Development of Mathematical Model to Predict Soymilk Fouling Deposit Mass on Heat Transfer Surfaces Using Dimensional Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

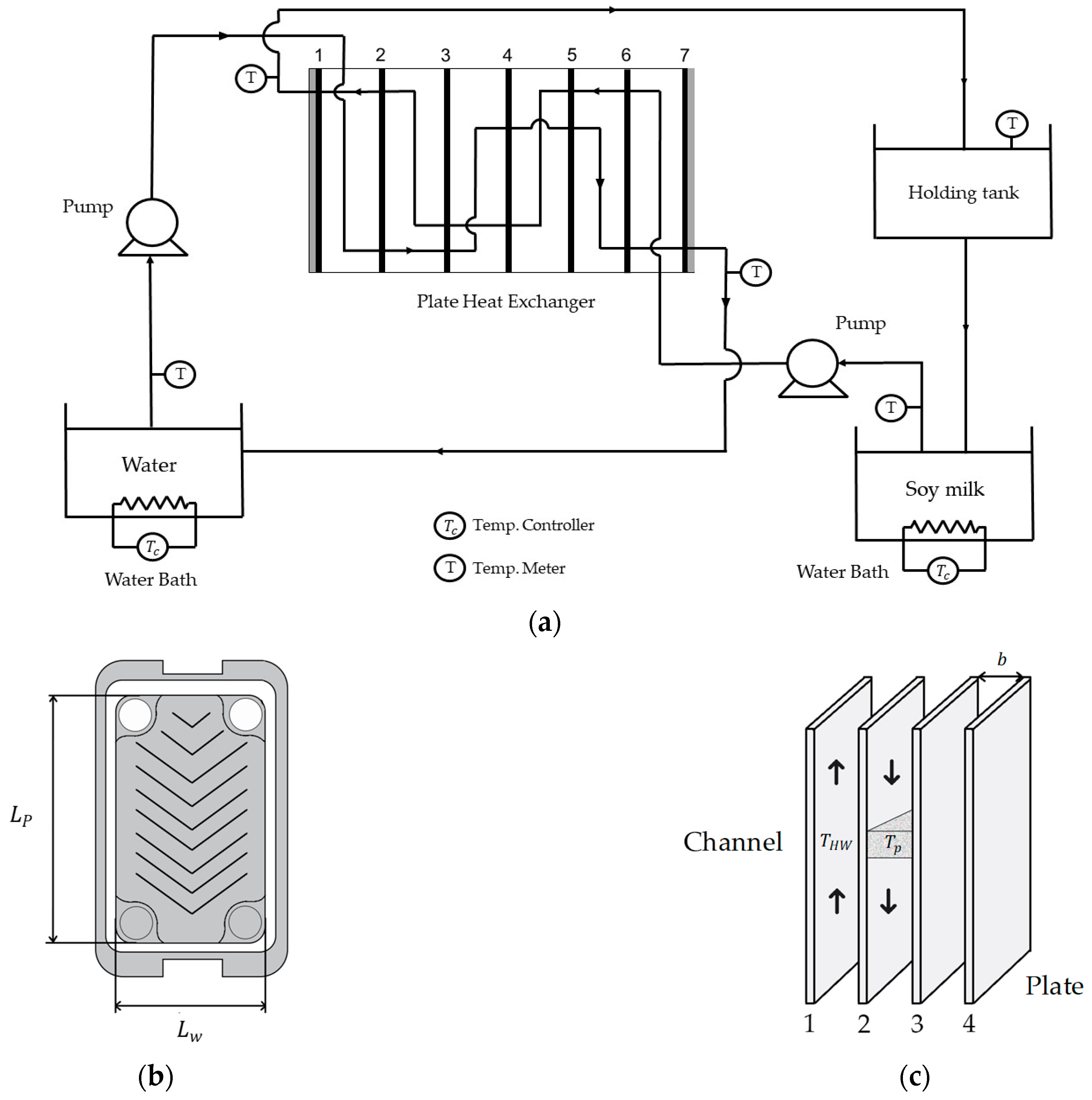

2.2. Experimental Set-Up

2.3. Fouling Experiments

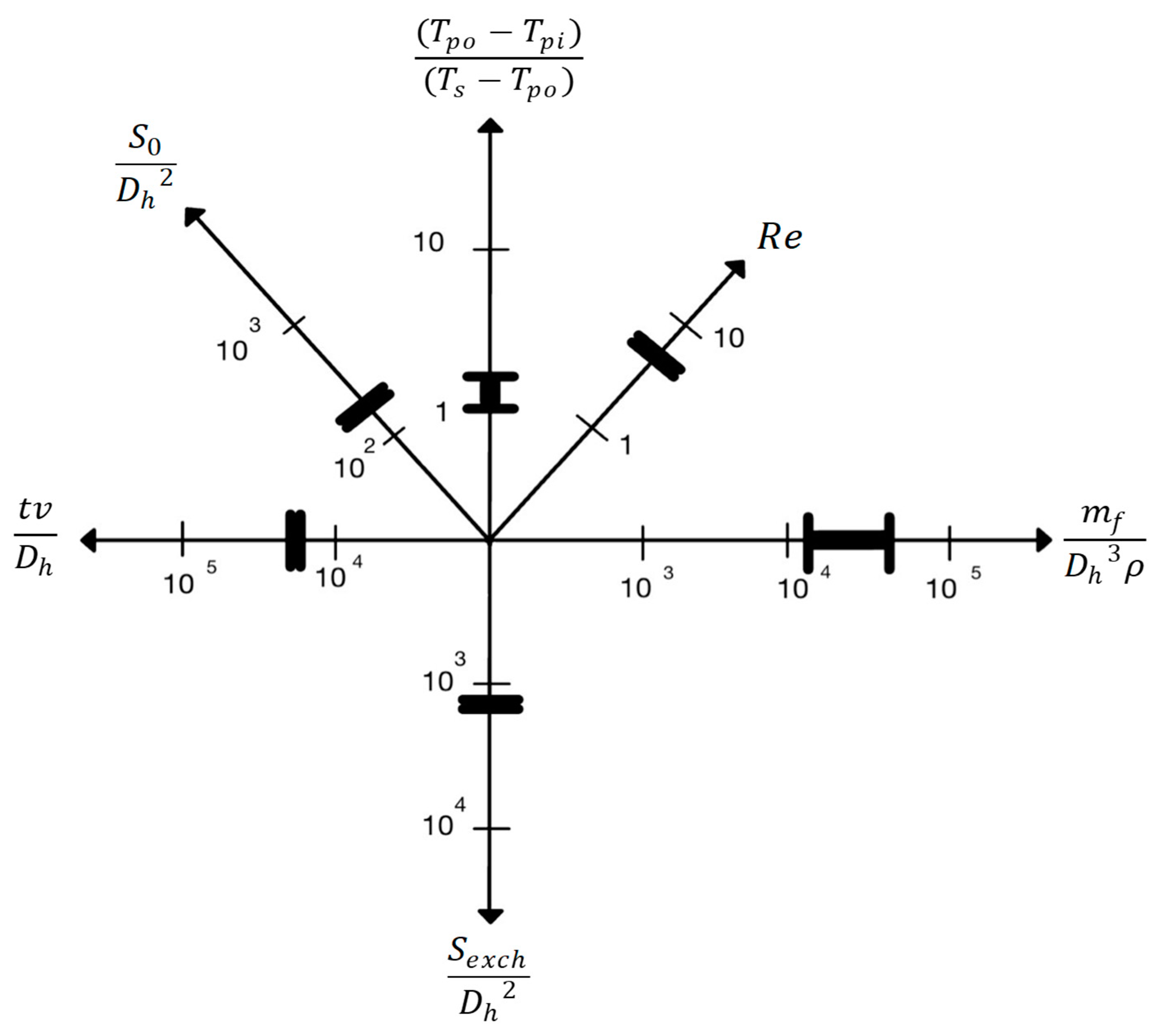

2.4. Dimensional Analysis of Fouling Deposit Mass

- (1)

- relates to the total fouling deposit mass formed on PHE, density of product, and the hydraulic diameter of the plate;

- (2)

- relates to the duration that the product contacts with the heated plate;

- (3)

- is the ratio of the difference of product outlet and inlet temperatures to the difference of surface and product outlet temperatures;

- (4)

- is Reynolds number;

- (5)

- is the ratio of the projected surface area per plate to the hydraulic diameter of the plate;

- (6)

- is the ratio of the total heat exchanging projected surface area to the hydraulic diameter of the flow channel.

2.5. Statistical Analysis

3. Results and Discussion

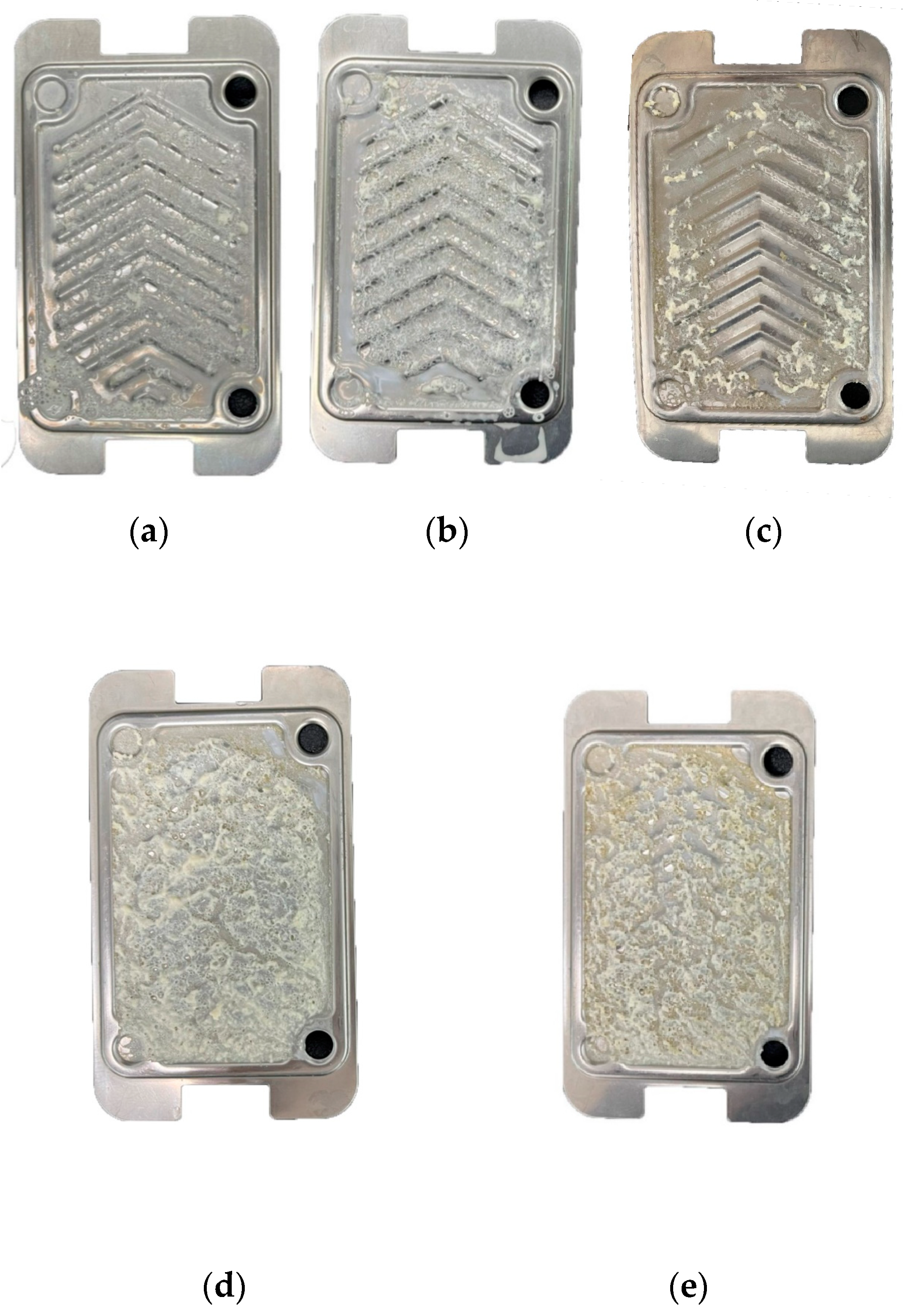

3.1. Predictive Model for Soymilk Fouling Deposit Mass on Heated Surface

3.2. Effect of Temperature

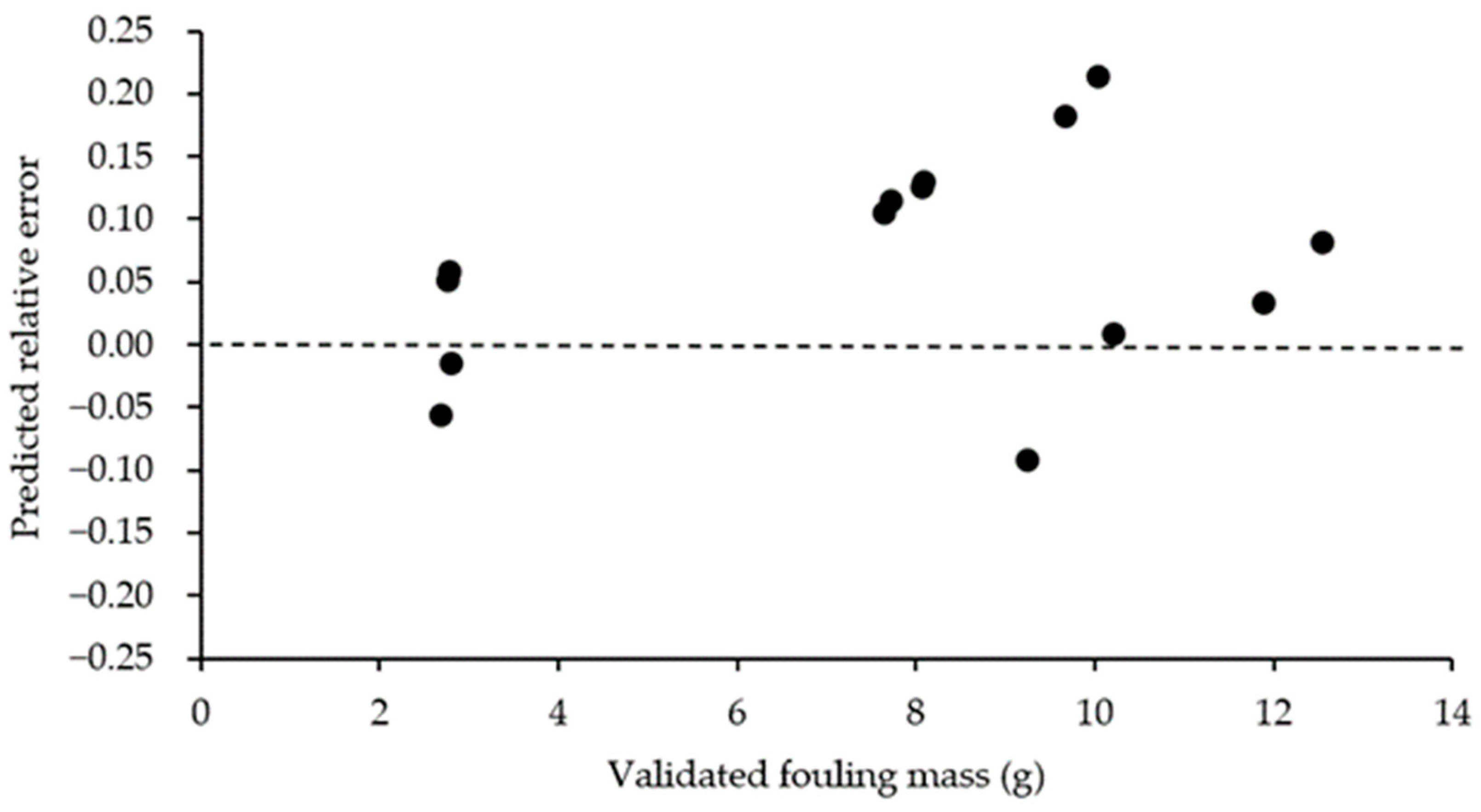

3.3. Prediction Performance of the Developed Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Teixeira, A.A. Thermal Food Preservation Techniques (Pasteurization, Sterilization, Canning and Blanching). In Conventional and Advanced Food Processing Technologies, 1st ed.; Bhattacharya, S., Ed.; John Wiley & Sons: Chichester, UK, 2015; Volume 2, pp. 115–128. [Google Scholar] [CrossRef]

- Wilkens, W.F.; Mattick, L.R.; Hand, D.B. Effect of processing method on oxidative off-flavors of soybean milk. Food Technol. 1967, 21, 1630–1633. [Google Scholar]

- Nelson, A.I.; Wei, L.S.; Steinberg, M.P. Foods from whole soybeans. In World Soybean Research Conference II: Proceedings, 1st ed.; Corbin, F.T., Ed.; West view press: Boulder, CO, USA, 1980; pp. 745–776. [Google Scholar] [CrossRef]

- Bansal, B.; Chen, X.D. A critical review of milk fouling in heat exchangers. Compr. Rev. Food Sci. F 2006, 5, 27–33. [Google Scholar] [CrossRef]

- Quevedo, M.; Kulozik, U.; Karbstein, H.P.; Emin, M.A. Kinetics of denaturation and aggregation of highly concentrated β-lactoglobulin under defined thermomechanical treatment. J. Food Eng. 2020, 274, 109825. [Google Scholar] [CrossRef]

- Awad, M.M. Fouling of heat transfer surfaces. In Heat Transfer—Theoretical Analysis, Experimental Investigations, and Industrial Systems; Belmiloudi, A., Ed.; InTech: Rijeka, Croatia, 2011; p. Ch. 20. [Google Scholar] [CrossRef]

- Fox, P.F. Heat-Induced Changes in Milk, 2nd ed.; International Dairy Federation: Brussels, Belgium, 1995. [Google Scholar]

- Fryer, P.J.; Robbins, P.T.; Green, C.; Schreier, P.J.R.; Pritchard, A.M.; Hasting, A.P.M.; Royston, D.G.; Richardson, J.F. A Statistical Model for Fouling of a Plate Heat Exchanger by Whey Protein Solution at UHT Conditions. Food Bioprod. Process. 1996, 74, 189–199. [Google Scholar] [CrossRef]

- Gu, Y.; Bouvier, L.; Tonda, A.; Delaplace, G. A mathematical model for the prediction of the whey protein fouling mass in a pilot scale plate heat exchanger. Food Control 2019, 106, 106729. [Google Scholar] [CrossRef]

- Alhuthali, S.; Delaplace, G.; Macchietto, S.; Bouvier, L. Whey protein fouling prediction in plate heat exchanger by combining dynamic modelling, dimensional analysis, and symbolic regression. Food Bioprod. Process. 2022, 134, 163–180. [Google Scholar] [CrossRef]

- Pan, F.; Chen, X.D.; Mercadé-Prieto, R.; Xiao, J. Numerical simulation of milk fouling: Taking fouling layer domain and localized surface reaction kinetics into account. Chem. Eng. Sci. 2019, 197, 306–316. [Google Scholar] [CrossRef]

- Petit, J.; Six, T.; Moreau, A.; Ronse, G.; Delaplace, G. β-lactoglobulin denaturation, aggregation, and fouling in a plate heat exchanger: Pilot-scale experiments and dimensional analysis. Chem. Eng. Sci. 2013, 101, 432–450. [Google Scholar] [CrossRef]

- Blanpain-Avet, P.; André, C.; Khaldi, M.; Bouvier, L.; Petit, J.; Six, T. Predicting the distribution of whey protein fouling in a plate heat exchanger using the kinetic parameters of the thermal denaturation reaction of β-lactoglobulin and the bulk temperature profiles. J. Dairy Sci. 2016, 99, 9611–9630. [Google Scholar] [CrossRef]

- Belmar-Beiny, M.T.; Gotham, S.M.; Paterson, W.R.; Fryer, P.J.; Pritchard, A.M. The effect of Reynolds number and fluid temperature in whey protein fouling. J. Food Eng. 1993, 19, 119–139. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Fu, N.; Mercade-Prieto, R.; Chen, X.D. A Comparative Study on Fouling and Cleaning Characteristics of Soy Protein Isolate (SPI). Int. J. Food Eng. 2018, 14, 20170381. [Google Scholar] [CrossRef]

- Indumathy, M.; Sobana, S.; Rames, C.P. Modelling of fouling in a plate heat exchanger with high temperature pasteurisation process. Appl. Therm. Eng. 2021, 189, 116674. [Google Scholar] [CrossRef]

- Post, S. Applied and Computational Fluid Mechanics, 1st ed.; Jones & Bartlett Publishers: Burlington, VT, USA, 2011; Chapter 4; pp. 157–200. [Google Scholar]

- Delaplace, G.; Loubière, K.; Ducept, F.; Jeantet, R. Dimensional Analysis of Food Processes, 1st ed.; ISTE Press-Elsevier: Great Britain, UK, 2015; pp. 1–73. [Google Scholar]

- Georgiadis, M.C.; Macchietto, S. Dynamic modelling and simulation of plate heat exchangers under milk fouling. Chem. Eng. Sci. 2000, 55, 1605–1619. [Google Scholar] [CrossRef]

- Oguntunde, A.O.; Akintoye, O.A. Measurement and comparison of density, specific heat and viscosity of cow’s milk and soymilk. J. Food Eng. 1991, 13, 221–230. [Google Scholar] [CrossRef]

- Liu, Z.; Chang, S.K.C.; Li, L.; Tatsumi, E. Effect of selective thermal denaturation of soybean proteins on soymilk viscosity and tofu’s physical properties. Food Res. Int. 2004, 37, 815–822. [Google Scholar] [CrossRef]

- Yang, W.; Li, D.; Chen, X.D.; Mercade-Prieto, R. Effect of calcium on the fouling of whey protein isolate on stainless steel using QCM-D. Chem. Eng. Sci. 2018, 117, 501–508. [Google Scholar] [CrossRef]

- Iwabuchi, S.; Yamauchi, F. Determination of glycinin and beta-conglycinin in soybean proteins by immunological methods. J. Agr. Food Chem. 1987, 35, 200–205. [Google Scholar] [CrossRef]

- Iwabuchi, S.; Yamauchi, F. Electrophoretic analysis of whey proteins present in soybean globulin fractions. J. Agr. Food Chem. 1987, 35, 205–209. [Google Scholar] [CrossRef]

- Mo, X.; Sun, X. Thermal and mechanical properties of plastics molded from urea-modified soy protein isolates. J. Am. Oil Chem. Soc. 2001, 78, 867–872. [Google Scholar] [CrossRef]

- Nagano, T.; Akasaka, T.; Nishinari, K. Study on the heat-induced conformational changes of β-conglycinin by FTIR and CD analysis. Food Hydrocolloid 1995, 9, 83–89. [Google Scholar] [CrossRef]

- Qingjun, Z.; Yufei, H.; Yeming, C.; Xiangzhen, K. Fouling behavior of soy milk in plate heat exchanger. Food Ferment. Ind. 2020, 46, 182–189. [Google Scholar]

- Zhang, B.Y.; Xu, S.; Villalobos-Santeli, J.A.; Huang, J.Y. Fouling characterization of camel milk with comparison to bovine milk. J. Food Eng. 2020, 285, 110085. [Google Scholar] [CrossRef]

- Chen, X.D.; Bala, P. Investigation of the influences of surface and bulk temperatures upon fouling of milk components onto a stainless steel probe. In Fouling and Cleaning in Food Processing’98; Jesus College: Cambridge, UK, 1998. [Google Scholar]

| Type of Variable | Symbol | Variable Name | Unit | Dimension |

|---|---|---|---|---|

| Target variable | Fouling mass | |||

| Physical variables | ||||

| Product | Density of product 1 | |||

| Dynamic viscosity of product 1 | ||||

| Process | The difference of surface temperature and the product outlet temperature | |||

| Velocity of product 1 | ||||

| The difference of inlet and outlet temperatures of product | ||||

| Heating time 1 | ||||

| Design | Hydraulic diameter 1 | |||

| Total heat exchanging projected surface area 1 | ||||

| Projected surface area per plate 1 |

| K | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| M | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 |

| L | 0 | 0 | 0 | −1 | 2 | 2 | 1 | 1 | −3 | 0 |

| T | 0 | 1 | 0 | −1 | 0 | 0 | 0 | −1 | 0 | 0 |

| Product Inlet Temperature (Tpi, °C) | Surface Temperature (Ts, °C) | Product Outlet Temperature (Tpo, °C) |

|---|---|---|

| 50 | 65 | 60.43 ± 0.34 |

| 50 | 70 | 65.67 ± 0.21 |

| 50 | 75 | 67.07 ± 0.46 |

| 50 | 80 | 70.24 ± 0.05 |

| 55 | 65 | 61.62 ± 0.28 |

| 55 | 70 | 66.85 ± 0.15 |

| 55 | 75 | 69.29 ± 0.24 |

| 55 | 80 | 70.73 ± 0.68 |

| 55 | 85 | 72.25 ± 0.11 |

| Exponent | Standard Error | p-Value | |

|---|---|---|---|

| 0.053 | 0.208 | <0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sritham, E.; Nunak, N.; Ongwongsakul, E.; Chaishome, J.; Schleining, G.; Suesut, T. Development of Mathematical Model to Predict Soymilk Fouling Deposit Mass on Heat Transfer Surfaces Using Dimensional Analysis. Computation 2023, 11, 83. https://doi.org/10.3390/computation11040083

Sritham E, Nunak N, Ongwongsakul E, Chaishome J, Schleining G, Suesut T. Development of Mathematical Model to Predict Soymilk Fouling Deposit Mass on Heat Transfer Surfaces Using Dimensional Analysis. Computation. 2023; 11(4):83. https://doi.org/10.3390/computation11040083

Chicago/Turabian StyleSritham, Eakasit, Navaphattra Nunak, Ekarin Ongwongsakul, Jedsada Chaishome, Gerhard Schleining, and Taweepol Suesut. 2023. "Development of Mathematical Model to Predict Soymilk Fouling Deposit Mass on Heat Transfer Surfaces Using Dimensional Analysis" Computation 11, no. 4: 83. https://doi.org/10.3390/computation11040083

APA StyleSritham, E., Nunak, N., Ongwongsakul, E., Chaishome, J., Schleining, G., & Suesut, T. (2023). Development of Mathematical Model to Predict Soymilk Fouling Deposit Mass on Heat Transfer Surfaces Using Dimensional Analysis. Computation, 11(4), 83. https://doi.org/10.3390/computation11040083