Consideration of Spatially Infinite Loads in the Problem for a Layer with a Cylindrical Cavity and Continuous Supports

Abstract

1. Introduction

- to develop a methodology for calculating the stress-strain state of a layer with a cylindrical cavity located on two continuous supports perpendicular to the cavity and given constant stress functions on the layer surfaces;

- analysis of the stress state of a concrete slab in places of stress concentration.

2. Materials and Methods

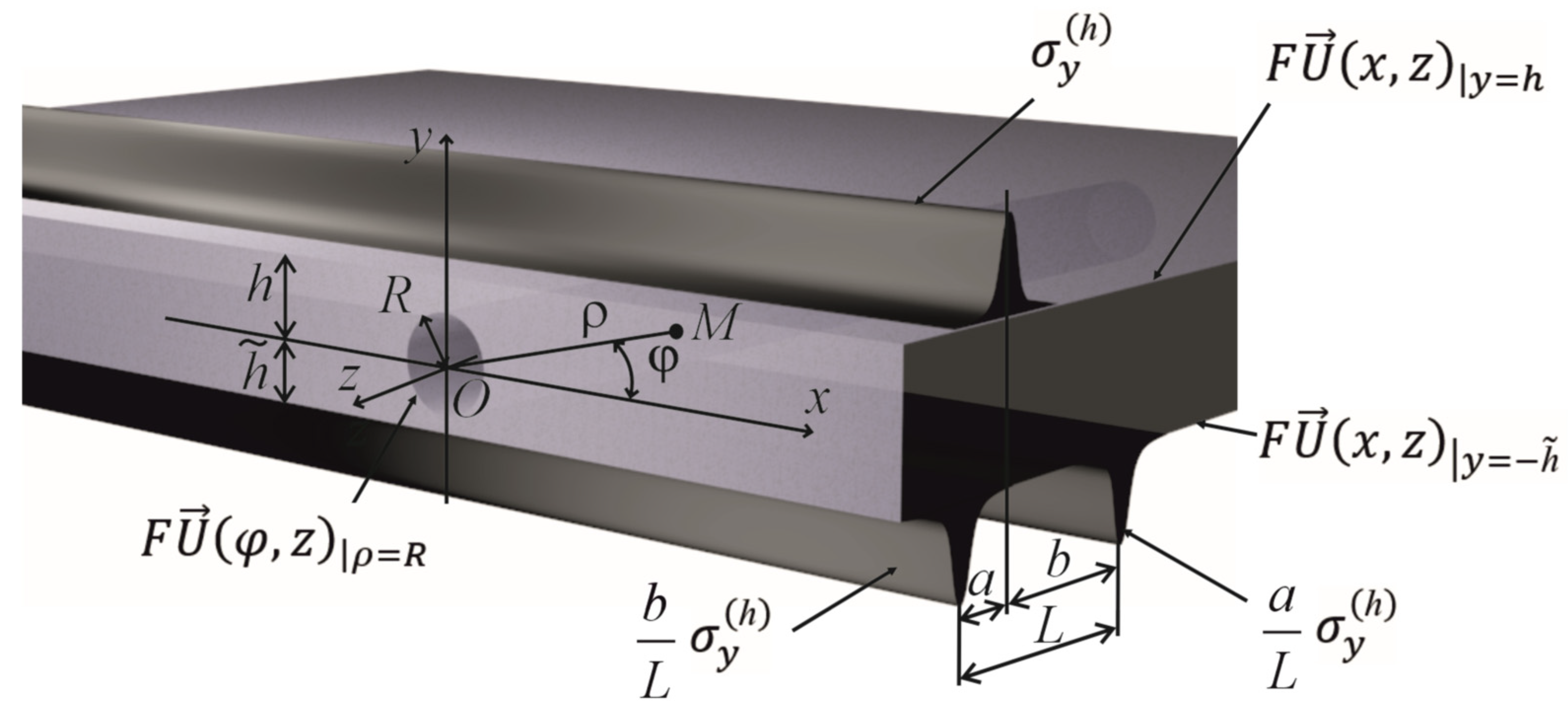

2.1. Calculation Model of a Layer with a Cylindrical Cavity, Assumptions About Elasticity and Isotropy

2.2. Solution Method

- -

- For the transition from the solutions of the cylindrical coordinate system to the solutions of the layer (at y > 0) and (at y < 0)

- -

- For the transition from the solutions of and for the layer to the solutions of of the cylindrical coordinate system

2.3. Creating and Solving a System of Equations

- , are the elements of the matrix:

3. Numerical Analysis of the Stress State of the Layer

3.1. Input Data for Numerical Calculation

3.2. Numerical Results Using the Finite Element Method

3.3. Numerical Results of the Proposed Analytical Method

4. Discussion

- 1

- The impact of the cavity is localized but extends over a considerable distance. At a distance exceeding four radii of the cavity, the stresses σₓ are almost indistinguishable from those in a solid slab, which confirms the correctness of the model.

- 2

- The method has proven to be effective in modeling complex boundary conditions. Calculations have shown that increasing the layer thickness (for example, to cm) is an effective way to reduce the maximum stresses to a safe level that does not exceed the calculated material resistance.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Description | Units |

| R | Radius of the cylindrical cavity | cm |

| h | Distance from the coordinate center to the upper boundary of the layer | cm |

| Distance from the coordinate center to the lower boundary of the layer | cm | |

| L | Distance between the centers of the continuous supports | cm |

| a, b | Distances defining the location of supports and applied load | cm |

| E | Modulus of elasticity (Young’s modulus) | MPa |

| ν | Poisson’s ratio | - |

| Calculated tensile strength of C25/30 concrete | MPa | |

| (x, y, z) | Cartesian coordinate system | - |

| (ρ, φ, z) | Cylindrical coordinate system | - |

| Unit vectors (orths) in the Cartesian coordinate system | - | |

| , , | Unit vectors (orths) in the cylindrical coordinate system | - |

| Total displacement vector | - | |

| Displacement vector for the auxiliary problem (layer without a cavity) | - | |

| Displacement vector for the main problem (cavity under compensating loads) | - | |

| σₓ, σy, σz | Normal stresses in the Cartesian coordinate system | MPa |

| σρ, σφ, σz | Normal stresses in the cylindrical coordinate system (σφ is the hoop stress) | MPa |

| τxy, τyz, τzx | Shear stresses in the Cartesian coordinate system | MPa |

| τρφ, τφz, τzρ | Shear stresses in the cylindrical coordinate system | MPa |

| Normal stress (load) applied to the upper surface (y = h) | MPa | |

| Normal stress (support reaction) on the lower surface (y = ) | MPa | |

| Basic solutions of the Lamé equation for the layer (Cartesian) | - | |

| Internal basic solutions of the Lamé equation for the cylinder | - | |

| External basic solutions of the Lamé equation for the cylinder | - | |

| λ, µ | Parameters of the Fourier series and integral transforms | - |

| γ | Parameter defined as √(λ2 + µ2) | - |

| , | Unknown coefficient functions for the layer solutions | - |

| Unknown coefficient functions for the cylindrical solutions | - | |

| D, Ak,j | Determinant and algebraic complements of the systems of equations | - |

| Transformed boundary condition functions | - | |

| Modified Bessel function of the first kind of order m | - | |

| Modified Bessel function of the second kind of order m | - |

References

- Golovanevskiy, V.; Kondratiev, A. Elastic properties of steel-cord rubber conveyor belt. Exp. Tech. 2021, 45, 217–226. [Google Scholar] [CrossRef]

- Kuhn, H.; Medlin, D. ASM Handbook, Volume 8: Mechanical Testing and Evaluation; ASM International: Materials Park, OH, USA, 2023. [Google Scholar]

- Kondratiev, A.V.; Gaidachuk, V.E.; Kharchenko, M.E. Relationships Between the Ultimate Strengths of Polymer Composites in Static Bending, Compression, and Tension. Mech. Compos. Mater. 2019, 55, 259–266. [Google Scholar] [CrossRef]

- Revo, S.L.; Avramenko, T.G.; Melnichenko, M.M.; Ivanenko, K.O. Physico-mechanical characteristics of nano-composite materials based on fluoroplastic. Bull. Taras Shevchenko Natl. Univ. Kyiv. Phys. Math. Sci. 2021, 3, 107–110. [Google Scholar]

- Zienkiewicz, O.C. The Finite Element Method in Engineering Science; McGraw-Hill: London, UK, 1971. [Google Scholar]

- Zienkiewicz, O.C.; Taylor, R.L.; Zhu, J.Z. The Finite Element Method: Its Basis and Fundamentals, 7th ed.; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Ansys. Static Structural Simulation Using Ansys Discovery. Available online: https://courses.ansys.com/index.php/courses/structural-simulation (accessed on 25 August 2025).

- Zasovenko, A.; Fasoliak, A. Mathematical modeling of the dynamics of an elastic half-medium with a cylindrical cavity reinforced by a shell under axisymmetric loads. New Mater. Technol. Metall. Mech. Eng. 2023, 2, 67–73. [Google Scholar] [CrossRef]

- Khechai, A.; Belarbi, M.O.; Bouaziz, A.; Rekbi, F.M.L. A general analytical solution of stresses around circular holes in functionally graded plates under various in-plane loading conditions. Acta Mech. 2023, 234, 671–691. [Google Scholar] [CrossRef]

- Boulakia, M.; Grandmont, C.; Lespagnol, F.; Zunino, P. Reduced Models for the Poisson Problem in Perforated Domains. HAL Open Sci. Arch. 2021, 89, 1–48. [Google Scholar]

- Timoshenko, S.P.; Goodier, J.N. Theory of Elasticity; McGraw-Hill: New York, NY, USA, 1970. [Google Scholar]

- Fesenko, A.; Vaysfel’d, N. The dynamical problem for the infinite elastic layer with a cylindrical cavity. Procedia Struct. Integr. 2021, 33, 509–527. [Google Scholar] [CrossRef]

- Jafari, M.; Chaleshtari, M.H.B.; Khoramishad, H.; Altenbach, H. Minimization of thermal stress in perforated composite plate using metaheuristic algorithms WOA, SCA and GA. Compos. Struct. 2023, 304, 116403. [Google Scholar] [CrossRef]

- Malits, P. Torsion of an elastic half-space with a cylindrical cavity by a punch. Eur. J. Mech. A Solids 2021, 89, 104308. [Google Scholar] [CrossRef]

- Yang, Z.; Bian, J.; Song, Y.; Yang, Y.; Sun, M. Scattering of cylindrical inclusions in half space with inhomogeneous shear modulus due to SH wave. Arch. Appl. Mech. 2021, 91, 3449–3461. [Google Scholar] [CrossRef]

- Nikolayev, A.G.; Protsenko, V.S. Obobshchennyy metod Fur’ye v Prostranstvennykh Zadachakh Teorii Uprugosti. In Nats. Aerokosm. Universitet im. N.Ye; Zhukovskogo “KHAI”: Khar’kov, Ukraine, 2011; pp. 10–344. ISBN 978-966-662-247-4. [Google Scholar]

- Nikolaev, A.G.; Shcherbakova, Y.A. Apparatus and applications of a generalized Fourier method for transversally isotropic bodies bounded by a plane and a paraboloid of rotation. J. Math. Sci. 2010, 171, 620–631. [Google Scholar] [CrossRef]

- Hiкoлaєв, O.Г.; Krainichenko, A.C. Some problems for transversaly isotropic space with periodic crack systems. Probl. Comput. Mech. Strength Struct. 2024, 1, 229–247. [Google Scholar] [CrossRef]

- Nikolaev, O.; Skitska, M. The method of determining optimal control of the thermoelastic state of a piece-homogeneous body using a stationary temperature field. Radioelectron. Comput. Syst. 2024, 2, 98–119. [Google Scholar] [CrossRef]

- Nikolaev, A.G.; Tanchik, E.A. Stresses in an infinite circular cylinder with four cylindrical cavities. J. Math. Sci. 2016, 217, 299–311. [Google Scholar] [CrossRef]

- Nikolaev, A.G.; Tanchik, E.A. The first boundary-value problem of the elasticity theory for a cylinder with N cylindrical cavities. Numer. Anal. Appl. 2015, 8, 148–158. [Google Scholar] [CrossRef]

- Nikolaev, A.G.; Tanchik, E.A. Stresses in an elastic cylinder with cylindrical cavities forming a hexagonal structure. J. Appl. Mech. Tech. Phys. 2016, 57, 1141–1149. [Google Scholar] [CrossRef]

- Protsenko, V.S.; Ukrayinets, N.A. Justification of the Generalized Fourier method for the mixed problem of elasticity theory in the half-space with the cylindrical cavity. Visn. ZNU. Phys. Math. Sci. 2016, 2, 213–221. [Google Scholar]

- Ukrayinets, N.; Murahovska, O.; Prokhorova, O. Solving a one mixed problem in elasticity theory for half-space with a cy-lindrical cavity by the generalized Fourier method. East. Eur. J. Enterp. Technol. 2021, 2, 48–57. [Google Scholar] [CrossRef]

- Protsenko, V.; Miroshnikov, V. Investigating a problem from the theory of elasticity for a half-space with cylindrical cavities for which boundary conditions of contact type are assigned. East. Eur. J. Enterp. Technol. 2018, 4, 43–50. [Google Scholar] [CrossRef]

- Miroshnikov, V.Y. Stress State of an Elastic Layer with a Cylindrical Cavity on a Rigid Foundation. Int. Appl. Mech. 2020, 56, 372–381. [Google Scholar] [CrossRef]

- Miroshnikov, V.; Denysova, T.; Protsenko, V. The study of the first main problem of the theory of elasticity for a layer with a cylindrical cavity. Strength Mater. Theory Struct. 2019, 103, 208–218. [Google Scholar] [CrossRef]

- Miroshnikov, V.; Younis, B.; Savin, O.; Sobol, V. A linear elasticity theory to analyze the stress state of an infinite layer with a cylindrical cavity under periodic load. Computation 2022, 10, 160. [Google Scholar] [CrossRef]

- Grebenikov, M.M.; Mironov, K.V. Stress state analysis of a layer with a longitudinal cavity and given non-classical mixed boundary conditions. In Science, Theory and Practice, Proceedings of the 29th International Scientific and Practical Conference, Tokyo, Japan, 8–11 June 2021; Pluzhnik, E., Liubchych, A., Eds.; International Science Group: New York, NY, USA, 2021; pp. 536–540. [Google Scholar]

- Nikichanov, V.V. Determination of the stress state of a layer with a cylindrical cavity under given smooth contact conditions on the layer boundaries and displacements on the cavity surface. In Scientific Collection “InterConf”, Proceedings of the 9th International Scientific and Practical Conference “Scientific Horizon in the Context of Social Crises”, Tokyo, Japan, 6–8 August 2021; Otsuki Press: Tokyo, Japan; pp. 208–213. Available online: https://ojs.ukrlogos.in.ua/index.php/interconf/issue/view/6-8.08.2021/569 (accessed on 25 August 2025).

- Miroshnikov, V.; Savin, O.; Sobol, V.; Nikichanov, V. Solving the problem of elasticity for a layer with N cylindrical embedded supports. Computation 2023, 11, 172. [Google Scholar] [CrossRef]

- Vitaly, M. Rotation of the layer with the cylindrical pipe around the rigid cylinder. In CAMPE 2021: Advances in Mechanical and Power Engineering, Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2023; pp. 314–322. [Google Scholar] [CrossRef]

- Sverdlov, S. Determination of the stress-strain state of a bearing connection. In Modern Trends in the Development of Economy, Technology and Industry, Collection of Scientific Papers “International Scientific Unity”, Proceedings of the 2nd International Scientific and Practical Conference, Toronto, ON, Canada, 12–14 February 2025; International Scientific Unity: Toronto, Canada, 2025; pp. 229–233. Available online: https://isu-conference.com/en/archive/modern-trends-in-the-development-of-economy-technology-and-industry-12-02-25/ (accessed on 25 August 2025).

- Denshchykov, O.Y. First Main Problem of the Theory of Elasticity for a Layer with Two Thick-Walled Pipes and One Cylindrical Cavity. J. Mech. Eng. Mash. 2025, 28, 44–53. [Google Scholar] [CrossRef]

- Kosenko, M. Solution to an elasticity problem for a layer with cylindrical embedded supports in the form of a cavity and a pipe: Rigid fixation. In Proceedings of the Interdisciplinary Scientific and Practical Conference “Modern Problems of the Development of the Aerospace Industry of Ukraine: Engineering, Business, Law”, Kharkiv, Ukraine, 5 November 2024; pp. 170–174. [Google Scholar]

- Ilin, O.; Kosenko, M.; Denshchykov, O. Analysis of the stress state of a reinforced layer with two cylindrical cavities and some contact-type conditions. Colloq. J. 2024, 19, 8–13. [Google Scholar] [CrossRef]

- Grebeniuk, I.; Kosenko, M.; Ilin, O. Taking into account the loss of adhesion of the reinforcing element with the layer in the calculation of the stress state. In Proceedings of the XXXI International Scientific and Practical Conference “Scientific Research in the Conditions of Rapid Development of Information Technologies”, Helsinki, Finland, 17–19 July 2024; pp. 97–99. Available online: https://isu-conference.com/wp-content/uploads/2024/07/Scientific_research_in_the_conditions_of_rapid_development_of_information_technologies_July_17_19_2024_Helsinki_Finland.pdf (accessed on 25 August 2025).

- Ilin, O.; Kosenko, M. Solving the problem of elasticity theory for a ball with a circular inclusion and a circular cavity under given boundary conditions of contact type. In Proceedings of the XXVIII International Scientific and Practical Conference “Development of Science in the Conditions of Deepening European Integration Processes”, Rome, Italy, 15–17 July 2024; pp. 162–165. Available online: https://eu-conf.com/en/events/development-of-science-in-the-conditions-of-deepening-european-integration-processes/ (accessed on 25 August 2025).

- Perfetto, D.; Pezzella, C.; Fierro, V.; Rezazadeh, N.; Polverino, A.; Lamanna, G. FE modelling techniques for the simulation of guided waves inplates with variable thickness. Procedia Struct. Integr. 2024, 52, 418–423. [Google Scholar] [CrossRef]

- Ministry of Regional Development and Construction of Ukraine. DBN V.2.6-98:2009. Konstruktsii Budynkiv i Sporud. Betonni and Zalizobetonni Konstruktsii. State Building Norms V.2.6-98:2009. Structures of Buildings and Erections. Concrete and Reinforced Concrete Structures. Main Provisions; Ukrarkhbudinform: Kyiv, Ukraine, 2011. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ukrayinets, N.; Alyoshechkina, T.; Miroshnikov, V.; Savin, O.; Younis, B.; Vynohradov, V.; Murahovska, O. Consideration of Spatially Infinite Loads in the Problem for a Layer with a Cylindrical Cavity and Continuous Supports. Computation 2025, 13, 270. https://doi.org/10.3390/computation13110270

Ukrayinets N, Alyoshechkina T, Miroshnikov V, Savin O, Younis B, Vynohradov V, Murahovska O. Consideration of Spatially Infinite Loads in the Problem for a Layer with a Cylindrical Cavity and Continuous Supports. Computation. 2025; 13(11):270. https://doi.org/10.3390/computation13110270

Chicago/Turabian StyleUkrayinets, Nataliia, Tetyana Alyoshechkina, Vitaly Miroshnikov, Oleksandr Savin, Basheer Younis, Vitalii Vynohradov, and Olena Murahovska. 2025. "Consideration of Spatially Infinite Loads in the Problem for a Layer with a Cylindrical Cavity and Continuous Supports" Computation 13, no. 11: 270. https://doi.org/10.3390/computation13110270

APA StyleUkrayinets, N., Alyoshechkina, T., Miroshnikov, V., Savin, O., Younis, B., Vynohradov, V., & Murahovska, O. (2025). Consideration of Spatially Infinite Loads in the Problem for a Layer with a Cylindrical Cavity and Continuous Supports. Computation, 13(11), 270. https://doi.org/10.3390/computation13110270