Abstract

It is critical for organizations to self-assess their Industry 4.0 readiness to survive and thrive in the age of the Fourth Industrial Revolution. Thereon, conceptualization or development of an Industry 4.0 readiness model with the fundamental model dimensions is needed. This paper used a systematic literature review (SLR) methodology with the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines and content analysis strategy to review 97 papers in peer-reviewed academic journals and industry reports published from 2000 to 2019. The review identifies 30 Industry 4.0 readiness models with 158 unique model dimensions. Based on this review, there are two theoretical contributions. First, this paper proposes six dimensions (Technology, People, Strategy, Leadership, Process and Innovation) that can be considered as the most important dimensions for organizations. Second, this review reveals that 70 (44%) out of total 158 total unique dimensions on Industry 4.0 pertain to the assessment of technology alone. This establishes that organizations need to largely improve on their technology readiness, to strengthen their Industry 4.0 readiness. In summary, these six most common dimensions, and in particular, the dominance of the technology dimension provides a research agenda for future research on Industry 4.0 readiness.

1. Introduction

Industry 4.0 readiness is described as the degree to which organizations are able to take advantage of Industry 4.0 technologies [1]. In other words, it is about companies being digitally prepared for Industry 4.0 technologies [2,3]. Digital transformation has changed the software and hardware side of organizations [4,5]. For instance, in engineering, three-dimensional simulations and printing are already in full scale practice, involving raw materials, finished product, and the production cycle [6]. Software-as-a-service applications are another window of opportunity. These opportunities can be best addressed under Industry 4.0 technologies, which can then contribute towards Industry 4.0 readiness. Moreover, Industry 4.0 readiness can also be studied from competitive, technological and organizational perspectives. Most of the studies classify Industry 4.0 as disruptive for the same reason.

In order to perform better, industry and academia have been making continuous attempts to develop and re-develop self-assessment models that can evaluate the Industry 4.0 readiness of organizations. Based on the models then, organizations can have two terminal states, least ready or most ready. There are multiple dimensions, which can also be filtered based on level of complexity. The output then can be used for benchmarking [7]. Attaining this Industry 4.0 readiness is both a very large and urgent interest and need of businesses now [8]. Identification of these Industry 4.0 readiness models is also significantly needed as it will enable companies to measure precedents and antecedents in the digital transformation process which can then lead to organizational transformation. In terms of implications, it will enable policy-makers and decision-takers to decide when and how to intervene, and will determine how to measure the success of digitalization. If not well addressed, this will create a digital divide on the company level, where the companies with inadequate focus on digitalization will be wiped out from the market [9,10].

Therefore, to successfully master Industry 4.0 readiness, academic and industry researchers have developed a variety of Industry 4.0 readiness models in the recent years. This paper aims to conduct a systematic literature review (SLR) to explore the breadth and depth of existing Industry readiness models first, and then to identify the most common dimensions from these models. The original and unique contribution of this review paper is focused on the discovery of most-common dimensions of models rather than the identification of models itself.

The remaining paper is organized in this sequence: Section 2 describes the theoretical background of this study with the research questions. Section 3 states the systematic literature review methodology and the fundamental review principles. Section 4 presents the findings and the results in terms of models and their dimensions. Based on these results, Section 5 then presents an articulated discussion in line with the research questions of this study. Finally, Section 6 concludes this paper with the contributions, implications, limitations and the avenues of future research.

2. Theoretical Background

Industry 4.0 readiness models are mostly designed with two unique angles, one of finding practice applicability of readiness models, and the other of finding users for the respective readiness models [11]. To satisfy that quest, both academia and industry have been working on to develop and improve the extant literature and pragmatic tools on Industry 4.0 readiness models. Interestingly, there has been a quick escalation in the number of Industry 4.0 readiness models in the recent few years [12]. However, it has also been discovered that a large number of academic Industry 4.0 readiness models are not known in industry, as they are less pragmatic in terms of fast-moving objectives of industry [13].

In that context, Felch and Sucky analysed Industry 4.0 readiness models in terms of business practice [14]. These models help a company identify its current standing and the change that is necessitated. However, not all readiness models are equally relevant or applicative, as certain readiness models are designed for all industry sectors, whereas others have a narrow scope. Either way, they are a great contribution to the topic of Industry 4.0 and Industry 4.0 readiness. All such readiness models are progressive but can vary in terms of short, medium or long-term purpose or benefits [15]. These models are also treated as a management tool for realignment, reconfiguration, and renewal of organization’s existing capacities and capabilities. In simple words, Industry 4.0 is interplay of state-of-the-art technologies. As per Felch and Sucky, it is important to know and study the existing Industry 4.0 readiness models irrespective of whether they originate from scientific (academia contribution) or from consultancies (industry contribution) [14].

In studying the existing Industry 4.0 readiness models, the challenge is that a large number of academic institutions and industry firms consider their readiness models as their classified property, and hence their complete or final version of model is not available publicly, which further adds to the existing set of research gaps on this important and continuously evolving topic. In this purview, the first and the most important research question that this review paper aims to answer is:

- Research Question 1: What are the existing Industry 4.0 readiness models (academia/industry)?

Next, organizations generally seem to be perplexed with the implementation of Industry 4.0 initiatives, as they mix means with ends on the topic, not understanding the cause and effect [12]. This happens because after the adoption of Industry 4.0 principles and technologies, most of organizational strategies will be revised, including a change in vision, mission, values, goals, and key performance indicators (KPI) [16]. Hence, the understanding and assessment of the most critical dimensions of Industry 4.0 readiness is important. In terms of previous literature, Brozzi studied dimensions from certain Industry 4.0 readiness models, but from the reference of small and medium enterprises (SMEs) only [17]. Likewise, the author Colli studied dimensions of four models, and the author Gokalp studied dimensions of seven models only [18]. In the most recent article, the author Basl highlighted some dimensions from certain existing Industry 4.0 models, but did not identify the most common ones, particularly through a systematic review [19,20]. Therefore, finding the most common Industry 4.0 readiness dimensions is a research gap as highlighted by different authors. Hence, the second research question of this study is:

- Research Question 2: What are the main dimensions used in the existing Industry 4.0 readiness models?

Industry 4.0 is essentially a technology revolution. Sibel like other Industry 4.0 writers have authored a paper on the different technologies of Industry 4.0 [21]. Usundag and Cevikcan developed a Technology Roadmap for Industry 4.0 [22]. It is a single document or method to transform an organization digitally, or to a weave a digital enterprise. Ghobakhloo also presented a strategic roadmap for Industry 4.0 with design principles and technology trends [23]. In terms of theory, a technological, organizational and environmental (TOE) framework emphasizes that technological innovations are a result of three contexts: technology, organization and environment. Here, the technological context focuses on how technological practices can add meaning to an organization. For example, Kuan and Chau used it with IS innovations [24], Srivastava and Teo used TOE for ICT [25], and Ardito used TOE for SMEs [26]. These empirical studies emphasize that technology initiatives are important for Industry 4.0 readiness. Furthermore, Basl indicated that ‘Technology’ can be considered as the most important dimension from the most popular Industry 4.0 readiness models, but this assertion lacks evidence [20]. As per more recent studies, the confirmation of ‘Technology’ being the most significant dimension is also a research gap. Therefore, the third and final research question of this study is:

- Research Question 3: Is ‘Technology’ the most significant dimension among the existing Industry 4.0 readiness models?

3. Methodology

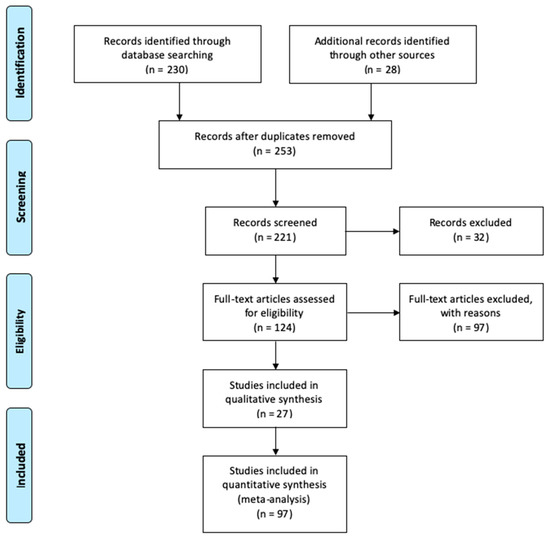

As this paper aims at specific results through three independent research questions, systematic literature review is more appropriate than the broad traditional literature review. Thereon, to contribute to the existing body of knowledge on Industry 4.0 readiness, systematic literature review (SLR) methodology of Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) by Moher and Liberati was deployed [27]. PRISMA is an evidence-based reporting standard that is effective for critical appraisal. The technique of SLR methodology is particularly helpful as it meticulously summarizes the available research in response to research questions [28]. Furthermore, the inclusion and exclusion criteria, with two attempts on the reduction of articles as per this technique leads to a targeted list of articles. In this paper, this review technique has helped considerably in exploring the various readiness models available, and then narrowing down the choices to merely Industry 4.0 readiness models and Industry 4.0 readiness dimensions. Overall, the steps of systematic methodology adapted for this review article are shown in Figure 1. By definition, a systematic review is an examination of a clearly formulated question that uses explicit methods to critically appraise research. This can be done with or without statistical procedures [29]. This literature review has been designed in a structured and rigorous manner. It is replicable, hence can be updated in the future with the state of art findings on Industry 4.0 readiness.

Figure 1.

PRISMA flowchart, adapted [27].

For data analysis, the methodology was further supported by content analysis, as it is often preferred in the social sciences. Content analysis can be described as a systematic technique in which certain words (codes) in a text are summarized within categories [30]. Likewise, for this review paper, themes were constructed based on similar contexts and meaning, which led to the findings that are depicted in the next section in this paper [31].

The scanning of existing literature on the topics related to Industry 4.0 Readiness was done, which led to 97 articles, with timeline spanning from 2000 to 2019. There were four search keywords used, spanning over 15 publishers and databases, as shown in Table 1. The systematic review considers both inclusion and exclusion criteria as shown in Table 2. There were three criteria used for inclusion and exclusion: literature type, language and timeline. Since the majority of the literature exists in English, this review tends to be comprehensive in terms of available literature. Secondly, magazine articles are considered to be less formal with missing academic rigor, hence those are excluded from this review. However, industry reports and whitepapers from credible and reputable consultancy houses have been considered. From this review of 124 screened full text articles, 27 (22%) were qualitative and 97 (78%) were quantitative. There were two elimination rounds conducted following PRISMA approach, which led to the targeted 97 articles which constitute this review results and discussion. These 97 articles range from 2000 to 2019. The first elimination round was based on sorting conceptual, theoretical and empirical studies. The second elimination round was extensive which was based on reading the full text, keeping only the literature based on the research objectives of the systematic review. Here, the papers which did not provide Industry 4.0 readiness model questionnaires and model dimensions were excluded. The findings or results obtained follow in the next section.

Table 1.

Search boundaries and keywords.

Table 2.

Inclusion and exclusion criteria.

4. Results

Following the research objectives of this review paper, the systematic literature review of targeted 97 articles on Industry 4.0 readiness highlights two main findings: a listing of existing Industry 4.0 readiness models and the identification of main dimensions from the existing Industry 4.0 readiness models. These two findings are further reiterated in this section.

4.1. Listing of Industry 4.0 Readiness Models

The review reveals 30 different Industry 4.0 readiness models from different developers or originators. It is interesting to observe that most of the readiness models on Industry 4.0 were conceived during the three-year period from 2016 to 2018. Hence, the field of Industry 4.0 readiness assessment tools is relatively new, and emerging. Nine of 30 (30%) of existing Industry 4.0 readiness models were contributed by industry, whereas the remaining 21 of 30 (70%) existing Industry 4.0 readiness models were contributed by academia. A list of Industry 4.0 readiness models is presented in Table 3 below.

Table 3.

List of Industry 4.0 Readiness Models.

4.2. Identification of Dimensions from Industry 4.0 Readiness Models

A thorough analysis of all the dimensions from 30 existing Industry 4.0 readiness models reveal an interesting finding of six most common dimensions used in these models (Technology, People, Strategy, Leadership, Process and Innovation). The first column of Table 4 below shows all the individual dimensions in terms of their exact wording used in the respective Industry 4.0 readiness models. The second column shows the count or numbers of these dimensions, once they have been pooled according to similarity of meaning and usage. The third column then shows the proposed pooled dimension, considering the similar individual dimensions. As shown in Table 4, the maximum number of individual dimensions used in the models are related to ‘Technology’, and hence those 70 dimensions connected or related with technology can be pooled under the proposed pooled dimension of ‘Technology’. Next, the second highest number of individual dimensions can be recorded under the proposed pooled dimension of ‘People’. The other three pooled dimensions (Strategy, Leadership, Process) proposed are almost equal in terms of the count of individual dimensions. The minimum number of individual dimensions used in the models, as found through this review paper, are related to ‘Innovation’. Thus, overall, combining these six main pooled dimensions showcase the nature and commonality of individual dimensions used in the existing Industry 4.0 readiness models.

Table 4.

Pooling of digital readiness model dimensions.

5. Discussion

This review paper was conceived on the basis of three research questions, as stated in the introduction section. This section will lead discussion on those three questions in the same order.

- Research Question 1. What are the existing Industry 4.0 readiness models (academia/industry)?

The majority of the consultancy firms treat their readiness models as their intellectual property which makes it difficult to openly identify and evaluate the landscape of existing readiness models. Another way to identify the models is through purpose. Purpose of readiness models can be descriptive, prescriptive or comparative. Identifying the target users of readiness models has always been an important viewpoint. The authors Felch and Sucky subscribe that there are existing models which do not serve the need adequately or can be further developed [14]. Hence, the ground work of this review paper can assist in development of future Industry 4.0 readiness models. Some organizations appear to be confounded with Industry 4.0 due to the uncertain and complex nature of technological innovations revolving around Industry 4.0 [45]. After the adoption of Industry 4.0 technologies, organization is meant to transform itself dynamically [46]. This has resulted in different model objectives for different organizations on Industry 4.0 readiness models.

In 2019, the authors Felch and Sucky analysed Industry 4.0 maturity models in terms of business practice [14]. As per the authors, there has been a quick escalation in the number of Industry 4.0 readiness models in the recent few years, which complements with the findings of this review. These tools help a company identify its current position and steps to be taken. Not all models are equally relevant or applicaable [12]. Some Industry 4.0 readiness models are designed for all industry sectors, whereas others have a narrow scope. Either way, they are a great contribution to the topic of Industry 4.0 [13]. Models can also be treated as a management tool for realignment, reconfiguration, and renewal of organization’s existing capacities and capabilities [14]. The systematic literature review conducted in this paper has led to the identification of 30 Industry 4.0 readiness models. These models are listed in Table 3 under Section 4.1. Remarkably, two major trends in the development of these Industry 4.0 readiness models are: (a) year-wise development, and (b) academia-industry split. In terms of evolution of the models, the initial readiness models starting from 2016 were more comprehensive and broader. Later by 2018, the models evolved to be more specific and specialized. Major contributions on the models were realized in 2018. In terms of academia-industry contributions, most of the originating models from 2016 were industry-conceived and industry-practiced. Thereon, the academic contributions on the models have been very recent in 2018 and 2019. In comparison, academic models are encouraged over industry models in terms of thorough reliability and validity, whereas industry models outperform academic ones as being more pragmatic. Next, in terms of dimensions, academic models mostly have a smaller number of dimensions, but industry models make use of a relatively large number of model dimensions in assessment of Industry 4.0 readiness. In terms of robustness, academic models are considered to be in better form. Surprisingly, industry models are more popular instead. Last, in terms of applicability, some models are generic that can be applied to several industry sectors without any customization, but most of the models from both academia and industry are specialized for specific industry sectors or domains or area of expertise. In summary, Table 3 precisely answers the first research question on the availability of existing Industry 4.0 readiness models.

- Research Question 2. What are the main dimensions used in the existing Industry 4.0 readiness models?

There are various self-assessment instruments in this regard as highlighted in addressing the first research question. The thematic analysis of models suggests that each model is different. However, main objective of readiness models is to identify the starting point and then sketch the development plan [47]. In terms of diversity of dimensions of Industry 4.0 readiness models, Brozzi classified that some models are broad and they have many dimensions for measuring Industry 4.0 readiness, whereas others are narrow with few number of assessment dimensions [17]. The need for more and varied dimensions in assessment is because convergence of organizational system with Industry 4.0 technologies is challenging [48]. Industry 4.0 can be framed on companies on three main levels. First is the Operations level, which require re-adaptation with Industry 4.0 technological developments and the inclusion of latest tools in product and service value creation. Second is the Organization level, which requires structural innovation, and team synergies realignment with Industry 4.0 landscape. Third is the Customers level, which requires increase in value with increase in customer demand and expectations of customers with respect to Industry 4.0. Drawing from past literature, Basl highlighted some dimensions from certain existing Industry 4.0 models, but did not identify the most common ones, particularly through a systematic review [20]. These gaps in the literature have been addressed in this review paper.

Analysing the 30 Industry 4.0 readiness models, there is a diversity of model dimensions. The heterogeneity of the Industry 4.0 readiness model dimensions is such that a total of 158 individual dimensions were discovered by systematically reviewing the existing Industry 4.0 readiness models. Table 4 under Section 4.2 lists all the dimensions extracted from the existing Industry 4.0 readiness models. These discrete dimensions were then pooled in terms of similarity, after which six different main model dimensions can be proposed: (a) Technology, (b) People, (c) Strategy, (d) Leadership, (e) Process and (f) Innovation. There are important managerial implications of this finding. First, SMEs usually lack the resources to implement large scale solutions, hence they can use the models with these six main dimensions to evaluate their Industry 4.0 readiness in a comprehensive manner. Second, research on future models for both small and large organizations can be expanded on these six most common dimensions. Third, future models designed on these six common dimensions will require minimum customization in various industries in terms of implementation and practicality, which will save cost and time both for managers. This answers the second research question of this systematic literature review.

- Research Question 3. Is ‘Technology’ the most significant dimension among the existing Industry 4.0 readiness models?

Industry 4.0 change is also known as a sea change, as it spreads all over within an organization. However, the main trigger of this change is from the digitalization [49]. In 2018, the authors Ustundag and Cevikcan suggested that an organization should transform digitally to fetch the benefits of Industry 4.0 readiness [22]. Furthermore, technology creates both pull and push that helps an organization in terms of its planning and roadmap. Kagermann classified technology as a strong contributor for Industry 4.0, mainly because Industry 4.0 is a concept based on nine pillars of technology (Big Data, Cloud, Industrial Internet, Horizontal and Vertical Integration, Simulation, Augmented Reality, Additive Manufacturing, Cyber Security and Advanced Manufacturing) [7]. Ghobakhloo presented a working plan for Industry 4.0 with design principles and technology trends [23]. There has been noteworthy growth in the number of readiness models [19], but most of the readiness models with respect to Industry 4.0 are focused on technology or digitization. Basl also indicated that ‘Technology’ can be considered as the most important dimension from the most popular Industry 4.0 readiness models, but this assertion lacked evidence [20]. This review paper has added evidence to that claim through SLR findings, showing that the greatest number of dimensions in Industry 4.0 readiness models are related to technology.

Drawing from the 30 Industry 4.0 readiness models, there are a total of 158 individual dimensions of which 70 dimensions (44%) pertain to technology. Table 4 under Section 4.2 lists all the dimensions extracted from the existing Industry 4.0 readiness models. These different, but similar, technology dimensions include dimensions such as: technological competence, technological infrastructure, technology readiness, technology usage, digital applications, digital capabilities, digital enablers, digitalization, and information and communication technology. This finding has major implications on policy making as well as research on future readiness models. In terms of policy-making, this finding helps government in policy making as it indicates that the economies and countries that want to progress on Industry 4.0 readiness should consider technology advancement as the core area or dimension. In terms of future research on business models, this review paper highlights some of the key technology dimensions that have been used in the existing models. This answers the third and the final research question of this systematic literature review.

6. Conclusions

Industry 4.0 readiness is a contemporary topic in management studies. This systematic literature review unearths 30 existing Industry 4.0 readiness models from both academia and industry in line with the first research question of this study. The review further explores the available 158 model dimensions used by different authors and firms to evaluate Industry 4.0 readiness, which subsequently answers the second and third research question of this study. In terms of contributions from a theoretical point of view, this study has two original contributions. First, this systematic literature review on Industry 4.0 readiness models provides an original contribution in the form of six most common dimensions pooling from 158 individual dimensions, deriving from 30 existing Industry 4.0 readiness models. These six dimensions (Technology, People, Strategy, Leadership, Process and Innovation) can be considered as the most important dimensions for most of the organizations, irrespective of their size and industry. Secondly, most of the Industry 4.0 readiness models have technology related dimensions for assessment. This study reveals that 70 (44%) out of total 158 total unique dimensions on Industry 4.0 pertain to the assessment of technology alone. This implies that organizations need to largely improve on their technology readiness, to strengthen their Industry 4.0 readiness. Furthermore, there is an increasing level of interest among academics and industry professionals about Industry 4.0 readiness [34,50,51].

In terms of study limitations, the review performed in this study was based on historical data, which is a snapshot of a given situation at a specific point in time. Secondly, this study used specific databases with certain keywords, as listed in the methodology section of this paper. As the number of research repositories and databases are increasing, and those are updated continuously, the body of knowledge is continuously expanding which contributes towards limitations and future research both. Overall, the systematic review of existing Industry 4.0 readiness models and dimensions highlighted in this paper are potent enough to set a research agenda for future. The proposed six pooled dimensions as the main dimensions in this review paper can be followed by semi-structured interviews and case studies that can yield new and valuable insights. Further, empirical studies through quantitative research can further establish the inter-relationships between these dimensions. In terms of implications, this review paper has significance for government policy, industry and SMEs. For policy-making, the findings of this study can help government to improve their economy through gap assessment on their Industry 4.0 readiness. For industry, organizations can improve their competitive advantage in domestic and international market by improving their readiness towards Industry 4.0 technologies. For SMEs, this review paper provides six main dimensions that all SMEs in common can benefit from in evaluating their Industry 4.0 readiness.

Author Contributions

Conceptualization: M.H.-H., M.A.S. and N.L.A.; methodology: M.H.-H., M.A.S. and N.L.A.; writing—original draft preparation: M.A.S.; writing—review and editing: M.H.-H. and N.L.A.; project administration: M.H.-H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Malaysian Technology Development Corporation (MTDC), grant number EP-2019-014, awarded to Universiti Kebangsaan Malaysia.

Acknowledgments

The authors are thankful and grateful to the editors and reviewers for their invaluable contribution.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Stentoft, J.; Jensen, K.W.; Philipsen, K.; Haug, A. Drivers and Barriers for Industry 4.0 Readiness and Practice: A SME Perspective with Empirical Evidence. In Proceedings of the 52nd Hawaii International Conference on System Sciences; HICSS Press: Hawaii, HI, USA, 2019; Volume 6, pp. 5155–5164. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution; Encyclopædia Britannica, Inc.: Chicago, IL, USA, 2017. [Google Scholar]

- Vazire, S. Implications of the Credibility Revolution for Productivity, Creativity, and Progress. Perspect. Psychol. Sci. 2018, 13, 411–417. [Google Scholar] [CrossRef] [PubMed]

- Haber, R.E.; Juanes, C.; Del Toro, R.; Beruvides, G. Artificial cognitive control with self-x capabilities: A case study of a micro-manufacturing process. Comput. Ind. 2015, 74, 135–150. [Google Scholar] [CrossRef]

- Wank, A.; Adolph, S.; Anokhin, O.; Arndt, A.; Anderl, R.; Metternich, J. Using a Learning Factory Approach to Transfer Industrie 4.0 Approaches to Small- and Medium-Sized Enterprises. Procedia CIRP 2016, 54, 89–94. [Google Scholar] [CrossRef]

- Williams, C.; Chen, P.L.; Agarwal, R. Rookies and Seasoned Recruits: How experience in different levels, firms and industries shapes strategic renewal in top management. Strateg. Manag. J. 2017, 38, 1391–1415. [Google Scholar] [CrossRef]

- Henning, K.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0; National Academy of Science and Engineering: Washington, DC, USA, 2013. [Google Scholar]

- Schaupp, E.; Abele, E.; Metternich, J. Potentials of Digitalization in Tool Management. Procedia CIRP 2017, 63, 144–149. [Google Scholar] [CrossRef]

- Canetta, L.; Barni, A.; Montini, E. Development of a Digitalization Maturity Model for the Manufacturing Sector. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Botha, A.P. Rapidly Arriving Futures: Future Readiness for Industry 4.0. S. Afr. J. Ind. Eng. 2018, 29, 148–160. [Google Scholar] [CrossRef]

- Sony, M. Key ingredients for evaluating Industry 4.0 readiness for organizations: A literature review. Benchmarking Int. J. 2019. [Google Scholar] [CrossRef]

- Haddara, M.; Elragal, A. The Readiness of ERP Systems for the Factory of the Future. Procedia Comput. Sci. 2015, 64, 721–728. [Google Scholar] [CrossRef]

- Felch, V.; Sucky, E. Maturity Models in the Age of Industry 4.0—Do the Available Models Correspond to the Needs of Business Practice? In Proceedings of the 52nd Hawaii International Conference on System Sciences, Hawaii, HI, USA, 8–11 January 2019; pp. 5165–5174. [Google Scholar]

- Erol, S.; Schumacher, A.; Sihn, W. Strategic guidance towards Industry 4.0—A three-stage process model. In Proceedings of the International Conference on Competitive Manufacturing (COMA), Stellenbosch, South Africa, 27–29 January 2016; pp. 495–501. [Google Scholar]

- Akdil, K.Y.; Ustundag, A.; Cevikcan, E. Maturity and Readiness Model for Industry 4.0 Strategy. In Industry 4.0: Managing the Digital Transformation; Springer Series in Advanced Manufacturing; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Brozzi, R.; Amico, R.D.D.; Monizza, G.P.; Marcher, C. Design of Self-Assessment Tools to Measure Industry 4.0 Readiness. A Methodological Approach for Craftsmanship SMEs. In IFIP International Conference on Product Lifecycle Management; Springer: Cham, Switzerland, 2018; Volume 540, pp. 566–578. [Google Scholar] [CrossRef]

- Colli, M.; Madsen, O.; Berger, U.; Møller, C.; Wæhrens, B.V.; Bockholt, M. Contextualizing the outcome of a maturity assessment for Industry 4.0. IFAC-PapersOnLine 2018, 51, 1347–1352. [Google Scholar] [CrossRef]

- Gökalp, E.; Şener, U.; Eren, P.E. Development of an Assessment Model for Industry 4.0: Industry 4.0-MM. In International Conference on Software Process Improvement and Capability Determination; Springer: Cham, Switzerland, 2017; Volume 770, pp. 128–142. [Google Scholar]

- Basl, J.; Doucek, P. A Metamodel for Evaluating Enterprise Readiness in the Context of Industry 4.0. Information 2019, 10, 89. [Google Scholar] [CrossRef]

- Sibel, Y. Industry 4.0 and Turkey: A Financial Perspective. In Strategic Design and Innovative Thinking in Business Operations; Springer: Cham, Switzerland, 2018; pp. 273–291. [Google Scholar]

- Ustundag, A.; Cevikcan, E. Industry 4.0: Managing the Digital Transformation; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Kuan, K.K.Y.; Chau, P.Y.K. A perception-based model for EDI adoption in small businesses using a technology-organization-environment framework. Inf. Manag. 2001, 38, 507–521. [Google Scholar] [CrossRef]

- Srivastava, S.C.; Teo, T.S.H. Facilitators for e-government development: An application of the technology-organization-environment framework. In Association for Information Systems—12th Americas Conference on Information Systems (AMCIS 2006 Proceedings); Association for Information Systems: Atlanta, GA, USA, 2006. [Google Scholar]

- Ardito, L.; Petruzzelli, A.M.; Panniello, U.; Garavelli, A.C. Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Bus. Process Manag. J. 2019, 25, 323–346. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Higgins, J.; Green, S. Cochrane Handbook for Systematic Reviews of Interventions; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Elo, S.; Kyngäs, H. The qualitative content analysis process. J. Adv. Nurs. 2008, 62, 107–115. [Google Scholar] [CrossRef]

- Roberts, C.W. Content Analysis. In International Encyclopedia of the Social & Behavioral Sciences, 2nd ed.; Elsevier: Oxford, UK, 2015; Volume 4, pp. 769–773. [Google Scholar] [CrossRef]

- Bibby, L.; Dehe, B. Defining and assessing industry 4.0 maturity levels–case of the defence sector. Prod. Plan. Control 2018, 29, 1030–1043. [Google Scholar] [CrossRef]

- Demeter, K. Assessing Industry 4.0 readiness: A multi-country industry level analysis. In Proceedings of the 25th Annual EurOMA Conference, Budapest, Hungary, 24–26 June 2018; 10p. [Google Scholar]

- Hamidi, S.R.; Aziz, A.A.; Shuhidan, S.M.; Aziz, A.A.; Mokhsin, M. SMEs maturity model assessment of IR4.0 digital transformation. Adv. Intell. Syst. Comput. 2018, 739, 721–732. [Google Scholar] [CrossRef]

- Horvat, D.; Stahlecker, T.; Zenker, A.; Lerch, C.; Mladineo, M. A conceptual approach to analysing manufacturing companies’ profiles concerning Industry 4.0 in emerging economies. Procedia Manuf. 2018, 17, 419–426. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2018, 127, 925–953. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.I. The Impact of Industry 4.0 on Supply Chains in Engineer-to-Order Industries—An Exploratory Case Study. IFAC-PapersOnLine 2018, 51, 122–127. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Baicu, A.V. Methods of Assessment and Training of a Company towards the Enterprise 4.0. In Proceedings of the 28th DAAAM International Symposium on Intelligent Manufacturing and Automation; DAAAM International: Vienna, Austria, 2017; pp. 1065–1073. [Google Scholar] [CrossRef]

- Gerlitz, L. Design Management as a Domain of Smart and Sustainable Enterprise: Business Modelling for Innovation and Smart Growth in Industry 4.0. Entrep. Sustain. Issues 2016, 3, 244–268. [Google Scholar] [CrossRef]

- Leyh, C.; Schäffer, T.; Bley, K.; Forstenhäusler, S. SIMMI 4.0—A Maturity Model for Classifying the Enterprise-wide IT and Software Landscape Focusing on Industry 4.0. In Proceedings of the 2016 Federated Conference on Computer Science and Information Systems (FedCSIS), Gdansk, Poland, 11–14 September 2016; Volume 8, pp. 1297–1302. [Google Scholar] [CrossRef]

- Pessl, E. Roadmap Industry 4.0—Implementation Guideline for Enterprises. Int. J. Sci. Technol. Soc. 2017, 5, 193–202. [Google Scholar] [CrossRef]

- Kannan, S.M.; Suri, K.; Cadavid, J.; Barosan, I.; Van Den Brand, M.; Alferez, M.; Gerard, S. Towards industry 4.0: Gap analysis between current automotive MES and industry standards using model-based requirement engineering. In Proceedings of the 2017 IEEE International Conference on Software Architecture Workshops (ICSAW), Gothenburg, Sweden, 5–7 April 2017; pp. 29–35. [Google Scholar] [CrossRef]

- Methavitakul, B.; Santiteerakul, S. Analysis of key dimension and sub-dimension for Supply Chian of Industry to fourth Industry Performance Measurement. In Proceedings of the 2018 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Singapore, 1 July–2 August 2006; pp. 191–195. [Google Scholar]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A Scenario-Based Approach to Learning for the Future of Production. Procedia CIRP 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Lichtblau, K.; Stich, V.; Bertenrath, R.; Blum, M.; Bleider, M.; Millack, A.; Schmitt, K.; Schmitz, E.; Schröter, M. Industrie 4.0 Readiness; Impuls-Stiftung: Aachen/Cologne, Germany, 2015. [Google Scholar]

- Schumacker, R.E.; Lomax, R.G. A Beginner’s Guide to Structural Equation Modeling; Lawrence Erlbaum Associates, Inc.: Mahwah, NJ, USA, 2004. [Google Scholar] [CrossRef]

- Magdiel, P.; Astrid, J.; Marmolejo-saucedo, J.A. Organizational Systems Convergence with the Industry 4.0 Challenge. In Best Practices in Manufacturing Processes; Springer: Cham, Switzerland, 2019; pp. 411–431. [Google Scholar] [CrossRef]

- Tsohou, A.; Lee, H.; Irani, Z. Innovative public governance through cloud computing: Information privacy, business models and performance measurement challenges. Transform. Gov. People Process Policy 2014, 8, 251–282. [Google Scholar] [CrossRef]

- Ertan, J. Digital Readiness of Swedish Organizations. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2018. [Google Scholar]

- Lokuge, S.; Sedera, D.; Grover, V.; Xu, D. Organizational readiness for digital innovation: Development and empirical calibration of a construct. Inf. Manag. 2018, 56, 445–461. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).