Offshore Oil and Gas Safety: Protection against Explosions

Abstract

1. Introduction

2. Main Certification Schemes for Protection against Explosions

2.1. European “ATmosphere Explosible” (ATEX)

- (1)

- 1999/92/EC ATEX directive for the protection of the user (personnel and workers)—“Minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres”;

- (2)

- 2014/34/EU ATEX directive for product safety—“Equipment and protective systems intended for use in potentially explosive atmospheres,” a new version of 94/9/EC.

2.2. “International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres” (IECEx)

- (1)

- Equipment—Only technical standards issued by Technical Committee 31 “Equipment for explosive atmospheres” of the International Electrotechnical Commission (IEC) can be used for the certification of equipment (only electrical equipment can be certified), while the certification through an IECEX Certification Body (ExCB) is required for all Categories of equipment (Categories 1, 2, and 3 in IECEx Ga, Gb, and Gc, respectively) (ATEX allows for the self-certification of equipment by the manufacturer in Category 3);

- (2)

- Service Facilities—In addition to the certification of equipment, the IECEx scheme allows the certification of the repair and overhaul of equipment (nothing similar is available in the ATEX scheme);

- (3)

- Persons—Certification for qualified persons who were properly trained and meet the prerequisites to implement safety requirement required by the IECEx scheme (nothing similar is available in the ATEX scheme);

- (4)

- Conformity Mark—It is issued by approved IECEx Certification Bodies (ExCBs) for the equipment manufactured and tested using appropriate IEC technical standards.

2.3. Other Main Certification Schemes for Protection against Explosions

2.3.1. USA

2.3.2. Canada

2.3.3. Eurasian Union

2.3.4. China

2.3.5. Brazil

2.3.6. Australia and New Zealand

3. Differences between the ATEX and IECEx Certification Schemes

- In the EU/EEA, the ATEX scheme is mandatory, and it is developed by the European Commission (government), while the IECEx scheme is operated by the International Electrotechnical Commission (IEC), i.e., regulated through an industry representative at international level.

- Safety of personnel is regulated under the ATEX scheme through the mandatory use of a separate directive, 1999/92/EC, while nothing similar is available through the IECEx.

- A certificate through an ATEX Notified Body is mandatory for equipment in Categories 1 and 2, while self-certification by the manufacturer is allowed for equipment in Category 3 (on the other hand, the IECEx scheme requires attestation of all categories of equipment through its Certified Bodies (ExCBs)).

- The ATEX scheme requires certification through any available technical standards that can meet Essential Health and Safety Requirements of the ATEX directives, while the IECEx requires use of the technical standards developed only by the International Electrotechnical Commission (IEC).

- Although the ATEX scheme uses terms “equipment” and “protective systems,” it covers both electrical and nonelectrical equipment (EN 13463 and EN ISO 80079 “Non-electrical equipment for explosive atmospheres”), while the IECEx covers only electrical equipment.

- The ATEX scheme explicitly does not include mobile offshore drilling units in its scope.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Towle, C. The IECEX Certification Scheme. Meas. Control 2003, 36, 154–155. [Google Scholar] [CrossRef]

- Marangon, A.; Carcassi, M. ATEX Directives: The New Approach. In Proceedings of the Conference Valutazione e Gestione del Rischio Negli Insediamenti Civili ed Industriali, Pisa, Italy, 17–19 October 2006; Available online: http://conference.ing.unipi.it/vgr2006/archivio/Archivio/2008/Archivio/2006/Articoli/700213.pdf (accessed on 19 January 2021).

- Leroux, P. New Regulations and Rules for ATEX Directives. IEEE Ind. Appl. Mag. 2007, 13, 43–51. [Google Scholar] [CrossRef]

- Kaiser, M.J.; Snyder, B. The five offshore drilling rig markets. Mar. Policy 2013, 39, 201–214. [Google Scholar] [CrossRef]

- Geng, J.; Murè, S.; Demichela, M.; Baldissone, G. ATEX-HOF Methodology: Innovation Driven by Human and Organizational Factors (HOF) in Explosive Atmosphere Risk Assessment. Safety 2020, 6, 5. [Google Scholar] [CrossRef]

- Tommasini, R.; Pons, E.; Palamara, F. Area Classification for Explosive Atmospheres: Comparison between European and North American Approaches. In Proceedings of the 60th Annual IEEE Petroleum and Chemical Industry Technical Conference, Chicago, IL, USA, 23–25 September 2013. [Google Scholar] [CrossRef]

- Pommé, R.; Sijrier, H.J. IECEX Certification Schemes versus ATEX Directives. In Proceedings of the PCIC Europe 2010, Oslo, Norway, 15–17 June 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1–8. Available online: https://ieeexplore.ieee.org/document/5525731 (accessed on 19 January 2021).

- Johnson, B.; House, P.; Mulder, R.; Pijpker, T.; Pomme, R. Role of IEC Standards. IEEE Ind. Appl. Mag. 2008, 14, 14–20. [Google Scholar] [CrossRef]

- Novák, P.; Kot, T.; Babjak, J.; Konečný, Z.; Moczulski, W.; Rodriguez López, Á. Implementation of Explosion Safety Regulations in Design of a Mobile Robot for Coal Mines. Appl. Sci. 2018, 8, 2300. [Google Scholar] [CrossRef]

- Palazzi, E.; Currò, F.; Fabiano, B. Accidental Continuous Releases from Coal Processing in Semi-Confined Environment. Energies 2013, 6, 5003–5022. [Google Scholar] [CrossRef]

- Hughes, A. Why Dust Explodes. Meas. Control 2012, 45, 271–272. [Google Scholar] [CrossRef]

- Abbasi, T.; Abbasi, S.A. Dust explosions–Cases, causes, consequences, and control. J. Hazard. Mater. 2007, 140, 7–44. [Google Scholar] [CrossRef] [PubMed]

- Eckhoff, R.K.; Li, G. Industrial Dust Explosions. A Brief Review. Appl. Sci. 2021, 11, 1669. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Differences and similarities of gas and dust explosions: A critical evaluation of the European ‘ATEX’directives in relation to dusts. J. Loss Prev. Process Ind. 2006, 19, 553–560. [Google Scholar] [CrossRef]

- Alves, J.J.; Neto, A.T.; Araújo, A.C.; Silva, H.B.; Silva, S.K.; Nascimento, C.A.; Luiz, A.M. Overview and Experimental Verification of Models to Classify Hazardous Areas. Process Saf. Environ. Prot. 2019, 122, 102–117. [Google Scholar] [CrossRef]

- Rangel, E.; Luiz, A.M.; de P. M. Filho, H.L. Area Classification is Not a Copy-and-Paste Process: Performing Reliable Hazardous-Area-Classification Studies. IEEE Ind. Appl. Mag. 2015, 22, 28–39. [Google Scholar] [CrossRef]

- Propst, J.E.; Barrios, L.A.; Lobitz, B. Applying the API Alternate Method for Area Classification. IEEE Trans. Ind. Appl. 2007, 43, 162–171. [Google Scholar] [CrossRef]

- Stefanowicz, D. An Overview of Hazardous Areas. Meas. Control 2003, 36, 142–144. [Google Scholar] [CrossRef][Green Version]

- McMillan, A.J. Hazardous Areas—An Overview. Meas. Control 1986, 19, 6–9. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, W.; Zhang, S. Effects of spark duration on minimum ignition energy for methane/air mixture. Process Saf. Prog. 2011, 30, 154–156. [Google Scholar] [CrossRef]

- Cui, G.; Li, Z.; Yang, C.; Zhou, Z.; Li, J. Experimental study of minimum ignition energy of methane–air mixtures at low temperatures and elevated pressures. Energy Fuels 2016, 30, 6738–6744. [Google Scholar] [CrossRef]

- Brkić, D.; Praks, P. Proper Use of Technical Standards in Offshore Petroleum Industry. J. Mar. Sci. Eng. 2020, 8, 555. [Google Scholar] [CrossRef]

- Thomas, G.A.N.; Reeve, P.T.N.; Spanhel, J.M. Sharing Information to Promote Oil and Gas Industry Standardisation in ISO. In Proceedings of the Offshore Technology Conference, Offshore Technology Conference, Houston, TX, USA, 1–4 May 1995. [Google Scholar] [CrossRef]

- Reeve, P.T.N.; Johansen, A.R.; Lautier, J. International Standards for the Oil and Natural Gas Industries: A Review Paper. In Proceedings of the Offshore Technology Conference, Offshore Technology Conference, Houston, TX, USA, 2–5 May 1994. [Google Scholar] [CrossRef]

- Arney, C.E. Toward One Set of International Standards for the Petroleum Industry Worldwide. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1992. [Google Scholar] [CrossRef]

- Wilson, D.E. Internationalization of Oil Industry Standards. In Offshore Technology Conference. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1992. [Google Scholar] [CrossRef]

- Agius, C.; Jachia, L. International IECEx System Evolution and Role of the United Nations, UNECE. In Proceedings of the 2012 Petroleum and Chemical Industry Conference Europe Conference Proceedings (PCIC EUROPE), Prague, Czech Republic, 19–21 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1–15. Available online: https://ieeexplore.ieee.org/document/6243265 (accessed on 19 January 2021).

- Rangel, E. Brazil moves from divisions to zones. In Proceedings of the Annual Petroleum and Chemical Industry Conference, New Orleans, LA, USA, 23–25 September 2002; IEEE: Piscataway, NJ, USA, 2002; Volume 49, pp. 23–30. [Google Scholar] [CrossRef]

- Hamer, P.S.; Bishop, D.N.; Bried, F. API RP 500-Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities. In Proceedings of the 1992 Conference of Industry Applications Society 39th Annual Petroleum and Chemical Industry Conference, San Antonio, TX, USA, 28–30 September 1992; IEEE: Piscataway, NJ, USA, 1992; pp. 37–42. [Google Scholar] [CrossRef]

- Bishop, D.N.; Jagger, D.M.; Propst, J.E. New area classification guidelines. In Proceedings of the Industry Applications Society 45th Annual Petroleum and Chemical Industry Conference, Indianapolis, IN, USA, 28–30 September 1998; IEEE: Piscataway, NJ, USA, 1998; pp. 9–19. [Google Scholar] [CrossRef]

- Carlson, R.; Flanders, P.; Roussel, B. Conversion from Division to Zone electrical classification-why and how the world’s largest oil company made the change. In Proceedings of the Industry Applications Society Forty-Seventh Annual Petroleum and Chemical Industry Technical Conference, San Antonio, TX, USA, 13 September 2000; IEEE: Piscataway, NJ, USA, 2000; pp. 1–9. [Google Scholar] [CrossRef]

- Hamer, P.S.; Wood, B.M.; Doughty, R.L.; Gravell, R.L.; Hasty, R.C.; Wallace, S.E.; Tsao, J.P. Flammable Vapor Ignition Initiated by Hot Rotor Surfaces within an Induction Motor: Reality or Not? IEEE Trans. Ind. Appl. 1999, 35, 100–111. [Google Scholar] [CrossRef]

- Muhammad Niazi, U.; Shakir Nasif, M.; Muhammad, M.; Khan, F. Investigating Vapour Cloud Explosion Dynamic Fatality Risk on Offshore Platforms by Using a Grid-Based Framework. Processes 2020, 8, 685. [Google Scholar] [CrossRef]

- Zhu, R.; Li, X.; Hu, X.; Hu, D. Risk Analysis of Chemical Plant Explosion Accidents Based on Bayesian Network. Sustainability 2020, 12, 137. [Google Scholar] [CrossRef]

- Jung, B.; Kim, J.H.; Seo, J.K. Investigation of the Structural Strength of Existing Blast Walls in Well-Test Areas on Drillships. J. Mar. Sci. Eng. 2020, 8, 583. [Google Scholar] [CrossRef]

- Luo, F.; Zhang, S.; Yang, D. Anti-Explosion Performance of Composite Blast Wall with an Auxetic Re-Entrant Honeycomb Core for Offshore Platforms. J. Mar. Sci. Eng. 2020, 8, 182. [Google Scholar] [CrossRef]

- Yu, G.; Zhang, L.; Jia, S.; Geng, Y.; Liu, J. Numerical Study on the Natural Convection of Air in a Cubic Cavity Subjected to a Yawing Motion. J. Mar. Sci. Eng. 2019, 7, 204. [Google Scholar] [CrossRef]

- Yu, G.; Jia, S.; Geng, Y. Numerical Investigation into the Two-Phase Convective Heat Transfer within the Hold of an Oil Tanker Subjected to a Rolling Motion. J. Mar. Sci. Eng. 2019, 7, 94. [Google Scholar] [CrossRef]

| ATEX | IECEx |

|---|---|

| Fixed platforms (including equipment onboard) on the EU/EEA continental shelf | Mobile units (including equipment onboard) on the EU/EEA continental shelf 2 |

| Facilities and equipment onshore the EU/EEA | Foreign mobile units (including equipment onboard) on the US continental shelf 3 |

| (i) Groups | |

|---|---|

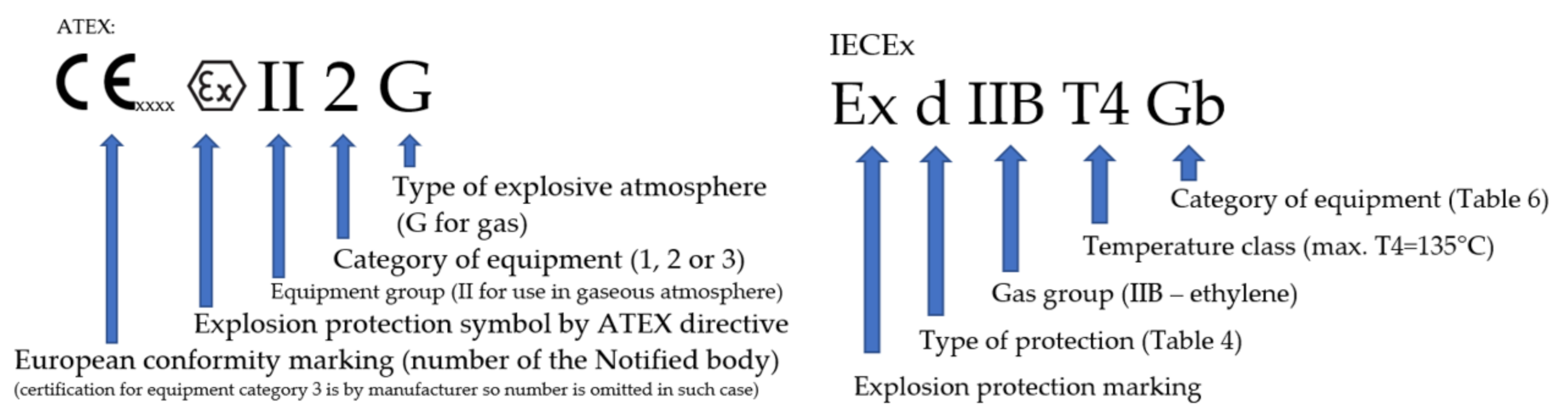

| Group I | Relevant to underground coal mines, where the occurrence of dust and methane firedamp is frequent [9,10,11,12,13,14] |

| Group II | Relevant to the oil and gas industry and refers to potentially gaseous explosive atmospheres |

| (ii) Categories | |

| Category 1 | Most strict and intended for use in areas with the highest risk of explosions |

| Category 2 | For use in areas in which explosive atmospheres are likely to occur |

| Category 3 | For areas with a low probability for explosions |

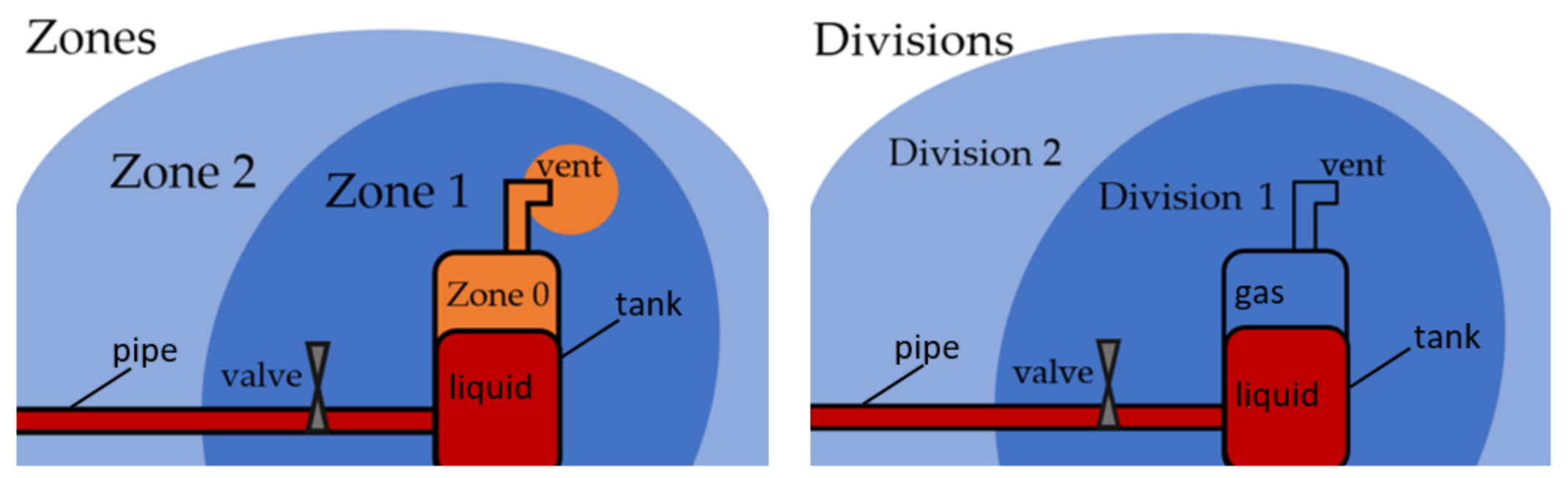

| (iii) Hazardous Zones | |

| Zone 0 | An explosive atmosphere is present continuously, for long periods, or frequently |

| Zone 1 | An explosive atmosphere is likely to occur occasionally in normal operation |

| Zone 2 | An explosive atmosphere is not likely to occur during normal operations (if it occurs, it only persists for a short period) |

| Zone | Category |

|---|---|

| Zone 0 | Category 1 |

| Zone 1 | Category 1 or 2 |

| Zone 3 | Category 1, 2, or 3 |

| Zone | Types of Protection | Technical Standard |

|---|---|---|

| Zone 0 | Ex ia—Intrinsic safety (higher grade) | IEC EN 60079-11 |

| Ex s—Specifically designed for Zone 0 | IEC 60079-33 | |

| Zone 0 and 1 | Ex ib—Intrinsic safety (lower grade) | IEC EN 60079-11 |

| Ex d—Flameproof enclosures | EN 13463-3 and IEC EN 60079-1 | |

| Ex e—Increased safety | IEC EN 60079-7 | |

| Ex p—Pressurizations | IEC EN 60079-2 and 13 | |

| Zone 0, 1, and 2 | Ex n—Type of protection | IEC EN 60079-15 |

| Ex o—Oil immersed | IEC EN 60079-6 | |

| Ex q—Powder filled | IEC EN 60079-5 |

| API 505, IEC-60079-10-1 | Zone 0 | Zone 1 | Zone 2 |

|---|---|---|---|

| Presence of explosive gases | >1000 h/year | 10 to 1000 h/year | <10 h/year |

| API 500 | Division 1 | Division 1 | Division 2 |

| Presence of explosive gases | >10 h/year | >10 h/year | <10 h/year |

| ATEX | Group 1G | Group 2G | Group 3G |

|---|---|---|---|

| IECEx | Group Ga | Group Gb | Group Gc |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brkić, D.; Stajić, Z. Offshore Oil and Gas Safety: Protection against Explosions. J. Mar. Sci. Eng. 2021, 9, 331. https://doi.org/10.3390/jmse9030331

Brkić D, Stajić Z. Offshore Oil and Gas Safety: Protection against Explosions. Journal of Marine Science and Engineering. 2021; 9(3):331. https://doi.org/10.3390/jmse9030331

Chicago/Turabian StyleBrkić, Dejan, and Zoran Stajić. 2021. "Offshore Oil and Gas Safety: Protection against Explosions" Journal of Marine Science and Engineering 9, no. 3: 331. https://doi.org/10.3390/jmse9030331

APA StyleBrkić, D., & Stajić, Z. (2021). Offshore Oil and Gas Safety: Protection against Explosions. Journal of Marine Science and Engineering, 9(3), 331. https://doi.org/10.3390/jmse9030331