Experimental Study on Corrosion Development Model and Fatigue Performance of Strand Steel for Coastal Structures

Abstract

1. Introduction

2. Sample Preparation

3. Time-Varying Model of Steel Strand Corrosion

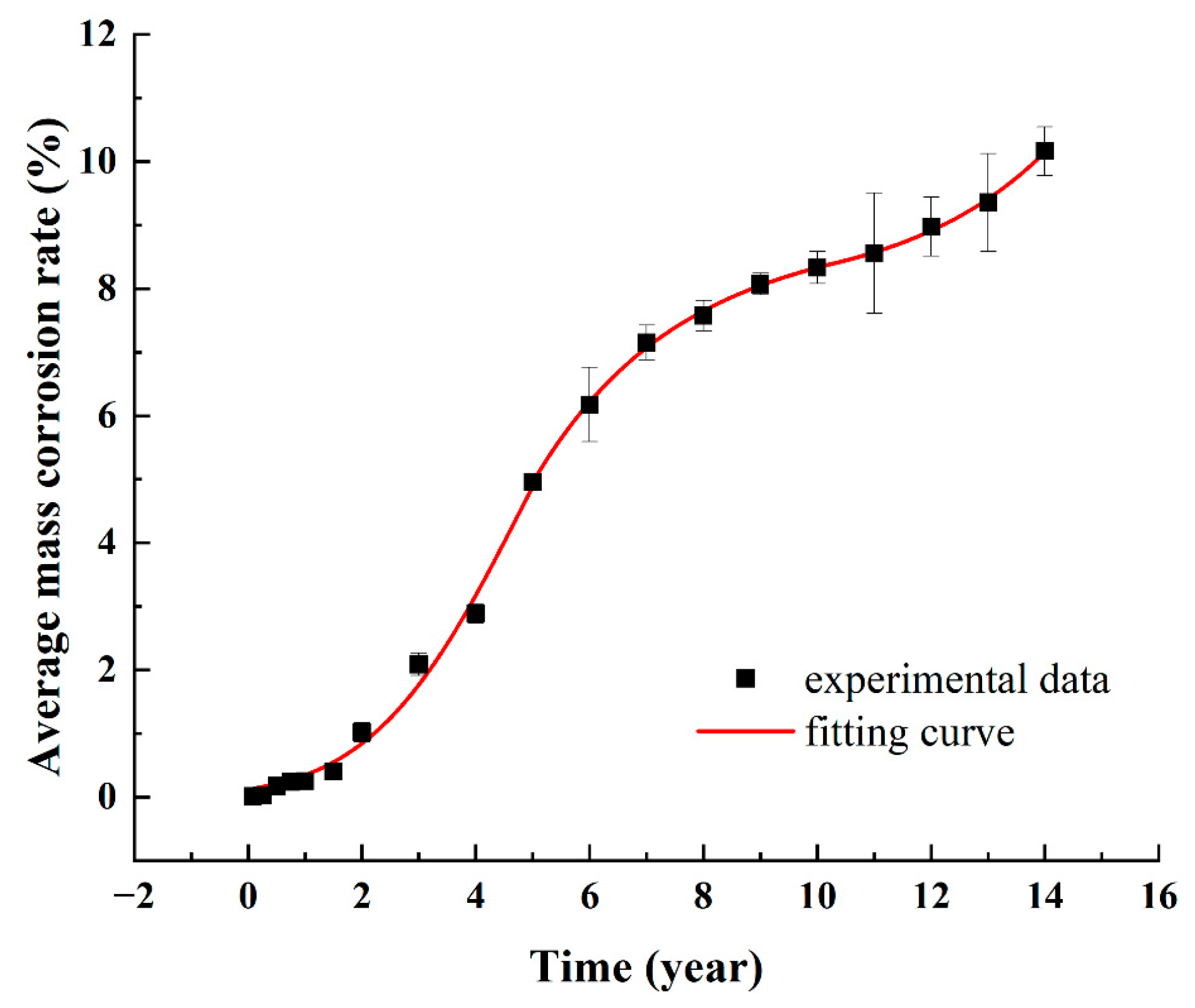

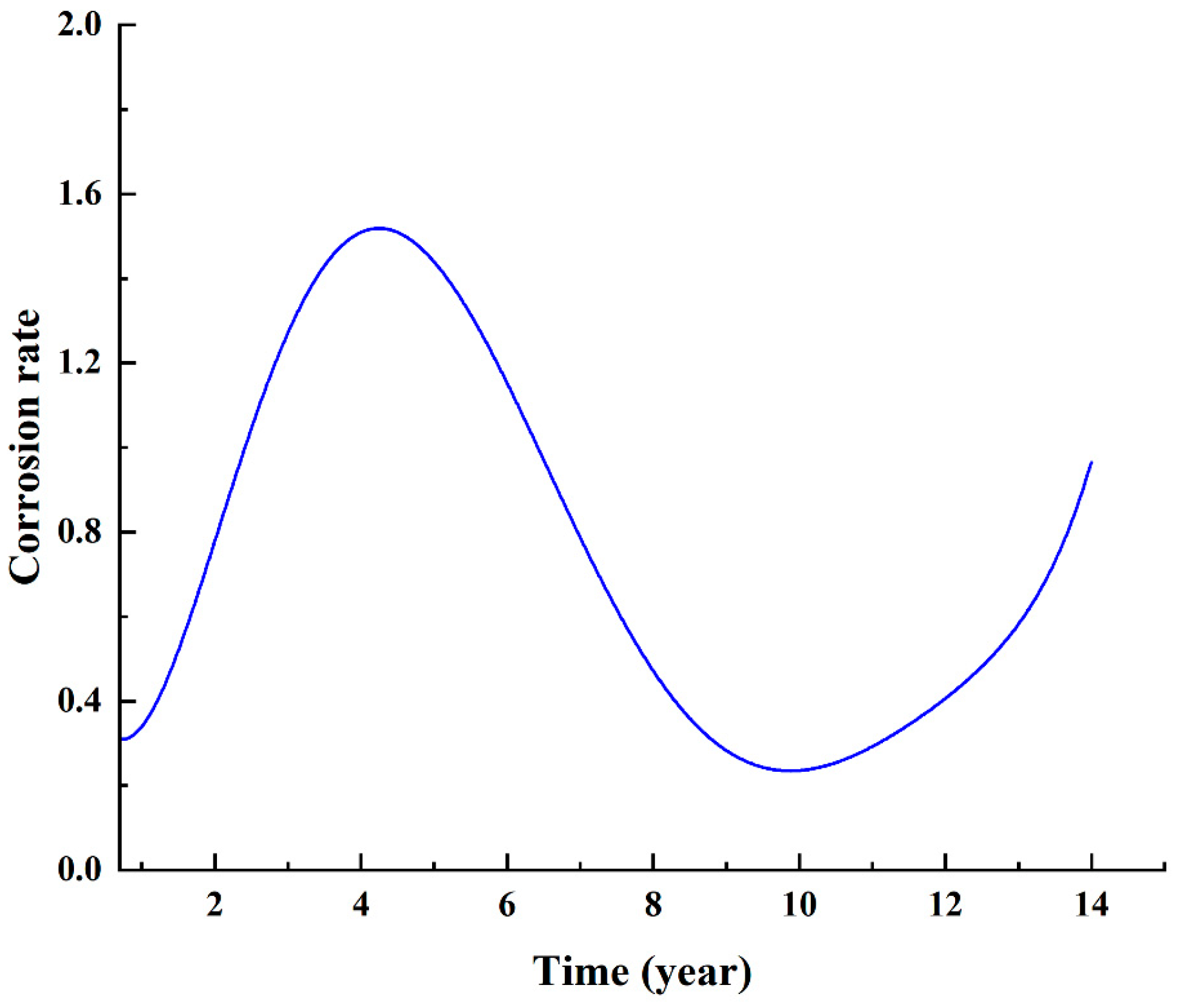

3.1. Time-Varying Model of Average Mass Corrosion Rate

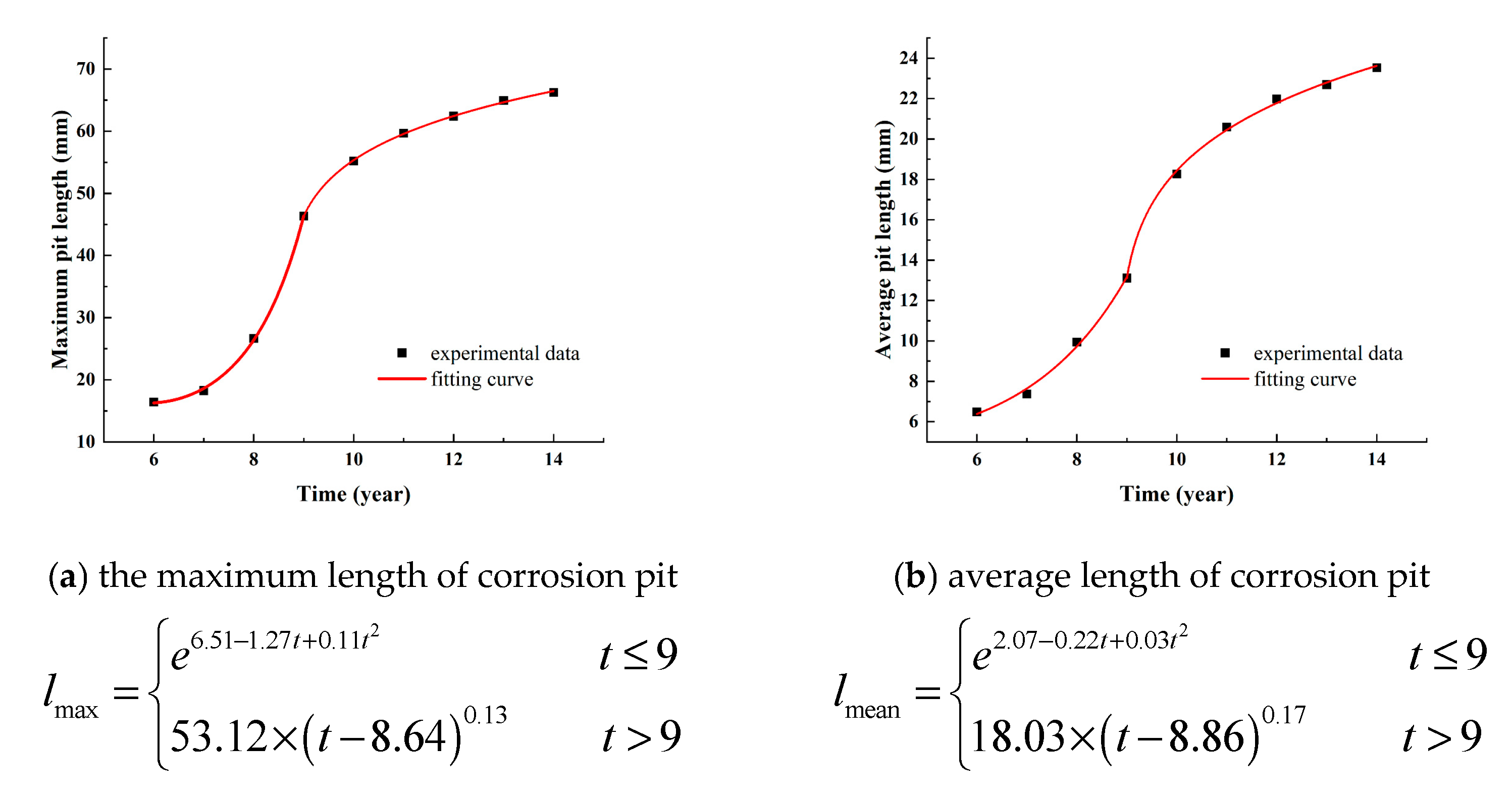

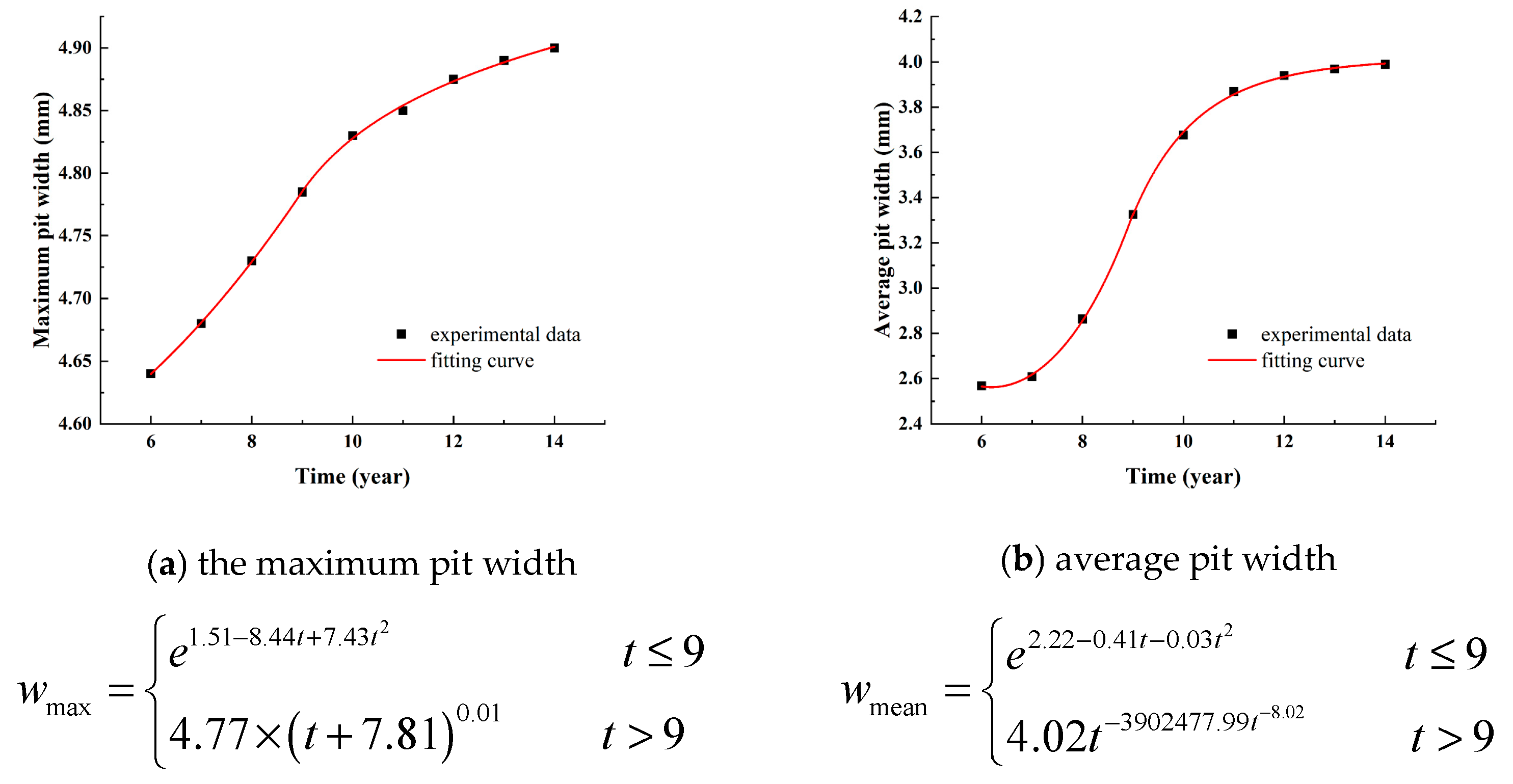

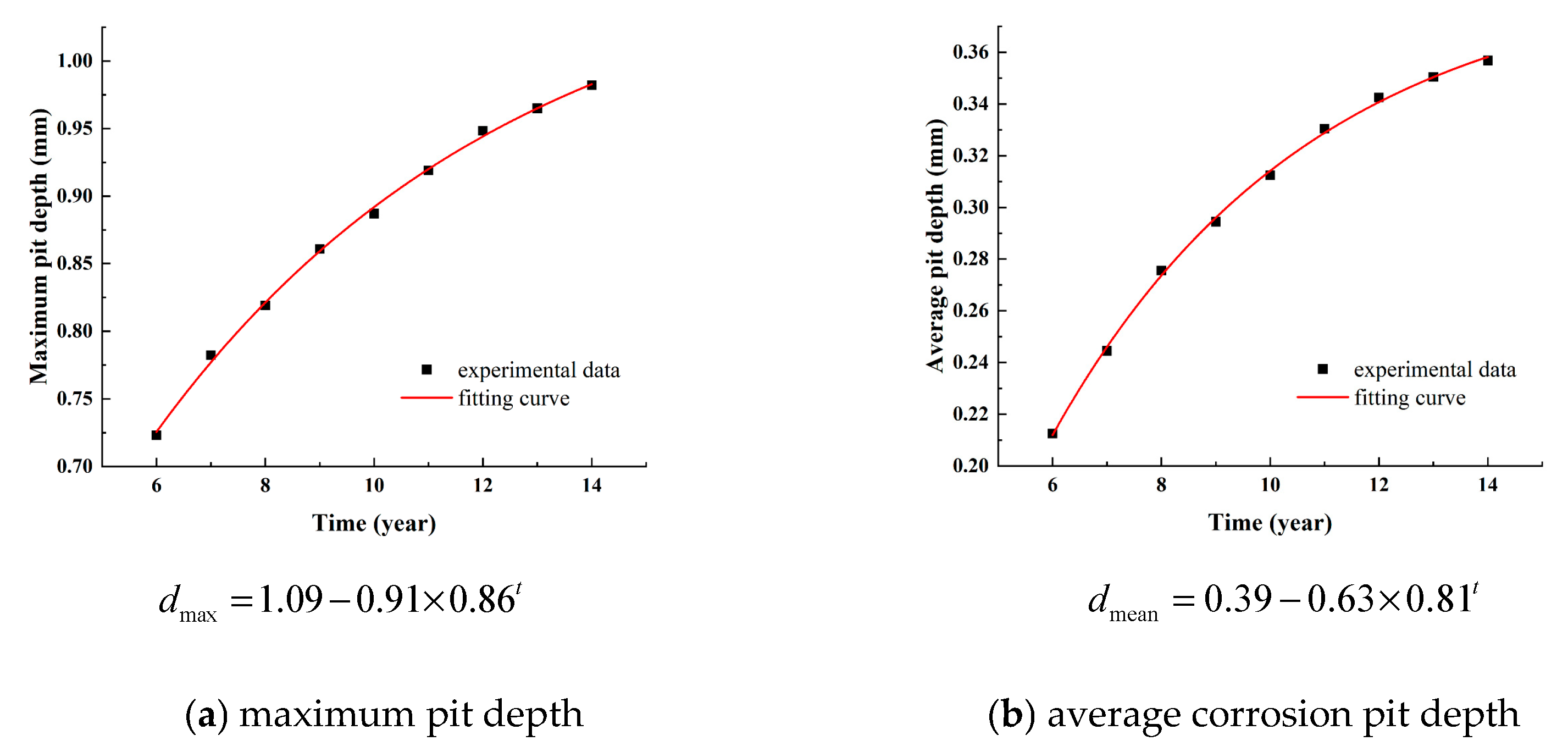

3.2. Time-Varying Model of Corrosion Pit

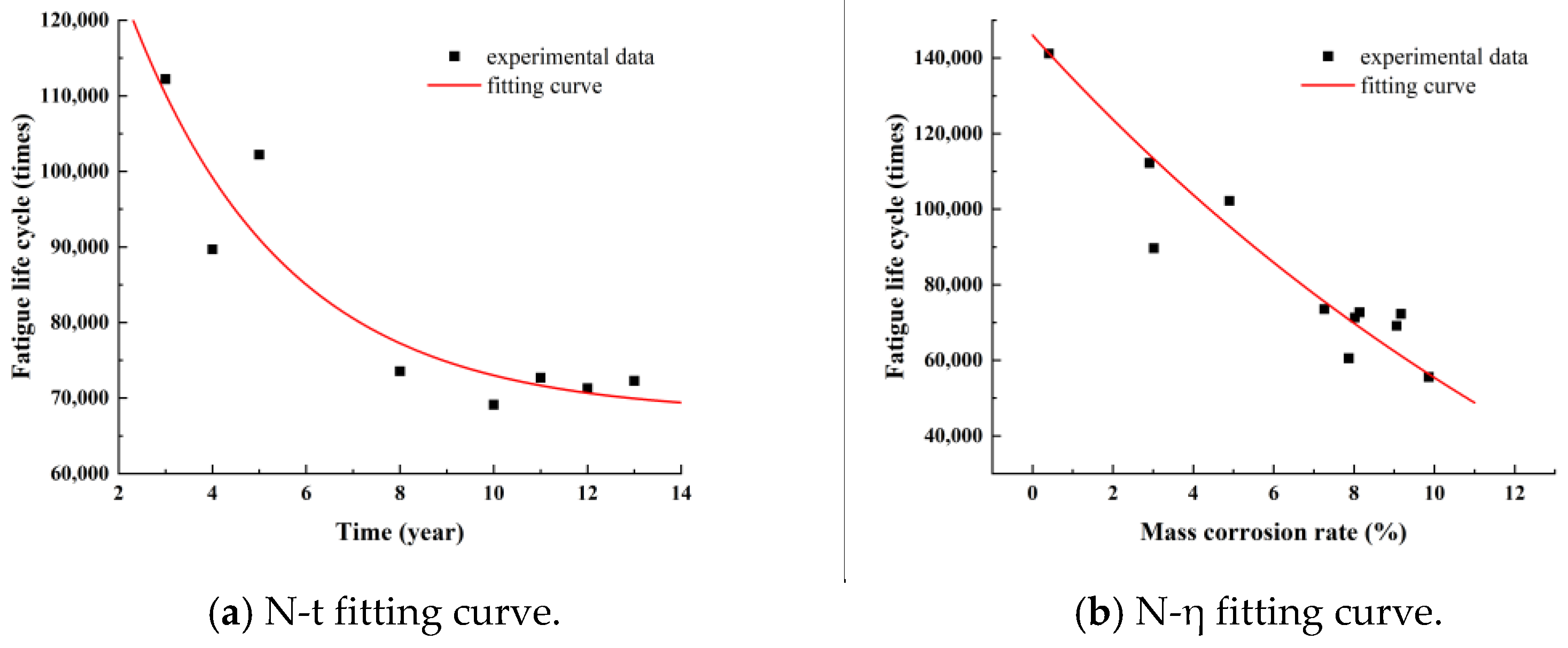

4. Experimental Study on Fatigue Performance of Corroded Steel Strand

4.1. Fatigue Test Equipment

4.2. Analysis of Test Data

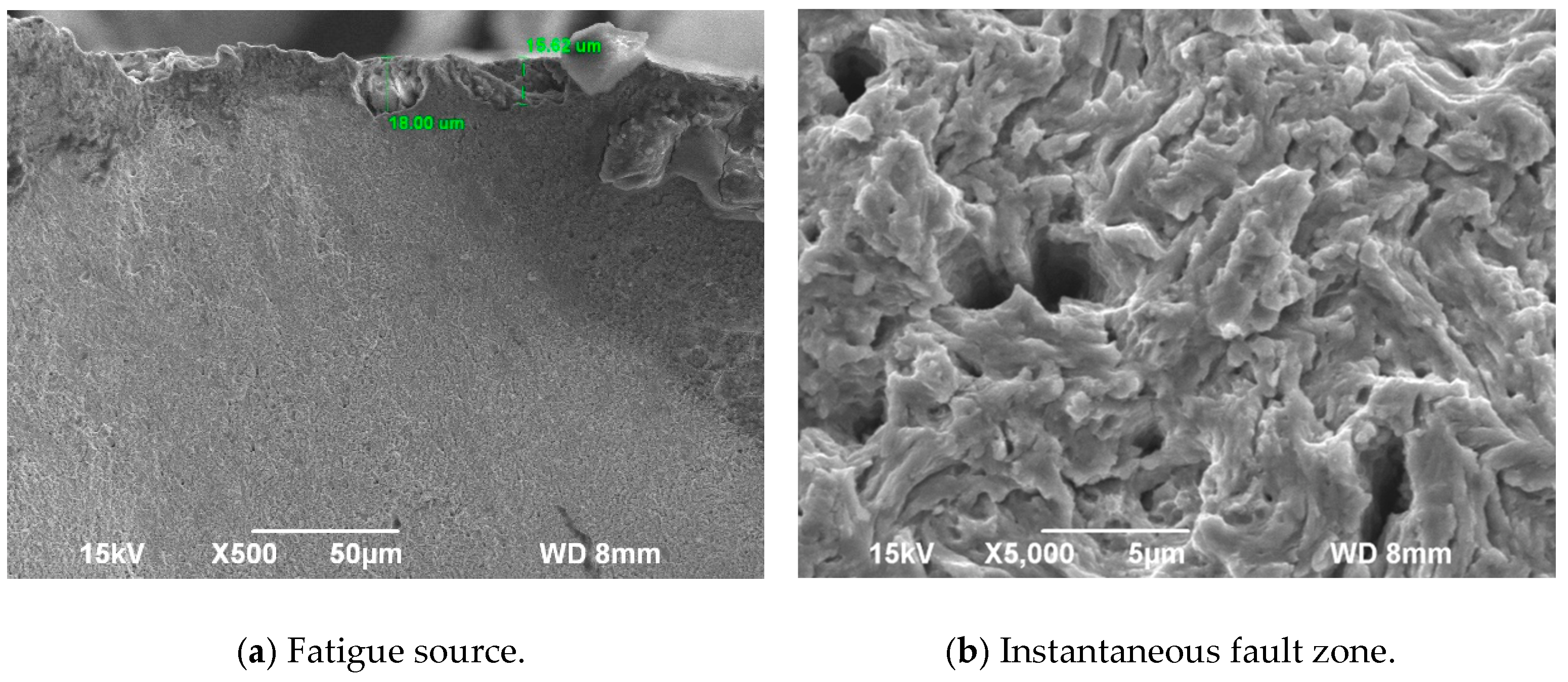

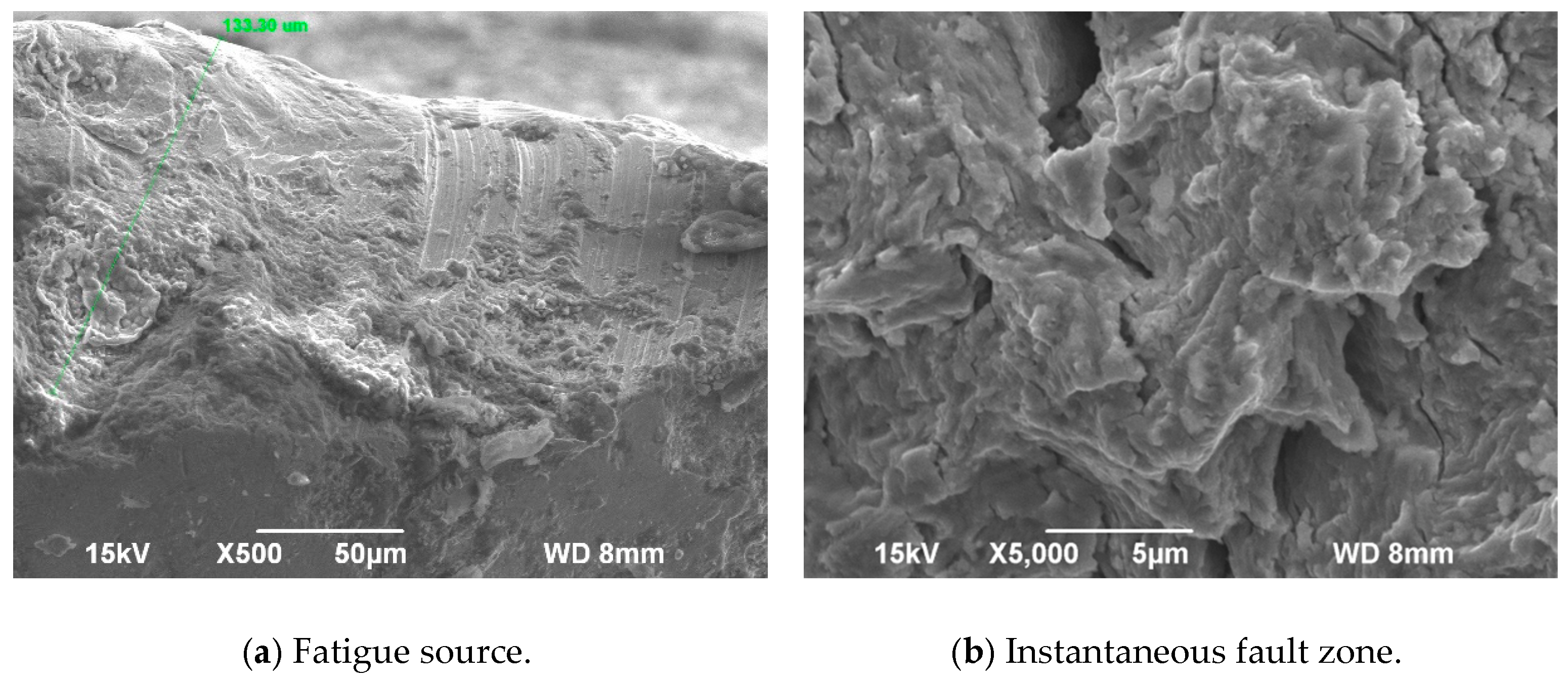

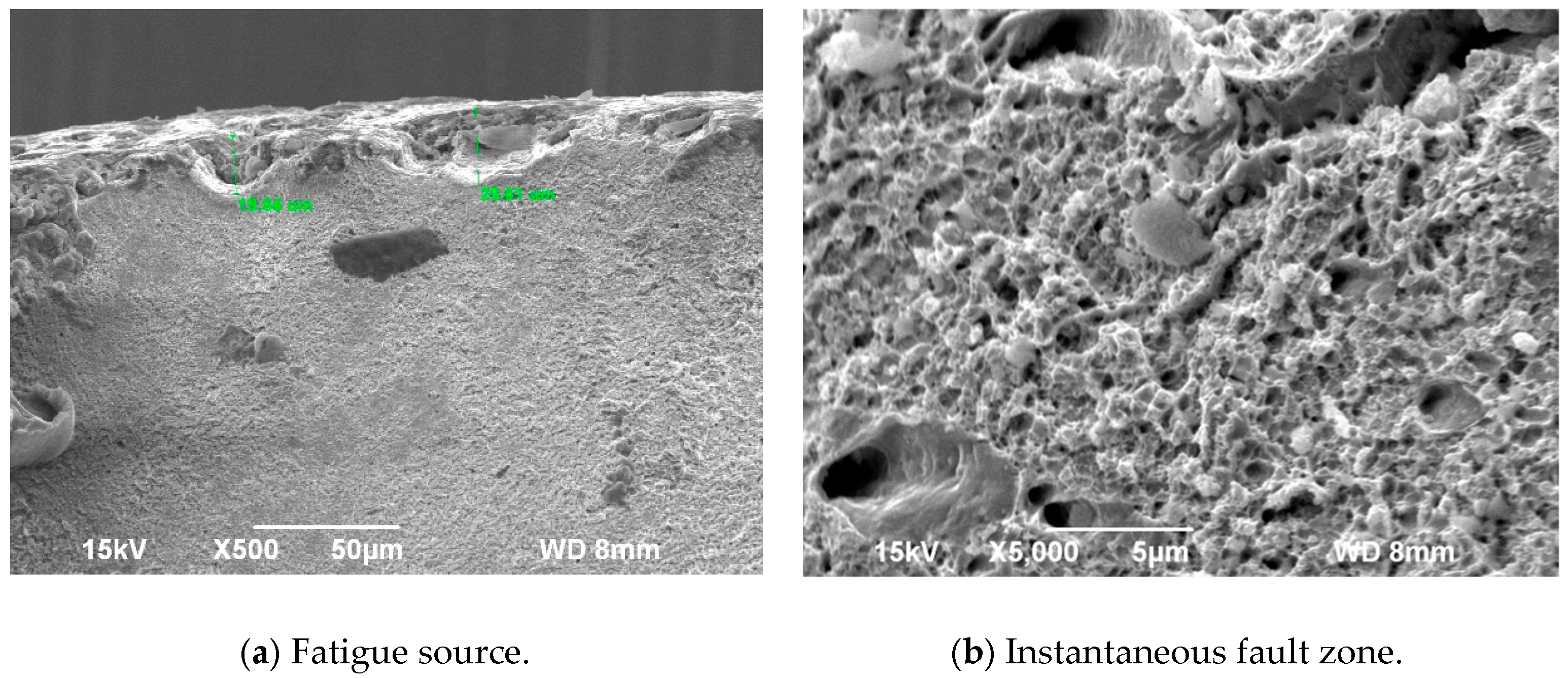

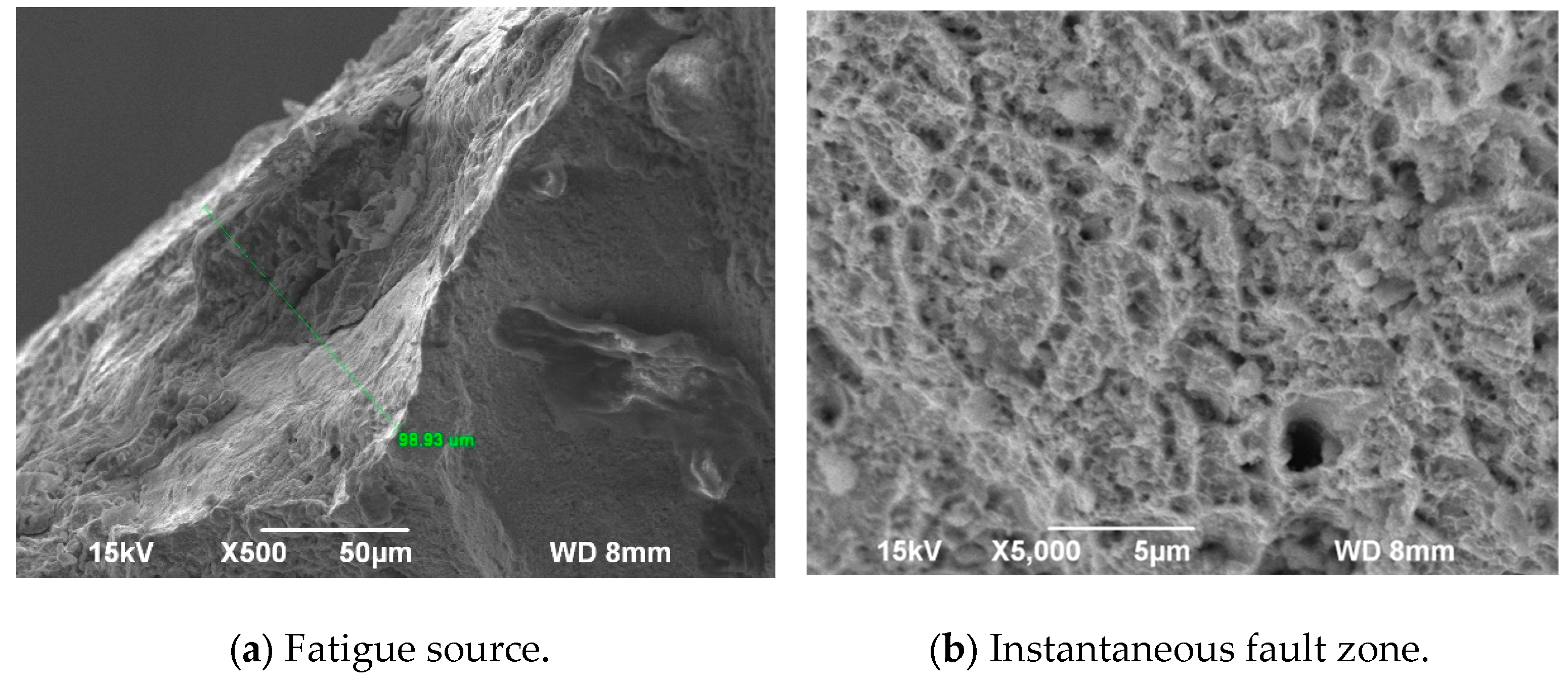

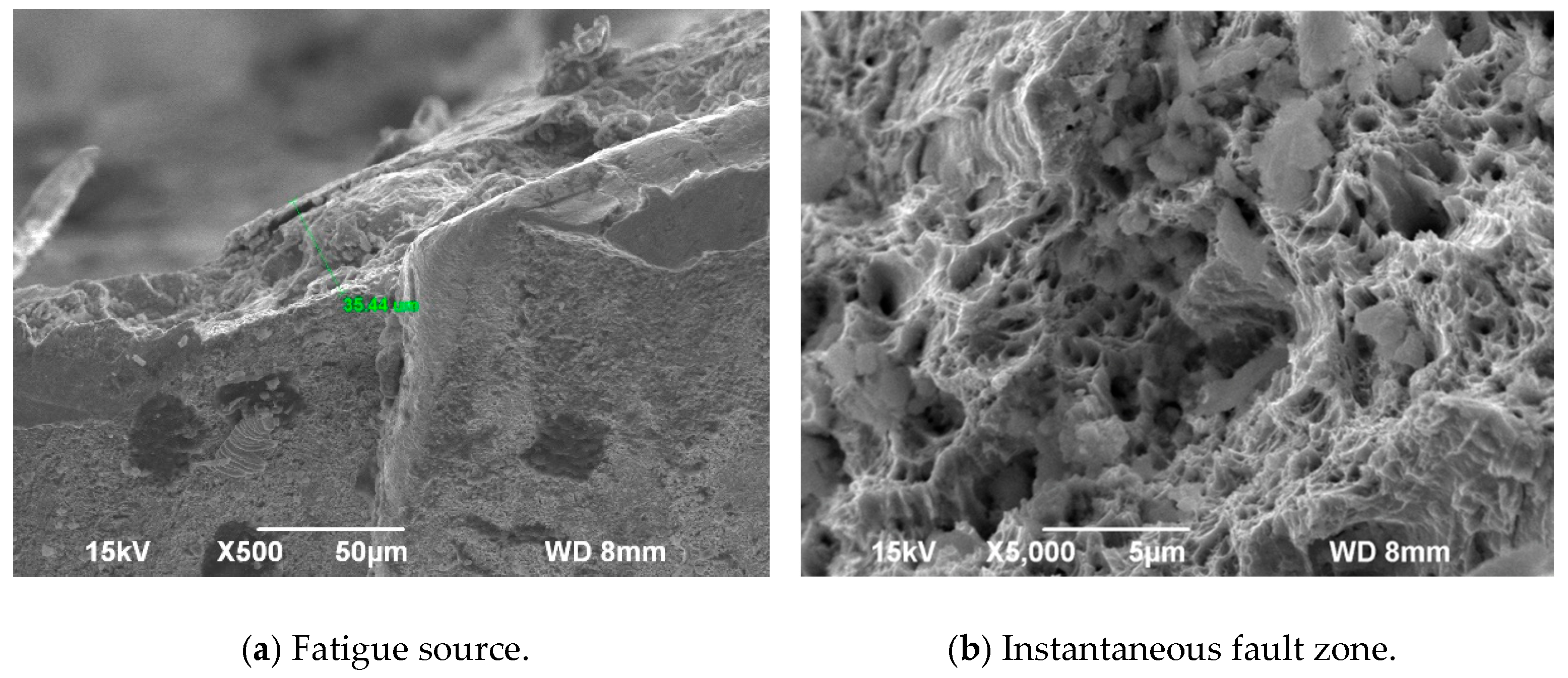

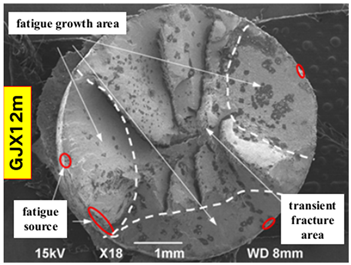

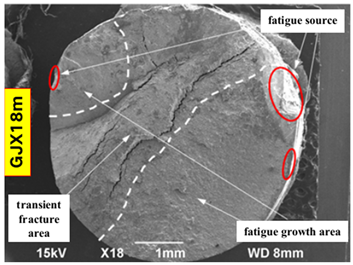

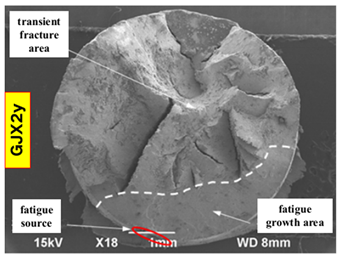

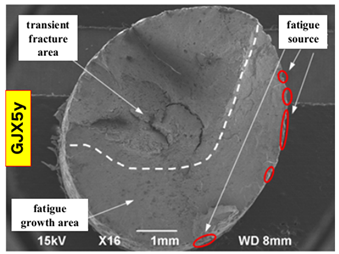

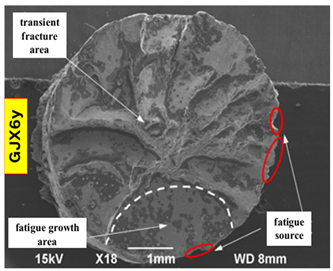

4.3. Scanning Electron Microscopy (SEM) Fracture Analysis

5. Conclusions

- (1)

- The fitting curve of the corrosion of steel strands in coastal environments is a piecewise function that can be used to predict the corrosion degree of exposed steel strands in the suspender after 15 years.

- (2)

- The size development of corrosion pits on the surface of steel strands has a certain relevance, but the corrosion development trend in three directions may be different at different time periods. With the increase in corrosion time, the corrosion time stops radially increasing at 8 years, and the depth and length of corrosion pits exhibit a nonlinear growth trend with time.

- (3)

- Fitting the fatigue life and service life of steel strands shows that the decline function of the fatigue performance with respect to the corrosion time is . The fitting curve for the corrosion degree is .

- (4)

- The higher the corrosion rate is, the lower the number of fatigue cycle times of the steel strand specimen is, indicating that the corrosion pit has a significant impact on the fatigue life of the steel strand. The existence of the corrosion pit will cause the fatigue life of the steel strand to drop compared with that of the intact steel strand.

- (5)

- The SEM results of fatigue ports show that multiple etch pits can initiate cracks in a single area, and a single etch pit can initiate cracks in multiple areas. Even if it is slightly rusted, as long as microscopic defects are formed on the surface of the steel strand, fatigue crack growth sources will be formed, and the probability of crack initiation at the defects will increase. With the gradual increase in the brittleness of the corroded steel strand, the plastic deformation increases and fatigue failure occurs.

- (6)

- In this study, fatigue fracturing was not analyzed by energy dispersive X-ray (EDAX), and there were no deep mechanistic studies. Therefore, the mechanism of fatigue fracture will be studied in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, R.; Miao, C.; Feng, Z.; Wei, T. Experimental study on the fatigue behavior of corroded steel wire. J. Constr. Steel Res. 2021, 176, 106375. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.L.; Shao, W.; Zhang, J.; Liao, S.; Manuel, T.F. Service life prediction and lateral bearing capacity analysis of piles considering coupled corrosion-Temperature deterioration Processes. J. Bridge Eng. 2021, 9, 614. [Google Scholar] [CrossRef]

- Melchers, R.E. Long-term durability of marine reinforced concrete structures. J. Mar. Sci. Eng. 2020, 8, 290. [Google Scholar] [CrossRef]

- Yu, X.R.; Yao, G.W.; Zhong, H.; Jiang, Y.X. Corrosion Characteristics and Mechanical Properties of Steel Strands under Coupling Effect of Alternating Load and Chloride Salt Environment. J. Build. Mater. 2021, 24, 1315–1321. [Google Scholar]

- Yue, J.X.; Lei, J.K.; Garbatov, Y.; Yang, K. Crack growth in Ni-Cr-Mo-V steel using ΔCTOD elastic–plastic model. J. Mar. Sci. Eng. 2022, 10, 1944. [Google Scholar] [CrossRef]

- Ren, X.; Sherif, M.; Wei, Y.Y.; Lyu, Y.H.; Sun, Y.; Ozbulut, O. Effect of corrosion on the tensile and fatigue performance of CFRP strand Sheet/Steel double strap joints. Eng. Struct. 2022, 260, 114240. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, C.; Cai, C.S.; Jiang, X.; Xiong, W. Corrosion fatigue analysis of stay cables under combined loads of random traffic and wind. Eng. Struct. 2020, 206, 110153. [Google Scholar] [CrossRef]

- Li, S.L.; Xu, Y.; Li, H.; Guan, X. Uniform and pitting corrosion modeling for high-strength bridge wires. J. Bridge Eng. 2014, 19, 04014025. [Google Scholar] [CrossRef]

- Jeon, C.H.; Nguyen, C.D.; Shim, C.S. Assessment of Mechanical Properties of Corroded Prestressing Strands. Appl. Sci. 2020, 10, 24055. [Google Scholar] [CrossRef]

- Oktavianus, Y.; Sofi, M.; Lumantarna, E.; Kusuma, G.; Duffield, C. Long-term performance of trestle bridges: Case study of an indonesian marine port structure. J. Mar. Sci. Eng. 2020, 8, 358. [Google Scholar] [CrossRef]

- Yu, F.; Jia, J.Q.; Yao, D.L.; Wu, F. Experimental analysis of fatigue properties of corroded prestressing strands. J. Harbin Eng. Univ. 2014, 35, 1487–1491; 1502. [Google Scholar]

- Nakamura, S.; Suzumura, K. Experimental study on fatigue strength of corroded bridge wires. J. Bridge Eng. 2013, 18, 200–209. [Google Scholar] [CrossRef]

- Kim, S.T.; Yoon, H.; Park, Y.H.; Jin, S.S.; Shin, S.; Yoon, S.M. Smart Sensing of PSC Girders Using a PC Strand with a Built-in Optical Fiber Sensor. Appl. Sci. 2021, 11, 359. [Google Scholar] [CrossRef]

- Li, H.; Ju, Y.; Li, D.S. Experimental and Numerical Study of the Fatigue Properties of Corroded Parallel Wire Cables. J. Bridge Eng. 2012, 17, 211–220. [Google Scholar] [CrossRef]

- Jeon, C.H.; Shim, C.S. flexural behavior of post-tensioned concrete beams with multiple internal corroded strands. Appl. Sci. 2020, 10, 7994. [Google Scholar] [CrossRef]

- Du, Y.; Sun, Y.K.; Li, G.Q. Mechanical Properties of High Tensile Steel Cables at Elevated Temperature. Eng. Mech. 2019, 40, 472–476. [Google Scholar] [CrossRef]

- Yu, X.R.; Yao, G.W.; Gu, L.F.; Fan, W.Q. Numerical and Experimental Study on the Steel Strands under the Coupling Effect of a Salt Spray Environment and Cyclic Loads. Materials 2020, 13, 736. [Google Scholar] [CrossRef]

- Hu, Z.W.; Jia, J.; Peng, W. Equivalent Relationship of Accelerated Corrosion of Bridge Hangers in Coastal Corrosion Environment. Bull. Sci. Technol. 2020, 36, 22–26. [Google Scholar]

- Li, S.L.; Zhu, S.Y.; Xu, Y.L.; Chen, Z.W.; Li, H. Long-term condition assessment of suspenders under traffic loads based on structural monitoring system: Application to the Tsing Ma Bridge. Struct. Control Health Monit. 2012, 19, 82–101. [Google Scholar] [CrossRef]

- Cetin, A.; Naess, A. Toward a proper statistical description of defects. Int. J. Fatigue 2012, 38, 100–107. [Google Scholar] [CrossRef]

- Chai, G.; Zhou, N.; Ciurea, S.; Andersson, M.; Peng, R.L. Local plasticity exhaustion in a very high cycle fatigue regime. Scr. Mater. 2012, 66, 769–772. [Google Scholar] [CrossRef]

- Xu, J.Q. Mechanics of Fatigue; China Science Publishing: Beijing, China, 2017. [Google Scholar]

- Liu, X.L.; Zhang, Z.; Tao, C.H. Fatigue Fractography Quantitative Analysis; National Defense Industry Press: Beijing, China, 2010. [Google Scholar]

| No. | Batch | Experiment Times/Years | Number of Test Samples |

|---|---|---|---|

| 1 | GJX1m | 1/12 | 3 |

| 2 | GJX3m | 3/12 | 3 |

| 3 | GJX6m | 6/12 | 3 |

| 4 | GJX9m | 9/12 | 3 |

| 5 | GJX1y | 1 | 3 |

| 6 | GJX18m | 1.5 | 3 |

| 7 | GJX2y | 2 | 3 |

| 8 | GJX3y | 3 | 3 |

| 9 | GJX4y | 4 | 3 |

| 10 | GJX5y | 5 | 3 |

| 11 | GJX6y | 6 | 3 |

| 12 | GJX7y | 7 | 3 |

| 13 | GJX8y | 8 | 6 |

| 14 | GJX9y | 9 | 6 |

| 15 | GJX10y | 10 | 6 |

| 16 | GJX11y | 11 | 6 |

| 17 | GJX12y | 12 | 6 |

| 18 | GJX13y | 13 | 6 |

| 19 | GJX14y | 14 | 6 |

|  |  |  |  |

| Before rusting | GJX1m | GJX3m | GJX6m | GJX9m |

|  |  |  |  |

| GJX1y | GJX18m | GJX2y | GJX3y | GJX4y |

| Fatigue Fracture | Characterization |

|---|---|

| This fracture is formed after the outer steel wire breaks off from the non-clamped section. It belongs to the multi-step fatigue fracture with multiple fatigue sources. Three main fatigue crack growth areas can be observed. The middle transient fracture area is stepped and surrounded by three main fatigue growth areas. |

| The fracture is formed after the fracture of the outer steel wire in the clamping section, which belongs to the step fracture with multiple fatigue sources. It is divided into primary and secondary fatigue crack growth zones. The middle transient fracture zone is stepped, and the two growth zones are on both sides of the transient fracture zone and do not intersect. |

| The fracture is formed after the fracture of the outer steel wire in the non-clamped section, which belongs to the step fracture with multiple fatigue sources. There is a large defect and the main fatigue growth zone, and there are still many small defects around them. The transient fault zone has steps, and their distribution is relatively disordered and irregular. |

| This fracture is formed when the central steel wire of the steel strand first breaks. It is a stepped fracture with multiple fatigue sources. The apparent main fatigue crack propagation zone can be seen. The transient fracture zone is in the middle of the section and is in the form of steps. |

| This fracture is caused by the fracture of the non-clamped section of the outer steel wire, which belongs to the step-type fracture with multiple fatigue sources. There are multiple fatigue growth zones, but finally, they converge into a main crack growth zone. The transient fracture zone has a step shape, and the fatigue source is apparent. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, W.; Fan, W. Experimental Study on Corrosion Development Model and Fatigue Performance of Strand Steel for Coastal Structures. J. Mar. Sci. Eng. 2023, 11, 665. https://doi.org/10.3390/jmse11030665

Peng W, Fan W. Experimental Study on Corrosion Development Model and Fatigue Performance of Strand Steel for Coastal Structures. Journal of Marine Science and Engineering. 2023; 11(3):665. https://doi.org/10.3390/jmse11030665

Chicago/Turabian StylePeng, Wei, and Weijie Fan. 2023. "Experimental Study on Corrosion Development Model and Fatigue Performance of Strand Steel for Coastal Structures" Journal of Marine Science and Engineering 11, no. 3: 665. https://doi.org/10.3390/jmse11030665

APA StylePeng, W., & Fan, W. (2023). Experimental Study on Corrosion Development Model and Fatigue Performance of Strand Steel for Coastal Structures. Journal of Marine Science and Engineering, 11(3), 665. https://doi.org/10.3390/jmse11030665