Analytical Solution and Numerical Simulation of Heat Transfer in Cylindrical- and Spherical-Shaped Bodies

Abstract

1. Introduction

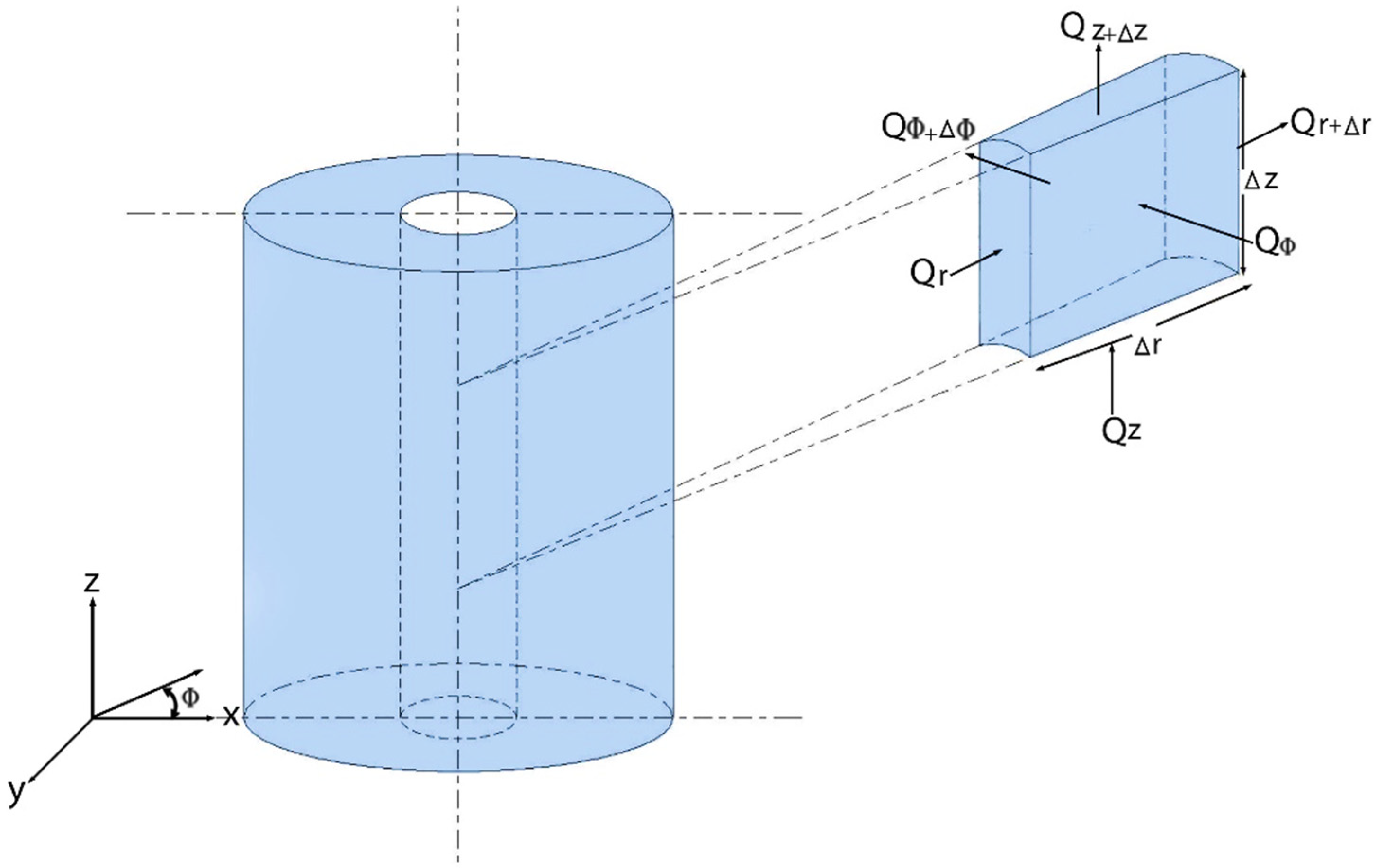

2. The Studied Problem

The Spatial Discretization of the Problem

3. The Analytical Solution

4. The Applied Numerical Methods

- The UPFD (unconditionally positive finite difference) method was proposed in [33] for the diffusion-advection-reaction equation a decade ago. We recently adapted it to Equation (10) as follows:

- 2.

- The pseudo-implicit (PI) method has the following two stages:

- 3.

- A two-stage version of the Rational Runge–Kutta methods [34] was applied as follows. First, a full step was taken by the standard FTCS (explicit Euler) scheme to calculate the predictor values:

- 4.

- A special, checkerboard-like spatial grid must be constructed if someone wants to use any version of the odd-even hopscotch methods [35]. The cells of this grid are labeled as odd and even, with the requirement that all the nearest neighbors of the even cells are odd and vice versa. In the case of the original version (denoted by OOEH here), the odd-even labels must be interchanged after each time step, as is displayed in Figure 5A. The standard FTCS formula was modified in the first stage to make it slightly more stable [31] by treating the convection and radiation terms in an “implicit” way:

- 5.

- In the case of the shifted-hopscotch (SH) algorithm, five stages constitute a two-step-long repeating block. Two of the stages are half- and the remaining three of them are full-length steps, as seen in Figure 5C. The first stage is for the odd cells only and is symbolized by a dark green box with the number one in the figure. It uses the formula

- 6.

- The asymmetric hopscotch (ASH) algorithm is almost the same as the SH one, but the repeating block is only one time-step long, as one can see in Figure 5D. It contains only three stages instead of five, which use the same Formulas (14)–(16), respectively.

- 7.

- The procedure of the leapfrog-hopscotch (LH) algorithm begins and ends with a half-length stage, but then all other stages have full time-step length (blue boxes in Figure 5B). At the first and intermediate stages, it uses Formulas (14) and (15). However, at the last stage (pink rectangle) it uses (15) again, but must be divided by two, including their appearances in the quantities w and A.

- 8.

- Although the Dufort–Frankel (DF) method [36] is a known explicit and unconditionally stable algorithm for the linear heat equation, it is rarely used. The formula adapted for the case of Equation (10) is:

- 9.

- One of the most common algorithms to solve the heat conduction equation is the explicit-Euler-based FTCS (forward time central space) algorithm. It can be adapted to our case in the standard way as follows:

5. Verification Using the Analytical Solution

6. Setup of the Reproduction of the Experimental Results

6.1. Material Properties

6.2. The Initial and the Boundary Conditions

7. Simulation Results

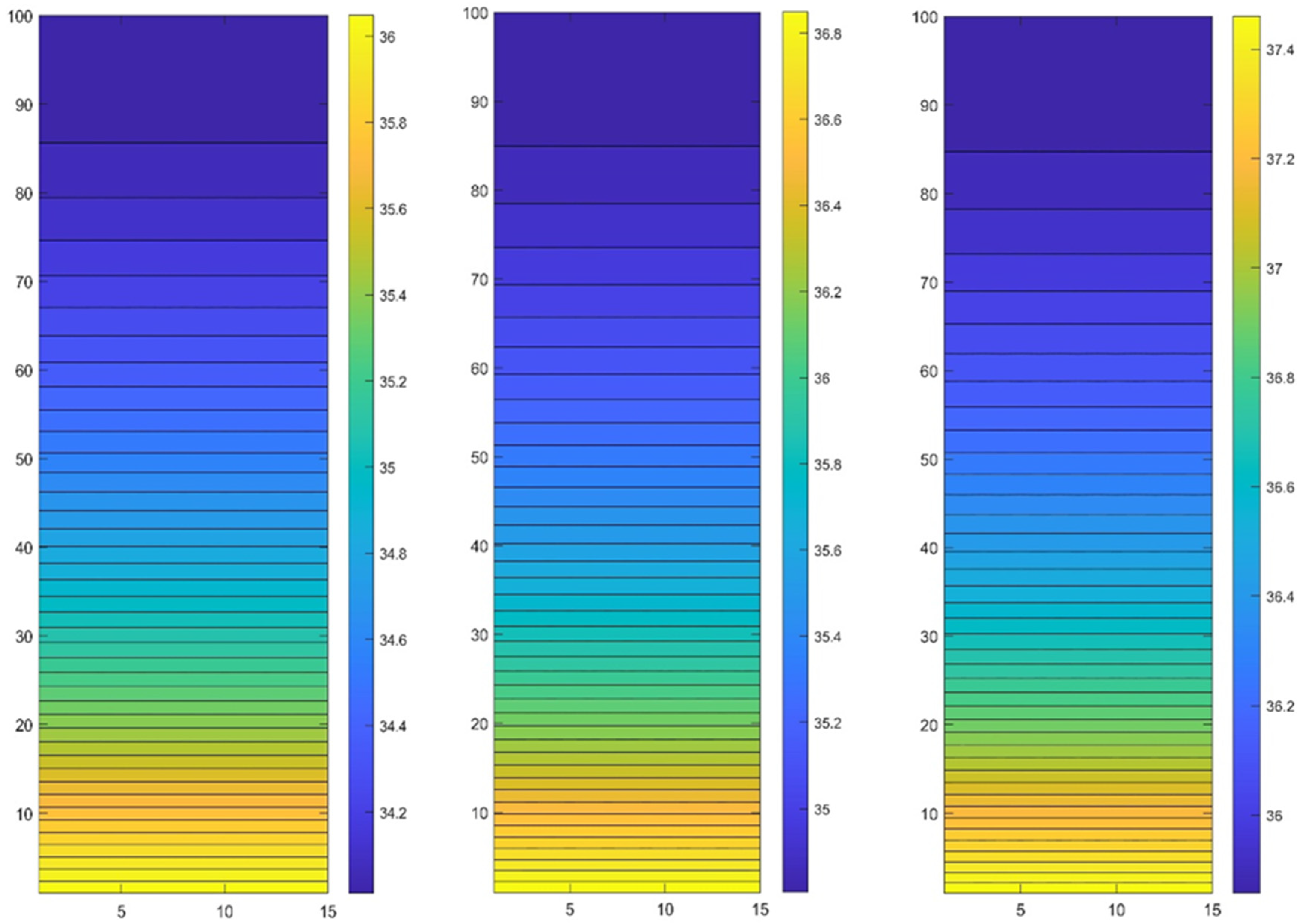

7.1. Results of the Numerical Methods

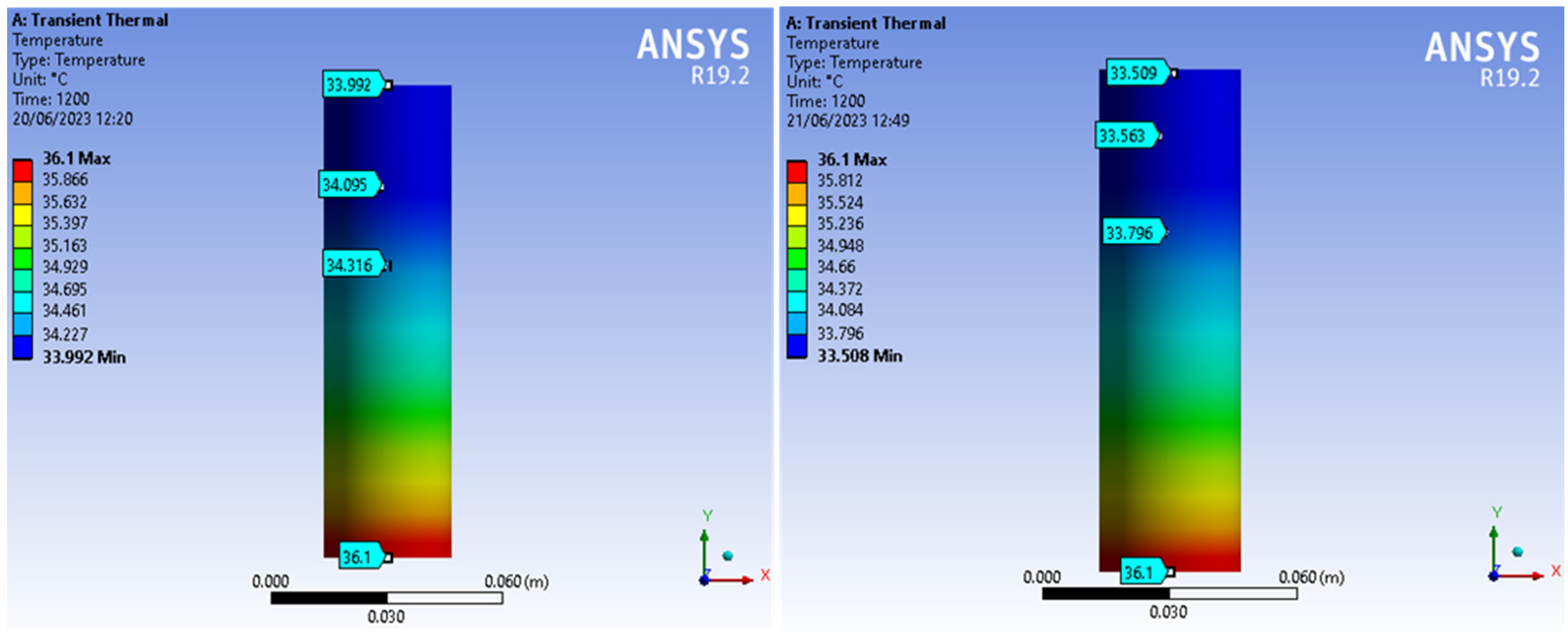

7.2. Ansys Simulation Results

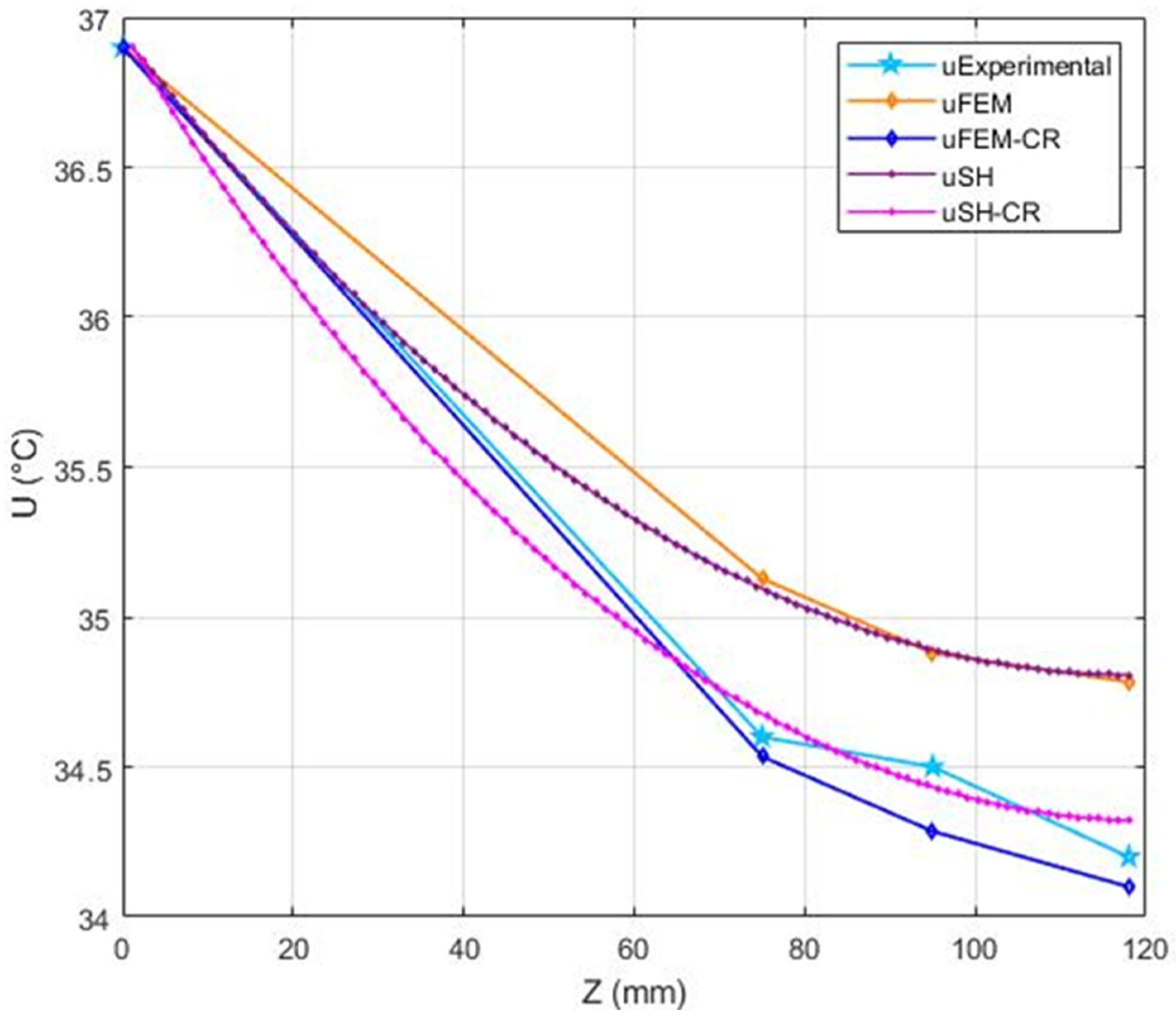

7.3. Comparison of the Results

8. Discussion and Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Quantity | Meaning, Unit |

| u | Temperature, Kelvin (K) |

| f | Shape function |

| η | Reduced variable |

| Qgen | Heat Generation, Watt (W) |

| Qconvection | Heat Convection, Watt (W) |

| Qradiation | Heat radiation, Watt (W) |

| ΔE | Change in Energy of an Element, Joule (J) |

| k | Thermal Conductivity (W/(m·K) |

| h | Convection Coefficient, (W/(m2·K) |

| Radiation Constant (W/(m2·K4) | |

| SB | Stefan–Boltzmann Constant W/(m2·K4) |

| α | (Thermal) Diffusivity |

| Density (kg/m3) | |

| c | Specific Heat (J/(kg·K) |

| C | Heat Capacity (J/K) |

| S | Surface Area (m2) |

| Element Volume (m3) | |

| φ | Azimuthal angle, Rad, deg |

| θ | Polar angle, Rad, deg |

| Δt | Time Interval (s) |

| R | Thermal Resistance (K/W) |

| r | Radius (m) |

| z | Height (m) |

| SH with CR | Shifted hopscotch with convection and radiation |

| FEM with CR | Finite element method with convection and radiation |

References

- Bennett, T. Transport by Advection and Diffusion; Wiley: New York, NY, USA, 2012. [Google Scholar]

- Ghez, R. Diffusion Phenomena: Cases and Studies; Dover Publications Inc.: Mineola, NY, USA, 2001. [Google Scholar]

- Pasquill, F.; Smith, F.B. Atmospheric Diffusion; Ellis Horwood Limited: West Sussex, UK, 1883. [Google Scholar]

- Heitjans, P.; Kärger, J. Diffusion in Condensed Matter: Methods, Materials, Models; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Michaud, G.; Alecian, G.; Richer, J. Atomic Diffusion in Stars; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Machta, J.; Zwanzig, R. Diffusion in a periodic lorentz gas. Phys. Rev. Lett. 1983, 50, 1959–1962. [Google Scholar] [CrossRef]

- Hoover, W.G. Time Reversibility, Computer Simulation, and Chaos; World Scientific: Singapore, 1999; Volume 13. [Google Scholar]

- Mátyás, L.; Tél, T.; Vollmer, J. Coarse-grained entropy and information dimension of dynamical systems: The driven Lorentz gas. Phys. Rev. E Stat. Phys. Plasmas Fluids Relat. Interdiscip Top. 2004, 69, 8. [Google Scholar] [CrossRef]

- Mátyás, L.; Barna, I.F. Geometrical origin of chaoticity in the bouncing ball billiard. Chaos Solitons Fractals 2011, 44, 1111–1116. [Google Scholar] [CrossRef]

- de Wijn, A.S.; Kantz, H. Vertical chaos and horizontal diffusion in the bouncing-ball billiard. Phys. Rev. E Stat. Phys. Plasmas Fluids Relat. Interdiscip Top. 2007, 75, 046214. [Google Scholar] [CrossRef] [PubMed]

- Klages, R.; Barna, I.F.; Mátyás, L. Spiral modes in the diffusion of a single granular particle on a vibrating surface. Phys. Lett. Sect. A Gen. At. Solid State Phys. 2004, 333, 79–84. [Google Scholar] [CrossRef]

- Barna, I.F.; Mátyás, L. Advanced Analytic Self-Similar Solutions of Regular and Irregular Diffusion Equations. Mathematics 2022, 10, 3281. [Google Scholar] [CrossRef]

- Kolev, M.K.; Koleva, M.N.; Vulkov, L.G. An Unconditional Positivity-Preserving Difference Scheme for Models of Cancer Migration and Invasion. Mathematics 2022, 10, 131. [Google Scholar] [CrossRef]

- Mbayi, C.K.; Munyakazi, J.B.; Patidar, K.C. Layer resolving fitted mesh method for parabolic convection-diffusion problems with a variable diffusion. J. Appl. Math. Comput. 2022, 68, 1245–1270. [Google Scholar] [CrossRef]

- Saleh, M.; Kovács, E.; Barna, I.F. Analytical and Numerical Results for the Transient Diffusion Equation with Diffusion Coefficient Depending on Both Space and Time. Algorithms 2023, 16, 184. [Google Scholar] [CrossRef]

- Cannon, J.R. The One-Dimensional Heat Equation; Cambridge University Press: Cambridge, UK, 1984. [Google Scholar]

- Williams, W.S.C. Nuclear and Particle Physics; Clarendon Press: Oxford, UK, 1991. [Google Scholar]

- Erdélyi, Z.; Schmitz, G. Reactive diffusion and stresses in spherical geometry. Acta Mater. 2012, 60, 1807–1817. [Google Scholar] [CrossRef]

- Roussel, M.; Erdélyi, Z.; Schmitz, G. Reactive diffusion and stresses in nanowires or nanorods. Acta Mater. 2017, 131, 315–322. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids; Oxford Science Publications: Oxford, UK, 1986. [Google Scholar]

- Rutherford Aris. The Mathematical Theory of Diffusion and Reaction in Permeable Catalysts; Oxford University Press Inc.: Oxford, UK, 1975. [Google Scholar]

- Rihan, Y. Analysis of transient heat conduction in a nuclear fuel rod. In Proceedings of the Arab International Conference: Recent Advances in Physics and Materials Science, Alexandria, Egypt, 18–20 September 2005. [Google Scholar] [CrossRef]

- Pandey, K.M.; Mahesh, M. Determination of Temperature Distribution in a Cylindrical Nuclear Fuel Rod—A Mathematical Approach. Int. J. Innov. 2010, 1, 464–468. [Google Scholar]

- Dieguez, P.M.; Sala, J.M. Heat transfer in a cylindrical geometry and application to reciprocating internal combustion engines. Energy 1993, 18, 987–995. [Google Scholar] [CrossRef]

- Kostin, G.; Rauh, A.; Gavrikov, A.; Knyazkov, D.; Aschemann, H. Heat Transfer in Cylindrical Bodies Controlled by a Thermoelectric Converter. IFAC-PapersOnLine 2019, 52, 139–144. [Google Scholar] [CrossRef]

- Tsega, E.G. Numerical Solution of Three-Dimensional Transient Heat Conduction Equation in Cylindrical Coordinates. J. Appl. Math. 2022, 2022, 1993151. [Google Scholar] [CrossRef]

- Mbroh, N.A.; Munyakazi, J.B. A robust numerical scheme for singularly perturbed parabolic reaction-diffusion problems via the method of lines. Int. J. Comput. Math. 2022, 99, 1139–1158. [Google Scholar] [CrossRef]

- Fteiti, M.; Ghalambaz, M.; Sheremet, M.; Ghalambaz, M. The impact of random porosity distribution on the composite metal foam-phase change heat transfer for thermal energy storage. J. Energy Storage 2023, 60, 106586. [Google Scholar] [CrossRef]

- Kumar, V.; Chandan, K.; Nagaraja, K.V.; Reddy, M.V. Heat Conduction with Krylov Subspace Method Using FeniCSx. Energies 2022, 15, 8077. [Google Scholar] [CrossRef]

- Ndou, N.; Dlamini, P.; Jacobs, B.A. Enhanced Unconditionally Positive Finite Difference Method for Advection–Diffusion–Reaction Equations. Mathematics 2022, 10, 2639. [Google Scholar] [CrossRef]

- Jalghaf, H.K.; Kovács, E.; Bolló, B. Comparison of Old and New Stable Explicit Methods for Heat Conduction, Convection, and Radiation in an Insulated Wall with Thermal Bridging. Buildings 2022, 12, 1365. [Google Scholar] [CrossRef]

- Mátyás, L.; Barna, I.F. General Self-Similar Solutions of Diffusion Equation and Related Constructions. Rom. J. Phys. 2022, 67, 101. [Google Scholar]

- Chen-Charpentier, B.M.; Kojouharov, H.V. An unconditionally positivity preserving scheme for advection-diffusion reaction equations. Math. Comput. Model. 2013, 57, 2177–2185. [Google Scholar] [CrossRef]

- Sottas, G. Rational Runge-Kutta methods are not suitable for stiff systems of ODEs. J. Comput. Appl. Math. 1984, 10, 169–174. [Google Scholar] [CrossRef]

- Gourlay, A.R.; McGuire, G.R. General Hopscotch Algorithm for the Numerical Solution of Partial Differential Equations. IMA J. Appl. Math. 1971, 7, 216–227. [Google Scholar] [CrossRef]

- Hirsch, C. Numerical Computation of Internal and External Flows, Volume 1: Fundamentals of Numerical Discretization; Wiley: Hoboken, NJ, USA, 1988. [Google Scholar]

- Cabezas, S.; Hegedűs, G.; Bencs, P. Thermal experimental and numerical heat transfer analysis of a solid cylinder in longitudinal direction. Analecta Tech. Szeged. 2023, 17, 16–27. [Google Scholar] [CrossRef]

- Holman, J.P. Heat Transfer, 10th ed.; McGraw-Hill Education: New York, NY, USA, 2009. [Google Scholar]

| Material | |||

| Steel C45 | 7800 | 40 | 480 |

| Time | Temperature in °C, at z = 75 mm | ||||

|---|---|---|---|---|---|

| Experiment | SH with CR | SH | FEM with CR | FEM | |

| 20 min | 33.9 | 33.941 | 34.298 | 33.796 | 34.316 |

| 24 min | 34.6 | 34.668 | 35.087 | 34.534 | 35.128 |

| 30 min | 35.7 | 35.514 | 36.07 | 35.283 | 36.036 |

| Time | Temperature in °C, at z = 95 mm | ||||

|---|---|---|---|---|---|

| Experiment | SH with CR | SH | FEM with CR | FEM | |

| 20 min | 33.7 | 33.71 | 34.099 | 33.563 | 34.095 |

| 24 min | 34.5 | 34.427 | 34.88 | 34.285 | 34.88 |

| 30 min | 35.5 | 35.30 | 35.92 | 35.093 | 35.856 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jalghaf, H.K.; Kovács, E.; Barna, I.F.; Mátyás, L. Analytical Solution and Numerical Simulation of Heat Transfer in Cylindrical- and Spherical-Shaped Bodies. Computation 2023, 11, 131. https://doi.org/10.3390/computation11070131

Jalghaf HK, Kovács E, Barna IF, Mátyás L. Analytical Solution and Numerical Simulation of Heat Transfer in Cylindrical- and Spherical-Shaped Bodies. Computation. 2023; 11(7):131. https://doi.org/10.3390/computation11070131

Chicago/Turabian StyleJalghaf, Humam Kareem, Endre Kovács, Imre Ferenc Barna, and László Mátyás. 2023. "Analytical Solution and Numerical Simulation of Heat Transfer in Cylindrical- and Spherical-Shaped Bodies" Computation 11, no. 7: 131. https://doi.org/10.3390/computation11070131

APA StyleJalghaf, H. K., Kovács, E., Barna, I. F., & Mátyás, L. (2023). Analytical Solution and Numerical Simulation of Heat Transfer in Cylindrical- and Spherical-Shaped Bodies. Computation, 11(7), 131. https://doi.org/10.3390/computation11070131