1. Introduction

In recent years, numerous sea-crossing bridges have been constructed worldwide. However, during the life cycle of these bridges, the harsh marine environment [

1], including hurricanes and ocean currents, can severely impact their service life and even cause instability or structural damage [

2], leading to potentially disastrous safety incidents. Most highway bridge destruction can be attributed to bridge collapse due to wave load impacts [

3]. Consequently, the design of wave load on the foundation structure of a sea-crossing bridge has emerged as a key component of the entire bridge design. Wave force is influenced by environmental factors such as water level and flow velocity as well as factors such as pile group arrangement, pile diameter, and cap size [

4].

In the last century, scholars began conducting extensive research on calculating wave force on the pile-group foundations of sea-crossing bridges [

5,

6]. The Morison formula [

7], derived from potential flow theory, is one of the most famous semi-theoretical formulas for calculating horizontal wave force on a small-scale vertical cylinder. However, the hydrodynamic coefficients for the inertial force and drag force in the formula are affected by various factors such as the Reynolds number and KC number, and their values must be determined precisely through experiments [

8], which has paved the way for the development of related experimental research. Thereafter, Sarpkaya and Justesen [

9,

10] obtained the force coefficient through numerous wave flume experiments. Based on their work, Boccotti [

11] conducted further experiments to study how the coefficients vary with the KC number and Re number. It is worth noting that the Morison formula is no longer applicable to large-scale structures such as pile groups and foundations, as waves reflect and diffract between such structures. MacCamy [

12] first proposed a diffraction theory based on the assumption of small-amplitude linear waves. Neelamani [

13] further verified the accuracy of the diffraction theory by carrying out a water flume test. Garrison [

14] has also regulated the Morison equation and diffraction theory’s applicable range. Terro [

15] modified the linear form of the Morison equation based on the numerical water flume, making it more accurate for nonlinear wave force estimation.

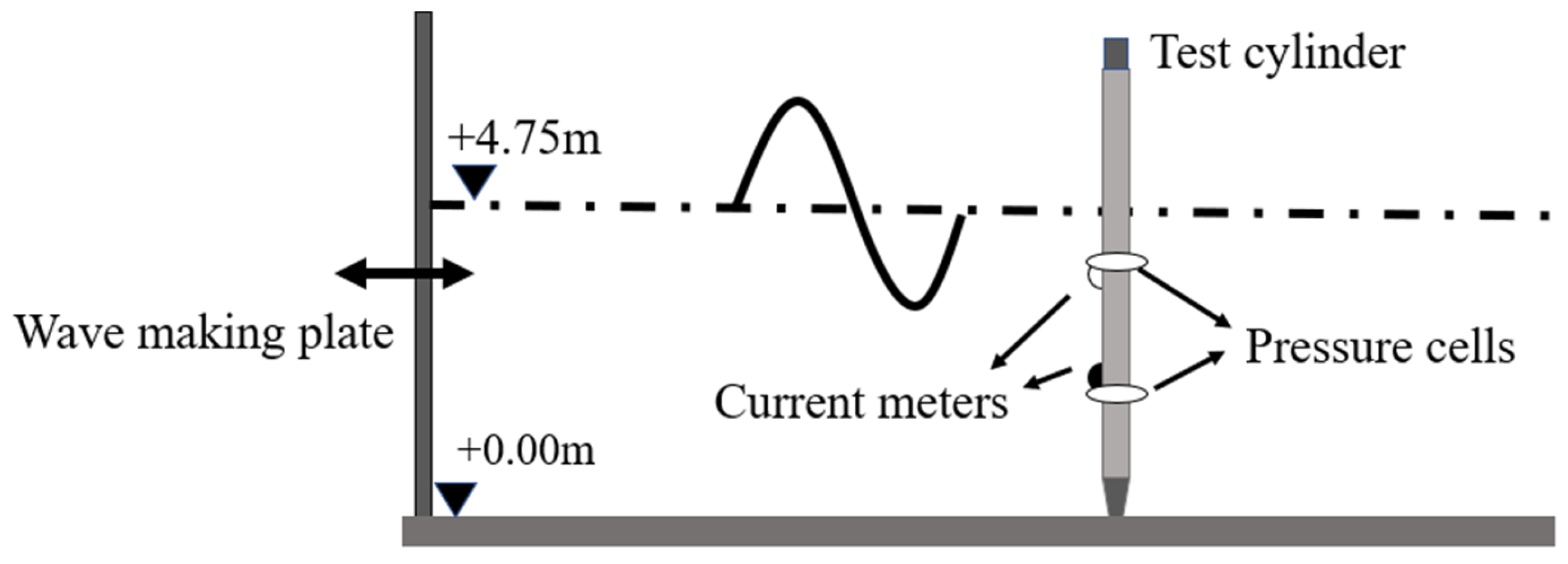

Although significant improvements have been made to theoretical methods, their application is still limited. For such cases, the physical water flume experiment is an appealing solution. Liu [

16] used a three-dimensional flume to determine the reduction coefficient of the wave force on a pile group by analyzing the force of four different types of inclined piles on the East Sea Bridge. Qu [

17] proposed a method to assess the total wave force using the effective diameter, which was determined through wave flume experiments. Based on this, an empirical formula was developed to calculate the wave force of various pile-supported structures in regular and irregular waves. Zhang [

18,

19] conducted wave flume experiments to study the wave force on pile groups with different arrangements under varying wave conditions. Moreover, Bonakdar [

20] used an artificial intelligence data analysis method to derive a new calculation formula for pile-group wave force based on wave flume experiments. However, the physical experiment is costly and has low universality, which brings many inconveniences to researchers when a large number of experiments are needed.

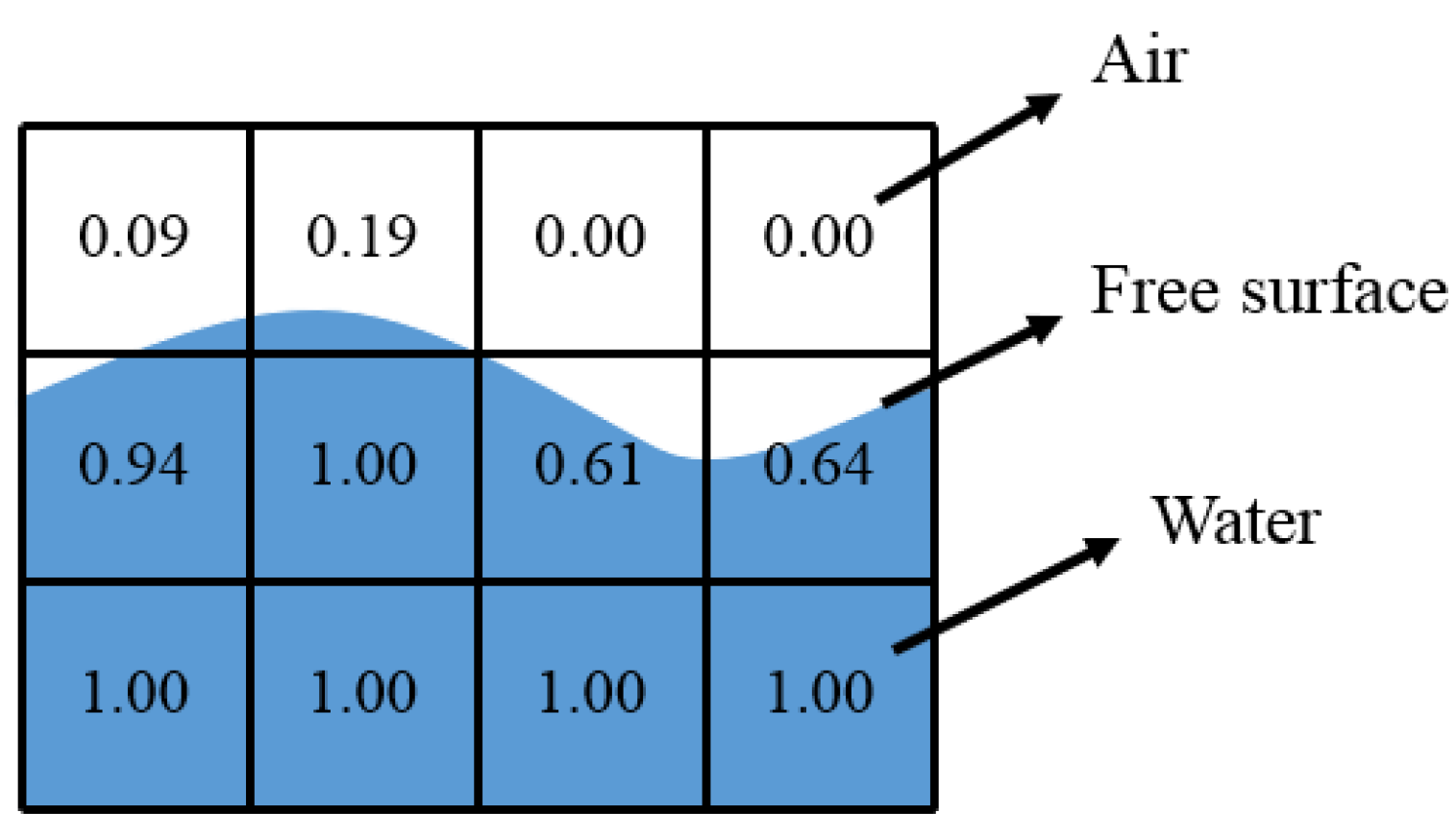

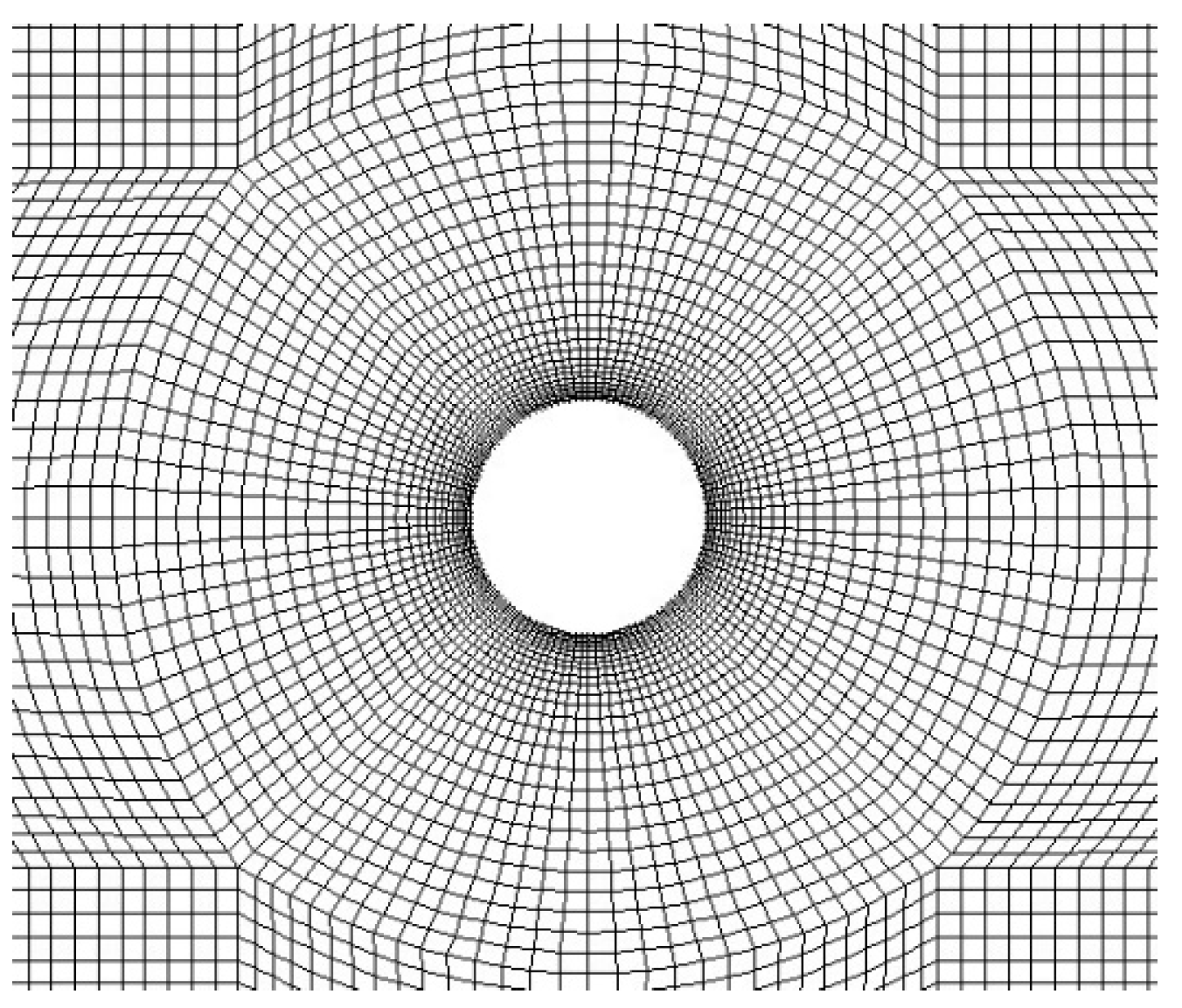

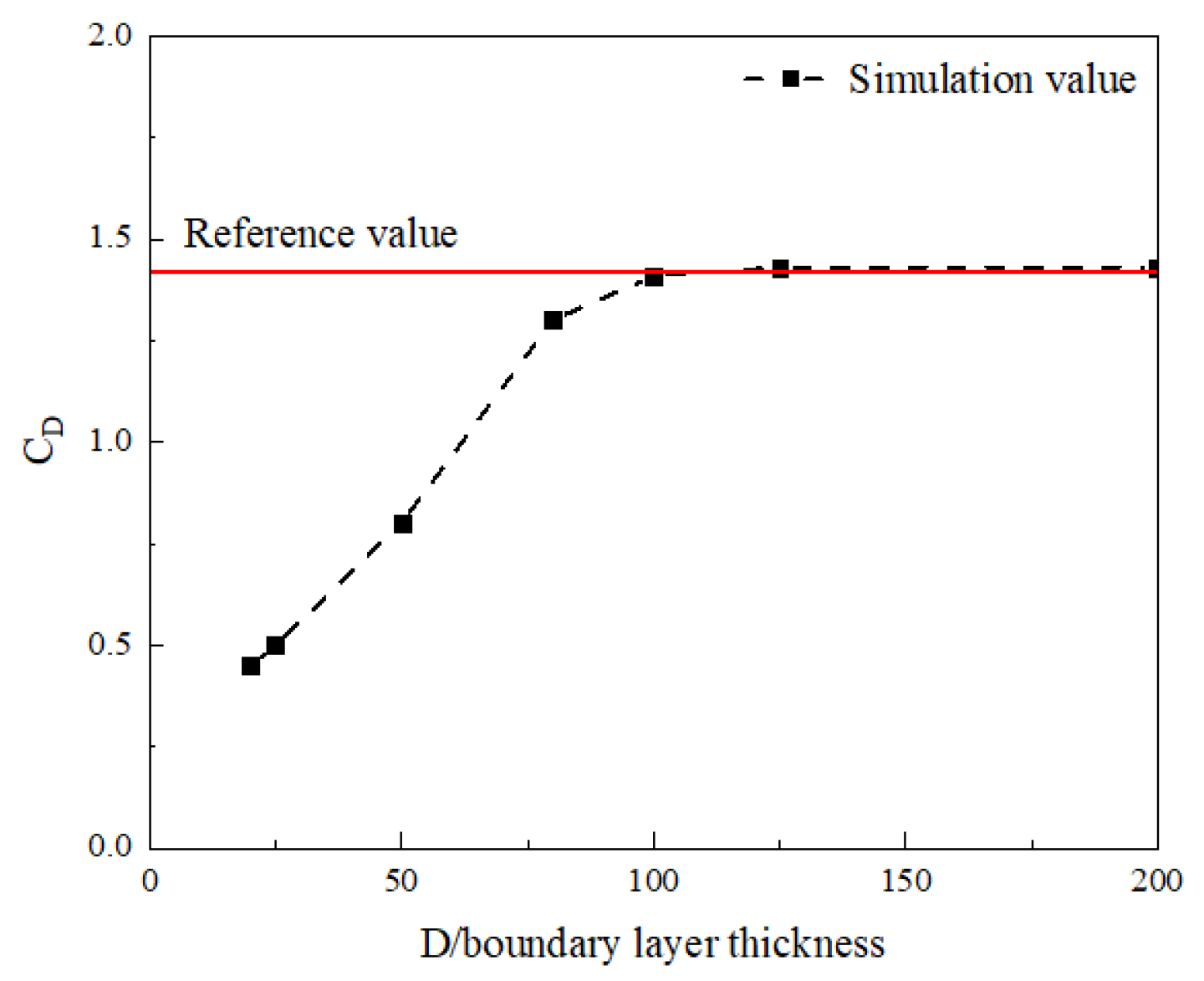

With the progress of computer technology, numerical flumes have developed rapidly, greatly reducing the time, economic costs, and labor costs required for experiments. Many scholars have also verified the accuracy of the numerical flume through comparisons with physical experiments [

21]. Dong [

22] studied the generation and propagation of the wave in a numerical viscous wave flume and accurately generated several incident waves. Huang [

23] created a two-dimensional wave–current interaction model and then proposed an empirical equation for the wave–current force acting on a box girder bridge. Deng [

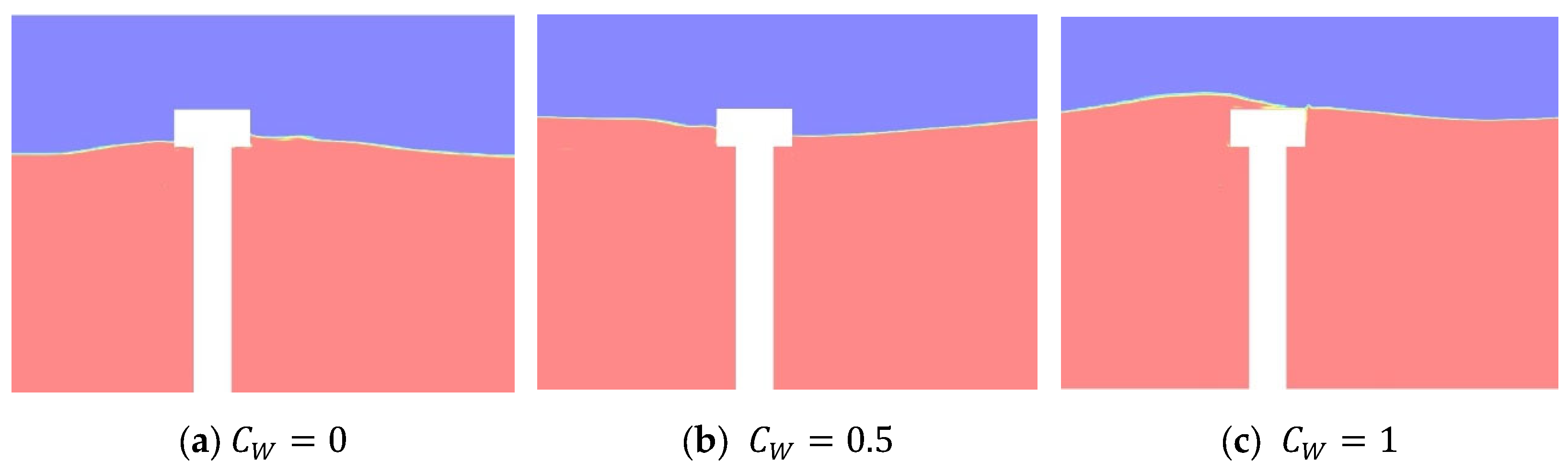

24] investigated the influences of wave height, wave length, cap dimension, and submerged depth on the cap effects through a numerical water flume. All these lay the foundation for solving the wave force of the pile group by numerical flume. However, research on the interaction between the cap and the pile group is limited, and the influence of pile arrangements and water levels on wave forces is rarely considered.

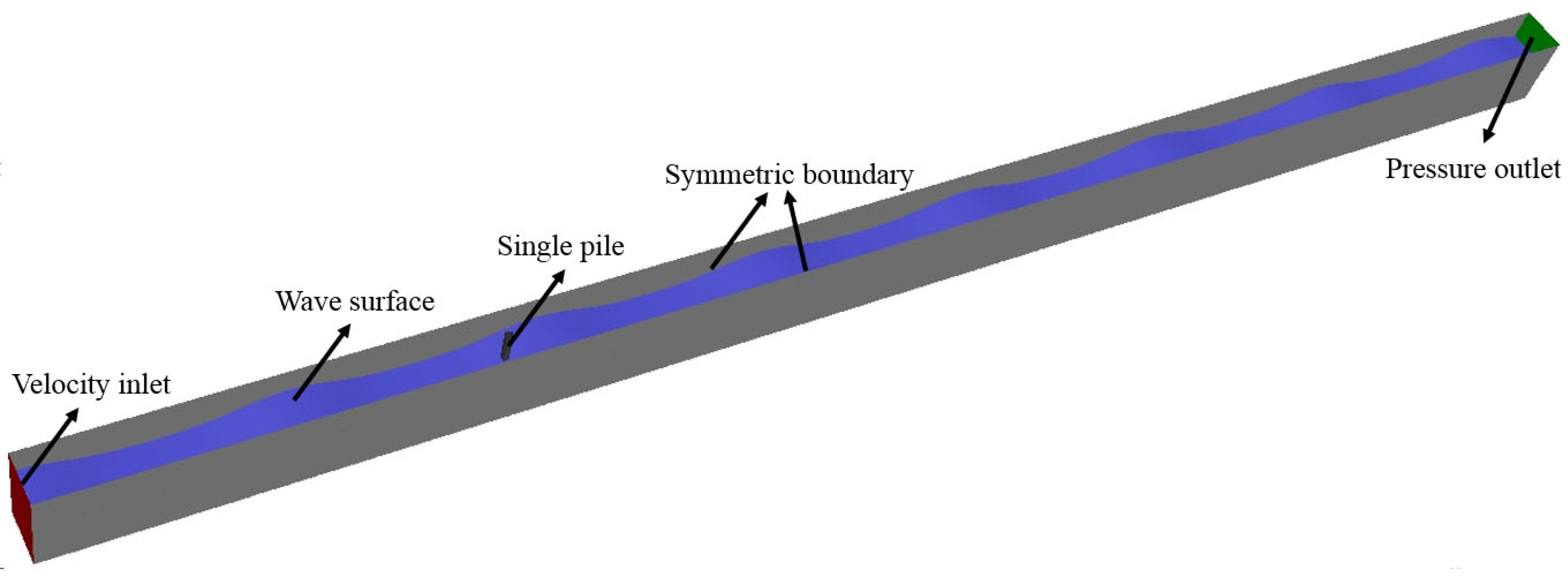

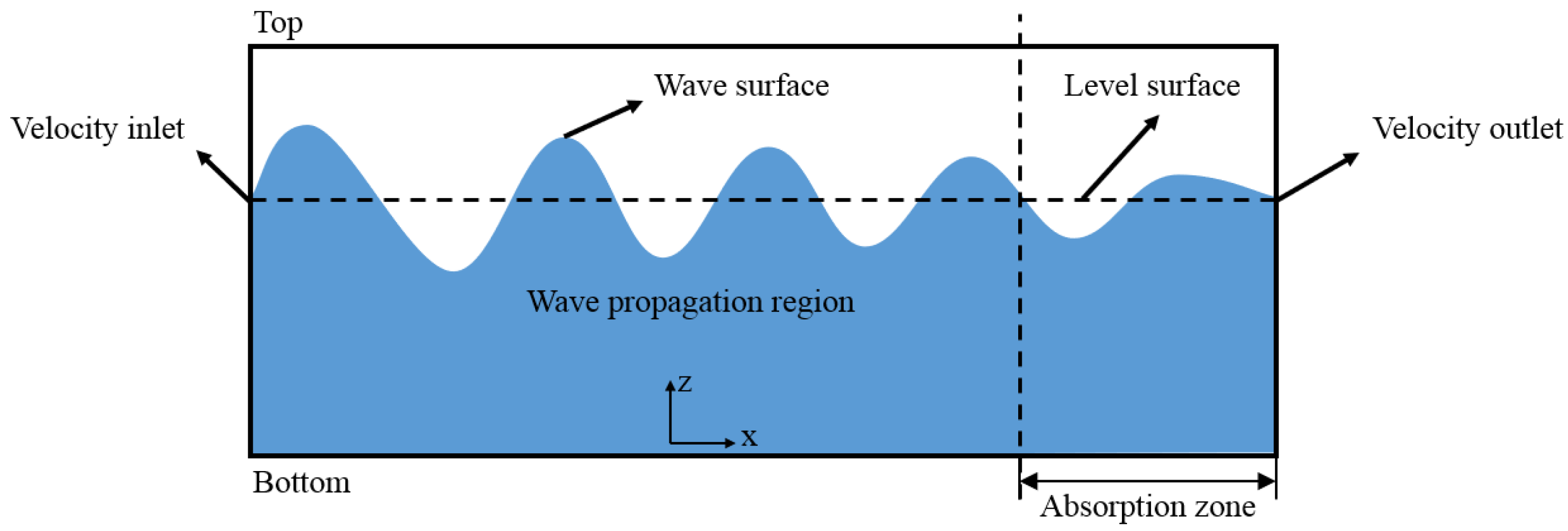

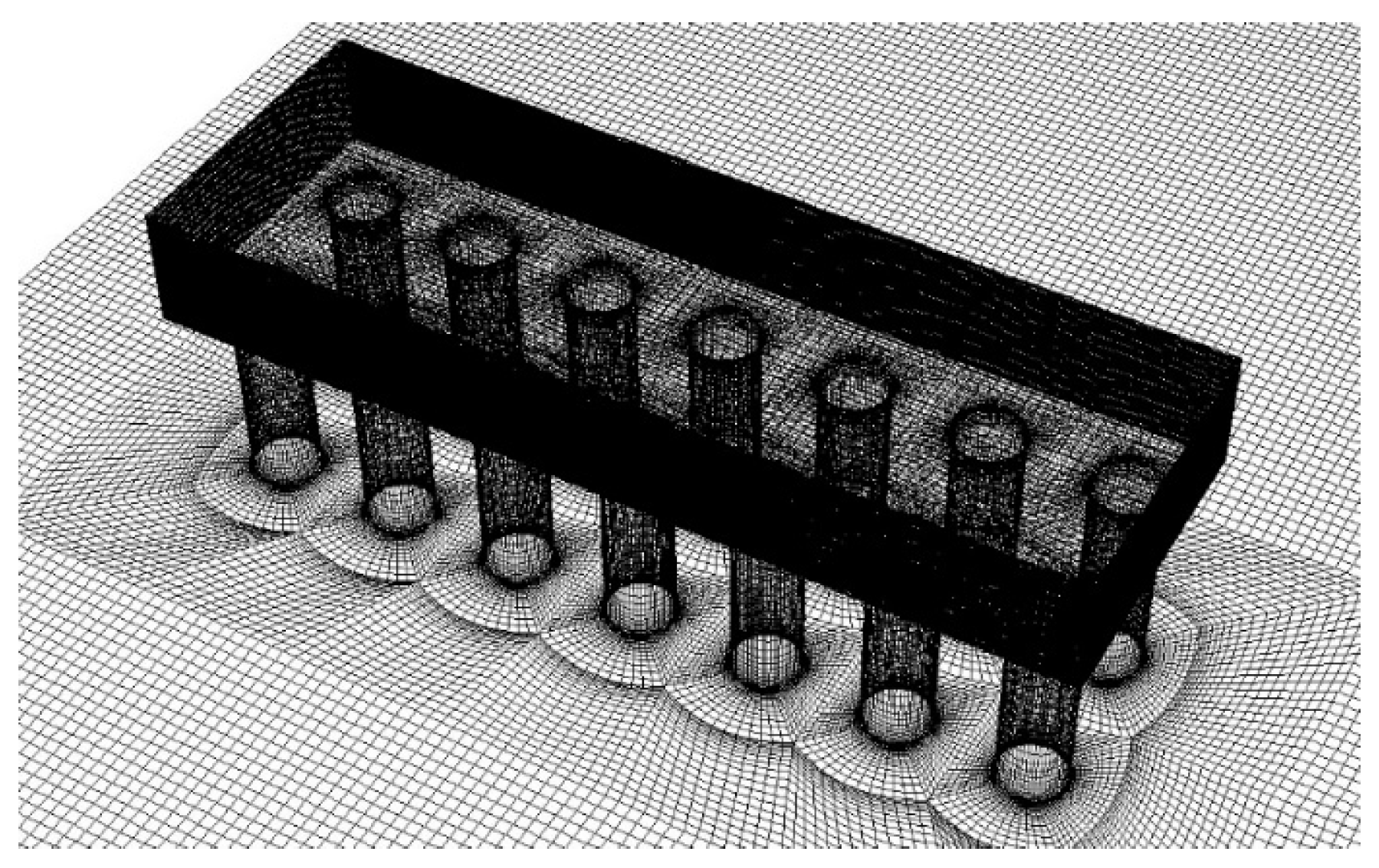

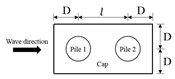

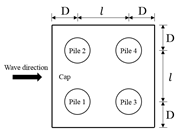

This paper aims to reveal the influence of the cap on wave forces acting on pile groups through a three-dimensional numerical water flume. The remainder of this paper is organized as follows.

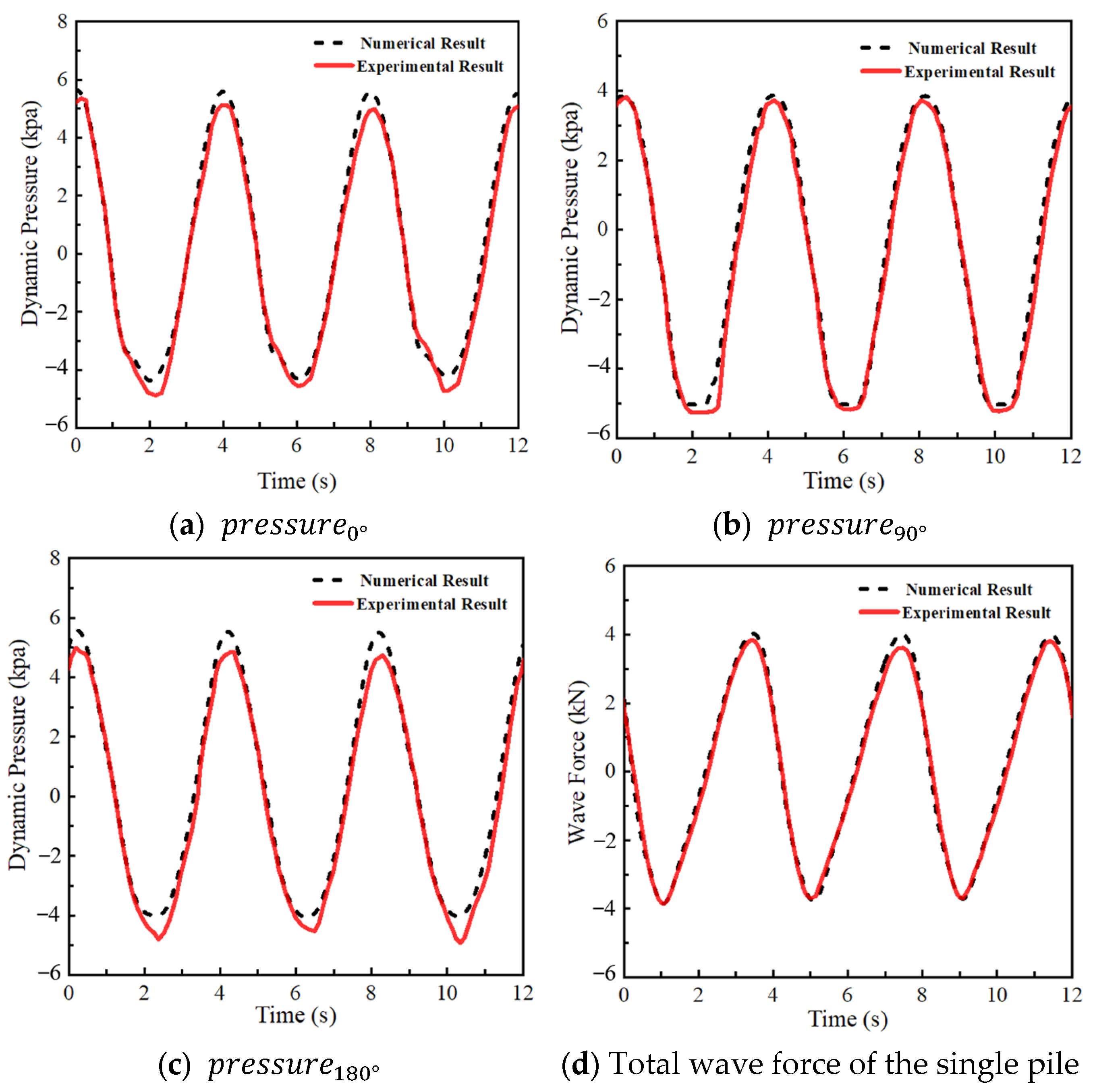

Section 2 briefly introduces the numerical methods used and the validation of the numerical flume, including wave generation and elimination, the grid size, and the boundary conditions. The numerical flume has been validated with the test results of the physical flume in the relevant literature. In

Section 3, the influence of the cap on the wave forces acting on the pile group with different arrangements and water levels is studied. In

Section 4, we establish a modified theoretical formula for calculating wave forces considering the cap effect. In

Section 5, an engineering project is simulated to verify the feasibility of the modified theoretical formula proposed in this paper. Conclusions are drawn in

Section 6.

4. Modified Theoretical Formula for Calculating Wave Forces Considering Cap Effect

We introduce

into the theoretical formula of wave forces on pile groups [

37], which can be expressed as follows:

where

is the wave-force time history of the whole pile group, and

is the wave-force time history of every single pile calculated by the Morison formula.

is the cap-interference coefficient.

is the shelter effect coefficient.

is the interference effect coefficient.

The shelter effect coefficient

can be calculated as follows:

where

is the wave force of a single pile in the pile group arranged in the parallel wave direction, and

is the wave force on a single pile.

Similarly, the interference effect coefficient

can be calculated as follows:

where

is the wave force of a single pile in the pile group arranged in the vertical wave direction, and

is the wave force of a single pile.

The value of

could not be found in the specifications or standards currently. In this paper, it can be assumed that

between each row of piles in the parallel wave direction is the same according to

Section 3. For each column of piles in a perpendicular wave direction,

can be selected according to the front and rear positions of the piles. The cap-interference coefficient of the front row pile can be linearly interpolated according to the length

of the back side pile cap according to

Figure 8. Similarly, the cap-interference coefficient of the back row pile can be linearly interpolated according to the length

of the front side pile cap according to

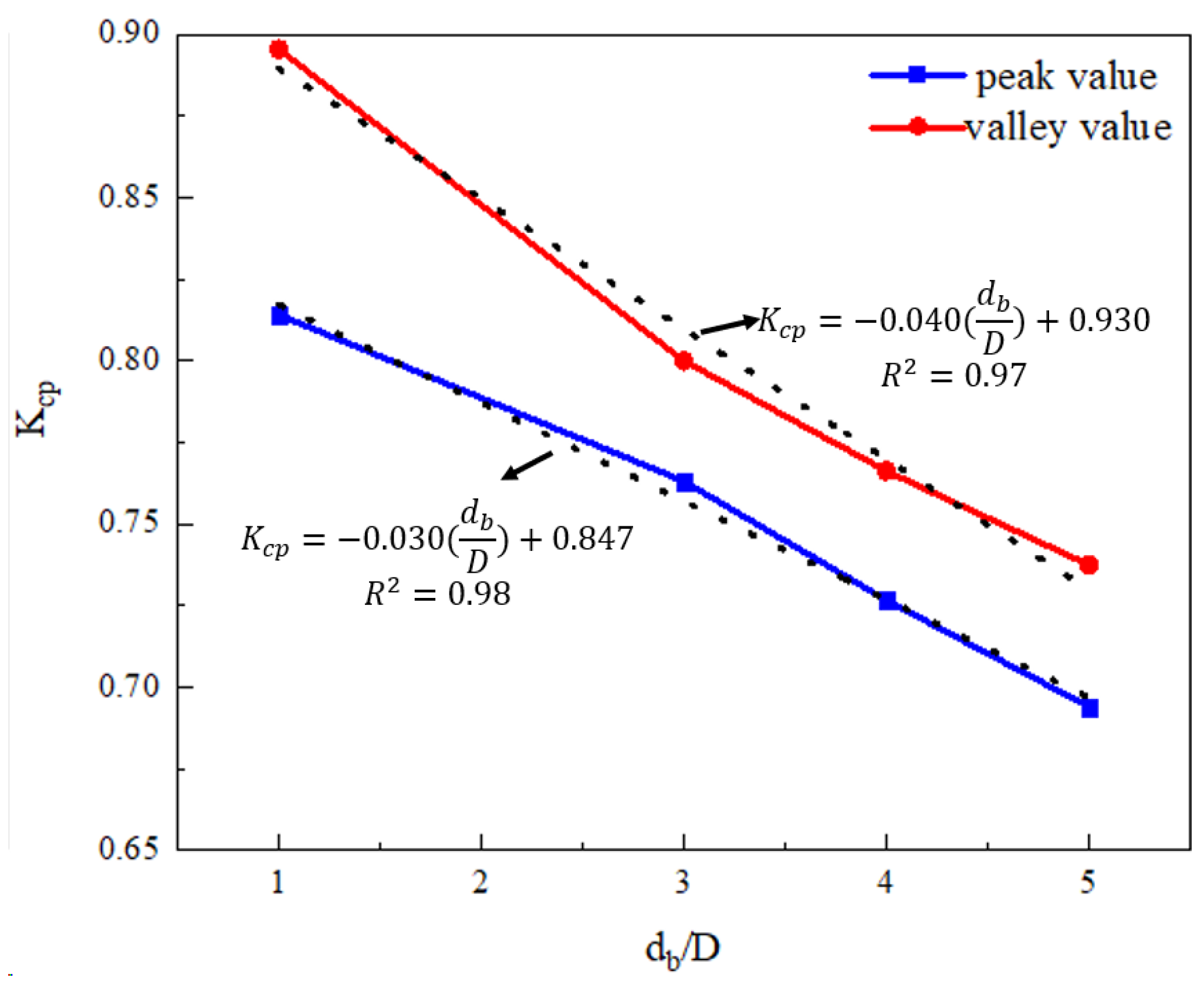

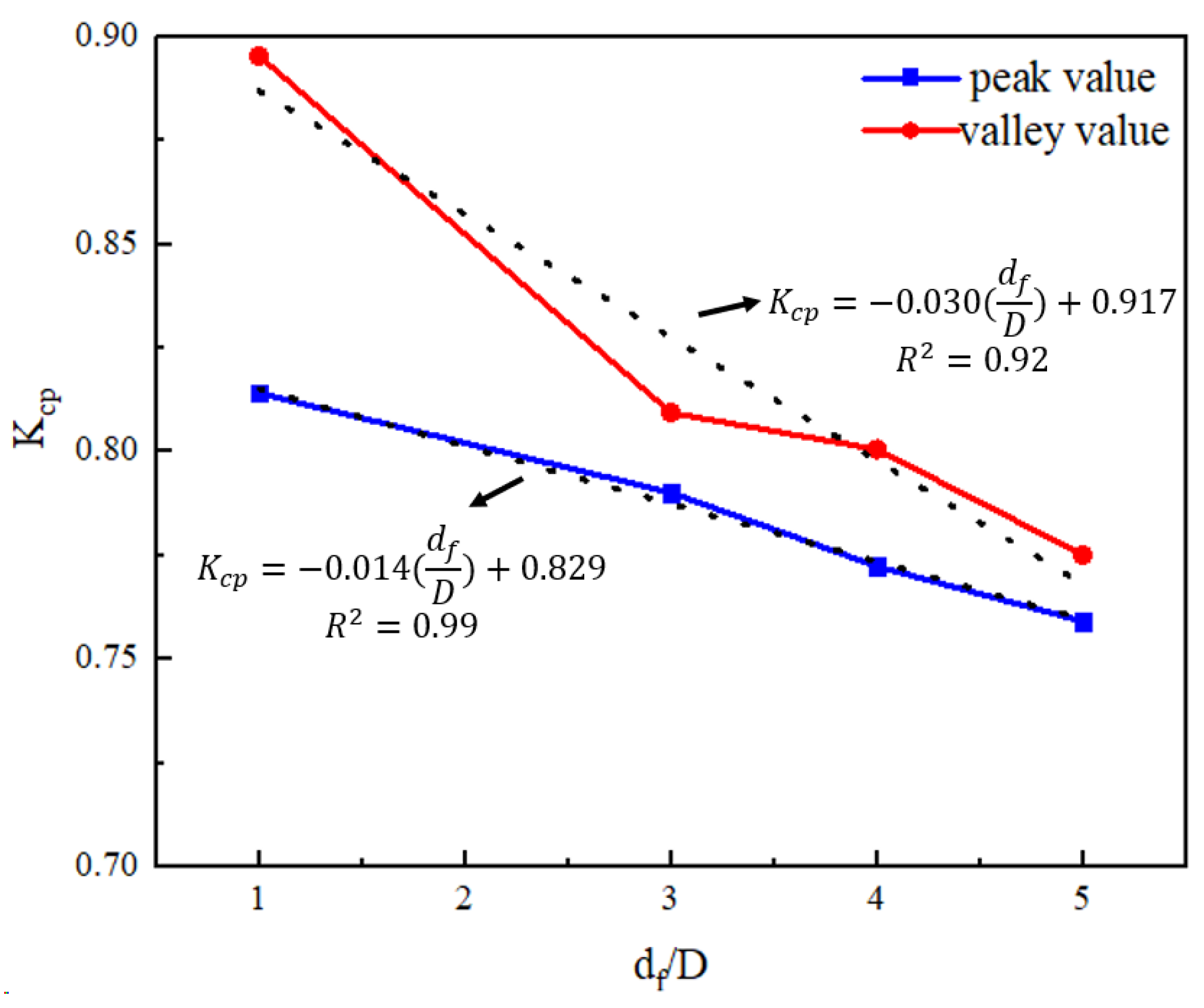

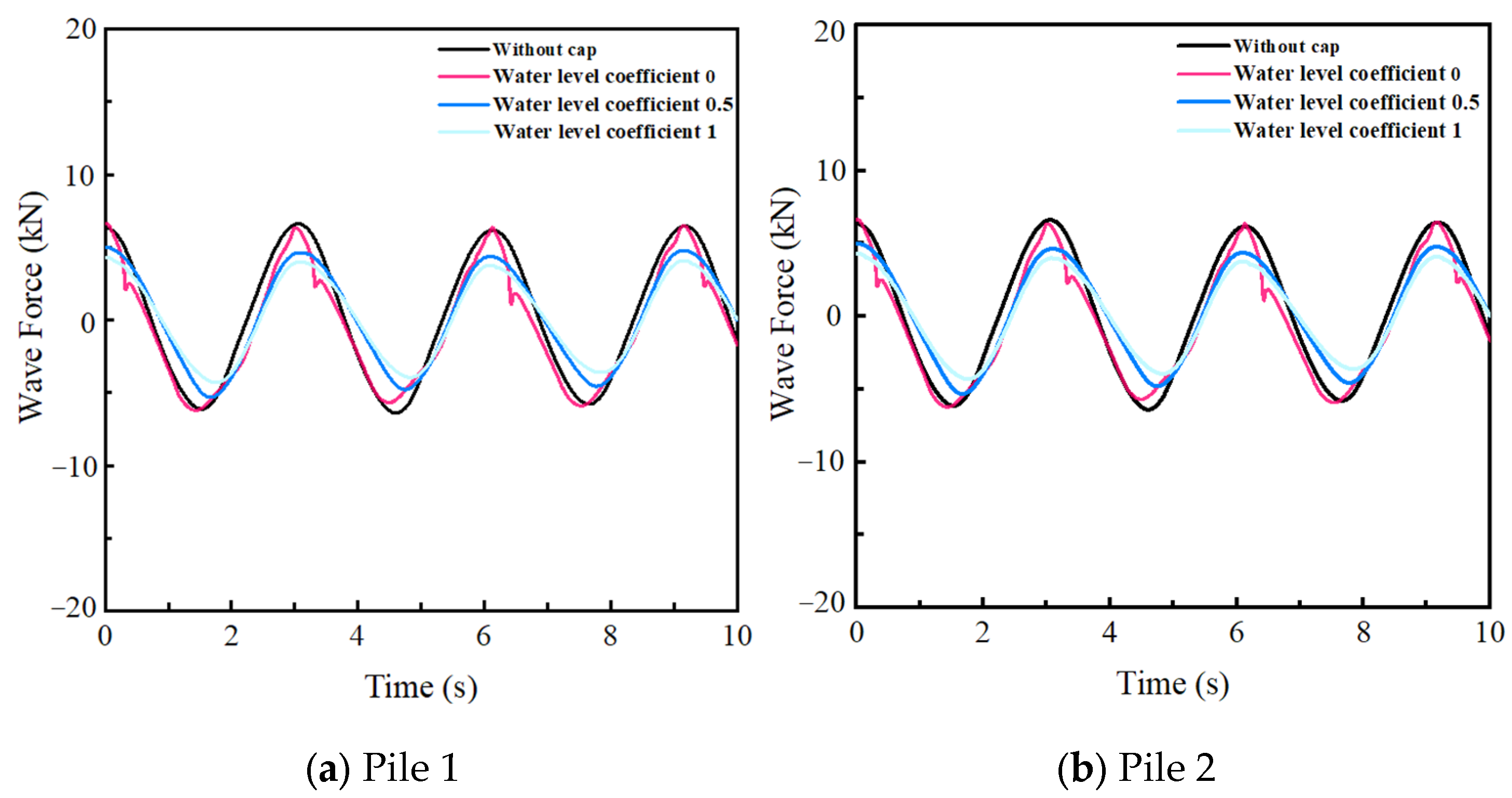

Figure 9. Considering that the pile cap has a stronger interference effect on the peak wave force and a weaker interference effect on the valley value, the interference coefficient of the valley value can be taken safely. A more unfavorable value can be obtained for the pile groups with more than two columns.

6. Conclusions

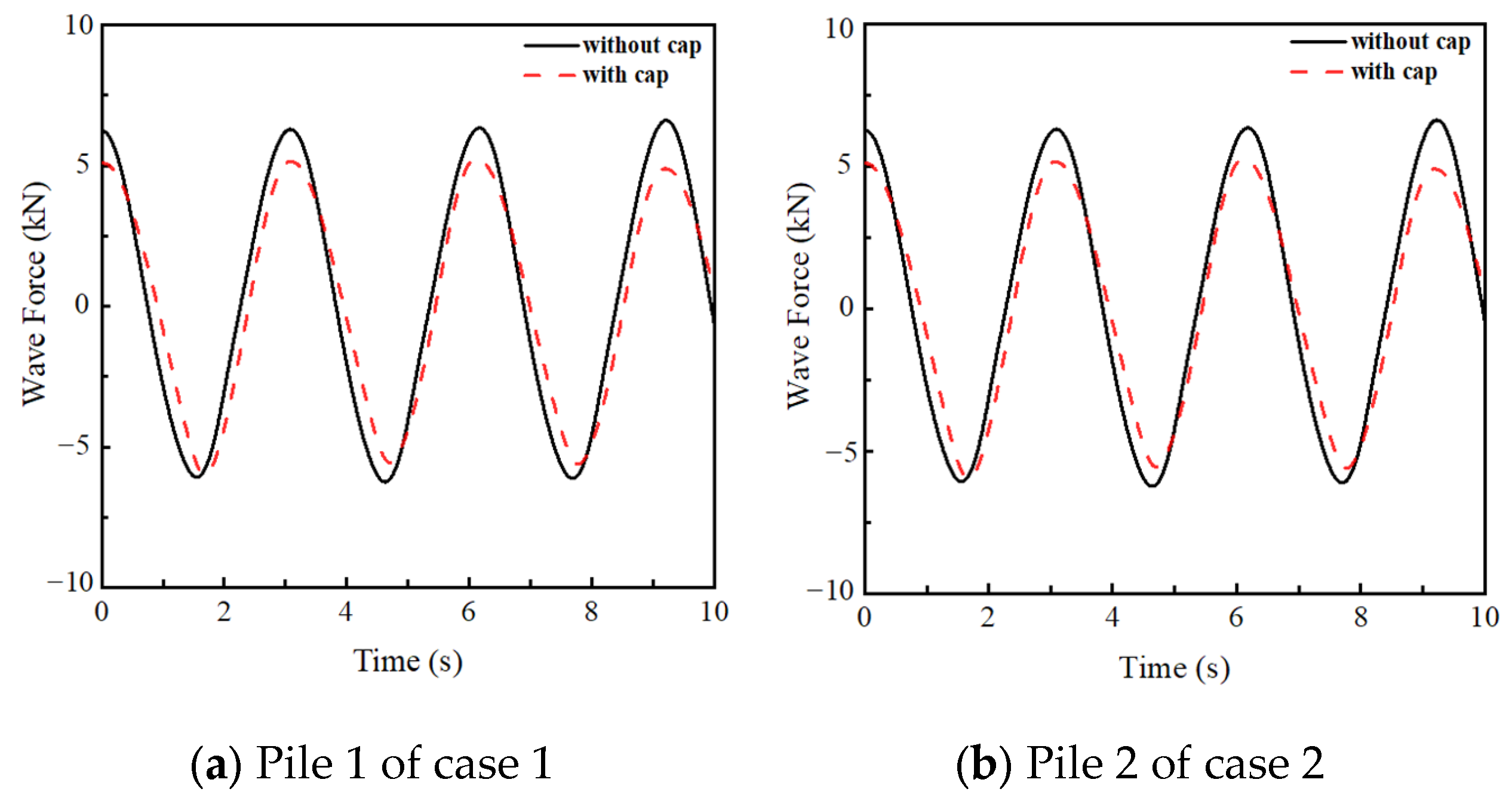

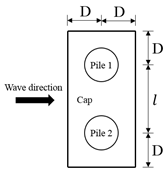

In this paper, a three-dimensional numerical wave flume is established to investigate the influence of the cap on wave forces acting on pile groups. The setup of the flume, including wave generation and elimination, the grid size, and the boundary conditions, has been validated with the test results of the physical flume in the relevant literature. The influence of the cap on the pile groups with different arrangements and water levels was studied. The cap-interference coefficient was defined, and its variation law was given. It was found that for the single row of piles perpendicular to the wave, the center distance of the pile and the width of the cap have little effect on . Meanwhile, for the single row of piles parallel to the wave, the cap length before and after the pile has a negative correlation with . The law of multi-row piles is similar to that of single-row piles.

We proposed a modified theoretical formula with for calculating wave forces on piles as a theoretical formula for calculating wave forces considering the cap effects. Based on the parametric analysis mentioned earlier, the recommended value of was given.

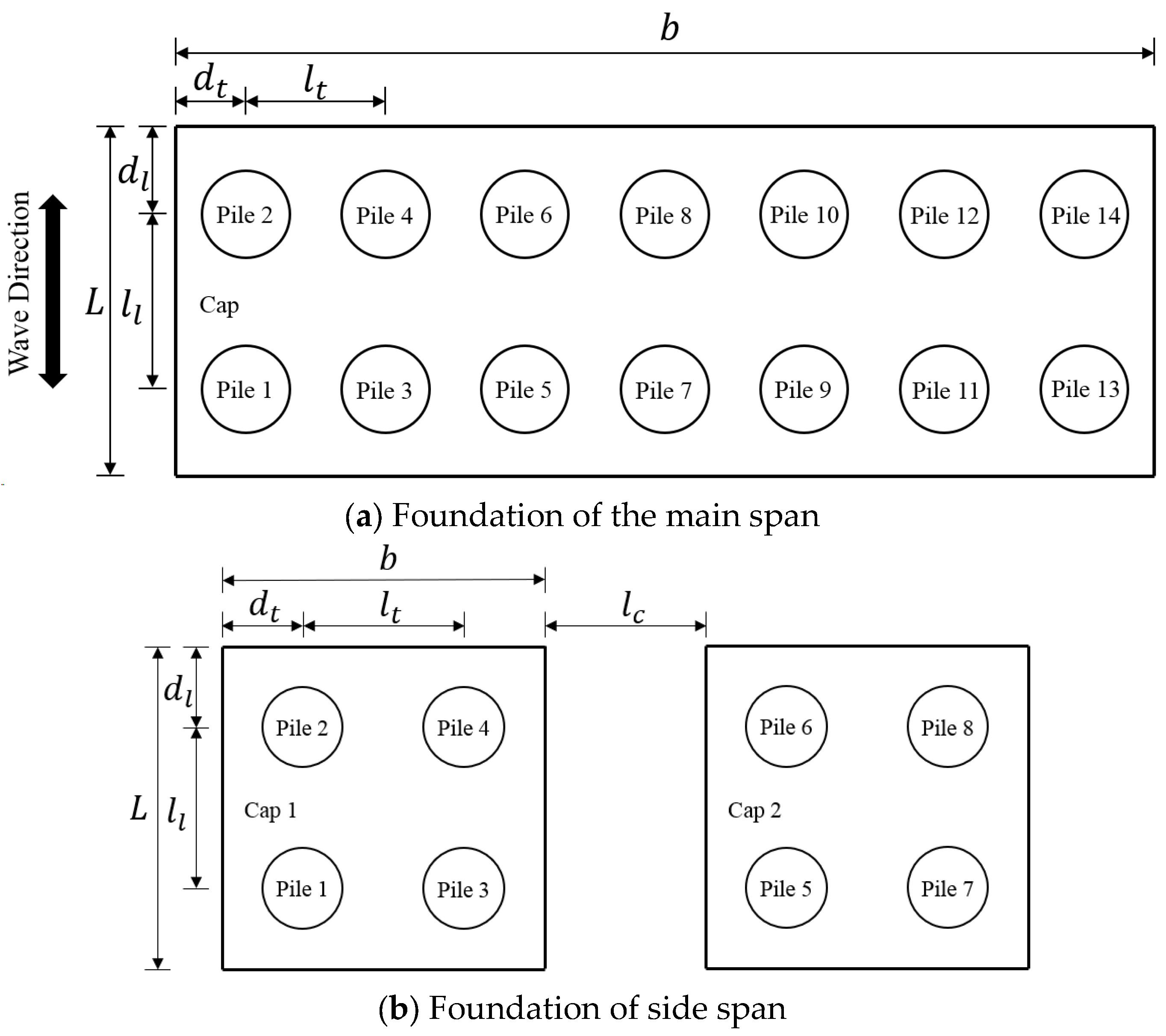

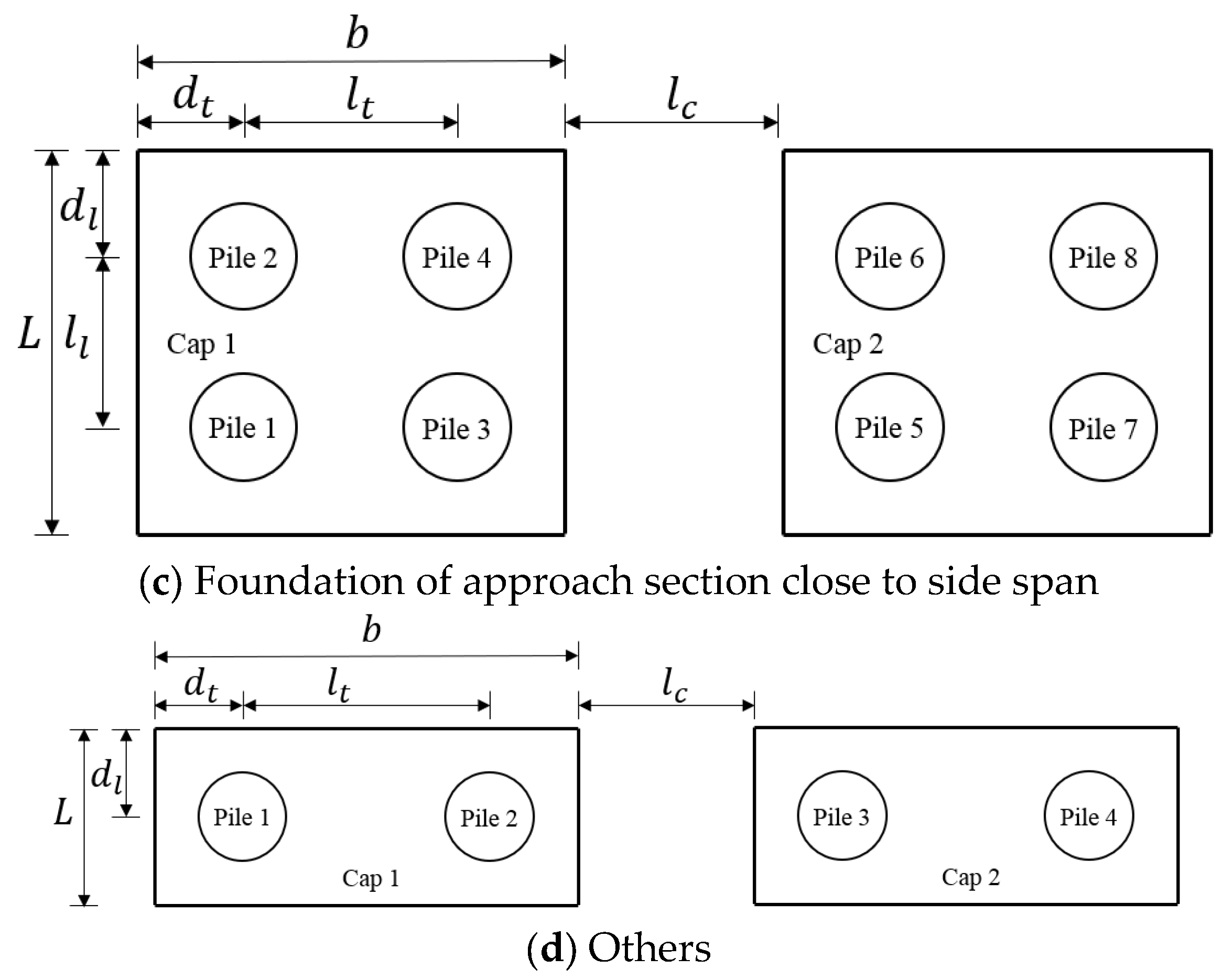

After that, four groups of pile-foundation structures in engineering projects were selected to verify the feasibility of numerical flumes in practical engineering. Comparing the results of the pile-group wave force calculated by the numerical water flume, specification value, and theoretical formula, it is concluded that the results from the numerical water flume are in good agreement with that of the theoretical formula, while the results of the specification value are more conservative. The methods used in this article and the obtained variation laws can provide a reference for engineering.

However, due to limitations in computer power and time, we were unable to calculate many different cases with different sizes of caps, resulting in certain limitations in the formula. At the same time, caps are not only square, but may also have shapes such as circles and triangles, which can be further explored in the future.