In Situ Formation of Nanoporous Silicon on a Silicon Wafer via the Magnesiothermic Reduction Reaction (MRR) of Diatomaceous Earth

Abstract

1. Introduction

2. Materials and Methods

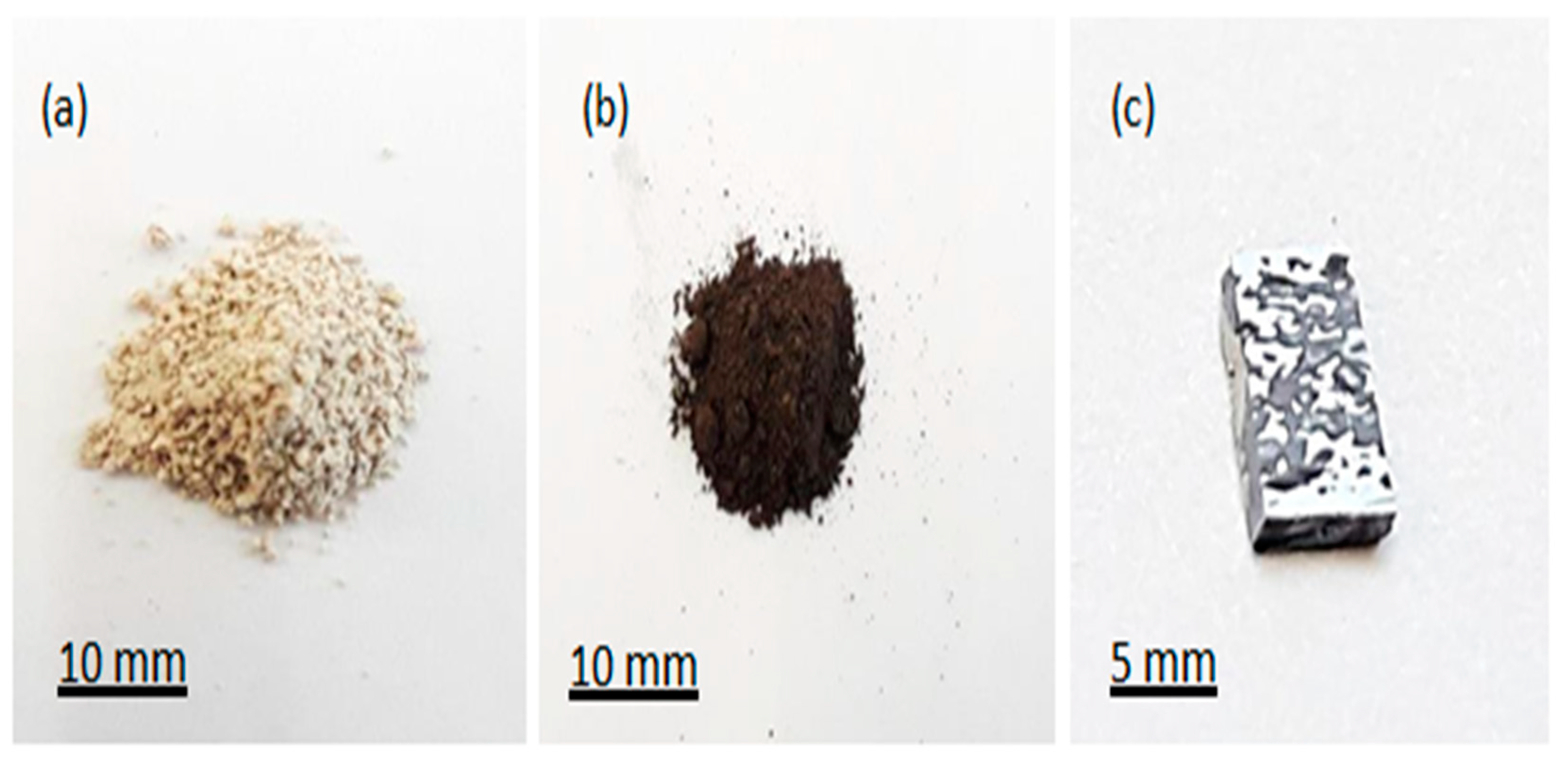

2.1. Sample Preparation

- Reduction temperature of 700 °C for 2.5 h;

- The molar ratio of SiO2 and Mg was 1:1.25.

- Diatomite earth was mixed with aqueous NaCl solution in the weight ratio 1:10. The mixture was well stirred using a magnetic stirrer at 70 °C.

- The solution was centrifuged and the slurry dried at 85 °C overnight.

- The obtained powder was mixed with magnesium powder in the molar ratio of 1:1.25 with a pestle and mortar.

2.2. Powder Particle Size and Surface Area

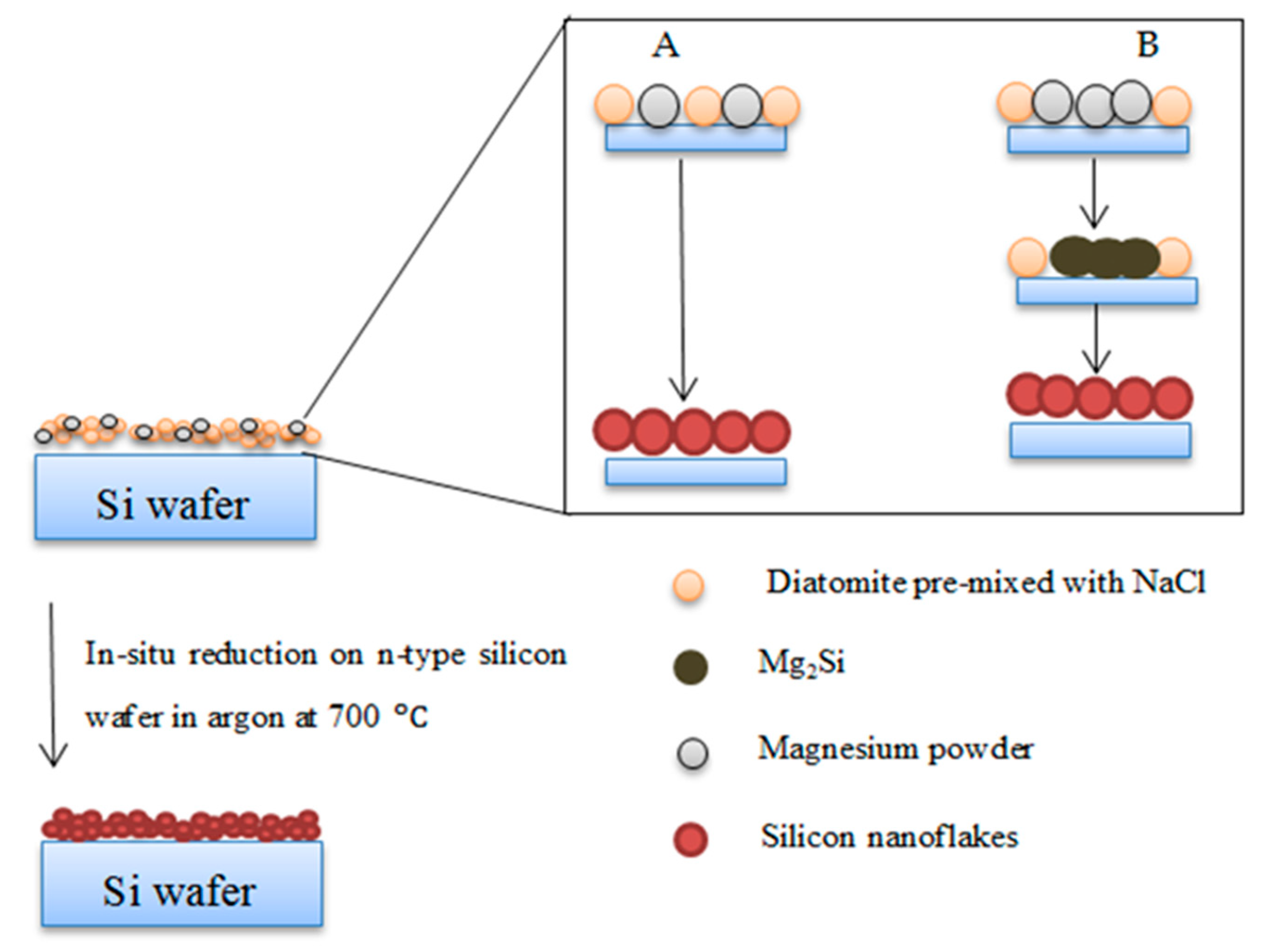

2.3. Synthesis of Silicon Nanoflakes on Silicon Wafer Substrate

2.4. Microstructural Analysis

2.5. X-ray Diffraction Analysis

2.6. Raman Spectroscopy

2.7. Optical Property Measurement

2.8. Atomic Force Microscopy

3. Results

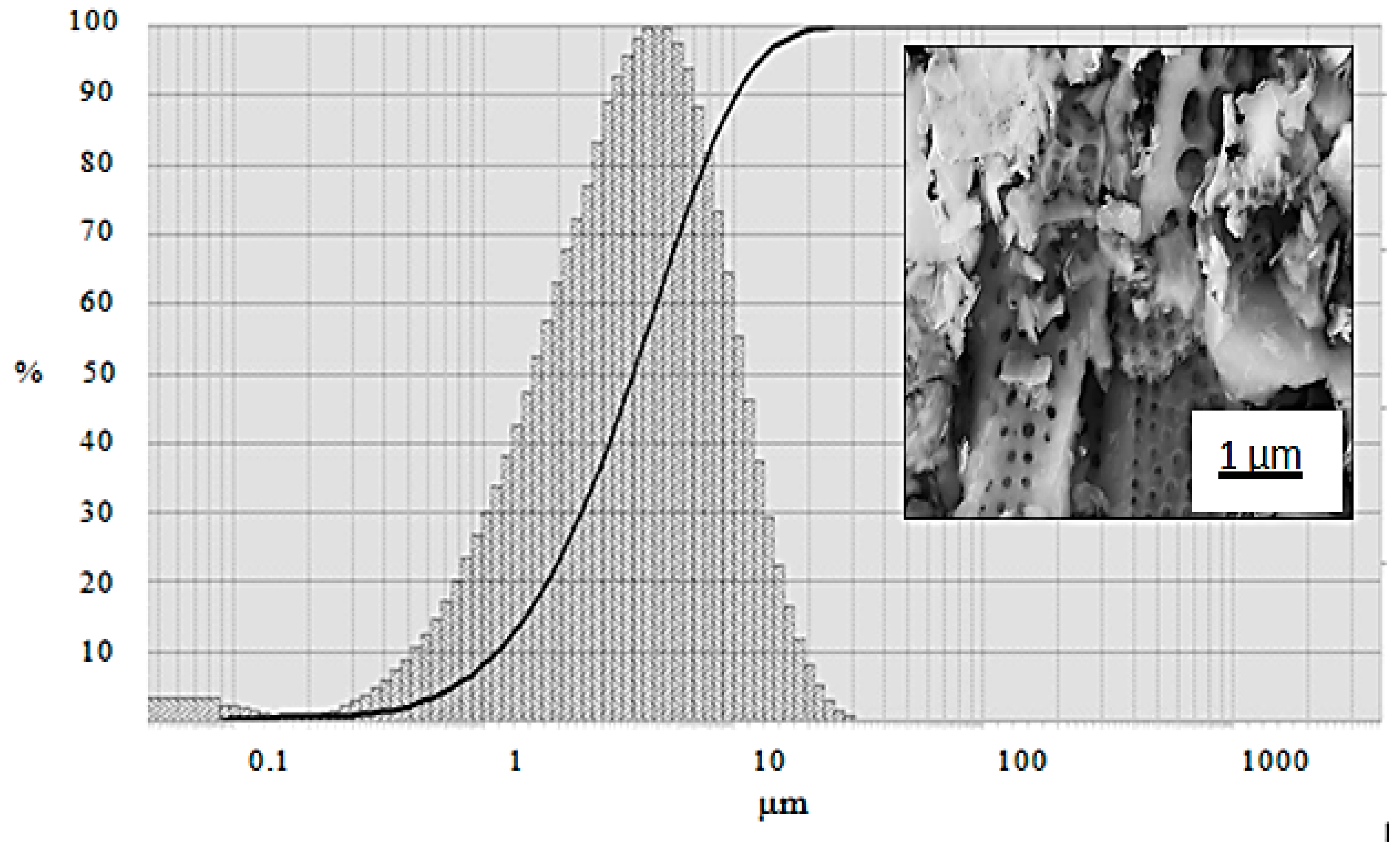

3.1. Powder Particle Size and Surface Area

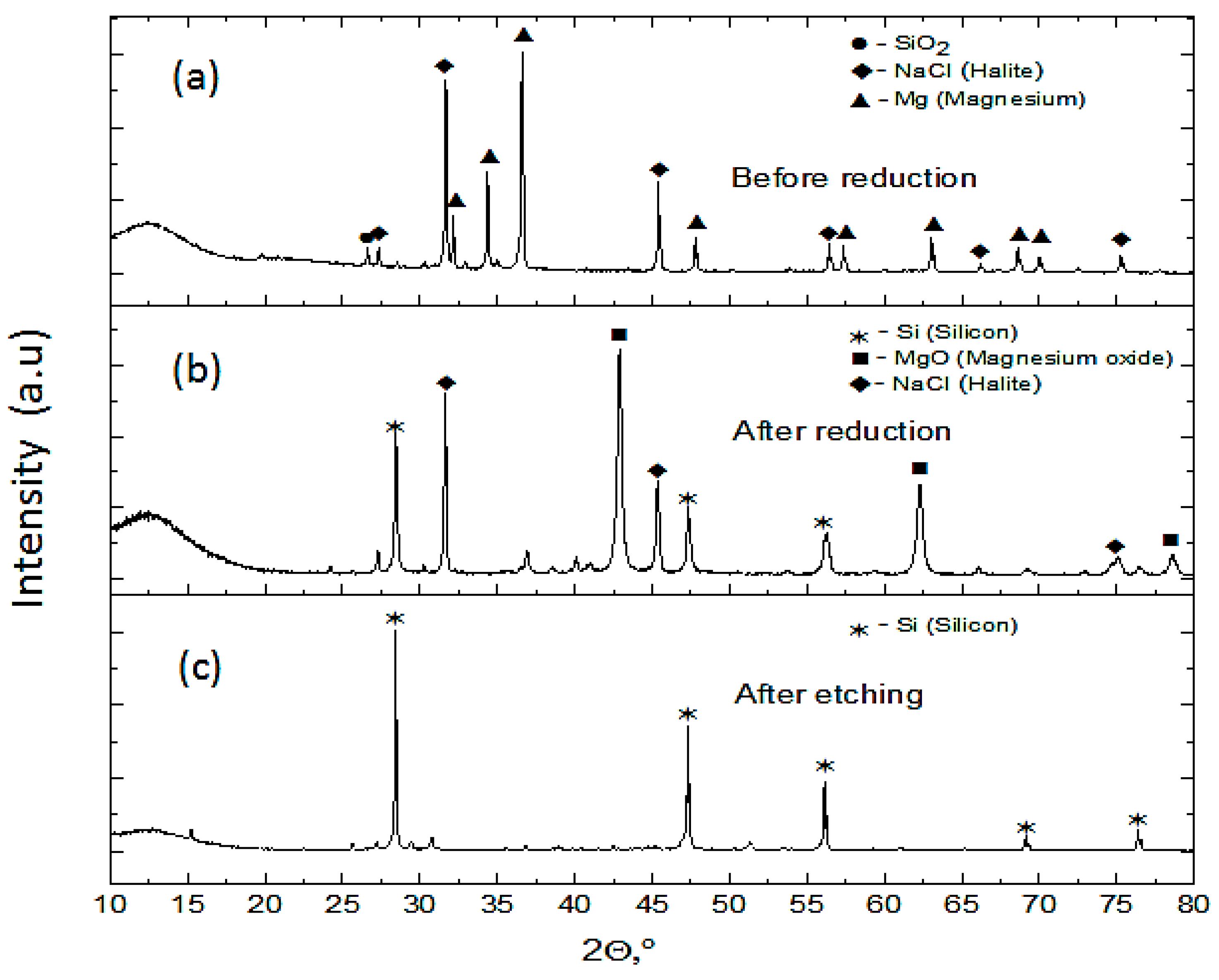

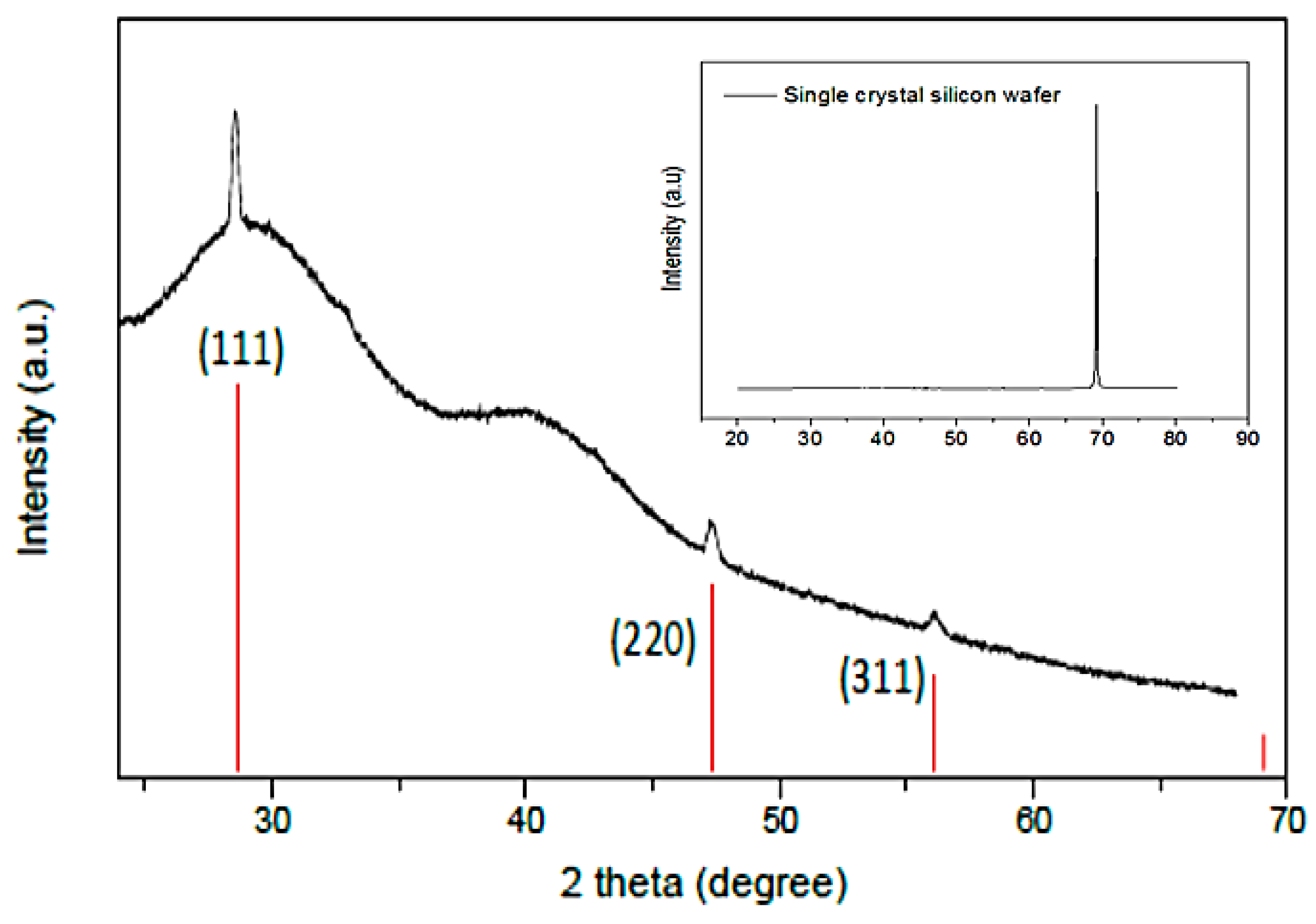

3.2. Phase Composition of the Reaction Mixture

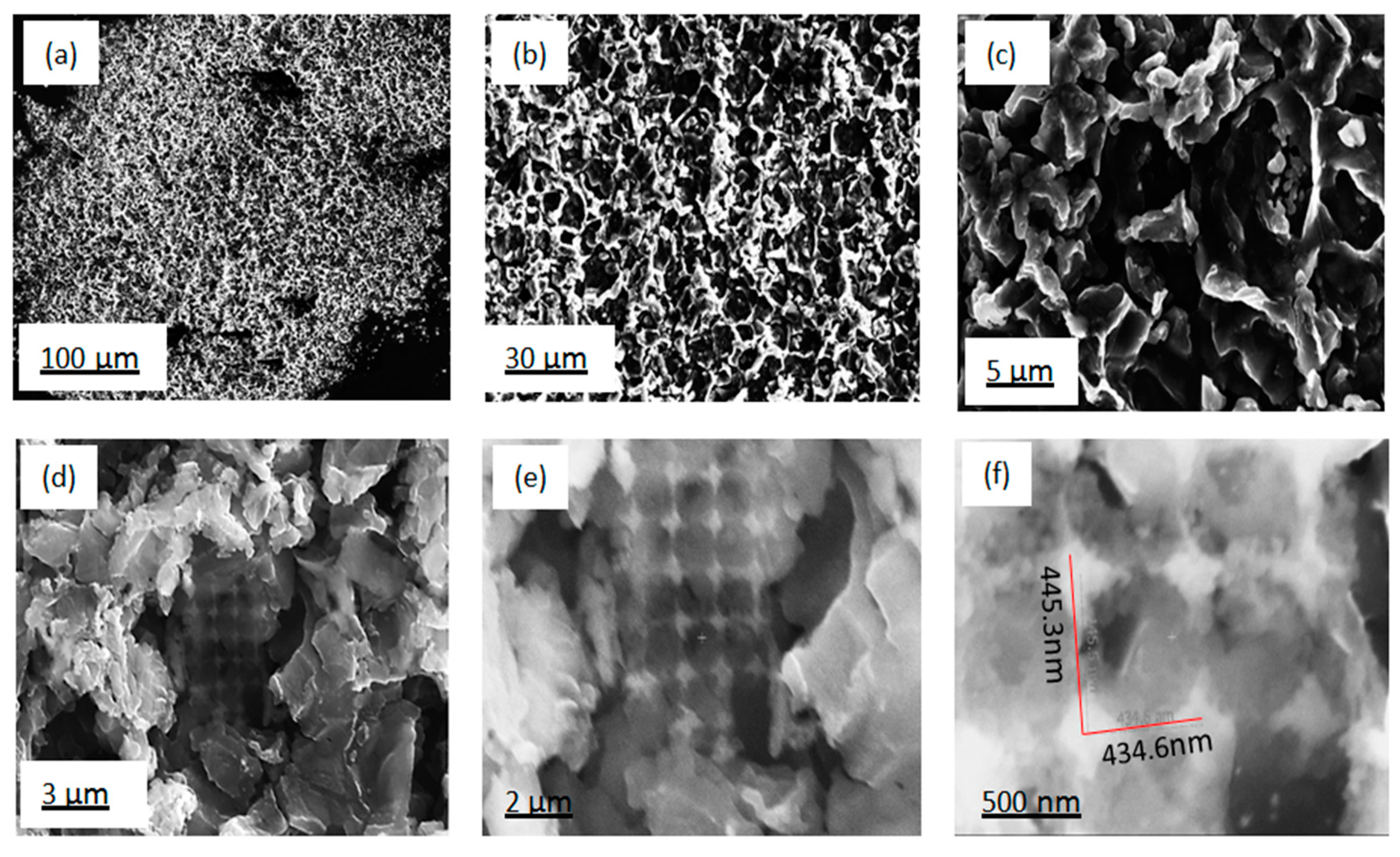

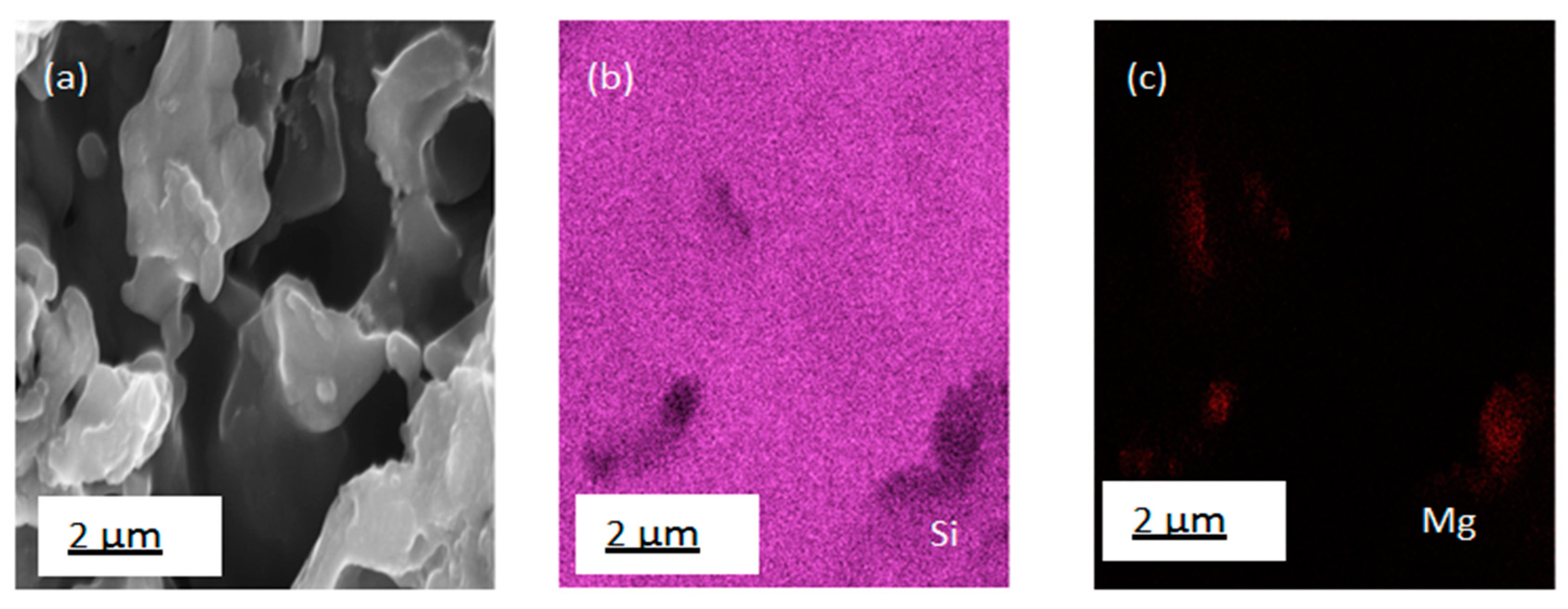

3.3. Microstructure of Silicon Nanoflakes

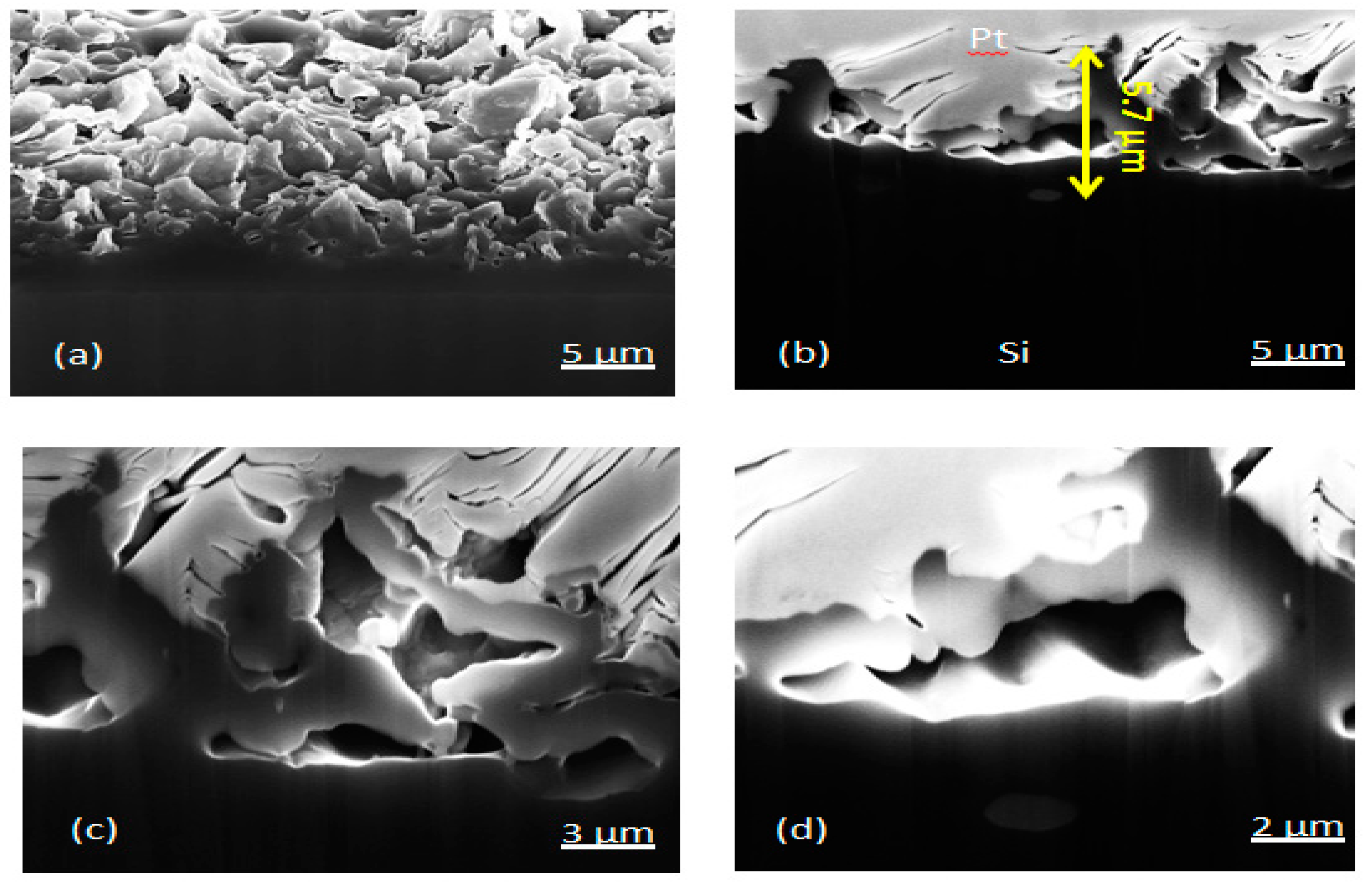

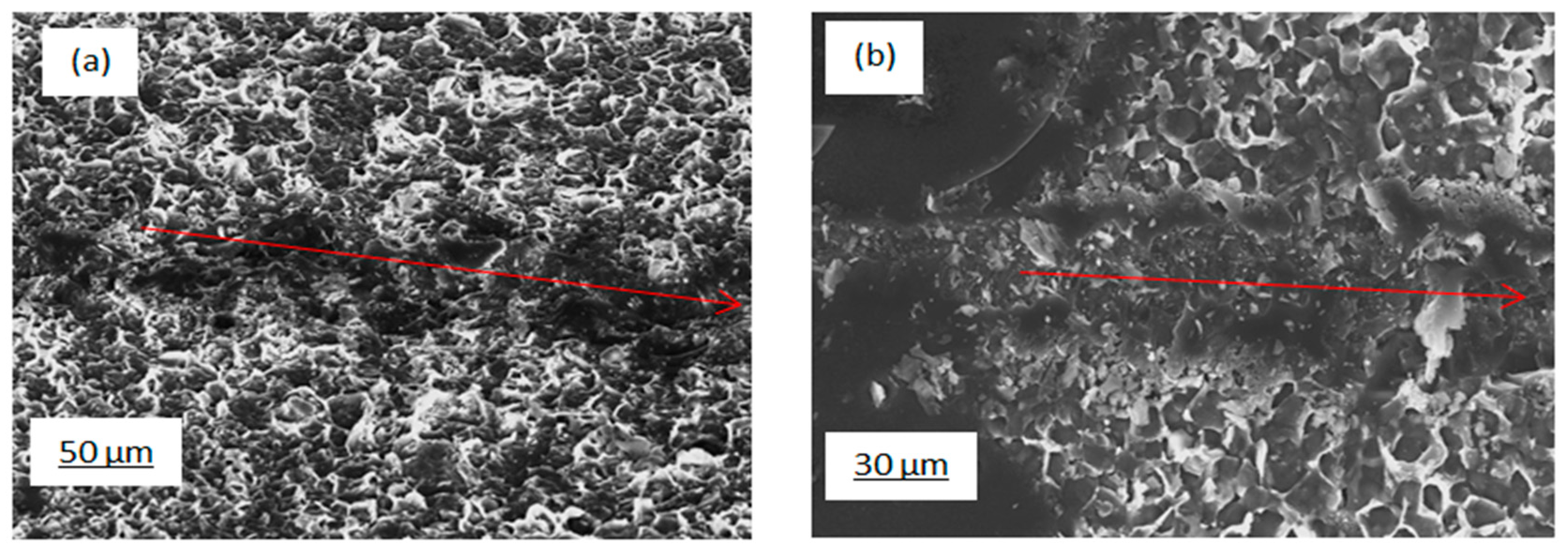

3.4. FIB-SEM Cross-Section Imaging

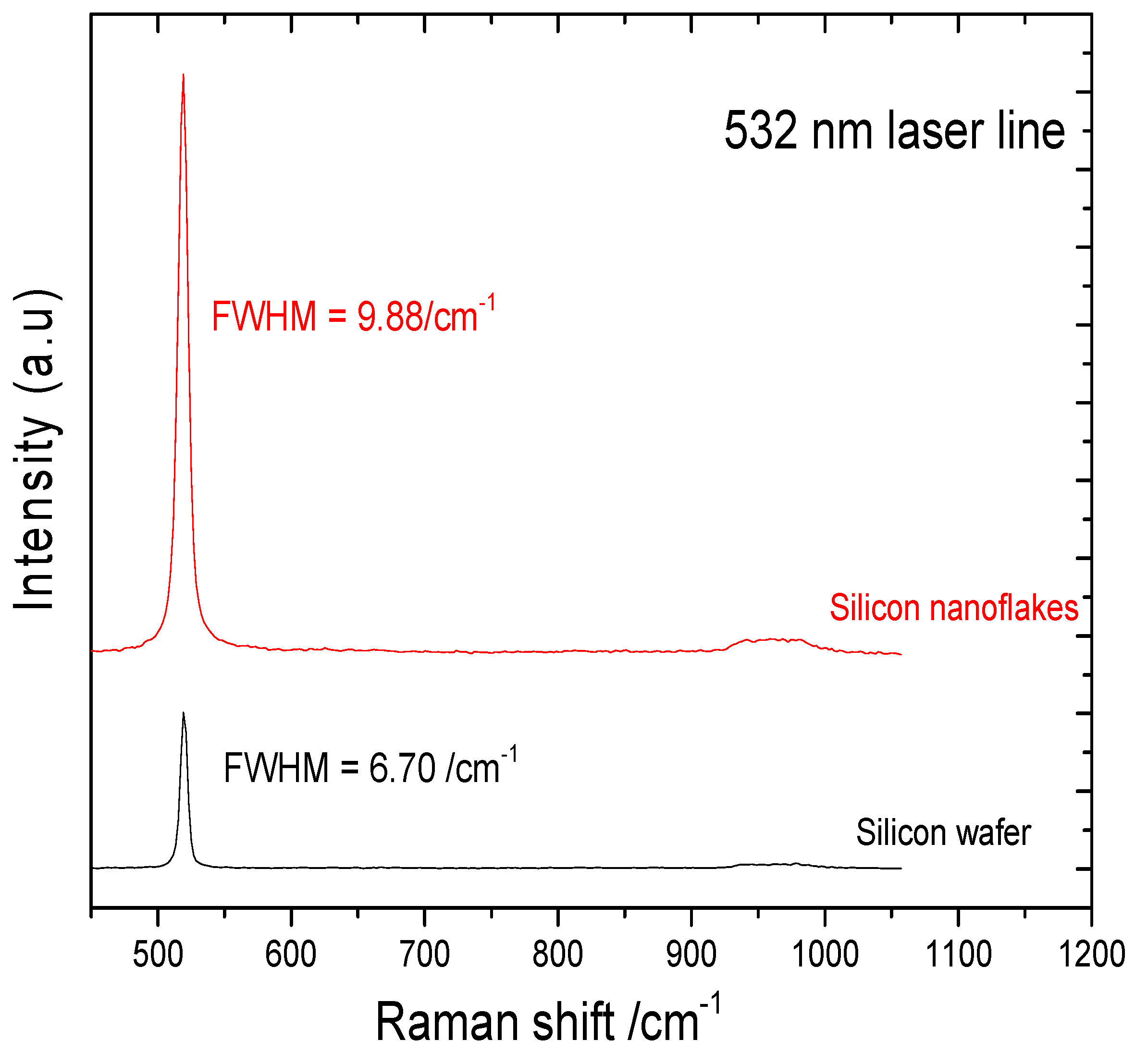

3.5. Raman Scattering of Silicon Nanoflakes

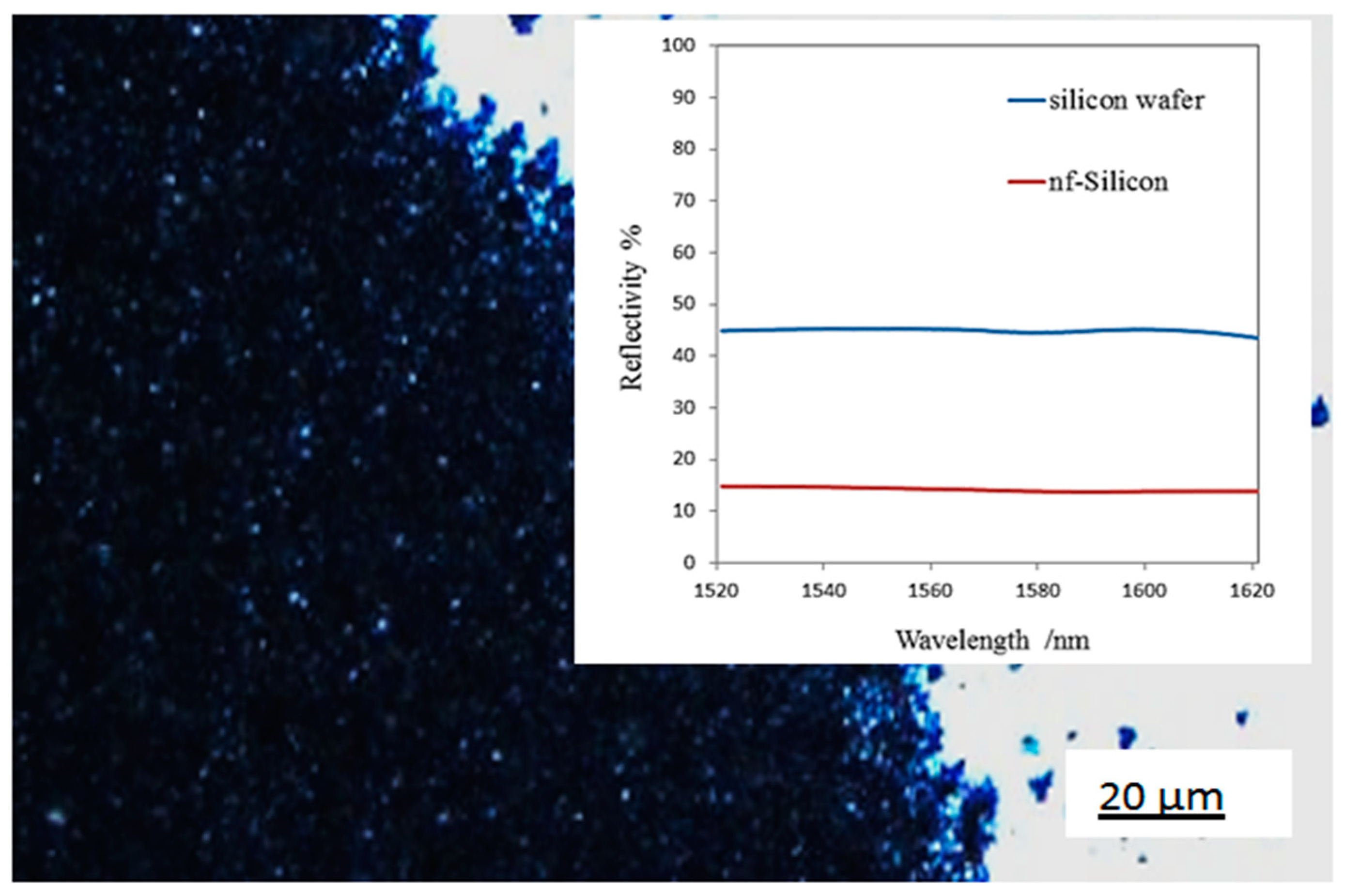

3.6. Optical Properties of Silicon Nanoflakes

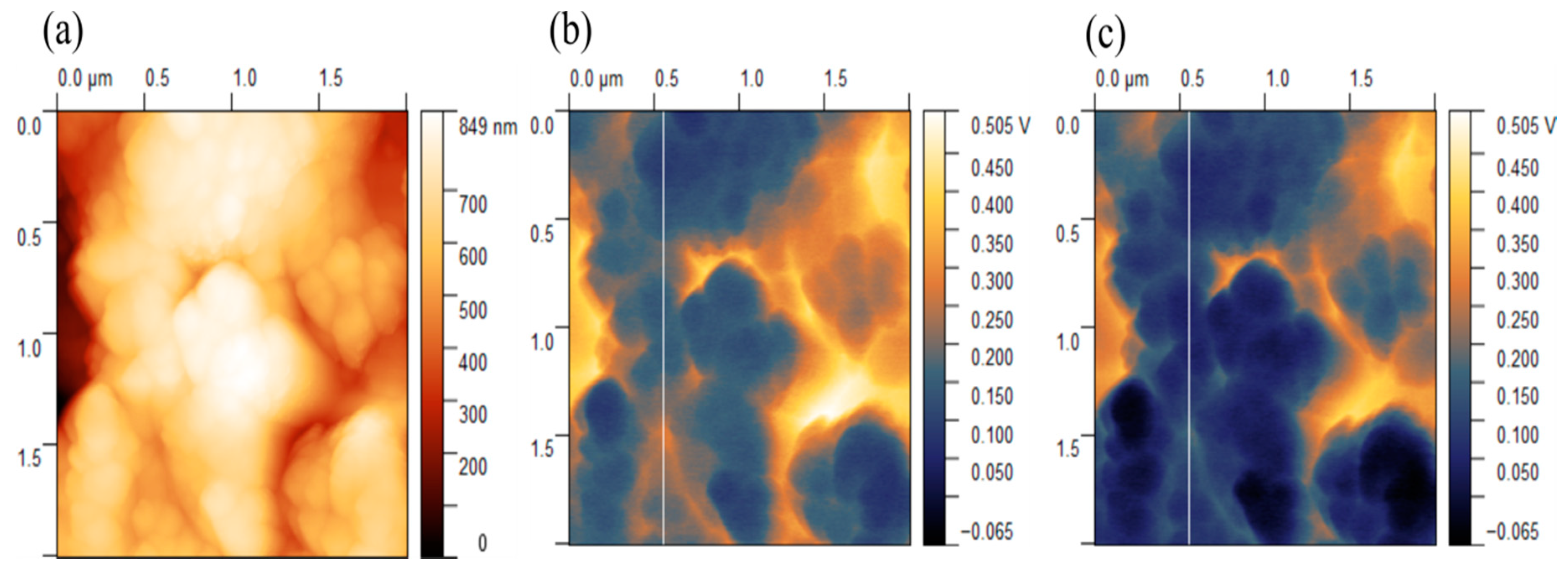

3.7. AFM Measurement

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Coxon, P.R.; Peters, M.; Hoex, B.; Cole, J.M.; Fray, D.J. Black silicon: Fabrication methods, properties and solar energy applications. Energy Environ. Sci. 2014, 7, 3223–3263. [Google Scholar] [CrossRef]

- Rong, J.; Masarapu, C.; Ni, J.; Zhang, Z.; Wei, B. Tandem structure of porous silicon film on single-walled carbon nanotube macrofilms for lithium-ion battery applications. ACS Nano 2010, 4, 4683–4690. [Google Scholar] [CrossRef] [PubMed]

- Ge, M.; Fang, X.; Rong, J.; Zhou, C. Review of porous silicon preparation and its application for lithium-ion battery anodes. Nanotechnology 2013, 24, 422001. [Google Scholar] [CrossRef] [PubMed]

- Barillaro, G.; Nannini, A.; Piotto, M. Electrochemical etching in HF solution for silicon micromachining. Sens. Actuators A Phys. 2002, 102, 195–201. [Google Scholar] [CrossRef]

- Oh, J.; Deutsch, T.G.; Yuan, H.C.; Branz, H.M. Nanoporous black silicon photocathode for H 2 production by photoelectrochemical water splitting. Energy Environ. Sci. 2011, 4, 1690–1694. [Google Scholar] [CrossRef]

- Sailor, M.J. Porous Silicon in Practice: Preparation, Characterization and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Berger, M.G.; Dieker, C.; Thonissen, M.; Vescan, L.; Luth, H.; Munder, H.; Theiss, W.; Wernke, M.; Grosse, P. Porosity superlattices: A new class of Si heterostructures. J. Phys. D Appl. Phys. 1994, 27, 1333. [Google Scholar] [CrossRef]

- Mazzoleni, C.; Pavesi, L. Application to optical components of dielectric porous silicon multilayers. Appl. Phys. Lett. 1995, 67, 2983–2985. [Google Scholar] [CrossRef]

- Berger, M.G.; Thönissen, M.; Arens-Fischer, R.; Münder, H.; Lüth, H.; Arntzen, M.; Theiβ, W. Investigation and design of optical properties of porosity superlattices. Thin Solid Films 1995, 255, 313–316. [Google Scholar] [CrossRef]

- Araki, M.; Koyama, H.; Koshida, N. Controlled electroluminescence spectra of porous silicon diodes with a vertical optical cavity. Appl. Phys. Lett. 1996, 69, 2956–2958. [Google Scholar] [CrossRef]

- Pavesi, L.; Mazzoleni, C.; Tredicucci, A.; Pellegrini, V. Controlled photon emission in porous silicon microcavities. Appl. Phys. Lett. 1995, 67, 3280–3282. [Google Scholar] [CrossRef]

- Berger, M.G.; Arens-Fischer, R.; Thönissen, M.; Krüger, M.; Billat, S.; Lüth, H.; Hilbrich, S.; Theiß, W.; Grosse, P. Dielectric filters made of PS: Advanced performance by oxidation and new layer structures. Thin Solid Films 1997, 297, 237–240. [Google Scholar] [CrossRef]

- Torres-Costa, V.; Martin-Palma, R.J. Application of nanostructured porous silicon in the field of optics. A review. J. Mater. Sci. 2010, 45, 2823–2838. [Google Scholar] [CrossRef]

- Steglich, M.; Zilk, M.; Schrempel, F.; Tünnermann, A.; Kley, E.B. Improvement of Ge-on-Si photodiodes by black silicon light trapping. Appl. Phys. Lett. 2013, 102, 111110. [Google Scholar] [CrossRef]

- Steglich, M.; Zilk, M.; Bingel, A.; Patzig, C.; Käsebier, T.; Schrempel, F.; Kley, E.-B.; Tünnermann, A. A normal-incidence PtSi photoemissive detector with black silicon light-trapping. J. Appl. Phys. 2013, 114, 183102. [Google Scholar] [CrossRef]

- Jane, A.; Dronov, R.; Hodges, A.; Voelcker, N.H. Porous silicon biosensors on the advance. Trends Biotechnol. 2009, 27, 230–239. [Google Scholar] [CrossRef] [PubMed]

- Stewart, M.P.; Buriak, J.M. Chemical and biological applications of porous silicon technology. Adv. Mater. 2000, 12, 859–869. [Google Scholar] [CrossRef]

- De Stefano, L.; Moretti, L.; Lamberti, A.; Longo, O.; Rocchia, M.; Rossi, A.M.; Arcari, P.; Rendina, I. Optical sensors for vapors, liquids, and biological molecules based on porous silicon technology. IEEE Trans. Nanotechnol. 2004, 3, 49–54. [Google Scholar] [CrossRef]

- Angelescu, A.; Kleps, I.; Mihaela, M.; Simion, M.; Neghina, T.; Petrescu, S.; Moldovan, N.; Paduraru, C.; Raducanu, A. Porous silicon matrix for applications in biology. Rev. Adv. Mater. Sci. 2003, 5, 440–449. [Google Scholar]

- Sailor, M.J.; Lee, E.J. Surface chemistry of luminescent silicon nanocrystallites. Adv. Mater. 1997, 9, 783–793. [Google Scholar] [CrossRef]

- Tilli, M.; Paulasto-Krockel, M.; Motooka, T.; Lindroos, V. (Eds.) Handbook of Silicon Based MEMS Materials and Technologies; William Andrew: Norwich, NY, USA, 2015. [Google Scholar]

- Otto, M.; Algasinger, M.; Branz, H.; Gesemann, B.; Gimpel, T.; Füchsel, K.; Käsebier, T.; Kontermann, S.; Koynov, S.; Naumann, V.; et al. Black silicon photovoltaics. Adv. Opt. Mater. 2015, 3, 147–164. [Google Scholar] [CrossRef]

- Lv, J.; Zhang, T.; Zhang, P.; Zhao, Y.; Li, S. Review application of nanostructured black silicon. Nanoscale Res. Lett. 2018, 13, 110. [Google Scholar] [CrossRef] [PubMed]

- Zong, P.A.; Makino, D.; Pan, W.; Yin, S.; Sun, C.; Zhang, P.; Wan, C.; Koumoto, K. Converting natural diatomite into nanoporous silicon for eco-friendly thermoelectric energy conversion. Mater. Des. 2018, 154, 246–253. [Google Scholar] [CrossRef]

- Lai, Y.; Thompson, J.R.; Dasog, M. Metallothermic Reduction of Silica Nanoparticles to Porous Silicon for Drug Delivery Using New and Existing Reductants. Chem. A Eur. J. 2018, 24, 7913–7920. [Google Scholar] [CrossRef] [PubMed]

- Entwistle, J.; Rennie, A.; Patwardhan, S. A review of magnesiothermic reduction of silica to porous silicon for lithium-ion battery applications and beyond. J. Mater. Chem. A 2018, 6, 18344–18356. [Google Scholar] [CrossRef]

- Bao, Z.; Weatherspoon, M.R.; Shian, S.; Cai, Y.; Graham, P.D.; Allan, S.M.; Ahmad, G.; Dickerson, M.B.; Church, B.C.; Kang, Z.; et al. Chemical reduction of three-dimensional silica micro-assemblies into microporous silicon replicas. Nature 2007, 446, 172–175. [Google Scholar] [CrossRef]

- Luo, W.; Wang, X.; Meyers, C.; Wannenmacher, N.; Sirisaksoontorn, W.; Lerner, M.M.; Ji, X. Efficient fabrication of nanoporous Si and Si/Ge enabled by a heat scavenger in magnesiothermic reactions. Sci. Rep. 2013, 3, 2222. [Google Scholar] [CrossRef]

- Calvert, R. Diatomaceous earth. J. Chem. Educ. 1930, 7, 2829. [Google Scholar] [CrossRef]

- Canham, L. (Ed.) Handbook of Porous Silicon; Springer International Publishing: Berlin, Germany, 2014; pp. 163–170. [Google Scholar]

- Inglethorpe, S.D.J. Industrial Minerals Laboratory Manual: Diatomite; Technical report WG/92/39; Mineralogy and Petrology Series; British Geological Survey: Nottingham, United Kingdom, 1993. [Google Scholar]

- Zheng, R.; Ren, Z.; Gao, H.; Zhang, A.; Bian, Z. Effects of calcination on silica phase transition in diatomite. J. Alloys Compd. 2018, 757, 364–371. [Google Scholar] [CrossRef]

- Chen, W.; Fan, Z.; Dhanabalan, A.; Chen, C.; Wang, C. Mesoporous silicon anodes prepared by magnesiothermic reduction for lithium ion batteries. J. Electrochem. Soc. 2011, 158, A1055–A1059. [Google Scholar] [CrossRef]

- Larbi, K.K.; Barati, M.; McLean, A. Reduction behaviour of rice husk ash for preparation of high purity silicon. Can. Metall. Q. 2011, 50, 341–349. [Google Scholar] [CrossRef]

- Casiraghi, C.; Ferrari, A.C.; Robertson, J. Raman spectroscopy of hydrogenated amorphous carbons. Phys. Rev. B 2005, 72, 085401. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Yap, C.C.R.; Tay, B.K.; Edwin, T.H.T.; Olivier, A.; Baillargeat, D. From bulk to monolayer MoS2: Evolution of Raman scattering. Adv. Funct. Mater. 2012, 22, 1385–1390. [Google Scholar] [CrossRef]

- Zuo, Z.; Zhang, S.; Wang, Y.; Guo, Y.; Sun, L.; Li, K.; Cui, G. Effective plasmon coupling in conical cavities for sensitive surface enhanced Raman scattering with quantitative analysis ability. Nanoscale 2019, 11, 17913–17919. [Google Scholar] [CrossRef] [PubMed]

- Stephens, R.B.; Cody, G.D. Optical reflectance and transmission of a textured surface. Thin Solid Films 1977, 45, 19–29. [Google Scholar] [CrossRef]

- Korsunsky, A.M.; Sapozhnikov, P.V.; Everaerts, J.; Salimon, A.I. Nature’s neat nanostructuration: The fascinating frustules of diatom algae. Mater. Today 2019, 22, 159–160. [Google Scholar] [CrossRef]

- Uchinokura, K.; Sekine, T.; Matsuura, E. Raman scattering by silicon. Solid State Commun. 1972, 11, 47–49. [Google Scholar] [CrossRef]

- Ikusika, O.O.; Zindove, T.J.; Okoh, A.I. Fossil Shell Flour in Livestock Production: A Review. Animals 2019, 9, 70. [Google Scholar] [CrossRef]

| Component. | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | Na2O |

|---|---|---|---|---|---|---|

| Quantity (wt%) | 86% | 5.5% | 2.5% | 0.78% | 1.39% | 0.22% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aggrey, P.; Abdusatorov, B.; Kan, Y.; Salimon, I.A.; Lipovskikh, S.A.; Luchkin, S.; Zhigunov, D.M.; Salimon, A.I.; Korsunsky, A.M. In Situ Formation of Nanoporous Silicon on a Silicon Wafer via the Magnesiothermic Reduction Reaction (MRR) of Diatomaceous Earth. Nanomaterials 2020, 10, 601. https://doi.org/10.3390/nano10040601

Aggrey P, Abdusatorov B, Kan Y, Salimon IA, Lipovskikh SA, Luchkin S, Zhigunov DM, Salimon AI, Korsunsky AM. In Situ Formation of Nanoporous Silicon on a Silicon Wafer via the Magnesiothermic Reduction Reaction (MRR) of Diatomaceous Earth. Nanomaterials. 2020; 10(4):601. https://doi.org/10.3390/nano10040601

Chicago/Turabian StyleAggrey, Patrick, Bakhodur Abdusatorov, Yuliya Kan, Igor A. Salimon, Svetlana A. Lipovskikh, Sergey Luchkin, Denis M. Zhigunov, Alexey I. Salimon, and Alexander M. Korsunsky. 2020. "In Situ Formation of Nanoporous Silicon on a Silicon Wafer via the Magnesiothermic Reduction Reaction (MRR) of Diatomaceous Earth" Nanomaterials 10, no. 4: 601. https://doi.org/10.3390/nano10040601

APA StyleAggrey, P., Abdusatorov, B., Kan, Y., Salimon, I. A., Lipovskikh, S. A., Luchkin, S., Zhigunov, D. M., Salimon, A. I., & Korsunsky, A. M. (2020). In Situ Formation of Nanoporous Silicon on a Silicon Wafer via the Magnesiothermic Reduction Reaction (MRR) of Diatomaceous Earth. Nanomaterials, 10(4), 601. https://doi.org/10.3390/nano10040601