTe/Sb2Te3 multilayer induced by grain growth and interface barrier. Appl. Phys. Lett. 2011, 99, 212105. [Google Scholar] [CrossRef]

- Chang, B.Y.; Park, S.M. Electrochemical impedance spectroscopy. Annu. Rev. Anal. Chem. 2010, 3, 207–229. [Google Scholar] [CrossRef]

- Jang, M.H.; Park, S.J.; Lim, D.H.; Park, S.J.; Cho, M.H.; Cho, S.J.; Cho, Y.H.; Lee, J.H. Effects of oxygen incorporation in GeSbTe films on electrical properties and thermal stability. Appl. Phys. Lett. 2010, 96, 092108. [Google Scholar] [CrossRef]

- Gervacio-Arciniega, J.J.; Prokhorov, E.; Espinoza-Beltrán, F.J.; Trapaga, G.; Prokhorov, E.; Espinoza-Beltr, F.J. Dielectric properties of Ge2Sb2Te5 phase-change films. J. Appl. Phys. 2013, 113, 113705. [Google Scholar]

- Huang, Y.H.; Huang, Y.J.; Hsieh, T.E. A study of phase transition behaviors of chalcogenide layers using in situ alternative-current impedance spectroscopy. J. Appl. Phys. 2012, 111, 123706. [Google Scholar] [CrossRef] [Green Version]

- Chaudhari, S.; Patil, R. Dielectric behavior and A. C. Conductivity in Cu-Ti Ferrites. Adv. Appl. Sci. Res. 2012, 3, 3848–3854. [Google Scholar]

- Rocha, P.R.; Schlett, P.; Kintzel, U.; Mailänder, V.; Vandamme, L.K.; Zeck, G.; Gomes, H.L.; Biscarini, F.; De Leeuw, D.M. Electrochemical noise and impedance of Au electrode/electrolyte interfaces enabling extracellular detection of glioma cell populations. Sci. Rep. 2016, 6, 34843. [Google Scholar] [CrossRef] [Green Version]

- Jiang, X.L.; Zhao, Y.G.; Chen, Y.S.; Li, D.; Luo, Y.X.; Zhao, D.Y.; Sun, Z.; Sun, J.R.; Zhao, H.W. Characteristics of different types of filaments in resistive switching memories investigated by complex impedance spectroscopy. Appl. Phys. Lett. 2013, 102, 253507. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avila, L.B.; Serrano Arambulo, P.C.; Dantas, A.; Cuevas-Arizaca, E.E.; Kumar, D.; Müller, C.K. Study on the Electrical Conduction Mechanism of Unipolar Resistive Switching Prussian White Thin Films. Nanomaterials 2022, 12, 2881. https://doi.org/10.3390/nano12162881

Avila LB, Serrano Arambulo PC, Dantas A, Cuevas-Arizaca EE, Kumar D, Müller CK. Study on the Electrical Conduction Mechanism of Unipolar Resistive Switching Prussian White Thin Films. Nanomaterials. 2022; 12(16):2881. https://doi.org/10.3390/nano12162881

Chicago/Turabian StyleAvila, Lindiomar B., Pablo C. Serrano Arambulo, Adriana Dantas, Edy E. Cuevas-Arizaca, Dinesh Kumar, and Christian K. Müller. 2022. "Study on the Electrical Conduction Mechanism of Unipolar Resistive Switching Prussian White Thin Films" Nanomaterials 12, no. 16: 2881. https://doi.org/10.3390/nano12162881

APA StyleAvila, L. B., Serrano Arambulo, P. C., Dantas, A., Cuevas-Arizaca, E. E., Kumar, D., & Müller, C. K. (2022). Study on the Electrical Conduction Mechanism of Unipolar Resistive Switching Prussian White Thin Films. Nanomaterials, 12(16), 2881. https://doi.org/10.3390/nano12162881