Direct Measurements of Bed Shear Stress under Swash Flows on Steep Laboratory Slopes at Medium to Prototype Scales

Abstract

1. Introduction

2. Materials and Methods

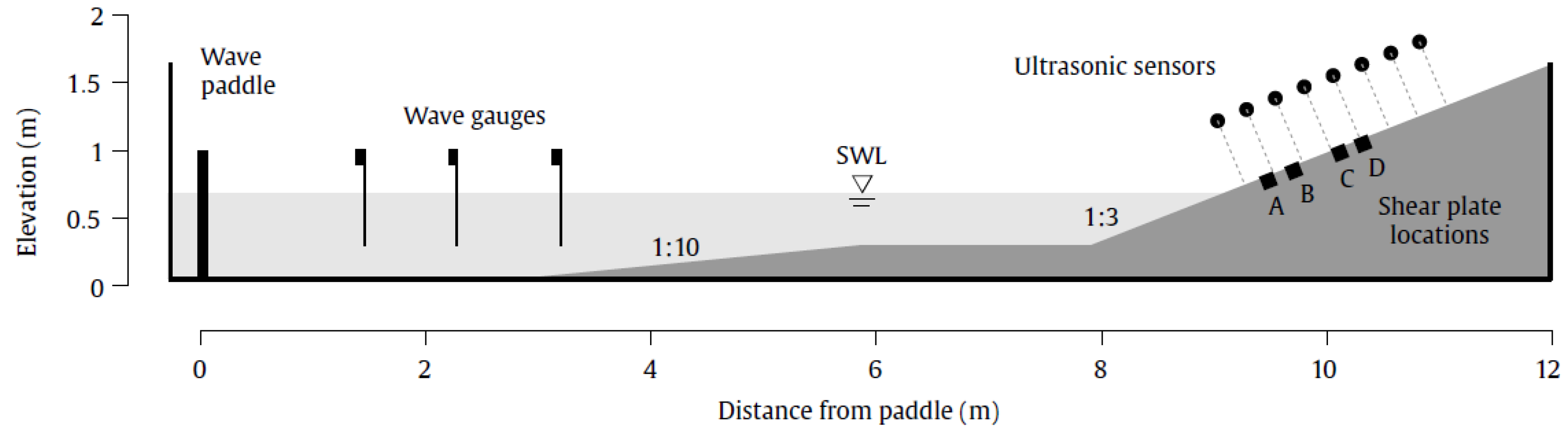

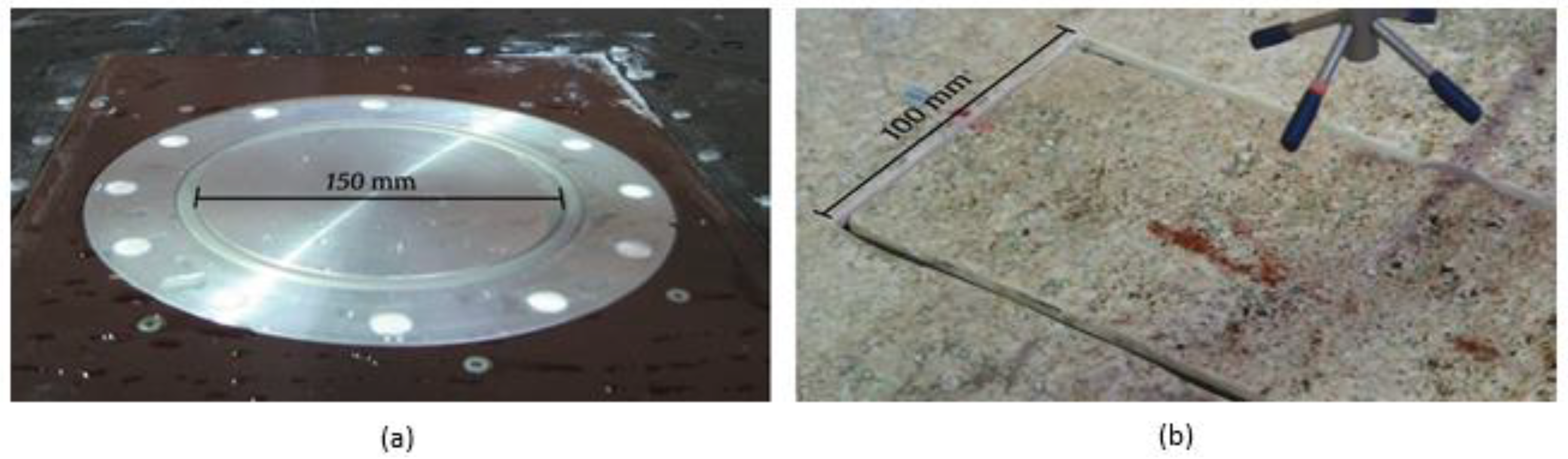

2.1. UNSW Water Research Laboratory (WRL)—Medium Scale

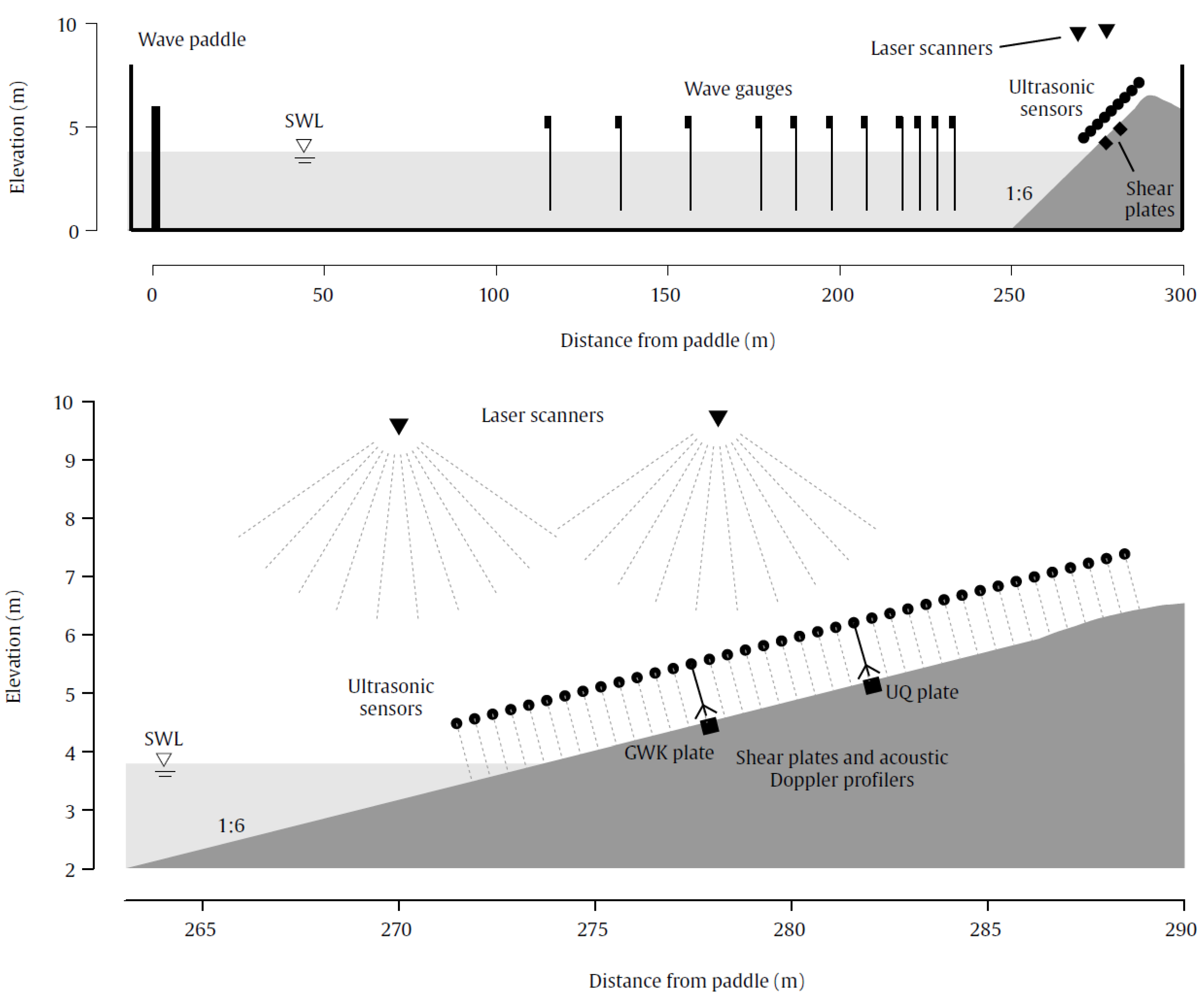

2.2. Große Wellenkanal (GWK)—Prototype Scale

3. Results

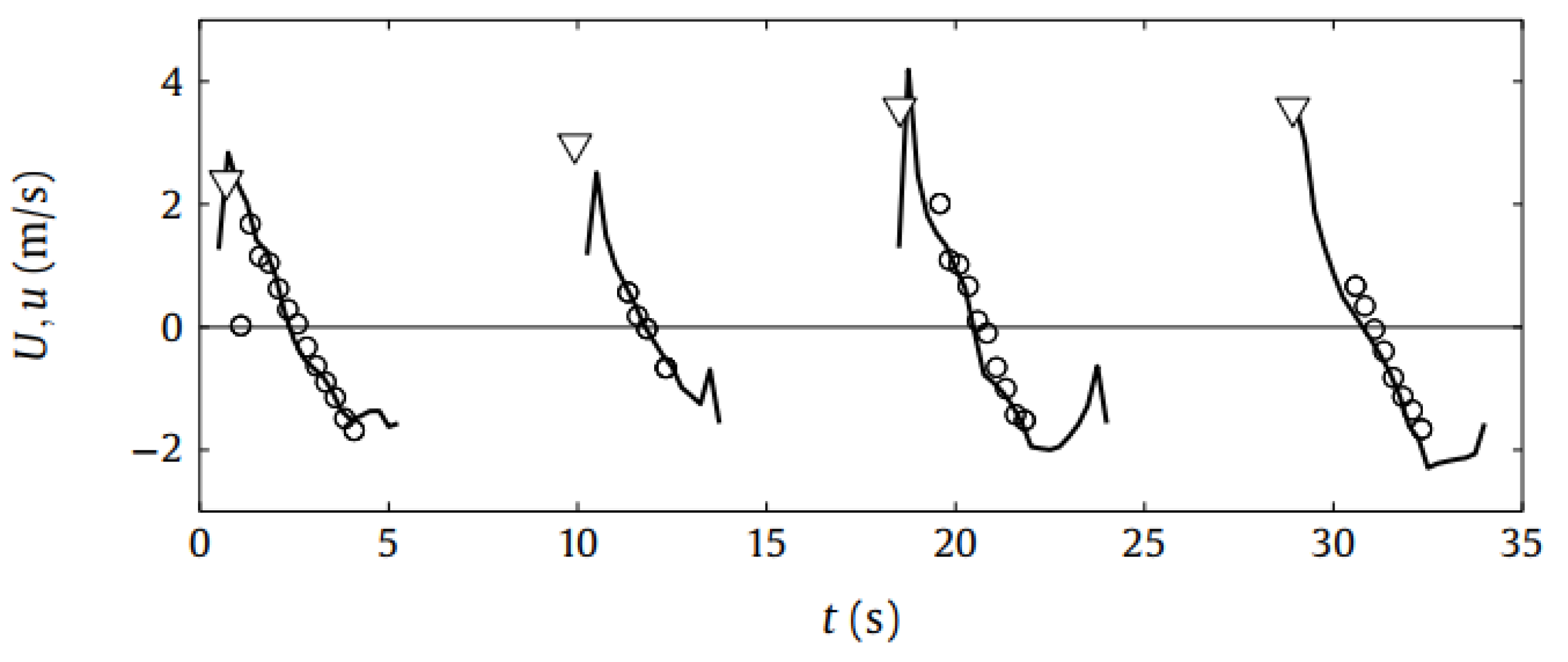

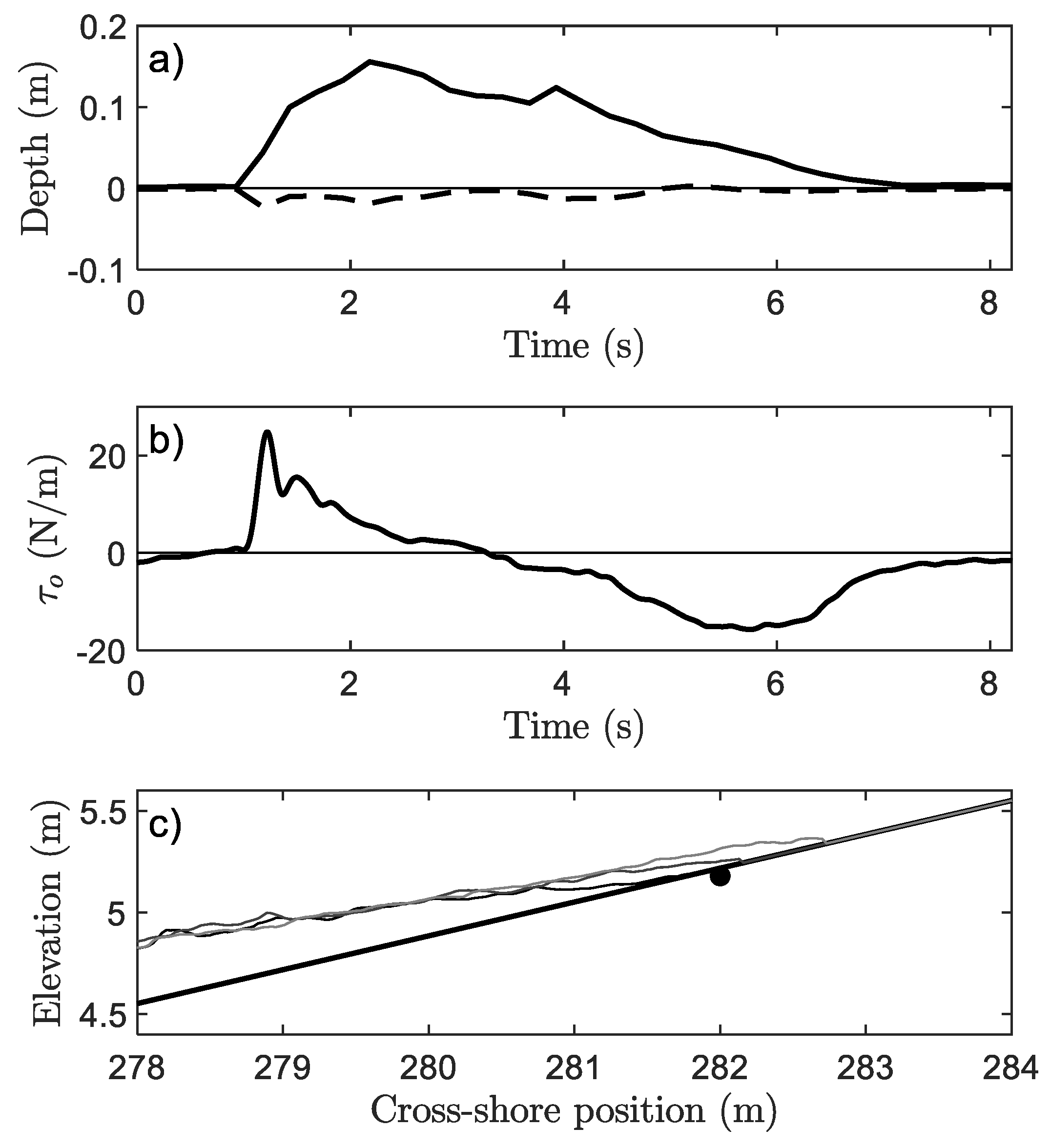

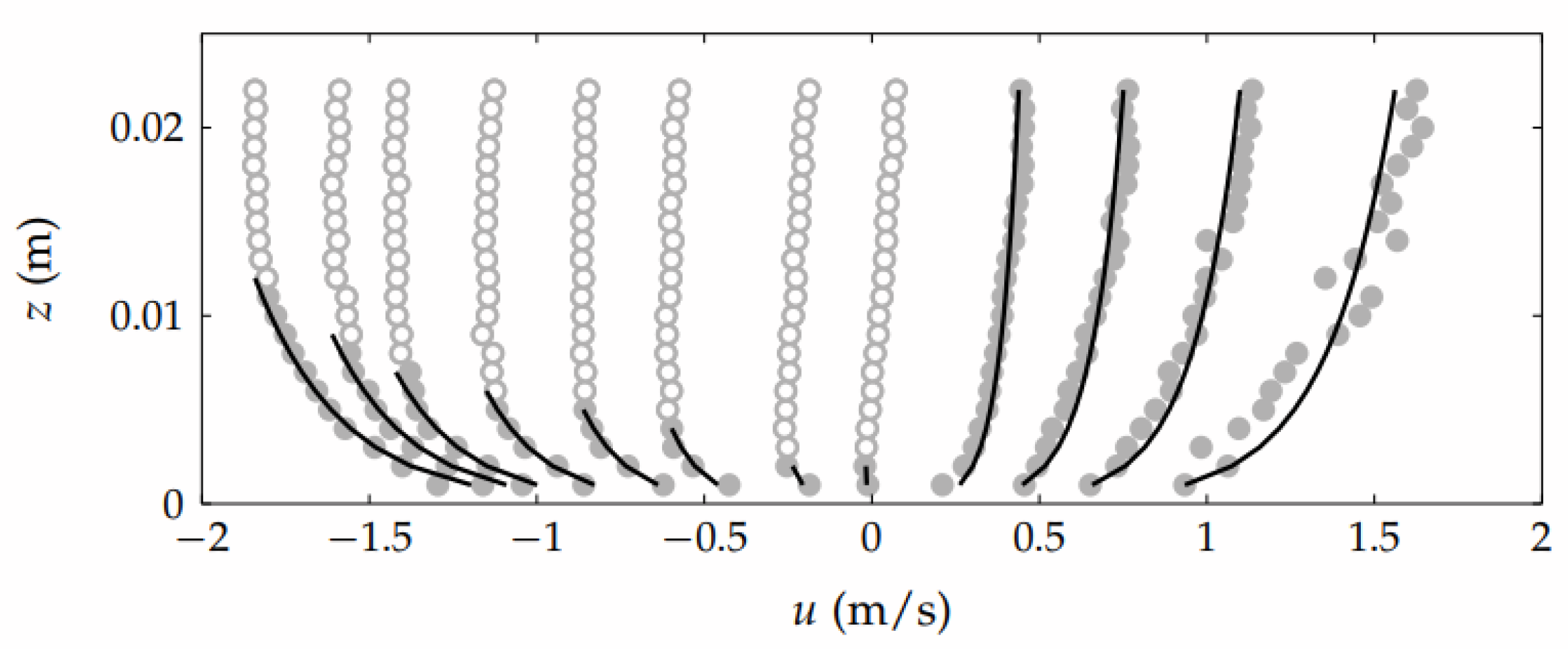

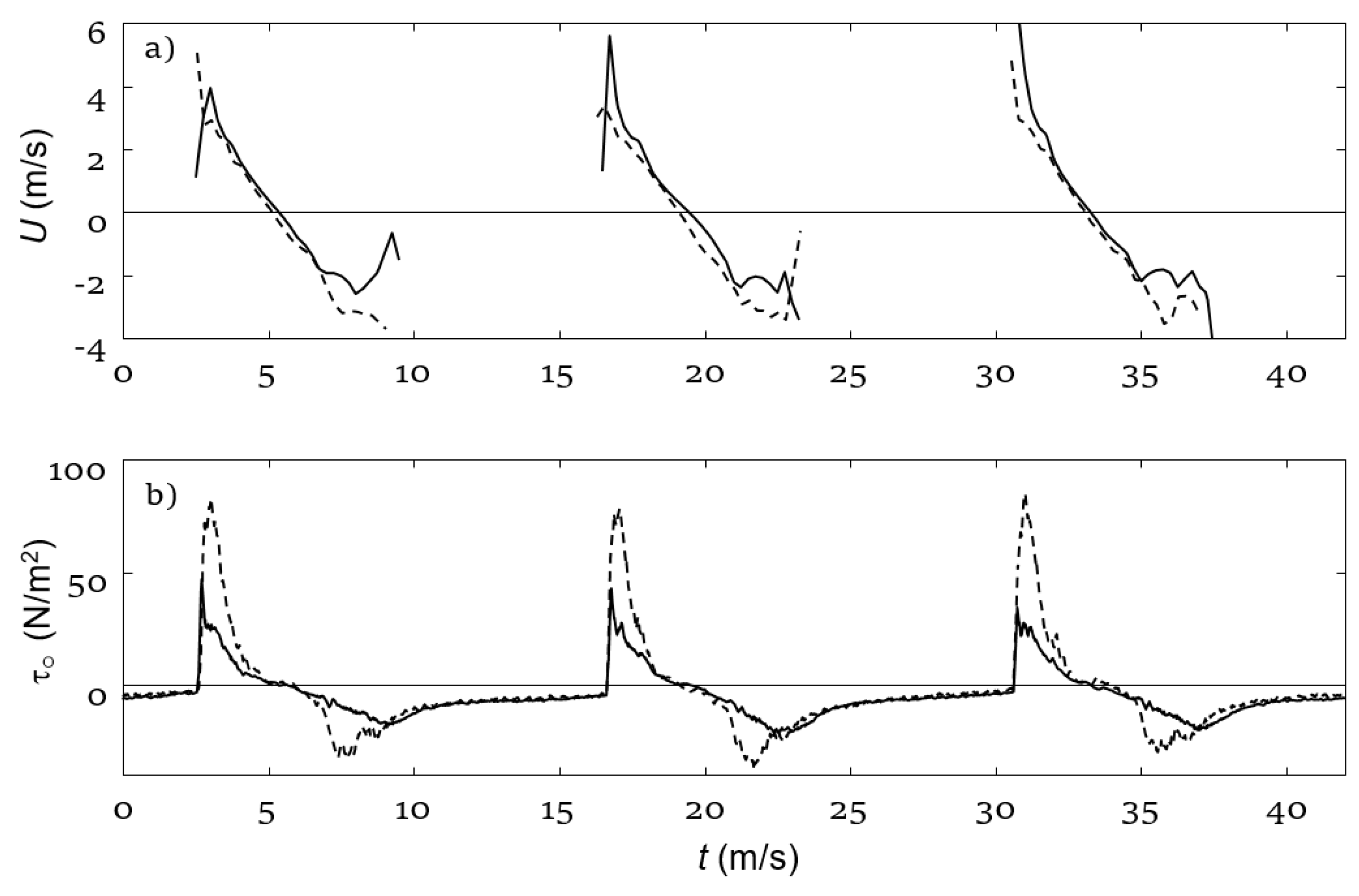

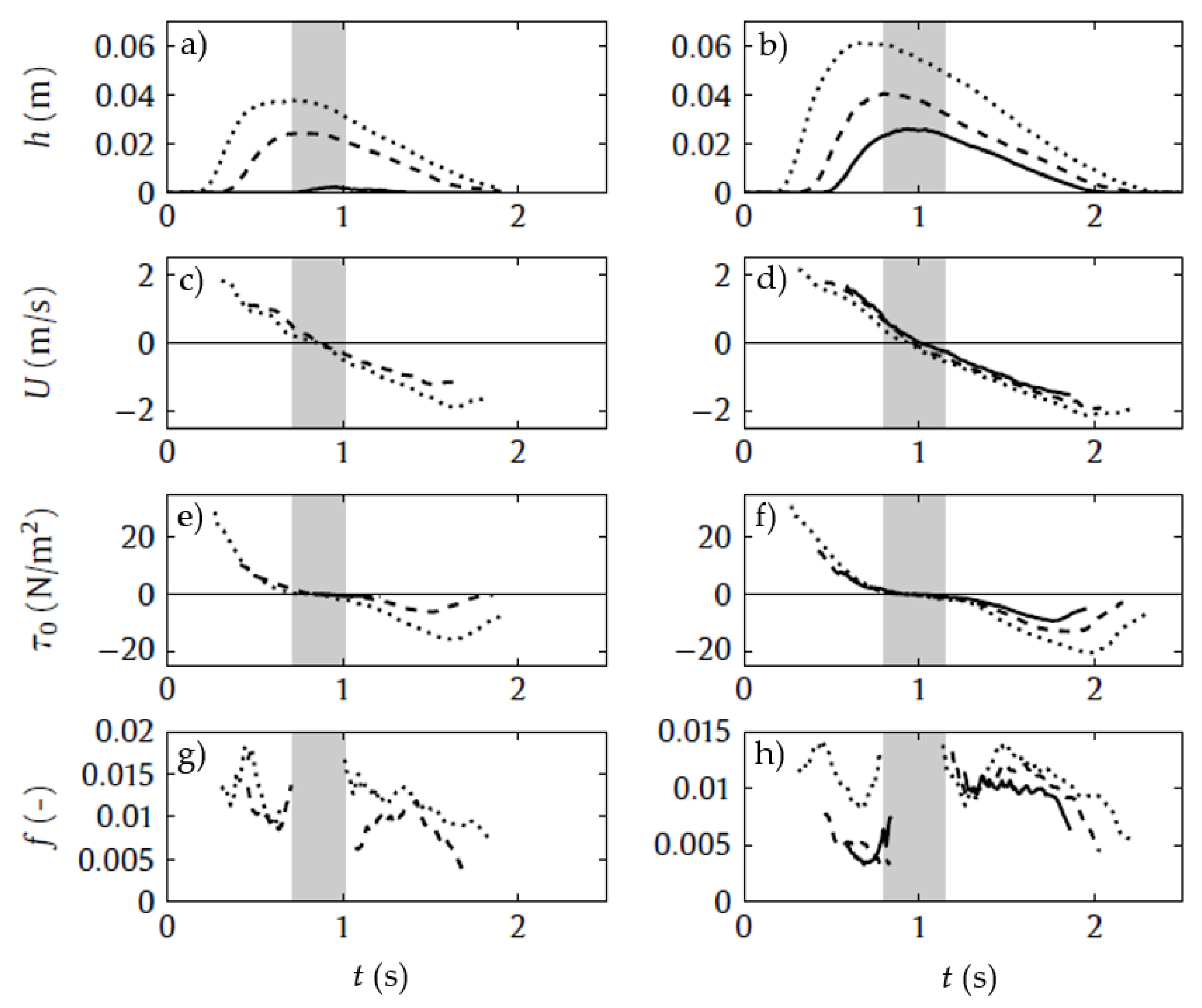

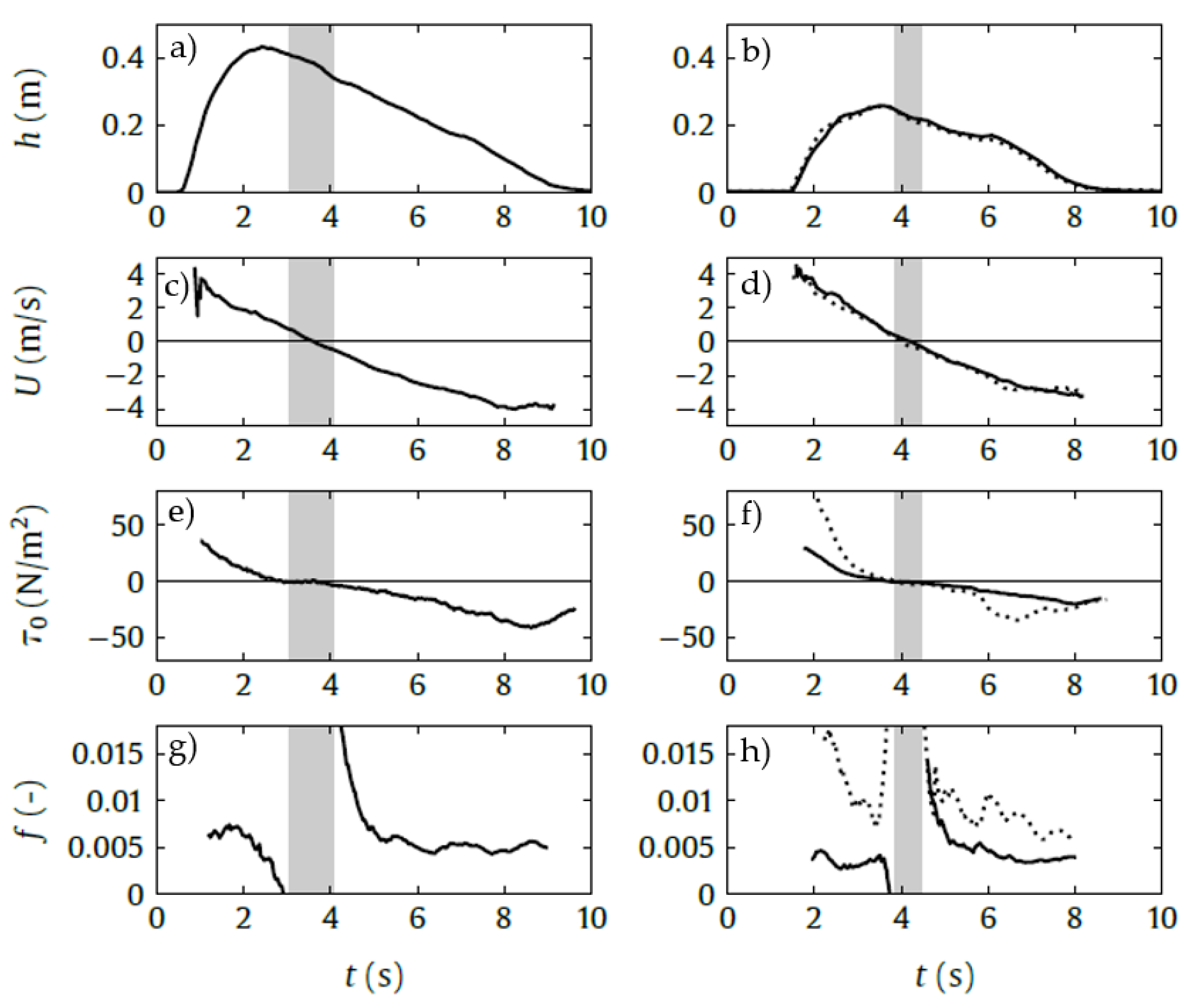

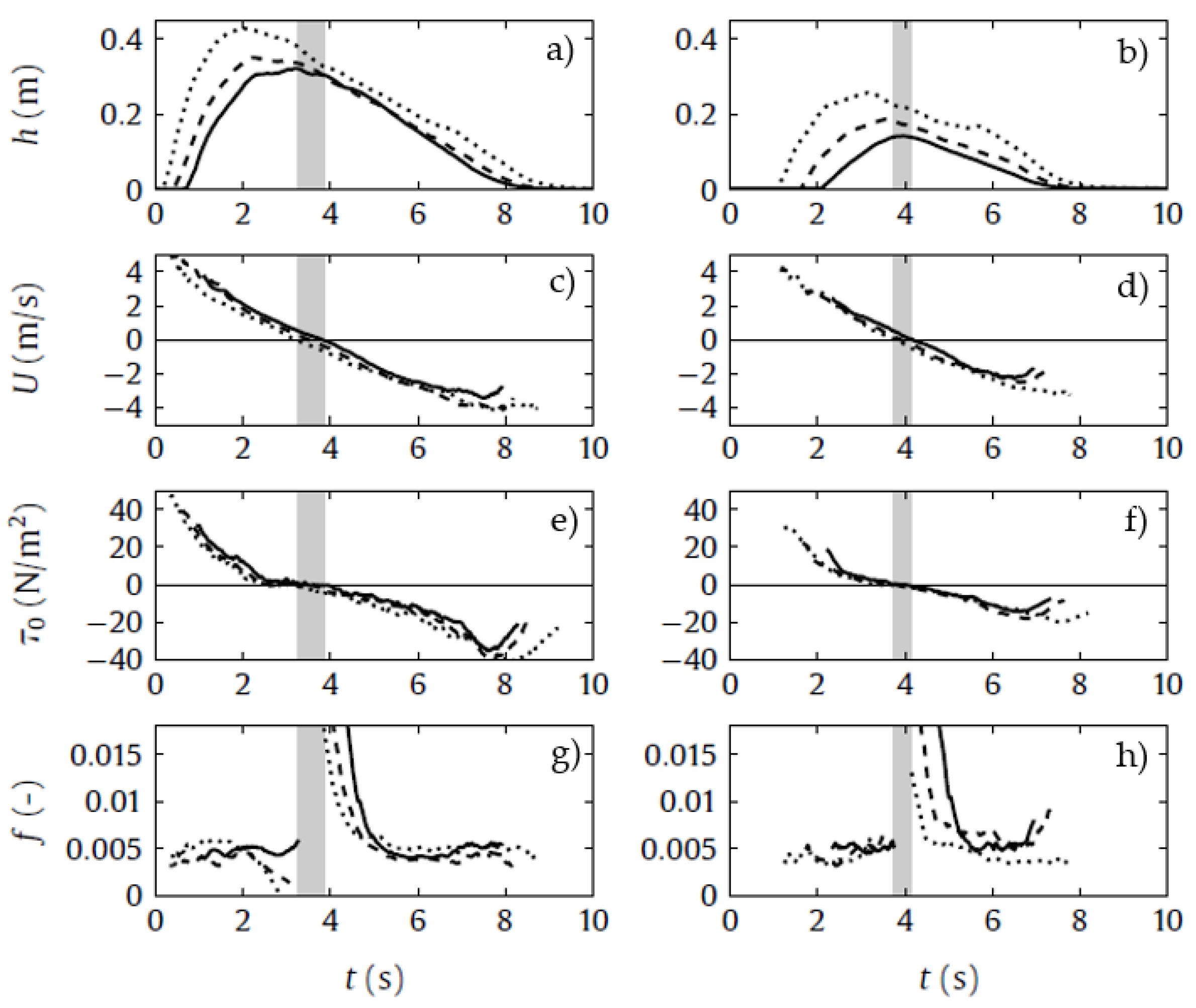

3.1. Swash Surface Profiles and Boundary Layer Development

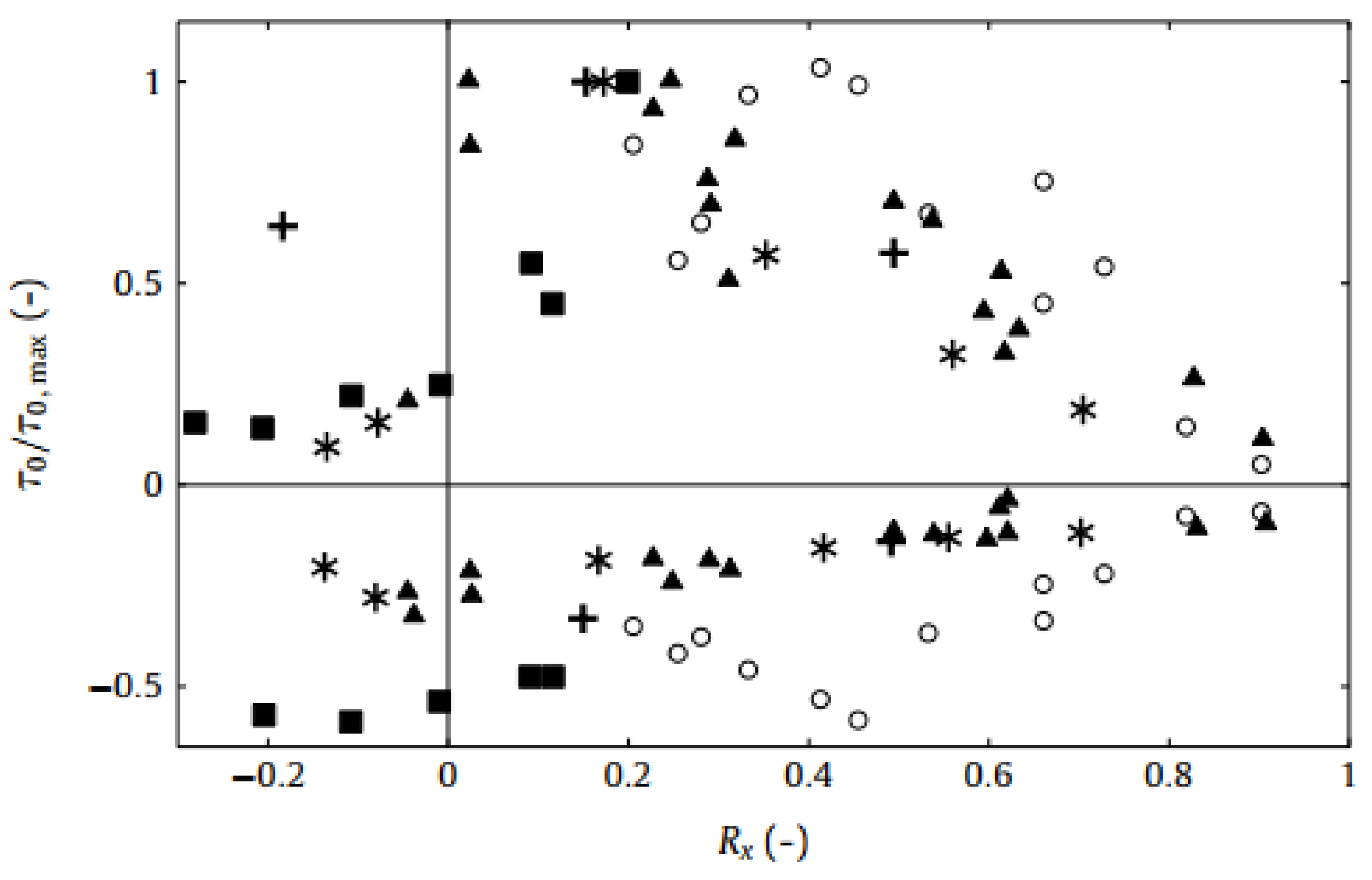

3.2. Influence of Bed Roughness on Bed Shear Stress

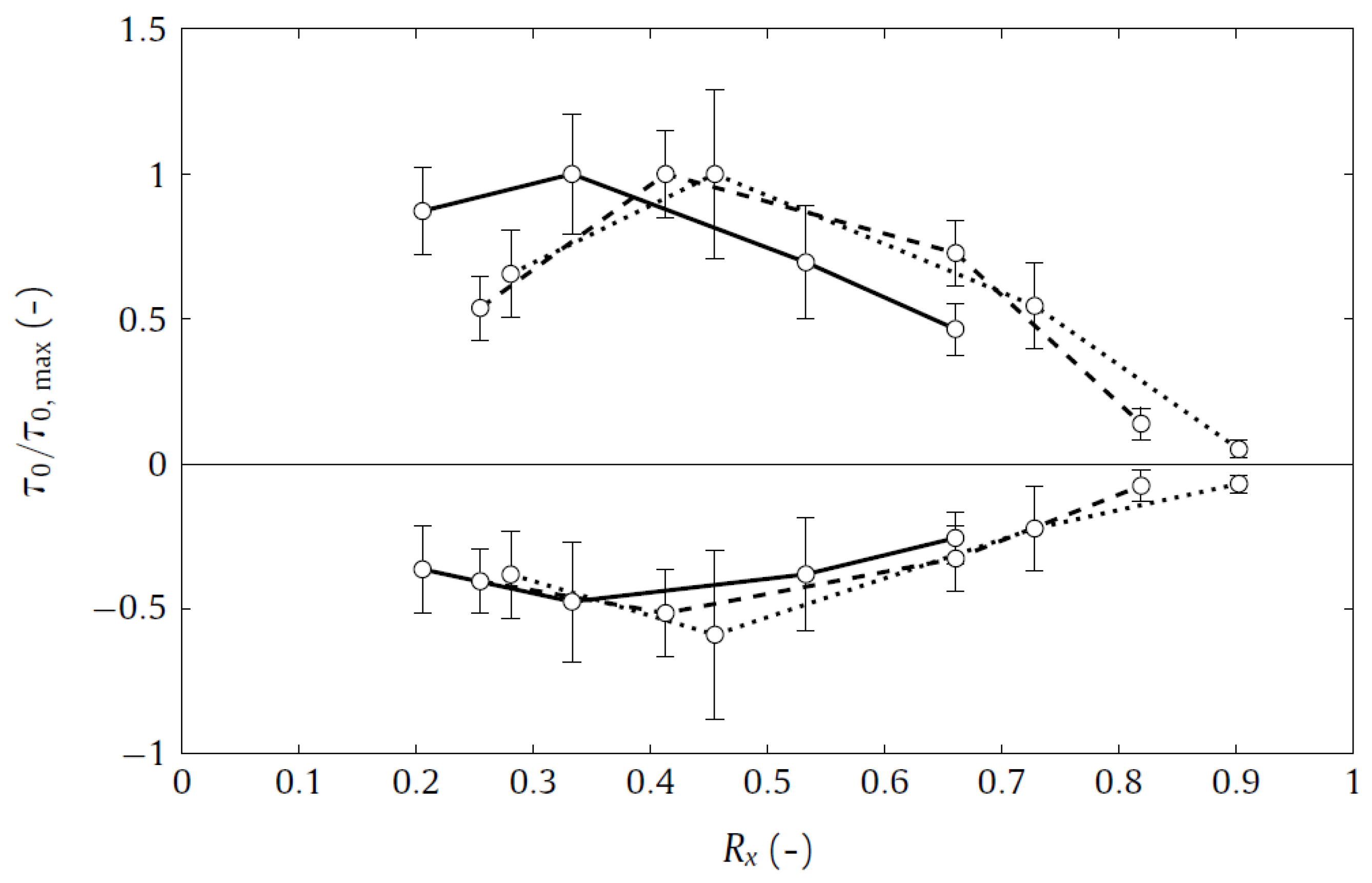

3.3. Influence of Cross-shore Position on Bed Shear Stress

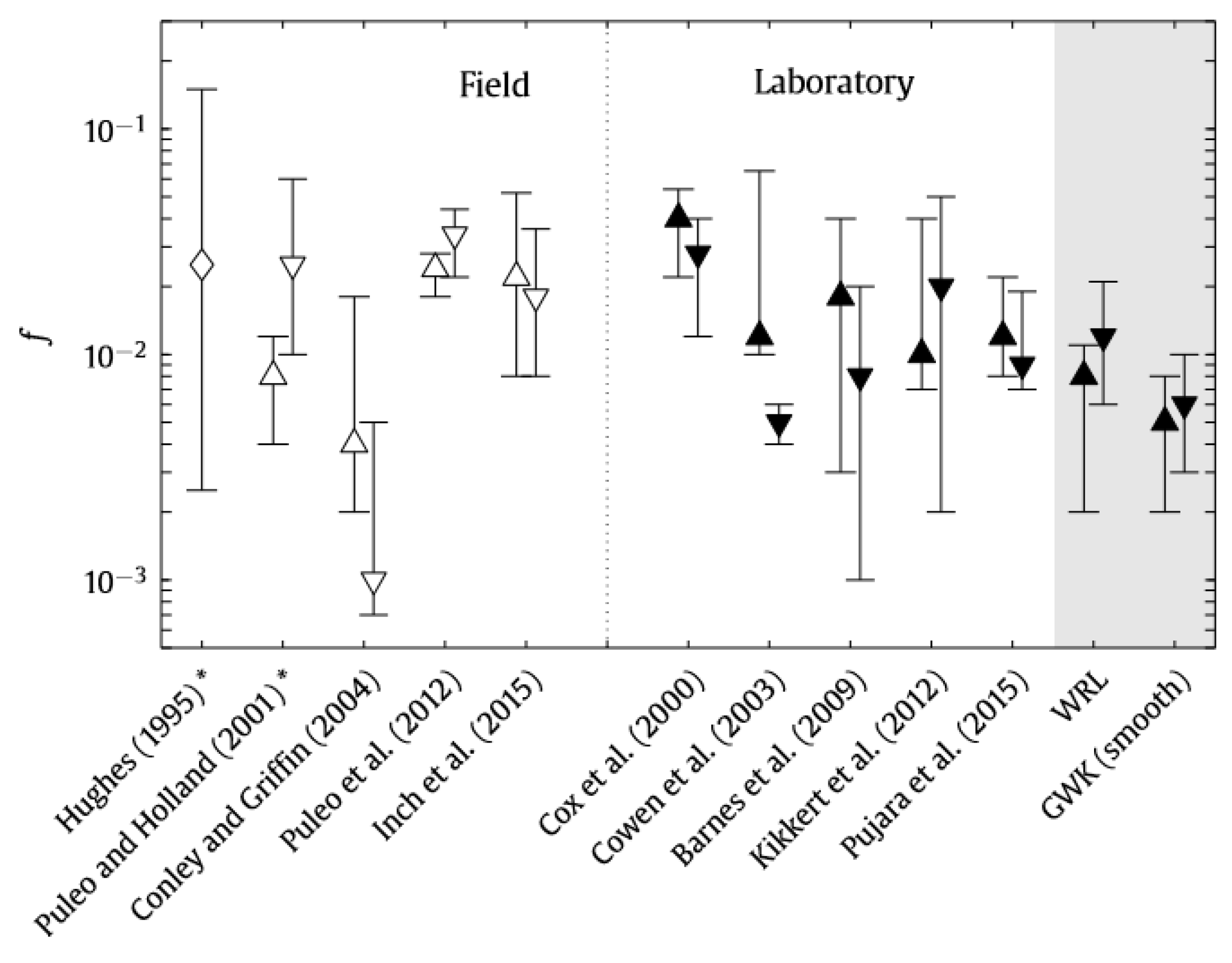

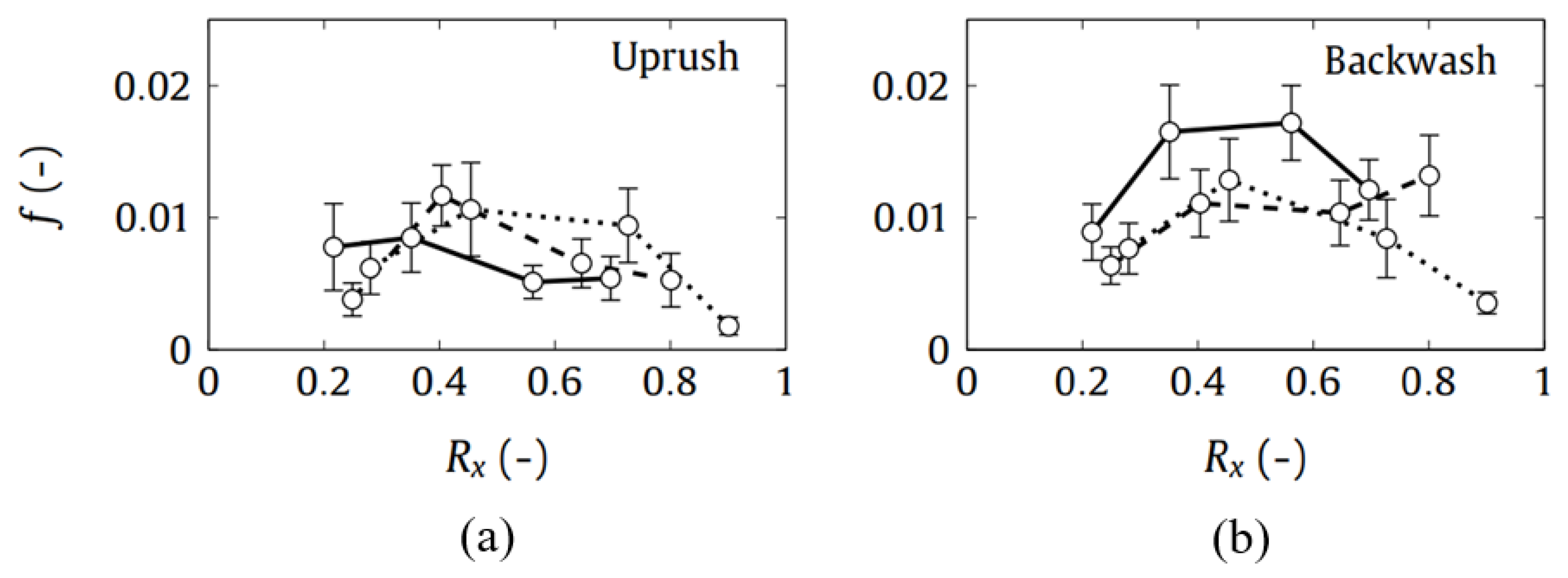

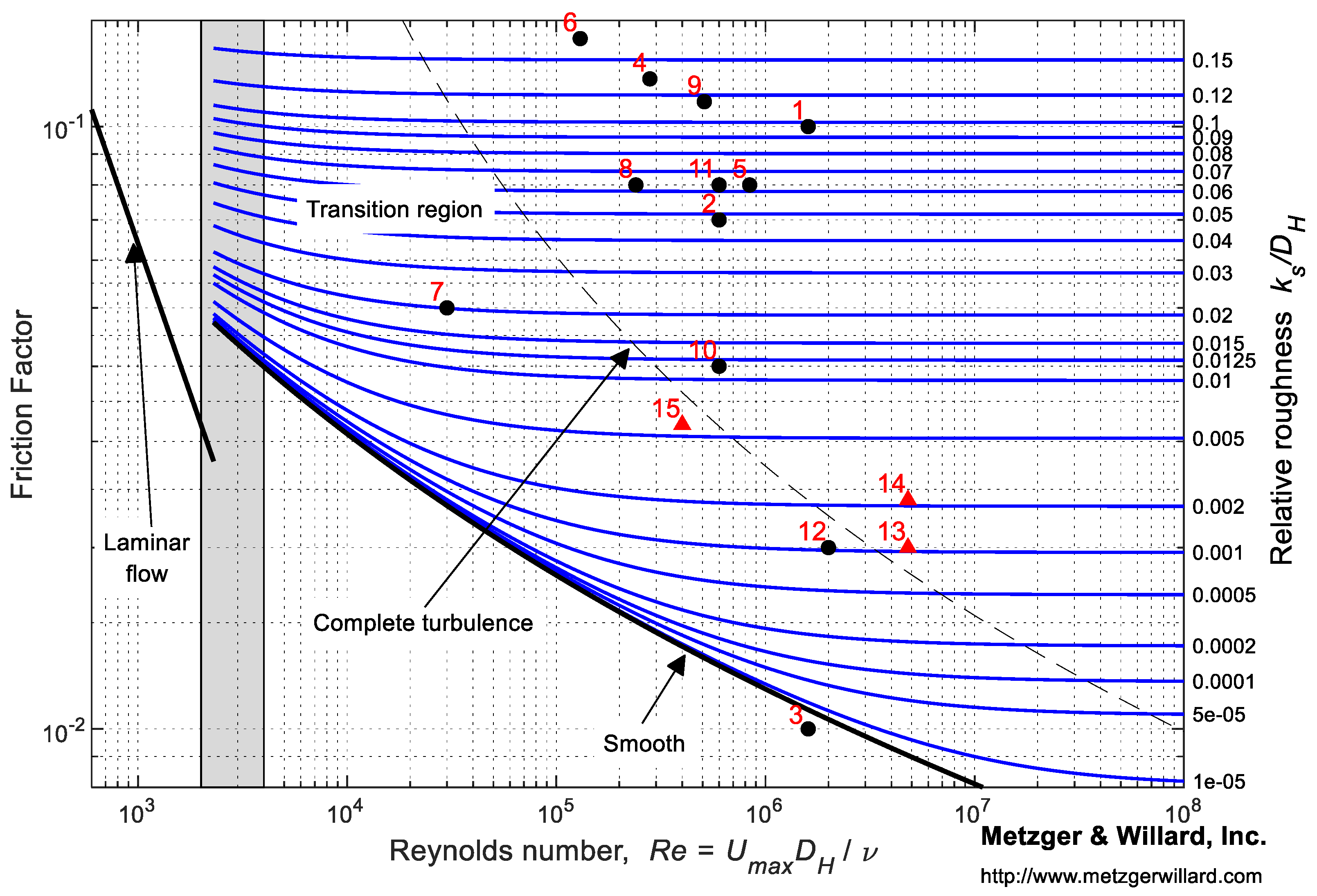

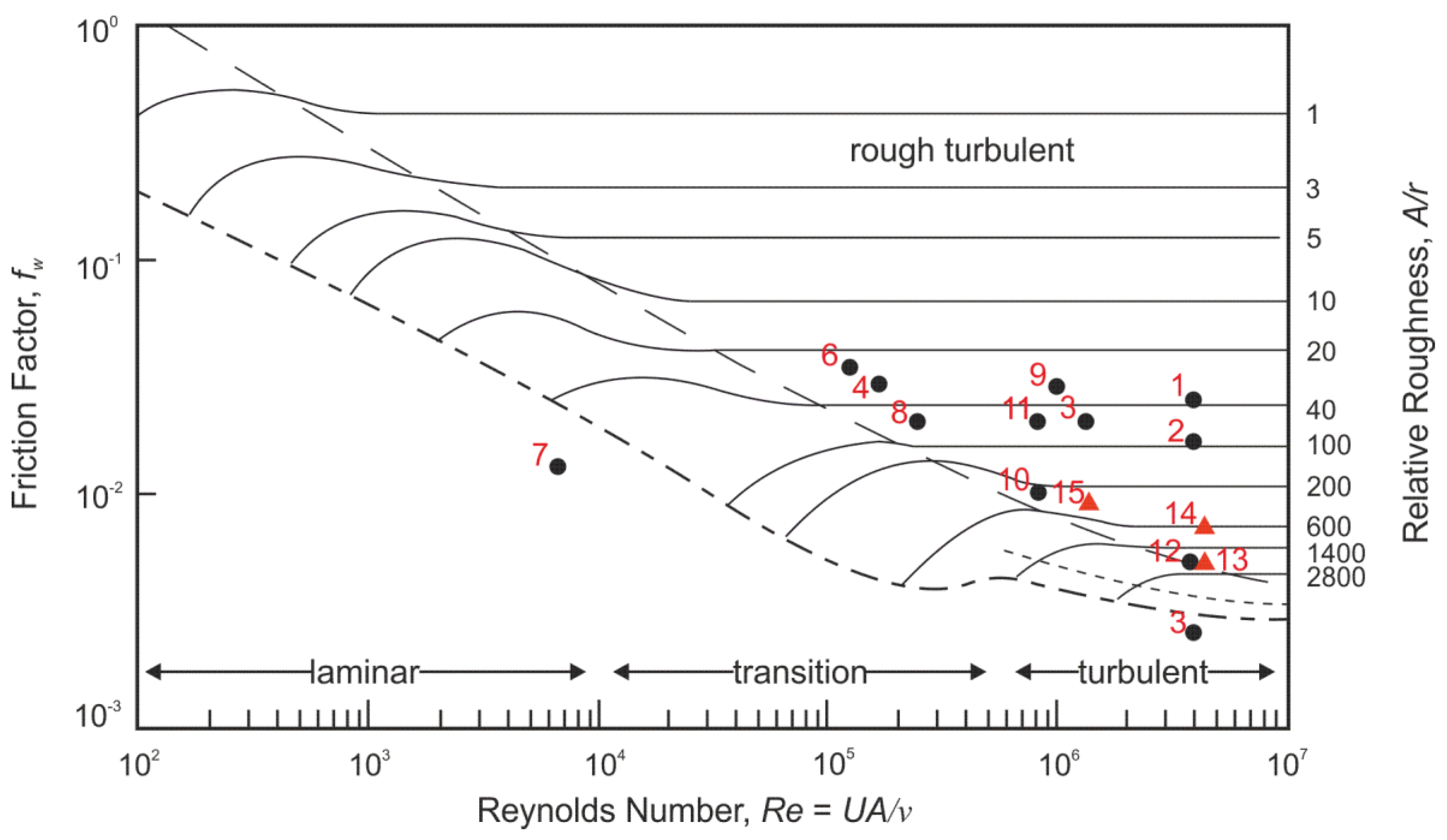

3.4. Friction Factors

3.4.1. Friction Factors (WRL Experiment)

3.4.2. Friction Factors (GWK Experiment)

3.4.3. Comparison of measured friction factors with previous studies

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rayleigh, L. On the resistance of fluids. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1876, 2, 430–441. [Google Scholar] [CrossRef]

- Putnam, J.; Johnson, J. The Dissipation of Wave Energy by Bottom Friction. Trans. Am. Geophys. Union 1949, 30, 67–74. [Google Scholar] [CrossRef]

- Jonsson, I.G. Wave boundary layers and friction factors. In Proceedings of the 10th International Conference on Coastal Engineering, Tokyo, Japan, 4–6 September 1966; ASCE: New York, NY, USA, 1966; pp. 127–148. [Google Scholar]

- Chardón-Maldonado, P.; Pintado-Patiño, J.C.; Puleo, J.A. Advances in swash-zone research: Small-scale hydrodynamic and sediment transport processes. Coast. Eng. 2015, 115, 8–25. [Google Scholar] [CrossRef]

- Conley, D.C.; Griffin, J.G. Direct measurements of bed stress under swash in the field. J. Geophys. Res. 2004, 109, C03050. [Google Scholar] [CrossRef]

- Cox, D.T.; Hobensack, W.; Sukumaran, A. Bottom Stress in the Inner Surf and Swash Zone. In Proceedings of the 27th International Conference on Coastal Engineering, Sydney, Australia, 16–21 July 2000; ASCE: New York, NY, USA, 2000; pp. 108–119. [Google Scholar]

- Cowen, E.A.; Sou, I.M.; Liu, P.L.F.; Raubenheimer, B. Particle Image Velocimetry Measurements within a Laboratory-Generated Swash Zone. J. Eng. Mech. 2003, 129, 1119–1129. [Google Scholar] [CrossRef]

- Hughes, M.G. Friction factors for wave uprush. J. Coast. Res. 1995, 4, 1089–1098. [Google Scholar]

- Puleo, J.A.; Holland, K.T. Estimating swash zone friction coefficients on a sandy beach. Coast. Eng. 2001, 43, 25–40. [Google Scholar] [CrossRef]

- Barnes, M.P.; O’Donoghue, T.; Alsina, J.M.; Baldock, T.E. Direct bed shear stress measurements in bore-driven swash. Coast. Eng. 2009, 56, 853–867. [Google Scholar] [CrossRef]

- Kikkert, G.A.; O’Donoghue, T.; Pokrajac, D.; Dodd, N. Experimental study of bore-driven swash hydrodynamics on impermeable rough slopes. Coast. Eng. 2012, 60, 149–166. [Google Scholar] [CrossRef]

- Puleo, J.A.; Lanckriet, T.M.; Wang, P. Near bed cross-shore velocity profiles, bed shear stress and friction on the foreshore of a microtidal beach. Coast. Eng. 2012, 68, 6–16. [Google Scholar] [CrossRef]

- Inch, K.; Masselink, G.; Puleo, J.A.; Russell, P.E.; Conley, D.C. Vertical structure of near-bed cross-shore flow velocities in the swash zone of a dissipative beach. Cont. Shelf Res. 2015, 101, 98–108. [Google Scholar] [CrossRef]

- Pujara, N.; Liu, P.L.-F.; Yeh, H. The swash of solitary waves on a plane beach: Flow evolution, bed shear stress and run-up. J. Fluid Mech. 2015, 779, 556–597. [Google Scholar] [CrossRef]

- Colebrook, C.F. Turbulent flow in pipes, with particular reference to the transition region between the smooth and rough pipe laws. J. ICE 1939, 11, 133–156. [Google Scholar] [CrossRef]

- Darcy, H. Recherches Expérimentales Relatives au Mouvement de L’eau Dans les Tuyaux (Experimental Research on the Movement of Water in the Pipes); Mallet-Bachelier: Paris, France, 1857. [Google Scholar]

- Fanning, J.T. A Practical Treatise on Hydraulic and Water Supply Engineering; D. Van Norstrand Company: New York, NY, USA, 1893. [Google Scholar]

- Reynolds, O. An experimental investigation of the circumstances which determine whether the motion of water shall be direct or sinuous, and of the law of resistance in parallel channels. Philos. Trans. R. Soc. 1883, 174, 935–982. [Google Scholar]

- Roelvink, D.; Reniers, A.; van Dongeren, A.; van Thiel de Vries, J.; McCall, R.; Lescinski, J. Modelling storm impacts on beaches, dunes and barrier islands. Coast. Eng. 2009, 56, 1133–1152. [Google Scholar] [CrossRef]

- Mansard, E.; Funke, E. The measurement of incident and reflected spectra using a least squares method. In Proceedings of the 17th International Conference on Coastal Engineering, Sydney, Australia, 23–28 March 1980; ASCE: New York, NY, USA, 1980; pp. 154–172. [Google Scholar]

- Barnes, M.P.; Baldock, T.E. Bed shear stress measurements in dam break and swash flows. In International Conference on Civil and Environmental Engineering; Hiroshima University: Hiroshima, Japan, 2006. [Google Scholar]

- Baldock, T.E.; Holmes, P. Swash hydrodynamics on a steep beach. In Proceedings of the Third Coastal Dynamics Conference, Plymouth, UK, 23–27 June 1997. [Google Scholar]

- Blenkinsopp, C.E.; Turner, I.L.; Masselink, G.; Russell, P.E. Validation of volume continuity method for estimation of cross-shore swash flow velocity. Coast. Eng. 2010, 57, 953–958. [Google Scholar] [CrossRef]

- Battjes, J.A. Surf similarity. In Proceedings of the 14th International Conference on Coastal Engineering, Copenhagen, Denmark, 24–28 June 1974; ASCE: New York, NY, USA, 1974. [Google Scholar]

- Martins, K.; Blenkinsopp, C.E.; Power, H.E.; Bruder, B.; Puleo, J.A.; Bergsma, E. High-resolution monitoring of wave transformation in the surf zone using a LiDAR scanner array. Coast. Eng. 2017, 128, 37–43. [Google Scholar] [CrossRef]

- Pero. Schubspannungsmesser Für den Einsatz am Meeresgrund (Shear Stress Plate for Use on the Seabed); PERO Gesellschaft für Meß und Steuertechnik GmbH: Sickte, Germany, unpublished work; 2007. (In German) [Google Scholar]

- Barr, D.I.H. Tables for the Calculation of Friction in Internal Flows; Thomas Telford Publishing: London, UK, 1995. [Google Scholar]

- Baldock, T.E.; Hughes, M.G. Field observations of instantaneous water slopes and horizontal pressure gradients in the swash zone. Cont. Shelf Res. 2006, 26, 574–588. [Google Scholar] [CrossRef]

- Neilsen, P. Bed shear stress, surface shape and velocity field near the tips of dam-breaks, tsunami and wave runup. Coast. Eng. 2018, 138, 126–131. [Google Scholar] [CrossRef]

- Baldock, T.E. Bed shear stress, surface shape and velocity field near the tips of dam-breaks, tsunami and wave runup. Discussion. Coast. Eng. 2018, 142, 77–81. [Google Scholar] [CrossRef]

- Briganti, R.; Dodd, N.; Pokrajac, D.; O’Donohugh, T. Non linear shallow water modelling of bore-driven swash: Description of the bottom boundary layer. Coast. Eng. 2011, 58, 463–477. [Google Scholar] [CrossRef]

- Barnes, M.P.; Baldock, T.E. A Lagrangian model for boundary layer growth and bed shear stress in the swash zone. Coast. Eng. 2010, 57, 385–396. [Google Scholar] [CrossRef]

- Sumer, B.M.; Sen, M.B.; Karagali, I.; Ceren, B.; Fredsøe, J.; Sottile, M.; Zilioli, L.; Fuhrman, D.R.H. Flow and sediment transport induced by a plunging solitary wave. J. Geophys. Res. 2011, 116, C01008. [Google Scholar] [CrossRef]

- Nielsen, P. Shear stress and sediment transport calculations for swash zone modelling. Coast. Eng. 2002, 45, 53–60. [Google Scholar] [CrossRef]

- Nielsen, P. Coastal Bottom Boundary Layers and Sediment Transport; World Scientific: Singapore, 1992. [Google Scholar]

- Kamphuis, J.W. Friction factor under oscillatory waves. J. Waterw. Port C-ASCE 1975, 101, 135–144. [Google Scholar]

- Davis, T.G. Moody Diagram. MATLAB Central File Exchange. Available online: https://www.mathworks.com/matlabcentral/fileexchange/7747-moody-diagram (accessed on 1 October 2019).

| Study | Roughness (mm) | Slope | Study Type | Primary Measurement Technique |

|---|---|---|---|---|

| Hughes (1995) [8] | 0.3–2.0 | 1:11–1:7 | Field | Capacitance gauge |

| Cox et al. (2000) [6] | 6.3 | 1:10 | Laboratory | Laser Doppler velocimetry |

| Puleo and Holland (2001) [9] | 0.26, 0.35, 0.44 | 1:12 | Field | Video camera |

| Cowen et al. (2003) [7] | Smooth | 1:20 | Laboratory | Particle image velocimetry |

| Conley and Griffin (2004) [5] | Medium sand | Dissipative | Field | Hot film anemometer |

| Barnes et al. (2009) [10] | 0.2, 5.8 | 1:12, 1:10 | Laboratory | Shear plate |

| Kikkert et al. (2012) [11] | 1.3, 5.5, 8.4 | 1:10 | Laboratory | Particle image velocimetry |

| Puleo et al. (2012) [12] | 0.2, 0.25 | 1:20 | Field | Acoustic Doppler profiler |

| Inch et al. (2015) [13] | 0.33 | 1:40 | Field | Acoustic Doppler profiler |

| Pujara et al. (2015) [14] | Smooth plywood | 1:12 | Laboratory | Shear plate |

| Test | Wave Type | T (s) | H (m) | Breaker Type | Dmax (m) | Umax (m/s) | Remax |

|---|---|---|---|---|---|---|---|

| 1 | Monochromatic | 2.2 | 0.11 | Plunging | 0.05 | 2.0 | 1.4 × 105 |

| 2 | Monochromatic | 3.2 | 0.22 | Plunging | 0.07 | 2.0 | 2.3 × 105 |

| 3 | Monochromatic | 3.2 | 0.16 | Collapsing | 0.06 | 1.7 | 1.3 × 105 |

| 4 | Monochromatic | 5.0 | 0.16 | Collapsing | 0.11 | 2.2 | 2.1 × 105 |

| Rough Tests | Smooth Tests | Wave Type | T (s) 1 | H (m) 1 | ξ0 | Breaker Type | Dmax (m) 2 | Umax (m/s) 2 | Remax 2 |

|---|---|---|---|---|---|---|---|---|---|

| R1 | S1 | Monochromatic | 8.0 | 0.88 | 1.8 | Plunging | 0.28 | 5.4 | 1.2 × 106 |

| S2 | Monochromatic | 8.0 | 0.99 | 1.7 | Plunging | 0.32 | 4.9 | 1.3 × 106 | |

| S3 | Monochromatic | 10.0 | 0.97 | 2.1 | Plunging | 0.33 | 4.3 | 1.6 × 106 | |

| S4 | Monochromatic | 12.0 | 0.61 | 3.2 | Plunging | 0.32 | 3.8 | 1.2 × 106 | |

| S5 | Monochromatic | 12.0 | 0.72 | 3.0 | Plunging | 0.35 | 5.0 | 1.7 × 106 | |

| R2 | S6 | Monochromatic | 12.0 | 0.95 | 2.6 | Plunging | 0.43 | 5.6 | 2.0 × 106 |

| S7 | Monochromatic | 14.0 | 0.63 | 3.8 | Collapsing | 0.35 | 3.7 | 1.2 × 106 | |

| S8 | Monochromatic | 14.0 | 0.85 | 3.3 | Plunging | 0.44 | 4.5 | 2.1 × 106 | |

| R3 | S9 | Irregular 3 | 12.0 | 0.82 | 2.8 | Plunging | 0.28 | 5.2 | 9.8 × 105 |

| 1. Measured offshore (120 m from paddle). 2. Measured in swash zone (above GWK shear plate). | |||||||||

| Study No. | Study Author | f (meas) | Re (106) | ks/DH | fw (meas) | Rew (106) | A/r |

|---|---|---|---|---|---|---|---|

| 1 | Hughes (1995) [8] | 0.1 | 1.6 | 0.0006 | 0.025 | 4 | 4000 |

| 2 | Puleo and Holland (2001) [9] | 0.07 | 0.6 | 0.0011 | 0.0165 | 4 | 5714 |

| 3 | Conley and Griffin (2004) [5] | 0.01 | 1.6 | 0.0003 | 0.0025 | 4 | 8000 |

| 4 | Puleo et al. (2012) [12] | 0.12 | 0.28 | 0.0006 | 0.029 | 0.17 | 980 |

| 5 | Inch et al. (2015) [13] | 0.08 | 0.84 | 0.0005 | 0.02 | 1.4 | 2970 |

| 6 | Cox et al. (2000) [6] | 0.14 | 0.13 | 0.0393 | 0.034 | 0.13 | 25 |

| 7 | Cowen et al. (2003) [7] | 0.05 | 0.03 | Smooth | 0.013 | 0.0068 | Smooth |

| 8 | Barnes et al. (2009) [10] | 0.08 | 0.24 | 0.0008 | 0.02 | 0.25 | 1250 |

| 9 | Barnes et al. (2009) [10] | 0.11 | 0.51 | 0.018 | 0.028 | 1.02 | 110 |

| 10 | Kikkert et al. (2012) [11] | 0.04 | 0.6 | 0.0033 | 0.01 | 0.84 | 433 |

| 11 | Kikkert et al. (2012) [11] | 0.08 | 0.6 | 0.0210 | 0.02 | 0.84 | 67 |

| 12 | Pujara et al. (2015) [14] | 0.02 | 2 | Smooth | 0.005 | 3.9 | Smooth |

| 13 | GWK (smooth) | 0.02 | 4.8 | 0.0001 | 0.005 | 4.5 | 7500 |

| 14 | GWK (rough) | 0.024 | 4.8 | 0.0009 | 0.006 | 4.5 | 1000 |

| 15 | WRL | 0.032 | 0.4 | 0.0002 | 0.008 | 1.4 | 466 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Howe, D.; Blenkinsopp, C.E.; Turner, I.L.; Baldock, T.E.; Puleo, J.A. Direct Measurements of Bed Shear Stress under Swash Flows on Steep Laboratory Slopes at Medium to Prototype Scales. J. Mar. Sci. Eng. 2019, 7, 358. https://doi.org/10.3390/jmse7100358

Howe D, Blenkinsopp CE, Turner IL, Baldock TE, Puleo JA. Direct Measurements of Bed Shear Stress under Swash Flows on Steep Laboratory Slopes at Medium to Prototype Scales. Journal of Marine Science and Engineering. 2019; 7(10):358. https://doi.org/10.3390/jmse7100358

Chicago/Turabian StyleHowe, Daniel, Chris E. Blenkinsopp, Ian L. Turner, Tom E. Baldock, and Jack A. Puleo. 2019. "Direct Measurements of Bed Shear Stress under Swash Flows on Steep Laboratory Slopes at Medium to Prototype Scales" Journal of Marine Science and Engineering 7, no. 10: 358. https://doi.org/10.3390/jmse7100358

APA StyleHowe, D., Blenkinsopp, C. E., Turner, I. L., Baldock, T. E., & Puleo, J. A. (2019). Direct Measurements of Bed Shear Stress under Swash Flows on Steep Laboratory Slopes at Medium to Prototype Scales. Journal of Marine Science and Engineering, 7(10), 358. https://doi.org/10.3390/jmse7100358