Multi-Dimensional Control Rules and Assessment Methods for Surface Engineering Data Quality in Oil and Gas Field

Abstract

1. Introduction

1.1. Motivation

1.2. Literature Review

1.3. Contributions

- (1)

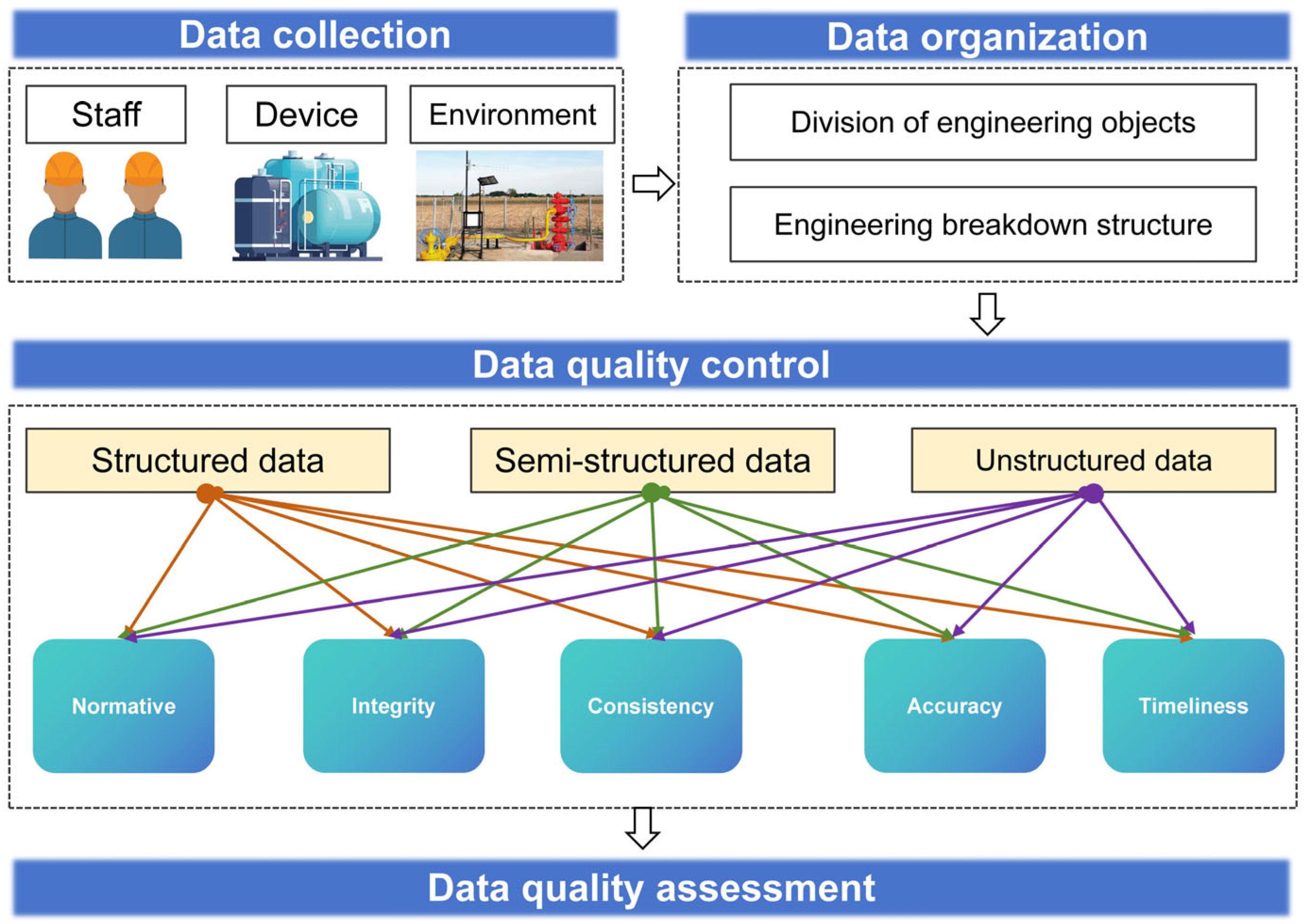

- To ensure standardized control of the data, classify the data types as structured, semi-structured, and unstructured and the quality characteristics as normative, integrity, consistency, accuracy, and timeliness.

- (2)

- Review rules for five characteristics based on quality characteristics have been established to fill the technical gap in the quantitative verification of oil and gas field engineering data quality.

- (3)

- By integrating the AHP and EWM, a combined subjective and objective weight calculation method was formed to achieve quantitative assessments and scientific diagnosis of data quality indicators.

- (4)

- Through project examples, it is known that the application of data review rules and quality assessment methods can systematically guarantee the quality of on-site delivered data, providing a standardized data governance paradigm and quantitative decision support for the digital transformation, intelligent operation, and maintenance of oil and gas field surface engineering.

1.4. Paper Organization

2. System Description

3. Digital Delivery Data Quality Rules

3.1. Normative

3.2. Integrity

3.3. Consistency

3.4. Accuracy

3.5. Timeliness

4. Digital Delivery Data Quality Assessment Methods

4.1. Data Quality Assessment System

4.2. Data Quality Quantification Method

4.3. Weighting Calculation Method

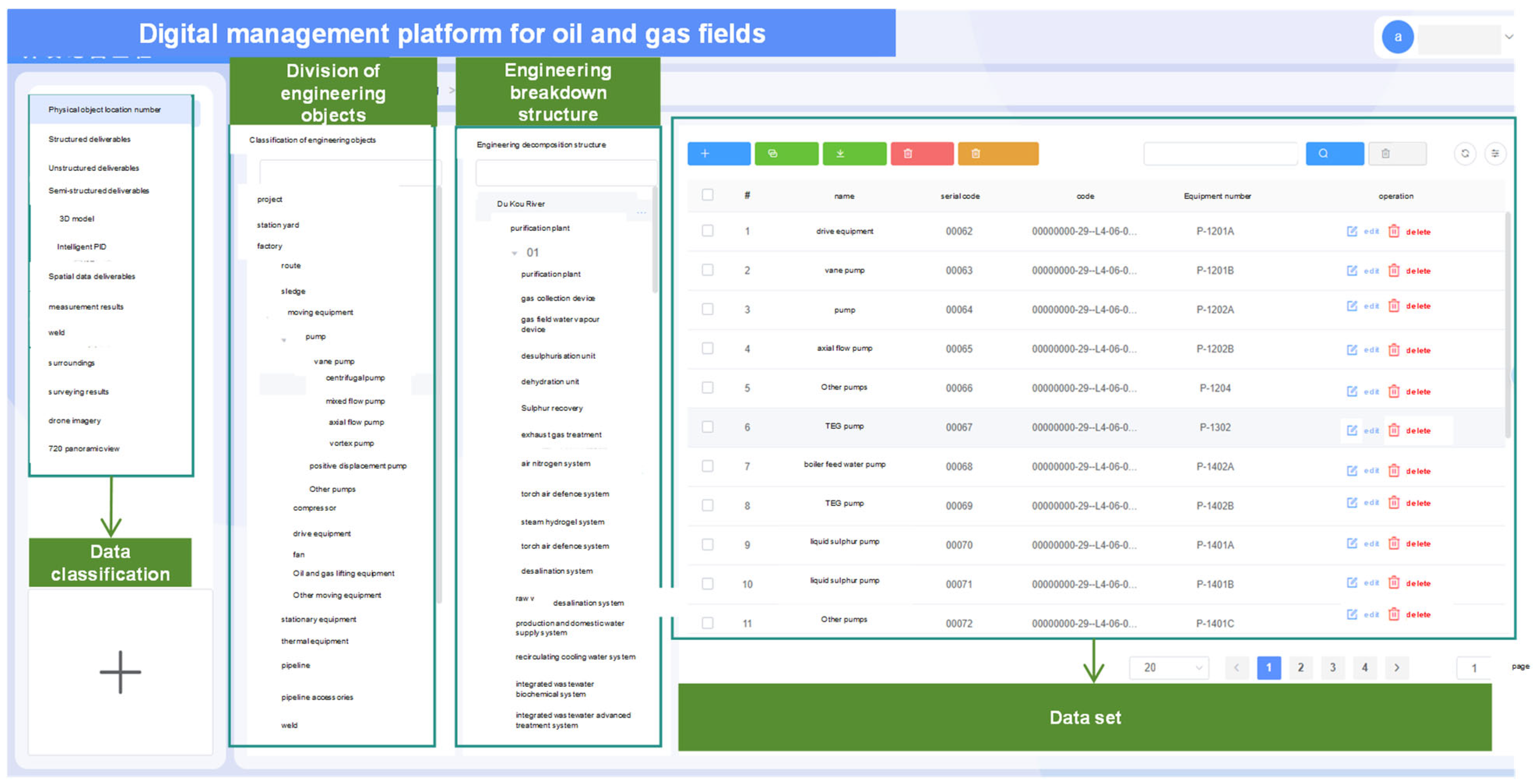

5. Digital Delivery of Data Organization Instances

5.1. Data Collection and Classification

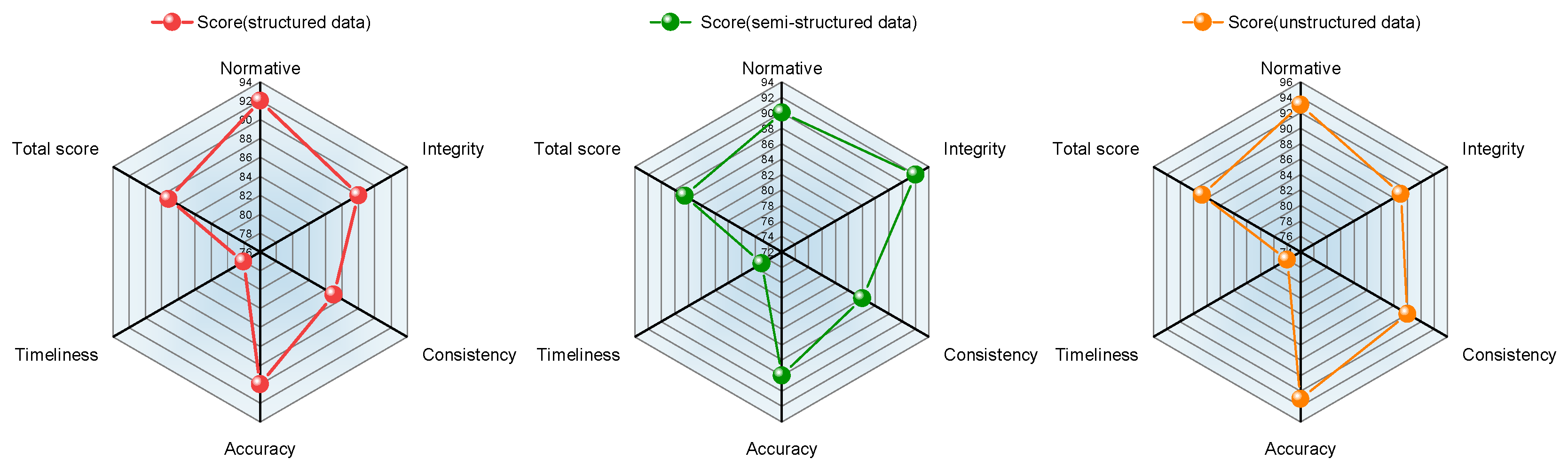

5.2. Weight Calculation Results

5.3. Data Quality Assessment Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sylthe, O.; Brewer, T. The impact of digitalization on offshore operations. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April 2018. [Google Scholar]

- Wang, H.F. The Research of Digital Construction of Daqing Oilfield. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2013. [Google Scholar]

- Qian, L. Problems and Countermeasures in Digital Construction of Oilfields. Small Medium-Sized Enterp. Manag. Technol. 2016, 1, 234. [Google Scholar]

- Fang, Z. Research on the Application of Internet of Things Technology in the Digital Construction of Oilfields. Chem. Eng. Des. Commun. 2021, 47, 11–12. [Google Scholar]

- Tai, L.M. Research and Discussion on the Digitization Examination of the Construction Drawing Design Document. Eng. Constr. Des. 2019, 24, 277–278. [Google Scholar]

- Zhang, P.H. Research of the Isomerous EDA Design Data Checkup Technology in Digitalization Test Systems. Master’s Thesis, Xidian Science and Technology University, Xi’an, China, 2009. [Google Scholar]

- Alwan, A.A.; Ciupala, M.A.; Brimicombe, A.J.; Ghorashi, S.A.; Baravalle, A.; Falcarin, P. Data Quality Challenges in Large-scale Cyber-Physical Systems: A Systematic Review. Inf. Syst. 2022, 105, 101951. [Google Scholar] [CrossRef]

- Zhang, X.X.; Du, P.; Chen, H.; Lu, Y.J.; Zhang, J.Q. Research and Implementation of Quality Inspection Model for Basic Data of Science and Technology Based on Custom Constraint Rules. J. Sci. Technol. Resour. China 2017, 49, 60–67. [Google Scholar]

- Song, H.T.; Yu, J.S.; Han, Q.L. Industrial Multivariate Time Series Data Quality Assessment Method. Appl. Comput. 2024, 44, 1743–1750. [Google Scholar]

- Wang, C.P.; Meng, L.; Feng, X.Z.; Wang, J.J.; Cui, X.Q.; Wu, R. Research and Application of Digital Technology in Surface Construction Engineering of Oil and Gas Fields. In Proceedings of the 32nd National Natural Gas Academic Conference (2020), Chongqing, China, 12–14 November 2020; pp. 3051–3072. [Google Scholar]

- Yin, C.L. Technical Integration and Integration of Heterogeneous Data Sources of Oilfield Digitisation. Chem. Manag. 2021, 34, 191–192. [Google Scholar]

- Cheng, M.L.; Xue, J.; Zhang, C.S.; Zhang, B.N.; Tang, Z.G. Practice and Exploration of Digital Construction of Surface Engineering in Desert Oilfields. China Instrum. 2021, 09, 81–84. [Google Scholar]

- Ren, S.H. Construction of Digital Construction Mode for Oilfield Stations. China Pet. Chem. Stand. Qual. 2023, 43, 50–52. [Google Scholar]

- Li, Y.; Lyu, H.; Liu, L.; Yin, L. Practice and Understanding of Oilfield Digitalisation Construction. China Plant Eng. 2023, 47–50. Available online: https://caod.oriprobe.com/articles/65482725/you_tian_shu_zi_hua_jian_she_de_shi_jian_yu_ren_sh.htm (accessed on 11 August 2025).

- Sun, F.T. Exploration and Practice of Internet of Things Technology in the Construction of Oilfield Digitization. Inf. Comput. 2025, 37, 76–78. [Google Scholar]

- Wang, C.C. Discussion on the Problems and Countermeasures of Digital Construction in Oilfields. China Pet. Chem. Stand. Qual. 2025, 45, 91–93. [Google Scholar]

- Chernov, A.V.; Chernova, V.A.; Kolganova, E.V. Prioritization of Key Areas of the Digitalization Strategy of Energy Complex Enterprises Based on the Analytical Hierarchy Process (AHP). Unconv. Resour. 2025, 6, 100154. [Google Scholar] [CrossRef]

- Yin, Y.; Song, C.; Jing, Y.; Zhang, S.; Ye, S.; Wang, Y.; Gao, P. EWMS: A Software Tool for Interactively Using Entropy Weight Coefficient Method for Aggregating Sustainability Indicators. Environ. Model. Softw. 2025, 19, 106500. [Google Scholar] [CrossRef]

- Han, G.; Feng, G.; Tang, C.; Pan, C.; Zhou, W.; Zhu, J. Evaluation of the Ventilation Mode in an ISO Class 6 Electronic Cleanroom by the AHP-Entropy Weight Method. Energy 2023, 284, 128586. [Google Scholar] [CrossRef]

- Jing, Y. Research on Safe Mining Risk Control System of Deep Phosphate Mine Based on Analytic Hierarchy Process and Fuzzy Comprehensive Evaluation Method. Master’s Thesis, Wuhan Institute of Technology, Wuhan, China, 2023. [Google Scholar]

- Wu, D.X. Construction Safety Risk Management of New Airport Project Based on Analytic Hierarchy Process. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 2023. [Google Scholar]

- Li, Z.H. Research on WRSN Charging Planning Algorithm Based on Energy Consumption Optimization and Analytic Hierarchy Process. Master’s Thesis, Guilin University of Technology, Guilin, China, 2023. [Google Scholar]

- Taggart, J.; Liaw, S.T.; Yu, H. Structured Data Quality Reports to Improve EHR Data Quality. Int. J. Med. Inform. 2015, 84, 1094–1098. [Google Scholar] [CrossRef] [PubMed]

- Presser, K.; Hinterberger, H.; Weber, D.; Norrie, M. A Scope Classification of Data Quality Requirements for Food Composition Data. Food Chem. 2016, 193, 166–172. [Google Scholar] [CrossRef] [PubMed]

- Du, H.L. Post-evaluation Research of Wind Power Projects Based on AHP-entropy Weight Method. Master’s Thesis, North China University of Technology, Beijing, China, 2023. [Google Scholar]

- Zou, L. Value Evaluation of WeChat Subscription Official Account Based on AHP-Entropy Weight Method and Grey Correlation Analysis. Master’s Thesis, Chongqing University of Technology, Chongqing, China, 2023. [Google Scholar]

- Wang, H.D. Ergonomic Research and Design of Automatic Follow Maintenance Cart Based on Simulation Analysis and AHP-Entropy Weight Method. Master’s Thesis, East China University of Science and Technology, Shanghai, China, 2022. [Google Scholar]

- Liu, Y.X. Research on Risk Evaluation and Optimization of Internal Control of Engineering Projects Based on FCE—Taking School A as an Example. Master’s Thesis, Chongqing University of Technology, Chongqing, China, 2023. [Google Scholar]

- Zhang, M.Y. Power Transmission Project Based on Fuzzy Comprehensive Evaluation Method Social Stability Risk Assessment. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2023. [Google Scholar]

- Q/SY 01015-2022; Specification for digital delivery of oil and gas field surface engineering. China National Petroleum Corporation: Beijing, China, 2022.

| Scale | Meaning |

|---|---|

| 1 | Equally important |

| 3 | Slightly more important |

| 5 | Moderately more important |

| 7 | Strongly more important |

| 9 | Extremely more important |

| 2/4/6/8 | Intermediate values between adjacent scales |

| Indicator Names | Subjective Weight | Consistency Test |

|---|---|---|

| Normative | 0.35 | √ |

| Integrity | 0.28 | √ |

| Consistency | 0.17 | √ |

| Accuracy | 0.12 | √ |

| Timeliness | 0.08 | √ |

| Sample | Normative Rate | Integrity Rate | Consistency Rate | Accuracy Rate | Timeliness Rate |

|---|---|---|---|---|---|

| 1 | 92 | 88 | 85 | 90 | 78 |

| 2 | 85 | 90 | 88 | 92 | 82 |

| 3 | 88 | 86 | 90 | 85 | 80 |

| 4 | 90 | 92 | 84 | 88 | 75 |

| 5 | 86 | 85 | 92 | 90 | 85 |

| 6 | 94 | 88 | 86 | 92 | 78 |

| 7 | 89 | 90 | 89 | 87 | 82 |

| 8 | 91 | 87 | 85 | 91 | 80 |

| 9 | 87 | 91 | 88 | 86 | 83 |

| 10 | 93 | 89 | 90 | 93 | 76 |

| Index Names | Objective Weight |

|---|---|

| Normative | 0.31 |

| Integrity | 0.23 |

| Consistency | 0.19 |

| Accuracy | 0.17 |

| Timeliness | 0.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, T.; Wang, F.; Huang, Z.; Zhang, W.; Chen, G.; Zhou, J.; Liu, C. Multi-Dimensional Control Rules and Assessment Methods for Surface Engineering Data Quality in Oil and Gas Field. Information 2025, 16, 701. https://doi.org/10.3390/info16080701

Xia T, Wang F, Huang Z, Zhang W, Chen G, Zhou J, Liu C. Multi-Dimensional Control Rules and Assessment Methods for Surface Engineering Data Quality in Oil and Gas Field. Information. 2025; 16(8):701. https://doi.org/10.3390/info16080701

Chicago/Turabian StyleXia, Taiwu, Feng Wang, Zhan Huang, Wei Zhang, Gangping Chen, Jun Zhou, and Cui Liu. 2025. "Multi-Dimensional Control Rules and Assessment Methods for Surface Engineering Data Quality in Oil and Gas Field" Information 16, no. 8: 701. https://doi.org/10.3390/info16080701

APA StyleXia, T., Wang, F., Huang, Z., Zhang, W., Chen, G., Zhou, J., & Liu, C. (2025). Multi-Dimensional Control Rules and Assessment Methods for Surface Engineering Data Quality in Oil and Gas Field. Information, 16(8), 701. https://doi.org/10.3390/info16080701