Migration of Leaked Oil Vapor in Underground Water-Sealed Oil Storage Cavern Considering the Influence of Fractures

Abstract

1. Introduction

2. Theory and Calculation Scheme

2.1. Gas–Liquid Two-Phase Flow Model of the Fracture–Pore Dual Medium in the Fractured Rock Mass

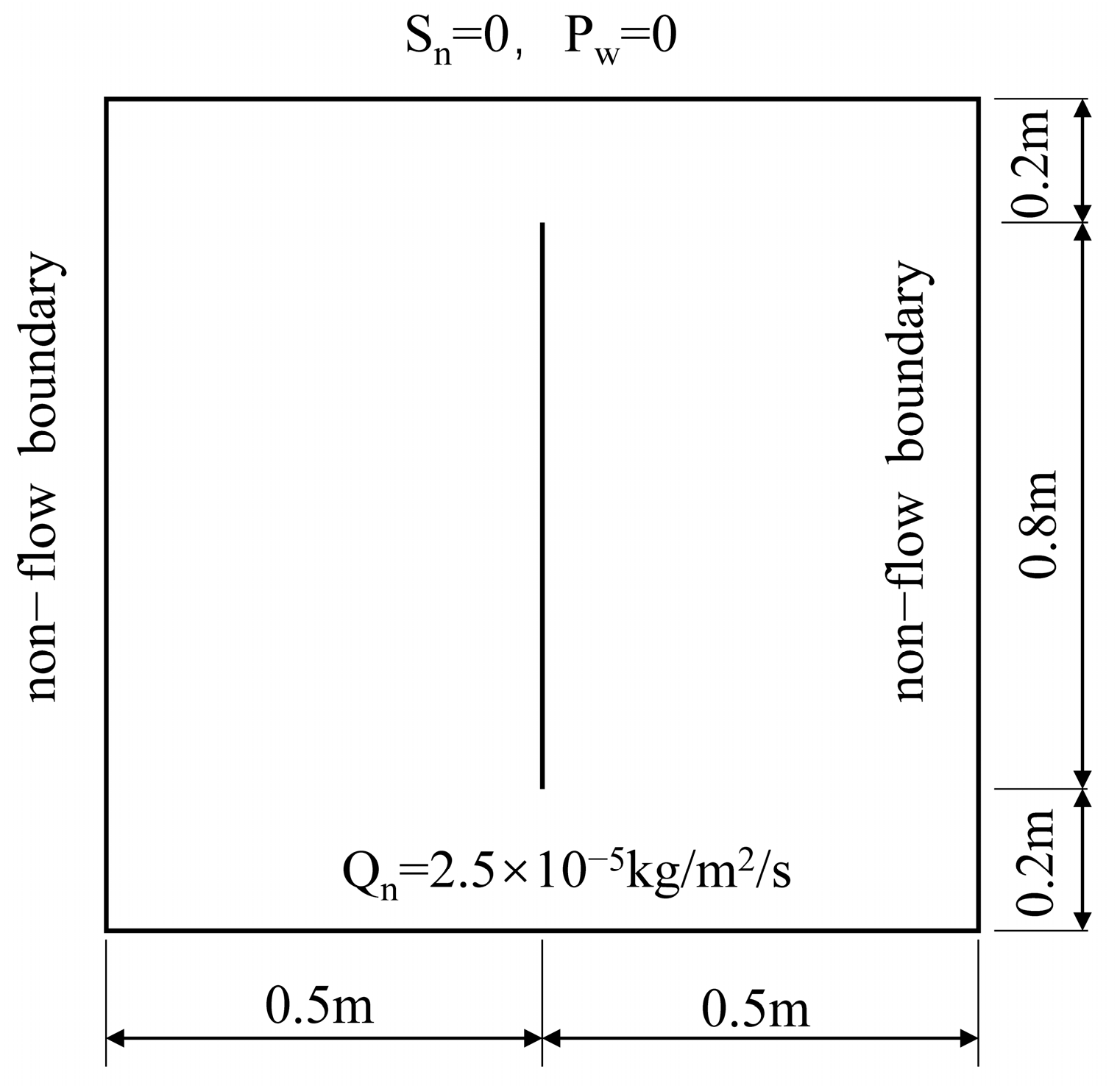

2.2. Numerical Realization and Verification of the Model

2.3. Numerical Simulation Scheme for the Influence of Single Fracture on Oil Vapor Leakage and Migration in Water-Sealed Oil Storage Caverns

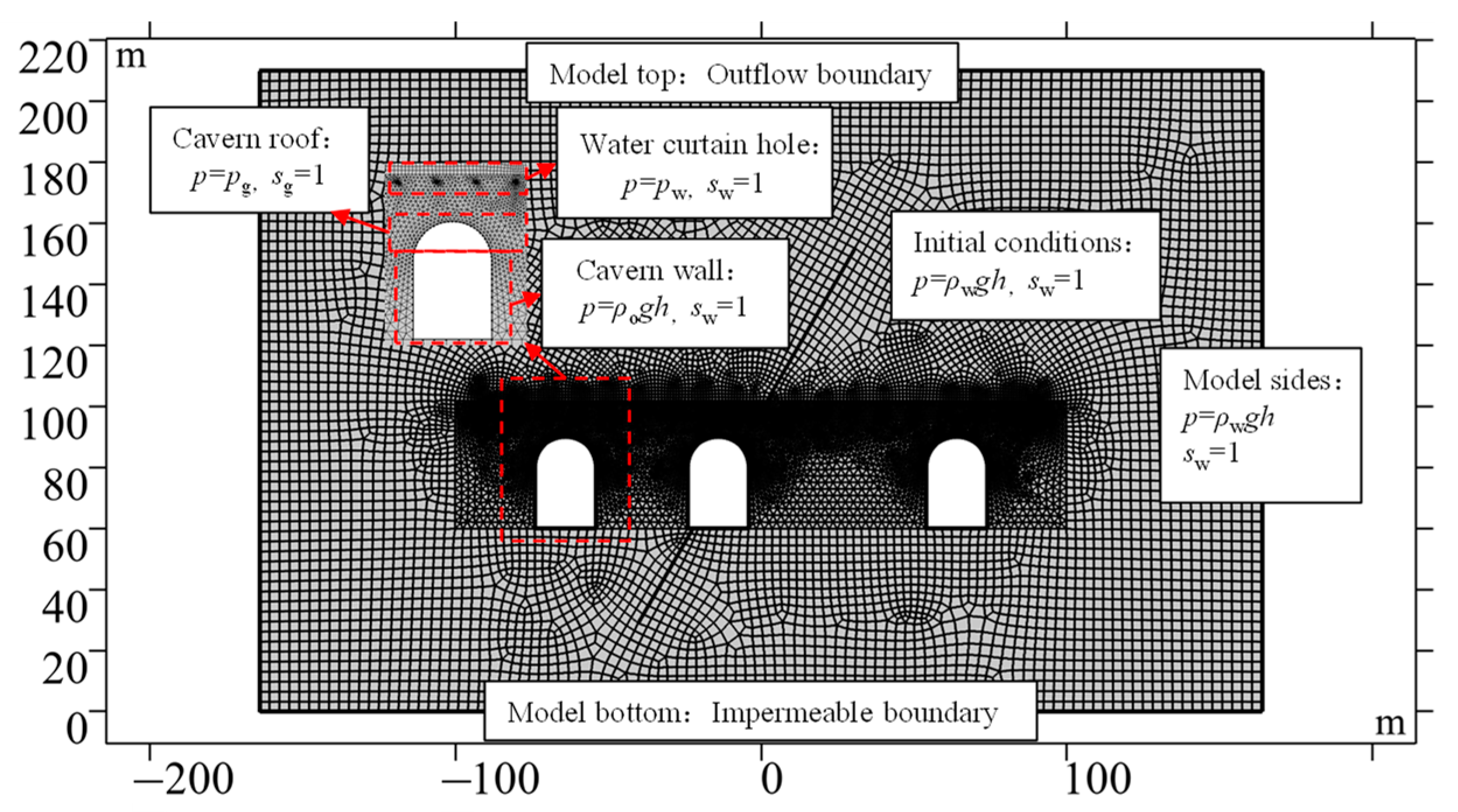

2.3.1. Calculation Model

2.3.2. Initial and Boundary Conditions

2.3.3. Parameter Values

3. Results and Analysis

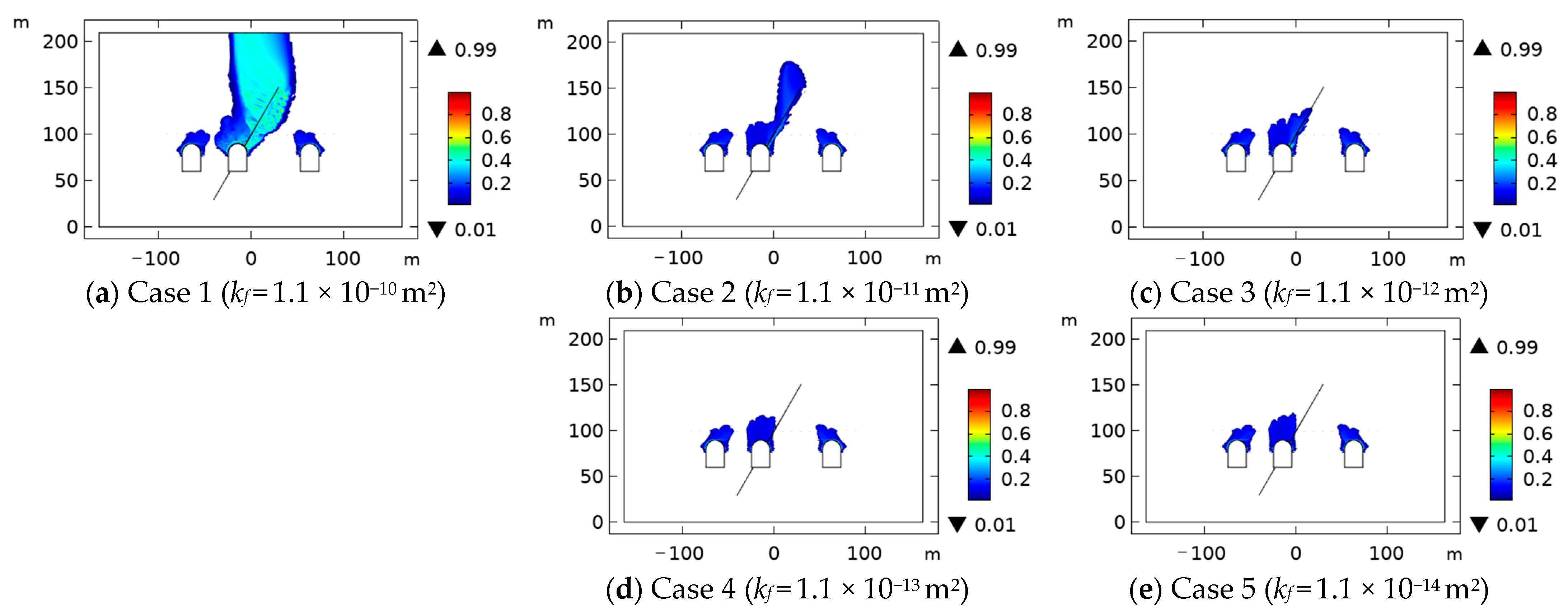

3.1. Effect of Fracture Permeability on the Migration of Leaked Oil Vapor

3.2. Effect of Fracture Width on the Migration of Leaked Oil Vapor

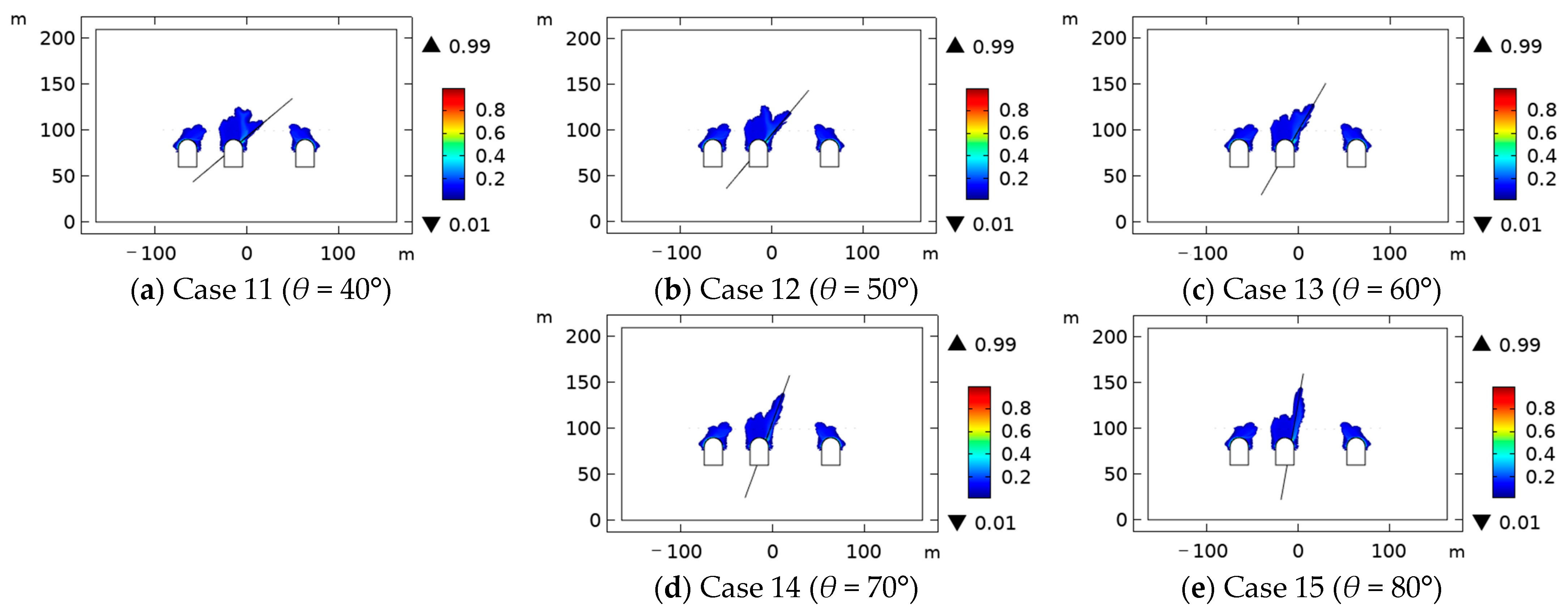

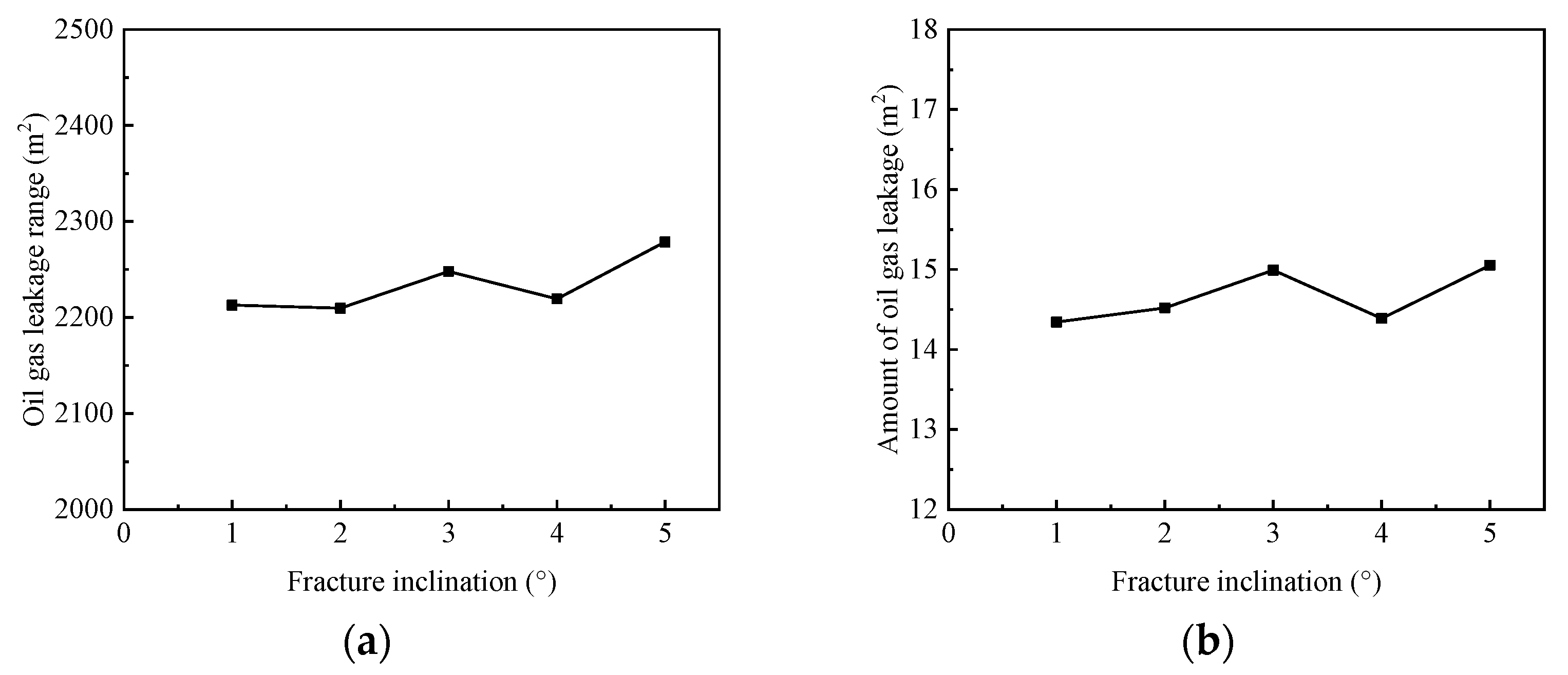

3.3. Effects of Fracture Inclination on the Migration of Leaked Oil Vapor

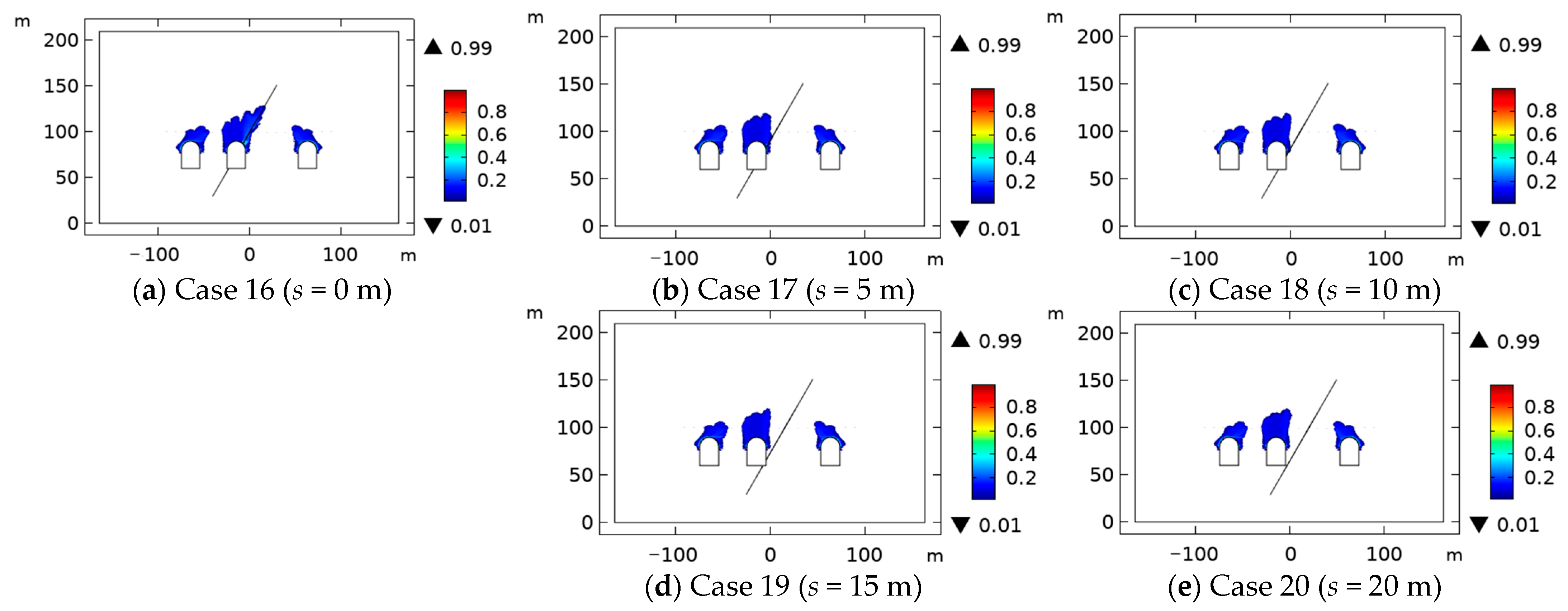

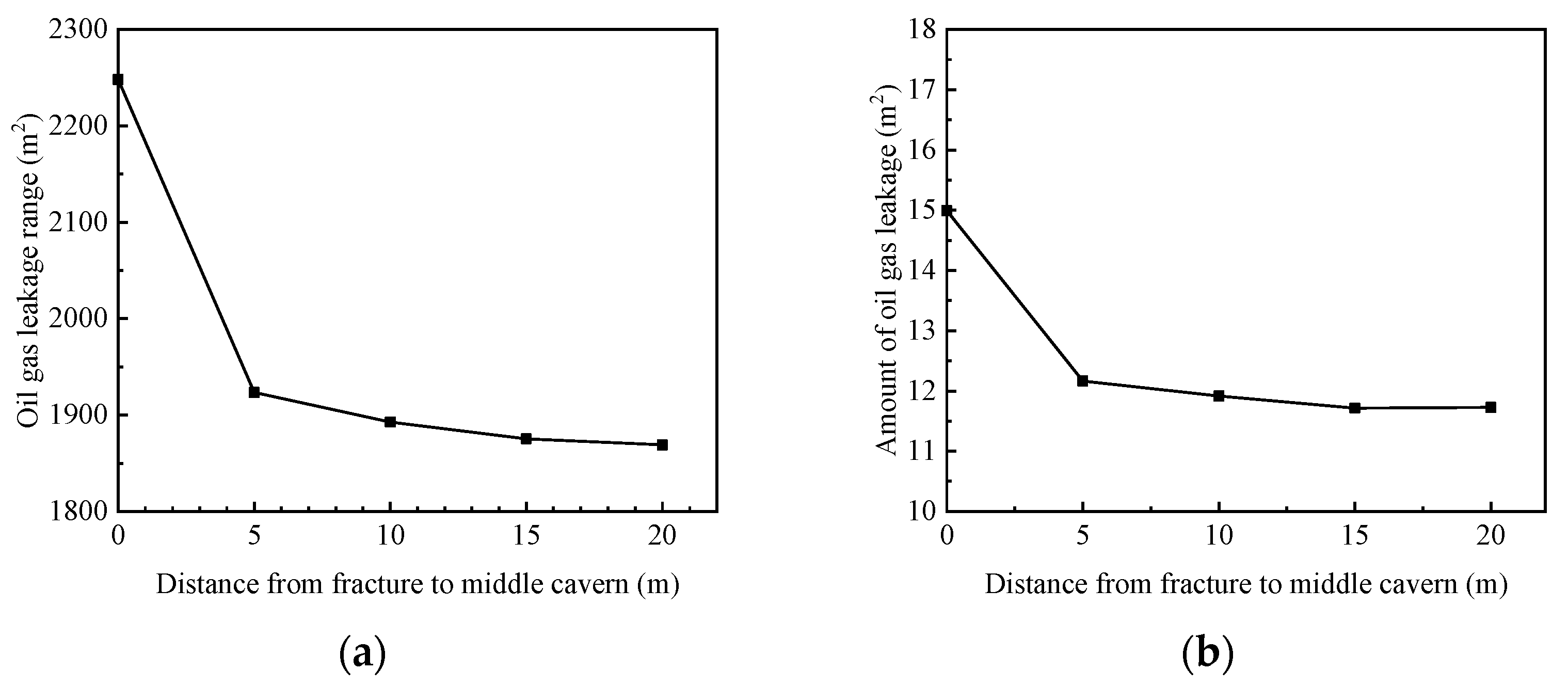

3.4. Effects of Fracture Position on the Migration of Leaked Oil Vapor

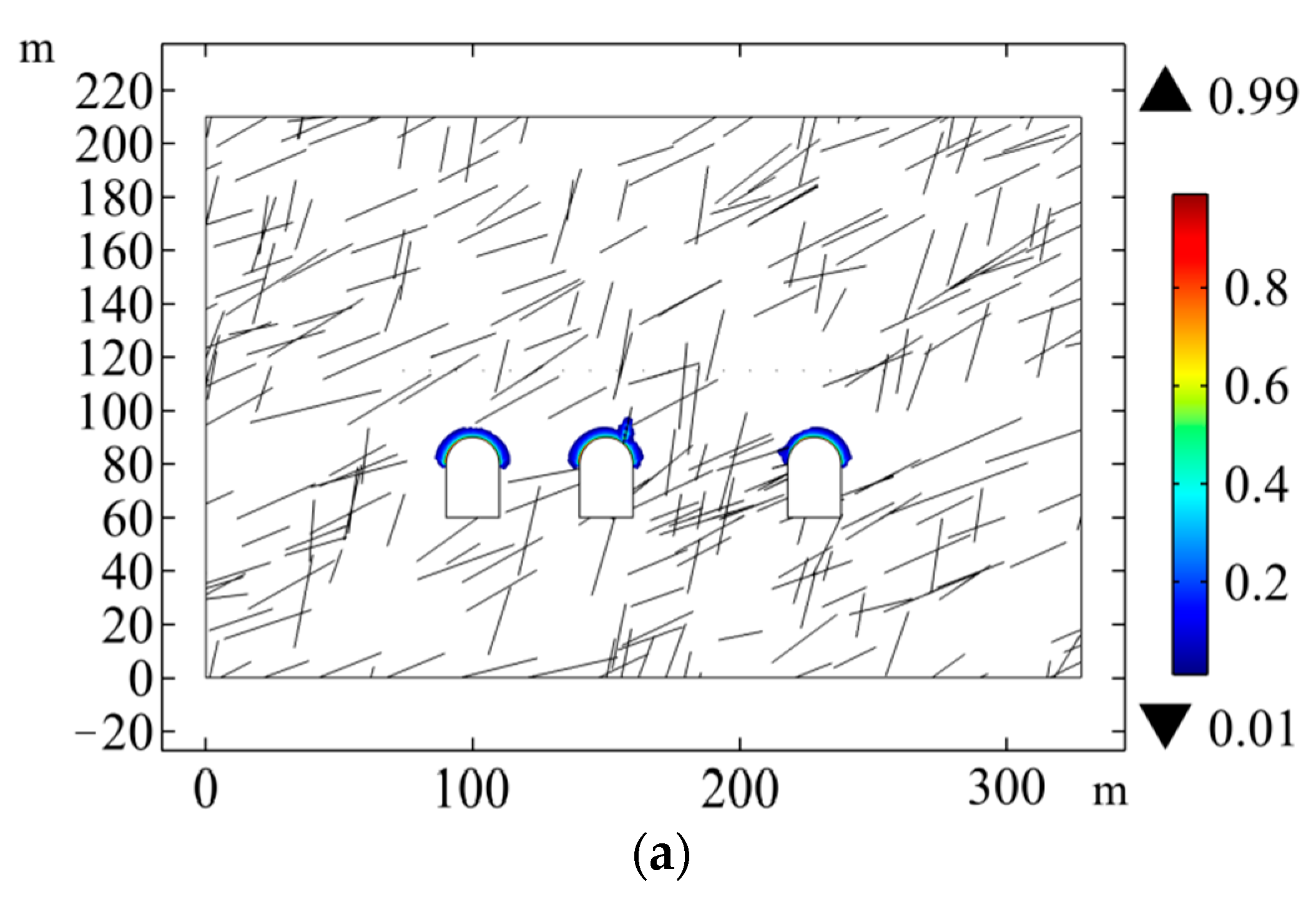

4. Engineering Application

4.1. Project Overview

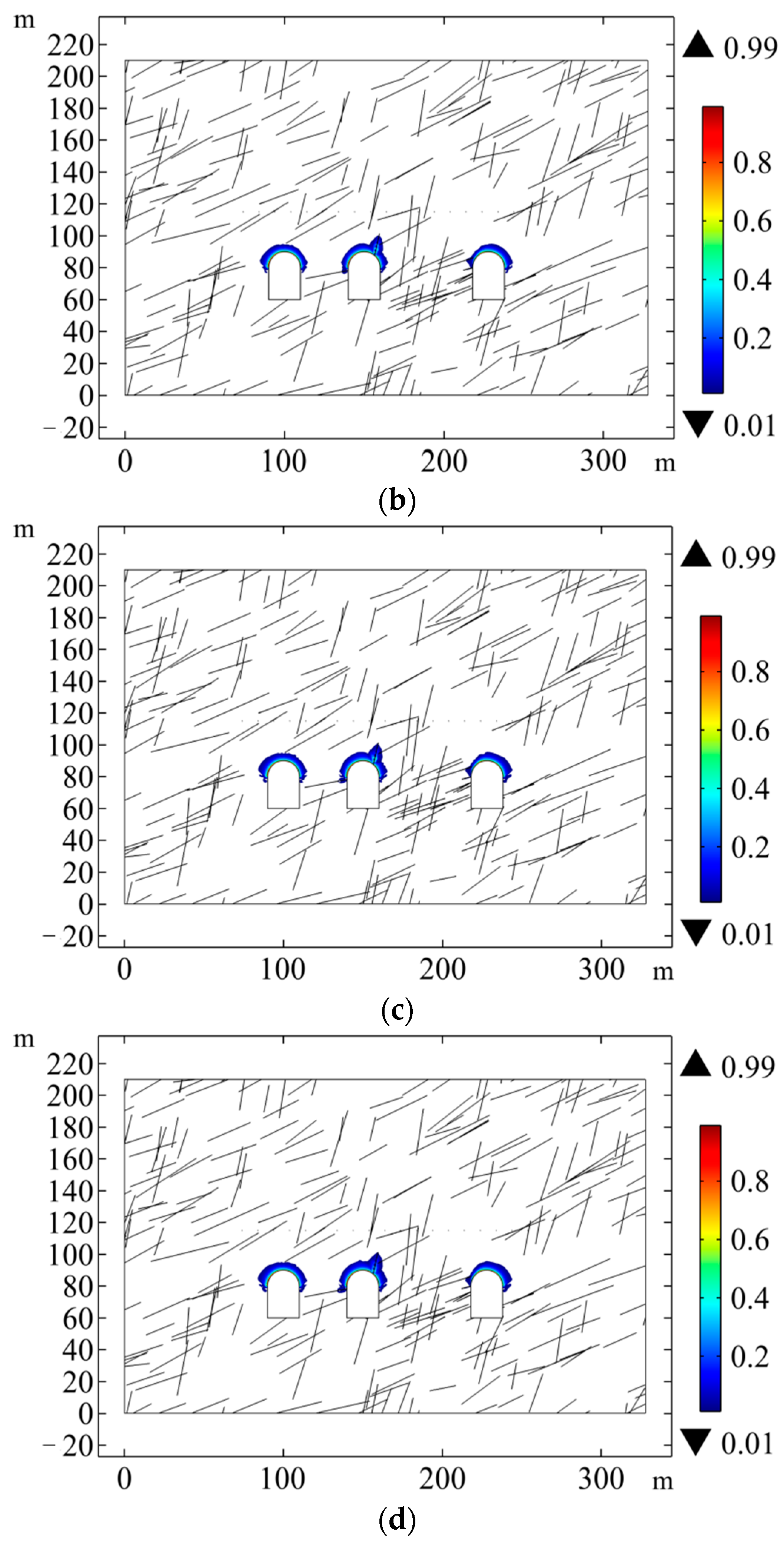

4.2. Fracture Network Model

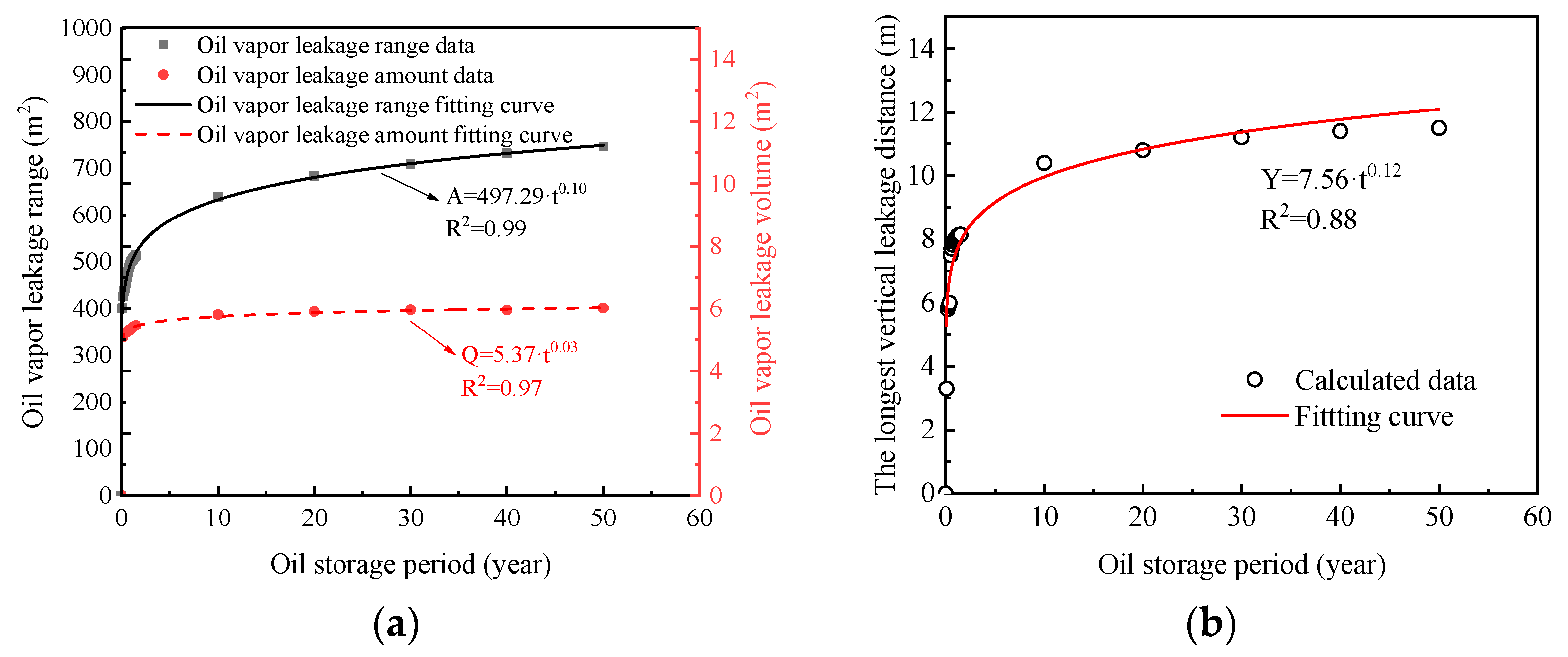

4.3. Calculation Result Analysis

- Range of oil vapor leakage: A = 497.29t0.1

- Leakage volume: Q = 5.37t0.03

- Longest vertical leakage distance: Y = 7.56t0.12

5. Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, M. Finite element analysis of a pilot gas storage in rock cavern under high pressure. Eng. Geol. 1998, 49, 353–361. [Google Scholar] [CrossRef]

- Mawire, A. Experimental and simulated thermal stratification evaluation of an oil storage tank subjected to heat losses during charging. Appl. Energ. 2013, 108, 459–465. [Google Scholar] [CrossRef]

- Ravandi, E.G.; Rahmannejad, R.; Karimi-Nasab, S.; Sarrafi, A. Application of Numerical Modelling and Genetic Programming in Hydrocarbon Seepage Prediction and Control for Crude Oil Storage Unlined Rock Caverns. Geofluids 2017, 2017, 6803294. [Google Scholar] [CrossRef]

- Qiao, L.; Li, S.; Wang, Z.; Tian, H.; Bi, L. Geotechnical monitoring on the stability of a pilot underground crude-oil storage facility during the construction phase in China. Measurement 2016, 82, 421–431. [Google Scholar] [CrossRef]

- Gao, B.; Pan, D.D.; Xu, Z.H.; Zhang, L.W.; Zhao, S.L. Effect of density, trace length, aperture, and direction angle on permeability performance of fracture networks. Int. J. Geomech. 2020, 20, 04020116. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, Z.; Fan, J.; Jiang, D.; Li, Z.; Chen, J. Research on gas leakage and collapse in the cavern roof of underground natural gas storage in thinly bedded salt rocks. J. Energy Storage 2020, 31, 101669. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Jiang, Y.; Liu, Y.-X.; Zhang, T. Theoretical research on gas seepage in the formations surrounding bedded gas storage salt cavern. Petrol. Sci. 2022, 19, 1766–1778. [Google Scholar] [CrossRef]

- Hu, C.; Chen, G.; Yang, R.; Tang, L.; Luo, Y. A case study on optimum identification of water curtain hydraulic pressure using three-phase flow numerical simulation. Environ. Earth Sci. 2019, 78, 300. [Google Scholar] [CrossRef]

- Gao, X.F.; Zhang, Y.J.; Hu, Z.J.; Huang, Y. Numerical investigation on the influence of surface flow direction on the heat transfer characteristics in a granite single fracture. Appl. Sci. 2021, 11, 751. [Google Scholar] [CrossRef]

- Yamamoto, H.; Pruess, K. Numerical Simulations of Leakage from Underground LPG Storage Caverns. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2004. [Google Scholar]

- Shi, H.B. Analysis and Evaluation of Water Sealing Conditions and Surrounding Rock Stability of Underground Water-Sealed Caverns in Huangdao. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2010. [Google Scholar]

- Wang, T.; Yang, C.; Ma, H.; Daemen, J.; Wu, H. Safety evaluation of gas storage caverns located close to a tectonic fault. J. Nat. Gas. Sci. Eng. 2015, 23, 281–293. [Google Scholar] [CrossRef]

- Tan, L. Study on the Influence of Fractured Rock Mass Structure of a Groundwater-Sealed Cavern in Yantai on the Stability of Surrounding Rock and Water Sealing Conditions. Ph.D. Thesis, China University of Geosciences, Wuhan, China, 2021. [Google Scholar]

- Ren, F.; Ma, G.; Wang, Y.; Fan, L. Pipe network model for unconfined seepage analysis in fractured rock masses. Int. J. Rock. Mech. Min. 2016, 88, 183–196. [Google Scholar] [CrossRef]

- Ren, F.; Ma, G.; Wang, Y.; Fan, L.; Zhu, H. Two-phase flow pipe network method for simulation of CO2 sequestration in fractured saline aquifers. Int. J. Rock. Mech. Min. 2017, 98, 39–53. [Google Scholar] [CrossRef]

- Lin, F.; Ren, F.; Luan, H.; Ma, G.; Chen, S. Effectiveness analysis of water-sealing for underground LPG storage. Tunn. Undergr. Space Technol. 2016, 51, 270–290. [Google Scholar] [CrossRef]

- Javadi, M.; Sayadi, S. Stochastic discontinuum analysis of hydrocarbon migration probability around an unlined rock cavern based on the discrete fracture networks. Tunn. Undergr. Space Technol. 2018, 81, 41–54. [Google Scholar] [CrossRef]

- Wijeratne, D.E.N.; Halvorsen, B.M. Computational study of fingering phenomenon in heavy oil reservoir with water drive. Fuel 2015, 158, 306–314. [Google Scholar] [CrossRef]

- Vasheghani Farahani, M.; Foroughi, S.; Norouzi, S.; Jamshidi, S. Mechanistic study of fines migration in porous media using lattice Boltzmann method coupled with rigid body physics engine. J. Energy Resour. Technol. 2019, 141, 123001. [Google Scholar] [CrossRef]

- Movahedi, H.; Vasheghani Farahani, M.; Masihi, M. Development of a Numerical Model for Single-and Two-Phase Flow Simulation in Perforated Porous Media. J. Energy Resour. Technol. 2020, 142, 042901. [Google Scholar] [CrossRef]

- Brooks, R.H.; Corey, A.T. Hydraulic properties of porous media. In Hydrology Papers; Colorado State University: Fort Collins, CO, USA, 1964; pp. 1–27. [Google Scholar]

- Zhang, B.; Li, W.; Feng, F.; Wu, B.; Cao, X. Numerical simulation for fluid-solid coupling charateristics in surrounding rock of underground water-sealed oil storage based. J. Eng. Geol. 2012, 20, 789–795. [Google Scholar]

| Case | Fracture Permeability (kf)/m2 | Fracture Width (df)/mm | Fracture Inclination (θ)/(°) | Distance from Fracture to Middle Cavern (s)/m |

|---|---|---|---|---|

| 1 | 1.1 × 10−10 m2 | 0.1 | 60 | 0 |

| 2 | 1.1 × 10−11 m2 | |||

| 3 | 1.1 × 10−12 m2 | |||

| 4 | 1.1 × 10−13 m2 | |||

| 5 | 1.1 × 10−14 m2 | |||

| 6 | 1.1 × 10−12 m2 | 0.05 | 60 | 0 |

| 7 | 0.075 | |||

| 8 | 0.1 | |||

| 9 | 0.125 | |||

| 10 | 0.15 | |||

| 11 | 1.1 × 10−12 m2 | 0.1 | 40 | 0 |

| 12 | 50 | |||

| 13 | 60 | |||

| 14 | 70 | |||

| 15 | 80 | |||

| 16 | 1.1 × 10−12 m2 | 0.1 | 60 | 0 |

| 17 | 5 | |||

| 18 | 10 | |||

| 19 | 15 | |||

| 20 | 20 |

| No. of Fracture Group | Density | Inclination | Trail Length | ||

|---|---|---|---|---|---|

| Mean (Degree) | Standard Deviation (Degree) | Mean (mm) | Standard Deviation (mm) | ||

| 1 | 0.001 | 76 | 5 | 24 | 6.4 |

| 2 | 0.002 | 24 | 6 | 28 | 7.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, D.; Jian, H.; Song, M.; Jiang, Z. Migration of Leaked Oil Vapor in Underground Water-Sealed Oil Storage Cavern Considering the Influence of Fractures. J. Mar. Sci. Eng. 2023, 11, 1248. https://doi.org/10.3390/jmse11061248

Tang D, Jian H, Song M, Jiang Z. Migration of Leaked Oil Vapor in Underground Water-Sealed Oil Storage Cavern Considering the Influence of Fractures. Journal of Marine Science and Engineering. 2023; 11(6):1248. https://doi.org/10.3390/jmse11061248

Chicago/Turabian StyleTang, Dong, Huixiang Jian, Min Song, and Zhongming Jiang. 2023. "Migration of Leaked Oil Vapor in Underground Water-Sealed Oil Storage Cavern Considering the Influence of Fractures" Journal of Marine Science and Engineering 11, no. 6: 1248. https://doi.org/10.3390/jmse11061248

APA StyleTang, D., Jian, H., Song, M., & Jiang, Z. (2023). Migration of Leaked Oil Vapor in Underground Water-Sealed Oil Storage Cavern Considering the Influence of Fractures. Journal of Marine Science and Engineering, 11(6), 1248. https://doi.org/10.3390/jmse11061248