Wear Characteristics Caused by Ti3AlC2 Particles under Impact-Sliding Conditions in Marine Engine

Abstract

1. Introduction

2. Materials and Methods

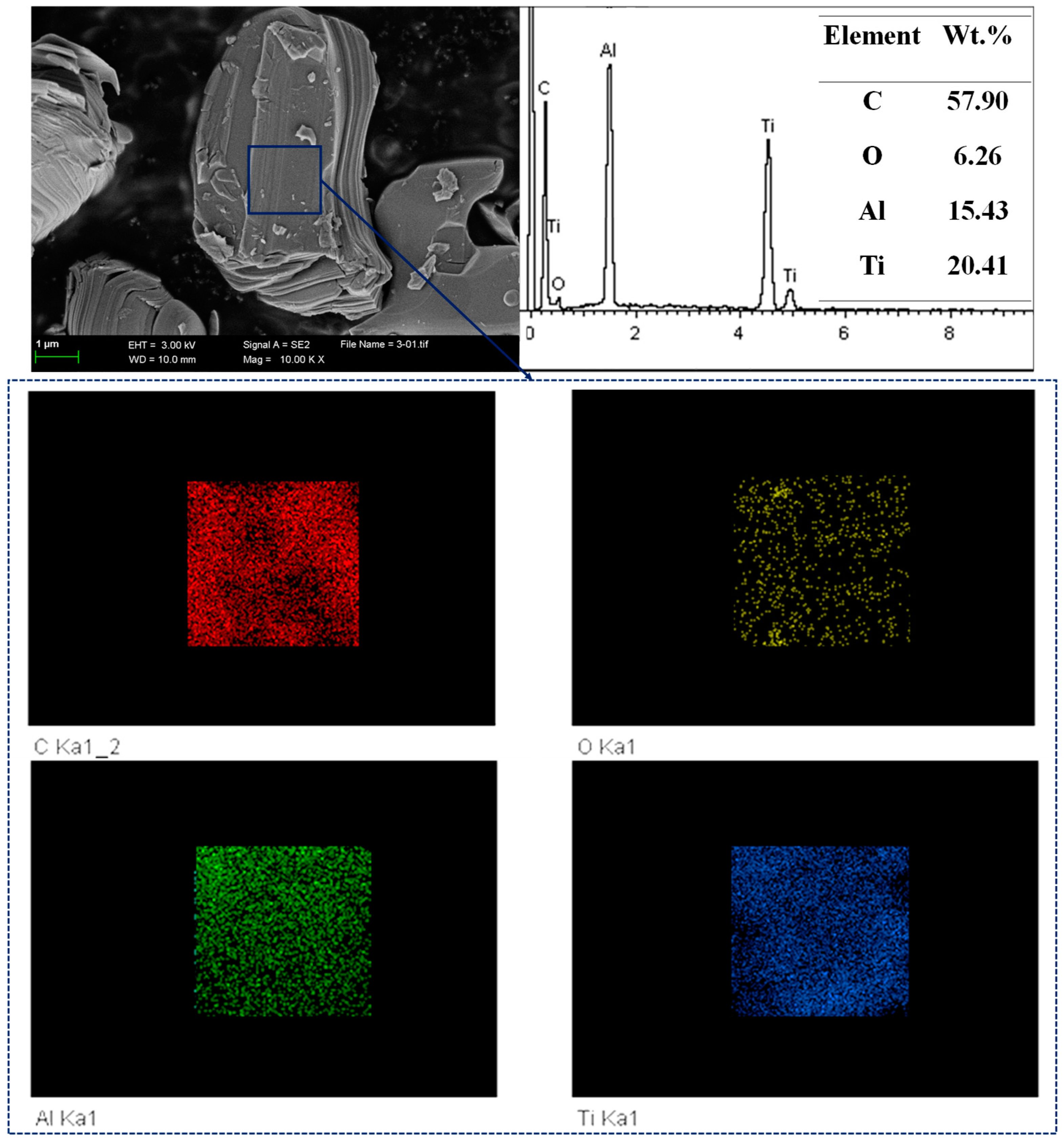

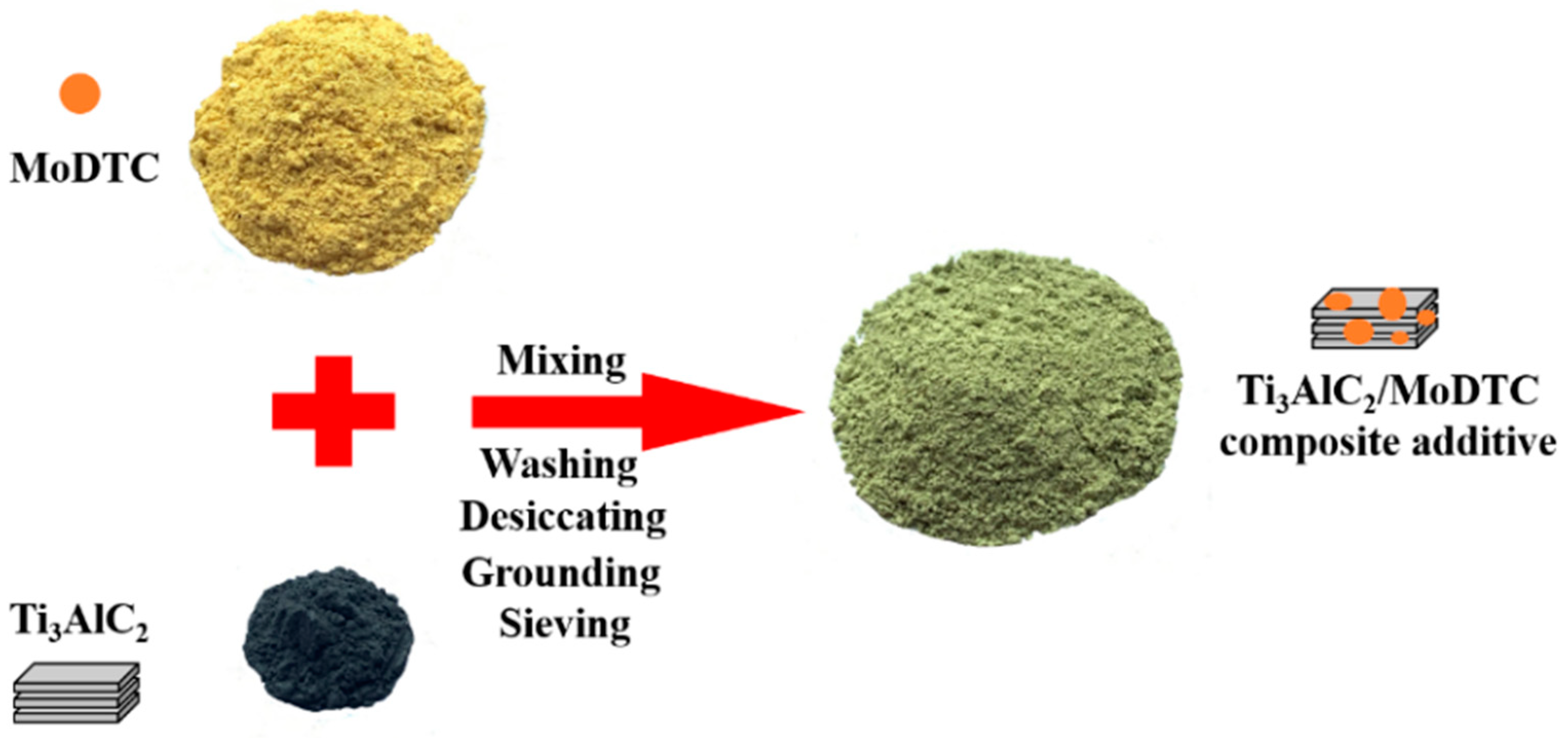

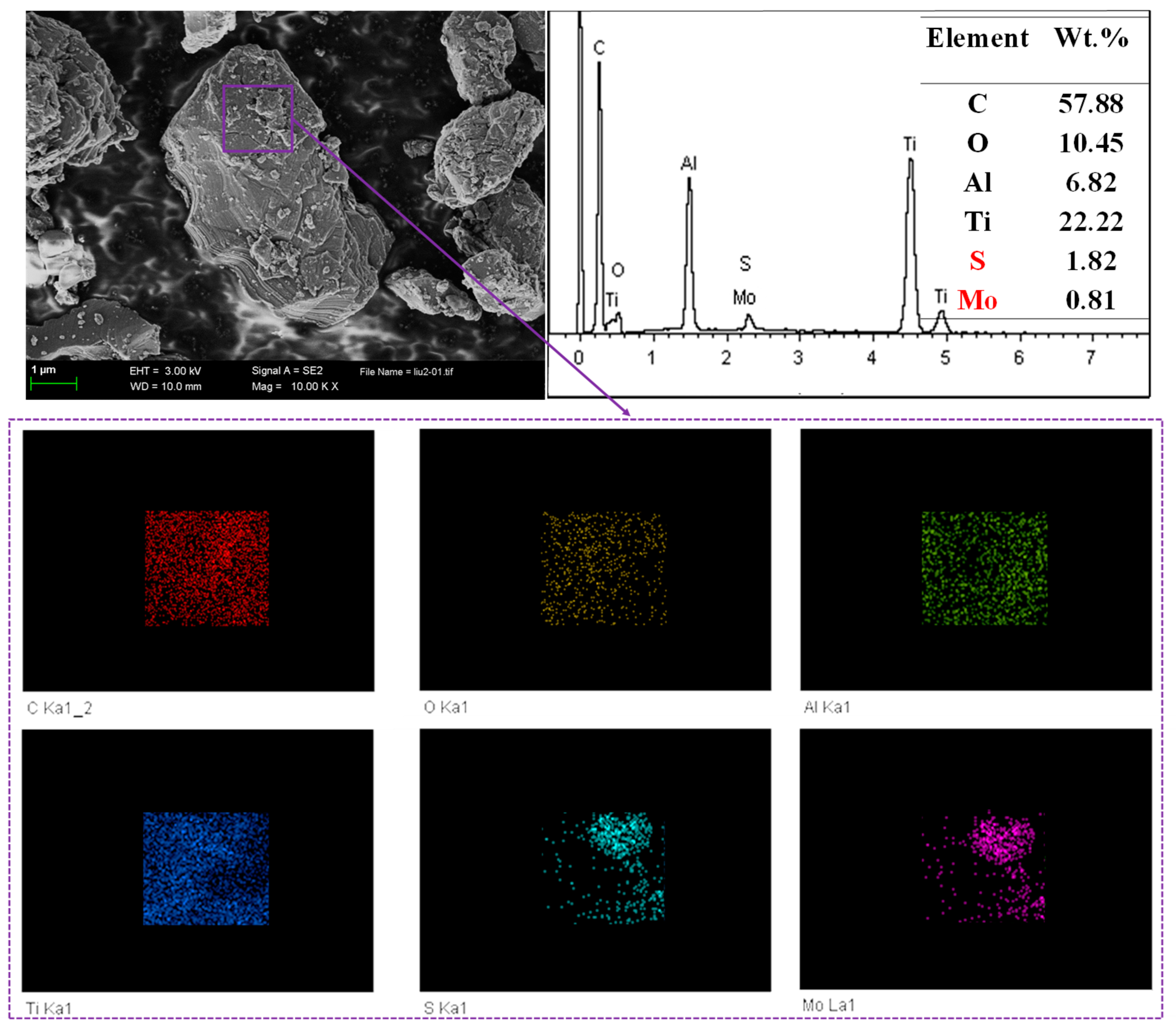

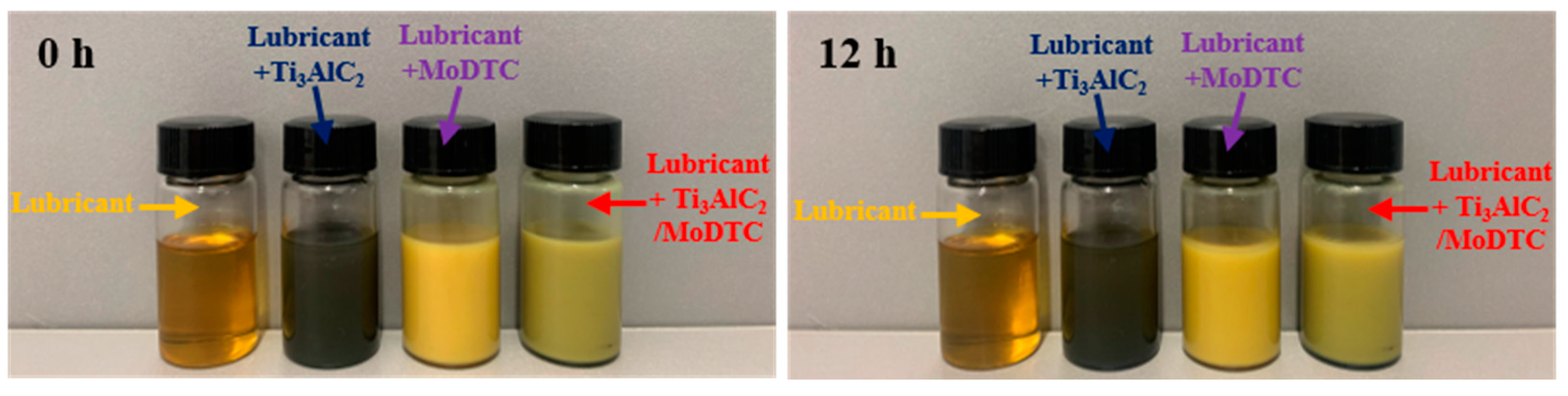

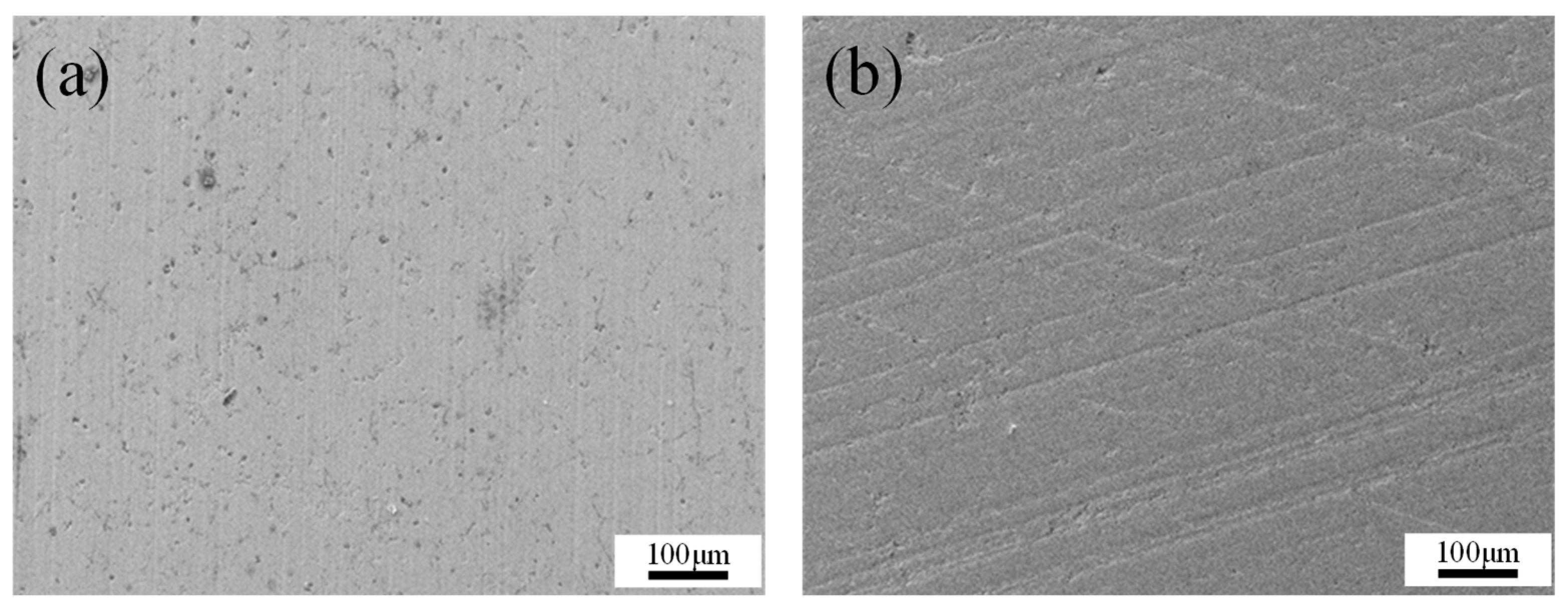

2.1. Experimental Materials

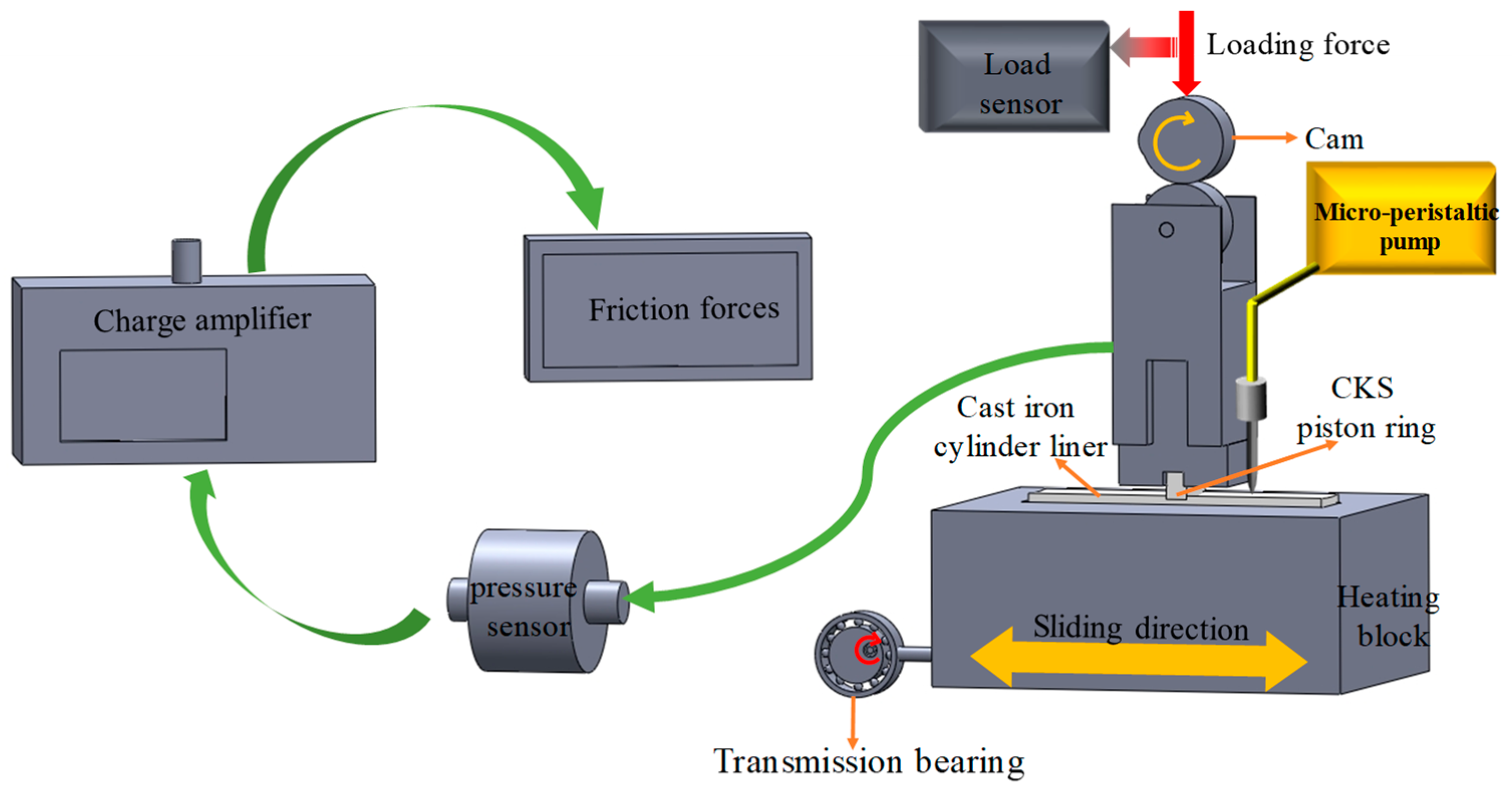

2.2. Friction and Wear Tests

3. Results

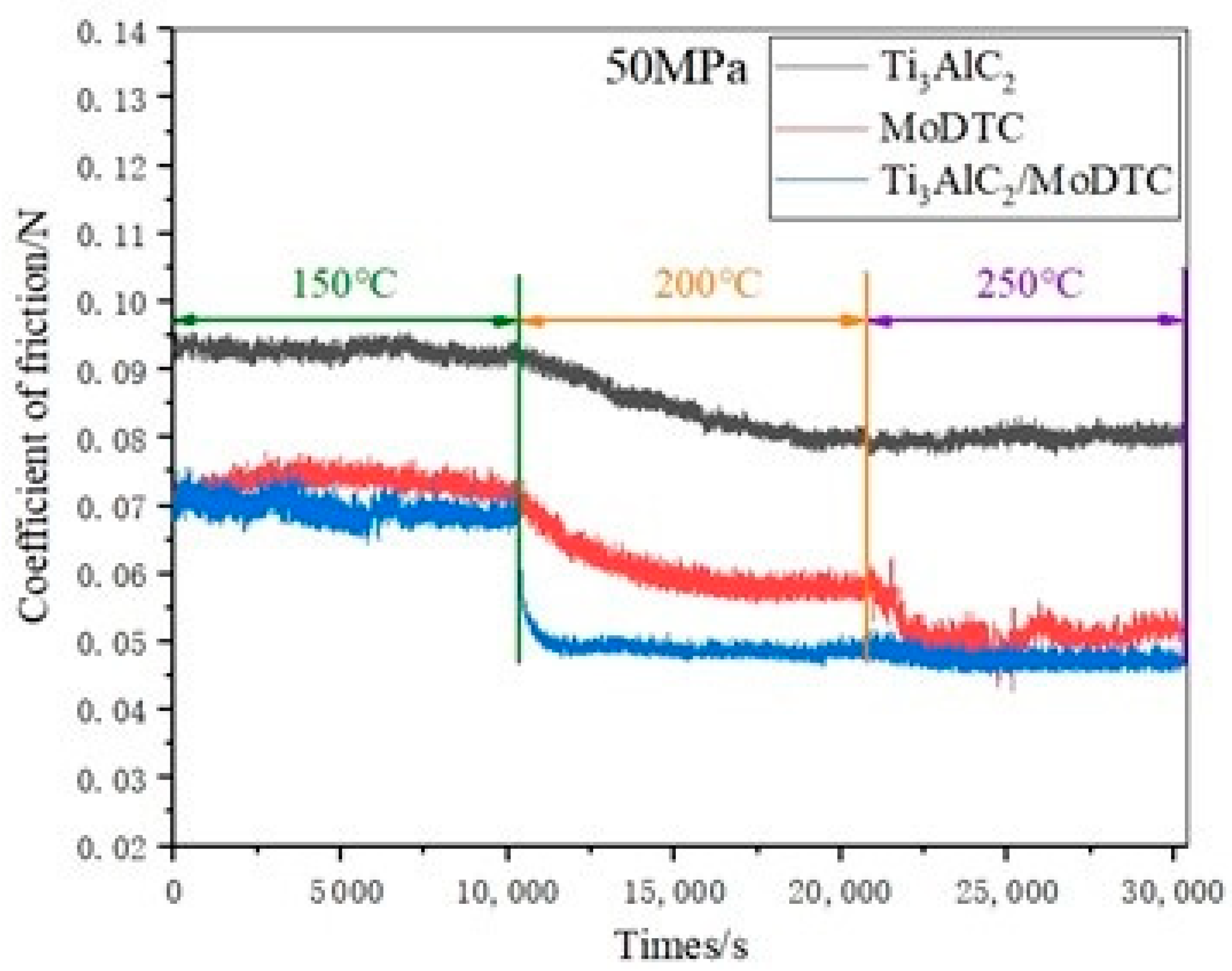

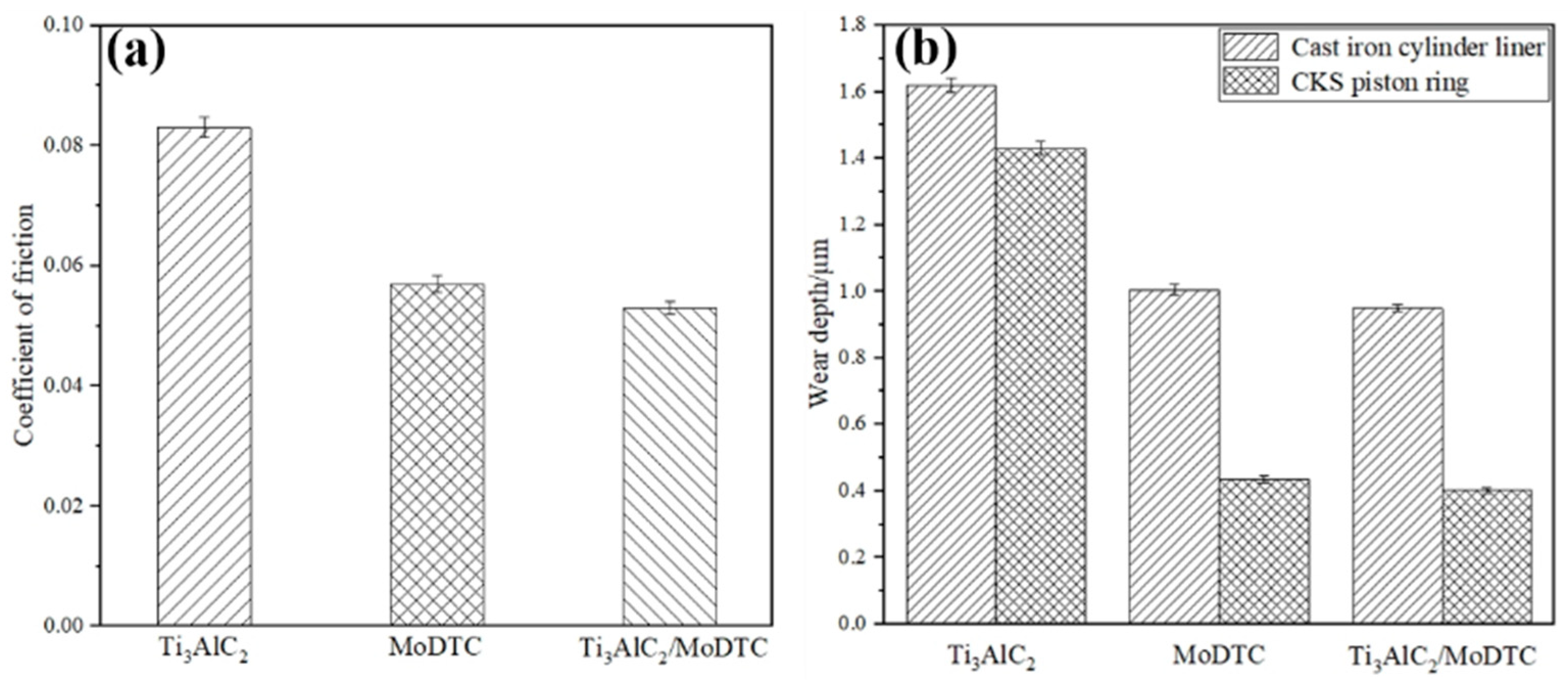

3.1. Friction and Wear Performance of Ti3AlC2, MoDTC and Ti3AlC2/MoDTC Composite Additives

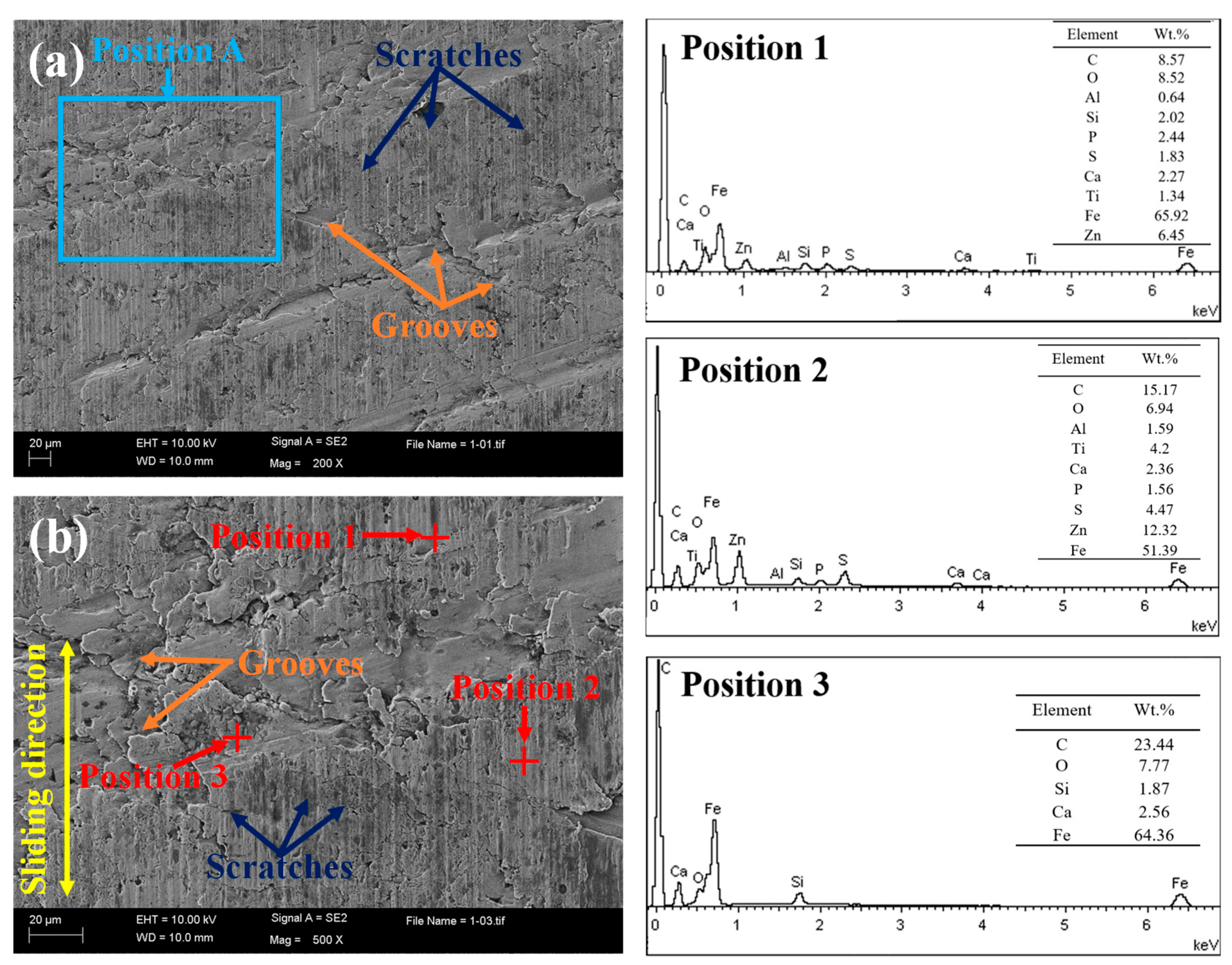

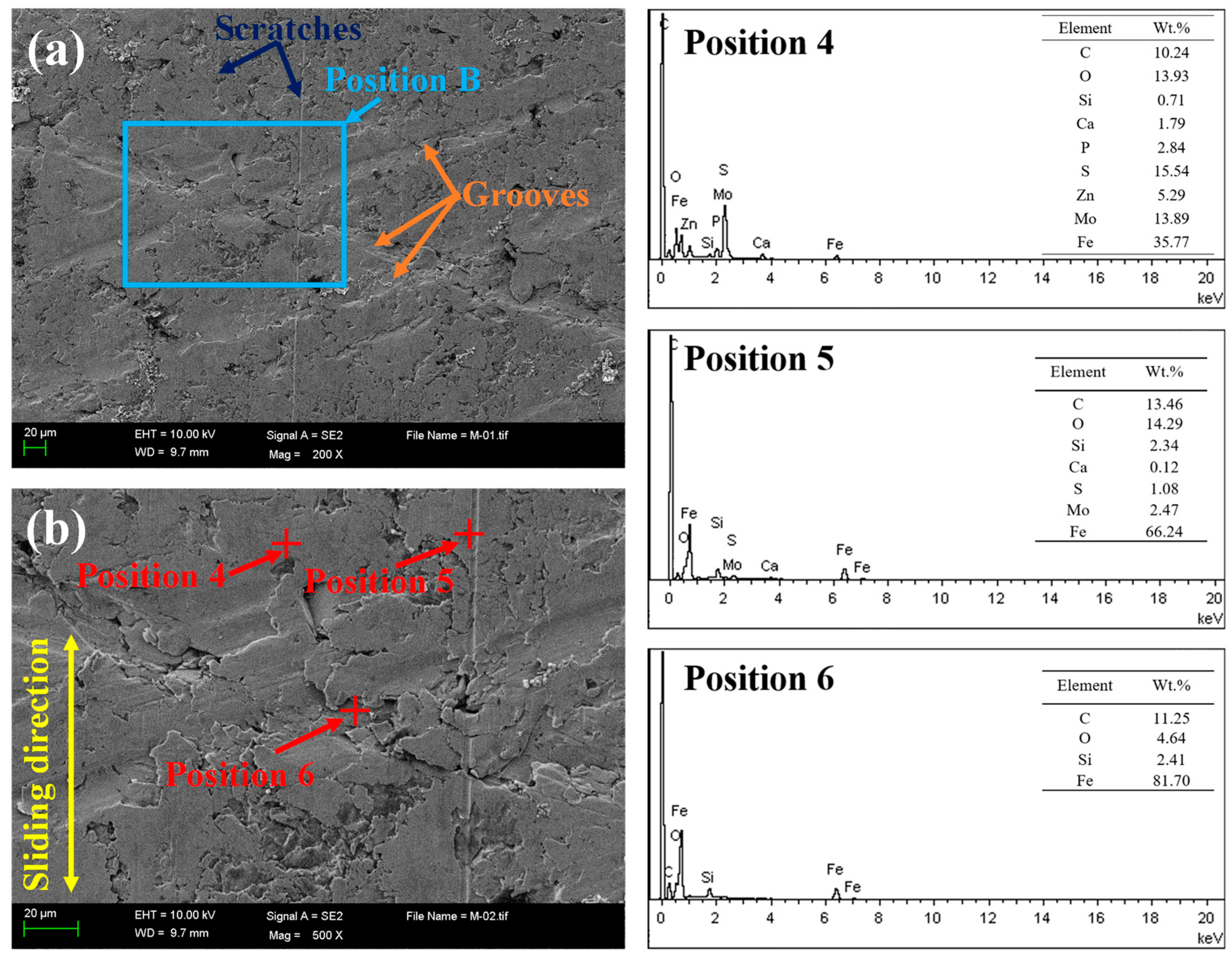

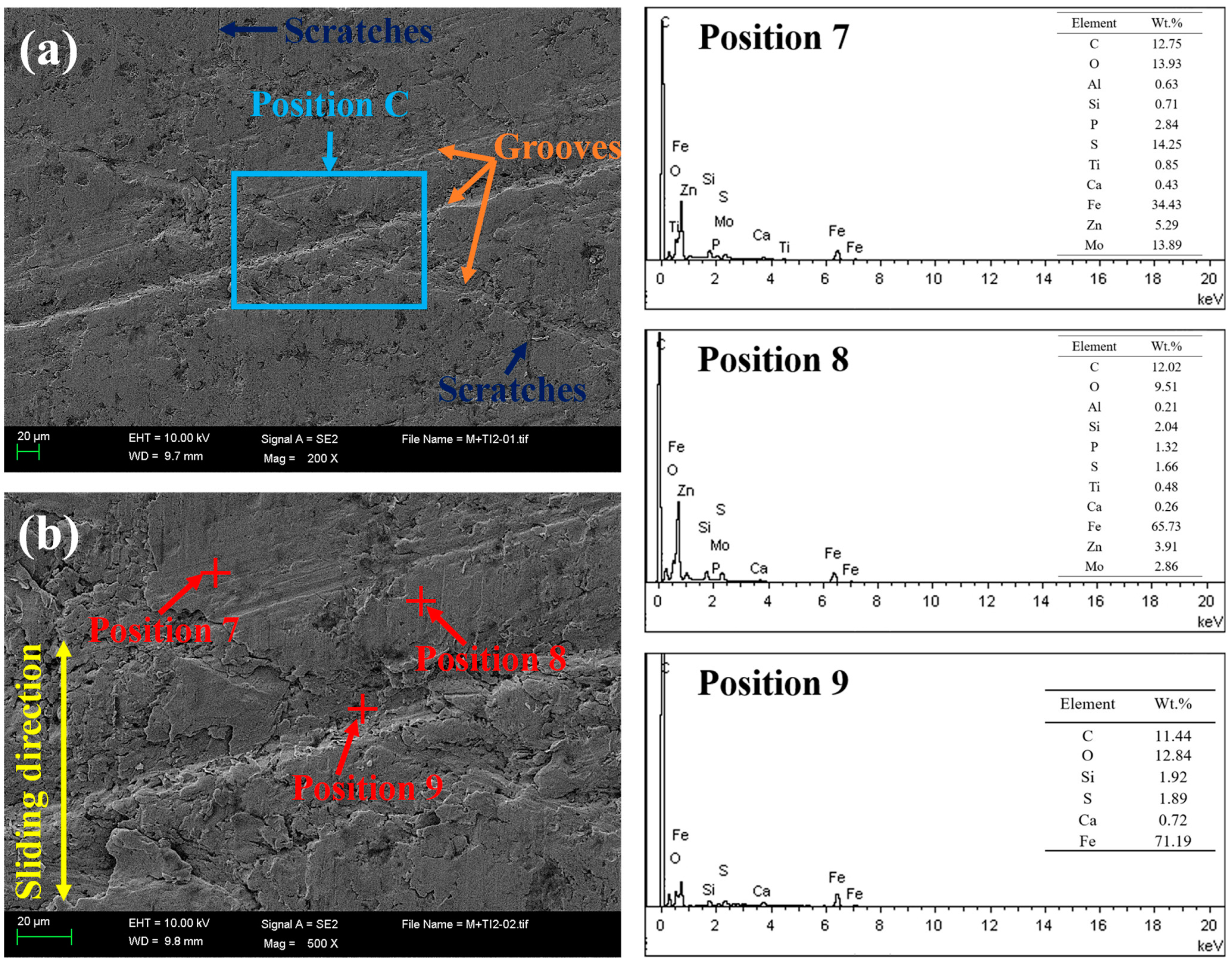

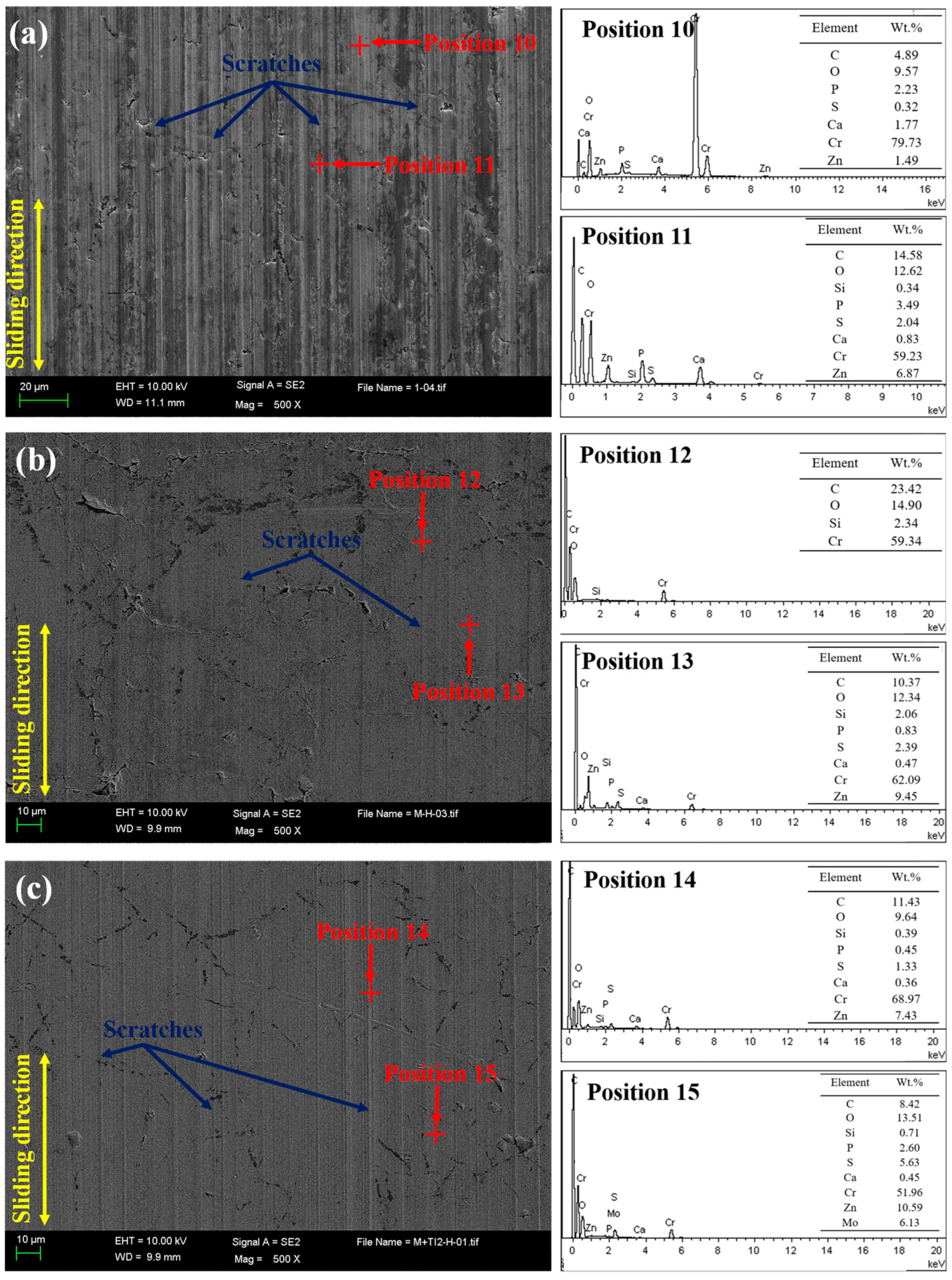

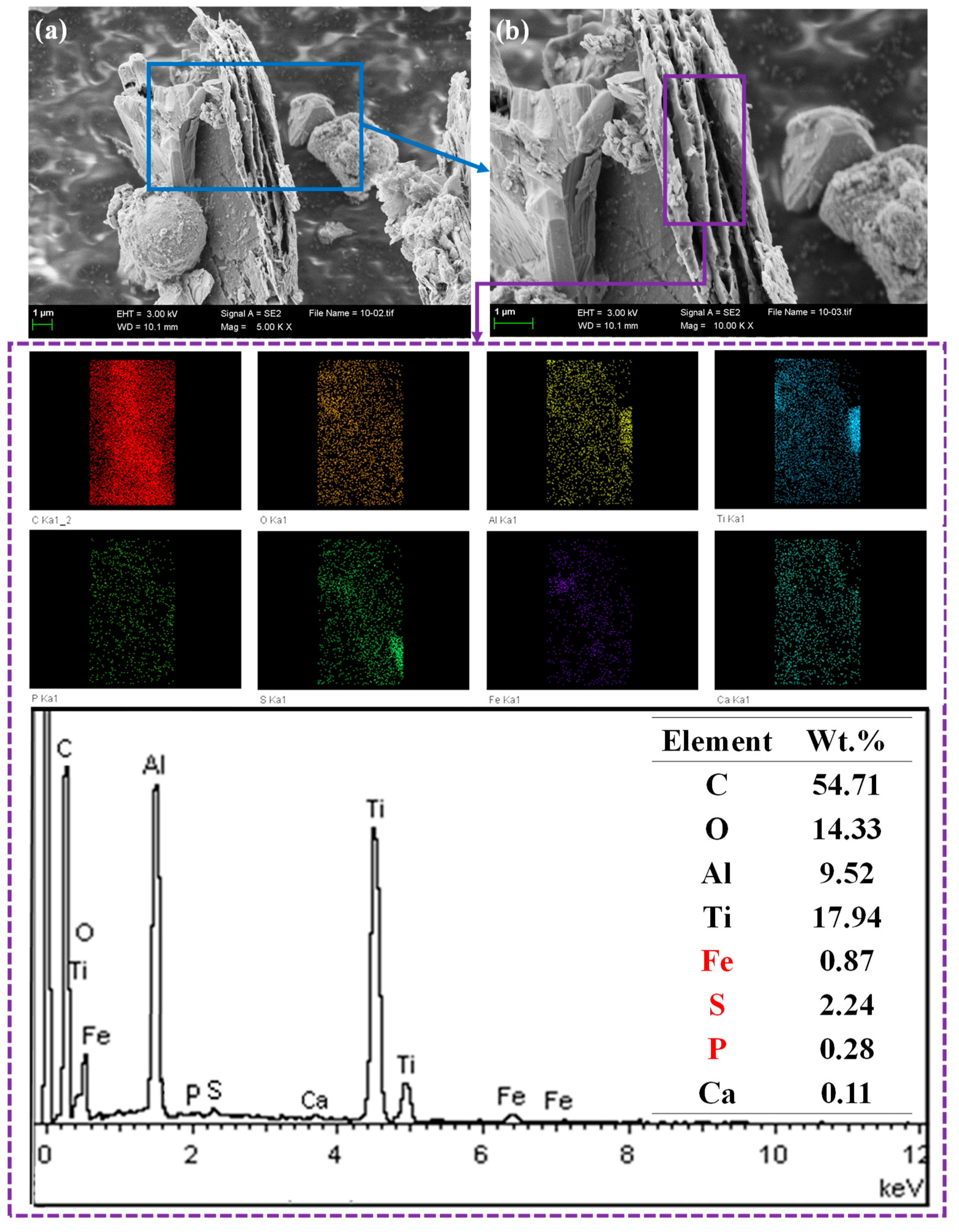

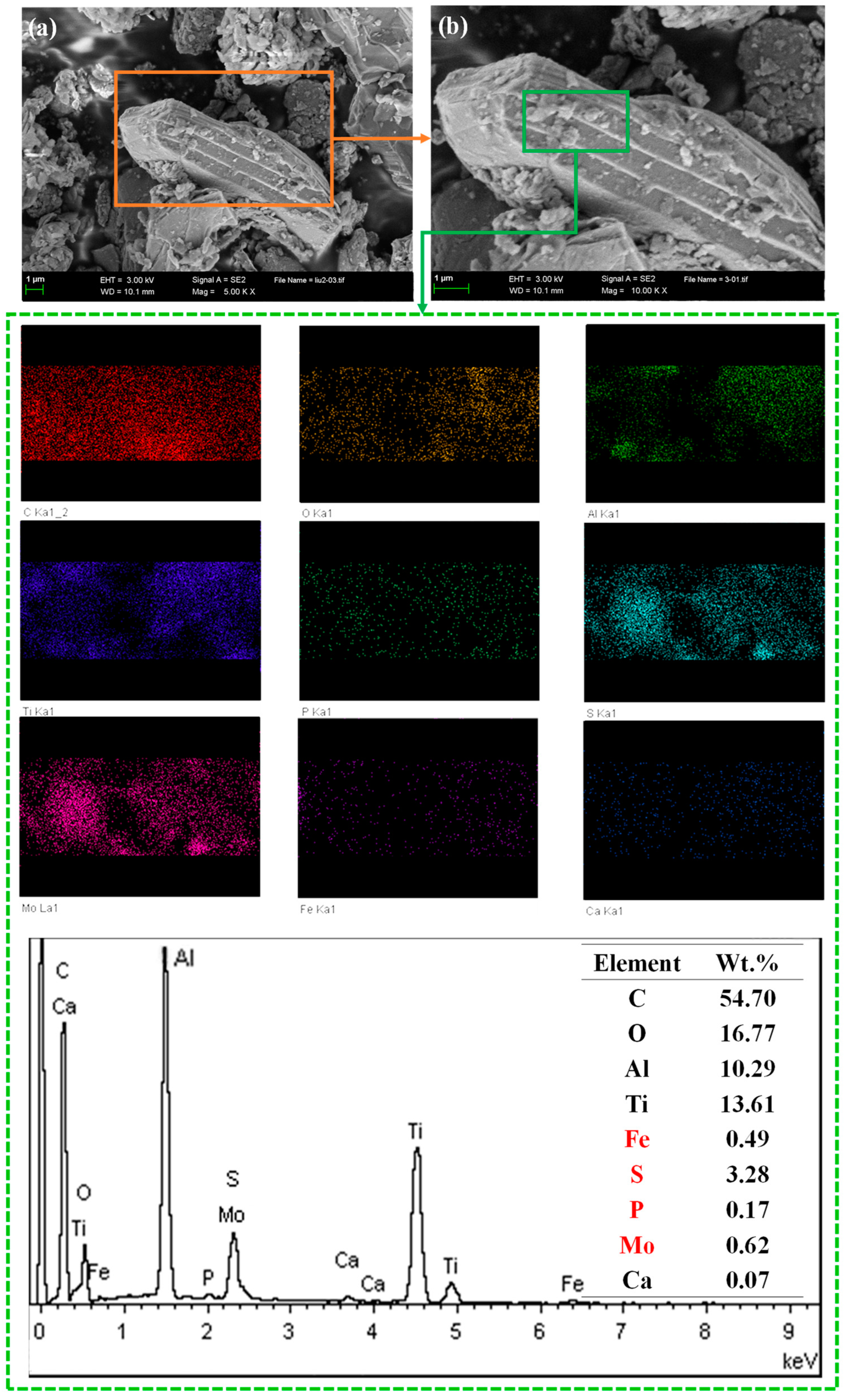

3.2. Worn Surfaces Analysis

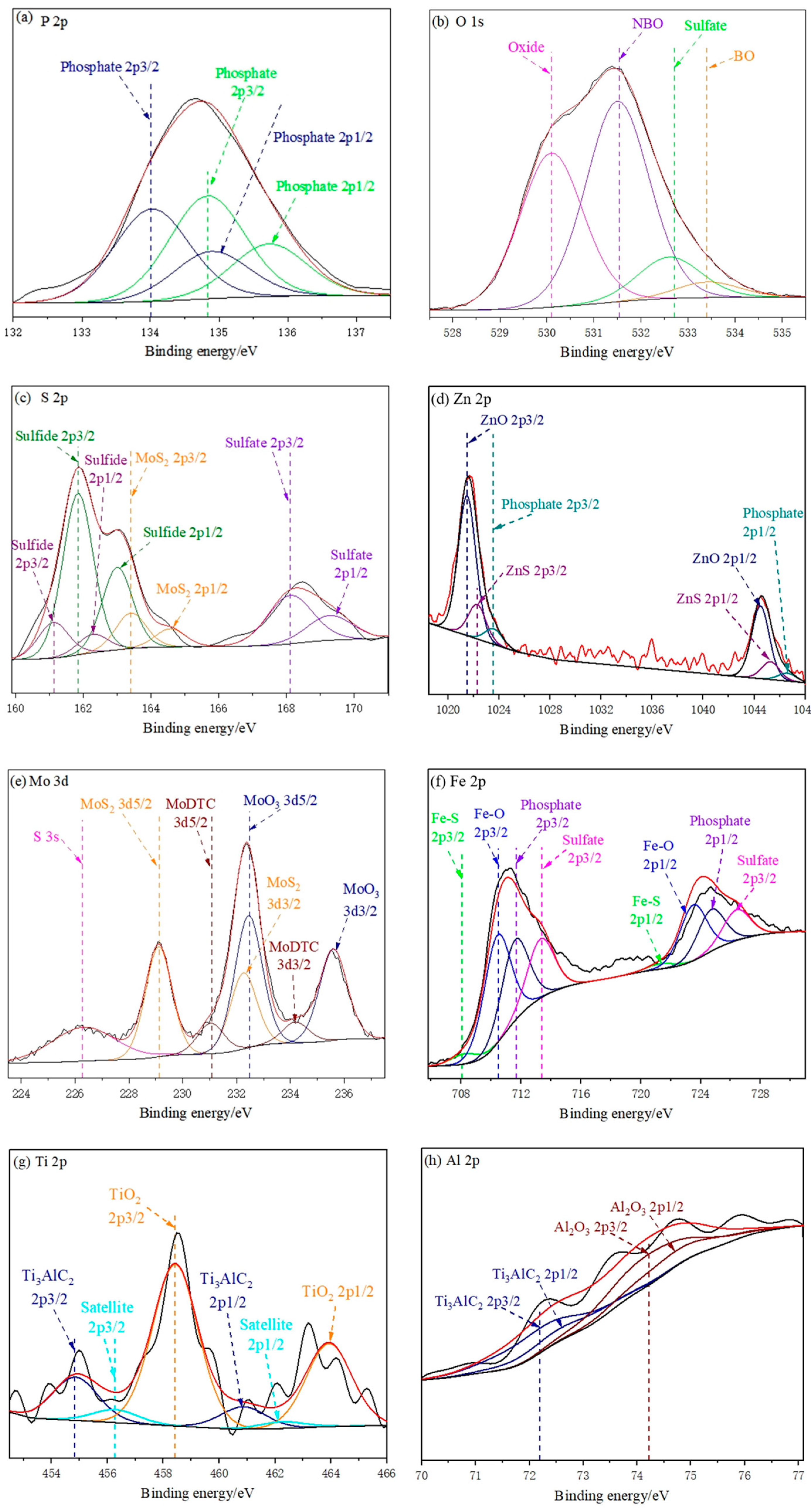

3.3. XPS Study of the Tribofilm on the Surface of the Worn Cast Iron Cylinder Liner Using the Ti3AlC2/MoDTC Composite Additive

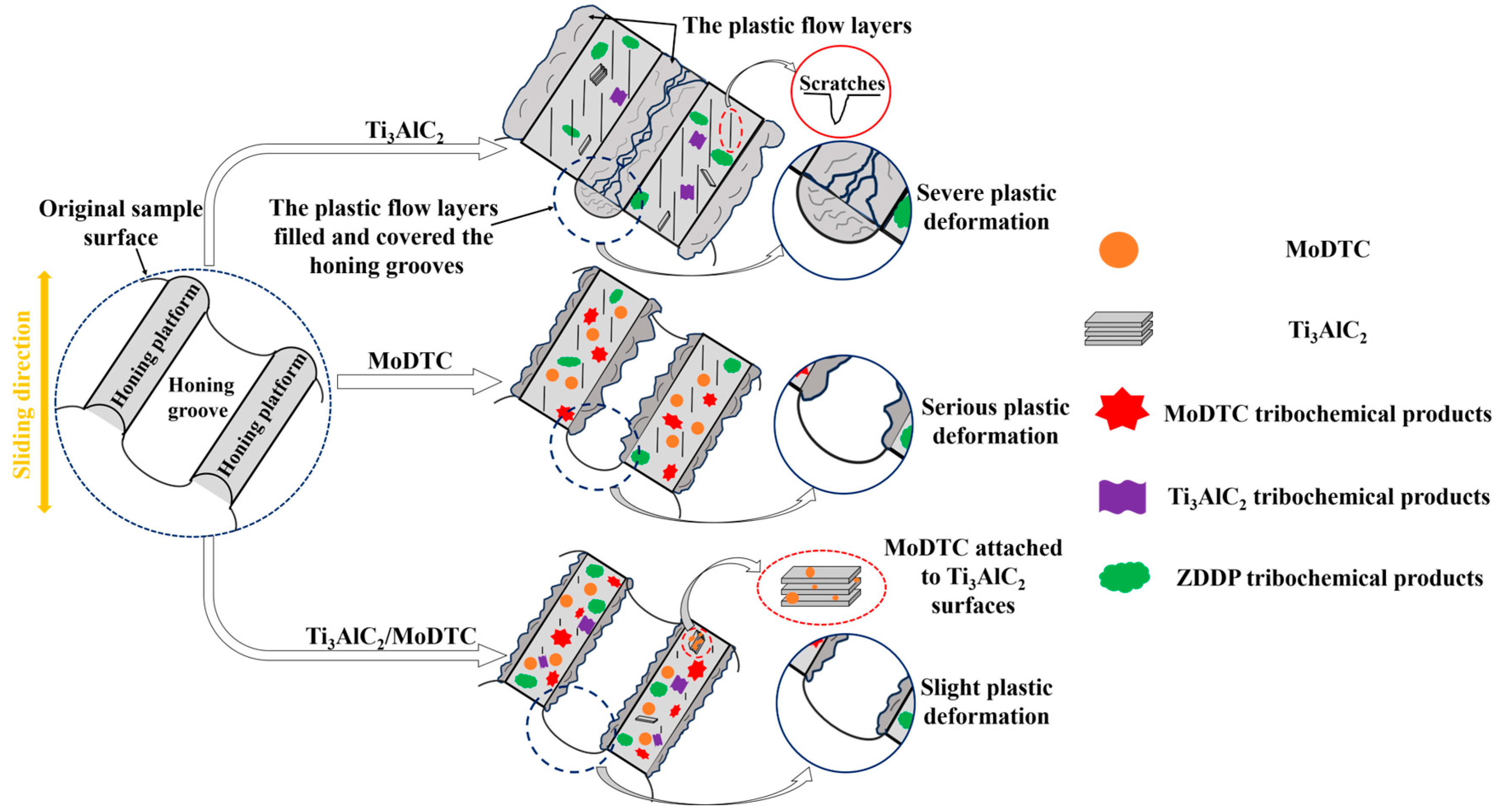

3.4. Failure Mechanism Analysis for Ti3AlC2, MoDTC and Ti3AlC2/MoDTC Composite Additives

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gupta, S.; Filimonov, D.; Palanisamy, T.; El-Raghy, T.; Barsoum, M.W. Ta2AlC and Cr2AlCAg-based composites-New solid lubricant materials for use over a wide temperature range against Ni-based superalloys and alumina. Wear 2007, 262, 1479–1489. [Google Scholar] [CrossRef]

- Ching, W.Y.; Mo, Y.X.; Aryal, S.; Rulis, P. Intrinsic Mechanical Properties of 20 MAX-Phase Compounds. J. Am. Ceram. Soc. 2013, 96, 2292–2297. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, X.M.; Jia, D.C.; Zhou, Y.; van der Zwaag, S. On the formation mechanisms and properties of MAX phases: A review. J. Eur. Ceram. Soc. 2021, 41, 3851–3878. [Google Scholar] [CrossRef]

- Wutthigrai, S.; Ittipon, F.; Sukit, L.; Kanoknan, P. A first principles investigation on the structural, elastic, and mechanical properties of MAX phase M3AlC2 (M = Ta, Ti, V) as a function of pressure. Comput. Condens. Matter 2022, 30, e00638. [Google Scholar] [CrossRef]

- Chen, H.F.; Hu, B.; Wang, J.W.; Wang, J.Q.; Gao, Y.F. Tribological properties of self-healing NiCrAlY/Cr3C2-Ti3AlC2 coating at high temperatures. Surf. Coat. Technol. 2023, 465, 129610. [Google Scholar] [CrossRef]

- Wang, S.; Cheng, J.; Zhu, S.Y.; Qiao, Z.H.; Yang, J.; Liu, W.M. Frictional properties of Ti3AlC2 ceramic against different counterparts in deionized water and artificial seawater. Ceram. Int. 2016, 42, 4578–4585. [Google Scholar] [CrossRef]

- Zhou, J.L.; Cheng, Y.H.; Yang, J.Y.; Wang, Q.Q.; Liang, X.B. Effects of WS2 and Ti3AlC2 additions on the high temperature wear properties of laser cladding YW1/NiCoCrAlY tool coating. Ceram. Int. 2021, 47, 35124–35133. [Google Scholar] [CrossRef]

- Fang, Y.; Feng, Y.X.; Liu, X.H.; Li, C.; Zhu, J.F.; Liu, Y. Influence of Mo doping on the tribological behavior of Ti3AlC2 ceramic at different temperatures. Ceram. Int. 2021, 47, 25520–25530. [Google Scholar] [CrossRef]

- Chen, H.F.; Du, Y.X.; Wang, D.J.; Zhang, C.; Yang, G.; Liu, B.; Gao, Y.F.; Shi, S.L. TiC/Ti3AlC2-Co plasma-sprayed coatings with excellent high-temperature tribological properties. Ceram. Int. 2018, 44, 22520–22528. [Google Scholar] [CrossRef]

- Li, S.C.; Xiao, G.J.; Chen, B.Q.; Zhuo, X.Q.; Zhao, Z.Y.; Huang, Y. Influence mechanism of abrasive belt wear on fatigue resistance of TC17 grinding surface. Eng. Fail. Anal. 2022, 141, 106644. [Google Scholar] [CrossRef]

- Yan, L.L.; Yue, W.; Wang, C.B.; Wei, D.P.; Xu, B. Comparing tribological behaviors of sulfur- and phosphorus-free organomolybdenum additive with ZDDP and MoDTC. Tribol. Int. 2012, 53, 150–158. [Google Scholar] [CrossRef]

- Vaitkunaite, G.; Espejo, C.; Thiebaut, B.; Neville, A.; Morina, A. Low friction tribofilm formation and distribution on an engine cylinder tested with MoDTC-containing low viscosity engine lubricants. Tribol. Int. 2022, 171, 107551. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Yue, W.; She, D.S.; Fu, Z.Q.; Huang, H.P.; Liu, J.J. Effects of surface nanocrystallization on tribological properties of 316L stainless steel under MoDTC/ZDDP lubrications. Tribol. Int. 2014, 79, 42–51. [Google Scholar] [CrossRef]

- Kassim, K.A.M.; Tokoroyama, T.; Murashima, M.; Umehara, N. The wear classification of MoDTC-derived particles on silicon and hydrogenated diamond-like carbon at room temperature. Tribol. Int. 2020, 147, 106176. [Google Scholar] [CrossRef]

- Evans, R.D.; Doll, G.L.; Hager, C.H.; Howe, J.Y. Influence of steel type on the propensity for tribochemical wear in boundary lubrication with a wind turbine gear oil. Tribol. Lett. 2010, 38, 25–32. [Google Scholar] [CrossRef]

- Morina, A.; Neville, A.; Priest, M.; Green, J.H. ZDDP and MoDTC interactions and their effect on tribological performance-tribofilm characteristics and its evolution. Tribol. Lett. 2006, 24, 243–256. [Google Scholar] [CrossRef]

- Kosarieh, S.; Morina, A.; Laine, E.; Flemming, J.; Neville, A. The effect of MoDTC-type friction modifier on the wear performance of a hydrogenated DLC coating. Wear 2013, 302, 890–898. [Google Scholar] [CrossRef]

- Graham, J.; Spikes, H.; Jensen, R. The friction reducing properties of molybdenum dialkyldithiocarbamate additives: Part II—Durability of friction reducing capability. Tribol. Trans. 2001, 44, 637–647. [Google Scholar] [CrossRef]

- Greenall, A.; Neville, A.; Morina, A.; Sutton, M. Investigation of the interactions between a novel, organic anti-wear additive, ZDDP and overbased calcium sulphonate. Tribol. Int. 2012, 46, 52–61. [Google Scholar] [CrossRef]

- Zhang, J.; Spikes, H. On the Mechanism of ZDDP Antiwear Film Formation. Tribol. Lett. 2016, 63, 24. [Google Scholar] [CrossRef]

- Zhang, J.; Ueda, M.; Campen, S.; Spikes, H. Boundary Friction of ZDDP Tribofilms. Tribol. Lett. 2021, 69, 8. [Google Scholar] [CrossRef]

- Costa, H.L.; Evangelista, K.S.; Cousseau, T.; Acero, J.S.R.; Kessler, F. Use of XANES and XPS to investigate the effects of ethanol contamination on anti-wear ZDDP tribofilms. Tribol. Int. 2021, 159, 106997. [Google Scholar] [CrossRef]

- Zhao, Z.K.; Shen, Y.; Liu, Y.; Xing, C.F.; Liu, J.; Fan, J.J.; Xu, J.J. Low and high temperature effects on friction and wear performance of Cr-plated cylinder liner. Wear 2024, 546–547, 205329. [Google Scholar] [CrossRef]

- Parsaeian, P.; Ghanbarzadeh, A.; Van Eijk, M.C.P.; Nedelcu, I.; Neville, A.; Morina, A. Show more A new insight into the interfacial mechanisms of the tribofilm formed by zinc dialkyl dithiophosphate. Appl. Surf. Sci. 2017, 403, 472–486. [Google Scholar] [CrossRef]

- Tse, J.S.; Song, Y.; Liu, Z.X. Effects of Temperature and Pressure on ZDDP. Tribol. Lett. 2007, 28, 45–49. [Google Scholar] [CrossRef]

- Aldana, P.U.; Vacher, B.; Le Mogne, T.; Belin, M.; Thiebaut, B.; Dassenoy, F. Action mechanism of WS2 nanoparticles with ZDDP additive in boundary lubrication regime. Tribol. Lett. 2014, 56, 249–258. [Google Scholar] [CrossRef]

- Mittal, P.; Rai, H.; Gosvami, N.N. Microscopic tribology of ADC12 alloy under lubricant containing ZDDP and MoDTC using in situ AFM. Tribol. Lett. 2013, 69, 35. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Dong, R.; Wang, X.G.; Liang, Y.J.; Zhang, M.; Yu, Q.L.; Tang, Z.P.; Lv, H.Y.; Wang, L.P.; Cai, M.R.; et al. Stable dispersibility of bentonite-type additive with gemini ionic liquid intercalation structure for oil-based drilling. Friction 2022, 11, 201–215. [Google Scholar] [CrossRef]

- Wang, W.W.; Li, C.D.; Yang, J.; Shen, Y.; Xu, J.J. Friction performance of MoDTP and ester-containing lubricants between CKS piston ring and cast iron cylinder liner. Lubr. Sci. 2018, 30, 33–43. [Google Scholar] [CrossRef]

- Li, W.H.; Yu, B.H.; Ye, B.; Shen, Y.; Huang, R.X.; Du, F.M. Effects of cast-iron surface texturing on the anti-scuffing performance under starved lubrication. Materials 2019, 12, 1586. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Wei, D.B.; Wu, P.F.; Cao, J.W.; Shijia, C.R.; Qu, X.H. Substance evolution and wear mechanism on friction contact area of brake disc for high-speed railway trains at high temperature. Eng. Fail. Anal. 2020, 111, 104472. [Google Scholar] [CrossRef]

- Wang, Y.J.; Jia, Z.; Ji, J.J.; Wei, B.L.; Heng, Y.B.; Liu, D.X. Determining the wear behavior of H13 steel die during the extrusion process of pure nickel. Eng. Fail. Anal. 2022, 134, 106053. [Google Scholar] [CrossRef]

- Natu, V.; Benchakar, M.; Canaff, C.; Habrioux, A.; Célérier, S.; Barsoum, M.W. A critical analysis of the X-ray photoelectron spectra of Ti3C2TZ MXenes. Matter 2021, 4, 1224–1251. [Google Scholar] [CrossRef]

- Heuberger, R.; Rossi, A.; Spencer, N.D. XPS study of the influence of temperature on ZnDTP tribofilm composition. Tribol. Lett. 2006, 25, 185–196. [Google Scholar] [CrossRef]

- Crobu, M.; Rossi, A.; Mangolini, F.; Spencer, N.D. Tribochemistry of bulk zinc metaphosphate glasses. Tribol. Lett. 2010, 39, 121–134. [Google Scholar] [CrossRef]

- Rumble, J.R.; Bickham, D.M.; Powell, C.J. The NIST X-ray photoelectron spectroscopy database. Surf. Interface Anal. 2004, 19, 241–246. [Google Scholar] [CrossRef]

- Wu, X.H.; Gong, K.L.; Zhao, G.Q.; Lou, W.J.; Wang, X.B.; Liu, W.M. Surface modification of MoS2 nanosheets as effective lubricant additives for reducing friction and wear in poly-alpha-olefin. Ind. Eng. Chem. Res. 2018, 57, 8105–8114. [Google Scholar] [CrossRef]

- Massoud, T.; Matos, R.P.D.; Mogne, T.L.; Belin, M.; Cobian, M.; Thiébaut, B.; Loehlé, S.; Dahlem, F.; Minfray, C. Effect of ZDDP on lubrication mechanisms of linear fatty amines under boundary lubrication conditions. Tribol. Int. 2020, 141, 105954. [Google Scholar] [CrossRef]

- Minfray, C.; Martin, J.M.; Esnouf, C.; Le Mogne, T.; Kersting, R.; Hagenhoff, B. A multi-technique approach of tribofilm char-acterisation. Thin Solid Films 2004, 447, 272–277. [Google Scholar] [CrossRef]

- Nedelcu, I.; Piras, E.; Rossi, A.; Pasaribu, H.R. XPS analysis on the influence of water on the evolution of zinc dialkyldithi ophosphate–derived reaction layer in lubricated rolling contacts. Surf. Interface Anal. 2012, 44, 1219–1224. [Google Scholar] [CrossRef]

- Huai, W.; Chen, X.; Lu, F.; Zhang, C.; Ma, L.; Wen, S. Tribological properties of sulfur- and phosphorus-free organic molybdenum compound as additive in oil. Tribol. Int. 2020, 141, 105944. [Google Scholar] [CrossRef]

- Wu, H.X.; Johnson, B.; Wang, L.P.; Dong, G.N.; Yang, S.C.; Zhang, J.F. High-efficiency preparation of oil-dispersible MoS2 nanosheets with superior anti-wear property in ultralow concentration. Nanopart. Res. 2017, 19, 339. [Google Scholar] [CrossRef]

- De Feo, M.; Minfray, C.; Bouchet, M.I.D.; Thiebaut, B.; Le Mogne, T.; Vacher, B.; Martin, J.M. Aging impact on tribological properties of MoDTC-containing base oil. Tribol. Int. 2015, 92, 126–135. [Google Scholar] [CrossRef]

- Ueda, M.; Kadiric, A.; Spikes, H. Wear of hydrogenated DLC in MoDTC-containing oils. Wear 2021, 474–475, 203869. [Google Scholar] [CrossRef]

- Arévalo-López, E.P.; Romero-Moreno, P.; Rosas-Huerta, J.L.; Huerta, L.; Minaud, C.; Marquina, M.L.; Escamilla, R.; Romero, M. Effect of Fe on Bi2Te3: Structure, magnetic properties, and XPS valence band. J. Alloys Compd. 2022, 899, 163297. [Google Scholar] [CrossRef]

- Iatsunskyi, I.; Gottardi, G.; Micheli, V. Atomic layer deposition of palladium coated TiO2/Si nanopillars: ToF-SIMS, AES and XPS characterization study. Appl. Surf. Sci. 2021, 542, 148603. [Google Scholar] [CrossRef]

- Wilhelmsson, O.; Palmquist, J.P.; Lewin, E.; Emmerlich, J.; Eklund, P.; Persson, P.O.A.; Högberg, H.; Li, S.; Ahuja, R.; Eriksson, O.; et al. Deposition and characterization of ternary thin films within the Ti-Al-C system by DC magnetron sputtering. Cryst. Growth 2006, 291, 290–300. [Google Scholar] [CrossRef]

- Naslund, L.A.; Persson, P.O.A.; Rosen, J. X-ray photoelectron spectroscopy of Ti3AlC2, Ti3C2Tz, and TiC provides evidence for the electrostatic interaction between laminated layers in MAX-Phase materials. Phys. Chem. C 2020, 124, 27732–27742. [Google Scholar] [CrossRef]

- Xue, M.; Tang, H.; Li, C.S. Preparation and tribological behaviour of laminated Ti3AlC2 crystals as additive in base oil. Adv. Appl. Ceram. 2014, 113, 245–250. [Google Scholar] [CrossRef]

| Sample | Sample Parameters | ||||

|---|---|---|---|---|---|

| Long (mm) | Wide (mm) | High (mm) | Roughness (µm) | Hardness (HV0.1) | |

| CKS piston ring | 11 | 3 | 4 | 0.24 | 705 |

| Cast iron cylinder liner | 43 | 8.5 | 6 | 0.72 | 238 |

| Test Stage | Speed (rpm) | Frequency (Hz) | Stroke (mm) | Peak Impact Load (MPa) | Temperature (°C) | Time (min) | Lubricant Feed Rate (mL/min) |

|---|---|---|---|---|---|---|---|

| Low load | 200 | 3.33 | 30 | 10 | 150 | 10 | 0.1 |

| High load | 200 | 3.33 | 30 | 50 | 150/200/250 | 180 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Shen, Y.; Liu, Z.; Yu, B.; Qu, J.; Li, L.; Zhang, G. Wear Characteristics Caused by Ti3AlC2 Particles under Impact-Sliding Conditions in Marine Engine. J. Mar. Sci. Eng. 2024, 12, 1777. https://doi.org/10.3390/jmse12101777

Liu J, Shen Y, Liu Z, Yu B, Qu J, Li L, Zhang G. Wear Characteristics Caused by Ti3AlC2 Particles under Impact-Sliding Conditions in Marine Engine. Journal of Marine Science and Engineering. 2024; 12(10):1777. https://doi.org/10.3390/jmse12101777

Chicago/Turabian StyleLiu, Jie, Yan Shen, Zhixiang Liu, Baihong Yu, Jinghao Qu, Leize Li, and Guogang Zhang. 2024. "Wear Characteristics Caused by Ti3AlC2 Particles under Impact-Sliding Conditions in Marine Engine" Journal of Marine Science and Engineering 12, no. 10: 1777. https://doi.org/10.3390/jmse12101777

APA StyleLiu, J., Shen, Y., Liu, Z., Yu, B., Qu, J., Li, L., & Zhang, G. (2024). Wear Characteristics Caused by Ti3AlC2 Particles under Impact-Sliding Conditions in Marine Engine. Journal of Marine Science and Engineering, 12(10), 1777. https://doi.org/10.3390/jmse12101777