1. Introduction

With the increasing depletion of onshore resources, the development and utilization of marine oil and gas energy has become an important development trend. Floating offshore platforms (FOPs) are increasingly important in the development of offshore oil and gas resources. Therefore, the design of platform positioning systems is particularly important. The positioning modes of FOP include multi-point mooring system (MPMS) [

1], dynamic positioning (DP) [

2], and combined positioning mode [

3]. Among them, the combined positioning mode has the best performance but is very expensive [

4]. MPMS has the characteristics of low investment, easy maintenance, and good adaptability to the marine environment and is widely used in FOP and barges in offshore waters [

5]. This type of ship is generally a non-powered, non-self-propelled ship and mainly relies on the mooring system to resist external environmental disturbances to suppress platform deflection to achieve mooring and positioning [

6].

MPMS is a nonlinear dynamic problem, so its design is complex [

7]. Kim et al. [

8] and Nguyen et al. [

9] modeled the system consisting of barge and mooring cables and adopted a PID control strategy to control the position and direction of the ship by changing the tension of the mooring cables. Zhang et al. [

10] established the MPMS forward and inverse solution models and determined the relationship between the MPMS position and the anchor Chain Ji et al. [

11,

12] designed an

-based robust control system for the ship mooring control allocation problem, which simultaneously carried out controller design and control allocation and uniformly handled system stability and control performance. Zhou et al. [

13] conducted a comparative study on the control design of single-point mooring and multi-point mooring and showed that reconfiguring the length of the catenary mooring can effectively suppress the platform pitch motion. Su et al. [

14] proposed an automatic mooring positioning scheme with the goal of uniform tension distribution and designed a cost-guaranteed control method for the mooring automatic positioning system considering input delay. Considering the unpredictability of marine environmental disturbances, control parameters must be adaptively modified to ensure optimal performance. Zhang et al. [

15] used a convolutional neural network (CNN) to extract fault features and DRNN to learn the dynamic change characteristics of MPMS to optimize

KP,

KI, and

KD and proposed an online self-learning PID based on DRNN in MPMS. Shin et al. [

16] used a fuzzy logic controller (FLC) to dynamically adjust control parameters so that it could effectively adapt to rapidly changing ocean conditions. Wang et al. [

17] used backstepping and integrated non-singular fast terminal sliding mode surface (INFTSMS) to suppress chattering and proposed an adaptive estimator to deal with unknown system uncertainties and external environmental interference. Zhang et al. [

18] combined a set value tracking algorithm based on structural reliability with an adaptive fuzzy estimator to derive an improved DSC law, which improved the convergence speed of the filtering error. Mao et al. [

19] used a deep neural network (DNN) method to predict the dynamic anchor chain tension in the event of anchor chain failure and verified that the significant increase in surge and sway motion caused by mooring breakage is the main controlling variable for mooring tension prediction. Failure or breakage of the mooring chain can cause the moored platform to drift severely or even stop operating [

20]. Simultaneously, for safety reasons, an excessively large change rate of the combined force of the MPMS can cause the anchor machine to jump in speed, posing a great challenge to the safety of the mooring cable. Although considering the limited input of the mooring system will greatly increase the difficulty of designing the control system, it is more in line with the actual application scenario.

The application of adaptive robust controllers in multiple fields such as hypersonic vehicle control [

21], nonlinear system adaptive control [

22], and medical robot control [

23] has demonstrated the importance and effectiveness of adaptive robust control methods in dealing with uncertainties and improving system robustness. So as to solve the above problems, this paper designs a robust adaptive dynamic surface (RADS) positioning control method with disturbance observer by combining disturbance observer, ADS and DSC under the condition of external time-varying disturbance and input constraint. This method constructs a disturbance observer to estimate the external environmental disturbance and uses its feedforward control to compensate for the control quantity, effectively weakening the chattering. Considering the existence of disturbance observation error, the adaptive law of the σ-corrected leakage term is used to estimate it and improve the control accuracy. An ADS is introduced to deal with input constraints, and the DSC technology is combined to avoid computational expansion. The Lyapunov function is selected to prove that the control law can ensure the consistent ultimate boundedness of all signals in the closed-loop system. Classification societies stipulate that the positioning error of MPMS is ≤3~5% of the water depth, and the pitch and heel angles are ≤1°. The proposed MPMS RADS positioning control method is applied to the “Kantan3” eight-point mooring platform to verify the effectiveness of the designed controller.

2. Problem Formulation and Preliminaries

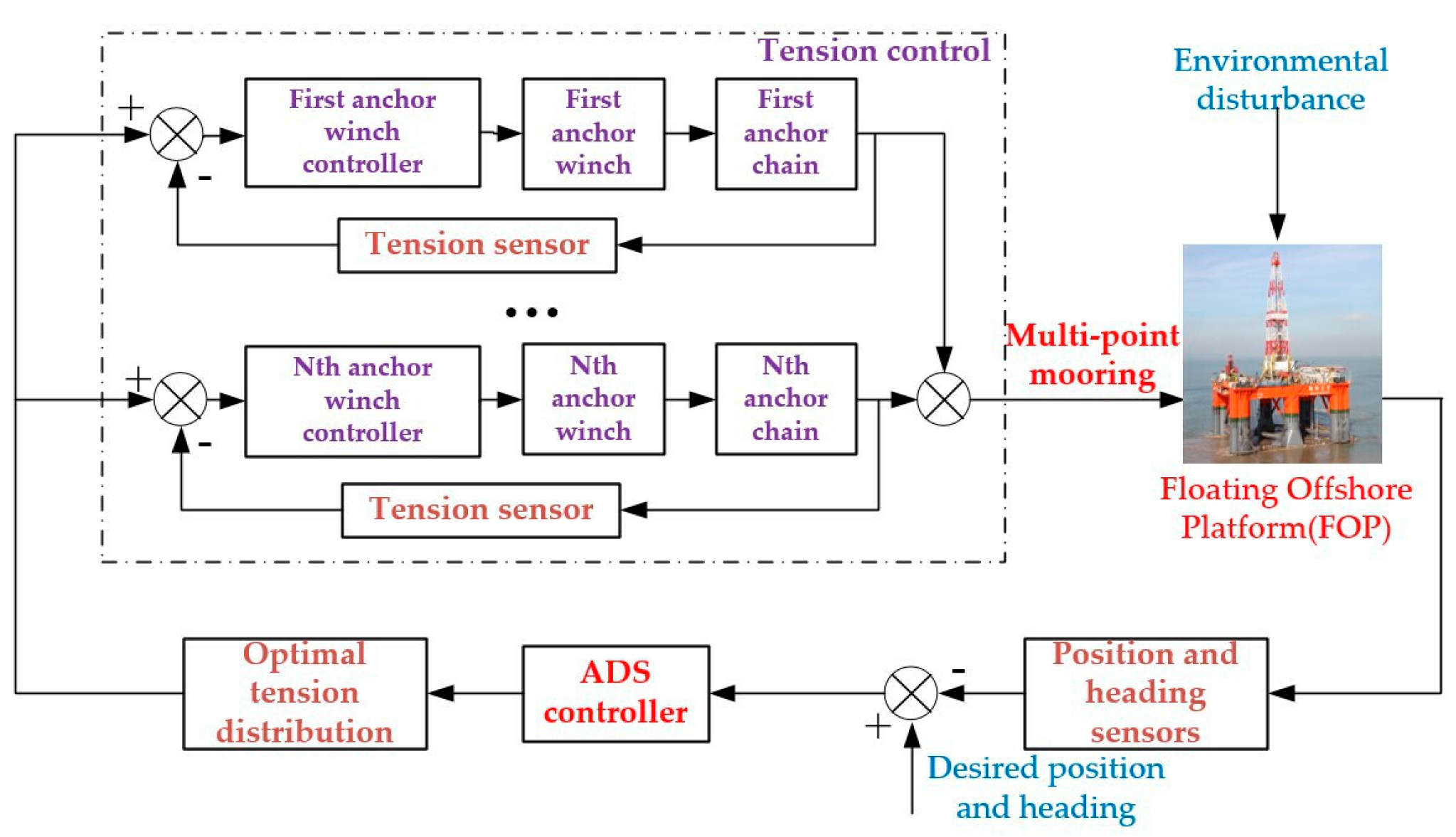

As shown in

Figure 1,

OOXOYOZO is an inertial coordinate frame fixed on the surface of the earth, with its origin taken at any point on the ground or sea surface. The

OOXO axis points to the initial motion direction of the platform in the static horizontal plane. The

OOYO axis and the

OOXO axis are in the same plane and perpendicular to the

OOXO axis. The

OOZO axis is perpendicular to the static water surface and points to the center of the earth in the positive direction, which conforms to the right-hand rule. The platform’s motion coordinate frame

OXYZ has its origin taken at the center of mass of the platform. The

OX axis is along the longitudinal axis of the platform and points to the bow. The

OY axis is consistent with the pitch axis and points to the starboard side. The

OZ axis points to the bottom of the platform.

The FOP moves at a low speed during operation, and its motion on the sea level is mainly studied. Therefore, the low-frequency motion model of FOP surge, sway, and yaw is established as follows [

24]:

where,

η = [

x,

y,

ψ]

T is the position vector of the platform in the earth-fixed coordinate frame, which consists of the platform’s surge position

x, the sway position

y, and the yaw angle

ψ.

ν = [

u,

υ,

r]

T is the velocity vector of the platform in the body-fixed coordinate frame, which is composed of the platform’s surge velocity

u, sway velocity

υ, and yaw rate

r.

R(

ψ) is the rotation matrix given by the following:

M is the inertia matrix including the additional mass,

D is the damping matrix including the mooring cable damping, and

is the resultant force and moment vector that the mooring system can provide. In addition, due to the physical characteristics of the FOP mooring system, the force that the mooring system provides cannot be infinite, and for safety reasons, excessive changes in the anchor cable tension should be avoided and the following saturation limits should be met:

where,

i = 1, 2, and 3 represent platform surge, sway, and yaw, respectively;

represent the desired control input calculated by the controller at the

i-th degree of freedom;

and

represent the maximum or minimum resultant force and moment that the mooring system can provide in the

i-th degree of freedom, respectively, and

is the difference between the actual control signal and the command control signal.

is the external environmental disturbance vector.

Assumption 1. The external disturbance wi(t), where i = 1, 2, and 3, are unknown time-varying yet bounded, and the rate change in the disturbance is bounded, such that, .

From Equation (3), it can be seen that the saturation limit has no effect when the expected control input is within the saturation limit; when the expected control input exceeds the saturation range, the saturation limit will cause the actual control force to deviate from the expectation, thereby causing the system control performance fall. Therefore, in the design process, this paper introduces an ADS, designs a RADS controller, and introduces a tension distribution algorithm to realize a multi-point mooring automatic positioning system in response to the situation where the mooring system input is limited. The positioning principle of the MPMS is shown in

Figure 2. The RADS controller calculates the resultant force and torque required for the FOP to maintain the desired position under the current disturbance and distributes the control resultant force to the eight mooring cables through the tension distribution algorithm. The anchor winch controls the mooring cables to reach the distribution value, thereby moving or maintaining the FOP at the desired position. This control method can not only ensure the positioning accuracy of the FOP but also ensure that the tension of the mooring cable changes relatively smoothly during the control process while taking into account the uniform distribution of the mooring cable tension to avoid the breakage of the mooring cable caused by excessive tension.

4. Simulation

To verify the validity of the designed control law, this section conducts simulation tests on the “Kantan3” eight-point moored semi-submersible FOP. The platform length is 91 m, the beam is 71 m, the working water depth is 250 m, the displacement is 25,240 t, and the platform model parameter correlation matrix is as follows:

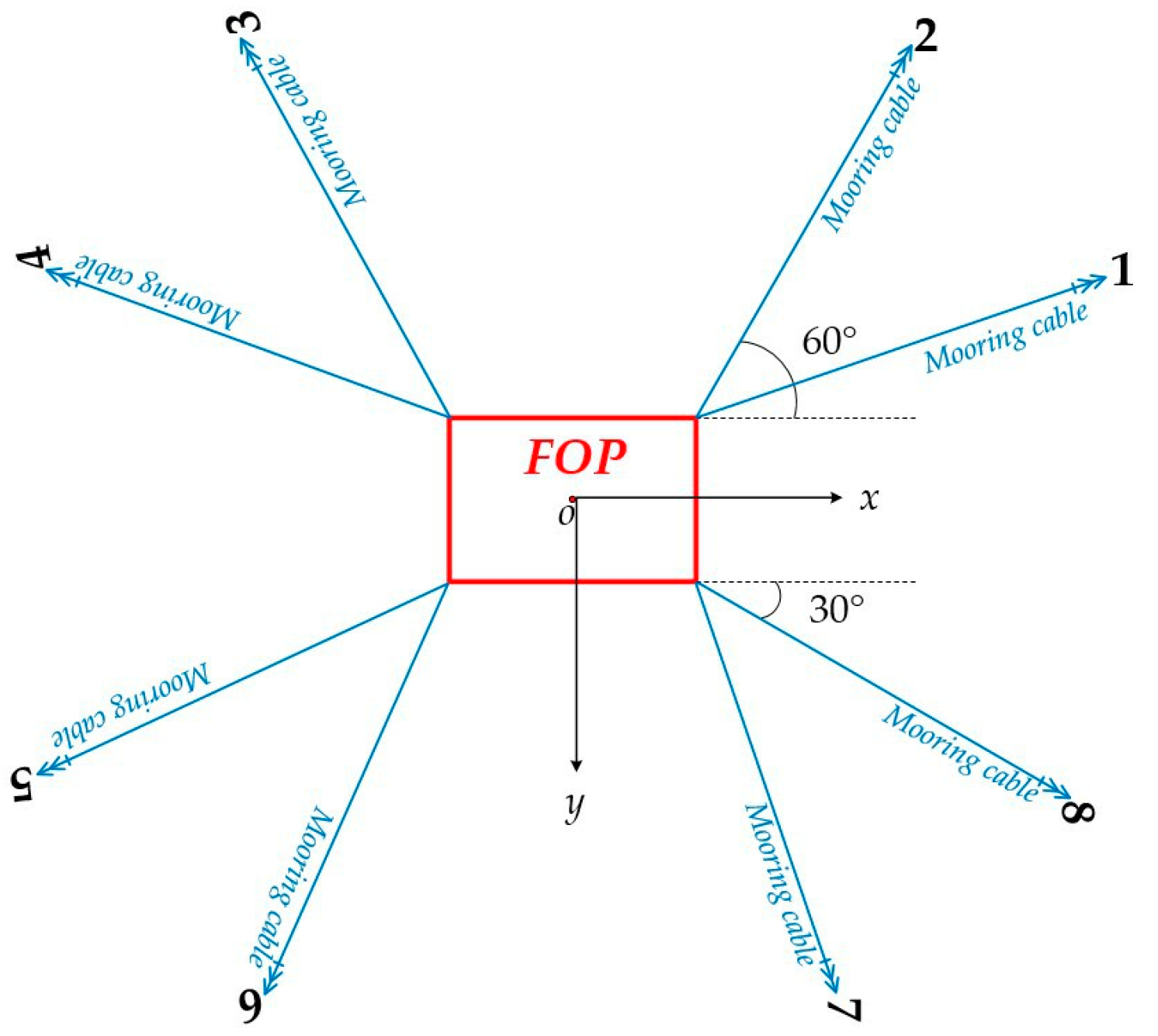

The mooring system of the “Kantan3” semi-submersible offshore platform consists of 8 anchor chains. The name order of the anchor chains is numbered counterclockwise. The anchor chain arrangement of the moored platform is shown in

Figure 3. The angles of each anchor chain, the position of the fairlead hole, and the coordinates of the anchor point are shown in

Table 1. The initial pretension of the mooring cable is 1.2 MN to ensure that the horizontal offset of the platform is within the appropriate range. The resultant force and moment limits provided by the eight-point mooring in the horizontal direction are shown in

Table 2.

A first-order Markov process is used to describe the unknown external environmental disturbances suffered by the FOP [

25], as follows:

where

is the external environment interference vector of the semi-submersible platform in the earth-fixed coordinate frame;

is the designed diagonal matrix of time constants;

is the zero-mean Gaussian white noise vector;

is a diagonal matrix with scaled amplitudes of

.

The MPMS control law proposed in this paper is used to simulate two different external disturbances corresponding to different sea conditions and is compared with the traditional PID control law.

where

=

diag(1.2 × 10

6, 1.5 × 10

6, 3.2 × 10

9),

=

diag(15, 15, 15),

=

diag(5 × 10

7, 5 × 10

7, 5 × 10

10).

Case 1: Choose b(0) = [0, 0, 0]T, = diag(5 × 103, 5 × 103, 5 × 104), = diag(103, 103, 103). Set desired position and heading for FOP as = [15 m, 15 m, 10°]T, and the initial states are η(0) = [0 m, 0 m, 0°]T, ν(0) = [0 m/s, 0 m/s, 0°/s]T, w(0) = [0, 0, 0]T, δ(0) = [0.1, 0.1, 0.1]T. The controller design parameters are ρ = [5 × 10−3, 5 × 10−3, 1 × 10−4]T, = diag(2, 2, 2), = diag(1.5, 1.5, 1.5), = diag(3 × 105, 6 × 105, 3 × 108), = diag(20, 20, 20), = 0.8, = 10−6 × diag(1, 1, 10−4), = 104 × diag(1, 1, 3 × 103).

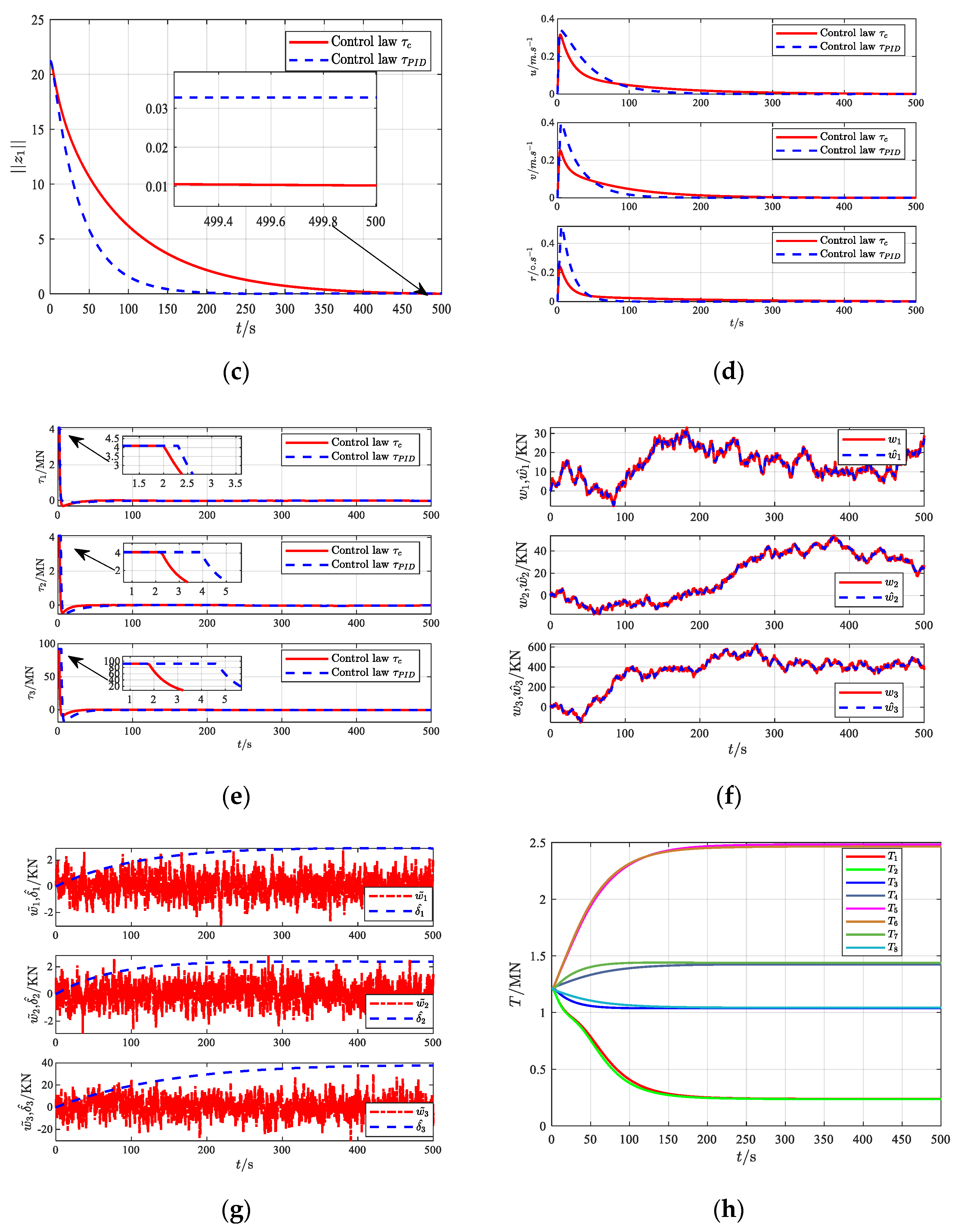

The simulation results of Case 1 are shown in

Figure 4a–h.

Figure 4a–c shows the positioning and tracking performance of the FOP. Both control laws can adjust the platform to the desired position. In comparison, the PID control law has a fast response speed, but the MPMS control law has a higher positioning accuracy, reaching within 3% of the working water depth.

Figure 4d shows the curves of the surge velocity, sway velocity, and yaw angular velocity of the FOP. Under the MPMS control law, the speed of the FOP is smoother, avoiding excessive change rate of the mooring system force, which causes the anchor machine to jump.

Figure 4e shows the boundedness of the control inputs

,

, and

. Under the control input constraints, the input constraint time of the MPMS control law is 2 s, and the input constraint time of the PID control is 4.5 s, which effectively avoids serious drift or even shutdown of the platform due to the breakage of the mooring cable.

Figure 4f shows that the constructed disturbance observer can provide an estimate of the unknown time-varying disturbance.

Figure 4g shows the error values of the interference observation on each component and the upper limit of the error of the adaptive estimation.

Figure 4h shows that the FOP is positioned to the desired position under the initial pre-tension of the mooring cable. The tension curves of the eight mooring cables change smoothly, and the tension distribution between the mooring cables at the same position is uniform.

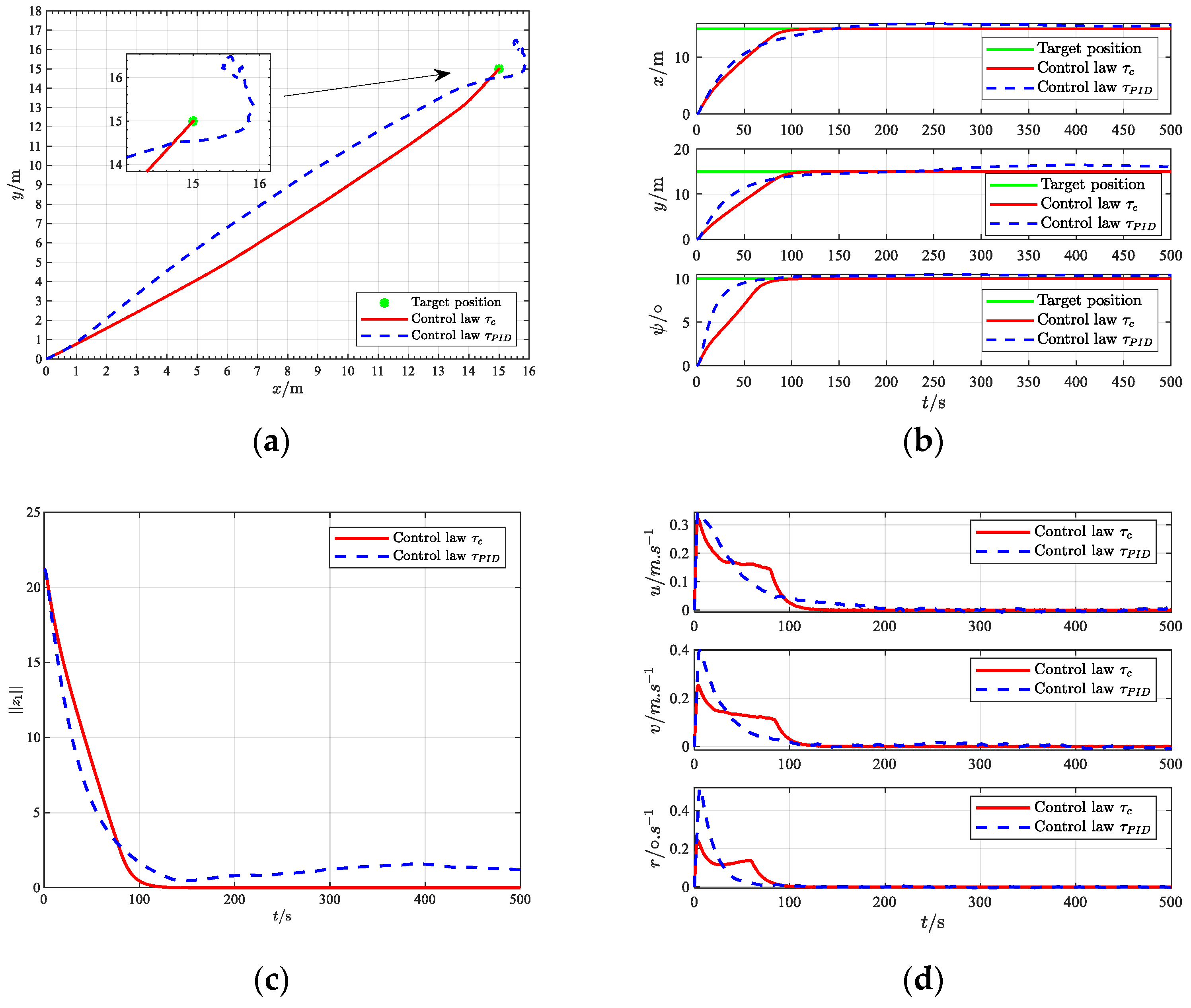

Case 2: Select b(0) = [0, 0, 0]T, = diag(103, 103, 103) the same as Case 1, and increase ς = diag(5 × 105, 5 × 105, 5 × 106) to 100 times that of Case 1. The simulation initial conditions and controller parameter design are the same as those in Case 1. The robustness of the proposed MPMS control law is verified when the platform is simulated under extreme sea conditions.

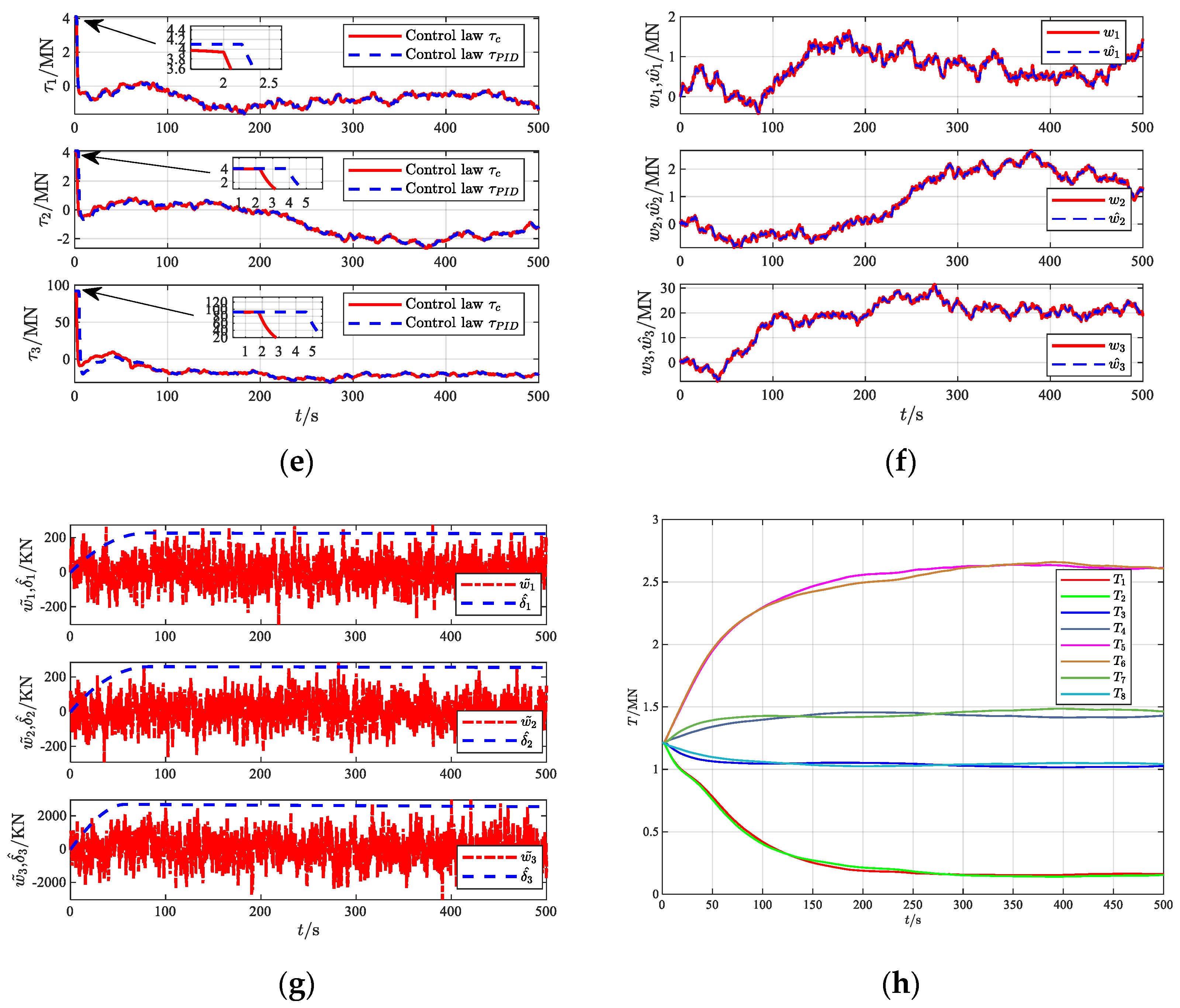

The simulation results of Case 2 are shown in

Figure 5a–h. It can be seen from

Figure 4a–c and

Figure 5a–c that the proposed MPMS control law shows excellent positioning performance in both Cases 1 and Cases 2. When the external unknown environmental disturbance increases, under the MPMS control law, it takes 150 s for the FOP to locate the target position, while under the traditional PID control law, the FOP drifts and the positioning performance is poor, indicating that the proposed MPMS control law has excellent robustness to external disturbances. As shown in

Figure 5d, under the MPMS control law, the surge speed, sway speed, and yaw rate of the FOP gradually decrease, and the speed changes more gently, effectively avoiding the breakage of the mooring line caused by the sudden change in the windlass speed. As shown in

Figure 5e, when the external unknown environmental disturbance increases, under the control input constraint condition, the input restricted time of the MPMS control law is the same as Case 1, which is 2 s, and the input restricted time of the PID control law increases to 4.8 s.

Figure 5f,g show that the constructed disturbance observer can provide the estimated value of the unknown time-varying disturbance in each component and the disturbance observation error value, as well as the upper limit of the adaptive estimation error. The results show that the adaptive law parameters of the σ-corrected leakage term are properly selected and there is no drift phenomenon.

Figure 5h shows that when the external unknown environmental disturbance increases, in order to resist the external environmental disturbance, the tension of the 8 mooring cables changes slightly and then stabilizes when the FOP is positioned to the desired position. The results show that the proposed MPMS control law has achieved satisfactory control effects, which can not only ensure the positioning requirements of the FOP but also take into account the uniform distribution of the mooring cable tension field. Therefore, the proposed MPMS control law is more effective for FOP MPMS with dynamic uncertainties, external time-varying disturbances, and input constraints.