Numerical Study on Infrared Radiation Signatures of Debris During Projectile Impact Damage Process

Abstract

1. Introduction

2. Numerical Calculation Model

2.1. SPH Method

2.2. Failure Criterion

2.3. Calculation of Particle Radiation Property Parameters

2.4. Radiation Transmission Method

3. Calculation Conditions

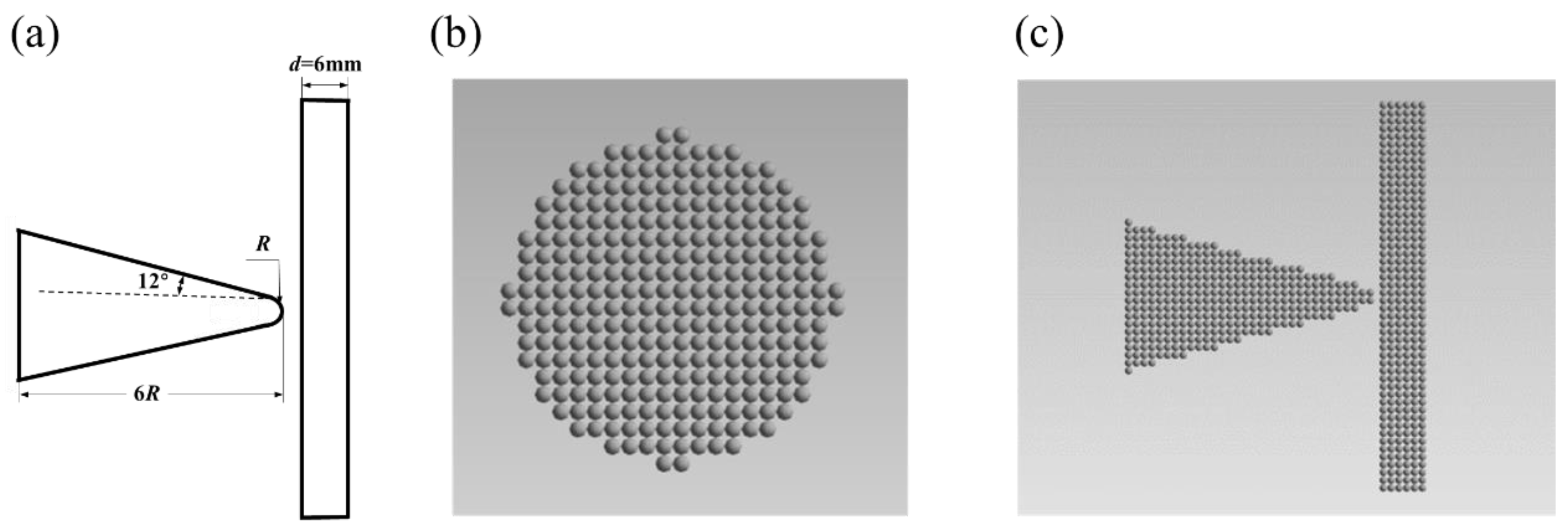

3.1. Geometry Model and Boundary Settings

3.2. Material Parameters

3.3. Calculation Condition Design

4. Results and Analysis

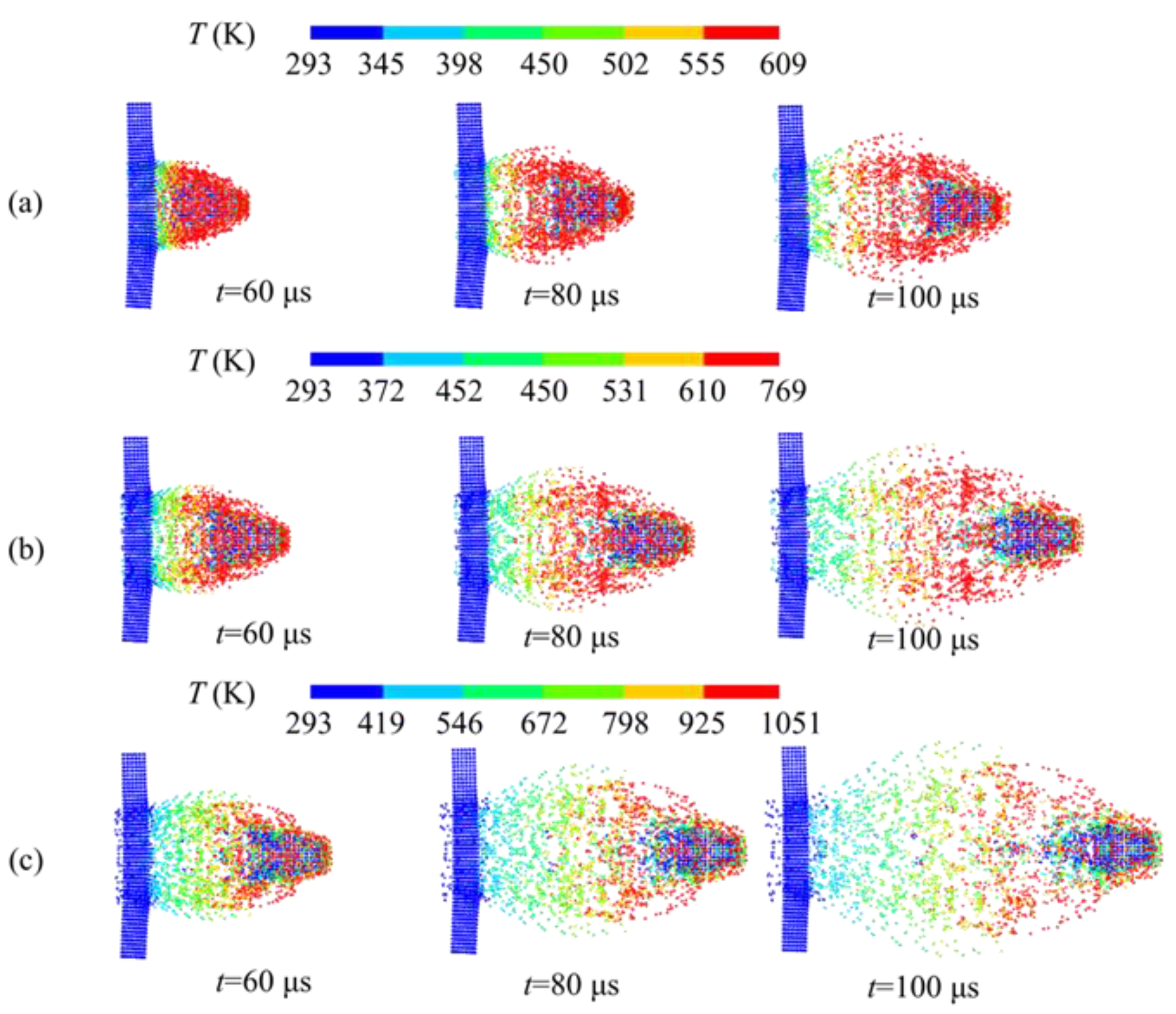

4.1. Temperature Distribution of Debris Cloud

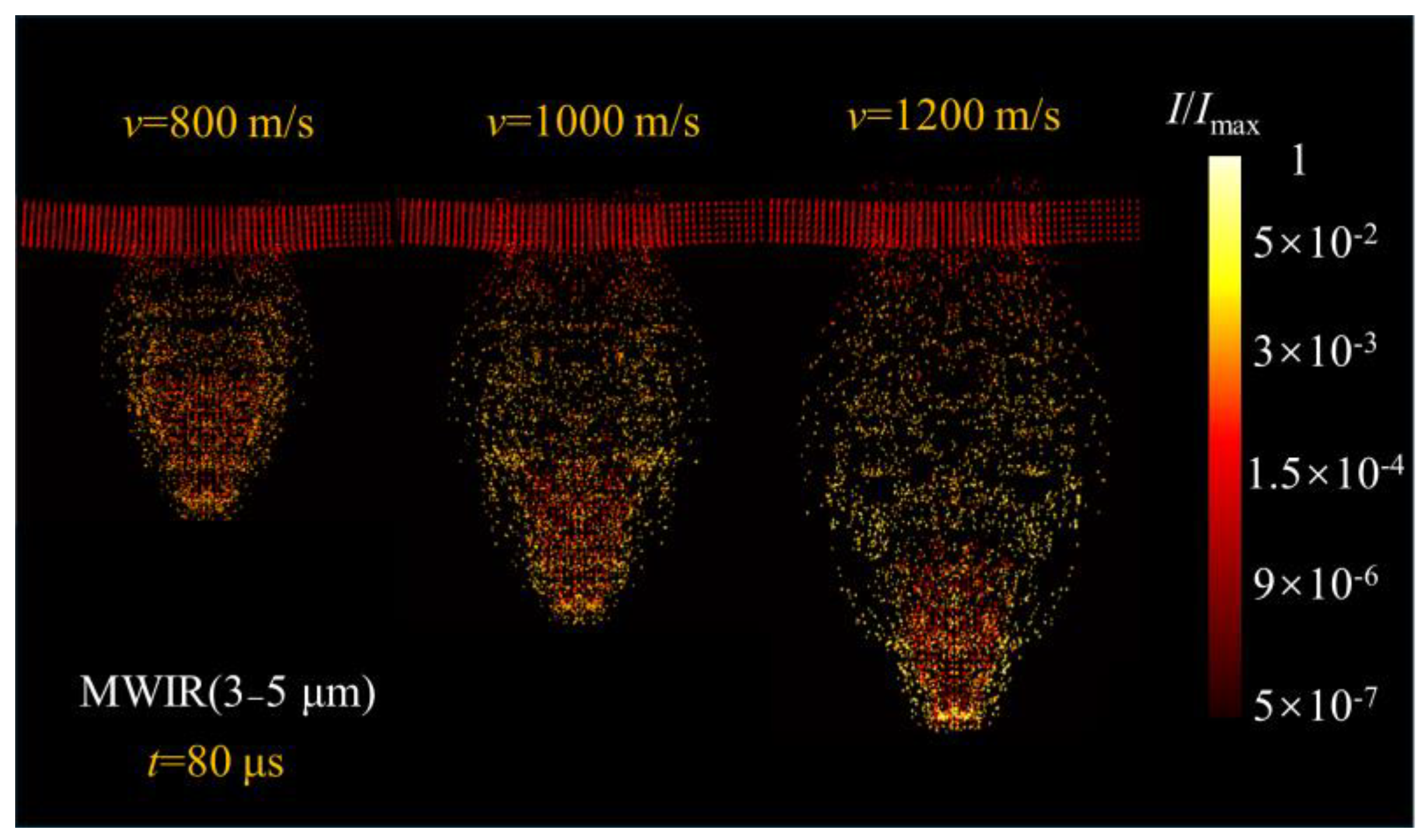

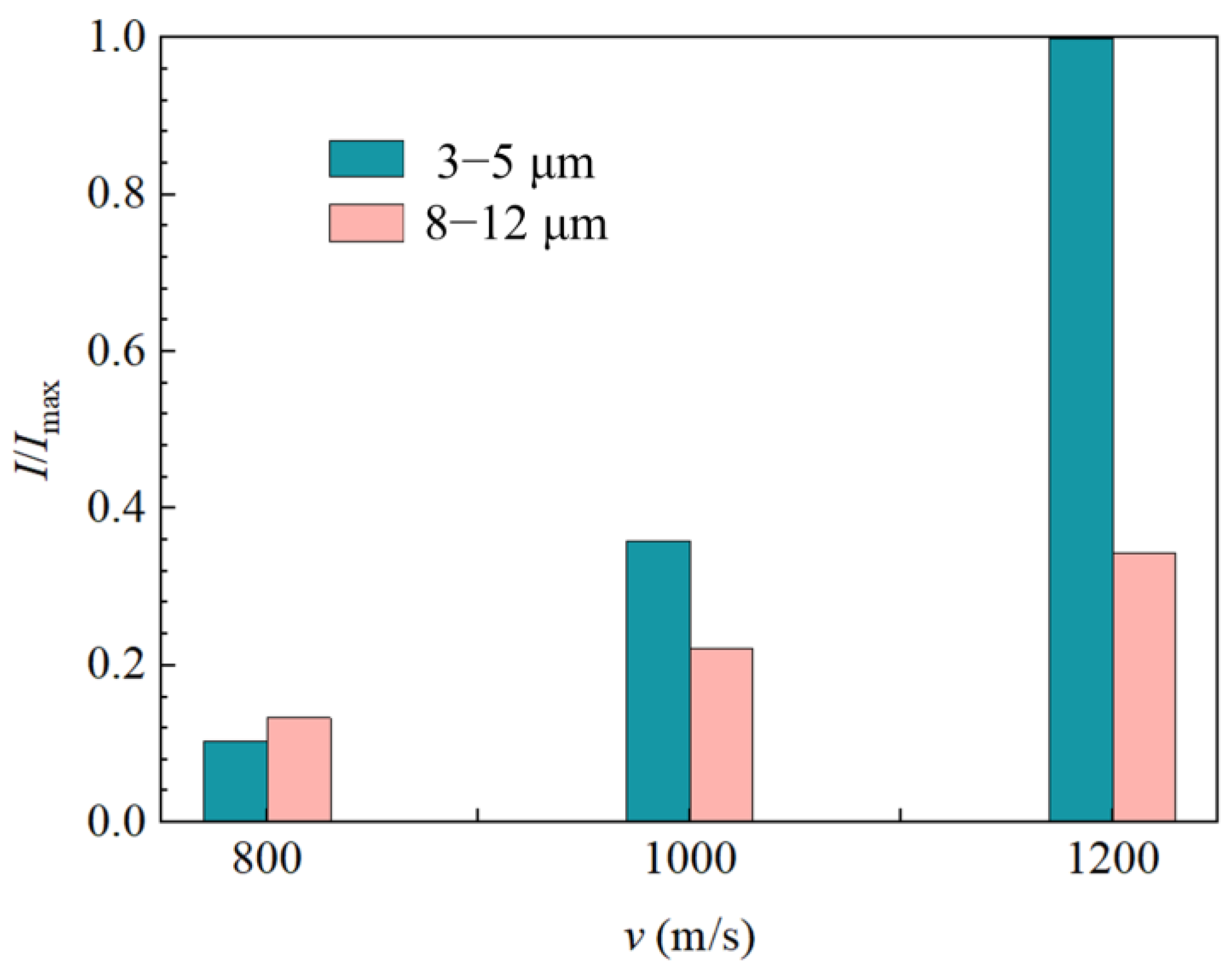

4.2. Effect of Target Impact Speed on Infrared Radiation

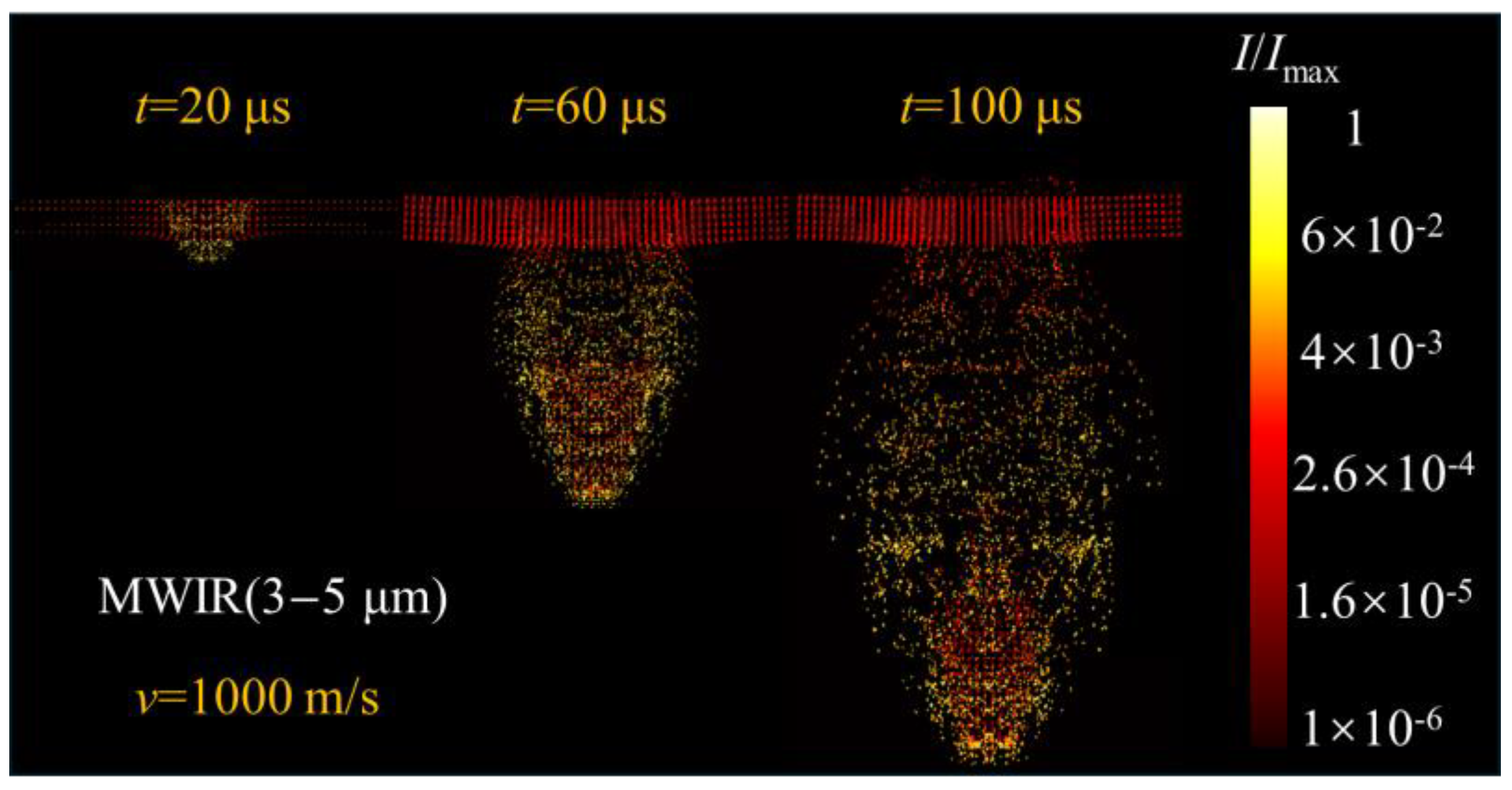

4.3. Dynamic Effects of Infrared Radiation from Debris Clouds

5. Conclusions

- (1)

- The impact velocity significantly influenced the temperature of the debris cloud. The fragment dispersion effect strengthened and the temperature increased with the impact velocities of the projectile. The temperature of the debris cloud increased by 150–200 K when the impact velocity increased by 200 m/s.

- (2)

- The MWIR (3–5 μm) infrared radiation intensity of the debris cloud exceeded that of the LWIR (8–12 μm) band, indicating that the MWIR (3–5 μm) was the best band for the detector.

- (3)

- The increase in the impact velocity enhanced the infrared radiation intensity of the debris cloud. The integrated intensity of the debris cloud at the impact velocity of 1200 m/s was nearly twice that at 1000 m/s.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SPH | Smoothed particle hydrodynamics |

| RMC | Reverse Monte Carlo |

| MWIR | Medium-wave infrared |

| LWIR | Long-wave infrared |

References

- Johnston, J.P.; Pereira, J.M.; Ruggeri, C.R.; Roberts, G.D. High speed thermal imaging on ballistic impact of triaxially braided composites. In Proceedings of the Annual Technical Conference of the American Society for Composites (ASC), West Lafayette, IN, USA, 23–25 October 2017. GRC-E-DAA-TN42986. [Google Scholar]

- Alesbrook, L.S.; Burchell, M.J.; Cornwell, L.T.; Corsaro, R.D.; Giovane, F.; Liou, J.C.; Tandy, J.; Wozniakiewicz, P.J. Hypervelocity impact induced light flash experiments on single and dual layer Kapton targets to develop a time of flight space dust and debris detector. Int. J. Impact Eng. 2024, 187, 104897. [Google Scholar] [CrossRef]

- Borges, M.C.S.R. Analytical methods for high speed impact behaviour of long rods. Master’s Thesis, Universidade de Lisboa, Lisaboa, Portugal, November 2019; 164p. [Google Scholar]

- Ma, K.; Chen, C.L.; Feng, N.; Yin, L.X.; Li, M.R.; Zhou, G. Characteristics of perforation and fragment group expansion of steel sheet impacted by cylindrical 93 tungsten projectile at hypervelocity. Acta Armamentarii 2021, 42, 2350–2359. [Google Scholar]

- Vollmer, M.; Möllmann, K.P. Infrared Thermal Imaging: Fundamentals, Research and Applications, 2nd ed.; John Wiley & Sons: Weinheim, Germany, 2018. [Google Scholar]

- Liu, G.R.; Liu, M.B. Smoothed Particle Hydrodynamics: A Meshfree Particle Method; World Scientific: Singapore, 2003. [Google Scholar]

- Aktay, L.; Johnson, A.F. FEM/SPH coupling technique for high velocity impact simulations. Adv. Mech. Eng. 2007, 5, 147–167. [Google Scholar]

- Zhang, X.; Guanghui, J.; Huang, H. Fragment identification and statistics method of hypervelocity impact SPH simulation. Chin. J. Aeronaut. 2011, 24, 18–24. [Google Scholar] [CrossRef]

- Lind, S.J.; Rogers, B.D.; Stansby, P.K. Review of smoothed particle hydrodynamics: Towards converged Lagrangian flow modelling. Proc. R. Soc. A. 2020, 476, 20190801. [Google Scholar] [CrossRef] [PubMed]

- Ma, K.; Li, M.R.; Chen, C.L.; Feng, N.; Zhao, N.; Ke, M.; Zhou, G. Simulation analysis of distribution of fragments of hypervelocity 93w projectile impacting on a steel plate target. Acta Armamentarii 2019, 40, 2022–2031. [Google Scholar]

- Wang, J.T.; Yu, W.L.; Wang, T.; Luo, Y.F.; Wang, S.L. Smoothed particle hydrodynamics algorithm applied in numerical simulation of layered metal targets impacted by long rod projectile. Combust. Explos. Shock Waves 2011, 31, 533–539. [Google Scholar]

- Huang, J.; Ma, Z.X.; Ren, L.S.; Li, Y.; Zhou, Z.X.; Liu, S. A new engineering model of debris cloud produced by hypervelocity impact. Int. J. Impact Eng. 2013, 56, 32–39. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Guan, G.S.; Zhang, W.; Pang, B.J. Characteristics of debris cloud produced by normal impact of spherical projectile on thin plate shield. Explos. Shock Waves 2007, 27, 546–552. [Google Scholar]

- Piekutowski, A.J. Debris clouds produced by the hypervelocity impact of nonspherical projectiles. Int. J. Impact Eng. 2001, 26, 613–624. [Google Scholar] [CrossRef]

- Wang, L.Y.; Jiang, W.J.; Li, M.; Ma, Y.Y. Experimental research on energy release behavior of W/Zr/Hf alloy fragment. Acta Armamentarii. 2019, 40, 1603–1610. [Google Scholar]

- Mihaly, J.M. Investigation of Hypervelocity Impact Phenomena Using Real-Time Concurrent Diagnostics. Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 21 May 2013. [Google Scholar]

- Meola, C.; Boccardi, S.; Boffa, N.D.; Ricci, F.; Simeoli, G.; Russo, P.; Carlomagno, G.M. New perspectives on impact damaging of thermoset-and thermoplastic-matrix composites from thermographic images. Compos. Struct. 2016, 152, 746–754. [Google Scholar] [CrossRef]

- Cai, Y.; Feng, X.; He, C.; Zhang, S.; Li, S.; Liu, J. A 7.62 mm energetic bullet filled with PTFE-Mg-based reactive materials for anti-drone application. J. Mater. Res. Technol. 2024, 30, 8749–8759. [Google Scholar] [CrossRef]

- Monaghan, J.J. Shock simulation by the particle method SPH. J. Comput. Phys. 1983, 52, 374–389. [Google Scholar] [CrossRef]

- Benz, W. Smooth particle hydrodynamics: A review. In The Numerical Modelling of Nonlinear Stellar Pulsations: Problems and prospects. 1st Eds.; Buchler, J.R., Ed.; NATO ASI Series; Springer: Dordrecht, The Netherlands, 1990; pp. 269–288. [Google Scholar]

- Chen, G.; Chen, F.Z.; Xu, W.F.; Chen, Y.M.; Huang, X.C. Investigation on the J-C ductile fracture parameters of 45 steel. Combust. Explos. Shock Waves. 2007, 27, 131–135. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Tuler, F.R.; Butcher, B.M. A criterion for the time dependence of dynamic fracture. Int. J. Fract. 1984, 26, 322–328. [Google Scholar] [CrossRef]

- Rice, J.R.; Tracey, D.M. On the ductile enlargement of voids in triaxial stress fields. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef]

- Bohren, C.F.; Huffman, D.R. Absorption and Scattering of Light by Small Particles; Wiley-VCH Verlag GmbH & Co KGaA: Weinheim, Germany, 1998. [Google Scholar]

- Planck, M. On the law of distribution of energy in the normal spectrum. Ann. Der Physic. 1901, 4, 553. [Google Scholar] [CrossRef]

- Deng, Y.F.; Zhang, Y.; Wu, H.P.; Zeng, X.Z. Dynamic mechanical properties and modification of J-C constitutive model of 6061-T651 aluminum alloy. J. Mech. Eng. 2020, 56, 74–81. [Google Scholar]

- Modest, M.F.; Mazumder, S. Radiative Heat Transfer, 4th ed.; Academic Press: Cambridge, UK, 2021. [Google Scholar]

| Elasticity Modulus (GPa) | Poisson’s ratio | Yield strength (MPa) | Hardening coefficient B (MPa) | Hardening index n | Density (kg/m3) | Hardening coefficient Q (MPa) | Hardening index b |

| 64.0 | 0.33 | 278.2 | 245.2 | 0.817 | 2700 | 58.3 | 9.16 |

| Modification factor | Strain rate sensitivity coefficient | Reference strain rate (1/s) | Specific heat capacity (J/kg/K) | Temperature softening coefficient | Temperature softening index | Reference temperature (K) | Melting temperature (K) |

| 0.1 | 0.0256 | 1.33 × 103 | 890 | 2.745 | 2.387 | 294 | 925 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, W.; Zhang, T.; Niu, Q. Numerical Study on Infrared Radiation Signatures of Debris During Projectile Impact Damage Process. Computation 2025, 13, 244. https://doi.org/10.3390/computation13100244

Gao W, Zhang T, Niu Q. Numerical Study on Infrared Radiation Signatures of Debris During Projectile Impact Damage Process. Computation. 2025; 13(10):244. https://doi.org/10.3390/computation13100244

Chicago/Turabian StyleGao, Wenqiang, Teng Zhang, and Qinglin Niu. 2025. "Numerical Study on Infrared Radiation Signatures of Debris During Projectile Impact Damage Process" Computation 13, no. 10: 244. https://doi.org/10.3390/computation13100244

APA StyleGao, W., Zhang, T., & Niu, Q. (2025). Numerical Study on Infrared Radiation Signatures of Debris During Projectile Impact Damage Process. Computation, 13(10), 244. https://doi.org/10.3390/computation13100244