Rock mass classification plays an important role in evaluating rock quality. There are many rock mass classifications, such as the rock mass rating (RMR) [

20,

21], rock mass quality Q-system (Q) [

22], geological strength index (GSI) [

23,

24], and the basic quality system (BQ) [

25,

26]. These classifications assess the rock mass quality by obtaining the parameters of rocks and engineered rock masses by using rock mechanical tests and engineering geological field investigations [

27]. However, the existing rock mass classifications cannot reflect the influence of seawater on the rock mass quality, and the effect of time of seawater erosion is ignored. The existing rock mass classification requires modification to make it applicable to the evaluation of the marine bedrock.

2.1. Determination of Evaluation Indexes

As a comprehensive rock mass classification that considers multiple factors, the RMR classification is the most widely used due to its reliability and practicality in rock quality evaluation [

28,

29,

30,

31,

32]. Celada et al. [

33] modified the RMR classification and proposed the RMR

14 classification. RMR

14 refines the rating of the structural surface conditions and introduces the alterability index,

Id2, which characterizes the resistance of the rock to softening and disintegration when in contact with water. The

Id2 index is helpful for the RMR

14 classification to evaluate the rock mass quality in water-rich subsurface rock engineering, especially for marine rock engineering. However, RMR

14 is mainly used to focus on underground rock tunneling engineering, and the environmental medium of the marine bedrock is different from the tunnel surrounding rock, resulting in the considerations and rating of the classification indices of RMR

14 not being applicable to the quality evaluation of marine bedrock. Therefore, an ocean rock mass rating (OMR) classification applicable to the marine bedrock at the end of monopile foundations for offshore wind turbines is proposed by modifying the RMR

14 classification.

The OMR classification includes five rating indices: the strength of intact rock (R1), the structural integrity of rock mass (R2), the discontinuities condition (R3), intact rock alterability (R4), and an adjustment factor for the effect of time (Ft). Since the OMR classification is used to evaluate the quality of the marine bedrock, the groundwater conditions are not considered.

2.2. Modification of Geological Indices

The five rating indices in the OMR classification from R1 to R4 are geological indices, and Ft is the adjustment factor for the effect of time. In order to adapt to the requirements of the OMR classification, it is necessary to modify the R1, R2, R3, and R4 indices and reset the ratings of the four indices based on the RMR14 classification and the conditions of the marine bedrock.

2.2.1. Resetting Ratings of Geological Indices in OMR Classification

The four geological indices considered in the OMR classification accounted for 15, 40, 20, and 10 points in the RMR14 classification, respectively. However, the impact of these four geological indices on the quality of the marine bedrock is quite different from that of tunnel rock. Long-term seawater–rock interactions are prevalent in marine rock engineering, and rock strength and disintegration resistance are more important to the quality of the marine bedrock. The structural integrity of the rock mass and discontinuities condition mainly influence the efficiency of seawater erosion. Therefore, the ratings of R1 and R4 should be higher than those of R2 and R3. Besides, the OMR classification neglects groundwater conditions, making the sum of the four geological indices less than 100 points. In summary, the rating of the four geological indices is reset according to the characteristics of marine rock engineering based on the analysis hierarchy process (AHP).

The AHP can be used to deal with complex problems by categorizing the decision-relevant elements into a structure of the goal, criteria, and options [

34,

35]. It is easy to employ, integrates the contributions of multiple factors, does not require additional quantitative information, and has been widely used in the design and modification of rock mass classifications. For the determination of the weights of the four geological indices for OMR classification, an AHP structure is established, as shown in

Figure 2. The AHP structure can be divided into three layers: the goal layer, the criteria layer, and the options layer. In this study, the AHP is used to assess the quality of marine bedrock, which is the goal layer. The four geologic indicators included in the OMR classification, which comprise the criteria layer, are used to determine judgment matrix

A based on the importance of each criterion in the goal layer. Finally, the synthetic weight of each criterion on the goal is calculated based on judgment matrix

A and is used to select the best result in the options layer.

Each criterion in the criteria layer has a different weight for the goal layer. In other words,

R1,

R2,

R3, and

R4 have different impacts on the quality of the marine bedrock. Judgment matrix

A [Equation (1)] can be constructed by citing the nine-point rating scale proposed by Sttay [

36,

37] (

Table 1). In the OMR classification, the ratings of the strength of intact rock,

R1, and the ratings of intact rock alterability,

R4, are considered equally important.

R1 and

R4 are slightly more important than the ratings of the structural integrity of rock mass,

R2, and moderately more important than the ratings of the discontinuities condition,

R3. The weights of the

R1~

R4 indices are computed based on matrix

A, as listed in

Table 2. By modifying the obtained weights, it can be found that

R1,

R2,

R3, and

R4 account for 35, 20, 10, and 35 points in OMR classification, respectively.

The statistical validation of the AHP analysis for the OMR classification is performed, and the consistency index (

CI) and consistency ratio (

CR) are calculated as follows [

37]:

where

λmax is the largest eigenvalue of judgment matrix

A,

n is the size of matrix

A, and

RI is the random consistency index based on the size of comparison matrix

A [

37]. If

CR is less than 0.10, the AHP analysis is reasonable, and the results can be accepted.

The results of the statistical validation of the above AHP analysis are presented in

Table 3. It can be found that the

CR is less than 0.10, which implies the AHP analysis of the OMR classification is acceptable. The ratings of the four geological indices in the OMR classification are 35, 20, 10, and 35 points, respectively.

The ratings of the four geological indices in the OMR classification are reset according to the impact on the quality of the marine bedrock. However, the ratings of these four geological indices are determined by the parameters that are easily accessible for tunnel engineering but difficult in offshore wind engineering. Therefore, the four geological indices are further modified to enable convenient utilization in offshore wind engineering.

2.2.2. Rating Modification of the Strength of Intact Rock R1

According to the RMR

14 classification, there is a stepwise correspondence between the saturated uniaxial compressive strength,

σc, and the rating index,

R1. The rating method jumps, which will cause changes in the score. In practice, linear interpolation is usually used to determine the

R1. Therefore, the correspondence between

σc and

R1 can be refined by the continuum regression approach [

38]. It is worth noting that the rating for

R1 in the OMR classification has increased from 15 to 35 points. The regression results are presented in Equation (4) and

Figure 3.

When it is inconvenient to obtain the saturated uniaxial compressive strength in offshore wind engineering, the point load test can be used to determine the point load strength index of the rock,

Is(50), which can be converted to

σc. The conversion relationship between the two is as follows [

25]:

where

Is(50) is the point load strength index of a standard specimen with a diameter of 50 mm.

The

R1 indices modified for continuity refinement are listed in

Table 4. In engineering practice, if

Table 4 does not include the obtained

σc and

Is(50), Equations (4) and (5) can be utilized for the determination of

R1.

2.2.3. Rating Modification of Structural Integrity of Rock Mass R2

The RMR

14 classification determines the structural integrity of rock mass based on the number of discontinuities,

dn, but in some rock engineering (especially offshore wind engineering), the acquisition of the

dn of the excavation surface is extremely difficult. Since the construction of offshore wind turbines requires drilling holes to investigate the geological conditions of the marine bedrock, the RQD is the most accessible index for the structural integrity of the rock mass, which does not require additional experimental tests. The original RMR classification applies the RQD to evaluate the structural integrity of rock mass. In RMR classification, the rating of RQD is divided into five intervals, showing a jumping characteristic similar to the strength index described above. According to the quality evaluation of the marine bedrock, the

R2 index accounts for 20 points in the OMR classification. Therefore, the continuous regression approach is adopted to modify the rating of

R2 in the OMR classification based on the RQD, as shown in

Figure 4. The continuity equation between RQD and

R2 index is as follows:

In order to express the relationship between RQD and

R2 in terms of a simple linear relationship, the detailed modification values of the

R2 index are listed in

Table 5. The ratings of the R2 of RQD not covered in

Table 5 can be calculated using Equation (6).

2.2.4. Rating Modification of Discontinuities Condition R3

Zhang et al. [

12] demonstrated (experimentally) that seawater erosion in the discontinuities of the rock mass is significant. In the OMR classification, strength deterioration caused by seawater erosion is usually expressed by

R1 and

R5, and the effect of time regarding seawater erosion on the discontinuities is represented by

Ft. Therefore, the discontinuous condition

R3 has a relatively low percentage of 10 points in the OMR classification. The RMR

14 classification refines the rating of the discontinuities with four factors, including continuity, roughness, infilling, and weathering, each of which is rated by five points. For the marine bedrock, the continuity of the discontinuities is difficult to access due to the limitations of drilling investigations. Therefore, a modified evaluation of the ratings of the discontinuities,

R3, is presented in

Table 6.

2.2.5. Rating Modification of Intact Rock Alterability R4

The RMR

14 classification introduces an index for evaluating intact rock alterability, which matches the characteristics of the marine bedrock. This index is represented by

R4 in the OMR classification, which highlights the fact that the rock is heavily softened and disintegrated by seawater. For offshore wind engineering with aggressive media (seawater), the rating of

R4 is taken as 35 points and is as important as rock strength,

R4. The rating of

R4 is based on a stepwise rating, and a continuity refinement equation is used instead of a stepwise rating approach to obtain

Figure 5 and Equation (7). The results of the modified evaluation of the ratings of intact rock alterability,

R4, are presented in

Table 7. The ratings of

R4 corresponding to

Id2 that are not listed in

Table 7 can be calculated by using Equation (7).

2.3. Determination of Adjustment Factor for the Effect of Time Ft

The monopile foundations for offshore wind turbines must be able to resist the cycling loads of wind and water to which the offshore wind turbine is subjected over a typical design life of at least 25 years [

39]. Such a long period of continuous action will make the pile-rock contact surface continuously separate. The seawater will gradually erode the rock around the monopile foundation, which will have a significant impact on the safety and long-term stability of the offshore wind turbine. Therefore, the deterioration of the marine bedrock during the long-term operation phase should be sufficiently considered at the design stage. The adjustment factor for the effect of time,

Ft, in the OMR classification can reflect the deterioration pattern of the marine bedrock over time.

However, the erosion time of the offshore wind monopile foundation is usually more than decades, and it is impractical to perform seawater erosion tests under the same environmental conditions due to the huge time and economic costs. Thus, it is necessary to conduct accelerated tests for seawater erosion. The accelerated test shortens the test period by enhancing the test conditions while keeping the failure mechanism unchanged. This test method improves efficiency and reduces cost, which has been widely used in geological engineering [

40,

41,

42,

43,

44].

In order to rationally design the accelerated test of seawater erosion, mechanical analysis of the marine bedrock for an offshore wind monopile foundation is required.

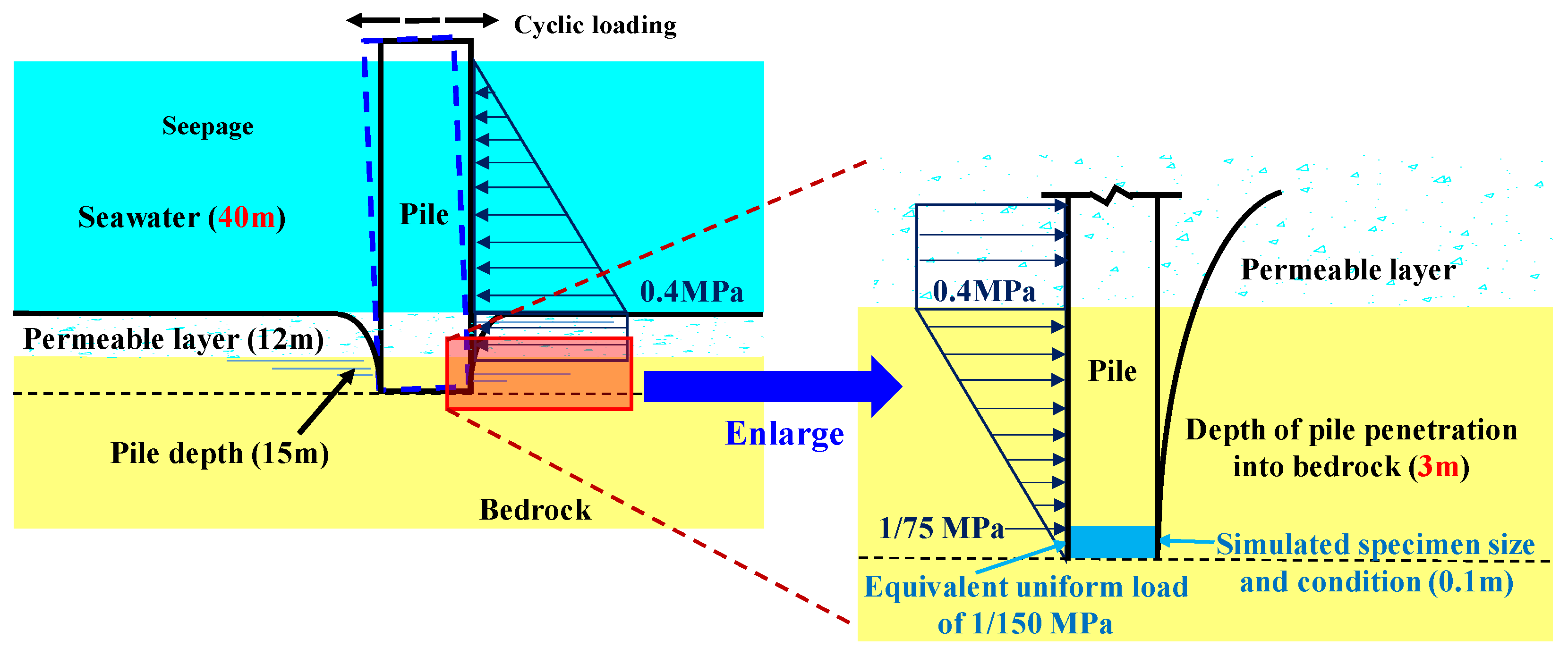

Figure 6 simulates the force condition of the monopile foundation. The seawater depth in the offshore wind engineering area is generally less than 40 m, so the seawater depth is considered to be 40 m. The depth of the monopile foundation is 10 m, of which 8 m is the permeable layer and 2 m is the bedrock layer. The 8 m permeable layer consists of submarine sediments, silt, and highly weathered rock layers, which can transmit a water pressure of 0.4 MPa. The 2 m bedrock layer is a weakly weathered rock layer, and its water pressure decreases linearly from 0.4 MPa to 0 MPa.

The rock specimen, seawater, and equipment for the accelerated test of seawater erosion are shown in

Figure 7. Three common types of seabed bedrock represented by granite, tuff, and sandstone were tested (namely plutonic, volcanic, and sedimentary rocks). These rocks are manufactured into specimens with a height of 100 mm and a diameter of 50 mm. From

Figure 6, it can be calculated that the pressure exerted on the rock specimen decreases linearly from 1/75 MPa to 0 MPa, which corresponds to a uniform load of 1/150 MPa. The seawater was taken from Fujian, China, and there was no inland freshwater or domestic sewage injection in the area, which is relatively close to the quality of the water under offshore conditions, totaling about 27 L of seawater. Seawater environments at different depths can be simulated using a deep-water simulation system (

Figure 7c), which can apply pressures from 0 to 0.7 MPa. Considering that the offshore wind turbine is usually operated for decades and taking into account the test conditions, experimental time, and geological conditions of the marine bedrock, the test pressure was set to be 0.5 MPa. Therefore, the acceleration factor is 75, which is calculated by 0.5/(1/150). Rock specimens are immersed for 3, 7, 15, 30, 45, and 60 days to simulate seawater erosion for 225, 525, 1125, 2250, 3375, and 4500 days. This implies that the accelerated test can simulate up to more than 12 years of seawater erosion. After the preset time has been reached, the rock specimens are removed immediately to test the physico-mechanical parameters and evaluate the discontinuity conditions. Finally, the OMR ratings of the rock specimens after different erosion times are determined, as listed in

Table 8. The

Ft rating is determined by the difference between the OMR rating after seawater erosion and the OMR in the natural state. Deviation indicates the variation between the OMR after the seawater erosion and the natural state.

It can be found that at the initial stage of the accelerated test (3

d–15

d), the OMR ratings of the three rock types decreased rapidly with an increase in time, whereas, at the later stage of the accelerated test (45

d–60

d), the OMR ratings stabilized. Among the three rock types, plutonic rock is the least affected by seawater erosion because of its dense structure. Its OMR rating after 60 days of accelerated test simulation decreases by only 8.51%. For the sedimentary rock, the deterioration of the rock by seawater erosion is the most significant due to high porosity. Its OMR rating decreases by 38.46% after 60 days of the accelerated test. The effect of seawater on volcanic rock is intermediate between the two rock types above, with a decrease in OMR rating of 15.61% after 60 days of the accelerated test. It is worth noting that the variation in

Ft with time shows a roughly logarithmic trend, so the quantitative correlations between

Ft and time for the three rock types can be fitted with Equation (8) based on the accelerated test results in

Table 8.

where

t is the time simulated by the accelerated test in days.

k and

b are two fitting parameters related to the rock types.

Figure 8 presents the fitting results of

Ft and time for three rock types.

Figure 8 indicates that the logarithmic form fits the quantitative correlations between

Ft and

t well, with a high

R2. Moreover, this fitting correlation ensures that

Ft is 0 at the natural state and stabilizes at the end. Based on the quantitative correlations between

Ft and

t, the

Ft ratings of offshore wind turbines over a 15-year period are given in

Table 9. For times longer than 15 years and the times not included in the table, the corresponding

Ft ratings can be estimated using the fitted quantitative correlations in

Figure 8.

There are different quantitative correlations for

Ft and

t for different rock types because only three typical rocks of the three rock types (plutonic rock, volcanic rock, and sedimentary rock) were tested, and not all of the rocks of the three rock types are included. It is not enough to construct reasonable correlations between

k,

b, and rock type, which deserves further study. However, it is sufficiently competent for engineering applications. By combining the results in

Table 4,

Table 5,

Table 6,

Table 7,

Table 8 and

Table 9, the OMR classification applicable to the marine bedrock of monopile foundations for offshore wind turbines is proposed in

Table A1, which is presented in

Appendix A.

In

Table 10, the rating indices in the rock mass classification and the respective advantages of the OMR, RMR

14, and RMR classification are compared. It can be found that the RMR

14 and RMR classifications are more suitable for overland geological engineering, such as for tunnels and slopes. The OMR classification applies to the marine bedrock of an offshore wind foundation without considering the groundwater conditions. Meanwhile, the OMR classification can reflect the effect of time regarding seawater erosion, which is the key to its applicability to marine bedrock.