Distributed Simulation Using Agents for the Internet of Things and the Factory of the Future

Abstract

1. Introduction

2. Agents as a Distributed Simulation Paradigm

3. Case Study 1

3.1. Description of a Retail Warehousing Environment

3.2. Description of the Agents in the Simulation Model

3.2.1. Data Analysis

3.2.2. Building the Simulation Model

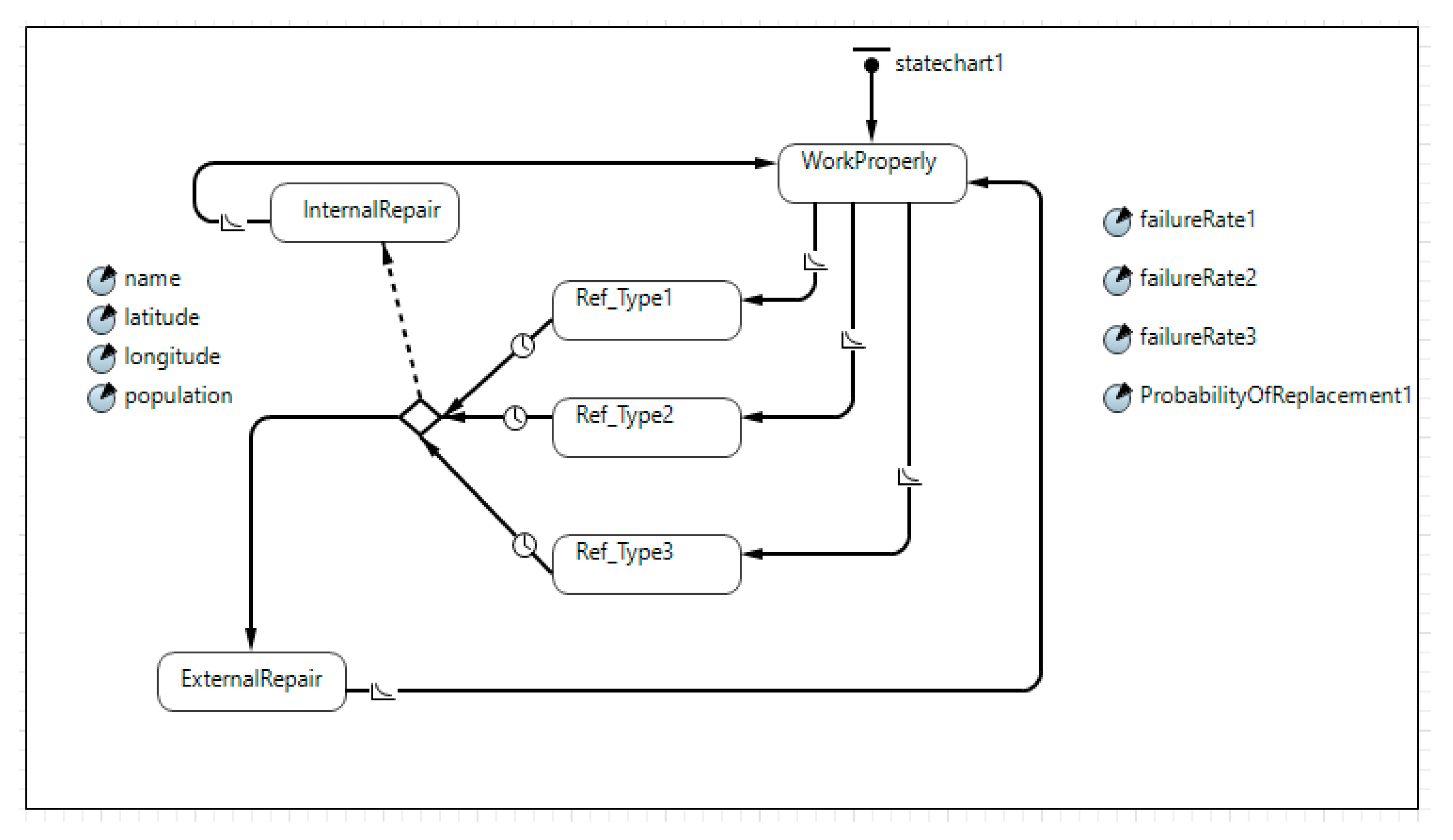

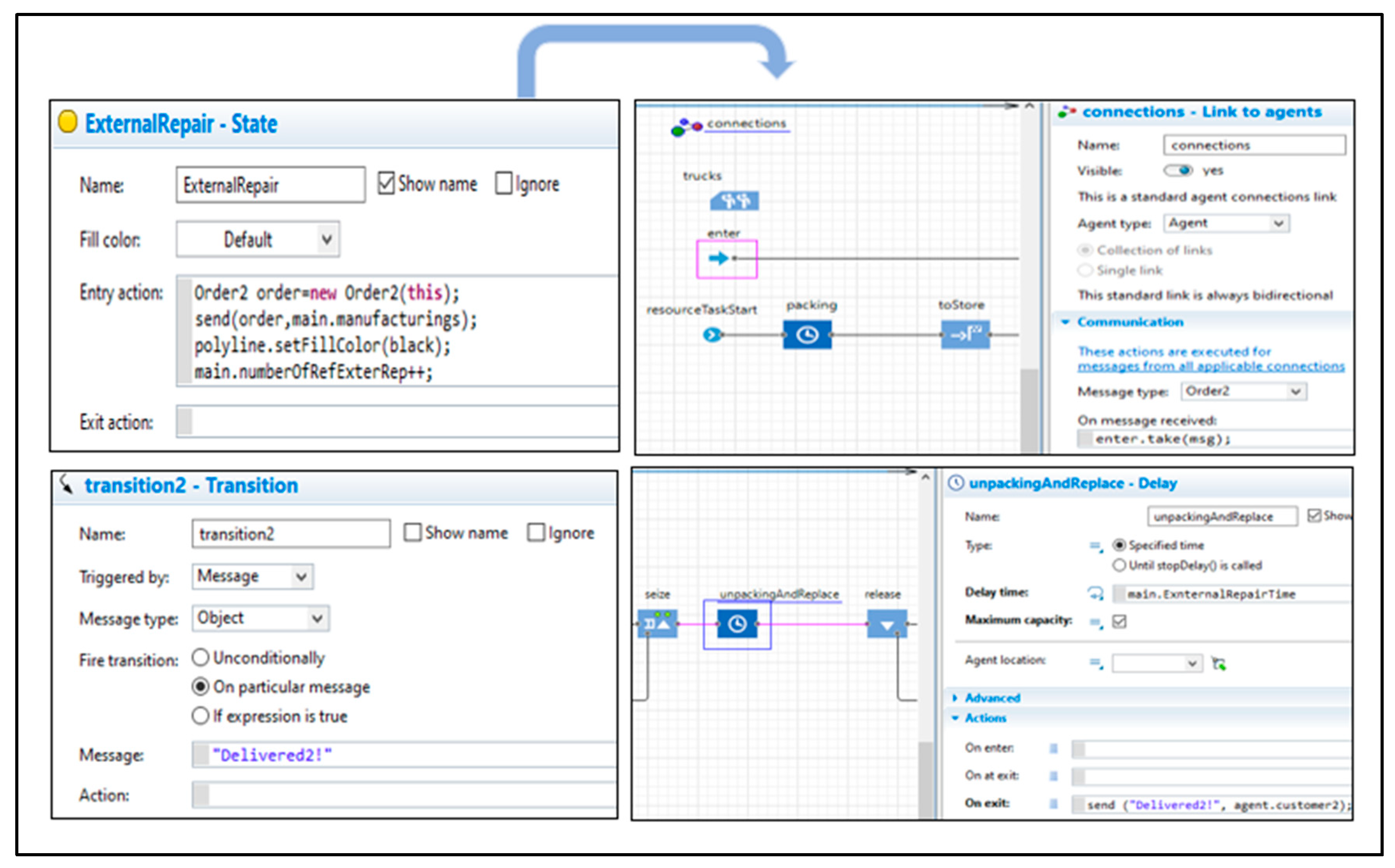

3.2.3. Hybrid Simulation Model

- Workers are always available;

- Worker movement time inside the warehouse is ignored;

- The queue in the model is based on first in first out (FIFO);

- Trucks are available all the time;

- The three types of refrigerators inside the Warehouse agent have the same behavior with different failure rate values.

3.2.4. Model Validation

- Face validation: the management of the warehouse facility approves the initial results of the simulation model.

- Statistical validation: A subset of historical data of Out of Service (OOS) time for 400 days was compared with simulation model output. It has been found that there is about a 3% relative difference between the ABM and real data of OOS obtained from the facility which suggests the ABM is practical to be used.

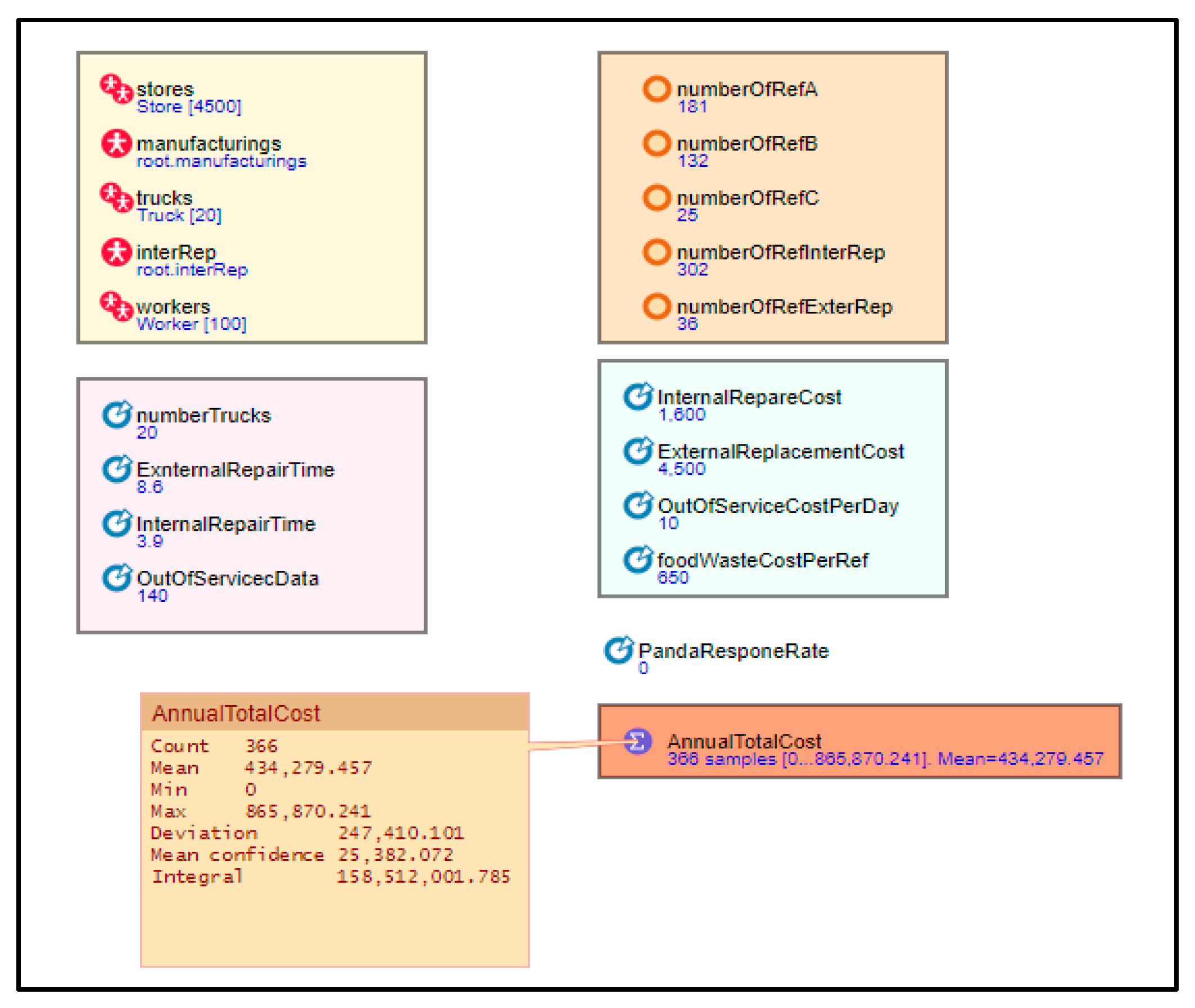

3.3. Results of the Simulation

3.3.1. ABM Results

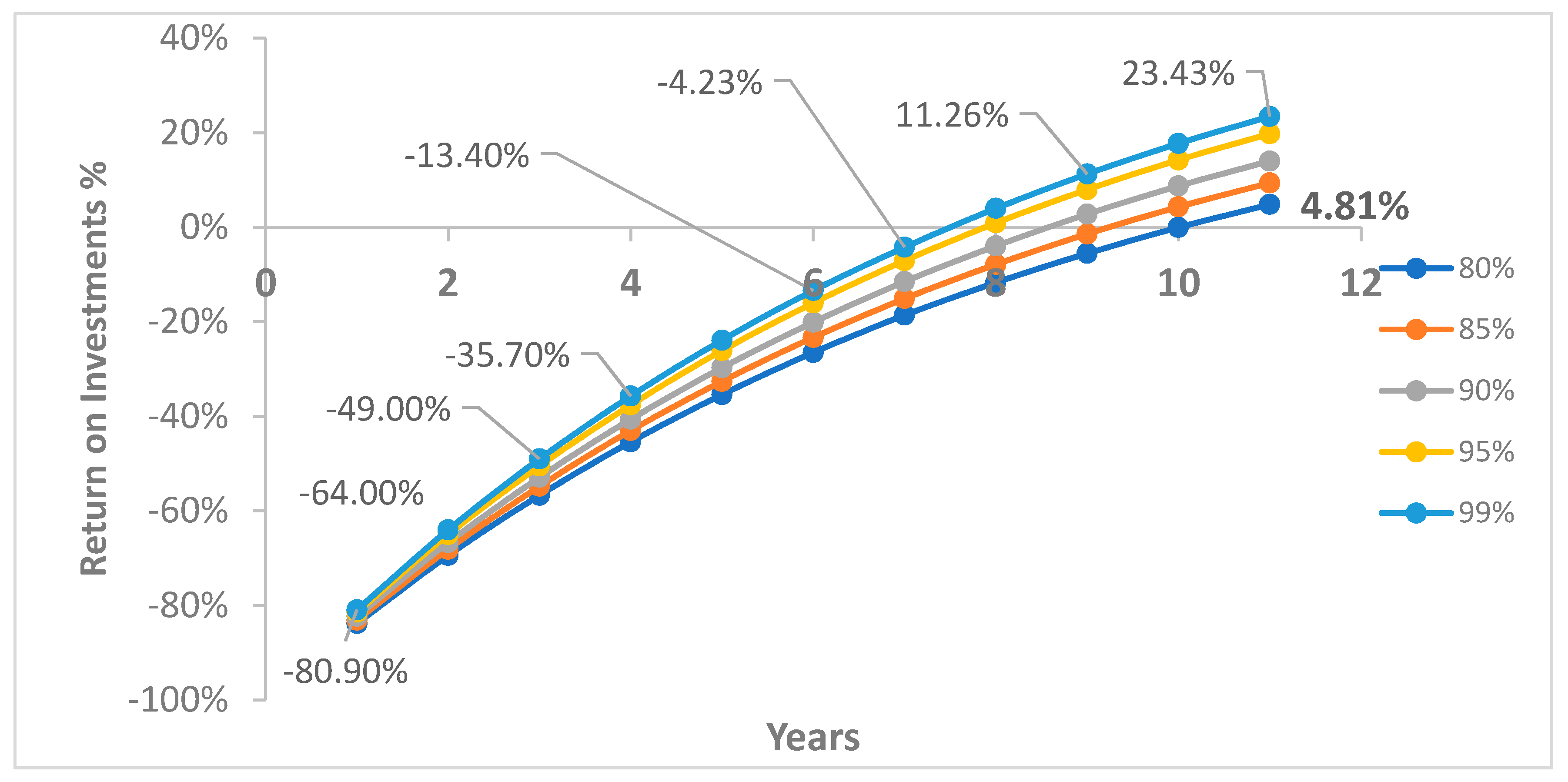

3.3.2. Economic Analysis-Return on Investment

4. Case Study 2

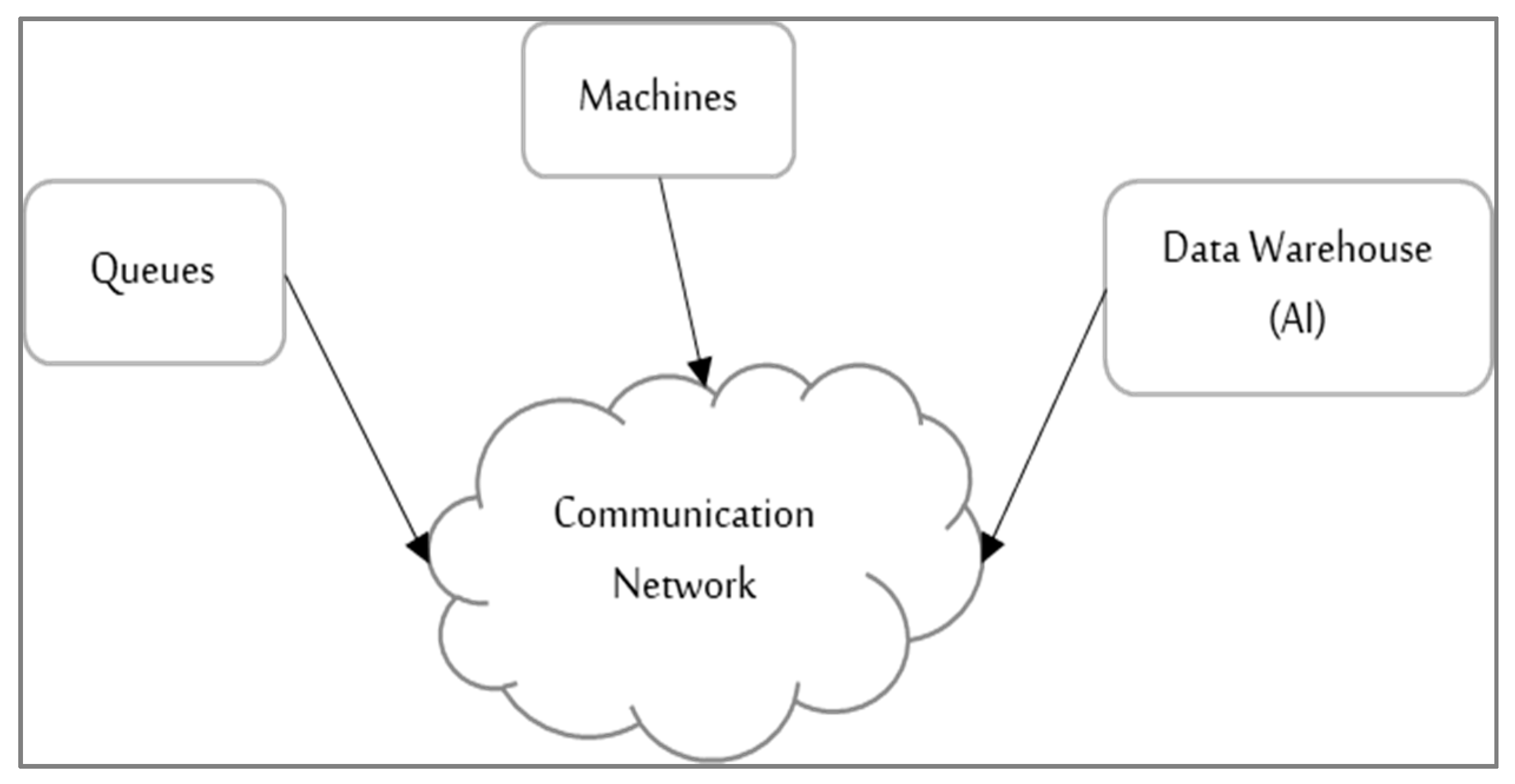

4.1. Description of Manufacturing Environment

4.2. Description of the Agents in the Simulation Model

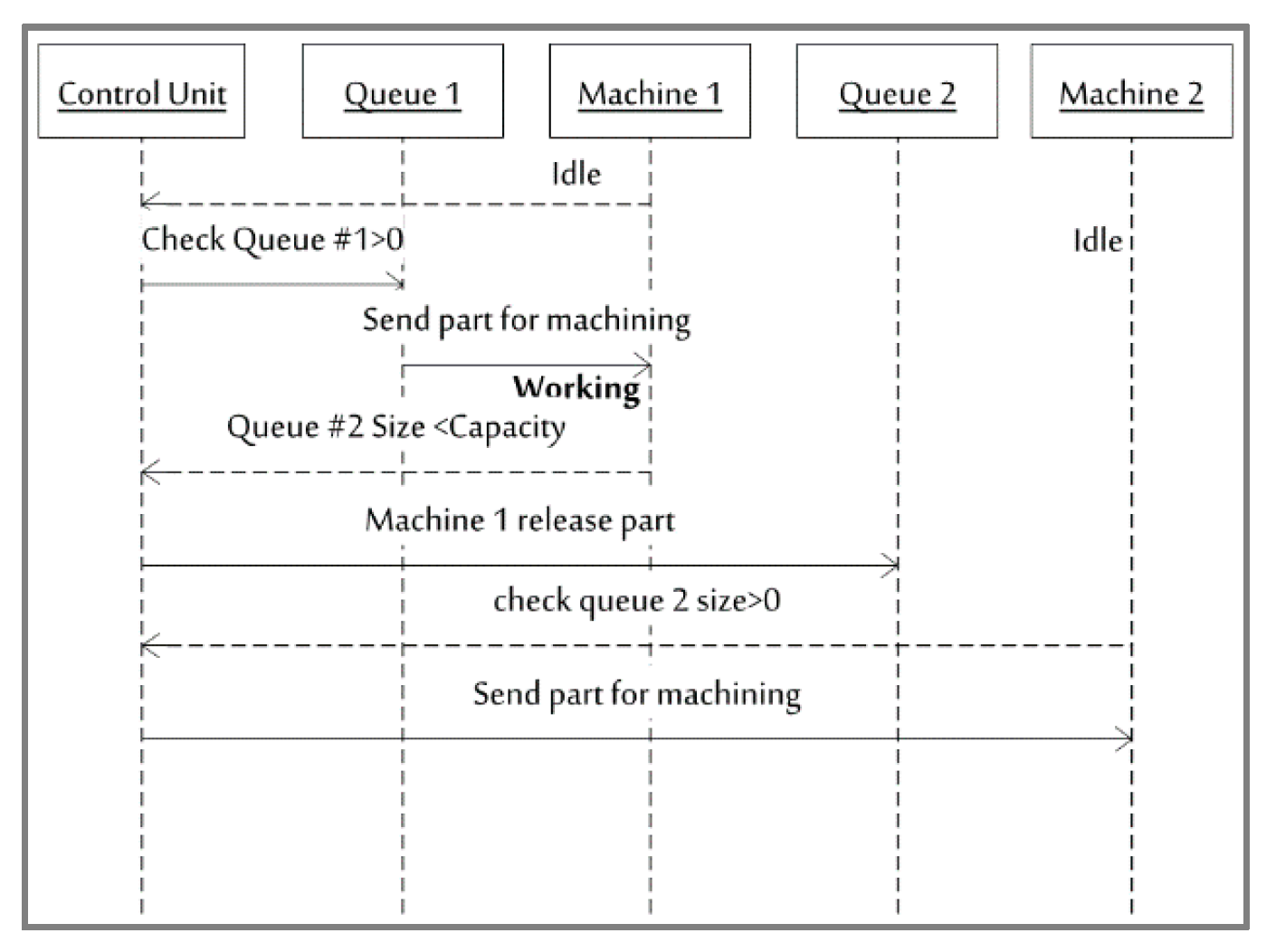

4.2.1. First Phase: Initial System Components Configuration

4.2.2. Second Phase: Process Plan

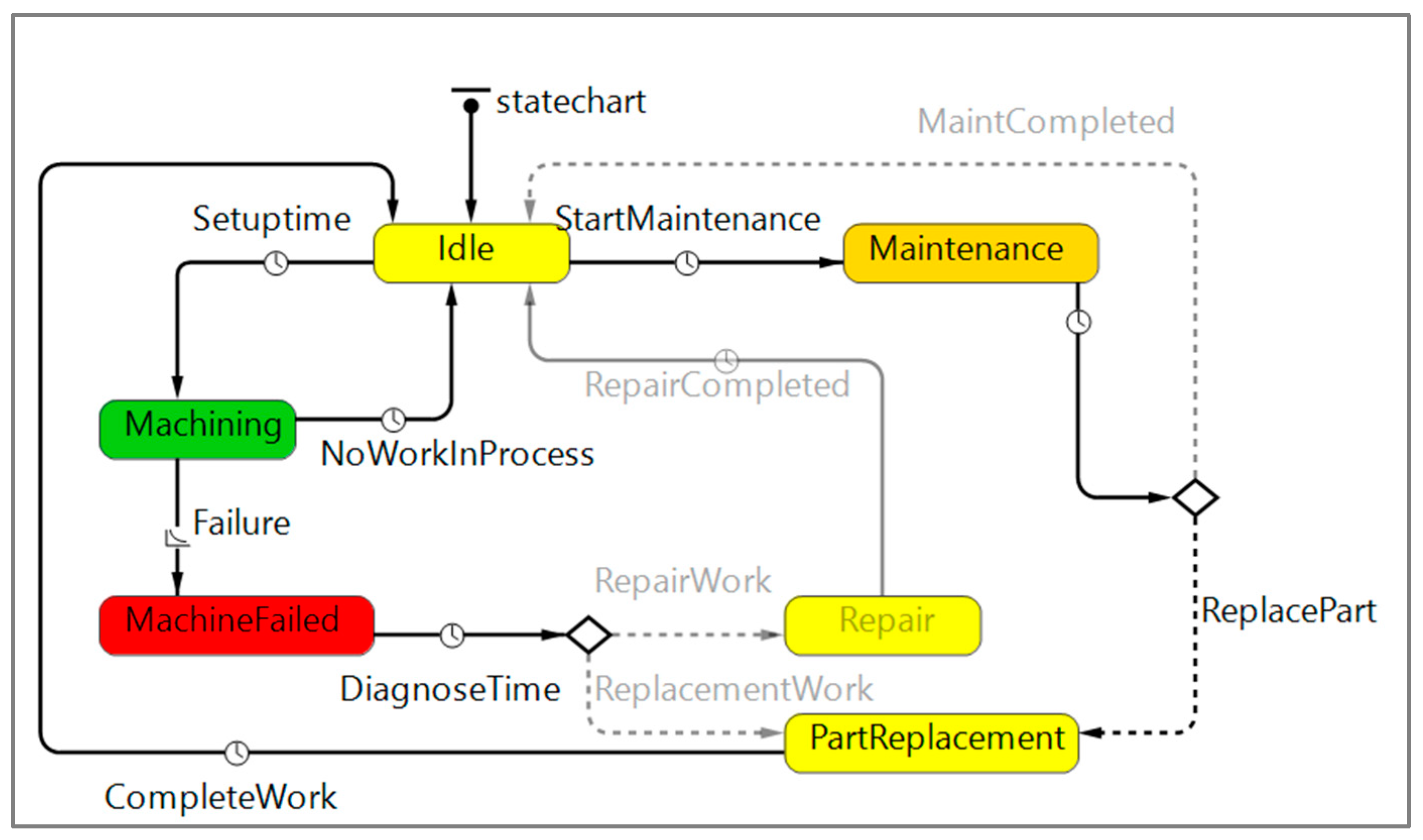

4.2.3. Third Phase: System Behavior

4.2.4. Forth Phase: System Configuration

- Availability of raw material;

- Movement time is not considered;

- First-in-first-out queue system;

- No rework parts.

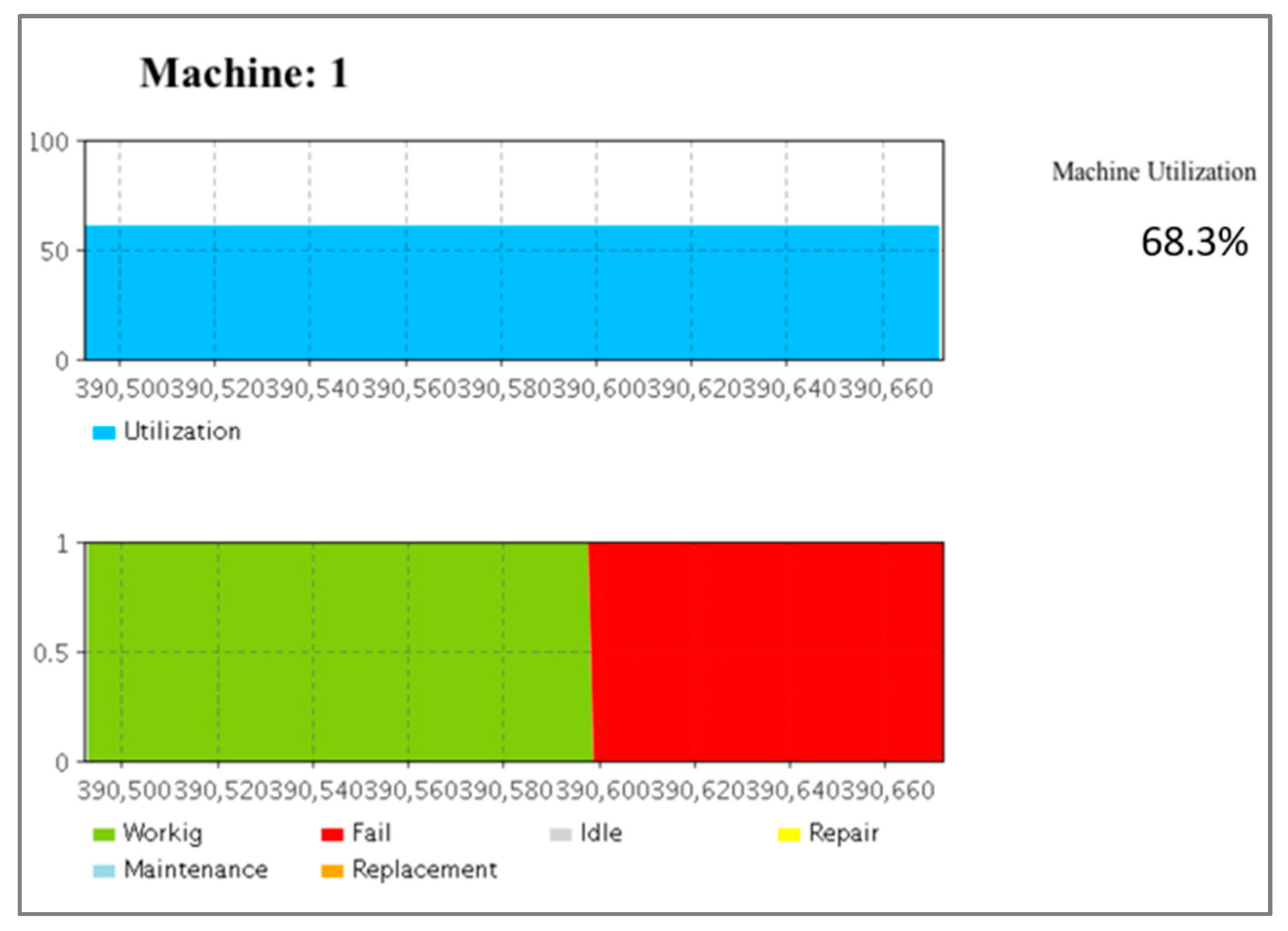

4.3. Results of the Simulation

5. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Fortino, G.; Russo, W.; Savaglio, C. Agent-oriented modeling and simulation of IoT networks. In Proceedings of the 2016 Federated Conference on Computer Science and Information Systems, Gdańsk, Poland, 11–14 September 2016; Available online: http://ceur-ws.org/Vol-1664/w2.pdf (accessed on 22 September 2020).

- Aguzzi, S.; Bradshaw, D.; Canning, M.; Cansfield, M.; Carter, P.; Cattaneo, G.; Gusmeroli, S.; Micheletti, G.; Rotondi, D.; Stevens, R. Definition of a Research and Innovation Policy Leveraging Cloud Computing and IoT Combination; Final Report; European Commission, SMART: Toronto, ON, Canada, 2013. [Google Scholar]

- Van der Hoek, W.; Wooldridge, M. Multi-Agent Systems. Found. Artif. Intell. 2008, 3, 887–928. [Google Scholar]

- Andrei, B. From System Dynamics and Discrete Event to Practical Agent Based Modeling: Reasons, Techniques, Tools. In Proceedings of the 22nd International Conference of the System Dynamics Society, Oxford, UK, 25–29 July 2004. [Google Scholar]

- Borshchev, A. The Big Book of Simulation Modeling: Multimethod Modeling with AnyLogic 6; AnyLogic North America: Oakbrook Terrace, IL, USA, 2013. [Google Scholar]

- Brailsford, S.C. Modeling human behavior—An (id)entity crisis? In Proceedings of the Winter Simulation Conference 2014, Savannah, GA, USA, 7–10 December 2014. [Google Scholar]

- Axtell, R. Why Agents?: On the Varied Motivations for Agent Computing in the Social Sciences; Working Paper No. 1; Center on Social and Economic Dynamics: Washington, DC, USA, November 2000. [Google Scholar]

- Basingab, M. Investigating The Adoption of Internet of Things Technology Using Agent-Based Simulation. In Proceedings of the International Conference on Industrial Engineering & Operations Management, Bangkok, Thailand, 5–7 March 2019; pp. 1539–1550. [Google Scholar]

- Hurtado, N.; Ruiz, M.; Orta, E.; Torres, J. Using simulation to aid decision making in managing the usability evaluation process. Inf. Softw. Technol. 2015, 57, 509–526. [Google Scholar] [CrossRef]

- Plaza, S.; Ortega, N.; Celaya, A.; Sánchez, J.A.; López de Lacalle, L.N.; Izquierdo, B. About the importance of simulation tools in the learning process of metal forming and moulding. Mater. Sci. Forum 2011, 692, 1. [Google Scholar] [CrossRef]

- Ni, H.; Rui, Y.; Wang, J.; Cheng, L. A Synthetic method for atmospheric diffusion simulation and environmental impact assessment of accidental pollution in the chemical industry in a WEBGIS context. Int. J. Environ. Res. Public Health 2014, 11, 9238–9255. [Google Scholar] [CrossRef] [PubMed]

- Nealon, J.; Moreno, A. Agent-based applications in health care. In Applications of Software Agent Technology in the Health Care Domain; Springer: Berlin/Heidelberg, Germany, 2003; pp. 3–18. [Google Scholar]

- Cabrera, E.; Taboada, M.; Iglesias, M.L.; Epelde, F.; Luque, E. Optimization of healthcare emergency departments by agent-based simulation. Procedia Comput. Sci. 2011, 4, 1880–1889. [Google Scholar] [CrossRef]

- Macal, C.M.; North, M.J. Agent-based modeling and simulation. In Proceedings of the 2009 Winter Simulation Conference (WSC), Austin, TX, USA, 13–16 December 2009. [Google Scholar]

- Carley, K.M.; Fridsma, D.B.; Casman, E.; Yahja, A.; Altman, N.; Chen, L.C.; Kaminsky, B.; Nave, D. BioWar: Scalable agent-based model of bioattacks. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2006, 36, 252–265. [Google Scholar] [CrossRef]

- Savaglio, C.; Ganzha, M.; Paprzycki, M.; Bădică, C.; Ivanović, M.; Fortino, G. Agent-based Internet of Things: State-of-the-art and research challenges. Future Gener. Comput. Syst. 2020, 102, 1038–1053. [Google Scholar] [CrossRef]

- Yazan, D.M.; Fraccascia, L. Sustainable operations of industrial symbiosis: An enterprise input-output model integrated by agent-based simulation. Int. J. Prod. Res. 2020, 58, 392–414. [Google Scholar] [CrossRef]

- Fraccascia, L.; Yazan, D.M.; Albino, V.; Zijm, H. The role of redundancy in industrial symbiotic business development: A theoretical framework explored by agent-based simulation. Int. J. Prod. Econ. 2020, 221, 107471. [Google Scholar] [CrossRef]

- García-Magariño, I.; Gray, G.; Muttukrishnan, R.; Asif, W. Agent-based IoT Coordination for Smart Cities Considering Security and Privacy. IEEE 2019, 221–226. [Google Scholar] [CrossRef]

- Inaba, T. Used Product Acquisition Control by Financial Incentives in Remanufacturing. in 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM). IEEE 2019. [Google Scholar] [CrossRef]

- Kano, T.; Yasui, K.; Mikami, T.; Asally, M.; Ishiguro, A. An agent-based model for interrelation between COVID-19 outbreak and economic activities. arXiv 2020, arXiv:2007.11988. [Google Scholar]

- Cuevas, E. An agent-based model to evaluate the COVID-19 transmission risks in facilities. Comput. Biol. Med. 2020, 121, 103827. [Google Scholar] [CrossRef] [PubMed]

- Afrin Fauzya, R.; Fadillah, R. Multi-Agent simulation in the inter-organizational trust model and knowledge sharing in the automotive industry. J. Tek. Ind. 2019, 20, 161–171. [Google Scholar]

- García-Magariño, I.; Sendra, S.; Lacuesta, R.; Lloret, J. Security in Vehicles With IoT by Prioritization Rules, Vehicle Certificates, and Trust Management. IEEE Internet Things J. 2019, 6, 5927–5934. [Google Scholar] [CrossRef]

- Houston, C.; Gooberman-Hill, S.; Mathie, R.; Kennedy, A.; Li, Y.; Baiz, P. Case study for the return on investment of internet of things using agent-based modelling and data science. Systems 2017, 5, 4. [Google Scholar] [CrossRef]

- Klügl, F. A validation methodology for agent-based simulations. In Proceedings of the 2008 ACM Symposium on Applied Computing, Fortaleza, Ceará, Brazil, 16–20 March 2008. [Google Scholar]

- Nagadi, K.; Rabelo, L.; Basingab, M.; Sarmiento, A.T.; Jones, A.; Rahal, A. A hybrid simulation-based assessment framework of smart manufacturing systems. Int. J. Comput. Integr. Manuf. 2018, 31, 115–128. [Google Scholar]

| Parameter | Value |

|---|---|

| Repair Time | 5 h |

| Number of Refrigeration units | 4500 Refrigerators |

| Number of Store locations | 150 Stores |

| Average Refrigeration unit/Store | 30 Refrigerators |

| Truck Loading Time | Uniform (2,3) h |

| Truck Speed | 60 km/h |

| Cost of Repair/Refrigerator | $3000 |

| Cost of food waste/Refrigerator | $650 |

| Response Rate | ||||

|---|---|---|---|---|

| Failure Rate Reduction | 80% | 85% | 90% | 95% |

| 80% | $137,425 | $134,955 | $132,485 | $130,015 |

| 85% | $105,801 | $103,164 | $101,246 | $99,329 |

| 90% | $72,180 | $70,850 | $69,580 | $68,281 |

| 95% | $31,169 | $30,584 | $29,999 | $29,414 |

| 99% | $5195 | $5098 | $5000 | $4902 |

| Years | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|---|

| Cost Saving | $795,020 | $795,020 | $795,020 | $795,020 | $795,020 | $795,020 | $795,020 | $795,020 | $795,020 | |

| PV(CS) | $704,805 | $624,827 | $553,925 | $491,068 | $435,344 | $385,943 | $342,148 | $303,323 | $268,903 | |

| Total PV(CS) | $704,805 | $1,329,631 | $1,883,556 | $2,374,624 | $2,809,967 | $3,195,911 | $3,538,059 | $3,841,382 | $4,110,285 | |

| Investment | 4 M | |||||||||

| PV(Invest) | 4 M | |||||||||

| ROI | −82.38% | −66.76% | −52.91% | −40.63% | −29.75% | −20.10% | −11.55% | −3.97% | 2.76% |

| Response Rate = 0.85 | ROI in Each Year | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Failure Reduction Rate | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 80% | −83.8% | −69.4% | −56.7% | −45.4% | −35.4% | −26.5% | −18.6% | −11.7% | −5.53% | −0.05% | 4.81% |

| 85% | −83.1% | −68.1% | −54.8% | −43.0% | −32.6% | −23.3% | −15.1% | −7.87% | −1.42% | 4.30% | 9.37% |

| 90% | −82.3% | −66.7% | −52.9% | −40.6% | −29.7% | −20.1% | −11.5% | −3.97% | 2.76% | 8.72% | 14.00% |

| 95% | −81.4% | −65.0% | −50.5% | −37.6% | −26.1% | −16.0% | −7.07% | 0.90% | 7.96% | 14.22% | 19.77% |

| 99% | −80.9% | −64.0% | −49.0% | −35.7% | −23.9% | −13.4% | −4.23% | 3.98% | 11.26% | 17.71% | 23.43% |

| Types of Machines | CNC Vertical | CNC Horizontal | Manual Operation | Tapping | |

|---|---|---|---|---|---|

| Sections | Milling | Drilling | Deburring | Tapping (Threading) | |

| Operations | |||||

| Thickness | √ | ||||

| Alignment | √ | √ | |||

| Bolt Holes | √ | √ | √ | ||

| Perpendicularity | √ | ||||

| No. | Parameters | Unit | CNC Horizontal Machine (Drilling) | CNC Vertical Machine (Milling) | Tapping Machine | |||

|---|---|---|---|---|---|---|---|---|

| Minimum Value | Maximum Value | Minimum Value | Maximum Value | Minimum Value | Maximum Value | |||

| 1 | Process Mean Time | Sec. | 100 | 140 | 80 | 100 | 30 | 50 |

| 2 | Maintenance Period | Days | 80 | 100 | 70 | 90 | 50 | 90 |

| 3 | Mean Time of Maintenance | Min. | 20 | 45 | 45 | 60 | 20 | 30 |

| 4 | Average Rate of Failure | 0.05 | 0.1 | 0.05 | 0.1 | 0.05 | 0.1 | |

| 5 | Mean Time of Repair | Min. | 30 | 60 | 30 | 60 | 30 | 60 |

| 6 | Mean Time of Replacement | Min. | 20 | 40 | 20 | 40 | 20 | 40 |

| 7 | Percentage of Replacement | 0.1 | 0.2 | 0.1 | 0.2 | 0.1 | 0.2 | |

| 8 | Diagnose Time | Min. | 10 | 2880 | 10 | 2880 | 10 | 2880 |

| 9 | Buffer Size | Part | 50 | 50 | 50 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basingab, M.; Nagadi, K.; Rahal, A.; Bukhari, H.; Alasim, F. Distributed Simulation Using Agents for the Internet of Things and the Factory of the Future. Information 2020, 11, 458. https://doi.org/10.3390/info11100458

Basingab M, Nagadi K, Rahal A, Bukhari H, Alasim F. Distributed Simulation Using Agents for the Internet of Things and the Factory of the Future. Information. 2020; 11(10):458. https://doi.org/10.3390/info11100458

Chicago/Turabian StyleBasingab, Mohammed, Khalid Nagadi, Ahmad Rahal, Hatim Bukhari, and Fahad Alasim. 2020. "Distributed Simulation Using Agents for the Internet of Things and the Factory of the Future" Information 11, no. 10: 458. https://doi.org/10.3390/info11100458

APA StyleBasingab, M., Nagadi, K., Rahal, A., Bukhari, H., & Alasim, F. (2020). Distributed Simulation Using Agents for the Internet of Things and the Factory of the Future. Information, 11(10), 458. https://doi.org/10.3390/info11100458