Probabilistic Comparison of Static and Dynamic Failure Criteria of Scour Protections

Abstract

1. Introduction

2. Materials and Methods

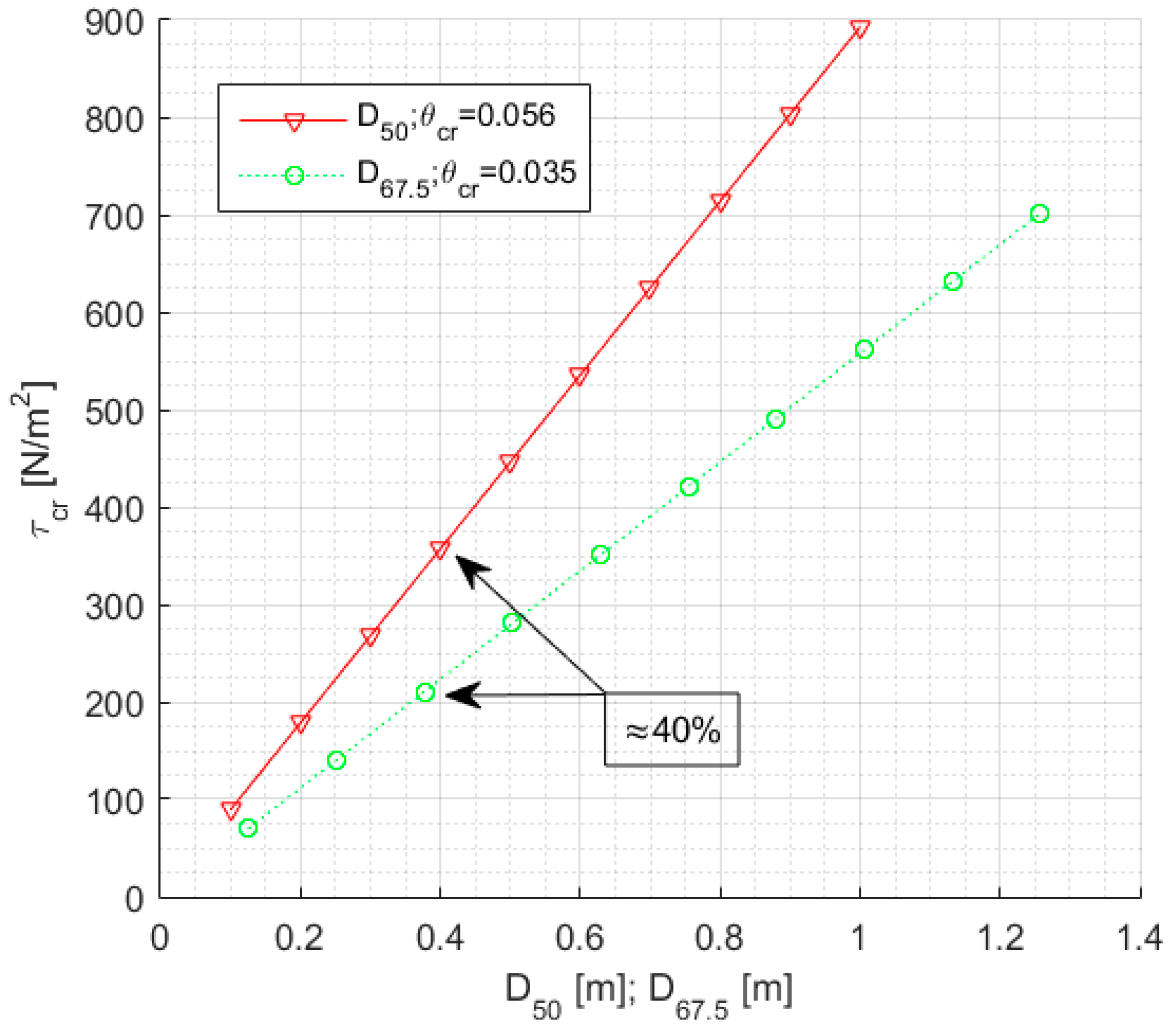

2.1. Failure Criteria

2.1.1. Statically Stable Scour Protections

2.1.2. Dynamically Stable Scour Protections

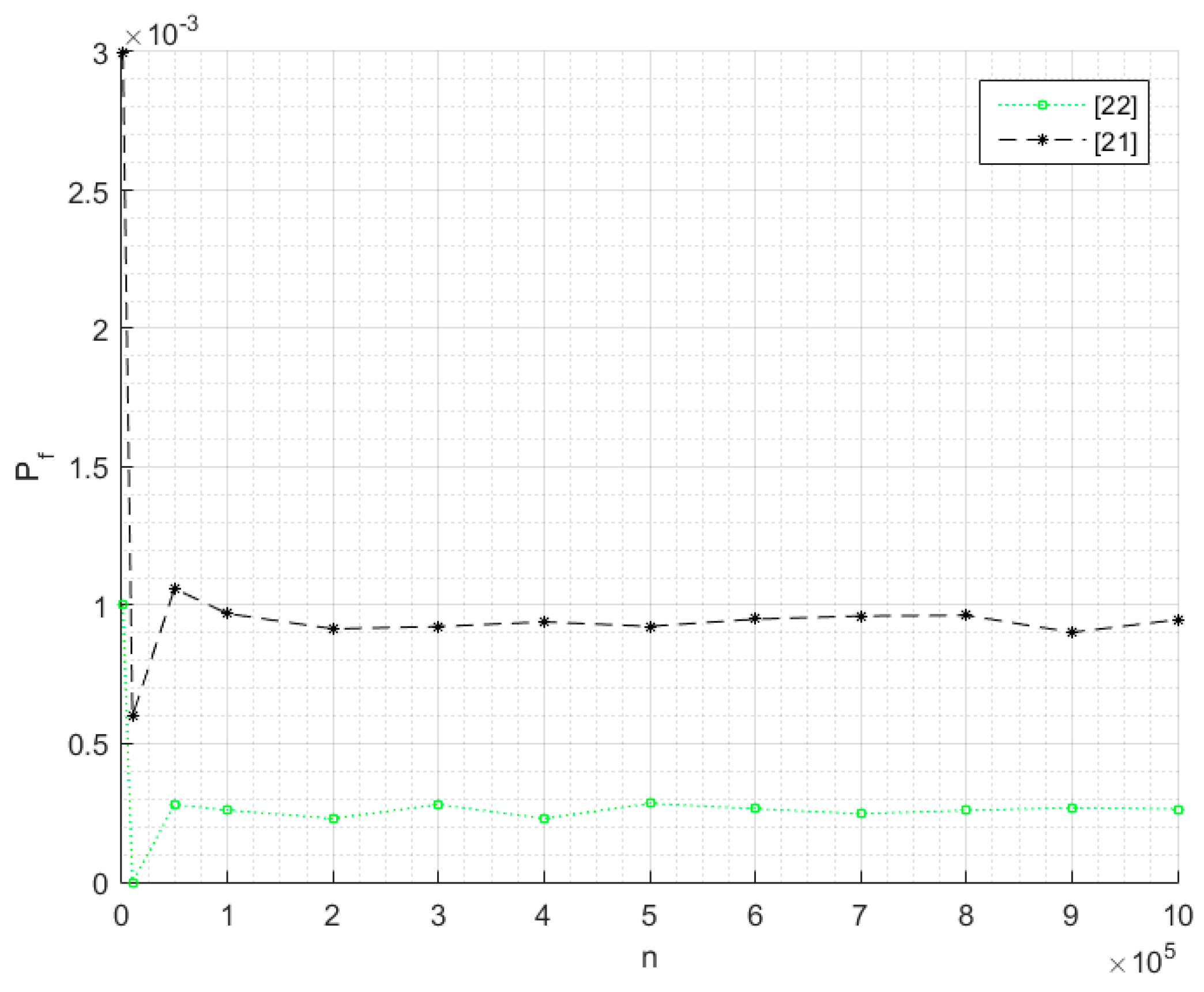

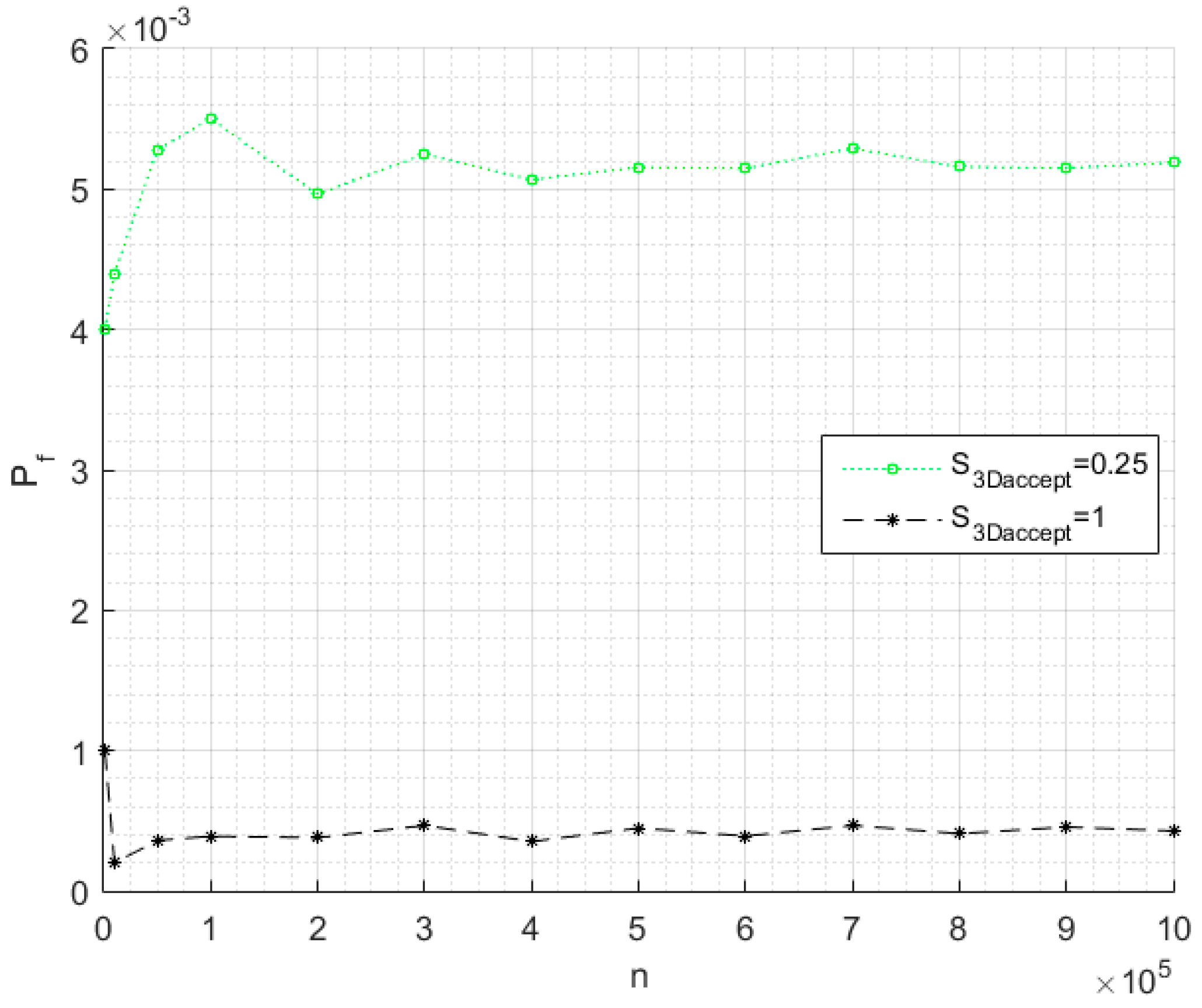

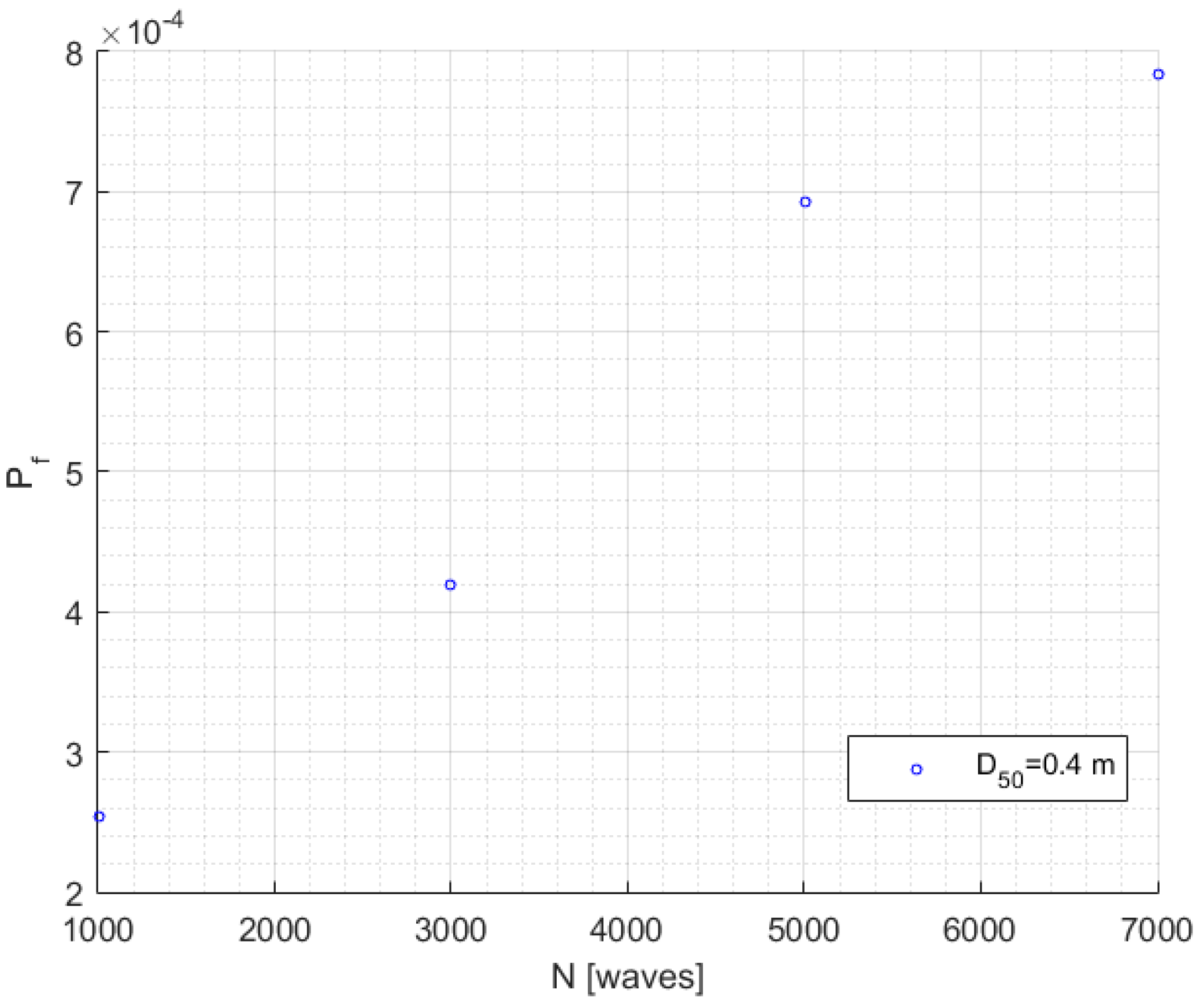

2.2. Non-Parametric Probability of Failure

3. Case Study

4. Results and Discussion

4.1. Reliability Assessment

4.1.1. Statically Stable Scour Protections

4.1.2. Dynamically Stable Scour Protections

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| # | number of times [−] |

| A | wave stroke [m] |

| ai | regression coefficients [−] |

| b0 | regression coefficient [−] |

| d | water depth [m] |

| D* | dimensionless grain size [−] |

| D50 | median stone diameter [m] |

| D15 | stone diameter for which 15% is finer by weight [m] |

| D67.5 | stone diameter for which 67.5% is finer by weight [m] |

| D85 | stone diameter for which 85% is finer by weight [m] |

| Dn50 | nominal median stone diameter [m] |

| f | limit state function [−] |

| fw | wave friction factor [−] |

| g | the gravitational acceleration m/s2 |

| Hs | significant wave height [m] |

| I | indicator function equal to 0 or 1 [−] |

| ks | bottom roughness [m] |

| N | number of waves [waves] |

| n | number of simulations [simulations] |

| Pf | probability of failure [−] |

| Pf0 | annual probability of failure [−] |

| s | specific density ratio [−] |

| S3D | damage number [−] |

| S3Daccept | acceptable damage number [−] |

| S3Dmeas | measured damage number [−] |

| S3Dpred | predicted damage number [−] |

| T | wave period [s] |

| Tm-1,0 | Energy wave period [s] |

| Tp | wave peak period [s] |

| Tr | return period [years] |

| Uc | depth-averaged current velocity [m/s] |

| Um | wave orbital velocity [m/s] |

| Ur | Ursel number [−] |

| ws | fall velocity of sediments [m/s] |

| X | vector of random variables [−] |

| α | amplification factor [−] |

| γ | JONSWAP peak enhancement factor [−] |

| δ | wave boundary layer thickness [m] |

| θ | Shields critical parameter [−] |

| ρs | density of the sediments or rock material [kg/m3] |

| ρw | density of water [kg/m3] |

| τc | current induced shear-stress [N/m2] |

| τcr | critical shear-stress [N/m2] |

| τw | wave induced shear-stress [N/m2] |

| τwc | combined wave and current induced shear-stress [N/m2] |

| τwcmax | maximum wave and current induced shear-stress [N/m2] |

References

- Bhattacharya, S. Challenges in Design of Foundations for Offshore Wind Turbines. Eng. Technol. Ref. 2014, 1–9. [Google Scholar] [CrossRef]

- Matutano, C.; Negro, V.; López-Gutiérrez, J.-S.; Esteban, M.D. Scour prediction and scour protections in offshore wind farms. Renew. Energy 2013, 57, 358–365. [Google Scholar] [CrossRef]

- De Vos, L.; De Rouck, J.; Troch, P.; Frigaard, P. Empirical design of scour protections around monopile foundations. Coast. Eng. 2011, 58, 540–553. [Google Scholar] [CrossRef]

- De Vos, L.; De Rouck, J.; Troch, P.; Frigaard, P. Empirical design of scour protections around monopile foundations. Part 2: Dynamic approach. Coast. Eng. 2012, 60, 286–298. [Google Scholar] [CrossRef]

- De Vos, L. Optimisation of Scour Protection Design for Monopiles and Quantification of Wave Run-Up—Engineering the Influence of an Offshore Wind Turbine on Local Flow Conditions. Ph.D. Thesis, University of Ghent, Ghent, Belgium, 2008. [Google Scholar]

- Schoesitter, P.; Audenart, S.; Baelus, L.; Bolle, A.; Brown, A.; das Neves, L.; Fazeres-Ferradosa, T.; Haerens, P.; Taveira-Pinto, F.; Troch, P.; et al. Feasibility of a dynamically stable rock armour layer scour protection for offshore wind farms. In Proceedings of the International Conference on Ocean, Offshore and Artic Engineering, San Francisco, CA, USA, 8–13 June 2014. [Google Scholar]

- Whitehouse, R.; Brown, A.; Audenaert, S.; Bolle, A.; Schoesitter, P.; Haerens, P.; Baelus, L.; Troch, P.; das Neves, L.; Fazeres-Ferradosa, T.; et al. Optimising scour protection stability at offshore foundations. In Proceedings of the 7th International Conference on Scour and Erosion, Pearth, Australia, 2–4 December 2014. [Google Scholar]

- Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Reis, M.T.; das Neves, L. Physical modelling of dynamic scour protections: Analysis of the Damage Number. Proc. Inst. Civ. Eng. Marit. Eng. 2018, 171, 11–24. [Google Scholar] [CrossRef]

- Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Romão, X.; Vanem, E.; Reis, T.; das Neves, L. Probabilistic Design and Reliability Analysis of Scour Protections for Offshore Windfarms. Eng. Fail. Anal. 2018, 91, 291–305. [Google Scholar] [CrossRef]

- Muzzammil, M. A reliability-based assessment of bridge pier scour in non-uniform sediments. J. Hydraul. Res. 2009, 47, 372–380. [Google Scholar] [CrossRef]

- Briaud, J.; Gardoni, P.; Yao, C. Statistical, risk and reliability analyses of bridge scour. J. Geotech. Geoenvironmental Eng. 2014, 140, 1–10. [Google Scholar] [CrossRef]

- Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Romão, X.; Reis, M.T.; Neves, L.D. Reliability assessment of offshore dynamic scour protections using copulas. Wind Eng. 2019, 43, 506–538. [Google Scholar] [CrossRef]

- Bai, Y.; Jing, W.-L. Chapter 34—Reliability of Ship Structures. In Marine Structural Design, 2nd ed.; Bai, Y., Jin, W., Eds.; Butterworth-Heinemann: Oxford, UK, 2016; pp. 627–644. [Google Scholar] [CrossRef]

- Clark, C.E.; Dupont, B. Reliability-based design optimization in offshore renewable energy systems. Renew. Sustain. Energy Rev. 2018, 97, 390–400. [Google Scholar] [CrossRef]

- Koç, M.L.; Balas, C.E. Reliability analysis of a rubble mound breakwater using the theory of fuzzy random variables. Appl. Ocean Res. 2013, 39, 83–88. [Google Scholar] [CrossRef]

- DMI. Horns Rev 3 Offshore Wind Farm—Metaocean; DMI—Danish Metereological Institute & Orbicon A/S: Copenhagen, Denmark, 2013. [Google Scholar]

- Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Rosa-Santos, P.; Chambel, J. A review of reliability analysis of offshore scour protections. Proc. Inst. Civ. Eng. Marit. Eng. 2019, 172, 104–117. [Google Scholar] [CrossRef]

- Shields, A.F. Application of Similarity Principles and Turbulence Research to Bed-Load Movement; Mitteilungen der Preussischen Versuchsanstalt f€ur Wasserbau und Schiffbau: Berlin, Germany, 1936; Volume 26, pp. 5–24. [Google Scholar]

- Liu, Z. Sediment Transport; Aalborg Universitet: Aalborg, Denmark, 2001. [Google Scholar]

- Nielsen, P. Coastal Bottom Boundary Layers and Sediment Transport: Advanced Series on Ocean Engineering; World Scientific: Singapore, 1992; Volume 4. [Google Scholar]

- Fredsøe, J.; Deigaard, R. Mechanics of Coastal Sediment Transport—Advanced Series on Ocean Engineering; World Scientific: Singapore, 1992; Volume 3. [Google Scholar]

- Soulsby, R. Dynamics of Marine Sands: A Manual for Practical Applications; Thomas Telford: London, UK, 1997. [Google Scholar]

- Dixen, M.; Hatipoglu, F.; Sumer, B.M.; Fredsøe, J. Wave boundary layer over a stone-covered bed. Coast. Eng. 2008, 55, 1–20. [Google Scholar] [CrossRef]

- Wiberg, P.L.; Sherwood, C.R. Calculating wave-generated bottom orbital velocities from surface-wave parameters. Comput. Geosci. 2008, 34, 1243–1262. [Google Scholar] [CrossRef]

- Schendel, A.; Goseberg, N.; Schlurmann, T. Experimental study on the performance of coarse grain materials as scour protection. In Proceedings of the Coastal Engineering Proceedings—34th International Conference on Costal Engineering, Seoul, Korea, 15–20 June 2014. [Google Scholar]

- Schendel, A.; Goseberg, N.; Schlurmann, T. Erosion Stability of Wide-Graded Quarry-Stone Material under Unidirectional Current. J. Waterw. Port Coast. Ocean Eng. 2016, 142, 1–19. [Google Scholar] [CrossRef]

- Hoffmans, G.; Verheij, H. Scour Manual; CRC Press: Rotterdam, The Netherlands, 1997. [Google Scholar]

- Whitehouse, R. Scour at Marine Structures: A Manual for Practical Applications; Institution of Civil Engineers: London, UK, 1998. [Google Scholar]

- Den Boon, J.H.; Sutherland, J.; Whitehouse, R.; Soulsby, R.; Stam, C.J.M.; Verhoeven, K.; Høgedal, M.; Hald, T. Scour behaviour and scour protection for monopile foundations of offshore wind turbines. In Proceedings of the European Wind Energy Conference & Exhibition, London, UK, 22–25 November 2004. [Google Scholar]

- Loosveldt, N.; Vannieuwenhuyse, K. Experimental Validation of Empirical Design of a Scour Protection around Monopiles under Combined Wave and Current Loading. Master’s Thesis, Ghent University, Ghent, Belgium, 2012. [Google Scholar]

- Fajardo, F.; Perez, J.; Alsina, M.; Marques, J.R. Simulation Methods for Reliability and Availability of Complex Systems; Springer: New York, NY, USA, 2010. [Google Scholar]

- Kristensen, H.; Gurieff, H.L.B.; Steer, J.; Richardt, N. Horns Rev 3 Results Report—Geo Investigation; Rambøll og Energinet: Copenhagen, Denmark, 2013. [Google Scholar]

- Energinet. Horns Rev 3 Offshore Wind Farm—Marine Mammals—Technical Report 043; Energinet, Orbicon A/S, BioConsult SH GmbH & Co.KG: Copenhagen, Denmark, 2014. [Google Scholar]

- Vanem, E. Joint statistical models for significant wave height and wave period in a changing climate. Mar. Struct. 2016, 49, 180–205. [Google Scholar] [CrossRef]

- Ferreira, J.; Soares, C.G. Modelling bivariate distributions of significant wave height and mean wave period. Appl. Ocean Res. 2002, 24, 31–45. [Google Scholar] [CrossRef]

- Wist, H.T.; Myrhaug, D.; Rue, H. Statistical properties of successive wave heights and successive wave periods. Appl. Ocean Res. 2004, 26, 114–136. [Google Scholar] [CrossRef]

- Muraleedharan, G.; Lucas, C.; Martins, D.; Soares, C.G.; Kurup, P. On the distribution of significant wave height and associated peak periods. Coast. Eng. 2015, 103, 42–51. [Google Scholar] [CrossRef]

- Venables, W.; Ripley, B. Modern Applied Statistics with S, 4th ed.; Springer: New York, NY, USA, 2002. [Google Scholar]

- Vattenfall. 2017. Available online: https://corporate.vattenfall.dk/globalassets/danmark/vores_vindmoller/horns_rev_3/hr3_nyhedsbrev_01.pdf (accessed on 1 November 2018).

- CIRIA; CUR; CETMEF. The Rock Manual: The Use of Rock in Hydraulic Engineering, 2nd ed.; CIRIA: London, UK, 2007. [Google Scholar]

- Rendón-Conde, C.; Heredia-Zavoni, E. Reliability assessment of mooring lines for floating structures considering statistical parameter uncertainties. Appl. Ocean Res. 2015, 52, 295–308. [Google Scholar] [CrossRef]

- Montes-Iturrizaga, R.; Heredia-Zavoni, E. Reliability analysis of mooring lines using copulas to model statistical dependence of environmental variables. Appl. Ocean Res. 2016, 59, 564–576. [Google Scholar] [CrossRef]

- Saruwatari, A.; Yoneko, Y.; Tajima, Y. Effects of wave, tidal current and ocean current coexistance on the wave and current predictions in the Tsugaru Strait. In Proceedings of the Coastal Engineering Proceedings, Seoul, Korea, 15–20 June 2014. [Google Scholar]

- Gidwani, R. Deriving Transition Probabilities for Decision Models. March 2016. Available online: https://www.hsrd.research.va.gov/for_researchers/cyber_seminars/archives/1096-notes.pdf (accessed on 12 July 2018).

- DNV. Classification Notes. N30.6—Structural Reliability Analysis of Marine Structures; Det Norske Veritas: Oslo, Norway, 1992. [Google Scholar]

- DNVGL. DNVGL—ST-0262—Lifetime Extension of Wind Turbines; Det Norske Veritas AS: Oslo, Norway, 2017. [Google Scholar]

- Mase, H.; Yasuda, T.; Reis, M.T.; Karunarathna, H.; Yang, J. Stability formula and failure probability analysis of wave-dissipating blocks considering wave breaking. J. Ocean Eng. Mar. Energy. 2015, 1, 45–54. [Google Scholar] [CrossRef]

- Galiatsatou, P.; Makris, C. Optimized Reliability Based Upgrading of Rubble Mound Breakwaters in a Changing Climate. J. Mar. Sci. Eng. 2018, 6, 92. [Google Scholar] [CrossRef]

- Weller, S.; Thies, P.; Gordelier, T.; Johanning, L. Reducing Reliability Uncertainties for Marine Renewable Energy. J. Mar. Sci. Eng. 2015, 3, 1349–1361. [Google Scholar] [CrossRef]

| α | Traditional Approach [21] | Traditional Approach [22] | Static Approach [3] | |

|---|---|---|---|---|

| fw [21] | fw [22] | |||

| 2 | 3 × 10−4 | 1 × 10−5 | 9 × 10−4 | 2 × 10−4 |

| 3 | 1 × 10−2 | 2 × 10−3 | ||

| 4 | 3 × 10−2 | 7 × 10−3 | ||

| α | Traditional Approach [21] | Traditional Approach [22] | Static Approach [3] | |

|---|---|---|---|---|

| fw [21] | fw [22] | |||

| 2 | 2.9 × 10−5 | 1 × 10−6 | 8.7 × 10−5 | 1.9 × 10−5 |

| 3 | 9.7 × 10−4 | 1.9 × 10−4 | ||

| 4 | 2.9 × 10−3 | 6 × 10−4 | ||

| S3Daccept | Pf | Pf0 |

|---|---|---|

| 0.25 | 5.2 × 10−3 | 4.8 × 10−4 |

| 1 | 4.2 × 10−4 | 4.07 × 10−5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Rosa-Santos, P.; Chambel, J. Probabilistic Comparison of Static and Dynamic Failure Criteria of Scour Protections. J. Mar. Sci. Eng. 2019, 7, 400. https://doi.org/10.3390/jmse7110400

Fazeres-Ferradosa T, Taveira-Pinto F, Rosa-Santos P, Chambel J. Probabilistic Comparison of Static and Dynamic Failure Criteria of Scour Protections. Journal of Marine Science and Engineering. 2019; 7(11):400. https://doi.org/10.3390/jmse7110400

Chicago/Turabian StyleFazeres-Ferradosa, Tiago, Francisco Taveira-Pinto, Paulo Rosa-Santos, and João Chambel. 2019. "Probabilistic Comparison of Static and Dynamic Failure Criteria of Scour Protections" Journal of Marine Science and Engineering 7, no. 11: 400. https://doi.org/10.3390/jmse7110400

APA StyleFazeres-Ferradosa, T., Taveira-Pinto, F., Rosa-Santos, P., & Chambel, J. (2019). Probabilistic Comparison of Static and Dynamic Failure Criteria of Scour Protections. Journal of Marine Science and Engineering, 7(11), 400. https://doi.org/10.3390/jmse7110400