Effect of Speed and Hull Length on the Hydrodynamic Performance of a Semi-Planing Hull of a Shallow-Draft Watercraft

Abstract

:1. Introduction

2. Verification Study with Experimental Results Using Hull 2743 from Series 50

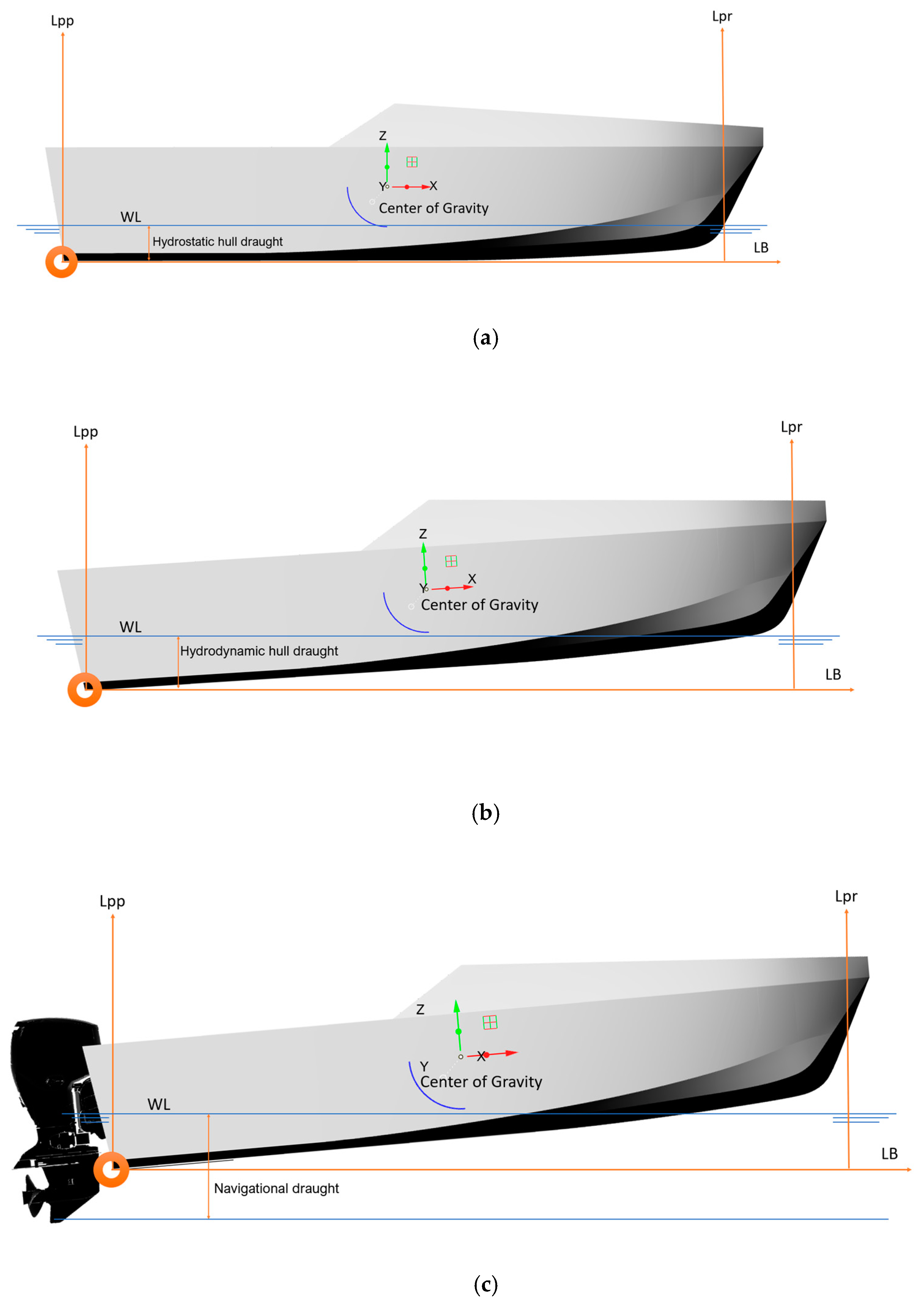

3. Hypotheses for Reducing the Draft of the Case Study

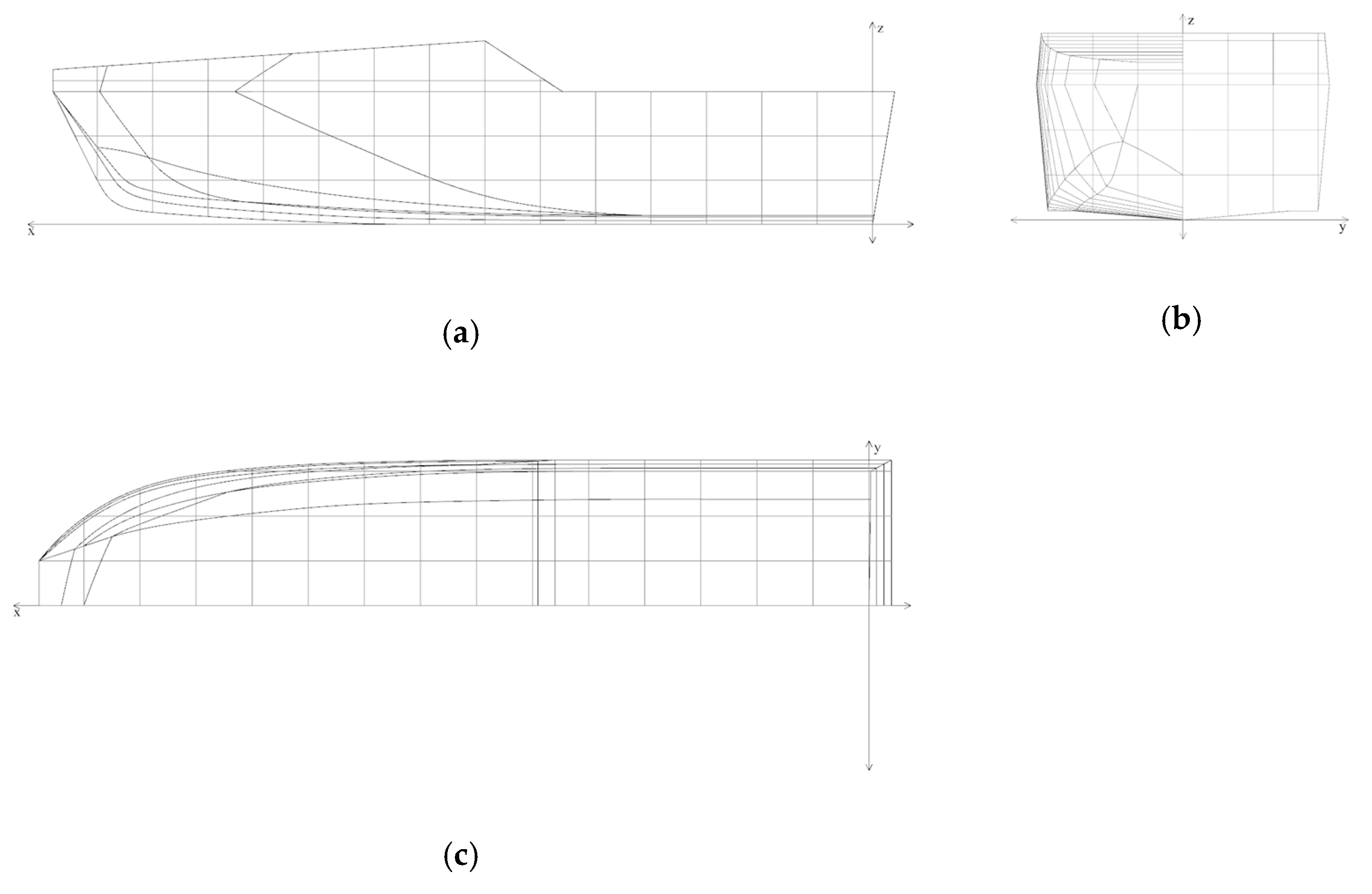

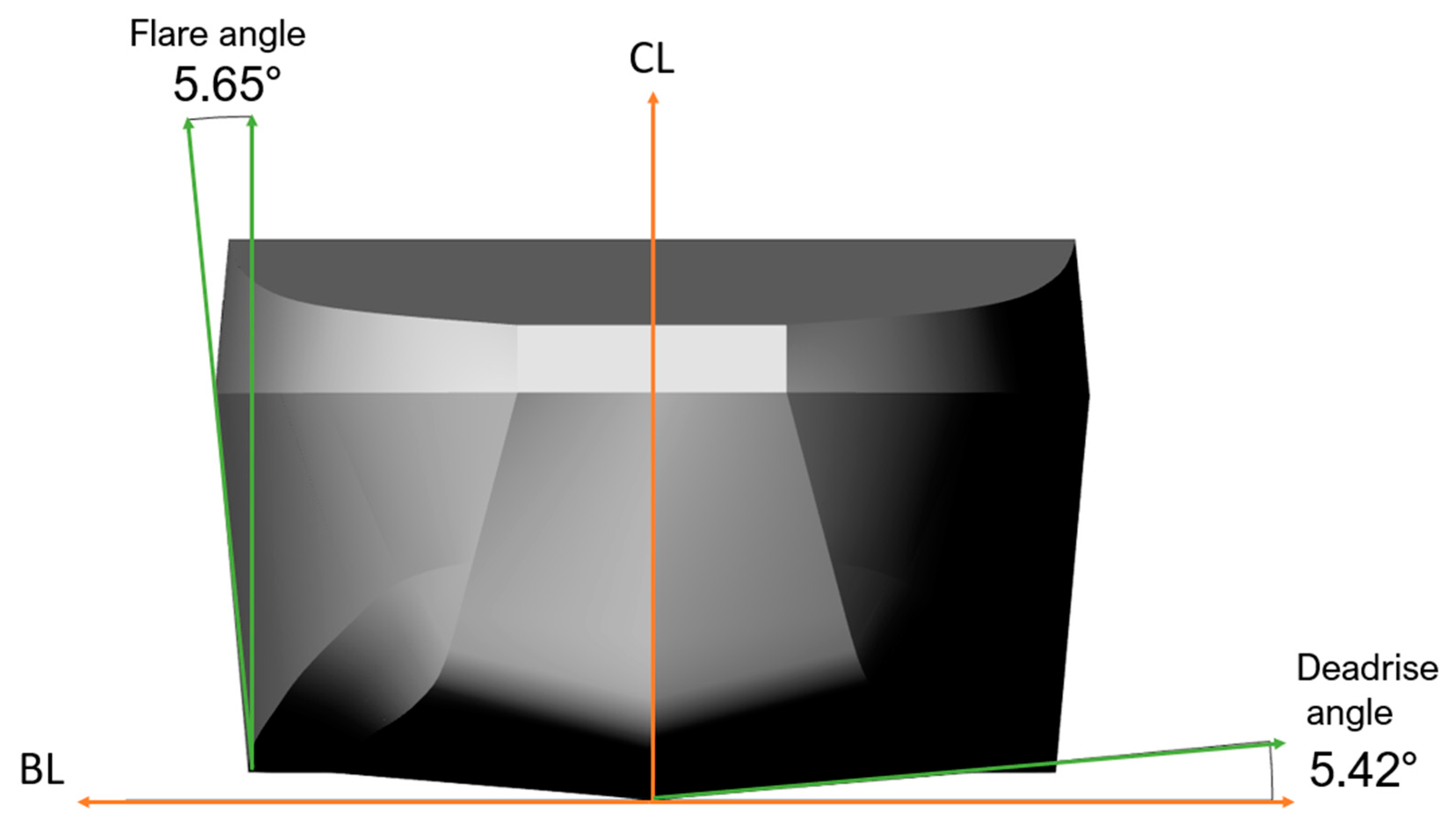

4. Case Study

5. Implemented Methodology

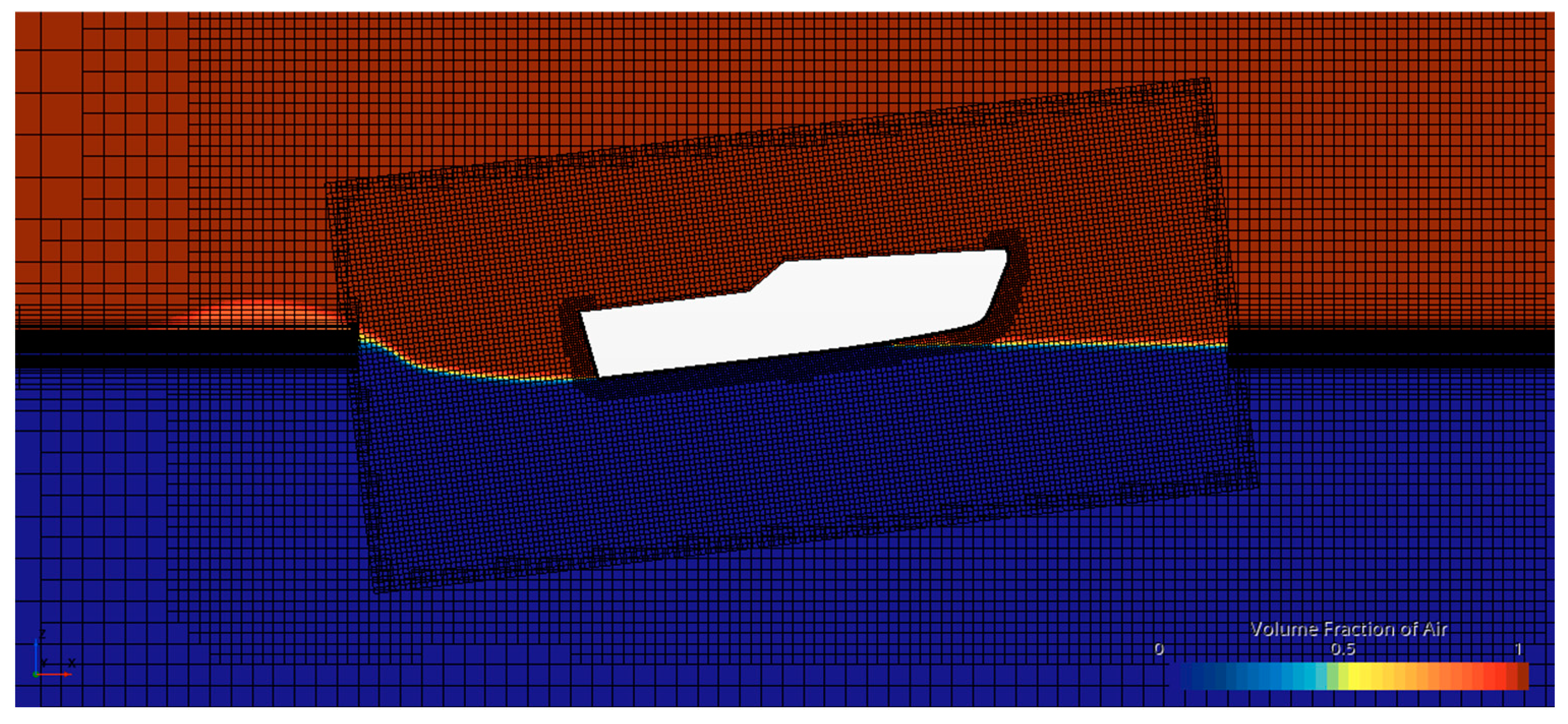

5.1. Numerical Methods

5.2. Boundary Conditions of the Model

- Inlet (velocity inlet): This represents the part through which the flow passes from the start (towards the bow of the hull) to the end (towards the stern of the hull—see Figure 6). Input turbulence parameters were the turbulence intensity and turbulent viscosity ratio, set at 0.01% and 10, respectively.

- Outlet (pressure outlet): This represents the location where the flow exits the domain and is defined as a pressure outlet boundary. It represents the plane located toward the stern of the watercraft with a normal direction in the negative x-axis.

- Side and Top (slip wall): The side and top of the domain were defined as a slip wall boundary condition, allowing the flow to move along the boundary. Therefore, the velocity at this location is not zero.

- Bottom (no-slip wall): The bottom of the domain was defined as a no-slip wall boundary condition.

- Symmetry Plane: Calm water conditions with no wave reflections were assumed. For this reason, it was possible to implement a symmetry plane boundary condition so that only half of the domain was simulated.

- Vessel Wall: The watercraft is represented by a wall element that prevents the flow from passing through it and takes the shape of the craft. This allows the analysis of the fluid that passes outside of the watercraft but not the watercraft itself.

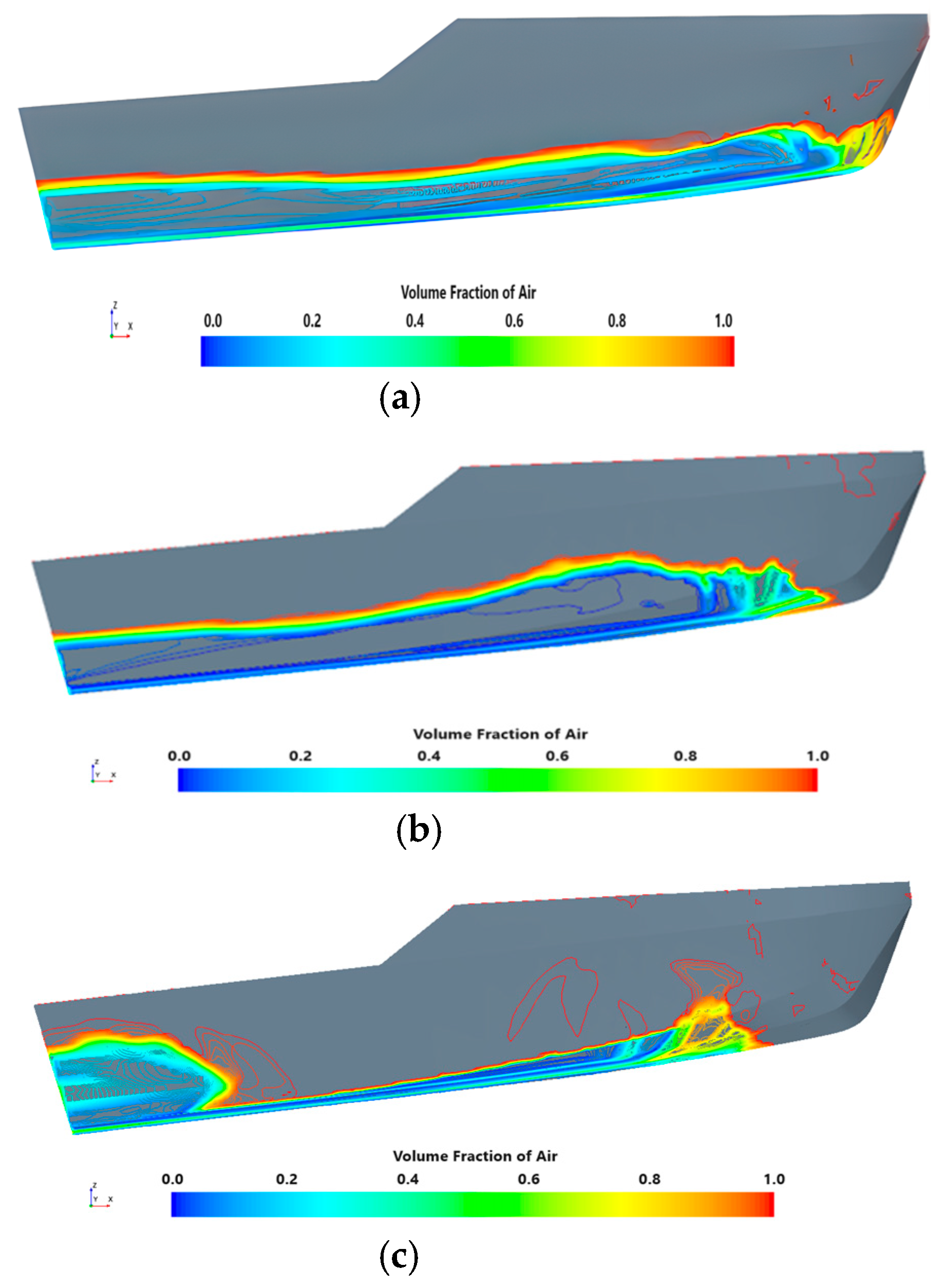

- Free Surface: This boundary is defined as an isosurface in STAR-CCM+ where the volume fraction of air is assumed to be 0.5.

5.3. Mesh Independence Analysis

5.4. Initial Conditions of the Computational Model

5.5. Meshing Approach

6. Results

6.1. Verification of Study Results

6.2. Mesh Independence Analysis Results

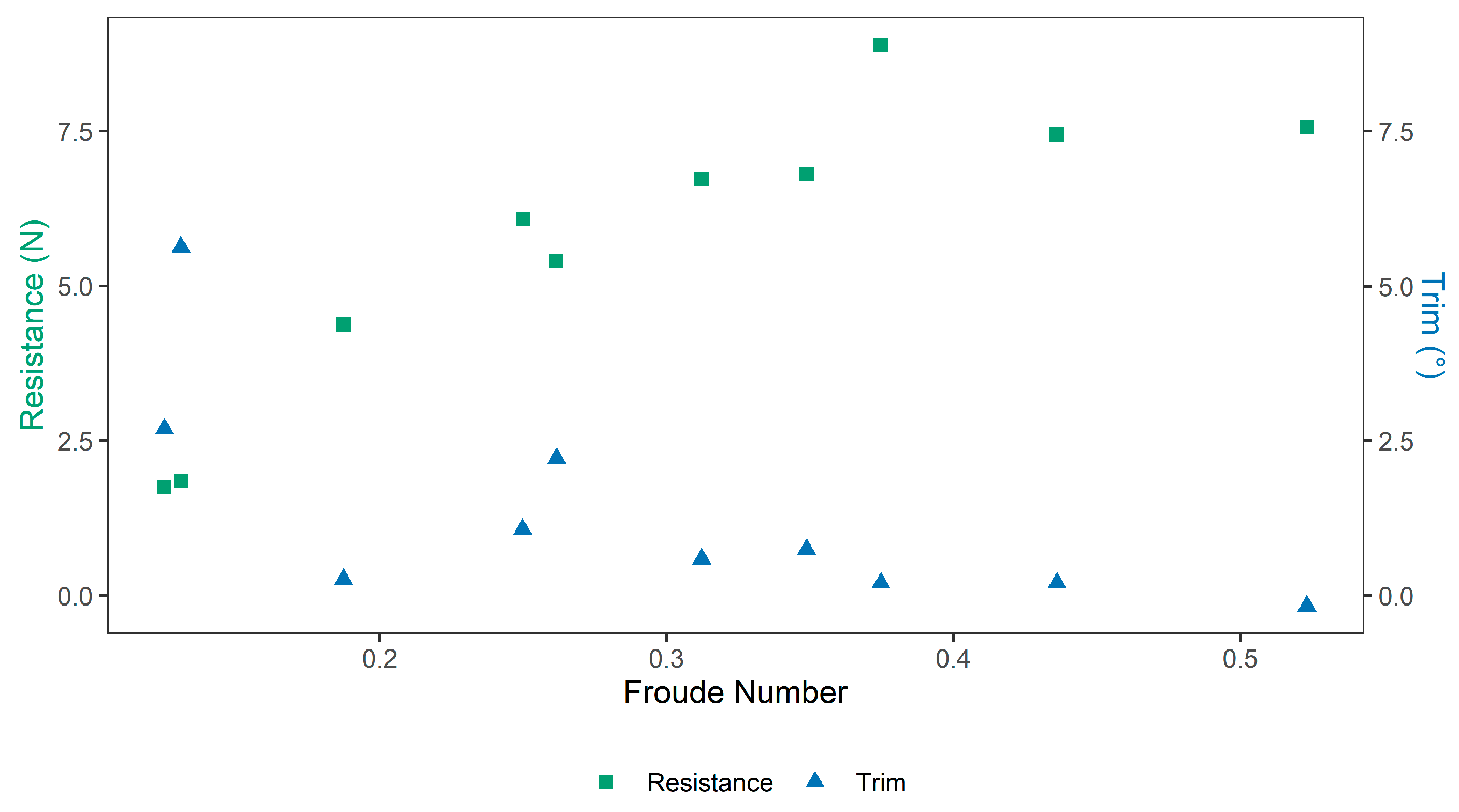

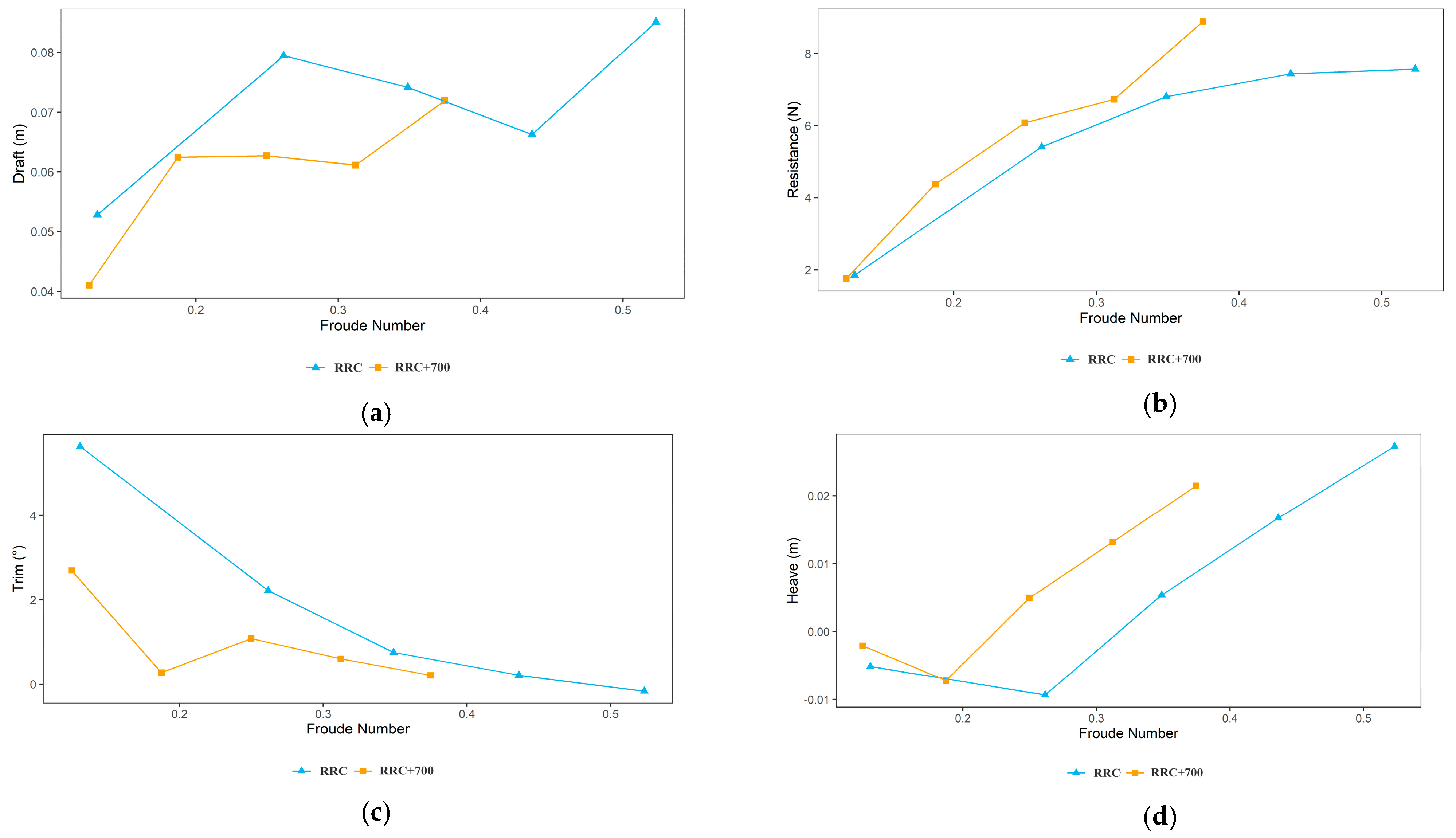

6.3. Results and Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| B/T | Beam-to-draft ratio |

| CAD | Computer-aided design |

| CFD | Computational fluid dynamics |

| ITTC | International Towing Tank Conference |

| LCG | Longitudinal center of gravity |

| RRC | River reconnaissance craft |

| URANS | Unsteady Reynolds-averaged Navier–Stokes |

References

- Camargo-Díaz, C.P.; Paipa-Sanabria, E.; Zapata-Cortes, J.A.; Briceño-Chaves, A.M.; Serna-Castaño, C.F. Review of Financing Mechanisms to Promote Decarbonization Alternatives in Rail and Inland Waterway Transport. Sustain. Sci. Pract. Policy 2023, 15, 966. [Google Scholar] [CrossRef]

- Wiegmans, B.; Konings, R. Inland Waterway Transport: Challenges and Prospects; Routledge: London, UK, 2016; ISBN 978-1-31757-566-5. [Google Scholar]

- De Barros, B.R.C.; De Carvalho, E.B.; Brasil Junior, A.C.P. Inland Waterway Transport and the 2030 Agenda: Taxonomy of Sustainability Issues. Clean. Eng. Technol. 2022, 8, 100462. [Google Scholar] [CrossRef]

- Hernández, A.E.; Macías, H.A. Los Intereses Nacionales Marítimos y Fluviales En Colombia. In Identidad e Intereses Nacionales de Colombia; Pastrana Buelvas, E., Reith, S., Cabrera Ortiz, F., Eds.; Fundación Konrad Adenauer y Escuela Superior de Guerra: Buenos Aires, Argentina, 2020; pp. 403–434. [Google Scholar]

- Ministerio de Transporte. Plan Maestro Fluvial de Colombia 2015; Ministerio de Transporte: Bogotá, Colombia, 2015.

- Schweighofer, J. The Impact of Extreme Weather and Climate Change on Inland Waterway Transport. Nat. Hazards 2014, 72, 23–40. [Google Scholar] [CrossRef]

- Pedersen, P.T. Review and Application of Ship Collision and Grounding Analysis Procedures. Mar. Struct. 2010, 23, 241–262. [Google Scholar] [CrossRef]

- Prakash, M.N.S.; Chandra, B. Numerical Estimation of Shallow Water Resistance of a River-Sea Ship Using CFD. Int. J. Comput. Appl. 2013, 71, 33–40. [Google Scholar]

- Alvarado, D.; Flores, E.; Paipa, E. Design and Validation by the Finite Element Method of the Structural Arrangement of a Riverine Low Draft Combat Boat. Ship Sci. Technol. 2021, 15, 21–35. [Google Scholar] [CrossRef]

- Campbell, R.; Terziev, M.; Tezdogan, T.; Incecik, A. Computational Fluid Dynamics Predictions of Draught and Trim Variations on Ship Resistance in Confined Waters. Appl. Ocean Res. 2022, 126, 103301. [Google Scholar] [CrossRef]

- Du, P.; Ouahsine, A.; Sergent, P.; Hu, H. Resistance and Wave Characterizations of Inland Vessels in the Fully-Confined Waterway. Ocean Eng. 2020, 210, 107580. [Google Scholar] [CrossRef]

- Mucha, P.; El Moctar, O.; Dettmann, T.; Tenzer, M. An Experimental Study on the Effect of Confined Water on Resistance and Propulsion of an Inland Waterway Ship. Ocean Eng. 2018, 167, 11–22. [Google Scholar] [CrossRef]

- Gómez Franco, A.; Montes Galván, O. Cálculos de Estabilidad de una Embarcación Rápida a Grandes Velocidades; Universitat Politècnica de Catalunya, Facultat de Nàutica de Barcelona, Departament de Ciència i Enginyeria Nàutiques: Barcelona, Spain, 2011; Enginyeria Tècnica Naval, especialitat en Propulsió i Serveis del Vaixell. [Google Scholar]

- Faltinsen, O.M. Hydrodynamics of High-Speed Marine Vehicles; Cambridge University Press: Cambridge, MA, USA, 2006; ISBN 978-0-52184-568-7. [Google Scholar]

- Barrass, C.B. (Ed.) Chapter 17—Ship Squat in Open Water and in Confined Channels. In Ship Design and Performance for Masters and Mates; Butterworth-Heinemann: Oxford, UK, 2004; pp. 148–163. ISBN 978-0-75066-000-6. [Google Scholar]

- Eloot, K.; Verwilligen, J.; Vantorre, M. An Overview of Squat Measurements for Container Ships in Restricted Water. In Proceedings of the International Conference on Safety and Operations in Canals and Waterways SOCW, Glasgow, UK, 15–16 September 2008; pp. 15–16. [Google Scholar]

- Morabito, M.G. Re-Analysis of Series 50 Tests of V-Bottom Motor Boats. In Proceedings of the SNAME Maritime Convention, Bellevue, WA, USA, 13 November 2013. [Google Scholar]

- Drouet, A.; Sergent, P.; Causeur, D.; Corrignan, P. Trim Optimisation in Waves. In Proceedings of the VII International Conference on Computational Methods in Marine Engineering, Nantes, France, 15–17 May 2017. [Google Scholar]

- Tran, T.G.; Van Huynh, Q.; Kim, H.C. Optimization Strategy for Planing Hull Design. Int. J. Nav. Archit. Ocean Eng. 2022, 14, 100471. [Google Scholar] [CrossRef]

- Martić, I.; Degiuli, N.; Borčić, K.; Grlj, C.G. Numerical Assessment of the Resistance of a Solar Catamaran in Shallow Water. J. Mar. Sci. Eng. 2023, 11, 1706. [Google Scholar] [CrossRef]

- Samuel, S.; Mursid, O.; Yulianti, S.; Kiryanto, K.; Iqbal, M. Evaluation of Interceptor Design to Reduce Drag on Planing Hull. Brodogradnja 2022, 73, 93–110. [Google Scholar] [CrossRef]

- Suneela, J.; Sahoo, P. Numerical Investigation of Interceptor Effect on Sea Keeping Behaviour of Planing Hull Advancing in Regular Head Waves. Brodogradnja 2021, 72, 73–92. [Google Scholar] [CrossRef]

- Degiuli, N.; Farkas, A.; Martić, I.; Zeman, I.; Ruggiero, V.; Vasiljević, V. Vienna model basin LTD Numerical and Experimental Assessment of the Total Resistance of a Yacht. Brodogradnja 2021, 72, 61–80. [Google Scholar] [CrossRef]

- Shih, T.-H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A New K-Epsilon Eddy Viscosity Model for High Reynolds Number Turbulent Flows: Model Development and Validation. Comput. Fluids 1994, 24, 227–238. [Google Scholar] [CrossRef]

- ITTC. Quality Manual 7.5-03-01-01: CFD General—Uncertainty Analysis in CFD Verification and Validation Methodology and Procedures. In Proceedings of the International Towing Tank Conference (ITTC), Zürich, Switzerland, 4 October 2017. [Google Scholar]

- Savitsky, D. Hydrodynamic Design of Planing Hulls. Mar. Technol. SNAME News 1964, 1, 71–95. [Google Scholar] [CrossRef]

- Niazmand Bilandi, R.; Dashtimanesh, A.; Mancini, S.; Vitiello, L. Comparative Study of Experimental and CFD Results for Stepped Planing Hulls. Ocean Eng. 2023, 280, 114887. [Google Scholar] [CrossRef]

- Suneela, J.; Krishnankutty, P.; Subramanian, V.A. Hydrodynamic Performance of Planing Craft with Interceptor-Flap Hybrid Combination. J. Ocean Eng. Mar. Energy 2021, 7, 421–438. [Google Scholar] [CrossRef]

- ITTC. Recommended Procedures and Guidelines: Practical Guidelines for Ship CFD Applications. In Proceedings of the International Towing Tank Conference (ITTC), Rio de Janeiro, Brazil, 28 August–3 September 2011. [Google Scholar]

- Leal, L.; Flores, E.; Fuentes, D.; Verma, B. Hydrodynamic Study of the Influence of Bulbous Bow Design for an Offshore Patrol Vessel Using Computational Fluid Dynamics. Ship Sci. Technol. 2018, 11, 29. [Google Scholar] [CrossRef]

- García, M.; Leal, L.; Verma, B.; Ruiz, N. Numerical Study for the Estimation of the Hydrodynamic Coefficients of Current Drag in Port Assistance Maneuvers (Dock) for the Colombian Navy Frigates by Means of CFD. Xiandai Shipin Keji 2022, 16, 35–42. [Google Scholar]

- Nagai, T.; Yoshida, Y. Minimum Resistance Hull Form of Planing Craft With Controlled Trim Angle. In Proceedings of the Sixth International Offshore and Polar Engineering Conference, Los Angeles, CA, USA, 26–31 May 1996. [Google Scholar]

- Le, T.-H.; Vu, M.T.; Bich, V.N.; Phuong, N.K.; Ha, N.T.H.; Chuan, T.Q.; Tu, T.N. Numerical Investigation on the Effect of Trim on Ship Resistance by RANSE Method. Appl. Ocean Res. 2021, 111, 102642. [Google Scholar] [CrossRef]

- Sheingart, Z. Hydrodynamics of High Speed Planing Hulls with Partially Ventilated Bottom and Hydrofoils; Massachusetts Institute of Technology, Department of Mechanical Engineering: Cambridge, MA, USA, 2014. [Google Scholar]

| Parameter | Symbol | RRC | Hull 2743 |

|---|---|---|---|

| Speed | 3.76 kn | 2.87 kn | |

| Maximum moulded breadth at design water line | 0.59 m | 0.31 m | |

| Froude number based on breadth | () | 1.56 | 1.62 |

| Breadth-to-Draft Ratio | 7.17 | 6.00 |

| Main Particular | Symbol | RRC | RRC+700 |

|---|---|---|---|

| Length overall | 7.60 m | 8.30 m | |

| Length of waterline | 7.04 m | 8.00 m | |

| Breadth | 2.46 m | 2.46 m | |

| Water Depth | 5 m | 5 m | |

| Draft/Draught | 0.343 m | 0.330 m | |

| Displacement | 4.095 t | 4.135 t | |

| Design Speed | 15 kn | 15 kn | |

| Longitudinal center of gravity (LCG) | 3.18 m | 3.60 m | |

| Vertical position of the center of gravity | 0.72 m | 0.72 m |

| Parameter | Description |

|---|---|

| Solver | 3D, unsteady, implicit |

| Turbulence model | |

| Multiphase model | VOF |

| Pressure-velocity coupling | SIMPLE |

| Turbulence model discretization | Second order |

| Temporal discretization | First order |

| Speed () | Froude Number Based on Breadth () | Dynamic Trim Angle () | Wetted Keel Length () | Static Trim () | |

|---|---|---|---|---|---|

| [] | [] | [] | [] | [] | |

| 9 | 4.63 | 0.96 | 3.10 | 10.07 | 9 |

| 12 | 6.17 | 1.28 | 5.96 | 6.65 | 12 |

| 15 | 7.72 | 1.59 | 5.60 | 6.28 | 15 |

| 18 | 9.26 | 1.91 | 6.28 | 4.95 | 18 |

| 21 | 10.80 | 2.23 | 6.22 | 4.10 | 21 |

| 24 | 12.35 | 2.55 | 5.27 | 4.06 | 24 |

| 27 | 13.89 | 2.87 | 5.21 | 3.23 | 27 |

| 30 | 15.43 | 3.19 | 5.35 | 2.32 | 30 |

| 32 | 16.46 | 3.40 | 5.45 | 1.84 | 32 |

| HULL–RRC+700 mm | 4.14 t—LCG (3.18 mm) | ||||||

|---|---|---|---|---|---|---|---|

| Speed () | Froude Number Based on Breadth () | Resistance () | Effective Power () | Brake Power () | Dynamic Trim Angle () | Static Trim () | |

| [] | [] | [] | [] | [] | [] | [] | |

| 9 | 4.63 | 0.96 | 4.01 | 24.92 | 45.31 | 2.45 | 0.49 |

| 12 | 6.17 | 1.28 | 5.36 | 44.39 | 80.71 | 4.77 | 0.64 |

| 15 | 7.72 | 1.60 | 5.86 | 60.67 | 110.31 | 4.68 | 0.59 |

| 18 | 9.26 | 1.92 | 5.85 | 72.59 | 131.98 | 5.29 | 0.54 |

| 21 | 10.80 | 2.24 | 5.72 | 82.9 | 150.73 | 5.34 | 0.46 |

| 24 | 12.35 | 2.56 | 5.7 | 94.32 | 171.49 | 4.61 | 0.39 |

| 27 | 13.89 | 2.88 | 5.82 | 108.38 | 197.05 | 4.41 | 0.30 |

| 30 | 15.43 | 3.20 | 6.08 | 125.79 | 228.71 | 4.33 | 0.25 |

| 32 | 16.46 | 3.41 | 6.32 | 139.57 | 253.71 | 4.28 | 0.19 |

| Initial Trim | −3° at 9 Knots in the Center of Coordinates for a Rigid Body |

| Initial Trim | −6° at 12 knots and 15 knots in the center of coordinates for a rigid body |

| Release Time | 11 s |

| Ramp Time | 22 s |

| RT Tests [N] | 4.4720 |

| RT model CFD [N] | 4.33 |

| % Difference | −3.175% |

| Condition | Type Convergence | Range of Convergence |

|---|---|---|

| i | Monotonic | |

| ii | Oscillatory | |

| iii | Divergence |

| RRC Simulation Mesh Verification Results | |||||||

|---|---|---|---|---|---|---|---|

| Mesh | No. of Cells [u] | Resistance [N] | Total Resistance Coefficient | Heave [m] | Trim [°] | Base Size [m] | Remarks |

| Fine | 1,829,406 | 8.499 | 0.00159994 | 0.02216 | −1.3400 | 0.450 | Total stabilization |

| Medium | 1,475,145 | 8.474 | 0.00159524 | 0.01630 | −1.4000 | 0.500 | Total stabilization |

| Coarse | 1,187,205 | 8.411 | 0.00158351 | 0.01805 | −1.4155 | 0.550 | Total stabilization |

| Parameters | Result |

|---|---|

| 0.550 | |

| 0.500 | |

| 0.450 | |

| 1.100 | |

| −0.025 | |

| −0.062 | |

| 0.401 | |

| 9.590 | |

| −1.67% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leal-Ruiz, L.D.; Camargo-Díaz, C.P.; Paipa-Sanabria, E.; Castro-Faccetti, C.; Candelo-Becerra, J.E. Effect of Speed and Hull Length on the Hydrodynamic Performance of a Semi-Planing Hull of a Shallow-Draft Watercraft. J. Mar. Sci. Eng. 2023, 11, 2328. https://doi.org/10.3390/jmse11122328

Leal-Ruiz LD, Camargo-Díaz CP, Paipa-Sanabria E, Castro-Faccetti C, Candelo-Becerra JE. Effect of Speed and Hull Length on the Hydrodynamic Performance of a Semi-Planing Hull of a Shallow-Draft Watercraft. Journal of Marine Science and Engineering. 2023; 11(12):2328. https://doi.org/10.3390/jmse11122328

Chicago/Turabian StyleLeal-Ruiz, Luis Daniel, Clara Paola Camargo-Díaz, Edwin Paipa-Sanabria, Claudia Castro-Faccetti, and John E. Candelo-Becerra. 2023. "Effect of Speed and Hull Length on the Hydrodynamic Performance of a Semi-Planing Hull of a Shallow-Draft Watercraft" Journal of Marine Science and Engineering 11, no. 12: 2328. https://doi.org/10.3390/jmse11122328

APA StyleLeal-Ruiz, L. D., Camargo-Díaz, C. P., Paipa-Sanabria, E., Castro-Faccetti, C., & Candelo-Becerra, J. E. (2023). Effect of Speed and Hull Length on the Hydrodynamic Performance of a Semi-Planing Hull of a Shallow-Draft Watercraft. Journal of Marine Science and Engineering, 11(12), 2328. https://doi.org/10.3390/jmse11122328