An Integrated PLS-SEM-TOPSIS-Sort Approach for Assessing ERP Solutions Acceptance Across Various Industries

Abstract

1. Introduction

2. Literature Review

3. Hypothesis Development

3.1. Work Compatibility (WC)

3.2. Perceived Usefulness (PU)

3.3. Perceived Ease of Use (PEoU)

3.4. External Factors (EF)

4. Research Methodology

4.1. Data Collection

4.2. PLS-SEM Approach

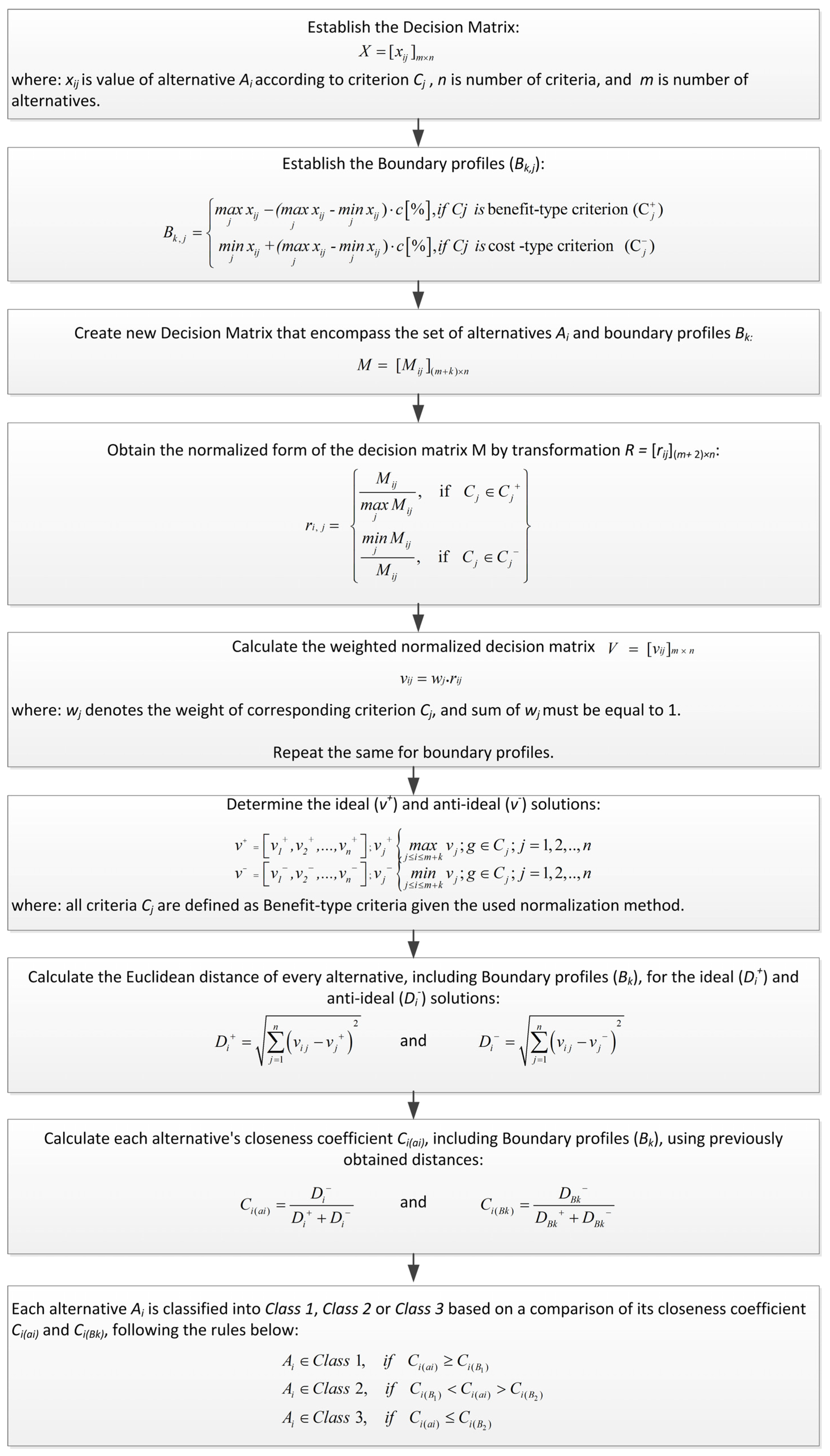

4.3. TOPSIS-Sort Approach

# --- TOPSIS-SORT function (returns results and thresholds as Series) def topsis_sort_step4_all_benefit(X, weights, criteria_types_norm, boundary_profiles): X = pd.DataFrame(X).copy() m, n = X.shape w = np.asarray(weights, dtype = float) w = w/w.sum() ctype = [str(ct).lower() for ct in criteria_types_norm] B = pd.DataFrame(boundary_profiles).copy() B.columns = X.columns M = pd.concat([X, B], axis = 0) R = pd.DataFrame(index = M.index, columns = M.columns, dtype = float) for j, ct in enumerate(ctype): col = M.iloc[:, j].astype(float).values if ct == “benefit”: denom = float(col.max()) R.iloc[:, j] = col/denom if denom != 0 else 0.0 else: numer = float(col.min()) col = np.where(col == 0.0, np.finfo(float).eps, col) R.iloc[:, j] = numer/col V = R * w v_plus = V.max().values v_minus = V.min().values D_plus_all = np.linalg.norm(V.values - v_plus, axis = 1) D_minus_all = np.linalg.norm(V.values - v_minus, axis = 1) Ci_all = D_minus_all/(D_plus_all + D_minus_all) Ci_alt = pd.Series(Ci_all[:m], index = X.index, name = “Ci”) Ci_prof = pd.Series(Ci_all[m:], index = B.index, name = “Ci”) thr_sorted = Ci_prof.sort_values(ascending = False) # Series thr_values = thr_sorted.values def _assign(ci): for idx, thr in enumerate(thr_values, start = 1): if ci >= thr: return idx return len(thr_values) + 1 classes = Ci_alt.apply(_assign) results = pd.DataFrame({“Ci”: Ci_alt, “Class”: classes}) return results, thr_sorted

5. Results and Discussion

5.1. PLS-SEM Method

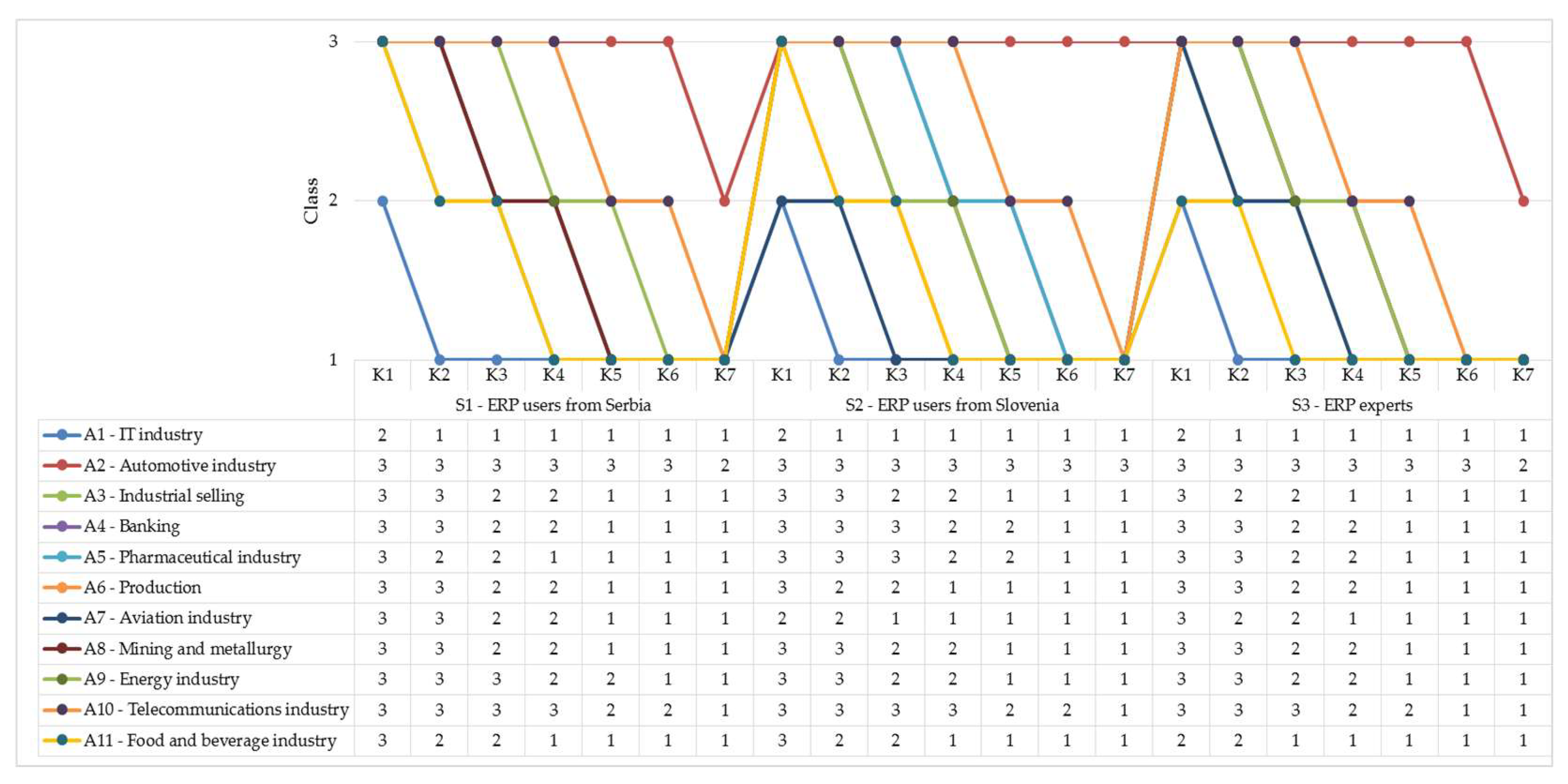

5.2. TOPSIS-Sort Method

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ERP | Enterprise Resource Planning |

| MCDA | Multi-Criteria Decision Analysis |

| PLS-SEM | Partial least squares structural equation modeling |

| BC | Balkan countries |

| EU | European Union |

| IT | Internet technology |

| VIKOR | VIsekriterijumsko KOmpromisno Rangiranje |

| TOPSIS | Technique for Order Performance by Similarity to the Ideal Solution |

| AHP | Analytic Hierarchy Process |

| CODAS | Combinative Distance-based Assessment |

| MACBETH | Measuring Attractiveness by a Categorization-Based Evaluation Technique |

| PROMETHEE | Preference Ranking Organization Method for Enrichment Evaluation |

| WC | Work Compatibility |

| PU | Perceived Usefulness |

| PEoU | Perceived Ease of Use |

| EF | External Factors |

| SC | System Complexity |

| SP | System Performance |

| UM | User manuals |

| SI | Social Influence |

| BPF | Business Process Fit |

| AT | Attitude to Use |

| CR | Composite Reliability |

| AVE | Average Variance Extracted |

| HTMT | Heterotrait-monotrait matrix |

Appendix A. Measurement Scale Items

| Construct and Scale Items | Min | Max | Mean | Std. Dev. | Skewness | Kurtosis | |

| Work Compatibility | |||||||

| WC_1 | Using ERP system is compatible with all aspects of my work. | 1 | 5 | 3.80 | 1.033 | −0.651 | −0.274 |

| WC_2 | Using ERP system fits well with the way I like to work. | 1 | 5 | 3.91 | 1.005 | −0.810 | −0.012 |

| WC_3 | Using ERP system fits into my work style. | 1 | 5 | 3.99 | 0.938 | −0.821 | 0.180 |

| Perceived Usefulness | |||||||

| PU_1 | Using ERP solution in my job enables me to accomplish tasks more quickly. | 1 | 5 | 3.99 | 1.003 | −1.035 | 0.624 |

| PU_2 | Using ERP solution improves my job performance. | 1 | 5 | 3.96 | 1.016 | −0.936 | 0.350 |

| Perceived Ease of Use | |||||||

| PEoU_1 | My interaction with ERP solution is clear and understandable. | 1 | 5 | 3.70 | 1.001 | −0.569 | −0.328 |

| PEoU_2 | I find ERP solution is easy to use. | 1 | 5 | 3.58 | 1.056 | −0.469 | −0.631 |

| System Complexity | |||||||

| SC_1 | Using the ERP system takes too much time for my normal duties. | 1 | 5 | 2.47 | 1.196 | 0.391 | −0.912 |

| SC_2 | Using the ERP system is so complicated. | 1 | 5 | 2.42 | 1.208 | 0.510 | −0.839 |

| SC_3 | Using the ERP system involves too much doing mechanical operations. | 1 | 5 | 2.55 | 1.136 | 0.337 | −0.845 |

| System Performance | |||||||

| SP_1 | It is fast to search data in the ERP system. | 1 | 5 | 3.82 | 1.089 | −0.883 | 0.060 |

| SP_2 | The ERP system loads quickly. | 1 | 5 | 3.98 | 0.936 | −0.851 | 0.165 |

| SP_3 | I was able to retrieve data quickly. | 2 | 5 | 3.98 | 0.887 | −0.777 | 0.054 |

| SP_4 | It is fast to create a new record (vendor, customer, etc.) in this system. | 1 | 5 | 3.99 | 0.975 | −0.864 | 0.226 |

| SP_5 | I finish my tasks in ERP system quickly | 1 | 5 | 3.85 | 0.987 | −0.731 | −0.130 |

| User Manuals | |||||||

| UM_1 | The content and index of the user manuals are useful. | 1 | 5 | 3.47 | 1.080 | −0.563 | −0.309 |

| UM_2 | The user manuals are current (up to date). | 1 | 5 | 3.45 | 1.093 | −0.471 | −0.365 |

| UM_3 | The user manuals are complete. | 1 | 5 | 3.54 | 1.056 | −0.518 | −0.225 |

| Social Influence | |||||||

| SI_1 | My supervisor is very supportive of the use of the ERP system for my job. | 1 | 5 | 4.25 | 1.011 | −1.314 | 0.961 |

| SI_2 | In general, the organization has supported the use of the ERP system. | 1 | 5 | 4.30 | 0.989 | −1.649 | 2.303 |

| SI_3 | People who are important to me think that I should use the ERP system. | 1 | 5 | 4.04 | 1.022 | −0.832 | −0.122 |

| Business Process Fit | |||||||

| BPF_1 | The ERP solution fits well with the business needs of me | 1 | 5 | 4.06 | 0.969 | −1.147 | 0.943 |

| BPF_2 | The ERP solution fits well with the business need of my department. | 1 | 5 | 4.09 | 0.972 | −1.153 | 0.937 |

| BPF_3 | I believe that there are not important problems with the way the ERP system is managed. | 1 | 5 | 3.60 | 1.065 | −0.521 | −0.469 |

| BPF_4 | The system maintenance and the way it is provided meet my need adequately. | 1 | 5 | 4.18 | 0.850 | −1.090 | 1.253 |

| Attitude to Use | |||||||

| AT_1 | Using the ERP system is a good idea. | 1 | 5 | 4.40 | 0.797 | −1.725 | 3.989 |

| AT_2 | I like the idea of using the ERP system to perform my job. | 1 | 5 | 4.19 | 0.941 | −1.165 | 0.806 |

References

- Durmishi, C.T.; Bilic, S. Integration of digital technologies by businesses in Western Balkan countries. Knowl. Int. J. 2024, 62, 85–90. Available online: https://ojs.ikm.mk/index.php/kij/article/view/6563 (accessed on 1 September 2025).

- Mullins, J.K.; Cronan, T.P. Enterprise systems knowledge, beliefs, and attitude: A model of informed technology acceptance. Int. J. Inf. Manag. 2021, 59, 102348. [Google Scholar] [CrossRef]

- Ram, J.; Corkindale, D.; Wu, M.L. ERP adoption and the value creation: Examining the contributions of antecedents. J. Eng. Technol. Manag. 2014, 33, 113–133. [Google Scholar] [CrossRef]

- Gupta, S.; Misra, S.C.; Kock, N.; Roubaud, D. Organizational, technological and extrinsic factors in the implementation of cloud ERP in SMEs. J. Organ. Change Manag. 2018, 31, 83–102. [Google Scholar] [CrossRef]

- Aggarwal, I.; Anirudh, A.; Buddala, R. Literature review: ERP implementation in various industries. In Proceedings of the 3rd Innovations in Power and Advanced Computing Technologies (i-PACT), Kuala Lumpur, Malaysia, 27–29 November 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Lee, S.; Kim, D. The effects of industry classification on a successful ERP implementation model. J. Inf. Process. Syst. 2016, 12, 169–181. [Google Scholar] [CrossRef]

- Eurostat. E-business Integration: Enterprise Resource Planning (ERP). Eurostat Statistics Explained 2024. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=E-business_integration#Enterprise_resource_planning_.28ERP.29 (accessed on 15 June 2025).

- Salimi, F.; Dankbaar, B.; Davidrajuh, R. A comprehensive study on the differences in ERP implementation between manufacturing and service industry. J. Int. Technol. Inf. Manag. 2006, 15, 2. [Google Scholar] [CrossRef]

- Goumas, S.; Charamis, D.; Tabouratzi, E. Accounting benefits of ERP systems across the different manufacturing industries of SMEs. Int. J. Econ. Bus. Adm. 2018, 6, 3–20. [Google Scholar] [CrossRef]

- Mutoriq, A.; Purwinarko, A. Measuring the acceptance level of user interface design of ERP system at PT Allure Alluminio using technology acceptance model (TAM) method. J. Adv. Inf. Syst. Technol. 2023, 5, 222–241. [Google Scholar] [CrossRef]

- Hussain, M.K.; Siddique, A.; Kazmi, H.; Obaidullah, N. Factors affecting user acceptance of ERP systems in SMEs. Bull. Multidiscip. Stud. 2024, 1, 1–13. [Google Scholar] [CrossRef]

- Razzaq, I.M.; Saputra, M. Analyzing end-user acceptance of SaaS-based ERP systems in hospitality in Bali: A UTAUT 3 model approach with SEM-PLS using R programming. In Proceedings of the 8th International Conference on Information Technology (InCIT), Chonburi, Thailand, 14–15 November 2024; pp. 301–306. [Google Scholar]

- Ijadi Maghsoodi, A.; Azizi-Ari, I.; Barzegar-Kasani, Z.; Azad, M.; Zavadskas, E.K.; Antucheviciene, J. Evaluation of the influencing factors on job satisfaction based on combination of PLS-SEM and F-MULTIMOORA approach. Symmetry 2018, 11, 24. [Google Scholar] [CrossRef]

- Ilin, V.; Ivetić, J.; Simić, D. Understanding the determinants of e-business adoption in ERP-enabled firms and non-ERP-enabled firms: A case study of the Western Balkan Peninsula. Technol. Forecast. Soc. Change 2017, 125, 206–223. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, J.; Li, Z. Digital technology implementation: The mediating role of the duality of digital technology affordance in open innovation practices. J. Eng. Technol. Manag. 2024, 73, 101832. [Google Scholar] [CrossRef]

- Hansen, K.; Haddara, M.; Langseth, M. Exploring multi-criteria decision-making methods in ERP selection. Procedia Comput. Sci. 2023, 219, 879–888. [Google Scholar] [CrossRef]

- Grandón, E.E.; Díaz-Pinzón, B.; Magal, S.R.; Rojas-Contreras, K. Technology acceptance model validation in an educational context: A longitudinal study of ERP system use. J. Inf. Syst. Eng. Manag. 2021, 6, em0134. [Google Scholar] [CrossRef] [PubMed]

- Fahmi, M.A.; Kostini, N.; Putra, W.B.T.S. Exploring hybrid learning readiness and acceptance model using the extended TAM 3 and TPB approach: An empirical analysis. Int. J. Res. Bus. Soc. Sci. 2022, 11, 321–334. [Google Scholar] [CrossRef]

- Salas, W.H. Model to improve an ERP implementation based on agile best practice: A Delphi study. Procedia Comput. Sci. 2023, 219, 1785–1792. [Google Scholar] [CrossRef]

- Botta-Genoulaz, V.; Millet, P.A. An investigation into the use of ERP systems in the service sector. Int. J. Prod. Econ. 2006, 99, 202–221. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Pimenov, D.Y.; Mikolajczyk, T.; Moldovan, L. Automation of production activities of an industrial enterprise based on the ERP system. Procedia Manuf. 2020, 46, 525–532. [Google Scholar] [CrossRef]

- Sadrzadehrafiei, S.; Chofreh, A.G.; Hosseini, N.K.; Sulaiman, R. The benefits of enterprise resource planning (ERP) system implementation in dry food packaging industry. Procedia Technol. 2013, 11, 220–226. [Google Scholar] [CrossRef]

- Zadeh, A.H.; Akinyemi, B.A.; Jeyaraj, A.; Zolbanin, H.M. Cloud ERP systems for small- and medium enterprises: A case study in the food industry. J. Cases Inf. Technol. 2018, 20, 53–70. [Google Scholar] [CrossRef]

- Salih, S.; Abdelsalam, S.; Hamdan, M.; Ibrahim, A.O.; Abulfaraj, A.W.; Binzagr, F.; Abdallah, A.E. The CSFs from the perspective of users in achieving ERP system implementation and post-implementation success: A case of Saudi Arabian food industry. Sustainability 2022, 14, 15942. [Google Scholar] [CrossRef]

- Nikam, S.; Mahatme, R.; More, R. To study factors influencing adoption of ERP system in the automobile sector. Online J. Distance Educ. E-Learn. 2023, 11, 1699–1707. Available online: https://www.tojsat.net/journals/tojdel/articles/v11i02/v11i02-87.pdf (accessed on 15 July 2025).

- Gaol, F.L.; Deniansyah, M.F.; Matsuo, T. The measurement impact of ERP system implementation on the automotive industry business process efficiency. Int. J. Bus. Inf. Syst. 2023, 43, 429–442. [Google Scholar] [CrossRef]

- Vukman, K.; Klarić, K.; Greger, K.; Perić, I. Driving efficiency and competitiveness: Trends and innovations in ERP systems for the wood industry. Forests 2024, 15, 230. [Google Scholar] [CrossRef]

- Hewavitharana, S.; Perera, A.; Perera, S.; Perera, P.; Nanayakkara, S. Framework for systematic adoption of ERP systems in the Sri Lankan construction industry. Built Environ. Proj. Asset Manag. 2025, 15, 629–646. [Google Scholar] [CrossRef]

- Grubić, G.; Ratković, M. The analysis of available ERP solutions and trends in industry of management information systems. Pract. Manag. 2012, 3, 86–92. [Google Scholar]

- Sternad, S.; Bobek, S. Impacts of TAM-based external factors on ERP acceptance. Procedia Technol. 2013, 9, 33–42. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Wamba, S.F.; Kamdjoug, J.R.K. Exploring the determinants of ERP adoption intention: The case of ERP-enabled emergency service. Int. J. Technol. Diffus. 2019, 10, 58–76. [Google Scholar] [CrossRef]

- Putri, A.D.; Lubis, M.; Azizah, A.H. Analysis of critical success factors (CSF) in enterprise resource planning (ERP) implementation using extended technology acceptance model (TAM) at trading and distribution company. In Proceedings of the 4th International Conference on Electrical, Telecommunication and Computer Engineering (ELTICOM), Medan, Indonesia, 3–4 September 2020; pp. 129–135. [Google Scholar] [CrossRef]

- Limantara, N.; Edbert, I.S.; Widjaya, P.J.; Adina, M. User acceptance analysis on intacs ERP distribution application using technology acceptance model. ICIC Express Lett. 2021, 15, 349–355. [Google Scholar] [CrossRef]

- Jin, W. Extension of VIKOR method for ERP software selection. In Proceedings of the International Society for Optical Engineering (SPIE), San Diego, CA, USA, 21–25 August 2022; Volume 12168, pp. 517–523. [Google Scholar] [CrossRef]

- Ayağ, Z.; Samanlioglu, F. A hesitant fuzzy linguistic terms set-based AHP-TOPSIS approach to evaluate ERP software packages. Int. J. Intell. Comput. Cybern. 2021, 14, 54–77. [Google Scholar] [CrossRef]

- Uddin, M.R.; Al Noman, A.; Tasnim, F.; Nafisa, N.; Hossain, S. A hybrid MCDM approach based on AHP and TOPSIS to select an ERP system in Bangladesh. In Proceedings of the IEEE International Conference on Information and Communication Technology for Sustainable Development (ICICT4SD), Dhaka, Bangladesh, 27–28 February 2021; pp. 161–165. [Google Scholar] [CrossRef]

- Aydoğmuş, H.Y.; Kamber, E.; Kahraman, C. ERP selection using picture fuzzy CODAS method. J. Intell. Fuzzy Syst. 2021, 40, 11363–11373. [Google Scholar] [CrossRef]

- Yurtyapan, M.S.; Aydemir, E. ERP software selection using intuitionistic fuzzy and interval grey number-based MACBETH method. Grey Syst. 2022, 12, 78–100. [Google Scholar] [CrossRef]

- Dağci Yüksel, B.; Ersöz, F. Evaluation of ERP software selection criteria with fuzzy AHP approach: An application in the metal production enterprises in the aviation industry. Int. J. Syst. Assur. Eng. Manag. 2024, 15, 2656–2667. [Google Scholar] [CrossRef]

- Qutaishat, F.; Abushakra, A.; Anaya, L.; Al-Omari, M. Investigating the factors affecting the intention to adopt cloud-based ERP systems during the COVID-19 era: Evidence from Jordan. Bus. Process Manag. J. 2023, 29, 653–670. [Google Scholar] [CrossRef]

- Siew, E.G.; Rosli, K.; Yeow, P.H. Organizational and environmental influences in the adoption of computer-assisted audit tools and techniques (CAATTs) by audit firms in Malaysia. Int. J. Account. Inf. Syst. 2020, 36, 100445. [Google Scholar] [CrossRef]

- Alsharari, N.M.; Al-Shboul, M.; Alteneiji, S. Implementation of cloud ERP in the SME: Evidence from UAE. J. Small Bus. Enterp. Dev. 2020, 27, 299–327. [Google Scholar] [CrossRef]

- Tarik, Z.; Muharem, K.; Tarik, M. ERP solution and end-user efficiency in Bosnia and Herzegovina. Technol. Educ. Manag. Inform. J. 2020, 9, 1562–1569. [Google Scholar] [CrossRef]

- Verma, A.K.; Tanwar, V.; Mago, B. Systematic review of theories of cloud ERP adoption in UAE. NeuroQuantology 2022, 20, 2738–2748. [Google Scholar]

- Murillo, G.G.; Novoa-Hernández, P.; Rodriguez, R.S. Technology acceptance model and Moodle: A systematic mapping study. Inf. Dev. 2021, 37, 617–632. [Google Scholar] [CrossRef]

- Cataldo, A.; Bravo-Adasme, N.; Lara, A.M.; Rojas, J. Factors influencing the post-implementation user satisfaction of SAP-ERPS. Ingeniare Rev. Chil. Ing. 2022, 30, 574–591. [Google Scholar] [CrossRef]

- Davis, F.D. Perceived usefulness, perceived ease of use, and user acceptance of information technology. Manag. Inf. Syst. Q. 1989, 13, 319–340. [Google Scholar] [CrossRef]

- Ferratt, T.W.; Prasad, J.; Dunne, E.J. Fast and slow processes underlying theories of information technology use. J. Assoc. Inf. Syst. 2018, 19, 3. [Google Scholar] [CrossRef]

- Veronica. An evaluation of the employee self-service feature of SAP system with technology acceptance model (TAM): A case study. In Proceedings of the IEEE International Conference on Information Management and Technology (ICIMTech), Bandung, Indonesia, 13–14 August 2020; pp. 761–766. [Google Scholar] [CrossRef]

- Jo, H. Key factors influencing loyalty and satisfaction toward ERP: Mediating role of flow. J. Knowl. Econ. 2023, 14, 2138–2155. [Google Scholar] [CrossRef]

- Tahriri, A.; Afsay, A. A meta-analysis of the factors affecting the behavior of auditors to acceptance of information technology. J. Value Behav. Account. 2021, 6, 1–40. [Google Scholar] [CrossRef]

- Ghallab, A.; Almuzaiqer, A.; Al-Hashedi, A.; Mohsen, A.; Bechkoum, K.; Aljedaani, W. Factors affecting intention to adopt open source ERP systems by SMEs in Yemen. In Proceedings of the IEEE International Conference on Intelligent Technology, System and Service for Internet of Everything (ITSS-IoE), Sana’a, Yemen, 1–2 November 2021; pp. 1–7. [Google Scholar] [CrossRef]

- Nwankpa, J.K. ERP system usage and benefit: A model of antecedents and outcomes. Comput. Hum. Behav. 2015, 45, 335–344. [Google Scholar] [CrossRef]

- Al Shbail, M.O.; Jaradat, Z.; Baker, M.B.; Almuiet, M. Individual and technological factors affecting the adoption of enterprise resource planning systems in the Jordanian banking sector. Int. J. Bus. Inf. Syst. 2024, 45, 118–141. [Google Scholar] [CrossRef]

- Marsudi, A.S.; Pambudi, R. The effect of enterprise resource planning (ERP) on performance with information technology capability as moderating variable. J. Econ. Bus. Account. Ventura. 2021, 24, 1–11. [Google Scholar] [CrossRef]

- AlMuhayfith, S.; Shaiti, H. The impact of enterprise resource planning on business performance: With the discussion on its relationship with open innovation. J. Open Innov. Technol. Mark. Complex. 2020, 6, 87. [Google Scholar] [CrossRef]

- Amado, A.; Belfo, F.P. Maintenance and support model within the ERP systems lifecycle: Action research in an implementer company. Procedia Comput. Sci. 2021, 181, 580–588. [Google Scholar] [CrossRef]

- Afsay, A.; Tahriri, A.; Rezaee, Z. A meta-analysis of factors affecting acceptance of information technology in auditing. Int. J. Account. Inf. Syst. 2023, 49, 100608. [Google Scholar] [CrossRef]

- Norzelan, N.A.; Mohamed, I.S.; Mohamad, M. Technology acceptance of artificial intelligence (AI) among heads of finance and accounting units in the shared service industry. Technol. Forecast. Soc. Change. 2024, 198, 123022. [Google Scholar] [CrossRef]

- Seethamraju, R.; Sundar, D.K. Influence of ERP systems on business process agility. IIMB Manag. Rev. 2013, 25, 137–149. [Google Scholar] [CrossRef]

- Fischer, M.; Heim, D.; Janiesch, C.; Winkelmann, A. Assessing process fit in ERP implementation projects: A methodological approach. In Designing the Digital Transformation; DESRIST 2017; Springer: Cham, Switzerland, 2017; pp. 3–20. [Google Scholar] [CrossRef]

- Becker, J.M.; Klein, K.; Wetzels, M. Hierarchical latent variable models in PLS-SEM: Guidelines for using reflective–formative type models. Long Range Plan. 2012, 45, 359–394. [Google Scholar] [CrossRef]

- Sternad Zabukovšek, S.; Kalinic, Z.; Bobek, S.; Tominc, P. SEM–ANN based research of factors’ impact on extended use of ERP systems. Cent. Eur. J. Oper. Res. 2019, 27, 703–735. [Google Scholar] [CrossRef]

- Hsu, S.H.; Chen, W.H.; Hsieh, M.J. Robustness testing of PLS, LISREL, EQS and ANN-based SEM for measuring customer satisfaction. Total Qual. Manag. Bus. Excell. 2006, 17, 355–372. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M.; Danks, N.P.; Ray, S. Partial Least Squares Structural Equation Modeling (PLS-SEM) Using R: A Workbook; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Hancerliogullari Koksalmis, G.; Damar, S. An empirical evaluation of a modified technology acceptance model for SAP ERP system. Eng. Manag. J. 2022, 34, 201–216. [Google Scholar] [CrossRef]

- Sternad Zabukovšek, S.; Tominc, P.; Deželak, Z.; Nalbandyan, G.; Bobek, S. Acceptance of GIS within ERP system: Research study in higher education. ISPRS Int. J. Geo-Inf. 2022, 11, 83. [Google Scholar] [CrossRef]

- Sternad Zabukovšek, S.; Picek, R.; Bobek, S.; Šišovska Klančnik, I.; Tominc, P. Technology acceptance model-based study of students’ attitudes toward use of enterprise resource planning solutions. J. Inf. Organ. Sci. 2019, 43, 49–71. [Google Scholar] [CrossRef]

- Khazaei, M.; Afrasiabi, R.; Omran, M.S. The impact of ERP utilization in the educational system on enhancing educational quality considering the mediating role of technology acceptance. Int. J. Educ. Cogn. Sci. 2025, 6, 71–81. [Google Scholar] [CrossRef]

- Sabokbar, H.F.; Hosseini, A.; Banaitis, A.; Banaitiene, N. A novel sorting method TOPSIS-Sort: An application for Tehran environmental quality evaluation. E+M Ekon. Manag. 2016, 19, 87–104. [Google Scholar] [CrossRef]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Aburumman, O.J.; Omar, K.; Al Shbail, M.; Aldoghan, M. How to deal with the results of PLS-SEM? In Explore Business, Technology Opportunities and Challenges After the Covid-19 Pandemic; Springer: Cham, Switzerland, 2022; pp. 1196–1206. [Google Scholar] [CrossRef]

- Kabir, K.H.; Hassan, F.; Mukta, M.Z.N.; Roy, D.; Darr, D.; Leggette, H.; Ullah, S.A. Application of the technology acceptance model to assess the use and preferences of ICTs among field-level extension officers in Bangladesh. Digit. Geogr. Soc. 2022, 3, 100027. [Google Scholar] [CrossRef]

- Cheng, Y.M. Towards an understanding of the factors affecting m-learning acceptance: Roles of technological characteristics and compatibility. Asia Pac. Manag. Rev. 2015, 20, 109–119. [Google Scholar] [CrossRef]

- Punniyamoorthy, M.; Mathiyalagan, P.; Parthiban, P. A strategic model using structural equation modeling and fuzzy logic in supplier selection. Expert Syst. Appl. 2011, 38, 458–474. [Google Scholar] [CrossRef]

- Gbongli, K.; Xu, Y.; Amedjonekou, K.M.; Kovács, L. Evaluation and classification of mobile financial services sustainability using structural equation modeling and multiple criteria decision-making methods. Sustainability 2020, 12, 1288. [Google Scholar] [CrossRef]

- Sternad Zabukovšek, S.; Bobek, S.; Zabukovšek, U.; Kalinić, Z.; Tominc, P. Enhancing PLS-SEM-enabled research with ANN and IPMA: Research study of enterprise resource planning (ERP) systems’ acceptance based on the technology acceptance model (TAM). Mathematics 2022, 10, 1379. [Google Scholar] [CrossRef]

- Hammad, M.Z.M.B.; Yahaya, J.B.; Mohamed, I.B. A model for enterprise resource planning implementation in the Saudi public sector organizations. Heliyon 2024, 10, e24531. [Google Scholar] [CrossRef]

- Norman, G. Likert scales, levels of measurement and the “laws” of statistics. Adv. Health Sci. Educ. 2010, 15, 625–632. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, B.; Ni, W.A. Hybrid model based on SEM and fuzzy TOPSIS for supplier selection. Mathematics 2022, 10, 3505. [Google Scholar] [CrossRef]

- Božanić, D.; Pamučar, D.; Bojanić, D. Modification of the analytic hierarchy process (AHP) method using fuzzy logic: Fuzzy AHP approach as a support to the decision-making process concerning engagement of the group for additional hindering. Serb. J. Manag. 2015, 10, 151–171. [Google Scholar] [CrossRef]

- Hajji, A.; Pellerin, R.; Gharbi, A.; Léger, P.M.; Babin, G. Toward valuable prediction of ERP diffusion in North American automotive industry: A simulation based approach. Int. J. Prod. Econ. 2016, 175, 61–70. [Google Scholar] [CrossRef]

- Görçün, Ö.F.; Mishra, A.R.; Aytekin, A.; Simic, V.; Korucuk, S. Evaluation of Industry 4.0 strategies for digital transformation in the automotive manufacturing industry using an integrated fuzzy decision-making model. J. Manuf. Syst. 2024, 74, 922–948. [Google Scholar] [CrossRef]

- Gessa, A.; Jiménez, A.; Sancha, P. Exploring ERP systems adoption in challenging times: Insights of SMEs stories. Technol. Forecast. Soc. Change. 2023, 195, 122795. [Google Scholar] [CrossRef]

- Powell, D. ERP systems in lean production: New insights from a review of lean and ERP literature. Int. J. Oper. Prod. Manag. 2013, 33, 1490–1510. [Google Scholar] [CrossRef]

- Itagi, F.S.; Satish, J.G.; Gaitonde, V.N.; Kulkarni, V.N.; Kotturshettar, B.B. Benefits and challenges of implementing ERP in pharmaceutical industries. AIP Conf. Proc. 2023, 2548, 011096. [Google Scholar] [CrossRef]

- Jayawickrama, U.; Liu, S.; Smith, M.H. Empirical evidence of an integrative knowledge competence framework for ERP systems implementation in UK industries. Comput. Ind. 2016, 82, 205–223. [Google Scholar] [CrossRef]

- Sałabun, W.; Wątróbski, J.; Shekhovtsov, A. Are MCDA methods benchmarkable? A comparative study of TOPSIS, VIKOR, COPRAS, and PROMETHEE II methods. Symmetry 2020, 12, 1549. [Google Scholar] [CrossRef]

- Zar, J.H. Significance testing of the Spearman rank correlation coefficient. J. Am. Stat. Assoc. 1972, 67, 578–580. [Google Scholar] [CrossRef]

- Cohen, J. A coefficient of agreement for nominal scales. Educ. Psychol. Meas. 1960, 20, 37–46. [Google Scholar] [CrossRef]

| Year | Author(s) | Aim of the Study | Methodology |

|---|---|---|---|

| 2013 | Sternad & Bobek [30] | Examination of external factors on ERP system acceptance | SEM |

| 2018 | Bhattacharya et al. [31] | Examination of determinants of the intention to adopt ERP system | SEM |

| 2020 | Putri et al. [32] | Analysis of critical success factors for ERP acceptance | SEM |

| 2021 | Limantara et al. [33] | Analysis of factors for ERP usage | SEM |

| 2021 | Ayağ & Samanlioglu [35] | ERP software packages selection | MCDA (hybrid fuzzy AHP–TOPSIS) |

| 2022 | Uddin et al. [36] | ERP system selection | MCDA (hybrid AHP–TOPSIS) |

| 2021 | Aydoğmuş et al. [37] | ERP selection | MCDA (fuzzy CODAS) |

| 2022 | Jin [34] | Extension of VIKOR method for ERP system selection | MCDA (VIKOR) |

| 2022 | Yurtyapan & Aydemir [38] | ERP system selection | MCDA (fuzzy and interval gray number-based MACBETH) |

| 2024 | Dağci Yüksel & Ersöz [39] | ERP software selection | MCDA (fuzzy AHP) |

| Cronbach’s Alpha (Cα) * | Composite Reliability (rhoa) ** | Composite Reliability (rhoc) *** | Average Variance Extracted (AVE) **** | |

|---|---|---|---|---|

| Attitude to Use | 0.807 | 0.830 | 0.911 | 0.837 |

| Business Process Fit | 0.750 | 0.821 | 0.845 | 0.592 |

| Perceived Ease of Use | 0.881 | 0.890 | 0.944 | 0.894 |

| Perceived Usefulness | 0.874 | 0.874 | 0.941 | 0.888 |

| Work Compatibility | 0.879 | 0.880 | 0.926 | 0.806 |

| Social Influence | 0.761 | 0.765 | 0.863 | 0.677 |

| System Performances | 0.858 | 0.862 | 0.899 | 0.640 |

| User Manuals | 0.902 | 0.906 | 0.939 | 0.837 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|

| Attitude to Use (1) | - | |||||||

| Business Process Fit (2) | 0.728 | |||||||

| Perceived Ease of Use (3) | 0.629 | 0.595 | ||||||

| Perceived Usefulness (4) | 0.799 | 0.795 | 0.653 | |||||

| Work Compatibility (5) | 0.857 | 0.812 | 0.724 | 0.868 | ||||

| Social Influence (6) | 0.623 | 0.725 | 0.459 | 0.581 | 0.654 | |||

| System Performances (7) | 0.644 | 0.738 | 0.637 | 0.625 | 0.644 | 0.486 | ||

| User Manuals (8) | 0.329 | 0.484 | 0.510 | 0.404 | 0.420 | 0.328 | 0.529 | - |

| Hypothesis | Construct | Estimated Path Coefficient (β) | p-Value (p) * | Remark |

|---|---|---|---|---|

| H1 | Work Compatibility → Attitude to Use | 0.404 | 0.000 * | accepted |

| H2 | Perceived Usefulness → Attitude to Use | 0.227 | 0.001 ** | accepted |

| H3 | Perceived Ease of Use → Attitude to Use | 0.048 | 0.367 n.s. | rejected |

| H4 | External Factors → Attitude to Use | 0.169 | 0.006 ** | accepted |

| Criteria | Subcriteria | Serbia | Slovenia | ||||

|---|---|---|---|---|---|---|---|

| Weight of Significant Criteria | Weight of Subcriteria in the Criteria | Global Weight of Subcriteria | Weight of Significant Criteria | Weight of Subcriteria in the Criteria | Global Weight of Subcriteria | ||

| Work Compatibility | WC_I | 0.332 | 0.333 | 0.110 | 0.695 | 0.321 | 0.223 |

| WC_II | 0.343 | 0.114 | 0.346 | 0.240 | |||

| WC_III | 0.324 | 0.108 | 0.333 | 0.232 | |||

| Perceived Usefulness | PU_I | 0.269 | 0.497 | 0.134 | 0.254 | 0.503 | 0.128 |

| PU_II | 0.503 | 0.135 | 0.497 | 0.126 | |||

| External Factors | EF–SP | 0.399 | 0.264 | 0.105 | 0.051 | 0.274 | 0.014 |

| EF–UM | 0.232 | 0.093 | 0.218 | 0.011 | |||

| EF–SI | 0.223 | 0.089 | 0.235 | 0.012 | |||

| EF–BPF | 0.281 | 0.112 | 0.273 | 0.014 | |||

| Criteria | Work Compatibility | Perceived Usefulness | Perceived Ease of Use | External Factors | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sub-Criteria | WC_I | WC_II | WC_III | PU_I | PU_II | PEoU_I | PEoU_II | SP | SC | UM | SI | BPF |

| Criteria Type (max/min) Alternative | max | max | max | max | max | max | max | max | min | max | max | max |

| A1 | 4.42 | 4.45 | 4.45 | 4.42 | 4.29 | 4.03 | 3.71 | 4.18 | 2.10 | 3.87 | 4.76 | 4.42 |

| A2 | 3.52 | 3.62 | 3.77 | 3.74 | 3.72 | 3.44 | 3.41 | 3.75 | 2.74 | 3.43 | 3.89 | 3.72 |

| A3 | 4.08 | 4.21 | 4.13 | 3.96 | 4.08 | 3.96 | 3.71 | 4.04 | 2.28 | 3.67 | 4.60 | 4.29 |

| A4 | 4.20 | 4.40 | 3.60 | 4.20 | 3.60 | 4.20 | 3.60 | 4.28 | 1.93 | 3.07 | 4.47 | 4.50 |

| A5 | 3.80 | 4.05 | 4.05 | 4.25 | 4.25 | 4.15 | 4.05 | 4.08 | 1.87 | 3.63 | 4.43 | 4.21 |

| A6 | 4.17 | 4.13 | 4.21 | 4.12 | 4.25 | 3.96 | 3.75 | 4.10 | 2.18 | 3.49 | 4.44 | 4.18 |

| A7 | 4.25 | 4.25 | 4.75 | 4.00 | 4.00 | 4.00 | 3.50 | 3.95 | 2.50 | 3.33 | 3.92 | 4.06 |

| A8 | 4.00 | 4.11 | 4.22 | 4.30 | 4.30 | 3.89 | 3.78 | 4.06 | 2.44 | 3.62 | 4.47 | 4.17 |

| A9 | 3.80 | 4.20 | 4.20 | 4.20 | 4.00 | 3.60 | 3.60 | 3.96 | 2.60 | 3.60 | 4.40 | 4.05 |

| A10 | 3.50 | 3.88 | 4.25 | 3.75 | 3.75 | 3.88 | 3.63 | 4.43 | 2.50 | 3.33 | 4.58 | 3.84 |

| A11 | 4.14 | 4.36 | 4.23 | 4.64 | 4.45 | 3.91 | 3.86 | 4.06 | 2.12 | 3.11 | 4.52 | 4.44 |

| Profile boundary B1 (c = 15%) | 4.28 | 4.33 | 4.58 | 4.51 | 4.32 | 4.09 | 3.95 | 4.32 | 2.00 | 3.75 | 4.63 | 4.38 |

| Profile boundary B2 (c = 35%) | 4.10 | 4.16 | 4.35 | 4.33 | 4.15 | 3.93 | 3.83 | 4.19 | 2.17 | 3.59 | 4.46 | 4.23 |

| Wj–S1 (ERP users from Serbia) | 0.110 | 0.114 | 0.108 | 0.134 | 0.135 | / | / | 0.105 | / | 0.093 | 0.089 | 0.112 |

| Wj–S2 (ERP users from Slovenia) | 0.223 | 0.240 | 0.232 | 0.128 | 0.126 | / | / | 0.014 | / | 0.011 | 0.012 | 0.014 |

| Wj–S3 (ERP experts from Serbia and Slovenia) | 0.062 | 0.206 | 0.113 | 0.041 | 0.081 | 0.028 | 0.028 | 0.122 | 0.014 | 0.049 | 0.032 | 0.223 |

| Alternatives | S1 ERP Users from Serbia | S2 ERP Users from Slovenia | S3 ERP Experts from Serbia and Slovenia | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Class 1 | Class 2 | Class 3 | Class 1 | Class 2 | Class 3 | Class 1 | Class 2 | Class 3 | |

| A1 | ✔ | ✔ | ✔ | ||||||

| A2 | ✔ | ✔ | ✔ | ||||||

| A3 | ✔ | ✔ | ✔ | ||||||

| A4 | ✔ | ✔ | ✔ | ||||||

| A5 | ✔ | ✔ | ✔ | ||||||

| A6 | ✔ | ✔ | ✔ | ||||||

| A7 | ✔ | ✔ | ✔ | ||||||

| A8 | ✔ | ✔ | ✔ | ||||||

| A9 | ✔ | ✔ | ✔ | ||||||

| A10 | ✔ | ✔ | ✔ | ||||||

| A11 | ✔ | ✔ | ✔ | ||||||

| Alternatives | PROMETHEE-Flowsort (ERP Users from Serbia) | PROMETHEE-Flowsort (ERP Users from Slovenia) | PROMETHEE-Flowsort (ERP Experts from Serbia and Slovenia) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Class 1 | Class 2 | Class 3 | Class 1 | Class 2 | Class 3 | Class 1 | Class 2 | Class 3 | |

| A1 | ✔ | ✔ | ✔ | ||||||

| A2 | ✔ | ✔ | ✔ | ||||||

| A3 | ✔ | ✔ | ✔ | ||||||

| A4 | ✔ | ✔ | ✔ | ||||||

| A5 | ✔ | ✔ | ✔ | ||||||

| A6 | ✔ | ✔ | ✔ | ||||||

| A7 | ✔ | ✔ | ✔ | ||||||

| A8 | ✔ | ✔ | ✔ | ||||||

| A9 | ✔ | ✔ | ✔ | ||||||

| A10 | ✔ | ✔ | ✔ | ||||||

| A11 | ✔ | ✔ | ✔ | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radić, A.; Bobek, S.; Arsić, S.; Nikolić, Đ.; Sternad Zabukovšek, S. An Integrated PLS-SEM-TOPSIS-Sort Approach for Assessing ERP Solutions Acceptance Across Various Industries. Information 2025, 16, 954. https://doi.org/10.3390/info16110954

Radić A, Bobek S, Arsić S, Nikolić Đ, Sternad Zabukovšek S. An Integrated PLS-SEM-TOPSIS-Sort Approach for Assessing ERP Solutions Acceptance Across Various Industries. Information. 2025; 16(11):954. https://doi.org/10.3390/info16110954

Chicago/Turabian StyleRadić, Aleksandra, Samo Bobek, Sanela Arsić, Đorđe Nikolić, and Simona Sternad Zabukovšek. 2025. "An Integrated PLS-SEM-TOPSIS-Sort Approach for Assessing ERP Solutions Acceptance Across Various Industries" Information 16, no. 11: 954. https://doi.org/10.3390/info16110954

APA StyleRadić, A., Bobek, S., Arsić, S., Nikolić, Đ., & Sternad Zabukovšek, S. (2025). An Integrated PLS-SEM-TOPSIS-Sort Approach for Assessing ERP Solutions Acceptance Across Various Industries. Information, 16(11), 954. https://doi.org/10.3390/info16110954