Rheological Properties of Graphene Modified Asphalt Binders

Abstract

1. Introduction

2. Materials and Methods

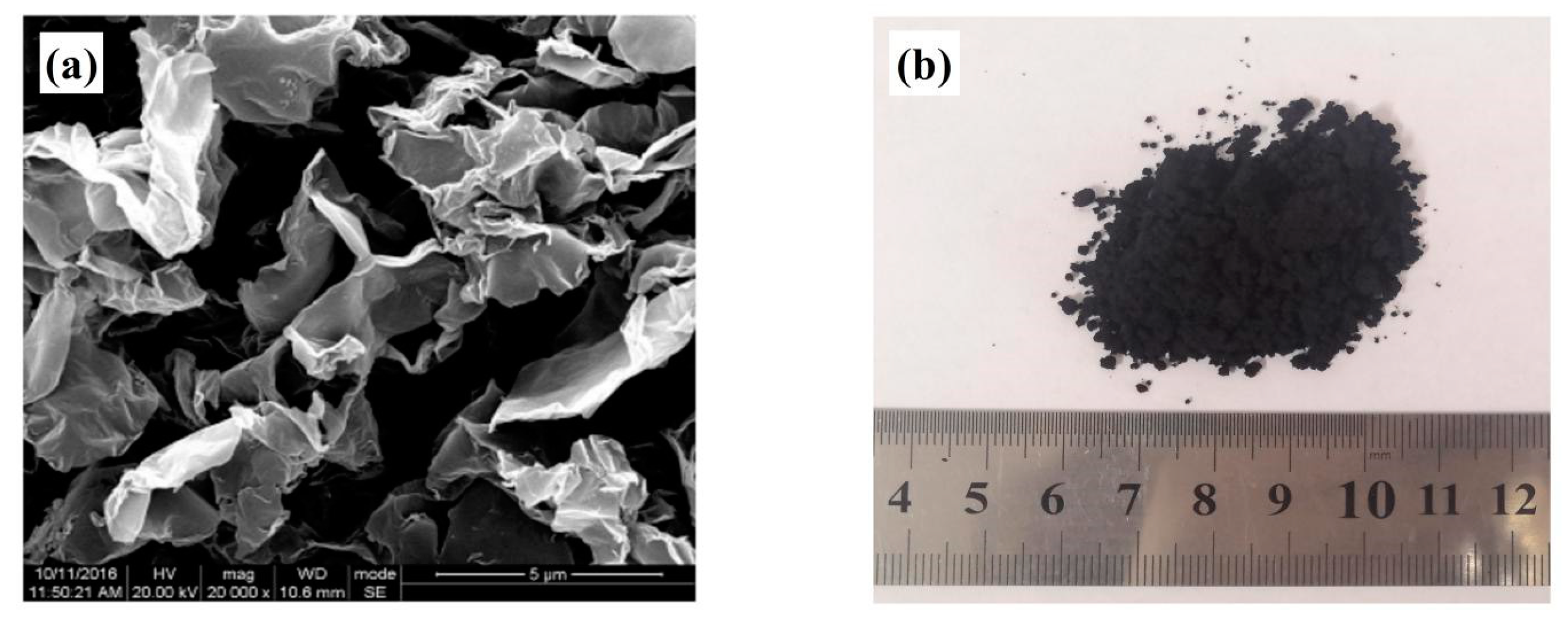

2.1. Materials

2.2. Preparation of GMAs

2.3. Test Methods

2.3.1. Strain Sweeps

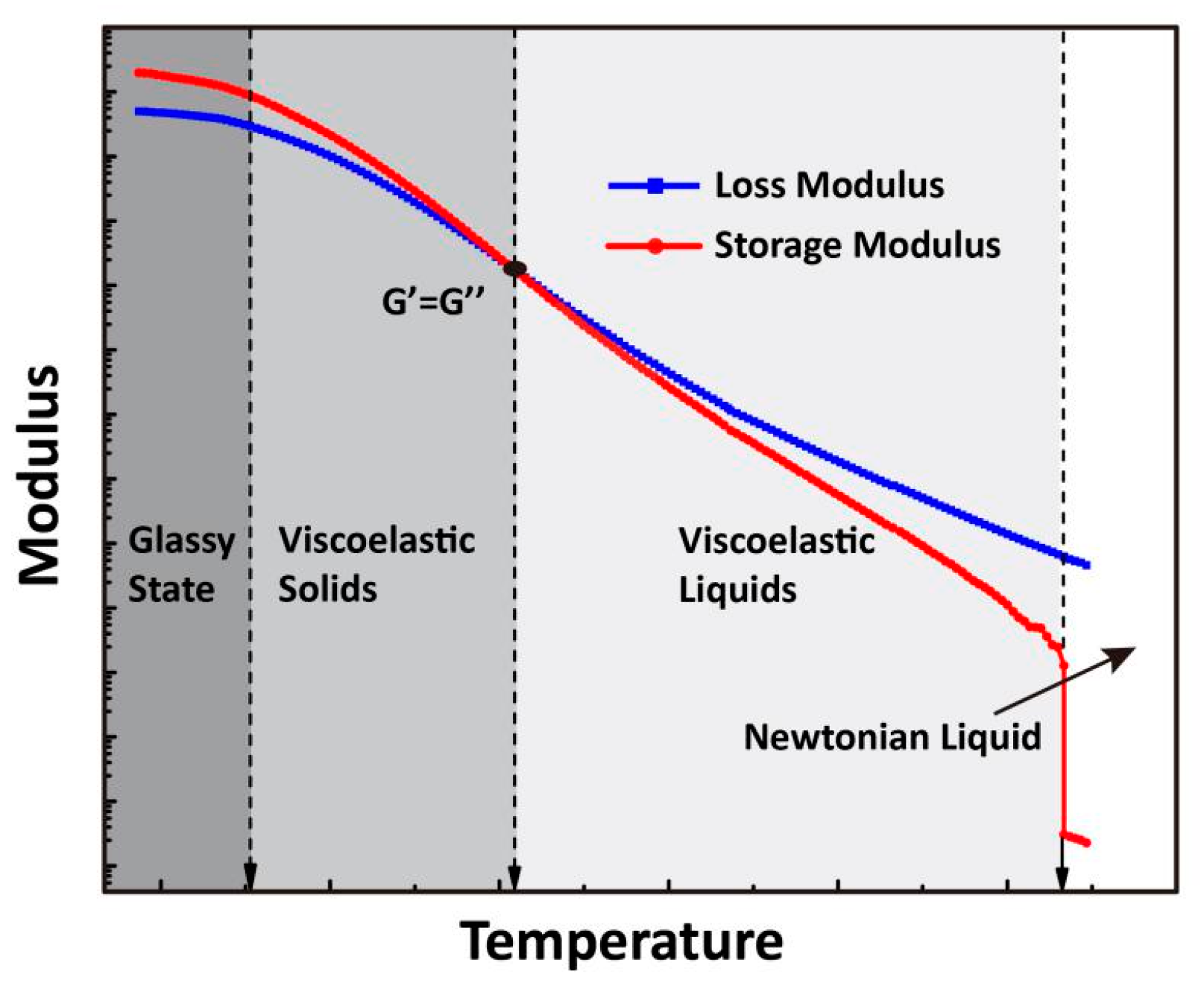

2.3.2. Temperature Sweeps

2.3.3. Rotational Viscosity Tests

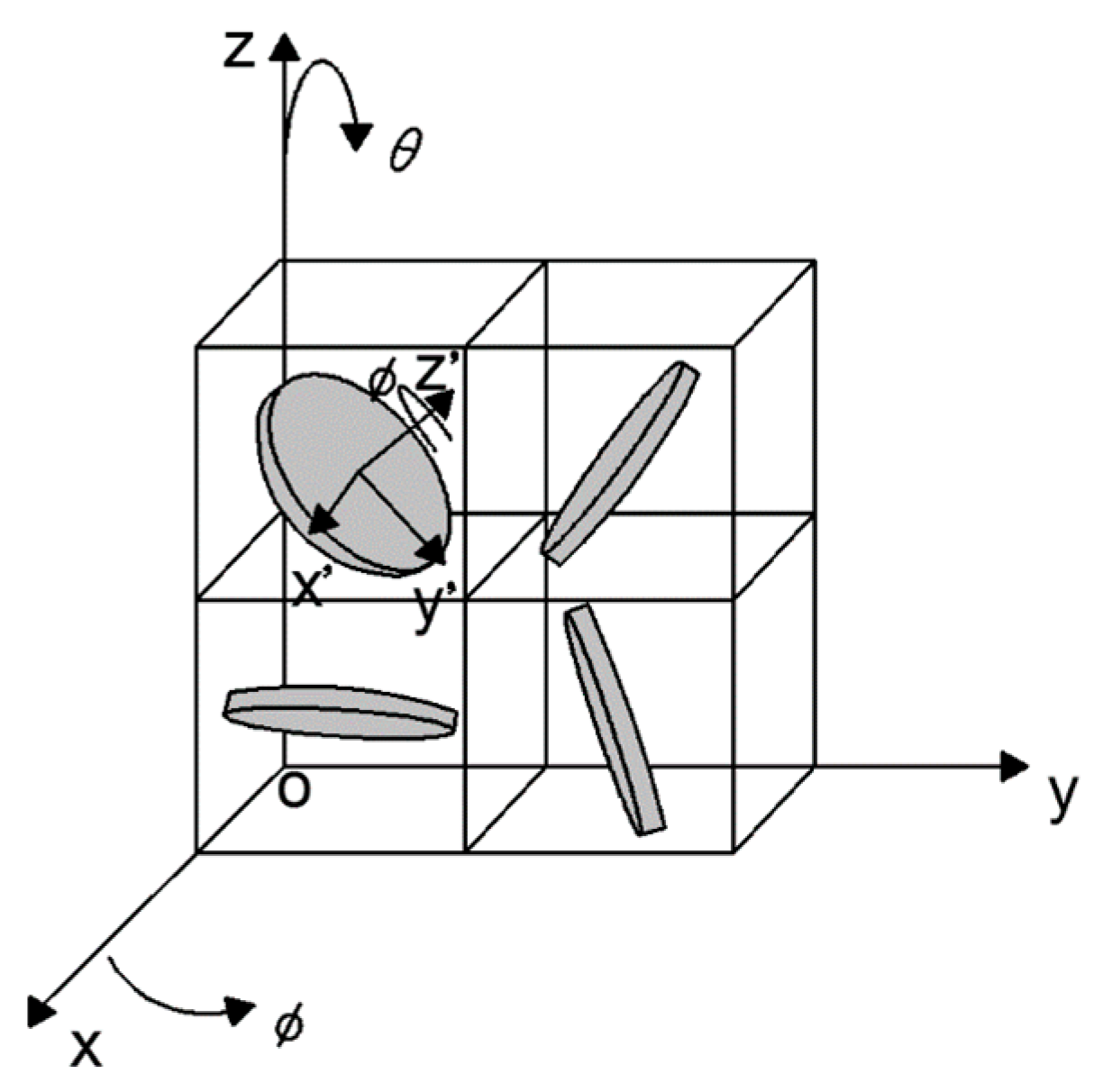

2.4. Percolation Model

2.5. Arrhenius Equation

3. Results and Discussion

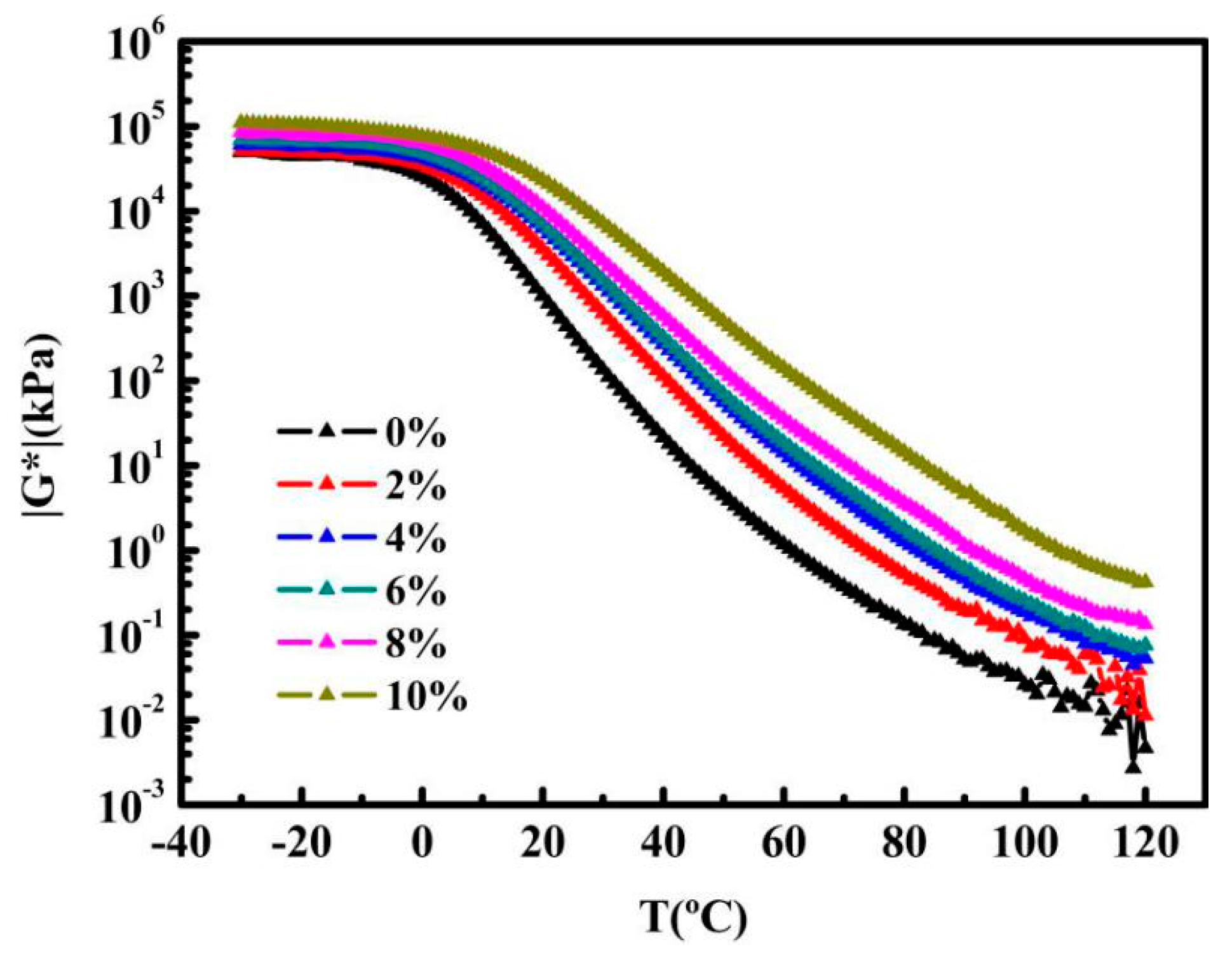

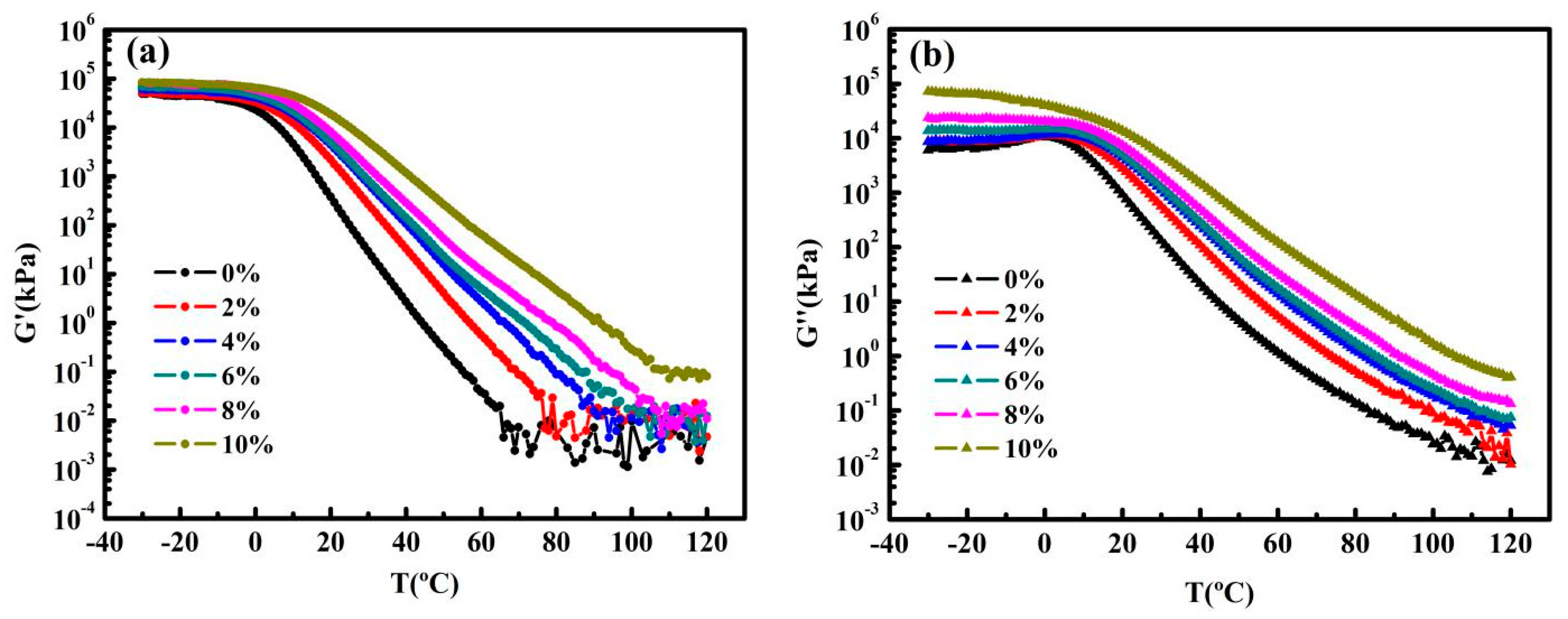

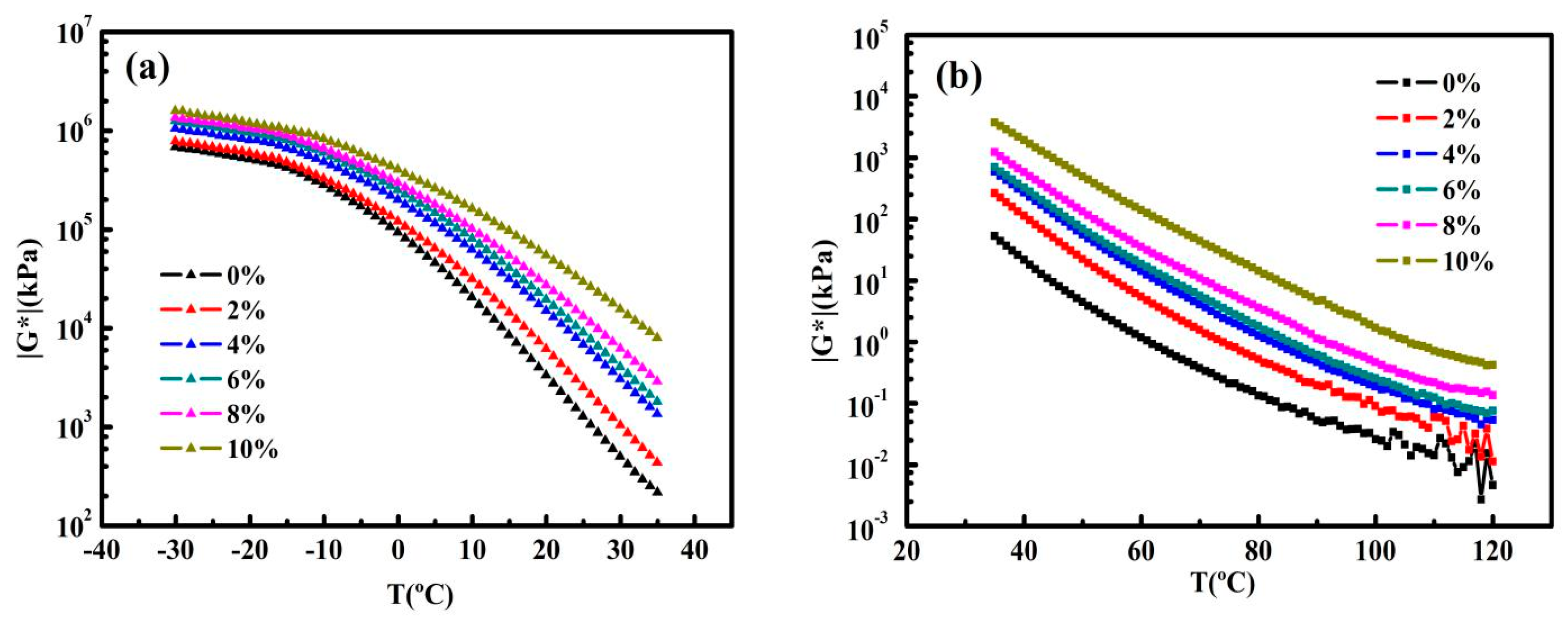

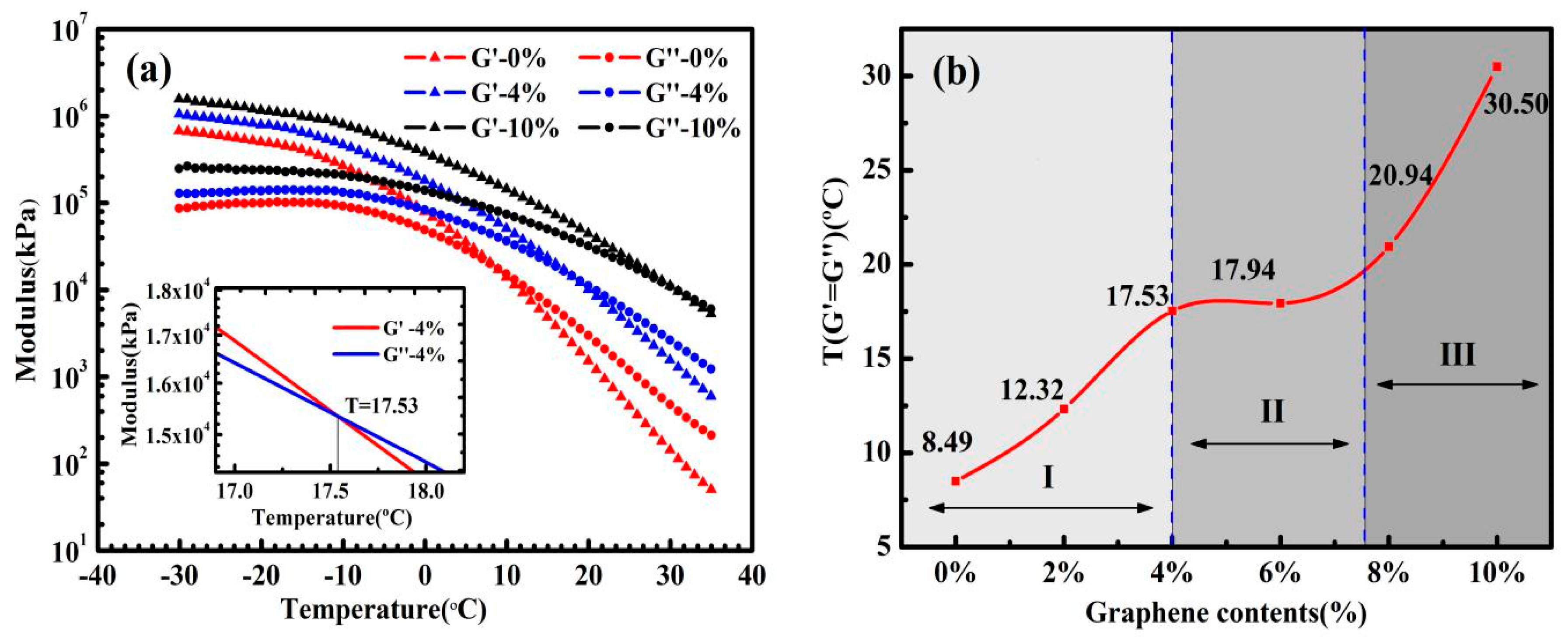

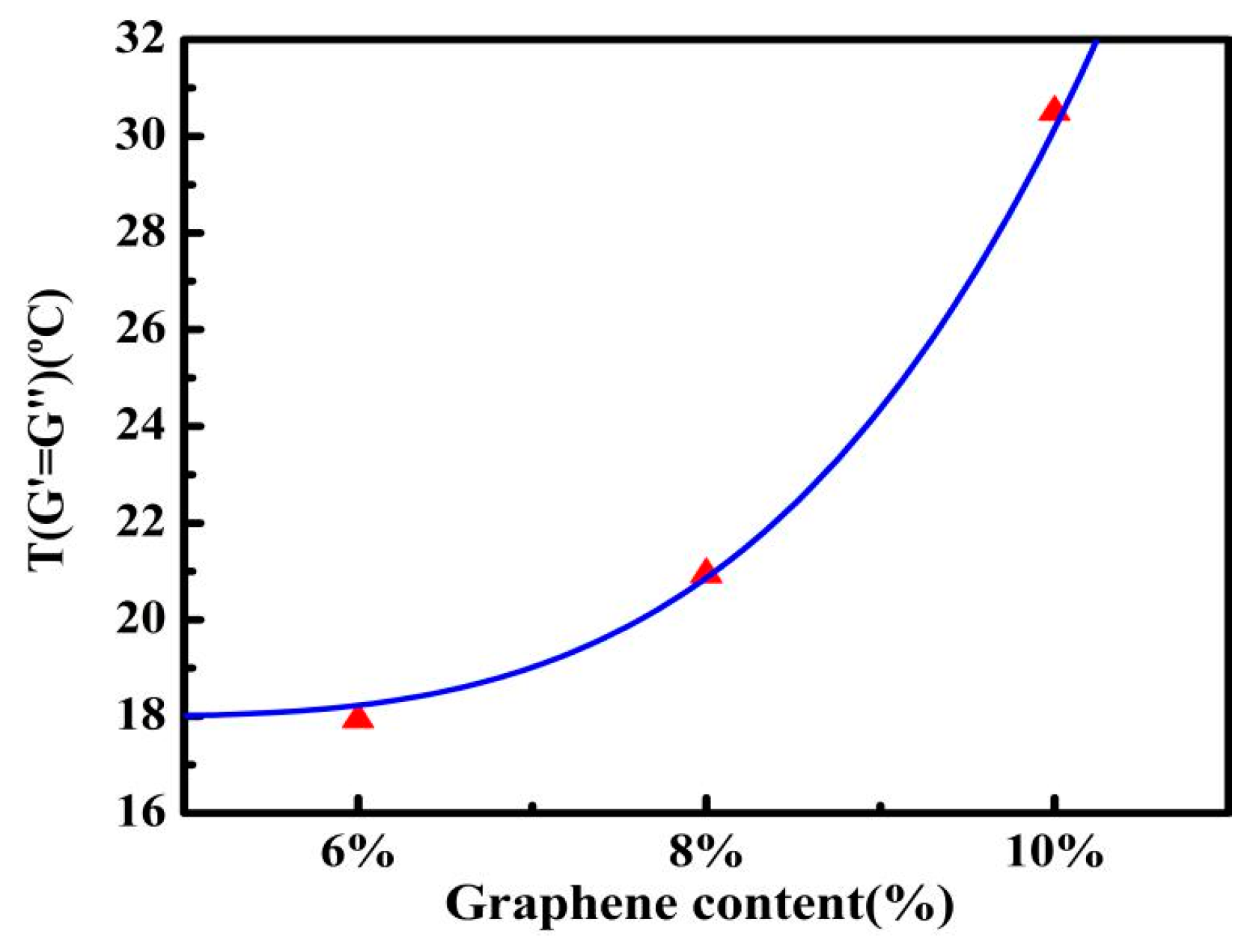

3.1. Rheological Analysis

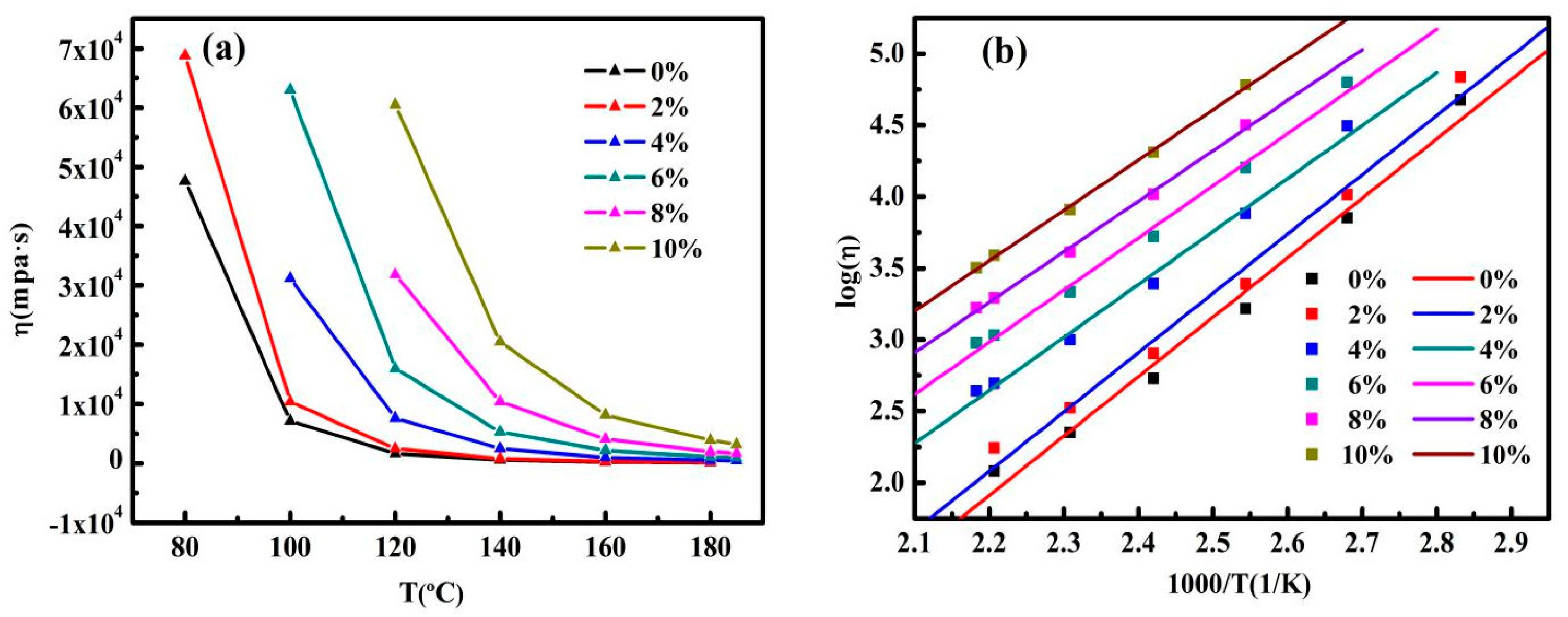

3.2. Rotational Viscosity Tests

4. Conclusions

- (1)

- At graphene content above 8%, the |G*| of GMAs at above 100 °C remains stable, which differs from those of graphene content below 8%. This implies that the percolation of GMAs occurs and graphene networks form at graphene content above 8%, which means that it is possible to make conductive asphalt concrete when the graphene content is higher than 8%;

- (2)

- The GMAs’ modification mechanisms are different before and after the percolation point, i.e., before the percolation threshold, graphene, which has a molecular structure similar to asphaltene, enhances asphalt to some extent, like increasing asphaltene, and after the percolation threshold, graphene improves asphalt because of the formed graphene networks;

- (3)

- In the temperature section of −30–120 °C, in comparison to control asphalt, as the graphene content increases, the moduli of GMAs rises gradually, and the phase angle and damping factor decrease. This illustrates that graphene boosts the elasticity and the high-temperature rutting resistance of asphalt;

- (4)

- The differences of moduli at higher temperatures between the GMAs and the control asphalt are greater than those at lower temperatures, predicting that the modification effect of graphene at higher temperatures is superior than those at lower temperatures, which is because the temperature susceptibility of graphene is much lower than that of control asphalt, and the rigid molecular structure of graphene frames GMAs at higher temperatures;

- (5)

- The temperature at δ reaching 90° rises gradually as a result of the increase in graphene content, indicating that the temperature of asphalt from viscoelastic fluid to Newtonian fluid is on the increase. When GMAs’ contents are 8% and 10%, they do not even reach 90° in the experimental temperature range. From this perspective, graphene enhances the strength and the high-temperature rutting resistance. This is also evidence that there is a percolation threshold at graphene content above 8%;

- (6)

- In terms of viscosity properties, it has been shown that adding graphene promotes the viscosity of all asphalt. The higher the content of graphene is, the bigger the viscosity is. The higher the temperature is, the closer the viscosity of different graphene content of GMAs is. Obviously, graphene improves the mixing temperature and compaction temperature of asphalts, which should be improved in the future to facilitate the pavement construction.

Author Contributions

Funding

Conflicts of Interest

References

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.W.; Jin, Z.; Katsukis, G.; Drahushuk, L.W.; Shimizu, S.; Shih, C.-J.; Wetzel, E.D.; Taggart-Scarff, J.K.; Qing, B.; Van Vliet, K.J.; et al. Layered and scrolled nanocomposites with aligned semi-infinite graphene inclusions at the platelet limit. Science 2016, 353, 364–367. [Google Scholar] [CrossRef]

- Gouzman, I.; Grossman, E.; Verker, R.; Atar, N.; Bolker, A.; Eliaz, N. Advances in polyimide-based materials for space applications. Adv. Mater. 2019, 31, 1807738. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Li, Z.C.; Wang, C.H.; Signetti, S.; Cunning, B.V.; Wu, X.Z.; Huang, Y.; Jiang, Y.; Shi, H.F.; Ryu, S.; et al. Folding large graphene-on-polymer films yields laminated composites with enhanced mechanical performance. Adv. Mater. 2018, 30, 1707449. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.H.; Xu, C.; Ma, C.Q.; Liu, Z.B.; Cheng, H.M.; Ren, W.C. Synergistic effect of aligned graphene nanosheets in graphene foam for high-performance thermally conductive composites. Adv. Mater. 2019, 31, 1900199. [Google Scholar] [CrossRef] [PubMed]

- Prasad, K.E.; Das, B.; Maitra, U.; Ramamurty, U.; Rao, C.N.R. Extraordinary synergy in the mechanical properties of polymer matrix composites reinforced with 2 nanocarbons. Proc. Natl. Acad. Sci. USA 2009, 106, 13186–13189. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.J.; Liu, Y.M.; Shi, T.; Gu, Y.; Zheng, B.M.; Zhang, K.; Xu, J.H.; Fu, Y.Y.; Shi, S.C. Study of mechanical properties and early-stage deformation properties of graphene-modified cement-based materials. Constr. Build. Mater. 2020, 257, 119498. [Google Scholar] [CrossRef]

- Li, L.W.; Zheng, Q.F.; Dong, S.F.; Wang, X.Y.; Han, B.G. The reinforcing effects and mechanisms of multi-layer graphenes on mechanical properties of reactive powder concrete. Constr. Build. Mater. 2020, 251, 118995. [Google Scholar] [CrossRef]

- Nobile, M.R.; Raimondo, M.; Naddeo, C.; Guadagno, L. Rheological and Morphological Properties of Non-Covalently Functionalized Graphene-Based Structural Epoxy Resins with Intrinsic Electrical Conductivity and Thermal Stability. Nanomaterials 2020, 10, 1310. [Google Scholar] [CrossRef]

- Sun, Z.F.; Zhao, J.; Wang, X.C.; Cui, E.Z.; Yu, H. Reinforcing Mechanisms of Graphene and Nano-TiC in Al2O3-Based Ceramic-Tool Materials. Nanomaterials 2020, 10, 1815. [Google Scholar] [CrossRef]

- Lee, M.G.; Lee, S.; Cho, J.; Bae, S.; Jho, J.Y. Effect of the Fluorination of Graphene Nanoflake on the Dispersion and Mechanical Properties of Polypropylene Nanocomposites. Nanomaterials 2020, 10, 1171. [Google Scholar] [CrossRef]

- Young, R.J.; Kinloch, I.A.; Gong, L.; Novoselov, K.S. The mechanics of graphene nanocomposites: A review. Compos. Sci. Technol. 2012, 72, 1459–1476. [Google Scholar] [CrossRef]

- Tohidi, S.; Parhizkar, M.; Bidadi, H.; Mohamad-Rezaei, R. High-performance chemiresistor-type NH3 gas sensor based on three-dimensional reduced graphene oxide/polyaniline hybrid. Nanotechnology 2020, 31, 415501. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; He, J.X.; Huang, G.; Zhou, C.; Feng, M.M.; Li, Y. Preparation and characteristics of ethylene Bis(Stearamide)-based graphene-modified asphalt. Materials 2019, 12, 757. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Gámiz, F.; Rubio-Gámez, M.C. Mechanical and thermal properties of graphene modified asphalt binders. Constr. Build. Mater. 2018, 180, 265–274. [Google Scholar] [CrossRef]

- Wu, S.H.; Tahri, O. State-of-art carbon and graphene family nanomaterials for asphalt modification. Road Mater. Pavement Des. 2019, 1–22. [Google Scholar] [CrossRef]

- Yang, Q.L.; Liu, Q.; Zhong, J.; Hong, B.; Wang, D.W.; Oeser, M. Rheological and micro-structural characterization of bitumen modified with carbon nanomaterials. Constr. Build. Mater. 2019, 201, 580–589. [Google Scholar] [CrossRef]

- Nazki, M.A.; Chopra, T.; Chandrappa, A.K. Rheological properties and thermal conductivity of bitumen binders modified with graphene. Constr. Build. Mater. 2020, 238, 117693. [Google Scholar] [CrossRef]

- Hafeez, M.; Ahmad, N.; Kamal, M.A.; Rafi, J.; Ul Haq, M.F.; Jamal; Zaidi, S.B.A.; Nasir, M.A. Experimental investigation into the structural and functional performance of graphene nano-platelet (GNP)-doped asphalt. Appl. Sci. 2019, 9, 686. [Google Scholar] [CrossRef]

- Le, J.L.; Marasteanu, M.; Turos, M. Graphene Nanoplatelet (GNP) Reinforced Asphalt Mixtures: A Novel Multifunctional Pavement Material (Final Report for NCHRP IDEA Project 173); Univ. Minn. Project Number: 20-30/IDEA 173; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2016. [Google Scholar]

- Luong, D.X.; Bets, K.V.; Algozeeb, W.A.; Stanford, M.G.; Kittrell, C.; Chen, W.; Salvatierra, R.V.; Ren, M.Q.; McHugh, E.A.; Advincula, P.A.; et al. Gram-scale bottom-up flash graphene synthesis. Nature 2020, 577, 647–651. [Google Scholar] [CrossRef]

- Service, R.F. Electricity turns garbage into high-quality graphene. Science 2020, 367, 496. [Google Scholar] [CrossRef]

- Kang, Y.; Zhou, D.H.; Wu, Q.; Liang, R.; Shangguan, S.X.; Liao, Z.W.; Wei, N. Molecular dynamics study on the glass forming process of asphalt. Constr. Build. Mater. 2019, 214, 430–440. [Google Scholar] [CrossRef]

- Sun, L.; Xin, X.T.; Ren, J.L. Asphalt modification using nano-materials and polymers composite considering high and low temperature performance. Constr. Build. Mater. 2017, 133, 358–366. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, C.; Liang, R.; Liu, Y.C.; Cheng, J.X.; Kang, Y. Fractional linear viscoelastic constitutive relations of anhydride-cured thermosetting rubber-like epoxy asphalt binders. Constr. Build. Mater. 2018, 170, 582–590. [Google Scholar] [CrossRef]

- Li, J.; Kim, J.-K. Percolation threshold of conducting polymer composites containing 3D randomly distributed graphite nanoplatelets. Compos. Sci. Technol. 2007, 67, 2114–2120. [Google Scholar] [CrossRef]

- Lux, F. Models proposed to explain the electrical conductivity of mixtures made of conductive and insulating materials. J. Mater. Sci. 1993, 28, 285–301. [Google Scholar] [CrossRef]

- Li, P.L.; Jiang, X.M.; Ding, Z.; Zhao, J.K.; Shen, M.H. Analysis of viscosity and composition properties for crumb rubber modified asphalt. Constr. Build. Mater. 2018, 169, 638–647. [Google Scholar] [CrossRef]

- Airey, G.D.; Rahimzadeh, B. Combined bituminous binder and mixture linear rheological properties. Constr. Build. Mater. 2004, 18, 535–548. [Google Scholar] [CrossRef]

- Zapién-Castillo, S.; Rivera-Armenta, J.L.; Chávez-Cinco, M.Y.; Salazar-Cruz, B.A.; Mendoza-Martínez, A.M. Physical and rheological properties of asphalt modified with SEBS/montmorillonite nanocomposite. Constr. Build. Mater. 2016, 106, 349–356. [Google Scholar] [CrossRef]

- Ouyang, C.F.; Wang, S.F.; Zhang, Y.; Zhang, Y.X. Thermo-rheological properties and storage stability of SEBS/kaolinite clay compound modified asphalts. Eur. Polym. J. 2006, 42, 446–457. [Google Scholar] [CrossRef]

- Kim, H.H.; Lee, S.J. Effect of crumb rubber on viscosity of rubberized asphalt binders containing wax additives. Constr. Build. Mater. 2015, 95, 65–73. [Google Scholar] [CrossRef]

- Liu, K.F.; Zhang, K.; Wu, J.L.; Muhunthan, B.; Shi, X.M. Evaluation of mechanical performance and modification mechanism of asphalt modified with graphene oxide and warm mix additives. J. Clean. Prod. 2018, 193, 87–96. [Google Scholar] [CrossRef]

- Liu, K.F.; Zhang, K.; Shi, X.M. Performance evaluation and modification mechanism analysis of asphalt binders modified by graphene oxide. Constr. Build. Mater. 2018, 163, 880–889. [Google Scholar] [CrossRef]

- Alatas, T.; Yilmaz, M. Effects of different polymers on mechanical properties of bituminous binders and hot mixtures. Constr. Build. Mater. 2013, 42, 161–167. [Google Scholar] [CrossRef]

- Wang, H.P.; Liu, X.Y.; Apostolidis, P.; Scarpas, T. Rheological behavior and its chemical interpretation of crumb rubber modified asphalt containing warm-mix additives. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 337–348. [Google Scholar] [CrossRef]

| Purity | Layers | Specific Surface Area | Scale | Electrical Conductivity |

|---|---|---|---|---|

| >97 wt % | <10 | 80–120 m2/g | <6 μm | >1000 S/m |

| Properties of Asphalt | Method | |

|---|---|---|

| Density@15 °C/g cm−3 | 1.034 | JTG E20-2011 T0603-2011 |

| Penetration@25 °C/0.1 mm | 68.0 | JTG E20-2011 T0604-2011 |

| Softening point (°C) | 48.5 | JTG E20-2011 T0606-2011 |

| Viscosity@60 °C/Pa s | 218.2 | JTG E20-2011 T0625-2011 |

| Ductility@15 °C/cm | >150 | JTG E20-2011 T0624-2011 |

| Flash point (°C) | 328 | JTG E20-2011 T0611-2011 |

| Fraass breaking point (°C) | −17.5 | JTG E20-2011 T0613-1993 |

| Graphene Contents (%) | A | Ea (kJ·mol−1) | R2 |

|---|---|---|---|

| 0% | 5.75 × 10−8 | 80.43 | 0.982 |

| 2% | 8.91 × 10−8 | 80.24 | 0.984 |

| 4% | 3.16 × 10−6 | 71.54 | 0.991 |

| 6% | 9.12 × 10−6 | 70.57 | 0.993 |

| 8% | 3.09 × 10−5 | 68.25 | 0.997 |

| 10% | 6.46 × 10−5 | 68.06 | 0.998 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Zhou, D.; Kang, Y. Rheological Properties of Graphene Modified Asphalt Binders. Nanomaterials 2020, 10, 2197. https://doi.org/10.3390/nano10112197

Yang L, Zhou D, Kang Y. Rheological Properties of Graphene Modified Asphalt Binders. Nanomaterials. 2020; 10(11):2197. https://doi.org/10.3390/nano10112197

Chicago/Turabian StyleYang, Lu, Dunhong Zhou, and Yang Kang. 2020. "Rheological Properties of Graphene Modified Asphalt Binders" Nanomaterials 10, no. 11: 2197. https://doi.org/10.3390/nano10112197

APA StyleYang, L., Zhou, D., & Kang, Y. (2020). Rheological Properties of Graphene Modified Asphalt Binders. Nanomaterials, 10(11), 2197. https://doi.org/10.3390/nano10112197