Review of Recent Efforts in Cooling Photovoltaic Panels (PVs) for Enhanced Performance and Better Impact on the Environment

Abstract

:1. Introduction

2. The Review

- 2.1

- Improving the generation of clean energy by cooling techniques to reduce environmental effects.

- 2.2

- Improving solar cell’s low efficiency.

- 2.3

- The use of cellulose nano-crystal (CNC) nanofluids as a cooling material.

2.1. Improving the Generation of Clean Energy by Cooling Techniques to Reduce Environmental Effects

2.2. Improving Solar Cells’ Low Efficiency

2.3. The Use of Cellulose Nano-Crystal (CNC) Nanofluids as Cooling Materials

3. Summary and Evaluation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, M. World Energy 2017–2050: Annual Report; Department of Economics, University of Utah: Salt Lake City, UT, USA, 2017. [Google Scholar]

- Hassani, S.; Saidur, R.; Mekhilef, S.; Taylor, R.A. Environmental and exergy benefit of nanofluid-based hybrid PV/T systems. Energy Convers. Manag. 2016, 123, 431–444. [Google Scholar] [CrossRef]

- Salari, A.; Taheri, A.; Farzanehnia, A.; Passandideh-Fard, M.; Sardarabadi, M. An updated review of the performance of nanofluid-based photovoltaic thermal systems from energy, exergy, economic, and environmental (4E) approaches. J. Clean. Prod. 2021, 282, 124318. [Google Scholar] [CrossRef]

- Esfe, M.H.; Kamyab, M.H.; Valadkhani, M. Application of nanofluids and fluids in photovoltaic thermal system: An updated review. Sol. Energy 2020, 199, 796–818. [Google Scholar] [CrossRef]

- Aldossary, A.; Mahmoud, S.; Al-Dadah, R. Technical feasibility study of passive and active cooling for concentrator PV in harsh environment. Appl. Therm. Eng. 2016, 100, 490–500. [Google Scholar] [CrossRef]

- He, W.; Chow, T.-T.; Ji, J.; Lu, J.; Pei, G.; Chan, L.S.A. Hybrid photovoltaic and thermal solar-collector designed for natural circulation of water. Appl. Energy 2006, 83, 199–210. [Google Scholar] [CrossRef]

- Kim, J.H.; Ahn, J.G.; Kim, J.T. Demonstration of the performance of an air-type photovoltaic thermal (PVT) system coupled with a heat-recovery ventilator. Energies 2016, 9, 728. [Google Scholar] [CrossRef] [Green Version]

- Shahsavar, A.; Ameri, M. Experimental investigation and modeling of a direct-coupled PV/T air collector. Sol. Energy 2010, 84, 1938–1958. [Google Scholar] [CrossRef]

- Cuce, E.; Bali, T.; Sekucoglu, S.A. Effects of passive cooling on performance of silicon photovoltaic cells. Int. J. Low-Carbon Technol. 2011, 6, 299–308. [Google Scholar] [CrossRef] [Green Version]

- Dixit, K.K.; Yadav, I.; Gupta, G.K.; Maurya, S.K. A review on cooling techniques used for photovoltaic panels. In Proceedings of the 2020 International Conference on Power Electronics & IoT Applications in Renewable Energy and Its Control (PARC), Mathura, India, 28–29 February 2020; pp. 360–364. [Google Scholar]

- Indugowda, C.S.; Ranjith, P.K. Cooling Methods for Increasing Efficiency of PV Panel. In Research Scholar (M-Tech Thermal Engineering); Assistant Professor, Department of Mechanical Engineering Global Academy of Technology; International Journal of Scientific Development and Research (IJSDR): Gujaratm, India, 2016. [Google Scholar]

- Odeh, S.; Behnia, M. Improving Photovoltaic Module Efficiency Using Water Cooling. Heat Transf. Eng. 2009, 30, 499–505. [Google Scholar] [CrossRef]

- Wu, S.-Y.; Chen, C.; Xiao, L. Heat transfer characteristics and performance evaluation of water-cooled PV/T system with cooling channel above PV panel. Renew. Energy 2018, 125, 936–946. [Google Scholar] [CrossRef]

- Lupu, A.G.; Homutescu, V.M.; Balanescu, D.T.; Popescu, E.A. A review of solar photovoltaic systems cooling technologies. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 444, p. 082016. [Google Scholar]

- Dubey, S.; Tiwari, G. Thermal modeling of a combined system of photovoltaic thermal (PV/T) solar water heater. Sol. Energy 2008, 82, 602–612. [Google Scholar] [CrossRef]

- Bahaidarah, H.M. Experimental performance evaluation and modeling of jet impingement cooling for thermal management of photovoltaics. Sol. Energy 2016, 135, 605–617. [Google Scholar] [CrossRef]

- Hasan, H.A.; Sopian, K.; Jaaz, A.H.; Al-Shamani, A.N. Experimental investigation of jet array nanofluids impingement in photovoltaic/thermal collector. Sol. Energy 2017, 144, 321–334. [Google Scholar] [CrossRef]

- Nadda, R.; Kumar, A.; Maithani, R. Efficiency improvement of solar photovoltaic/solar air collectors by using impingement jets: A review. Renew. Sustain. Energy Rev. 2018, 93, 331–353. [Google Scholar] [CrossRef]

- Mehrotra, S.; Rawat, P.; Debbarma, M.; Sudhakar, K. Performance of a solar panel with water immersion cooling technique. Int. J. Sci. Environ. Technol. 2014, 3, 1161–1172. [Google Scholar]

- Zhu, L.; Boehm, R.F.; Wang, Y.; Halford, C.; Sun, Y. Water immersion cooling of PV cells in a high concentration system. Sol. Energy Mater. Sol. Cells 2011, 95, 538–545. [Google Scholar] [CrossRef]

- Rosa-Clot, M.; Tina, G.M.; Scandura, P. Submerged photovoltaic solar panel: SP2. Renew. Energy 2010, 35, 1862–1865. [Google Scholar] [CrossRef]

- Maiti, S.; Banerjee, S.; Vyas, K.; Patel, P.; Ghosh, P.K. Self regulation of photovoltaic module temperature in V-trough using a metal–wax composite phase change matrix. Sol. Energy 2011, 85, 1805–1816. [Google Scholar] [CrossRef]

- Hachem, F.; Abdulhay, B.; Ramadan, M.; El Hage, H.; El Rab, M.G.; Khaled, M. Improving the performance of photovoltaic cells using pure and combined phase change materials—Experiments and transient energy balance. Renew. Energy 2017, 107, 567–575. [Google Scholar] [CrossRef]

- Anderson, W.G.; Dussinger, P.M.; Sarraf, D.B.; Tamanna, S. Heat pipe cooling of concentrating photovoltaic cells. In Proceedings of the 2008 33rd IEEE Photovoltaic Specialists Conference, San Diego, CA, USA, 11–16 May 2008; pp. 1–6. [Google Scholar]

- Gang, P.; Huide, F.; Tao, Z.; Jie, J. A numerical and experimental study on a heat pipe PV/T system. Sol. Energy 2011, 85, 911–921. [Google Scholar] [CrossRef]

- Hou, L.; Quan, Z.; Zhao, Y.; Wang, L.; Wang, G. An experimental and simulative study on a novel photovoltaic-thermal collector with micro heat pipe array (MHPA-PV/T). Energy Build. 2016, 124, 60–69. [Google Scholar] [CrossRef]

- Jouhara, H.; Szulgowska-Zgrzywa, M.; Sayegh, M.; Milko, J.; Danielewicz, J.; Nannou, T.; Lester, S. The performance of a heat pipe based solar PV/T roof collector and its potential contribution in district heating applications. Energy 2017, 136, 117–125. [Google Scholar] [CrossRef] [Green Version]

- Popovici, C.G.; Hudişteanu, S.V.; Mateescu, T.D.; Cherecheş, N.C. Efficiency improvement of photovoltaic panels by using air cooled heat sinks. Energy Procedia 2016, 85, 425–432. [Google Scholar] [CrossRef] [Green Version]

- Radwan, A.; Ahmed, M. The influence of microchannel heat sink configurations on the performance of low concentrator photovoltaic systems. Appl. Energy 2017, 206, 594–611. [Google Scholar] [CrossRef]

- Gilmore, N.; Timchenko, V.; Menictas, C. Microchannel cooling of concentrator photovoltaics: A review. Renew. Sustain. Energy Rev. 2018, 90, 1041–1059. [Google Scholar] [CrossRef]

- Elqady, H.I.; Abo-Zahhad, E.M.; Radwan, A.; El-Shazly, A.; Elkady, M. Thermal and electrical performances of actively cooled concentrator photovoltaic system. Appl. Therm. Eng. 2021, 196, 117295. [Google Scholar] [CrossRef]

- Teo, H.; Lee, P.; Hawlader, M. An active cooling system for photovoltaic modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Minea, A.A.; El-Maghlany, W.M. Influence of hybrid nanofluids on the performance of parabolic trough collectors in solar thermal systems: Recent findings and numerical comparison. Renew. Energy 2018, 120, 350–364. [Google Scholar] [CrossRef]

- Karaaslan, I.; Menlik, T. Numerical study of a photovoltaic thermal (PV/T) system using mono and hybrid nanofluid. Sol. Energy 2021, 224, 1260–1270. [Google Scholar] [CrossRef]

- Naiman, I.; Ramasamy, D.; Kadirgama, K. Experimental and one dimensional investigation on nanocellulose and aluminium oxide hybrid nanofluid as a new coolant for radiator. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 469, p. 01209. [Google Scholar]

- Alwaeli, A.H.A.; Chaichan, M.T.; Kazem, H.A.; Sopian, K. Comparative study to use nano-(Al2O3, CuO, and SiC) with water to enhance photovoltaic thermal PV/T collectors. Energy Convers. Manag. 2017, 148, 963–973. [Google Scholar] [CrossRef]

- Sami, S. Analysis of Nanofluids Behavior in a PV-Thermal-Driven Organic Rankine Cycle with Cooling Capability. Appl. Syst. Innov. 2020, 3, 12. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Jing, D. Investigation of the performance of photovoltaic/thermal system by a coupled TRNSYS and CFD simulation. Sol. Energy 2017, 143, 100–112. [Google Scholar] [CrossRef]

- Mojiri, A.; Taylor, R.; Thomsen, E.; Rosengarten, G. Spectral beam splitting for efficient conversion of solar energy—A review. Renew. Sustain. Energy Rev. 2013, 28, 654–663. [Google Scholar] [CrossRef]

- Joshi, S.S.; Dhoble, A.S. Experimental investigation of solar photovoltaic thermal system using water, coconut oil and silicone oil as spectrum filters. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3227–3236. [Google Scholar] [CrossRef]

- Aste, N.; Del Pero, C.; Leonforte, F. Water PVT Collectors Performance Comparison. Energy Procedia 2017, 105, 961–966. [Google Scholar] [CrossRef]

- Abbas, N.; Awan, M.B.; Amer, M.; Ammar, S.M.; Sajjad, U.; Ali, H.M.; Zahra, N.; Hussain, M.; Badshah, M.A.; Jafry, A.T. Applications of nanofluids in photovoltaic thermal systems: A review of recent advances. Phys. A: Stat. Mech. Its Appl. 2019, 536, 122513. [Google Scholar] [CrossRef]

- Alzahrani, M.; Shanks, K.; Mallick, T.K. Advances and limitations of increasing solar irradiance for concentrating photovoltaics thermal system. Renew. Sustain. Energy Rev. 2020, 138, 110517. [Google Scholar] [CrossRef]

- Lamnatou, C.; Vaillon, R.; Parola, S.; Chemisana, D. Photovoltaic/thermal systems based on concentrating and non-concentrating technologies: Working fluids at low, medium and high temperatures. Renew. Sustain. Energy Rev. 2020, 137, 110625. [Google Scholar] [CrossRef]

- Ji, J.; Guo, C.; Sun, W.; He, W.; Wang, Y.; Li, G. Experimental investigation of tri-functional photovoltaic/thermal solar collector. Energy Convers. Manag. 2014, 88, 650–656. [Google Scholar] [CrossRef]

- Nasrin, R.; Hasanuzzaman, M.; Rahim, N.A. Effect of high irradiation and cooling on power, energy and performance of a PVT system. Renew. Energy 2018, 116, 552–569. [Google Scholar] [CrossRef]

- Jia, Y.; Ran, F.; Zhu, C.; Fang, G. Numerical analysis of photovoltaic-thermal collector using nanofluid as a coolant. Sol. Energy 2019, 196, 625–636. [Google Scholar] [CrossRef]

- Fudholi, A.; Zohri, M.; Rukman, N.S.B.; Nazri, N.S.; Mustapha, M.; Yen, C.H.; Sopian, K. Exergy and sustainability index of photovoltaic thermal (PVT) air collector: A theoretical and experimental study. Renew. Sustain. Energy Rev. 2019, 100, 44–51. [Google Scholar] [CrossRef]

- Tan, W.C.; Chong, K.K.; Tan, M.H. Performance study of water-cooled multiple-channel heat sinks in the application of ultra-high concentrator photovoltaic system. Sol. Energy 2017, 147, 314–327. [Google Scholar] [CrossRef]

- Hu, M.; Zheng, R.; Pei, G.; Wang, Y.; Li, J.; Ji, J. Experimental study of the effect of inclination angle on the thermal performance of heat pipe photovoltaic/thermal (PV/T) systems with wickless heat pipe and wire-meshed heat pipe. Appl. Therm. Eng. 2016, 106, 651–660. [Google Scholar] [CrossRef] [Green Version]

- Hernandez-Perez, J.; Carrillo, J.; Bassam, A.; Flota-Banuelos, M.; Patino-Lopez, L. Thermal performance of a discontinuous finned heatsink profile for PV passive cooling. Appl. Therm. Eng. 2020, 184, 116238. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, J.; Zheng, W.; Zhang, Y.; Meng, Q. Comparative and sensitive analysis of the annual performance between the conventional and the heat pipe PV/T systems. Case Stud. Therm. Eng. 2021, 28, 101380. [Google Scholar] [CrossRef]

- Hadipour, A.; Zargarabadi, M.R.; Rashidi, S. An efficient pulsed-spray water cooling system for photovoltaic panels: Experimental study and cost analysis. Renew. Energy 2021, 164, 867–875. [Google Scholar] [CrossRef]

- Raju, M.; Sarma, R.N.; Suryan, A.; Nair, P.P.; Nižetić, S. Investigation of optimal water utilization for water spray cooled photovoltaic panel: A three-dimensional computational study. Sustain. Energy Technol. Assess. 2022, 51, 101975. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Zhu, L.; Yin, B.; Xiang, H.; Huang, Q. Direct liquid-immersion cooling of concentrator silicon solar cells in a linear concentrating photovoltaic receiver. Energy 2014, 65, 264–271. [Google Scholar] [CrossRef]

- Chandel, S.; Agarwal, T. Review of cooling techniques using phase change materials for enhancing efficiency of photovoltaic power systems. Renew. Sustain. Energy Rev. 2017, 73, 1342–1351. [Google Scholar] [CrossRef]

- Amalu, E.H.; Fabunmi, O.A. Thermal control of crystalline silicon photovoltaic (c-Si PV) module using Docosane phase change material (PCM) for improved performance. Sol. Energy 2022, 234, 203–221. [Google Scholar] [CrossRef]

- Farhana, K.; Kadirgama, K.; Mohammed, H.A.; Ramasamy, D.; Samykano, M.; Saidur, R. Analysis of efficiency enhancement of flat plate solar collector using crystal nano-cellulose (CNC) nanofluids. Sustain. Energy Technol. Assess. 2021, 45, 101049. [Google Scholar] [CrossRef]

- Ramachandran, K.; Hussein, A.; Kadirgama, K.; Ramasamy, D.; Azmi, W.; Tarlochan, F. Thermophysical properties measurement of nano cellulose in ethylene glycol/water. Appl. Therm. Eng. 2017, 123, 1158–1165. [Google Scholar] [CrossRef]

- Samylingam, L.; Anamalai, K.; Kadirgama, K.; Samykano, M.; Ramasamy, D.; Noor, M.; Najafi, G.; Rahman, M.; Xian, H.W.; Sidik, N.A.C. Thermal analysis of cellulose nanocrystal-ethylene glycol nanofluid coolant. Int. J. Heat Mass Transf. 2018, 127, 173–181. [Google Scholar] [CrossRef]

- Benedict, F.; Kadirgama, K.; Ramasamy, D.; Noor, M.M.; Samykano, M.; Rahman, M.M.; Sagmesh, B. Nanocellulose as heat transfer liquid in heat exchanger. In Proceedings of the AIP Conference Proceedings, Kuantan, Malaysia, 11 January 2019; Volume 2059, p. 020044. [Google Scholar]

- Ibrahim, I.N.; Sazali, N.; Ramasamy, D.; Jamaludin, A.S.; Sharip, M.S.; Ibrahim, H. Effect of impregnate nanocellulose with ethylene glycol for car radiator application. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 58, 43–50. [Google Scholar]

- Razali, S.A.; Sidik, N.A.C.; Koten, H. Cellulose Nanocrystals: A Brief Review on Properties and General Applications. J. Adv. Res. Des. 2019, 60, 1–15. [Google Scholar]

- Ramachandran, K.; Kadirgama, K.; Ramasamy, D.; Azmi, W.H.; Tarlochan, F. Investigation on effective thermal conductivity and relative viscosity of cellulose nanocrystal as a nanofluidic thermal transport through a combined experimental–Statistical approach by using Response Surface Methodology. Appl. Therm. Eng. 2017, 122, 473–483. [Google Scholar] [CrossRef]

- Benedict, F.; Kumar, A.; Kadirgama, K.; Mohammed, H.A.; Ramasamy, D.; Samykano, M.; Saidur, R. Thermal Performance of Hybrid-Inspired Coolant for Radiator Application. Nanomaterials 2020, 10, 1100. [Google Scholar] [CrossRef]

- Gan, P.G.; Sam, S.T.; Bin Abdullah, M.F.; Omar, M.F. Thermal properties of nanocellulose-reinforced composites: A review. J. Appl. Polym. Sci. 2019, 137, 48544. [Google Scholar] [CrossRef] [Green Version]

- Sandhya, M.; Ramasamy, D.; Kadirgama, K.; Harun, W.S.W.; Saidur, R. Experimental study on properties of hybrid stable & surfactant-free nanofluids GNPs/CNCs (Graphene nanoplatelets/cellulose nanocrystal) in water/ethylene glycol mixture for heat transfer application. J. Mol. Liq. 2021, 348, 118019. [Google Scholar]

- Ramachandran, K.; Kadirgama, K.; Ramasamy, D.; Samykano, M.; Samylingam, L.; Tarlochan, F.; Najafi, G. Evaluation of specific heat capacity and density for cellulose nanocrystal-based nanofluid. J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 51, 169–186. [Google Scholar]

- Anamalai, K.; Samylingam, L.; Kadirgama, K.; Samykano, M.; Najafi, G.; Ramasamy, D.; Rahman, M.M. Multi-objective optimization on the machining parameters for bio-inspired nanocoolant. J. Therm. Anal. 2018, 135, 1533–1544. [Google Scholar] [CrossRef]

- Kadirgama, K.; Anamalai, K.; Ramachandran, K.; Ramasamy, D.; Samykano, M.; Kottasamy, A.; Rahman, M.M. Thermal analysis of SUS 304 stainless steel using ethylene glycol/nanocellulose-based nanofluid coolant. Int. J. Adv. Manuf. Technol. 2018, 97, 2061–2076. [Google Scholar] [CrossRef]

- George, M.; Pandey, A.; Rahim, N.A.; Tyagi, V.; Shahabuddin, S.; Saidur, R. Concentrated photovoltaic thermal systems: A component-by-component view on the developments in the design, heat transfer medium and applications. Energy Convers. Manag. 2019, 186, 15–41. [Google Scholar] [CrossRef] [Green Version]

- Elminshawy, N.A.; El-Ghandour, M.; Elhenawy, Y.; Bassyouni, M.; El-Damhogi, D.; Addas, M.F. Experimental investigation of a V-trough PV concentrator integrated with a buried water heat exchanger cooling system. Sol. Energy 2019, 193, 706–714. [Google Scholar] [CrossRef]

- Khodadadi, M.; Farshad, S.A.; Ebrahimpour, Z.; Sheikholeslami, M. Thermal performance of Nanofluid with employing of NEPCM in a PVT-LFR system. Sustain. Energy Technol. Assess. 2021, 47, 101340. [Google Scholar] [CrossRef]

- Sharma, R.; Singh, S.; Mehra, K.S.; Kumar, R. Performance enhancement of solar photovoltaic system using different cooling techniques. Mater. Today Proc. 2021, 46, 11023–11028. [Google Scholar] [CrossRef]

- Tahmasbi, M.; Siavashi, M.; Norouzi, A.M.; Doranehgard, M.H. Thermal and electrical efficiencies enhancement of a solar photovoltaic-thermal/air system (PVT/air) using metal foams. J. Taiwan Inst. Chem. Eng. 2021, 124, 276–289. [Google Scholar] [CrossRef]

- Paul, S.J.; Kumar, U.; Jain, S. Photovoltaic cells cooling techniques for energy efficiency optimization. Mater. Today Proc. 2020, 46, 5458–5463. [Google Scholar] [CrossRef]

- Rao, V.T.; Sekhar, Y.R. Comparative analysis on embodied energy and CO2 emissions for stand-alone crystalline silicon photovoltaic thermal (PVT) systems for tropical climatic regions of India. Sustain. Cities Soc. 2021, 78, 103650. [Google Scholar]

- Yao, J.; Dou, P.; Zheng, S.; Zhao, Y.; Dai, Y.; Zhu, J.; Novakovic, V. Co-generation ability investigation of the novel structured PVT heat pump system and its effect on the “Carbon neutral” strategy of Shanghai. Energy 2021, 239, 121863. [Google Scholar] [CrossRef]

- Singh, H.P.; Arora, S.; Sahota, L.; Arora, M.K.; Jain, A.; Singh, A. Evaluation of the performance parameters of a PVT system: Case study of composite environmental conditions for different Indian cities. Mater. Today Proc. 2022, 57, 1975–1982. [Google Scholar] [CrossRef]

- Fu, Z.; Li, Y.; Liang, X.; Lou, S.; Qiu, Z.; Cheng, Z.; Zhu, Q. Experimental investigation on the enhanced performance of a solar PVT system using micro-encapsulated PCMs. Energy 2021, 228, 120509. [Google Scholar] [CrossRef]

- Muzaidi, N.A.S.; Fikri, M.A.; Wong, K.N.S.W.S.; Sofi, A.Z.M.; Mamat, R.; Adenam, N.M.; Adli, H.K. Heat absorption properties of CuO/TiO2/SiO2 trihybrid nanofluids and its potential future direction towards solar thermal applications. Arab. J. Chem. 2021, 14, 103059. [Google Scholar] [CrossRef]

- Hassani, S.; Taylor, R.A.; Mekhilef, S.; Saidur, R. A cascade nanofluid-based PV/T system with optimized optical and thermal properties. Energy 2016, 112, 963–975. [Google Scholar] [CrossRef]

- Raja, S.; Gangadevi, R.; Marimuthu, R.; Baskaran, M. Performance evaluation of water and air based PVT solar collector for hydrogen production application. Int. J. Hydrogen Energy 2020, 45, 7498–7507. [Google Scholar]

- Bamisile, O.; Huang, Q.; Dagbasi, M.; Adebayo, V.; Okonkwo, E.C.; Ayambire, P.; Ratlamwala, T.A. Thermo-environ study of a concentrated photovoltaic thermal system integrated with Kalina cycle for multi-generation and hydrogen production. Int. J. Hydrogen Energy 2020, 45, 26716–26732. [Google Scholar] [CrossRef]

- Tiwari, S.; Agrawal, S.; Tiwari, G. PVT air collector integrated greenhouse dryers. Renew. Sustain. Energy Rev. 2018, 90, 142–159. [Google Scholar] [CrossRef]

- Udomkun, P.; Romuli, S.; Schock, S.; Mahayothee, B.; Sartas, M.; Wossen, T.; Njukwe, E.; Vanlauwe, B.; Müller, J. Review of solar dryers for agricultural products in Asia and Africa: An innovation landscape approach. J. Environ. Manag. 2020, 268, 110730. [Google Scholar] [CrossRef]

- Çiftçi, E.; Khanlari, A.; Sözen, A.; Aytaç, I.; Tuncer, A.D. Energy and exergy analysis of a photovoltaic thermal (PVT) system used in solar dryer: A numerical and experimental investigation. Renew. Energy 2021, 180, 410–423. [Google Scholar] [CrossRef]

- Anand, B.; Shankar, R.; Murugavelh, S.; Rivera, W.; Prasad, K.M.; Nagarajan, R. A review on solar photovoltaic thermal integrated desalination technologies. Renew. Sustain. Energy Rev. 2021, 141, 110787. [Google Scholar] [CrossRef]

- Nieto-Maestre, J.; Muñoz-Sánchez, B.; Fernández, A.G.; Faik, A.; Grosu, Y.; García-Romero, A. Compatibility of container materials for Concentrated Solar Power with a solar salt and alumina based nanofluid: A study under dynamic conditions. Renew. Energy 2019, 146, 384–396. [Google Scholar] [CrossRef]

- Veeramanikandan, M.; Sathish, D.; Jeryrajkumar, L.; Boovendravarman, S. Effective study on developments in photovoltaic thermal (PV/T) water heating system. Mater. Today Proc. 2020, 42, 584–589. [Google Scholar] [CrossRef]

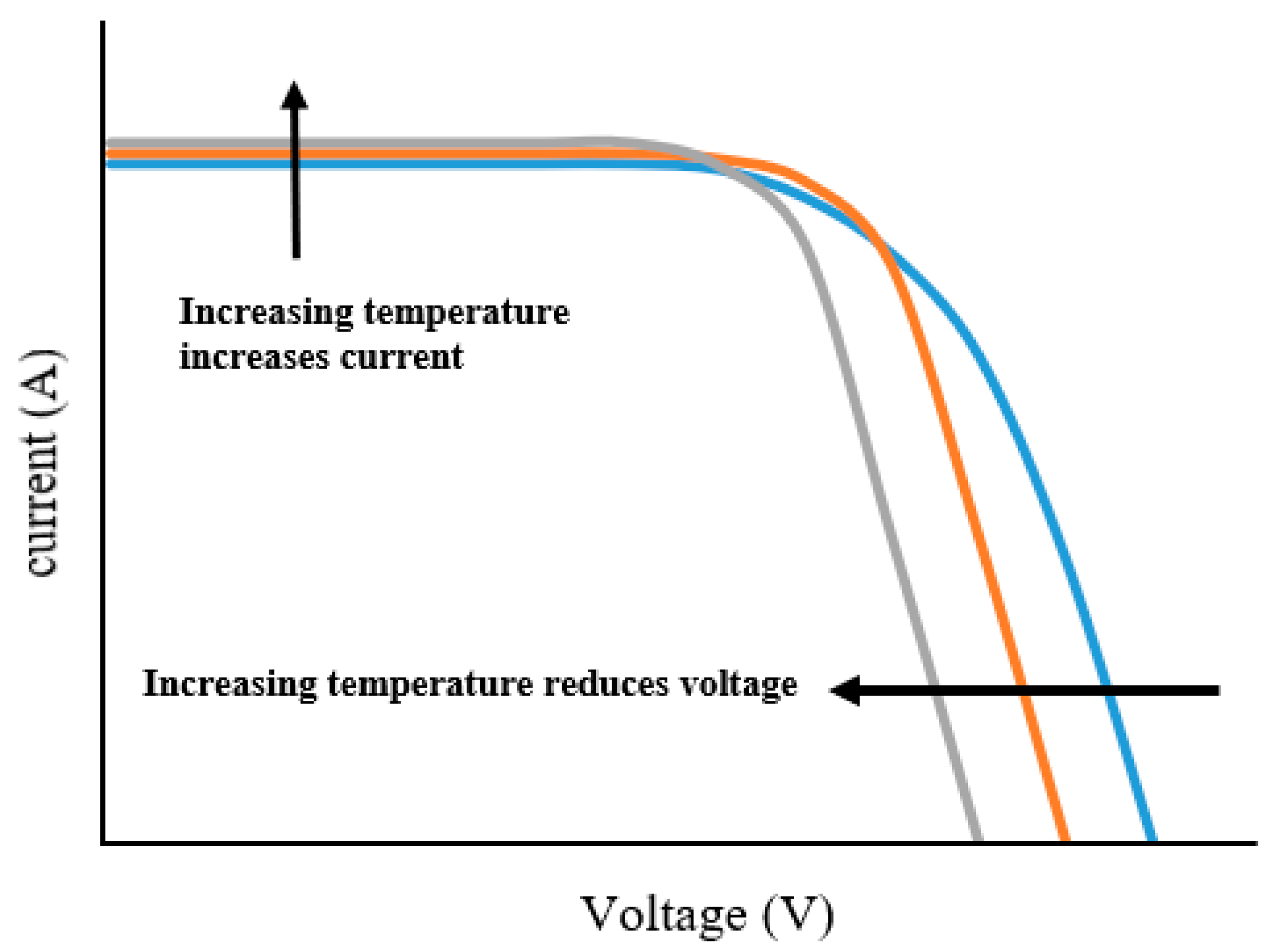

- Amelia, A.R.; Irwan, Y.M.; Leow, W.Z.; Irwanto, M.; Safwati, I.; Zhafarina, M. Investigation of the effect temperature on photovoltaic (PV) panel output performance. Int. J. Adv. Sci. Eng. Inf. Technol. 2016, 6, 682–688. [Google Scholar]

- Khan, S.A.; Bicer, Y.; Koç, M. Design and analysis of a multi-generation system with concentrating photovoltaic thermal (CPV/T) and hydrogen storage. Int. J. Hydrogen Energy 2020, 45, 3484–3498. [Google Scholar] [CrossRef]

- Chow, T.T. A Review on Photovoltaic/Thermal Hybrid Solar Technology. Appl. Energy 2010, 87, 365–379. [Google Scholar] [CrossRef]

- Chemisana, D. Building Integrated Concentrating Photovoltaics: A review. Renew. Sustain. Energy Rev. 2011, 15, 603–611. [Google Scholar] [CrossRef]

- Libra, M.; Petrík, T.; Poulek, V.; Tyukhov, I.I.; Kouřím, P. Changes in the Efficiency of Photovoltaic Energy Conversion in Temperature Range with Extreme Limits. IEEE J. Photovolt. 2021, 11, 1479–1484. [Google Scholar] [CrossRef]

- Good, C.; Chen, J.; Dai, Y.; Hestnes, A.G. Hybrid photovoltaic-thermal systems in buildings—A review. Energy Procedia 2015, 70, 683–690. [Google Scholar] [CrossRef] [Green Version]

- Bijjargi, Y.S.; Kale, S.S.; Shaikh, K.A. Cooling techniques for photovoltaic module for improving its conversion efficiency: A review. Int. J. Mech. Eng. Technol. (IJMET) 2016, 7, 22–38. [Google Scholar]

- Slimani, M.E.-A.; Amirat, M.; Kurucz, I.; Bahria, S.; Hamidat, A.; Chaouch, W.B. A detailed thermal-electrical model of three photovoltaic/thermal (PV/T) hybrid air collectors and photovoltaic (PV) module: Comparative study under Algiers climatic conditions. Energy Convers. Manag. 2017, 133, 458–476. [Google Scholar] [CrossRef]

- Nazri, N.S.; Fudholi, A.; Mustafa, W.; Yen, C.H.; Mohammad, M.; Ruslan, M.H.; Sopian, K. Exergy and improvement potential of hybrid photovoltaic thermal/thermoelectric (PVT/TE) air collector. Renew. Sustain. Energy Rev. 2019, 111, 132–144. [Google Scholar] [CrossRef]

- Herrando, M.; Markides, C. Hybrid PV and solar-thermal systems for domestic heat and power provision in the UK: Techno-economic considerations. Appl. Energy 2016, 161, 512–532. [Google Scholar] [CrossRef] [Green Version]

- Piotrowski, L.J.; Simões, M.G.; Farret, F.A. Feasibility of water-cooled photovoltaic panels under the efficiency and durability aspects. Sol. Energy 2020, 207, 103–109. [Google Scholar] [CrossRef]

- Singh, K.; Singh, S.; Kandpal, D.C.; Kumar, R. Experimental performance study of photovoltaic solar panel with and without water circulation. Mater. Today Proc. 2021, 46, 6822–6827. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Zhang, S.; Tian, D.; Tian, Z. Preparation and characterization of new nano-particle mixed as thermal storage material. Appl. Therm. Eng. 2019, 163, 114386. [Google Scholar] [CrossRef]

- Arat, A.A.K. Effect of Increasing The Concentration Of KAl (SO4)2·12H2O On Some Optical Properties of the Solutions Prepared. Adv. Phys. Theor. Appl. 2014, 30. [Google Scholar]

- Al-Bermany, A.K.J. Prepare and Study Some Mechanical and Electrical Properties of KAl(SO4)2·12H2O as Aqueous Solutions. Chem. Mater. Res. 2009, 3, 65–74. [Google Scholar]

- Sun, M.; Liu, L.; Ma, F.; Jing, M.; Cui, K.; Lin, L. Investigating the effect of graphene nanoplatelets on the thermal conductivity of KAl(SO4)2 12H2O. Mater. Res. Express 2018, 5, 045513. [Google Scholar] [CrossRef]

- Abdallah, S.R.; Elsemary, I.M.; Altohamy, A.A.; Abdelrahman, M.; Attia, A.A.; Abdellatif, O.E. Experimental investigation on the effect of using nano fluid (Al2O3-Water) on the performance of PV/T system. Therm. Sci. Eng. Prog. 2018, 7, 1–7. [Google Scholar] [CrossRef]

- Sardarabadi, M.; Hosseinzadeh, M.; Kazemian, A.; Passandideh-Fard, M. Experimental investigation of the effects of using metal-oxides/water nanofluids on a photovoltaic thermal system (PVT) from energy and exergy viewpoints. Energy 2017, 138, 682–695. [Google Scholar] [CrossRef]

- Hussein, H.A.; Numan, A.H.; Abdulrahman, R.A. Improving the hybrid photovoltaic/thermal system performance using water-cooling technique and Zn-H2O nanofluid. Int. J. Photoenergy 2017, 2017, 6919054. [Google Scholar] [CrossRef] [Green Version]

- Nasrin, R.; Rahim, N.A.; Fayaz, H.; Hasanuzzaman, M. Water/MWCNT nanofluid based cooling system of PVT: Experimental and numerical research. Renew. Energy 2018, 121, 286–300. [Google Scholar] [CrossRef]

- Hassan, A.; Wahab, A.; Qasim, M.A.; Janjua, M.M.; Ali, M.A.; Ali, H.M.; Jadoon, T.R.; Ali, E.; Raza, A.; Javaid, N. Thermal management and uniform temperature regulation of photovoltaic modules using hybrid phase change materials-nanofluids system. Renew. Energy 2019, 145, 282–293. [Google Scholar] [CrossRef]

- Karami, N.; Rahimi, M. Heat transfer enhancement in a PV cell using Boehmite nanofluid. Energy Convers. Manag. 2014, 86, 275–285. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.; Sopian, K.; Kazem, H.A.; Chaichan, M.T. Novel criteria for assessing PV/T solar energy production. Case Stud. Therm. Eng. 2019, 16, 100547. [Google Scholar] [CrossRef]

- Ramdani, H.; Ould-Lahoucine, C. Study on the overall energy and exergy performances of a novel water-based hybrid photovoltaic-thermal solar collector. Energy Convers. Manag. 2020, 222, 113238. [Google Scholar] [CrossRef]

- Wang, G.; Yao, Y.; Wang, B.; Hu, P. Design and thermodynamic analysis of an innovative hybrid solar PV-CT system with multi-segment PV panels. Sustain. Energy Technol. Assess. 2020, 37, 100631. [Google Scholar] [CrossRef]

- Kumar, S.; Thakur, R.; Singhy, A.; Tripathi, R.; Sethi, M. A review of heat removal mechanism in concentrated PVT systems using beam splitter. Mater. Today Proc. 2022, 50, 952–961. [Google Scholar] [CrossRef]

- Ustaoglu, A.; Ozbey, U.; Torlaklı, H. Numerical investigation of concentrating photovoltaic/thermal (CPV/T) system using compound hyperbolic–trumpet, V-trough and compound parabolic concentrators. Renew. Energy 2020, 152, 1192–1208. [Google Scholar] [CrossRef]

- Wang, G.; Wang, F.; Shen, F.; Chen, Z.; Hu, P. Novel design and thermodynamic analysis of a solar concentration PV and thermal combined system based on compact linear Fresnel reflector. Energy 2019, 180, 133–148. [Google Scholar] [CrossRef]

- Youssef, W.B.; Maatallah, T.; Menezo, C.; Nasrallah, S.B. Assessment viability of a concentrating photovoltaic/thermal-energy cogeneration system (CPV/T) with storage for a textile industry application. Sol. Energy 2018, 159, 841–851. [Google Scholar] [CrossRef]

- Bashirnezhad, K.; Ghavami, M.; Alrashed, A.A. Experimental investigations of nanofluids convective heat transfer in different flow regimes: A review. J. Mol. Liq. 2017, 244, 309–321. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H. A Review on Nanofluids: Preparation, Stability Mechanisms, and Applications. J. Nanomater. 2011, 2012, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Barot Vishalkumar, G.; Panchal, K.D. Nanofluid: A tool to increase the efficiency of solar collector. Int. J. Innov. Eng. Technol. 2015, 5, 350–355. [Google Scholar]

- Yang, L.; Luo, X.B.; Luo, S.L. Assessment on Toxicity of Nanomaterials. In Nanomaterials for the Removal of Pollutants and Resource Reutilization; Elsevier: Amsterda, The Netherlands, 2019; pp. 273–292. [Google Scholar]

- Ben Cheikh, S.; Ben Cheikh, R.; Cunha, E.; Lopes, P.E.; Paiva, M.C. Production of cellulose nanofibers from Alfa grass and application as reinforcement for polyvinyl alcohol. Plast. Rubber Compos. 2018, 47, 297–305. [Google Scholar] [CrossRef]

- Ranalder, L.; Busch, H.; Hansen, T.; Brommer, M.; Couture, T.; Gibb, D.; Sverrisson, F. Renewables in Cities 2021 Global Status Report; REN21 Secretariat: Paris, France, 2021. [Google Scholar]

| Techniques | Advantages | Limitations |

|---|---|---|

| Air cooling Photovoltaic/Thermal [6,7,8,9,10] |

|

|

| Water cooling Photovoltaic/Thermal [11,12,13,14] |

|

|

| PV/water spraying [15,16,17,18] |

|

|

| PV/water immersion cooling [19,20,21] |

|

|

| PV/Phase-Change Materials cooling [10,22,23] |

|

|

| Cooling of PV/Heat Pipes [24,25,26,27] |

|

|

| PV/Microchannel heat sink cooling [28,29,30,31,32] |

|

|

| PV/Nano-fluids cooling [33,34,35,36,37] |

|

|

| PV/Spectrum filter [38,39,40] |

|

|

| Cooling Technique | Method/Paradigm | Finding/Results |

|---|---|---|

| Forced water [41] | Comparison of the overall efficiency between covered and uncovered PVT. | The overall annual efficiency of covered PVT is 42.3% and 52.6% for uncovered one. |

| PV/T Nanofluids [42] | Numerical and experimental in the current work, a comprehensive assessment of nanoparticle applications in photovoltaic (PV) cooling was conducted. | Photovoltaic systems can benefit from nanofluids to improve their thermal, electrical and overall efficiency. |

| CPV/T cooling mediums [43] | A thorough literature analysis is offered, outlining the benefits, drawbacks and promise of current CPVT research. There are graphical and tabular summaries of several distinct CPVT design offers in this section. | Multijunction, non-silicon-based solar cells are chosen for high concentration ratios due to their good performance at high operating temperatures. Silicon-based monocrystalline solar cells, on the other hand, are favored at lower concentration ratios due to their cost-effectiveness and off-the-shelf availability. |

| CPV/T cooling mediums [44] | Previous studies show the temperature of the cooling medium for photovoltaic cells (low, medium, high) and the applications in which this heat can be used. In addition, it shows the type and efficiency of the photovoltaic cells used and the type of working fluid. | PVT analysis using inexpensive and readily accessible spectrum filters liquids (UV–VIS–NIR). Electrical and thermal efficiency averages 12.53 percent and 47 percent, respectively. |

| PV/T spectrum filter [40] | A UV–VIS–NIR spectrophotometer is used to analyze the absorption and transmission of 200–2500 nm wavelength solar spectrums of various liquids | The output power, conversion efficiency and total energy efficiency of the proposed combination system are higher than those of a standard solar concentration PV system under the same conditions, as per the outcomes |

| Forced air [45] | Using a varied flow rate of air to cool PV cells and comparing its efficiency to conventional PV | Thermal efficiency improved from 30.3 percent to 46 percent, while electrical efficiency increased from 9.5 percent to 10.2 percent, according to the findings. In comparison to the traditional cell, the flow increased from 0.021 kg/s to 0.042 kg/s |

| Forced water [46] | Experimental examination of the performance of a photovoltaic panel under the influence of different solar rays with stabilization of the amount of coolant flow and the inlet temperature of the coolant. | High sun radiation and the volume flow rate of the cooling fluid have significant influence on PVT performance, according to the research. |

| PV/T Nanofluids [47] | investigate the achievement of a nanofluid-based PV/T collector using various nanofluids, particle volume concentrations and mass flow rates. | 1: The PV/T collector with Al2O3/water as a coolant has a greater electrical and thermal power than one with TiO2/water. 2: Nanoparticle concentration improves the nanofluid heat transfer coefficient, PV power and PV efficiency. |

| Forced air [48] | Experimental performance of the PVT (air) and mathematical models were compared with commercial PV. | The results showed an improvement in the performance of air-cooled photovoltaic cells, with great agreement between the theoretical and experimental results |

| PV/heatsink [49] | The thermal efficiency sinks for various designs with varying fin thicknesses and fin heights, as well as their effect on PV, were evaluated using a simulation model. | For CPV cells, a multi-channel heat sink is used. The conversion efficiency was around 32 percent, and the net power was around 4050 W, thanks to a 91 °C cell temperature and 0.6 m/s flow velocity. |

| PV/heat pipe [50] | The thermal performance of two systems (wickless heat pipe PV/T and wire-meshed heat pipe PV/T) operating at varying inclination degrees was investigated experimentally using a solar simulator. | At no reduction in the temperature, wickless and wire-meshed heat pipe PV/T systems’ thermal efficiencies were 52.8 percent and 51.5 percent, respectively. |

| PV/heatsink [51] | Different degrees of the heatsink’s fin width and their influence on hydraulic performance, as well as the temperature level and uniformity of the PV module, are investigated using numerical simulations using CFD software. | The suggested heatsink design has superior hydraulic properties, resulting in increased heat transmission while utilizing the same amount of material as a traditional design. |

| PV/heat pipe [52] | During the day and at night, the heat loss coefficients of Formal PV/T and PV with heat pipe systems are inversely proportional. Based on data from a typical climatic year in Shanghai, the impacts of each on the annually successful supply days, yearly heat gain and yearly electric gain are compared and analyzed in this study. | The PV/heat pipe system’s decreased night-time heat loss greatly enhances photo thermal performance while somewhat lowering photovoltaic performance when compared to a normal PV/T system. |

| PV/spraying water [53] | When compared to a steady-spray water cooling system and an uncooled PV module, a pulsed-spray water cooling system is developed for solar panels to enhance efficiency and reduce water usage throughout the cooling process. | The results demonstrate that the solar panel’s highest electrical energy generation improves by roughly 33.3 percent, 27.7% and 25.9%, respectively, as compared to non-cooled panels while using spray water cooling (steady and pulsed) and non-cooled panels. |

| PV/spraying water [54] | To better understand the heat transfer characteristics between the solar panel and water, the impact of the water spray’s mass percent on heat transfer coefficients was investigated by calculating the best quantity of total spray water to use for cleaning and cooling PV. | At an optimal flow of 170 L/h, the electrical efficiency of the system was 15.73 percent, with a panel energy capacity of 40.25 W, and the system produced a peak power of 39.48 W, while the pump needed 0.77 W of power |

| PV/immersion [55] | For linear concentrating photovoltaic systems, cooling by the immersion of solar cells in dimethyl silicon oil is suggested as a heat diffusion solution. | The electrical behavior of the silicon-oil-immersed cells is steady, and after 270 days, no significant efficiency deterioration was found. |

| PV/immersion [20] | A dish concentrator (250X) with tracking was used to test a unique CPV system that used de-ionized water for cooling by immersing. | The temperature distribution of the module is very uniform; however, after a wide time of immersion in de-ionized water, the cell module’s electrical efficiency drops. |

| PV/PCM [56] | To lower the working temperature, solar panels using phase-change materials (PCM) are employed. | PV–PCM integrated systems have been shown to increase electricity efficiency by up to 5%. According to the findings, inorganic PCMs offer a high potential for PV cooling. |

| PV/PCM [57] | Under hot climatic circumstances, this study illustrates how to use paraffin wax (PCM) to reduce the running temperature of a c-Si PV module. | The use of a PCM improves the performance of a c-Si PV panel by controlling its thermal properties, which is critical for its reliable operation in hot regions. |

| Application | Challenge/Question | Materials Used | Finding/Results |

|---|---|---|---|

| Improve the solar collector’s efficiency [58] | Low energy efficiency and low output temperature in solar collectors. | Addition of nanoparticles (Al2O3 and CNC) to a basic fluid. | The flat plate solar collector’s energy gain and thermal efficiency were both increased. For 0.5 percent Al2O3, the greatest efficiency was 2.48 percent, while for 0.5 percent CNC nanofluids, it was 8.46 percent. Using CNC/water-EG nanofluid in a flat plate solar collector, an increase in efficiency of around 5.8% may be attained. |

| Strengthening the thermo-physical characteristics of the solar collector’s fluid [59] | Base fluids are suffering from low thermal physical properties. | Using nano cellulose at different concentrations and different temperatures. | Because the nanofluid displays greater thermal conductivity and viscosity at elevated temperatures, it may be deduced that it is suitable for use in a higher-temperature environment. |

| Improve machining performances [60] | Flank wear, chipping and abrasion are the most common causes of MWF machining failure. | Adding cellulose nanocrystal at different concentrations and different temperatures to cooling fluid. | As the CNC volume concentration and temperature grow, the thermal conductivity of the base fluid increases, enhancing its influence on the cutting machine. |

| In a heat exchanger, nanocellulose is used as a heat transfer liquid [61] | Investigate the performance of car radiator coolant using a cooling material consisting of cellulose nanoparticles combined with Ethylene Glycol. | As a coolant, cellulose nanoparticles combined with Ethylene Glycol were used. | It may be observed that employing cellulose nanoparticles in a car radiator as a cooler in combination with ethylene glycol is practical and improves the heat transfer rate. |

| Impregnate nano-cellulose with EG for car radiator applications [62] | Nanoparticles improve the convective heat transfer performance of the base fluid. | As a coolant, cellulose nanoparticles combined with Ethylene Glycol were used. | When compared to distilled water, the use of nanocellulose with Ethylene Glycol for automobile radiator applications demonstrates a higher heat absorption effectiveness. |

| Using cellulose nanocrystals in different thermal applications [63] | Increase the use of crystal nanocellulose in a variety of applications. | Adding crystal nanocellulose to certain materials. | CNCs have attracted the attention of business and academia due to their unique qualities, which include cheap cost, renewable resource extraction, minimal toxicity and good mechanical strength. |

| Thermal applications [64] | In most technical applications, the low heat transfer capability of conventional thermal transport fluids is an unresolved problem. | Addition of crystal nanocellulose materials to the base liquid. | Thermal conductivity and relative viscosity increase with the volume concentration of nanoparticals and the temperature. |

| Coolant of automotive engine radiator [35] | Enhance radiator performance. | Enhance the thermo-physical properties of base fluid by adding nanomateials to it with different volume concentrations and different temperatures. | The thermal conductivity Al2O3/CNC composite nanofluids’ enhancement increases with the temperature and volume concentration. |

| Car radiator application [65] | The rapid rise in energy demand needs additional improvements in the heat transfer process as well as a decrease in energy loss owing to inefficient system operation. | Changing percentages of hybrid metal oxides just like Al2O3 and TiO2 both with and without CNC taken from the plant base. | The mono Al2O3 nanofluids outperformed the CNC and TiO2 nanofluids in terms of thermal conductivity enhancement. The Al2O3/CNC nanofluids, on the other hand, had better thermal conductivity than Al2O3/TiO2 nanofluids (mono and hybrid) |

| General thermal application [66] | Because of its exceptional mechanical characteristics, renewability and biodegradability, nanocellulose has gotten a lot of interest in research and industry in recent years as a nanoscale material for reinforcing polymer matrix composites. | Incorporating nanocellulose with other compounds to form nanocomposites. | Nanocellulose has enhanced the thermal and thermomechanical properties of nanocomposites in general. |

| Radiator for automobiles [67] | In numerous engineering processes, standard working fluids (such as water, motor lubricant and ethylene glycol) have a limited ability to transmit heat. | Graphene nanoplatelets (GNPs) and cellulose nanocrystal (CNC) spread in a base fluid. | The colloidal stability of GNPs/CNC nanofluids at a 0.1 percent volume concentration was exceptional in the base fluid of EG: W at a 60:40 ratio. Traditional heat transfer fluids may be replaced with the present hybrid nanofluid, resulting in more efficient and compact thermal structures. |

| Thermal applications [68] | Invent nanofluid with the highest thermal conductivity and specific heat capacity. | CNC (nanomaterial) distributed in a combination of ethylene glycol and distilled water. | The density has a proportionate relationship to volume concentration and an inverse relationship with temperature, according to the results of the experiments. The specific heat capacity, on the other hand, has a proportionate relationship with temperature and an inverse connection with volume concentration. |

| Machining process cooling [69] | To increase product quality and the cutting equipment’s life, it is critical to reduce heat generated during machining. | CNC is dispersed in a combination of ethylene glycol distilled water. | When CNC-based nanofluids are utilized, the total heat generated at the cutting tool and the temperature created at the chip when milling both improve dramatically. |

| Machining process cooling [70] | Coolant handling and disposal costs are considerable, and with the potential of harmful materials, the disposal of spent coolant is a major issue, since it may have a negative impact on the environment. | Nanofluid made of ethylene glycol and nanocellulose. | The greatest temperature measurement achieved with MWF is 225 °C, but the greatest temperature reading produced with nano-fluid is 154 °C, reflecting a decreased temperature distribution for the chip developed during milling. |

| Materials Used | Problem/Challenge | Concentration | Finding |

|---|---|---|---|

| Add nano-carbon to KAl(SO4)2·12H2O/Na2SO4·10H2O | Energy shortage | 1 wt% nano-carbon | The proposed combination is low-priced, easy-to-prepare and accessible, lowering the cost of an energy storage device [103]. |

| Dissolve KAl(SO4)2·12H2O in distilled water | Improving the optical specifications of the water. | 0.05%, 0.075%, 0.1%, 0.125 and 0.15 gm./mL | The optical characteristics of these solutions are shown to vary continuously with an increasing concentration in this investigation. Because the ultrasonic absorption coefficient rises for the reason of concentration, it may be employed as a coating for moving bodies to detect using ultrasonic technology [104,105]. |

| Coupled KAl(SO4)2·12H2O with GN | Improving the thermal conductivity of the KAl(SO4)2·12H2O. | 0.5%, 1%, 1.5%, 2%, 2.5% | The conductivity of KAl(SO4)2·12H2O/GN compounds increases considerably as the GN concentration increased [106]. |

| Use nano-(Al2O3, CuO and SiC) with water | When the temperature of solar cells rises, their efficiency falls. | 0.5, 1, 2, 3 and 4% | The results revealed that when nanoparticles were introduced to water, thermal conductivity rose, and SiC nanofluid had a higher stability than the other nanofluids investigated [36]. |

| Al2O3-water nanofluid | Enhancing the PV/T overall efficiency of the system. | 0.05, 0.075, 0.1, 0.2, 0.3 | The average amount of electrical energy of nanofluid-based PVTS rises by 16.3, 24.6 and 17.1 percent for 0.05, 0.1 and 0.3 percent, respectively [107]. |

| Al2O3, TiO2 and ZnO distributed in water | Enhancement of energy, exergy and entropy generation compared to the PV unit. | 0.2 wt.% | PVT/ZnO and PVT/TiO2 systems have greater total energy and exergy efficiency than other systems [108]. |

| Cellulose nanoparticles Ethylene glycol Water | Low energy efficiency and low output temperature plague solar collectors. | 0–1.3% | Because the nanofluid displays greater thermal conductivity and viscosity at elevated temperatures, it may be deduced that it is suitable for use in a higher temperature environment [58]. |

| Zn-water | During the summer season, heat is retained inside the PV cells. | 0 to 0.5% wt. | When compared to water-based PVTS, the electrical energy of Zn–water nanofluid-based PVTS increased by 20% [109]. |

| MWCNT/water | PVT’s thermal performance should be improved. | 0 to 1% wt. | PVTS using MWCNT and water had about 0.14 and 3.67 percent greater TE and EE than pure water. If you compare it to fresh water, the findings of the experimental and numerical tests indicated that using MWCNT/water increases the overall power efficiency by 4.11 and 3.81 percent, respectively [110] |

| GNP/water | PV electric generation decreases when the temperature of photovoltaic (PV) panels continues to rise. | 0 to 0.15% volume fraction | The NF volume proportion and the HTF flow rate were varied between 0 and 0.15 percent and 20–40 LPM, respectively. According to their findings, the PVTS’s overall efficiency improved by 14.1, 12.6 and 10.9 percent at flow rates of 40, 30 and 20 LPM, respectively [111] |

| Boehmite water | For the PV cell, evaluate the cooling performance using water-based Boehmite nanofluids. | 0.01, 0.1 and 0.5 wt.% | When nanoparticles are present, the average temperature of the PV cell is significantly lower than that of the base fluid [112]. |

| Added Nanomaterial Type | Properties | Finding |

|---|---|---|

| Graphene nanoplatelets and CNC [67] | GNPs with characteristics of an 800 m2/g specific surface area, 99.9% purity, 3 mm size and 1.5 µm diameter were employed. Volume concentrations (0.1% to 0.2%) | For 30 days, the examined nanofluids remained stable, with no significant sedimentation. The findings of GNPs/CNC nanofluids at a 0.1 percent volume concentration showed outstanding colloidal stability in the base fluid of EG:W at a 60:40 ratio. |

| Al2O3, TiO2 and CNC [65] | The sizes of the smaller and larger particles are 50–90 nm and 1–5 µm, respectively. Volume concentrations (0.1%, 0.5% and 0.9%) Temperatures ranging from 30 °C to 70 °C | The mono Al2O3 nanofluids outperformed the CNC and TiO2 nanofluids in terms of thermal conductivity enhancement. The Al2O3/CNC hybrid nanofluids, on the other hand, had better thermal conductivity than the other mono and hybrid nanofluids (Al2O3/TiO2). |

| Al2O3/CNC composite nanofluids are made in a 60:40 ratio [35] | Volume concentrations are 0.1%, 0.5% and 0.9%. Temperatures ranging from 30 °C to 70 °C | With an increasing temp. and volume fraction, the thermal conductivity of Al2O3/CNC composite nanofluids improves. |

| Al2O3/CNC distributed in a base mixture water to ethylene glycol (40:60) [61] | Nanoparticles’ average size is 13 nm with a spherical shape. CNC volume concentrations are 0.1%, 0.5%, 0.9% and 1.3% | The rate of heat transfer rises as the flow rate of the coolant or working fluid in the radiator cooling system increases. |

| Al2O3 and CNC [58] | Using 0.5% Al2O3 and 0.5% CNC, volume fractions are 0.1%, 0.3% and 0.5%. CNC crystal diameter from 9 to 14 nm | The thermal conductivity of nanofluids rose, but viscosity decreased as the temperature climbed. Nanofluids have the potential to improve the efficiency of flat-plate solar collectors. |

| Nano cellulose, ethylene glycol and water [59] | It was carried out at temperatures of 30–70 °C and volume concentrations of up to 1.3 percent. | It can be concluded that the nanofluid is applicable in a higher temperature environment since the nanofluid exhibits enhanced thermal conductivity and viscosity at the elevated temperature. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hajjaj, S.S.H.; Aqeel, A.A.K.A.; Sultan, M.T.H.; Shahar, F.S.; Shah, A.U.M. Review of Recent Efforts in Cooling Photovoltaic Panels (PVs) for Enhanced Performance and Better Impact on the Environment. Nanomaterials 2022, 12, 1664. https://doi.org/10.3390/nano12101664

Hajjaj SSH, Aqeel AAKA, Sultan MTH, Shahar FS, Shah AUM. Review of Recent Efforts in Cooling Photovoltaic Panels (PVs) for Enhanced Performance and Better Impact on the Environment. Nanomaterials. 2022; 12(10):1664. https://doi.org/10.3390/nano12101664

Chicago/Turabian StyleHajjaj, Sami Salama Hussen, Ahmad Abdul Kareem Ahmad Aqeel, Mohamed Thariq Hameed Sultan, Farah Syazwani Shahar, and Ain Umaira Md Shah. 2022. "Review of Recent Efforts in Cooling Photovoltaic Panels (PVs) for Enhanced Performance and Better Impact on the Environment" Nanomaterials 12, no. 10: 1664. https://doi.org/10.3390/nano12101664

APA StyleHajjaj, S. S. H., Aqeel, A. A. K. A., Sultan, M. T. H., Shahar, F. S., & Shah, A. U. M. (2022). Review of Recent Efforts in Cooling Photovoltaic Panels (PVs) for Enhanced Performance and Better Impact on the Environment. Nanomaterials, 12(10), 1664. https://doi.org/10.3390/nano12101664