Effect of Cross-Joints Fin on the Thrust Performance of Bionic Pectoral Fins

Abstract

:1. Introduction

2. Methodology

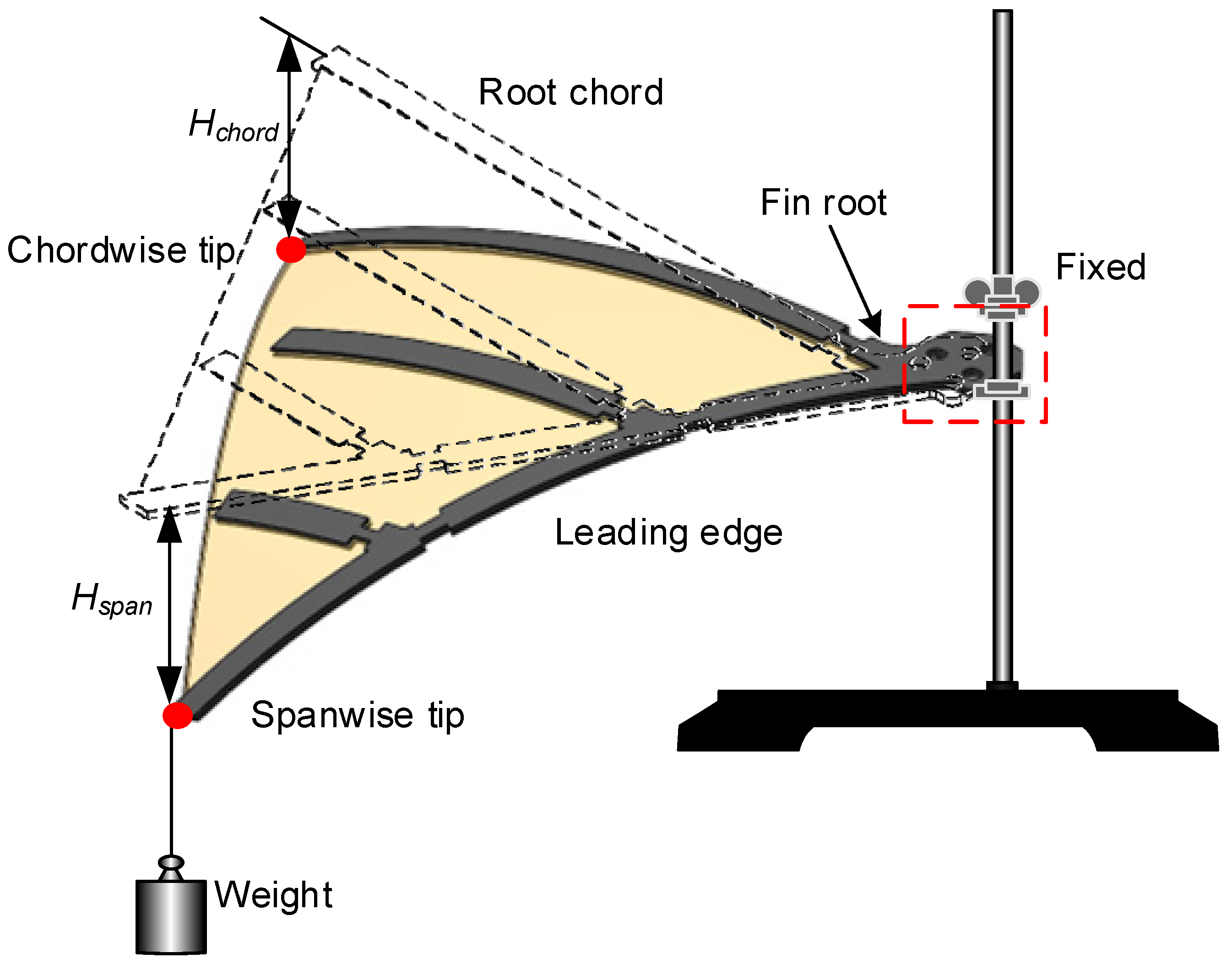

2.1. Cross-Joints Fin Design

2.2. Motion Parameters

2.3. Experiment Setup

3. Results and Discussion

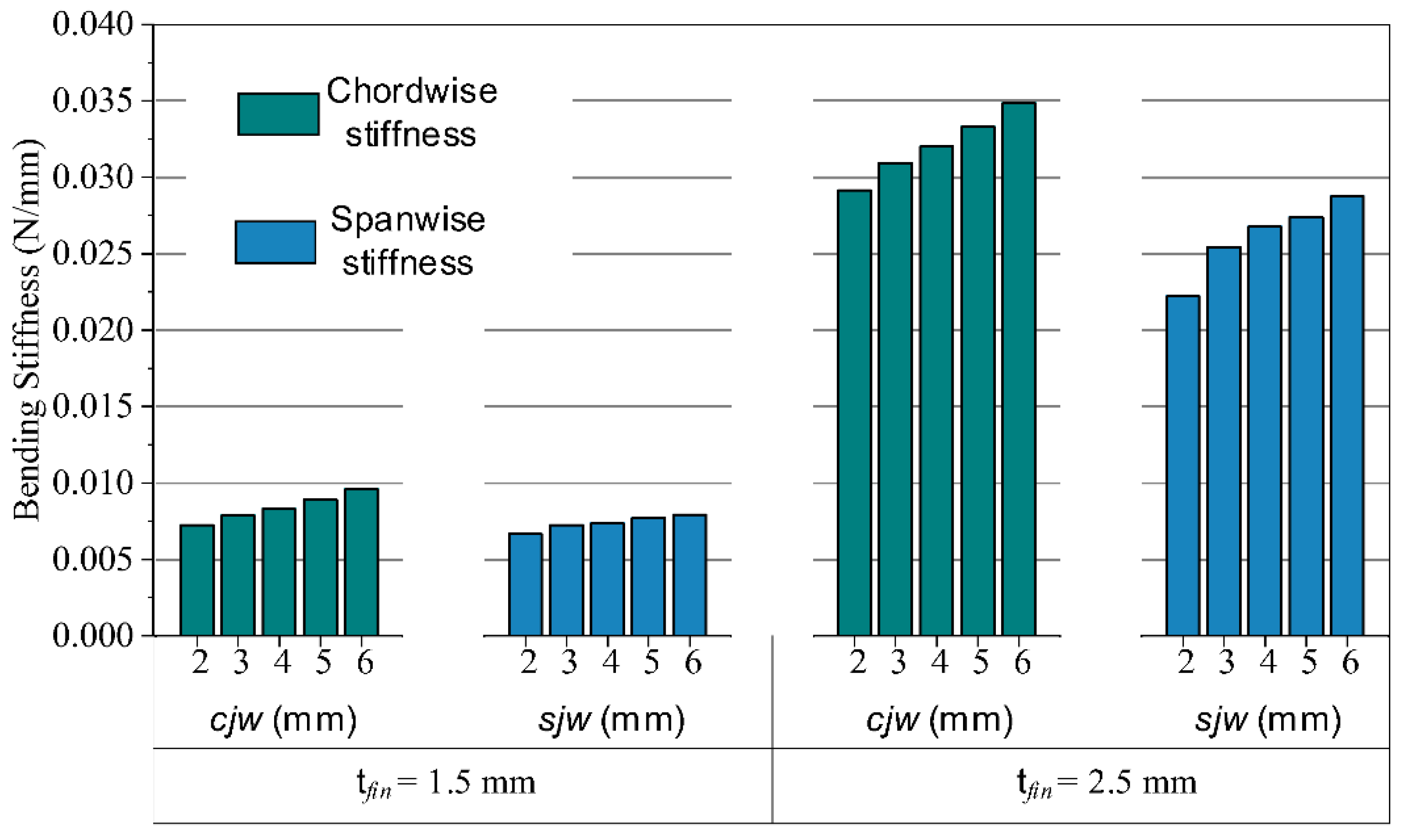

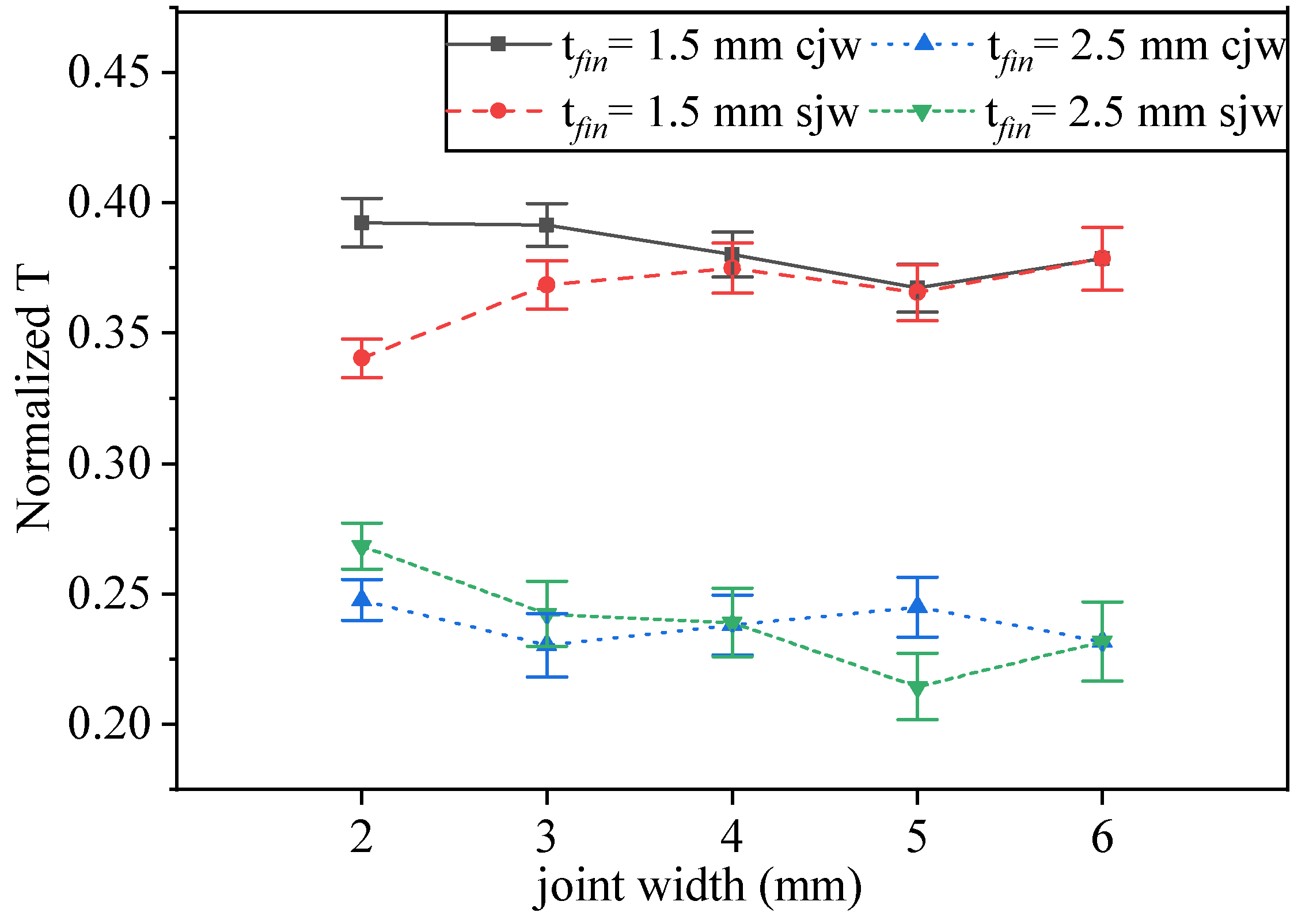

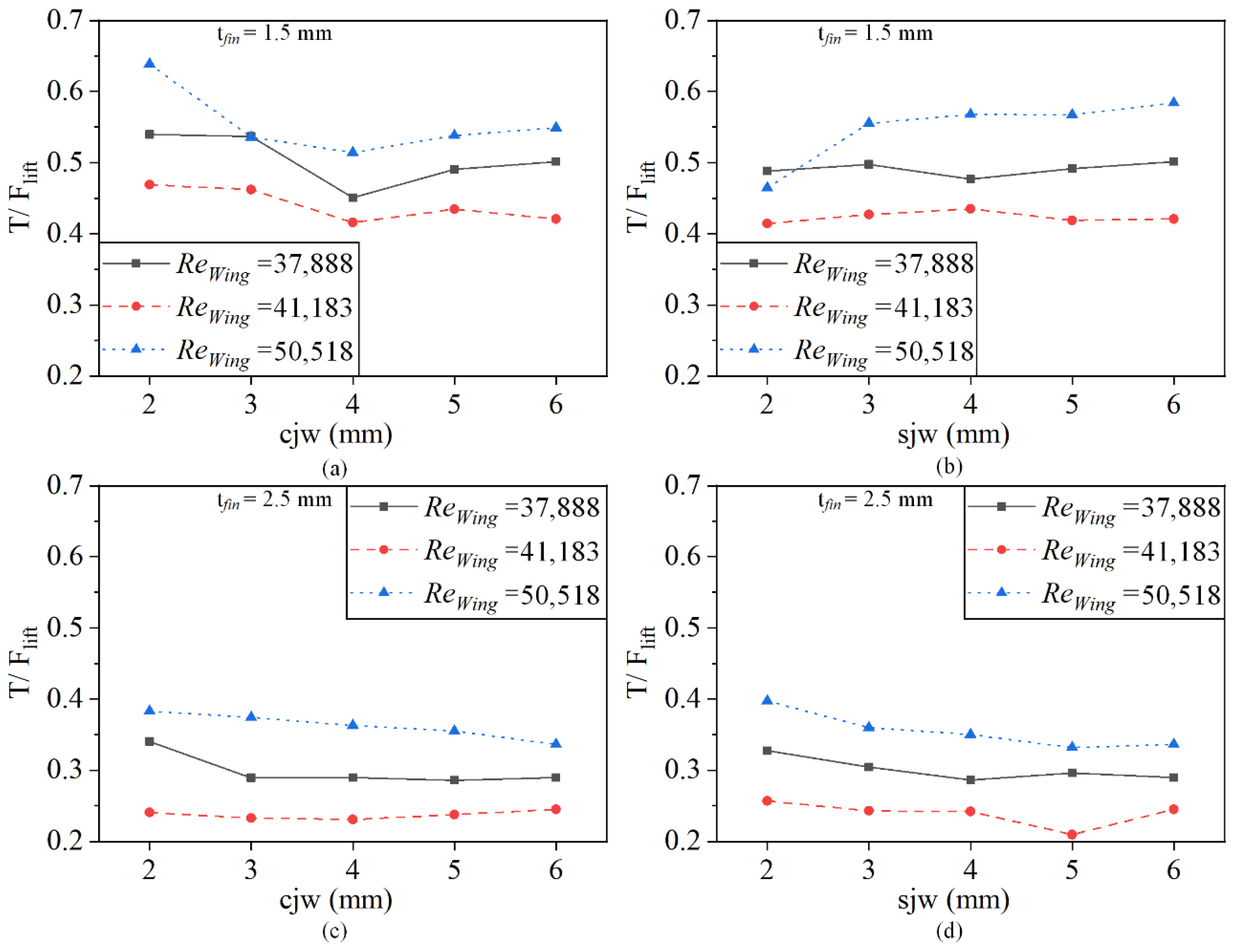

3.1. Thrust Performance with Spanwise and Chordwise Stiffness

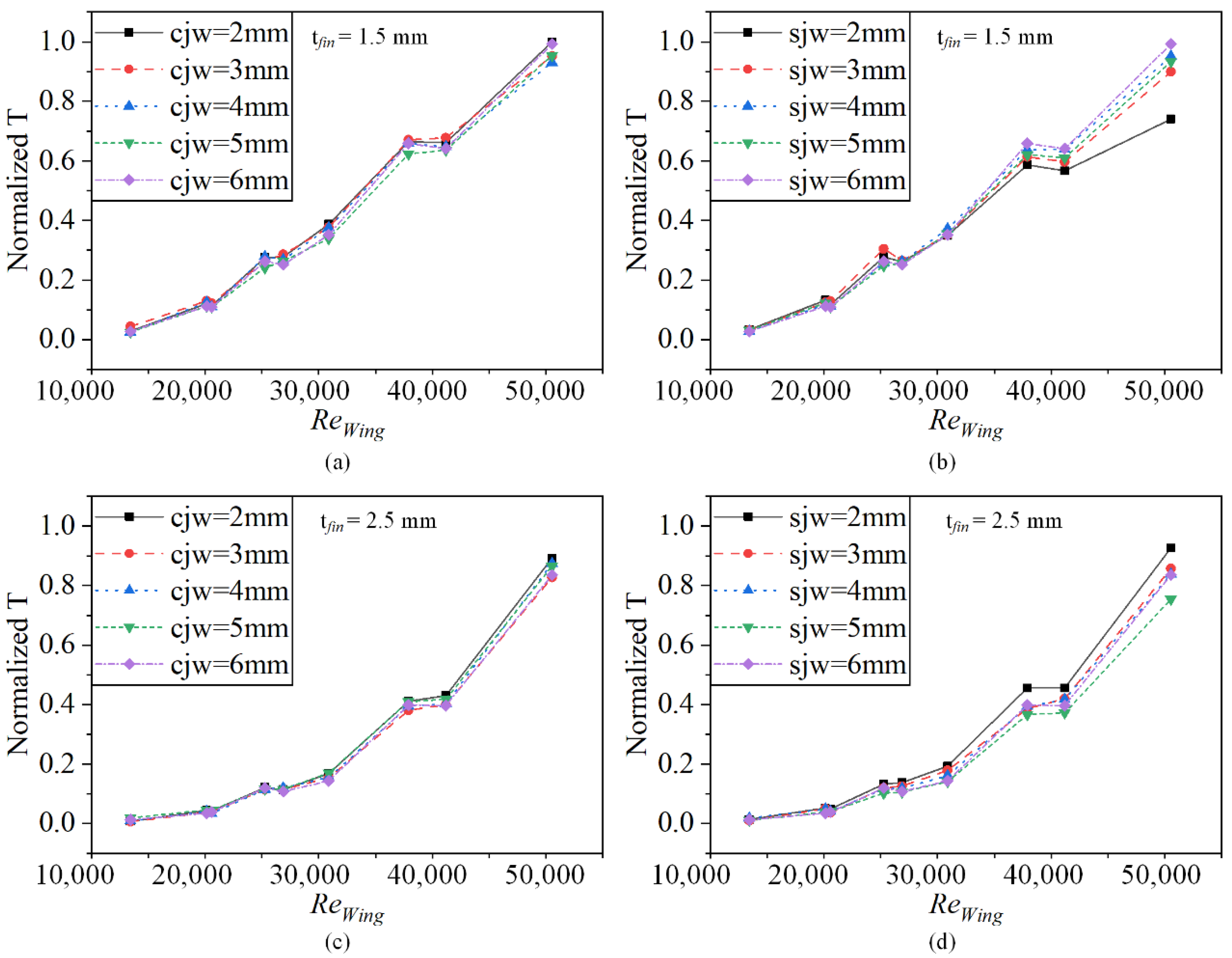

3.2. Stiffness Variation at High Wing Tip Reynolds Number

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rosenberger, L.J. Pectoral fin locomotion in batoid fishes: Undulation versus oscillation. J. Exp. Biol. 2001, 204, 379–394. [Google Scholar] [CrossRef]

- Maia, A.M.; Wilga, C.A.; Lauder, G.V. Biomechanics of locomotion in sharks, rays, and chimaeras. Biol. Sharks Relat. 2012, 1, 125–151. [Google Scholar]

- Russo, R.S.; Blemker, S.S.; Fish, F.E.; Bart-Smith, H. Biomechanical model of batoid (skates and rays) pectoral fins predicts the influence of skeletal structure on fin kinematics: Implications for bio-inspired design. Bioinspiration Biomim. 2015, 10, 046002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clark, R.P.; Smits, A.J. Thrust production and wake structure of a batoid-inspired oscillating fin. J. Fluid Mech. 2006, 562, 415–429. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Frank, F.; Christian, S.; Keith, M.; Liu, G.; Dong, H.; Hilary, B.S. Hydrodynamic Performance of Aquatic Flapping: Efficiency of Underwater Flight in the Manta. Aerospace 2016, 3, 20. [Google Scholar]

- Schaefer, J.T.; Summers, A.P. Batoid wing skeletal structure: Novel morphologies, mechanical implications, and phylogenetic patterns. J. Morphol. 2005, 264, 298–313. [Google Scholar] [CrossRef] [PubMed]

- Lindsey, C.C. Form, Function, and Locomotory Habits in Fish. Fish Physiol. 1978, 7, 1–100. [Google Scholar]

- Rosenberger, L.J.; Westneat, M.W. Functional morphology of undulatory pectoral fin locomotion in the stingray Taeniura lymma (Chondrichthyes: Dasyatidae). J. Exp. Biol. 1999, 202, 3523–3539. [Google Scholar] [CrossRef] [PubMed]

- Lauder, G.V. Function of the caudal fin during locomotion in fishes: Kinematics, flow visualization, and evolutionary patterns. Am. Zool. 2000, 40, 101–122. [Google Scholar] [CrossRef] [Green Version]

- Arastehfar, S.; Chew, C.M. Effects of root chord movement on thrust generation of oscillatory pectoral fins. Bioinspir. Biomim. 2020, 16, 036009. [Google Scholar] [CrossRef]

- Bianchi, G.; Cinquemani, S.; Resta, F. Bio-Inspired Design of an Underwater Robot Exploiting Fin Undulation Propulsion. Appl. Sci. 2021, 11, 2556. [Google Scholar] [CrossRef]

- Chen, J. Flexible tensegrity wing design and insights in principles of swimming kinematics of batoid rays. Bioinspir. Biomim. 2021, 16, 056007. [Google Scholar] [CrossRef] [PubMed]

- Xing, C.; Cao, Y.; Cao, Y.; Pan, G.; Huang, Q. Asymmetrical Oscillating Morphology Hydrodynamic Performance of a Novel Bionic Pectoral Fin. J. Mar. Sci. Eng. 2022, 10, 289. [Google Scholar] [CrossRef]

- Cai, Y.; Bi, S.; Li, G.; Hildre, H.P.; Zhang, H. From Natural Complexity to Biomimetic Simplification: The Realization of Bionic Fish Inspired by the Cownose Ray. IEEE Robot. Autom. Mag. 2018, 26, 27–38. [Google Scholar] [CrossRef]

- Arastehfar, S.; Chew, C.-M.; Jalalian, A.; Gunawan, G.; Yeo, K.S. A Relationship Between Sweep Angle of Flapping Pectoral Fins and Thrust Generation. J. Mech. Robot. 2018, 11, 011014. [Google Scholar] [CrossRef]

- Chew, C.-M.; Arastehfar, S.; Gunawan, G.; Yeo, K.S. Study of sweep angle effect on thrust generation of oscillatory pectoral fins. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 6271–6276. [Google Scholar]

- Arastehfar, S.; Gunawan, G.; Yeo, K.S.; Chew, C.-M. Effects of pectoral fins’ spanwise flexibility on forward thrust generation. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, China, 5–8 December 2017; pp. 110–115. [Google Scholar]

- Chew, C.-M.; Lim, Q.-Y.; Yeo, K. Development of propulsion mechanism for Robot Manta Ray. In Proceedings of the 2015 IEEE International Conference on Robotics and Biomimetics (ROBIO), Zhuhai, China, 6–9 December 2015; pp. 1918–1923. [Google Scholar]

- Zhou, C.; Low, K.H. Better Endurance and Load Capacity: An Improved Design of Manta Ray Robot (RoMan-II). J. Bionic Eng. 2010, 7, S137–S144. [Google Scholar] [CrossRef]

- Yang, S.; Qiu, J.; Han, X. Kinematics modeling and experiments of pectoral oscillation propulsion robotic fish. J. Bionic Eng. 2009, 6, 174–179. [Google Scholar]

- Suzumori, K.; Endo, S.; Kanda, T.; Kato, N.; Suzuki, H. A bending pneumatic rubber actuator realizing soft-bodied manta swimming robot. In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Roma, Italy, 10–14 April 2007; pp. 4975–4980. [Google Scholar]

- Zhang, L.; Bi, S.; Cai, Y.; Niu, C.; Ma, H. Effect analysis of chordwise flexibility on propulsion performance of oscillating pectoral foils. In Proceedings of the 2012 IEEE International Conference on Robotics and Biomimetics (ROBIO), Guangzhou, China, 11–14 December 2012; pp. 765–770. [Google Scholar]

- Lucas, K.N.; Thornycroft, P.J.; Gemmell, B.J.; Colin, S.P.; Costello, J.H.; Lauder, G.V. Effects of non-uniform stiffness on the swimming performance of a passively-flexing, fish-like foil model. Bioinspir. Biomim. 2015, 10, 056019. [Google Scholar] [CrossRef] [Green Version]

- Reddy, N.S.; Sen, S.; Har, C. Effect of flexural stiffness distribution of a fin on propulsion performance. Mech. Mach. Theory 2018, 129, 218–231. [Google Scholar] [CrossRef]

- Kancharala, A.K.; Philen, M.K. Study of flexible fin and compliant joint stiffness on propulsive performance: Theory and experiments. Bioinspir. Biomim. 2014, 9, 036011. [Google Scholar] [CrossRef]

- Luo, Y.; Xiao, Q.; Shi, G.; Pan, G.; Chen, D. The effect of variable stiffness of tuna-like fish body and fin on swimming performance. Bioinspir. Biomim. 2020, 16, 016003. [Google Scholar] [CrossRef] [PubMed]

- Bi, S.; Cai, Y. Effect of spanwise flexibility on propulsion performance of a flapping hydrofoil at low Reynolds number. Chin. J. Mech. Eng. 2012, 25, 12–19. [Google Scholar] [CrossRef]

- He, J.; Cao, Y.; Huang, Q.; Pan, G.; Dong, X.; Cao, Y. Effects of Bionic Pectoral Fin Rays’ Spanwise Flexibility on Forwarding Propulsion Performance. J. Mar. Sci. Eng. 2022, 10, 783. [Google Scholar] [CrossRef]

- Zhu, H.; Sha, Y.; Ding, H. Research On Fish Variable Stiffness: A Review. In Proceedings of the 2021 IEEE International Conference on Unmanned Systems (ICUS), Beijing, China, 15–17 October 2021; pp. 224–231. [Google Scholar]

- Cao, Y.; Lu, Y.; Cai, Y.; Bi, S.; Pan, G. CPG-fuzzy-based control of a cownose-ray-like fish robot. Ind. Robot. Int. J. Robot. Res. Appl. 2019, 46, 779–791. [Google Scholar] [CrossRef]

- Automation, A.I. F/T Sensor: Nano17 IP65/IP68. Available online: https://www.ati-ia.com/products/ft/ft_models.aspx?id=Nano17+IP65%2fIP68 (accessed on 1 May 2022).

- Zhu, R.; Wang, J.; Dong, H.; Bart-Smith, H. Effects of Chordwise or Spanwise Non-uniform Stiffness on Propulsive Performance of Square Foil. In Proceedings of the AIAA Scitech 2021 Forum, Virtual, 11–15 January 2021. [Google Scholar]

| Fin Thickness | Joints with | |||||

|---|---|---|---|---|---|---|

| tfin = 1.5 mm | sjw = 6 mm | cjw = 2 mm | cjw = 3 mm | cjw = 4 mm | cjw = 5 mm | cjw = 6 mm |

| cjw = 6 mm | sjw = 2 mm | sjw = 3 mm | sjw = 4 mm | sjw = 5 mm | sjw = 6 mm | |

| tfin = 2.5 mm | sjw = 6 mm | cjw = 2 mm | cjw = 3 mm | cjw = 4 mm | cjw = 5 mm | cjw = 6 mm |

| cjw = 6 mm | sjw = 2 mm | sjw = 3 mm | sjw = 4 mm | sjw = 5 mm | sjw = 6 mm | |

| Parameters | Value | ||

|---|---|---|---|

| A0 (amplitude) | 30° | 50° | 70° |

| f (frequency) | 0.4 Hz | 0.4 Hz | 0.8 Hz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Cao, Y.; Pan, G.; Huang, Q.; Dong, X.; Cao, Y. Effect of Cross-Joints Fin on the Thrust Performance of Bionic Pectoral Fins. J. Mar. Sci. Eng. 2022, 10, 869. https://doi.org/10.3390/jmse10070869

Lu Y, Cao Y, Pan G, Huang Q, Dong X, Cao Y. Effect of Cross-Joints Fin on the Thrust Performance of Bionic Pectoral Fins. Journal of Marine Science and Engineering. 2022; 10(7):869. https://doi.org/10.3390/jmse10070869

Chicago/Turabian StyleLu, Yang, Yonghui Cao, Guang Pan, Qiaogao Huang, Xin Dong, and Yong Cao. 2022. "Effect of Cross-Joints Fin on the Thrust Performance of Bionic Pectoral Fins" Journal of Marine Science and Engineering 10, no. 7: 869. https://doi.org/10.3390/jmse10070869

APA StyleLu, Y., Cao, Y., Pan, G., Huang, Q., Dong, X., & Cao, Y. (2022). Effect of Cross-Joints Fin on the Thrust Performance of Bionic Pectoral Fins. Journal of Marine Science and Engineering, 10(7), 869. https://doi.org/10.3390/jmse10070869