Effects of Different Design Parameters on the Vortex Induced Vibration of FRP Composite Risers Using Grey Relational Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Riser Geometries

2.3. Flow Situation and Forces

2.4. OA Sampling

2.5. Finite Element (FE) Modeling

3. Results and Discussion

3.1. Natural Frequencies

3.2. Time History of Displacements and von Mises Stresses for All Study Cases

3.3. Maximum Displacements and Von Mises Stresses for All Study Cases

3.4. Lock-In Phenomenon for Study Case 3

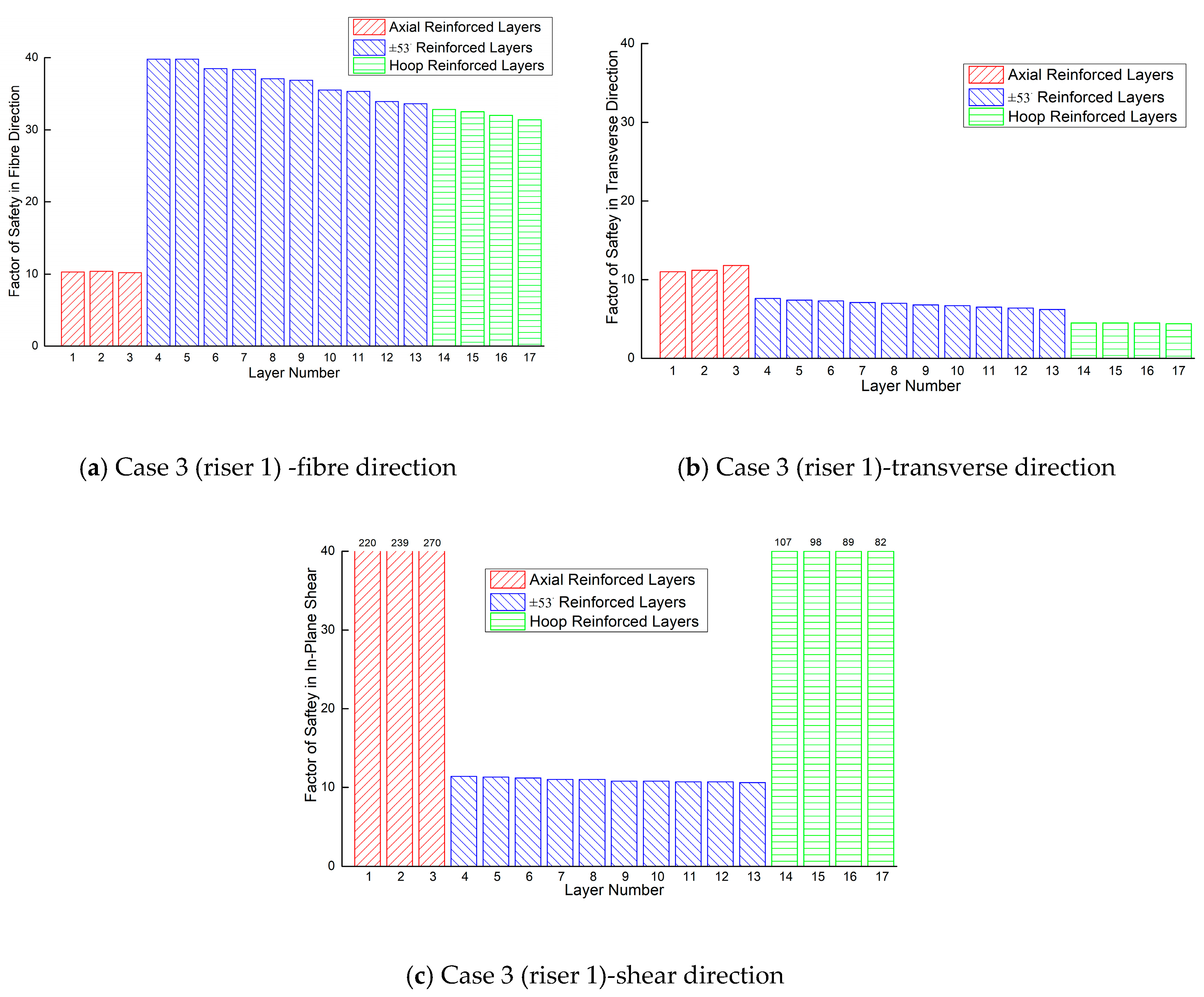

3.5. Stress Distributions in Every Layers for Study Case 3

3.6. Grey Relational Analysis of Multiple Parameters

4. Conclusions

- (1)

- Lock-in might occur for study cases 1 and 3 according to the relationship between natural frequency and vortex shedding frequency and the range of reduced velocity.

- (2)

- After an initial growth, the in-line flow displacement and von Mises stress maintain a relatively stable value and vibrate with a modest amplitude, while a significant vibration in the crossflow direction is obvious.

- (3)

- In general, deeper water depth and faster current velocities lead to a more severe VIV response.

- (4)

- Simple support leads to larger displacement compared with the fixed support.

- (5)

- Depending the dominant force, maximum von Mises stresses occur at the top/bottom of the risers, followed by the middle parts.

- (6)

- According to the von Mises stresses distribution of steel risers and FS in each composite lamina of FRP composite risers, stress failure does not occur for any of the cases studied.

- (7)

- The Grey relational grade of the five parameters are: .

Author Contributions

Funding

Conflicts of Interest

References

- Balazs, G.L.; Borosnyoi, A. Long-term behavior of FRP. In Composites in Construction: A Reality; Edoardo, C., Gaetano, M., Antonio, N., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2001; pp. 84–91. [Google Scholar]

- Jansons, J.O.; Glejbol, K.; Rytter, J.; Aniskevich, A.N.; Arnautov, A.K.; Kulakov, V.L. Effect of water absoption, elevated temperatures and fatigue on the mechanical properties of carbon-fiber-reinforced epoxy composites for flexible risers. Mech. Compos. Mater. 2002, 38, 299–310. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Nathaniel, G.; Agbomerie, C.O.; Hou, X.; Ye, J. Composite risers for deep waters using a numerical modelling approach. Compos. Struct. 2018, 210, 486–499. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Shankar, K.; Morozov, E.V. Tailored local design of deep sea FRP composite risers. Adv. Compos. Mater. 2015, 24, 375–397. [Google Scholar] [CrossRef]

- Ochoa, O.O.; Salama, M.M. Offshore composites: Transition barriers to an enabling technology. Compos. Sci. Technol. 2005, 65, 2588–2596. [Google Scholar] [CrossRef]

- Sparks, C.P.; Odru, P.; Bono, H.; Metivaud, G. Mechanical Testing of High-Performance Composite Tubes for TLP Production Risers. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 1988. [Google Scholar]

- Salama, M.M.; Johnson, D.B.; Long, J.R. Composite production riser-testing and qualification. SPE Prod. Facil. 1998, 13, 170–177. [Google Scholar] [CrossRef]

- Salama, M.M.; Stjern, G.; Storhaug, T.; Spencer, B.; Echtermeyer, A. The first offshore field installation for a composite riser joint. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002. [Google Scholar]

- Smith, K.L.; Leveque, M.E. Ultra-Deepwater Production Systems Technical-Progress Report; Conoco Phillips Company: Houston, TX, USA, 2003. [Google Scholar]

- Smith, K.L.; Leveque, M.E. Ultra-Deepwater Production Systems Technical-Final Report; Conoco Phillips Company: Houston, TX, USA, 2005. [Google Scholar]

- Picard, D.; Hudson, W.; Bouquier, L.; Dupupet, G.; Zivanovic, I. Composite carbon thermoplastic tubes for deepwater application. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2007. [Google Scholar]

- Chen, Y.; Seemann, R.; Krause, D.; Tay, T.E.; Tan, V.B. Prototyping and testing of composite riser joints for deepwater application. J. Reinf. Plast. Compos. 2016, 35, 95–110. [Google Scholar] [CrossRef]

- Karayaka, M.; Wu, S.; Wang, S.; Lu, X.; Partha Ganguly, B.P. Composite Production Riser Dynamics and its Effects on Tensioners, Stress Joints, and Size of Deep Water Tension Leg Platform. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1998. [Google Scholar]

- Huang, K.Z. Composite TTR Design for an Ultradeepwater TLP. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005. [Google Scholar]

- Kim, W.K. Composite Production Riser Assessment. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2007. [Google Scholar]

- Ward, E.G.; Ochoa, O.O.; Kim, W.; Gilbert, R.M.; Jain, A.; Miller, C.; Denison, E. A Comparative Risk Analysis of Composite and Steel Production Risers; Texas A&M University: College Station, TX, USA, 2007. [Google Scholar]

- Wang, C.; Shankar, K.; Morozov, E.V. Global design and analysis of deep sea FRP composite risers under combined environmental loads. Adv. Compos. Mater. 2017, 26, 79–98. [Google Scholar] [CrossRef]

- Wang, C.; Shankar, K.; Morozov, E.V. Tailored design of top-tensioned composite risers for deep-water applications using three different approaches. Adv. Mech. Eng. 2017, 9, 1–18. [Google Scholar] [CrossRef]

- Omar, A.F.; Karayka, M.; Murray, J.J. A Comparative Study of the Performance of Top-tensioned Composite and Steel Risers under Vertex-induced Loading. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 1999. [Google Scholar]

- Rakshit, T.; Atluri, S.; Dalton, C. VIV of a composite riser at moderate Reynolds number using CFD. J. Offshore Mech. Arct. Eng. 2008, 130, 011009. [Google Scholar] [CrossRef]

- Toh, W.; Tan, L.B.; Jaiman, R.K.; Tay, T.E. A comprehensive study on composite risers: Material solution, local end fitting design and global response. Mar. Struct. 2018, 61, 155–169. [Google Scholar] [CrossRef]

- Tan, L.B.; Chen, Y.; Jaiman, R.K.; Sun, X.; Tan, V.B.C.; Tay, T.E. Coupled fluid–structure simulations for evaluating a performance of full-scale deepwater composite riser. Ocean Eng. 2015, 94, 19–35. [Google Scholar] [CrossRef]

- Tsahalis, D.; Jones, T.W. Vortex-induced Vibrations of a Flexible Cylinder near a Plane Boundary in Steady Flow. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1981. [Google Scholar]

- Tsahalis, D.T. Vortex-induced vibrations due to steady and wave-induced currents of a flexible cylinder near a plane boundary. J. Offshore Mech. Arct. Eng. 1987, 109, 112–118. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Owen, A. Programs Construct and Manipulate Orthogonal Arrays; Department of Statistics, Stanford University: Stanford, CA, USA, 2005. [Google Scholar]

- Stabile, G.; Matthies, H.G.; Borri, C. A novel reduced order model for vortex induced vibrations of long flexible cylinders. Ocean Eng. 2018, 156, 191–207. [Google Scholar] [CrossRef] [Green Version]

- Gabbai, R.D.; Benaroya, H. An overview of modeling and experiments of vortex-induced vibration of circular cylinders. J. Sound Vibrat. 2005, 282, 575–616. [Google Scholar] [CrossRef]

- Morán, J.; Granada, E.; Míguez, J.L.; Porteiro, J. Use of Grey relational analysis to assess and optimize small biomass boilers. Fuel Process. Technol. 2006, 87, 123–127. [Google Scholar] [CrossRef]

- Wang, C.; Cui, Y.; Ge, S.; Sun, M.; Jia, Z. Experimental study on vortex-induced vibration of risers considering the effects of different design parameters. Appl. Sci. 2018, 8, 2411. [Google Scholar] [CrossRef]

- Wang, C.; Shankar, K.; Ashraf, M.A.; Morozov, E.V.; Ray, T. Surrogate-assisted optimisation design of composite riser. Proc. Inst. Mech. Eng. Part L 2016, 230, 18–34. [Google Scholar] [CrossRef]

- Chakrabarti, S.K. Handbook of Offshore Engineering, 1st ed.; Elsevier: London, UK, 2005; Volume 1. [Google Scholar]

- American Petroleum Institute (API). Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms-Working Stress Design; American Petroleum Institute: Washington, DC, USA, 2000. [Google Scholar]

- Wang, C.; Sun, M.; Shankar, K.; Xing, S.; Zhang, L. CFD simulation of vortex induced vibration for FRP composite riser with different modeling methods. Appl. Sci. 2018, 8, 684. [Google Scholar] [CrossRef]

- Wang, C.; Ge, S.; Sun, M.; Jia, Z.; Han, B. Comparative study of vortex-induced vibration of frp composite risers with large length to diameter ratio under different environmental situations. Appl. Sci. 2019, 9, 517. [Google Scholar] [CrossRef]

- Blevins, R.D. Flow-Induced Vibration, 2nd ed.; Krieger Publishing Company: Malabar, FL, USA, 2001. [Google Scholar]

- American Bureau of Shipping (ABS). Guide for Building and Classing Subsea Riser Systems: Design Requirements and Loads; American Bureau of Shipping: Houston, TX, USA, 2008. [Google Scholar]

- Kaw, A.K. Mechanics of Composite Materials, 2nd ed.; CSC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Det Norske Veritas (DNV). Offshore Standard for Composite Components (DNV-OS-C501); Det Norske Veritas: Høvik, Norway, 2009. [Google Scholar]

- Sun, C.T.; Li, S. Three-dimensional effective elastic constant for thick laminates. J. Compos. Mater. 1988, 22, 629–639. [Google Scholar] [CrossRef]

- Bogetti, T.A.; Hoppel, C.P.R.; Drysdale, W.H. Three-Dimensional Effective Property and Strength Prediction of Thick Laminated Composite Media; Aberdeen Proving Ground, United States Army Research Laboratory: Adelphi, MD, USA, 1995. [Google Scholar]

- Jiang, B.C.; Szu-Lang, T.; Chien-Chih, W. Machine vision-based gray relational theory applied to ic marking inspection. IEEE Trans. Semicond. Manuf. 2002, 15, 531–539. [Google Scholar] [CrossRef]

- Lin, S.J.; Lu, I.J.; Lewis, C. Grey relation performance correlations among economics, energy use and carbon dioxide emission in taiwan. Energy Policy 2007, 35, 1948–1955. [Google Scholar] [CrossRef]

- Fung, C.P. Manufacturing process optimization for wear property of fiber-reinforced polybutylene terephthalate composites with Grey relational analysis. Wear 2003, 254, 298–306. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Modulus (GPa) | Tangent Modulus (GPa) | ν | Yield Stress (MPa) | Ultimate Stress (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|---|---|

| X80 steel | 7850 | 207 | 1.25 | 0.3 | 555 | 625 | 5.868 |

| Titanium | 4430 | 113.8 | 0.53 | 0.342 | 880 | 950 | 14 |

| Material | Density (kg/m3) | E1 (GPa) | E2 = E3 (GPa) | G12 = G13 (GPa) | ν12 = ν13 | G23 (GPa) | ν23 | (MPa) | (MPa) | (MPa) | (MPa) | τ12 (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AS4-Epoxy | 1530 | 135.4 | 9.37 | 4.96 | 0.32 | 3.20 | 0.46 | 1732 | 1256 | 49.4 | 167.2 | 71.2 |

| Riser | I.D. (m) | O.D. (m) | Lay-Ups | t_liner (mm) | t_0 (mm) | t_±θ (mm) | t_90 (mm) | ±θ (°) |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.25 | 0.311 | [liner/03/(+53,−53)5 /904] | 2 | 1.70 | 1.64 | 1.75 | 53 |

| 2 | 0.25 | 0.329 | [liner/90/(0/90)10] | 2 | 1.385 | / | 2.15 | / |

| 3 | 0.25 | 0.3 | X80 steel |

| Case No. | Riser | Velocity (m/s) | Water Depth (m) | Re | Turbulent Intensity (%) | Gravity (N) | Tension Force (N) | Buoyancy (N) |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0.36 | 12.5 | 105,623 | 3.77 | 5600 | 11,200 | 9529 |

| 2 | 1 | 1.22 | 25.0 | 357,943 | 3.24 | 11,200 | 22,400 | 19,058 |

| 3 | 1 | 2.13 | 37.5 | 624,934 | 3.02 | 16,800 | 33,600 | 28,587 |

| 4 | 2 | 0.36 | 25.0 | 111,736 | 3.74 | 14,591 | 29,183 | 21,328 |

| 5 | 2 | 1.22 | 37.5 | 378,660 | 3.21 | 21,887 | 43,774 | 31,992 |

| 6 | 2 | 2.13 | 12.5 | 661,104 | 3.00 | 7296 | 14,591 | 10,664 |

| 7 | 3 | 0.36 | 37.5 | 101,887 | 3.79 | 62,309 | 93,463 | 26,600 |

| 8 | 3 | 1.22 | 12.5 | 345,283 | 3.25 | 20,770 | 31,154 | 8867 |

| 9 | 3 | 2.13 | 25.0 | 602,830 | 3.03 | 41,539 | 62,309 | 17,734 |

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | Case 7 | Case 8 | Case 9 | |

|---|---|---|---|---|---|---|---|---|---|

| natural frequency /(Hz) | 7.21 | 1.89 | 0.94 | 2.45 | 1.17 | 9.47 | 0.94 | 7.87 | 2.01 |

| vortex shedding frequency fs/(Hz) | 0.23 | 0.82 | 1.51 | 0.22 | 0.78 | 1.42 | 0.24 | 0.85 | 1.56 |

| reduced velocity Ur | 0.16 | 2.07 | 7.26 | 0.45 | 3.18 | 0.68 | 1.28 | 0.52 | 3.53 |

| Case No. | Riser | Etension (GPa) | Ebending (GPa) | L/Douter | Tension Force (N) | Current Velocity (m/s) | VIV Amplitude (m) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 40.5 | 35.7 | 40 | 11,200 | 0.36 | 7.01 × 10−5 |

| 2 | 1 | 40.5 | 35.7 | 80 | 22,400 | 1.22 | 7.66 × 10−3 |

| 3 | 1 | 40.5 | 35.7 | 121 | 33,600 | 2.13 | 9.42 × 10−2 |

| 4 | 2 | 59.1 | 56.8 | 76 | 29,183 | 0.36 | 4.42 × 10−4 |

| 5 | 2 | 59.1 | 56.8 | 114 | 43,774 | 1.22 | 1.31 × 10−2 |

| 6 | 2 | 59.1 | 56.8 | 38 | 14,591 | 2.13 | 1.37 × 10−3 |

| 7 | 3 | 207 | 207 | 125 | 93,463 | 0.36 | 3.76 × 10−4 |

| 8 | 3 | 207 | 207 | 42 | 31,154 | 1.22 | 1.41 × 10−4 |

| 9 | 3 | 207 | 207 | 83 | 62,309 | 2.13 | 7.01 × 10−3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Ge, S.; Jaworski, J.W.; Liu, L.; Jia, Z. Effects of Different Design Parameters on the Vortex Induced Vibration of FRP Composite Risers Using Grey Relational Analysis. J. Mar. Sci. Eng. 2019, 7, 231. https://doi.org/10.3390/jmse7070231

Wang C, Ge S, Jaworski JW, Liu L, Jia Z. Effects of Different Design Parameters on the Vortex Induced Vibration of FRP Composite Risers Using Grey Relational Analysis. Journal of Marine Science and Engineering. 2019; 7(7):231. https://doi.org/10.3390/jmse7070231

Chicago/Turabian StyleWang, Chunguang, Shiquan Ge, Justin W. Jaworski, Liping Liu, and Zhirong Jia. 2019. "Effects of Different Design Parameters on the Vortex Induced Vibration of FRP Composite Risers Using Grey Relational Analysis" Journal of Marine Science and Engineering 7, no. 7: 231. https://doi.org/10.3390/jmse7070231

APA StyleWang, C., Ge, S., Jaworski, J. W., Liu, L., & Jia, Z. (2019). Effects of Different Design Parameters on the Vortex Induced Vibration of FRP Composite Risers Using Grey Relational Analysis. Journal of Marine Science and Engineering, 7(7), 231. https://doi.org/10.3390/jmse7070231