Innovative Low-Cost Carbon/ZnO Hybrid Materials with Enhanced Photocatalytic Activity towards Organic Pollutant Dyes’ Removal

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

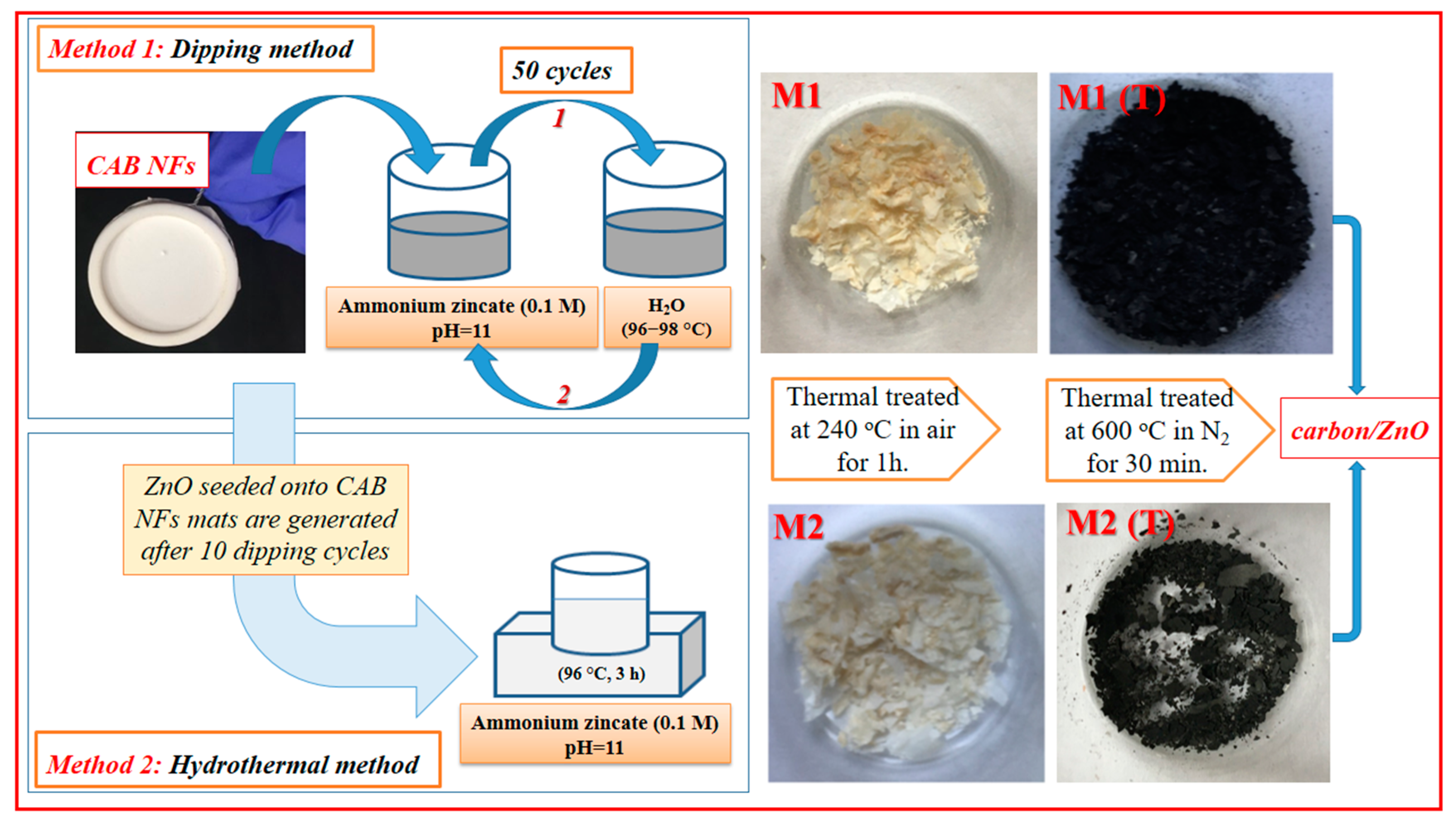

2.2. Carbon/ZnO Hybrid Nanostructures Preparation

2.3. Characterization of Materials

2.4. Photocatalytic Tests

3. Results

3.1. X-ray Diffraction (XRD) Characterization

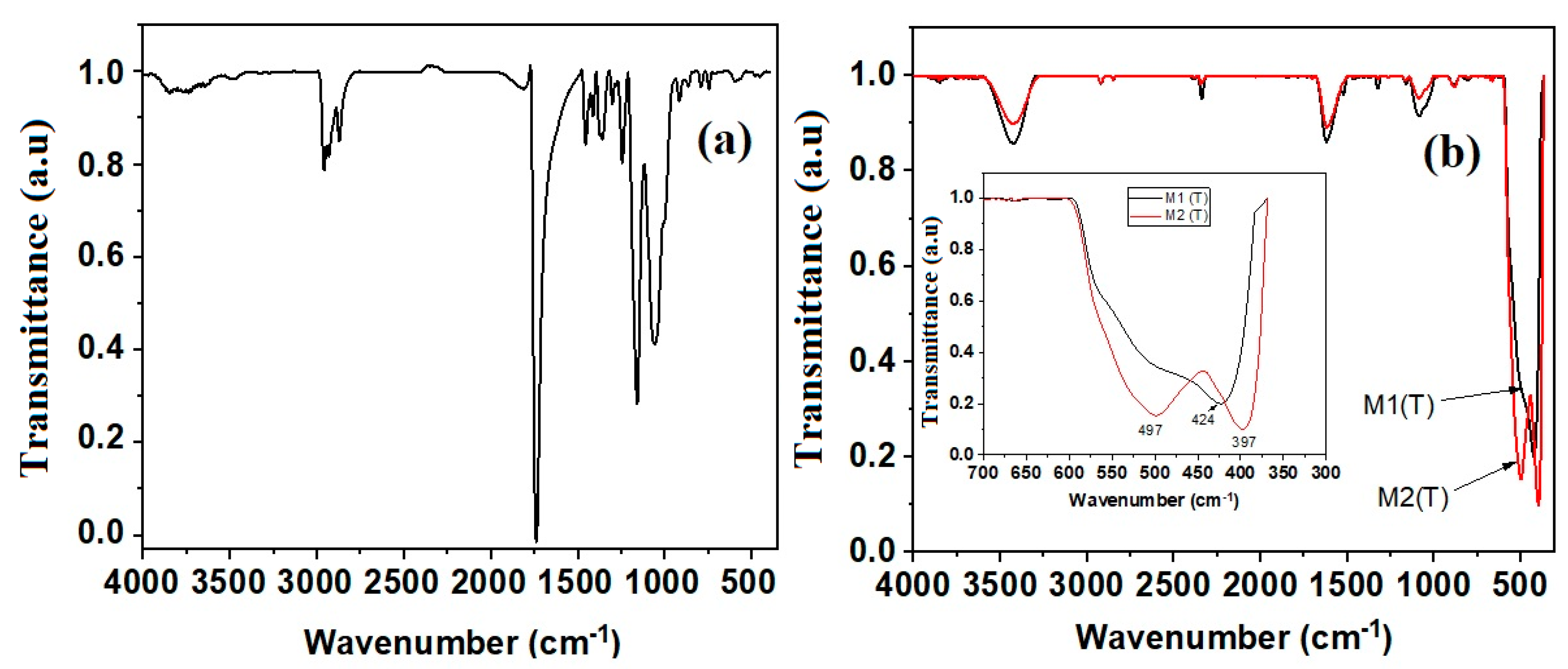

3.2. Fourier Transform Infrared (FTIR) Analysis

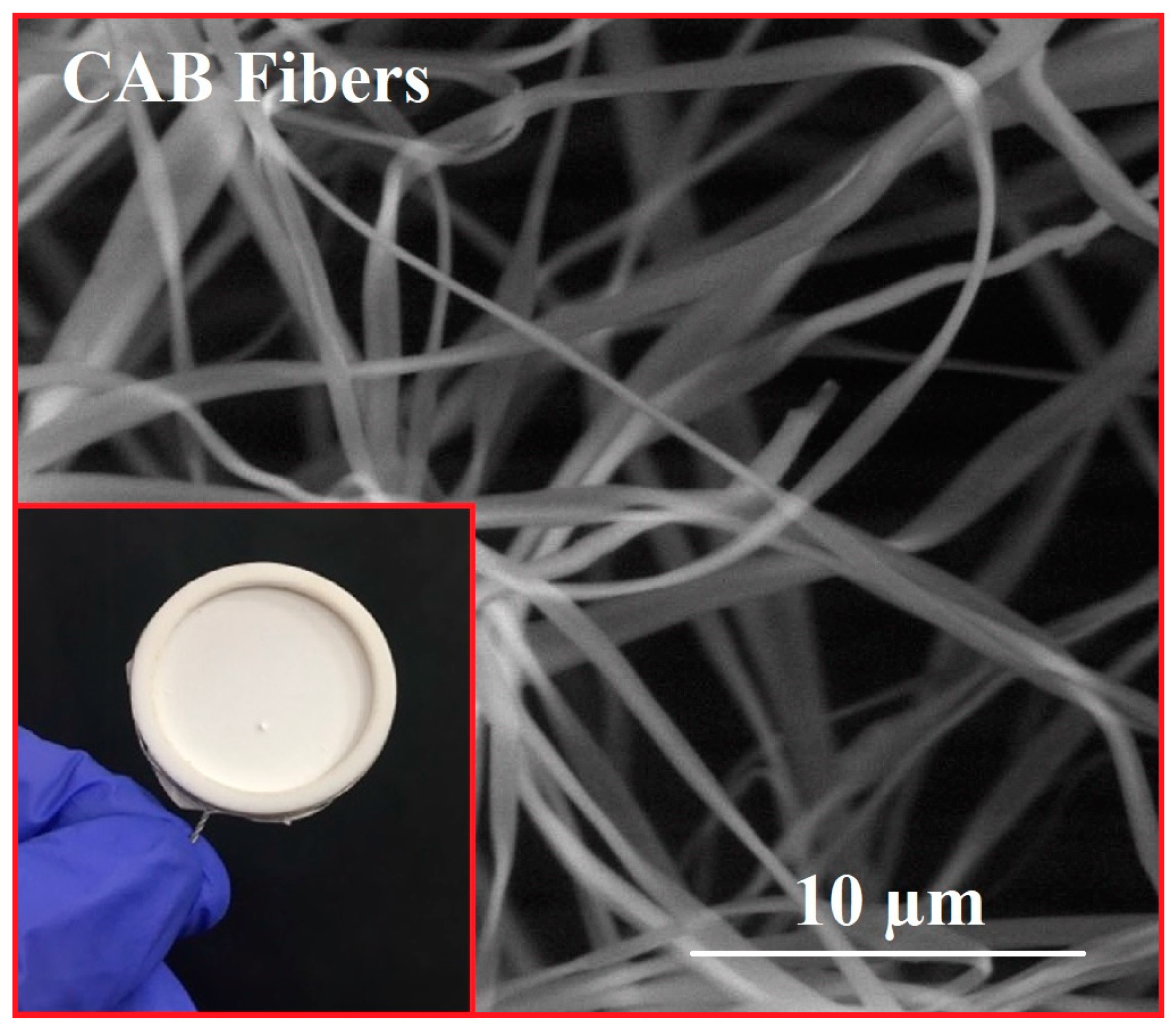

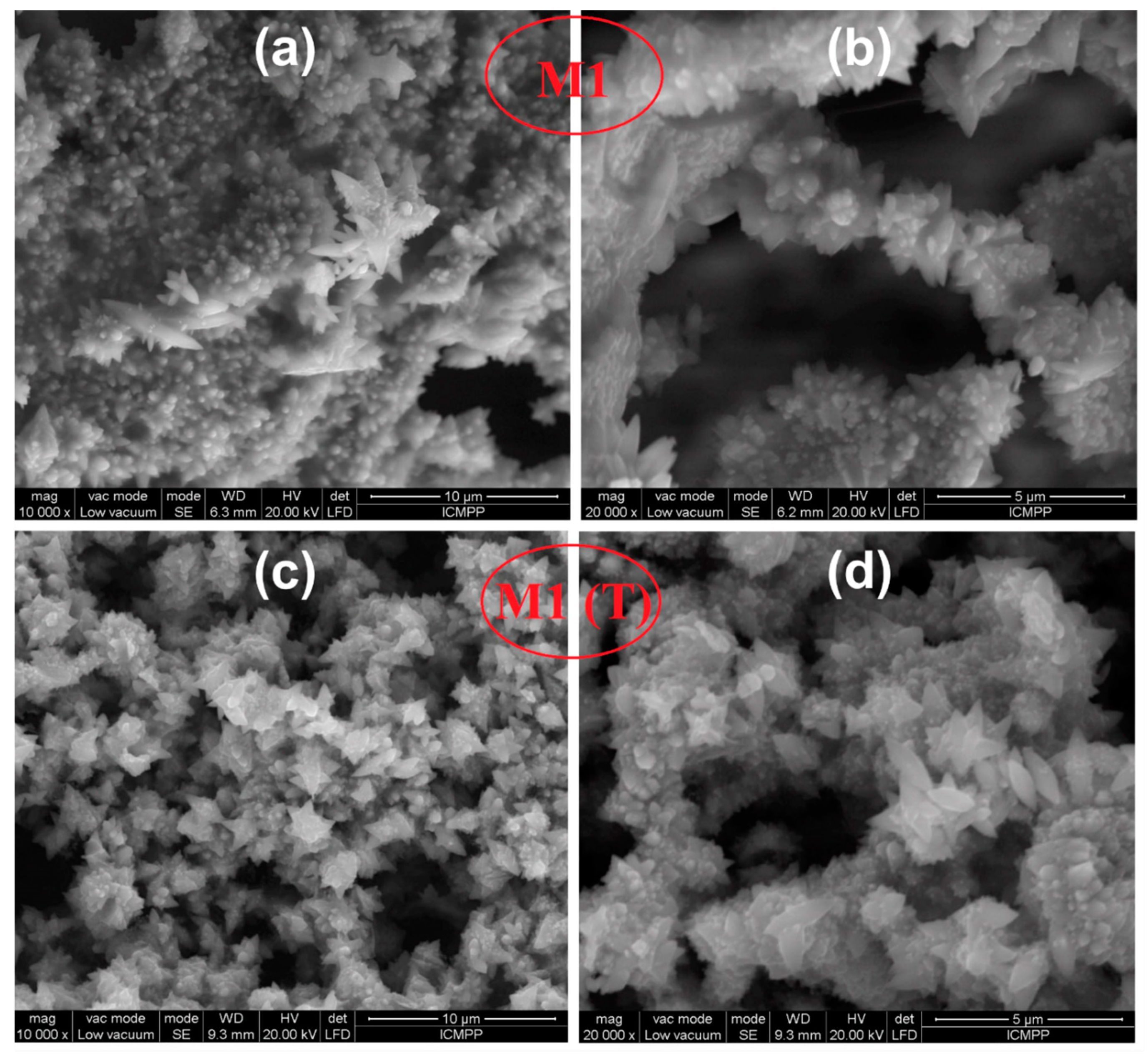

3.3. Morphological Characterization

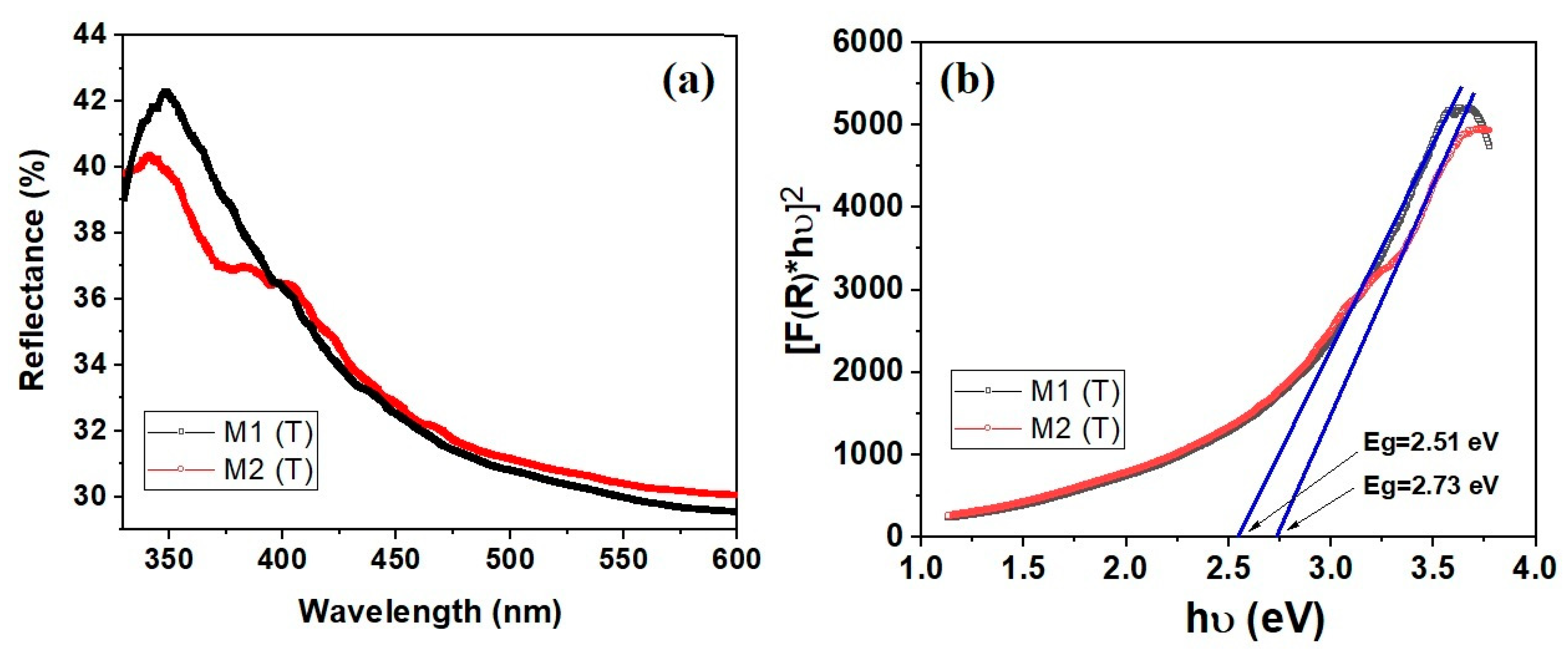

3.4. Optical Properties

3.5. Photoluminescence Study

3.6. Adsorption/Photocatalytic Properties

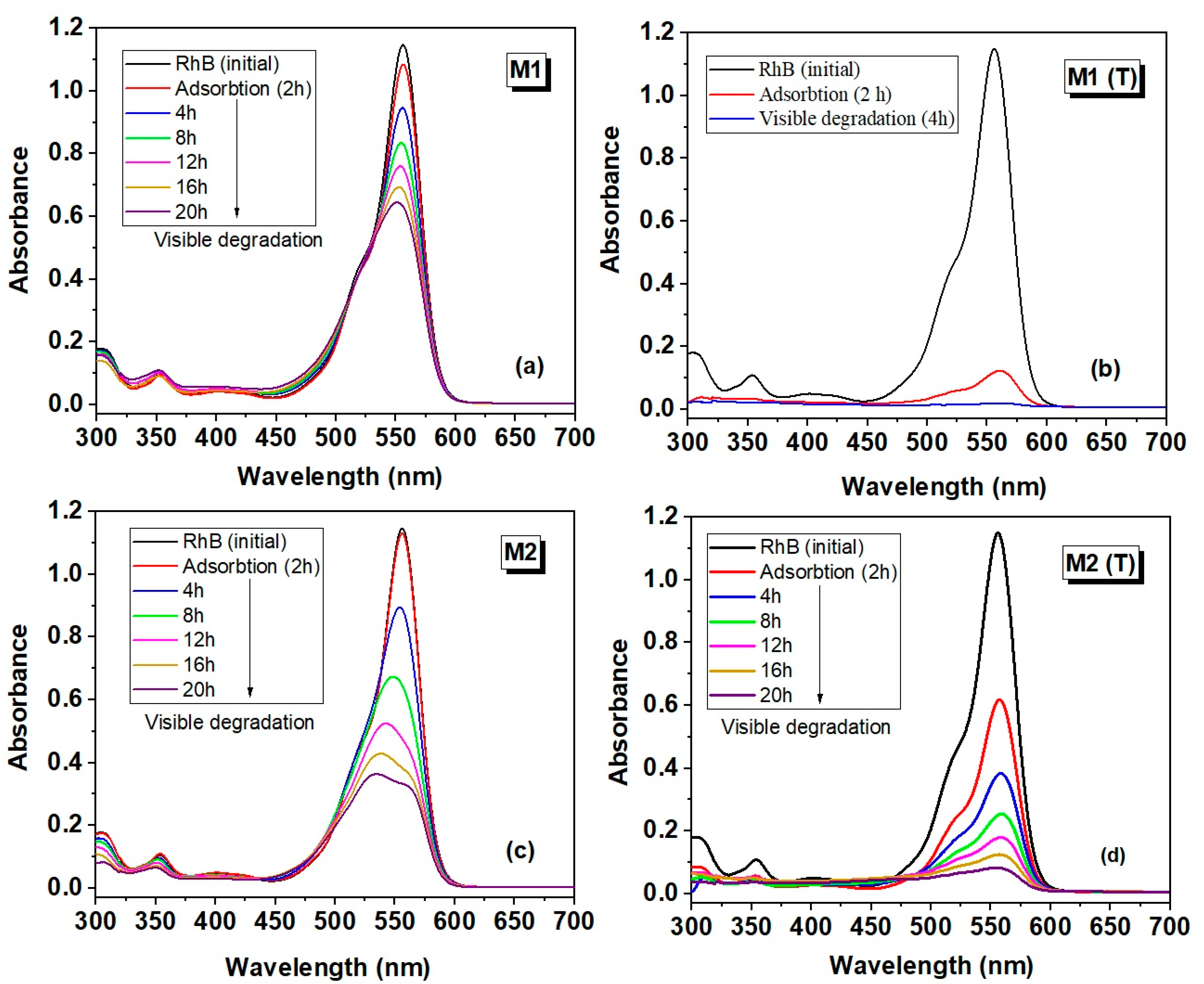

3.6.1. Adsorption/Photocatalytic Properties of Carbon/ZnO Hybrid Nanostructures for Degradation of Organic Pollutants

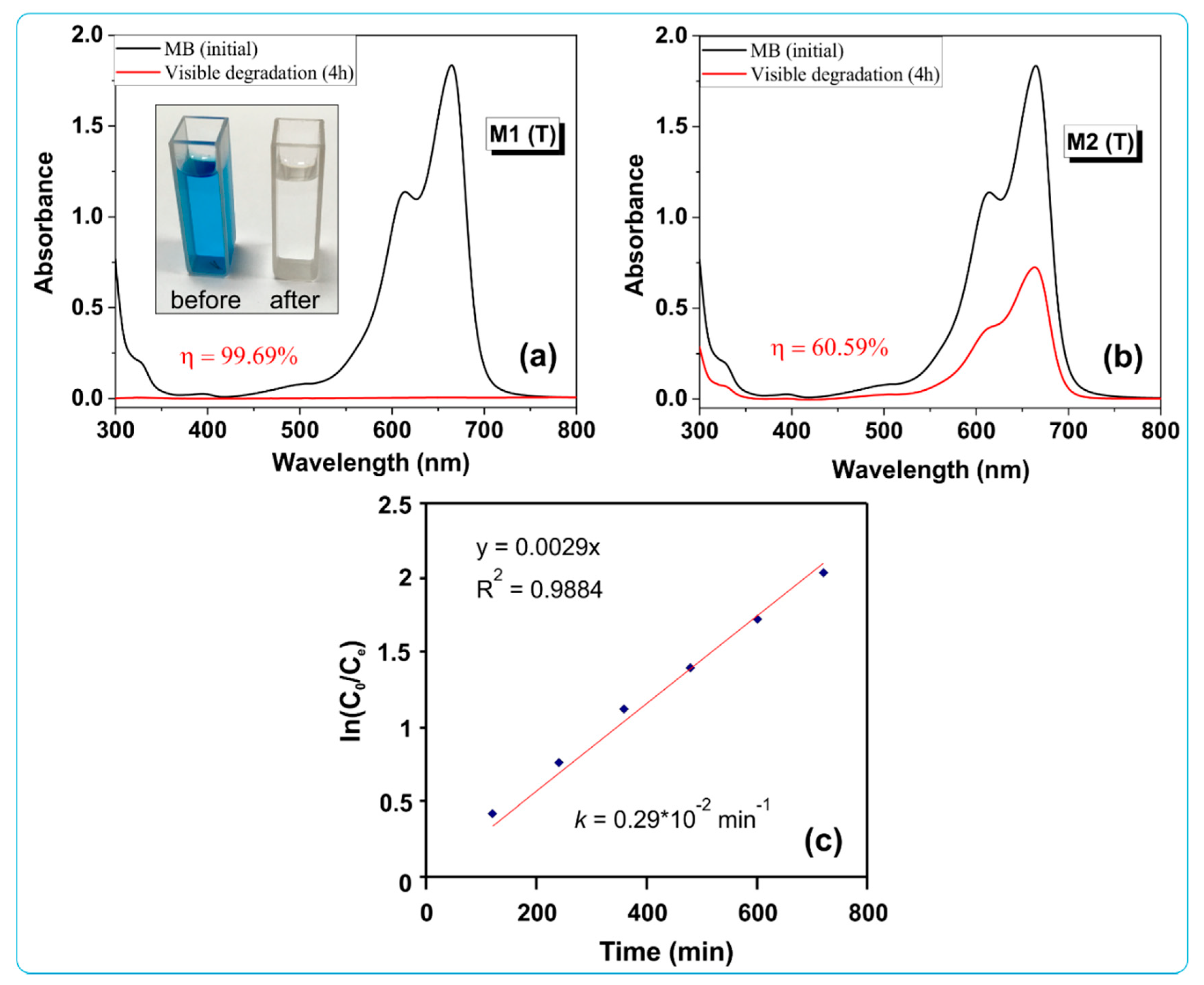

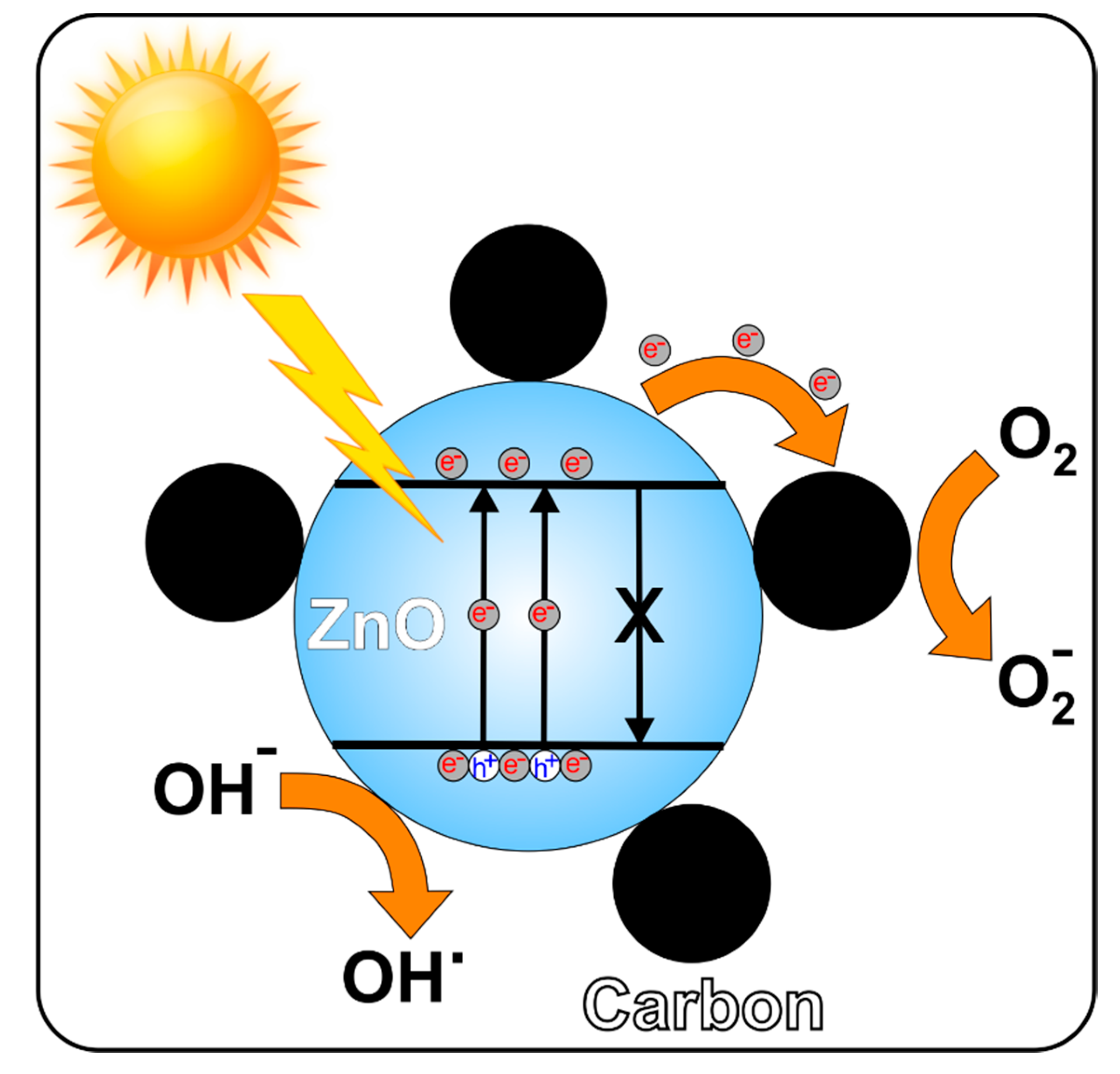

3.6.2. Photocatalytic Activity of Carbon/ZnO Hybrid Nanostructures for Degradation of Methylene Blue (MB) Dye

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pascariu, P.; Homocianu, M. ZnO-based ceramic nanofibers: Preparation, properties and applications. Ceram. Int. 2019, 45, 11158–11173. [Google Scholar] [CrossRef]

- Singh, K.; Kumar, P.; Srivastava, R. An overview of textile dyes and their removal techniques: Indian perspective. Pollut. Res. 2017, 36, 790–797. [Google Scholar]

- Djurisic, A.B.; Chen, X.; Leung, Y.H.; Ng, A.M.C. ZnO nanostructures: Growth, properties and applications. J. Mater. Chem. 2012, 22, 6526–6535. [Google Scholar] [CrossRef]

- Bolink, H.J.; Coronado, E.; Repetto, D.; Sessolo, M. Air stable hybrid organic-inorganic light emitting diodes using ZnO as the cathode. Appl. Phys. Lett. 2007, 91, 223501. [Google Scholar] [CrossRef]

- Liao, Y.J.; Cheng, C.W.; Wu, B.H.; Wang, C.Y.; Chen, C.Y.; Gwo, S.; Chen, L.J. Low threshold room-temperature UV surface plasmon polariton lasers with ZnO nanowires on single-crystal aluminum films with Al2O3 interlayers. RSC Adv. 2019, 9, 13600–13607. [Google Scholar] [CrossRef]

- Yoon, C.; Jeon, B.; Yoon, G. Development of Al foil-based sandwich-type ZnO piezoelectric nanogenerators. AIP Adv. 2020, 10, 045018. [Google Scholar] [CrossRef]

- Kumar, R.; Umar, A.; Kumar, G.; Nalwa, H.S. Antimicrobial properties of ZnO nanomaterials: A review. Ceram. Int. 2017, 43, 3940–3961. [Google Scholar] [CrossRef]

- Saha, J.K.; Bukke, R.N.; Mude, N.N.; Jang, J. Remarkable stability improvement of ZnO TFT with Al2O3 gate insulator by yttrium passivation with spray pyrolysis. Nanomaterials 2020, 10, 976. [Google Scholar] [CrossRef]

- Gao, G.; Yu, L.; Vinu, A.; Shapter, J.G.; Batmunkh, M.; Shearer, C.J.; Yin, T.; Huang, P.; Cui, D. Synthesis of ultra-long hierarchical ZnO whiskers in a hydrothermal system for dye-sensitised solar cells. RSC Adv. 2016, 6, 109406–109413. [Google Scholar] [CrossRef]

- Pascariu, P.; Cojocaru, C.; Samoila, P.; Airinei, A.; Olaru, N.; Rusu, D.; Rosca, I.; Suchea, M. Photocatalytic and antimicrobial activity of electrospun ZnO:Ag nanostructures. J. Alloys Compd. 2020, 834, 155144. [Google Scholar] [CrossRef]

- Pascariu, P.; Cojocaru, C.; Olaru, N.; Samoila, P.; Airinei, A.; Ignat, M.; Sacarescu, L.; Timpu, D. Novel rare earth (RE-La, Er, Sm) metal doped ZnO photocatalysts for degradation of Congo-Red dye: Synthesis, characterization and kinetic studies. J. Environ. Manag. 2019, 239, 225–234. [Google Scholar] [CrossRef] [PubMed]

- Lang, J.; Wang, J.; Zhang, Q.; Li, X.; Han, Q.; Wei, M.; Sui, Y.; Wang, D.; Yang, J. Chemical precipitation synthesis and significant enhancement in photocatalytic activity of Ce-doped ZnO nanoparticles. Ceram. Int. 2016, 42, 14175–14181. [Google Scholar] [CrossRef]

- Macías-Sánchez, J.J.; Hinojosa-Reyes, L.; Caballero-Quintero, A.; De la Cruz, W.; Ruiz-Ruiz, E.; Hernández-Ramírez, A.; Guzmán-Mar, J.L. Synthesis of nitrogen-doped ZnO by sol–gel method: Characterization and its application on visible photocatalytic degradation of 2,4-D and picloram herbicides. Photochem. Photobiol. Sci. 2015, 14, 536–542. [Google Scholar] [CrossRef]

- Adnan, M.A.M.; Julkapli, N.M.; Hamid, S.B.A. Review on ZnO hybrid photocatalyst: Impact on photocatalytic activities of water pollutant degradation. Rev. Inorg. Chem. 2016, 36, 77–104. [Google Scholar]

- Rahimi, K.; Yazdani, A.; Ahmadirad, M. Facile preparation of zinc oxide nanorods surrounded by graphene quantum dots both synthesized via separate pyrolysis procedures for photocatalyst application. Mat. Res. Bull. 2018, 98, 148–154. [Google Scholar] [CrossRef]

- Xu, J.; Cui, Y.; Han, Y.; Hao, M.; Zhang, X. ZnO–graphene composites with high photocatalytic activities under visible light. RSC Adv. 2016, 6, 96778–96784. [Google Scholar] [CrossRef]

- Xu, S.; Fu, L.; Pham, T.S.H.; Yu, A.; Han, F.; Chen, L. Preparation of ZnO flower/reduced grapheme oxide composite with enhanced photocatalytic performance under sunlight. Ceram. Int. 2015, 41, 4007–4013. [Google Scholar] [CrossRef]

- Mu, J.; Shao, C.; Guo, Z.; Zhang, Z.; Zhang, M.; Zhang, P.; Chen, B.; Liu, Y. High Photocatalytic activity of ZnO-Carbon nanofiber heteroarchitectures. ACS Appl. Mater. Interfaces 2011, 3, 590–596. [Google Scholar] [CrossRef]

- Batmunkh, M.; Biggs, M.J.; Shapter, J.G. Carbonaceous dye-sensitized solar cell photoelectrodes. Adv. Sci. 2015, 2, 1400025. [Google Scholar] [CrossRef]

- Hu, C.; Lu, T.; Chen, F.; Zhang, R. A brief review of graphene–metal oxide composites synthesis and applications in photocatalysis. J. Chin. Adv. Mater. Soc. 2013, 1, 21–39. [Google Scholar] [CrossRef]

- Concina, I.; Ibupoto, Z.H.; Vomiero, A. Semiconducting metal oxide nanostructures for water splitting and photovoltaics. Adv. Energy Mater. 2017, 7, 1700706. [Google Scholar] [CrossRef]

- Shi, S.; Zhuang, X.; Cheng, B.; Wang, X. Solution blowing of ZnO nanoflake-encapsulated carbon nanofibers as electrodes for supercapacitors. J. Mater. Chem. A 2013, 1, 13779–13788. [Google Scholar] [CrossRef]

- Samuel, E.; Joshi, B.; Kim, M.W.; Kim, Y.I.; Swihart, M.T.; Yoon, S.S. Hierarchical zeolitic imidazolate framework-derived manganese-doped zinc oxide decorated carbon nanofiber electrodes for high performance flexible supercapacitors. Chem. Eng. J. 2019, 371, 657–665. [Google Scholar] [CrossRef]

- Zhang, L.; Aboagye, A.; Kelkar, A.; Lai, C.; Fong, H. A review: Carbon nanofibers from electrospun polyacrylonitrile and their applications. J. Mater. Sci. 2014, 49, 463–480. [Google Scholar] [CrossRef]

- Lee, B.S.; Yu, W.R. Electrospun carbon nanofibers as a functional composite platform: A review of highly tunable microstructures and morphologies for versatile applications. Funct. Compos. Struct. 2020, 2, 012001. [Google Scholar] [CrossRef]

- Pascariu, P.; Olaru, L.; Matricala, A.L.; Olaru, N. Photocatalytic activity of ZnO nanostructures grown on electrospun CAB ultrafine fibers. Appl. Surf. Sci. 2018, 455, 61–69. [Google Scholar] [CrossRef]

- Pascariu, P.; Airinei, A.; Olaru, N.; Olaru, L.; Nica, V. Photocatalytic degradation of Rhodamine B dye using ZnO–SnO2 electrospun ceramic nanofibers. Ceram. Int. 2016, 42, 6775–6781. [Google Scholar] [CrossRef]

- Cojocaru, C.; Pascariu Dorneanu, P.; Airinei, A.; Olaru, N.; Samoila, P.; Rotaru, A. Design and evaluation of electrospun polysulfone fibers and polysulfone/NiFe2O4 nanostructured composite as sorbents for oil spill cleanup. J. Taiwan Inst. Chem. Eng. 2017, 70, 267–281. [Google Scholar] [CrossRef]

- Thamer, B.M.; El-Hamshary, H.; Al-Deyab, S.S.; El-Newehy, M.H. Functionalized electrospun carbon nanofibers for removal of cationic dye. Arab. J. Chem. 2019, 12, 747–759. [Google Scholar] [CrossRef]

- Yun, S.I.; Kim, S.H.; Kim, D.W.; Kim, Y.A.; Kim, B.H. Facile preparation and capacitive properties of low-cost carbon nanofibers with ZnO derived from lignin and pitch as supercapacitor electrodes. Carbon 2019, 149, 637–645. [Google Scholar] [CrossRef]

- Samanta, P.K.; Bandyopadhyay, A.K. Chemical growth of hexagonal zinc oxide nanorods and their optical properties. Appl. Nanosci. 2012, 2, 111–117. [Google Scholar] [CrossRef]

- Ge, M.Y.; Wu, H.P.; Niu, L.; Liu, J.F.; Chen, S.Y.; Shen, P.Y.; Zeng, Y.W.; Wang, Y.W.; Zhang, G.Q.; Jiang, J.Z. Nanostructured ZnO: From monodisperse nanoparticles to nanorods. J. Cryst. Growth 2007, 305, 162–166. [Google Scholar] [CrossRef]

- Seow, Z.L.S.; Wong, A.S.W.; Thavasi, V.; Jose, R.; Ramakrishna, S.; Ho, G.W. Controlled synthesis and application of ZnO nanoparticles, nanorods and nanospheres in dye-sensitized solar cells. Nanotechnology 2009, 20, 045604. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.H.; Sue, H.J.; Cheng, X. Solid-state dye-sensitized solar cells based on ZnO nanoparticle and nanorod array hybrid photoanodes. Nanoscale Res. Lett. 2011, 6, 517. [Google Scholar] [CrossRef]

- Anzlovar, A.; Orel, Z.C.; Kogej, K.; Zigon, M. Polyol-mediated synthesis of zinc oxide nanorods and nanocomposites with poly(methyl methacrylate). J. Nanomater. 2012, 2012, 760872. [Google Scholar] [CrossRef]

- Hayashi, S.; Nakamori, N.; Kanamori, H. Generalized theory of average dielectric constant and its application to infrared absorption by ZnO small particles. J. Phys. Soc. Jpn. 1979, 46, 176–183. [Google Scholar] [CrossRef]

- Wu, L.; Wu, Y.; Pan, X.; Kong, F. Synthesis of ZnO nanorod and the annealing effect on its photoluminescence property. Opt. Mater. 2006, 28, 418–422. [Google Scholar] [CrossRef]

- Zhao, Q.; Xie, H.; Ning, H.; Liu, J.; Zhang, H.; Wang, L.; Wang, X.; Zhu, Y.; Li, S.; Wu, M. Intercalating petroleum asphalt into electrospun ZnO/Carbon nanofibers as enhanced free-standing anode for lithium-ion batteries. J. Alloys Compd. 2018, 737, 330–336. [Google Scholar] [CrossRef]

- García-Díaz, I.; López, F.A.; Alguacil, F.J. Carbon nanofibers: A new adsorbent for copper removal from wastewater. Metals 2018, 8, 914. [Google Scholar] [CrossRef]

- Morales, A.E.; Mora, E.S.; Pal, U. Use of diffuse reflectance spectroscopy for optical characterization of un-supported nanostructures. Rev. Mex. Fisica 2007, 53, 18–22. [Google Scholar]

- Güler, Ö.; Güler, S.H.; Başgöz, Ö.; Albayrak, M.G.; Yahia, I.S. Synthesis and characterization of ZnO-reinforced with grapheme nanolayer nanocomposites: Electrical conductivity and optical band gap analysis. Mater. Res. Express 2019, 6, 095602. [Google Scholar] [CrossRef]

- Tien, H.N.; Luan, V.H.; Ho, L.T.; Kho, N.T.; Hahn, S.H.; Chung, J.S.; Shin, E.W.; Hur, S.H. One-pot synthesis of a reduced graphene oxide–zinc oxide sphere composite and its use as a visible light photocatalyst. Chem. Eng. J. 2013, 229, 126–133. [Google Scholar] [CrossRef]

- Pandy, P.; Kurchania, R.; Haque, F.Z. Structural, diffuse reflectance and photoluminescence study of cerium doped ZnO nanoparticles synthesized through simple sol-gel method. Optik 2015, 126, 3310–3315. [Google Scholar] [CrossRef]

- Durmus, Z.; Kurt, B.Z.; Durmus, A. Synthesis and characterization of Graphene Oxide/Zinc Oxide (GO/ZnO) nanocomposite and its utilization for photocatalytic degradation of basic fuchsin dye. ChemistrySelect 2019, 4, 271–278. [Google Scholar] [CrossRef]

| Sample | 2θ (°) | dhkl (Å) | D (nm) | Lattice Parameters | ε (%) | L (nm) | ||

|---|---|---|---|---|---|---|---|---|

| a (Å) | c (Å) | c/a | ||||||

| M1 (T) | 31.78 | 2.813 | 22.88 | 3.249 | 5.201 | 1.601 | 0.564 | 1.954 |

| 34.46 | 2.6 | 20.73 | ||||||

| 36.26 | 2.475 | 21.39 | ||||||

| M2 (T) | 31.76 | 2.815 | 36.13 | 3.251 | 5.207 | 1.602 | 0.353 | 1.957 |

| 34.42 | 2.603 | 33.17 | ||||||

| 36.24 | 2.476 | 30.94 | ||||||

| Photocatalyst Type | Type and Concentration of Dye | Amount of Photocatalyst (g/L) | Light Source | Reaction Rate Constant k (min−1) | η (%) | Ref. |

|---|---|---|---|---|---|---|

| ZnO/RGO | MB (10 mg/L) | 1.25 | UV (100 W) | 0.0395 | − | [17] |

| ZnO/GQDs | MB (2.5 × 10−5 M/L) | − | 250 W | 0.018 (150 min) | − | [15] |

| ZnO/GO | Basic Fuchsin (20 mg/L) | 0.2 | UV | 0.00845 (300 min) | 92.5 | [44] |

| ZnO/Graphene | MO (5 × 10−5 M/L) | 0.08 | VIS (300 W) | 0.0116 | − | [16] |

| ZnO/CNFs | RhB (10 mg/L) | 1 | UV (50 W) | 0.07533 | − | [18] |

| Carbon/ZnO | MB (10 mg/L) | 0.5 | Vis (100 W) | 0.002 (240 min) | 97.97 | This work |

| RhB (5 mg/L) | − | 98.34 | ||||

| CR (10 mg/L) | − | 91.93 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pascariu, P.; Olaru, N.; Rotaru, A.; Airinei, A. Innovative Low-Cost Carbon/ZnO Hybrid Materials with Enhanced Photocatalytic Activity towards Organic Pollutant Dyes’ Removal. Nanomaterials 2020, 10, 1873. https://doi.org/10.3390/nano10091873

Pascariu P, Olaru N, Rotaru A, Airinei A. Innovative Low-Cost Carbon/ZnO Hybrid Materials with Enhanced Photocatalytic Activity towards Organic Pollutant Dyes’ Removal. Nanomaterials. 2020; 10(9):1873. https://doi.org/10.3390/nano10091873

Chicago/Turabian StylePascariu, Petronela, Niculae Olaru, Aurelian Rotaru, and Anton Airinei. 2020. "Innovative Low-Cost Carbon/ZnO Hybrid Materials with Enhanced Photocatalytic Activity towards Organic Pollutant Dyes’ Removal" Nanomaterials 10, no. 9: 1873. https://doi.org/10.3390/nano10091873

APA StylePascariu, P., Olaru, N., Rotaru, A., & Airinei, A. (2020). Innovative Low-Cost Carbon/ZnO Hybrid Materials with Enhanced Photocatalytic Activity towards Organic Pollutant Dyes’ Removal. Nanomaterials, 10(9), 1873. https://doi.org/10.3390/nano10091873