Lateral Buckling of Subsea Pipelines Triggered by Sleeper with a Nonlinear Pipe–Soil Interaction Model

Abstract

:1. Introduction

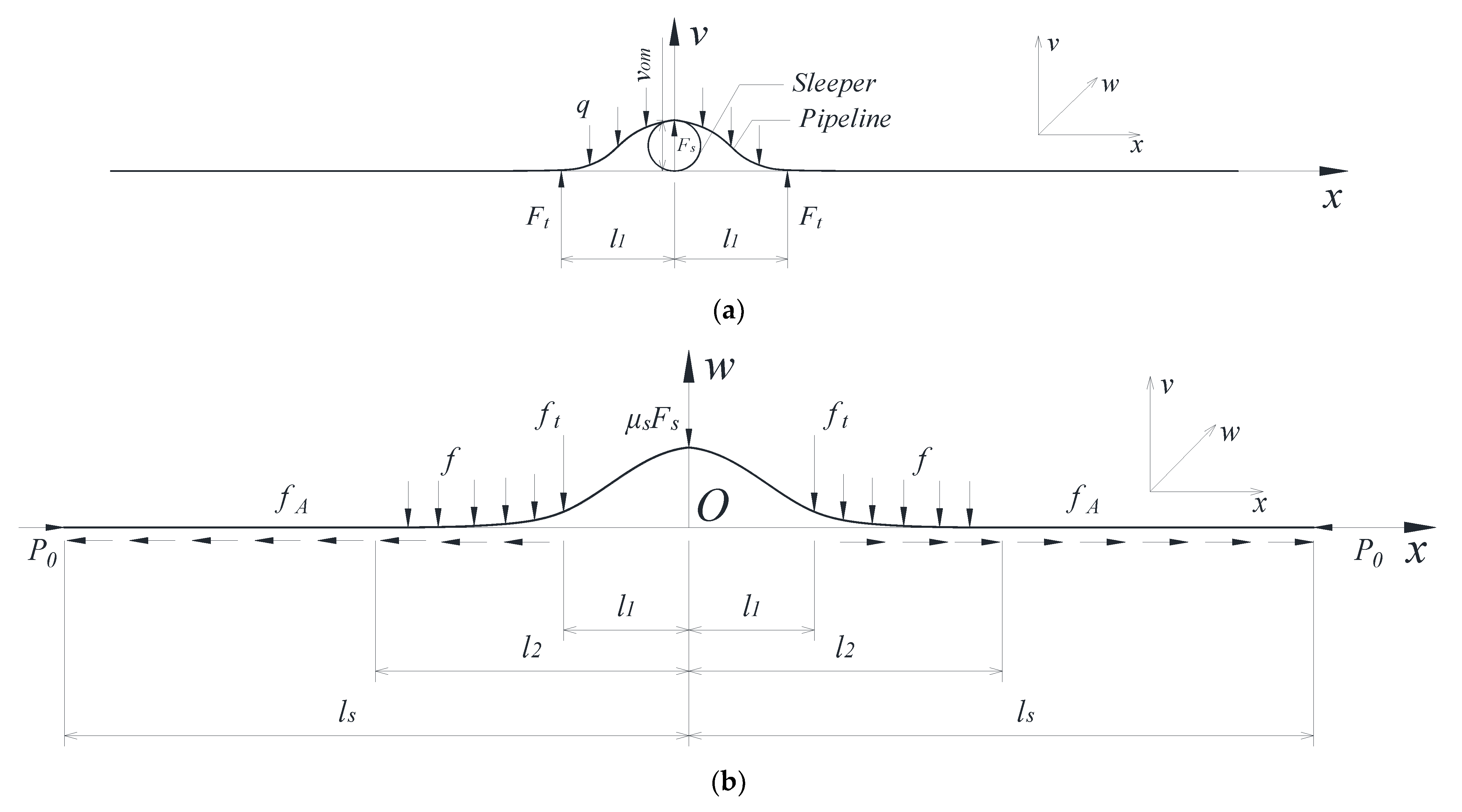

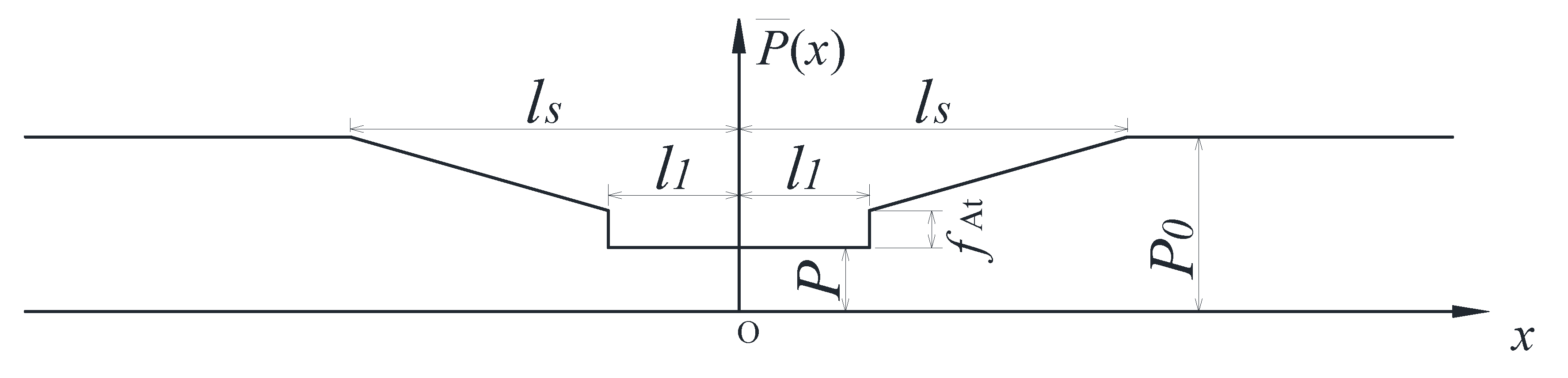

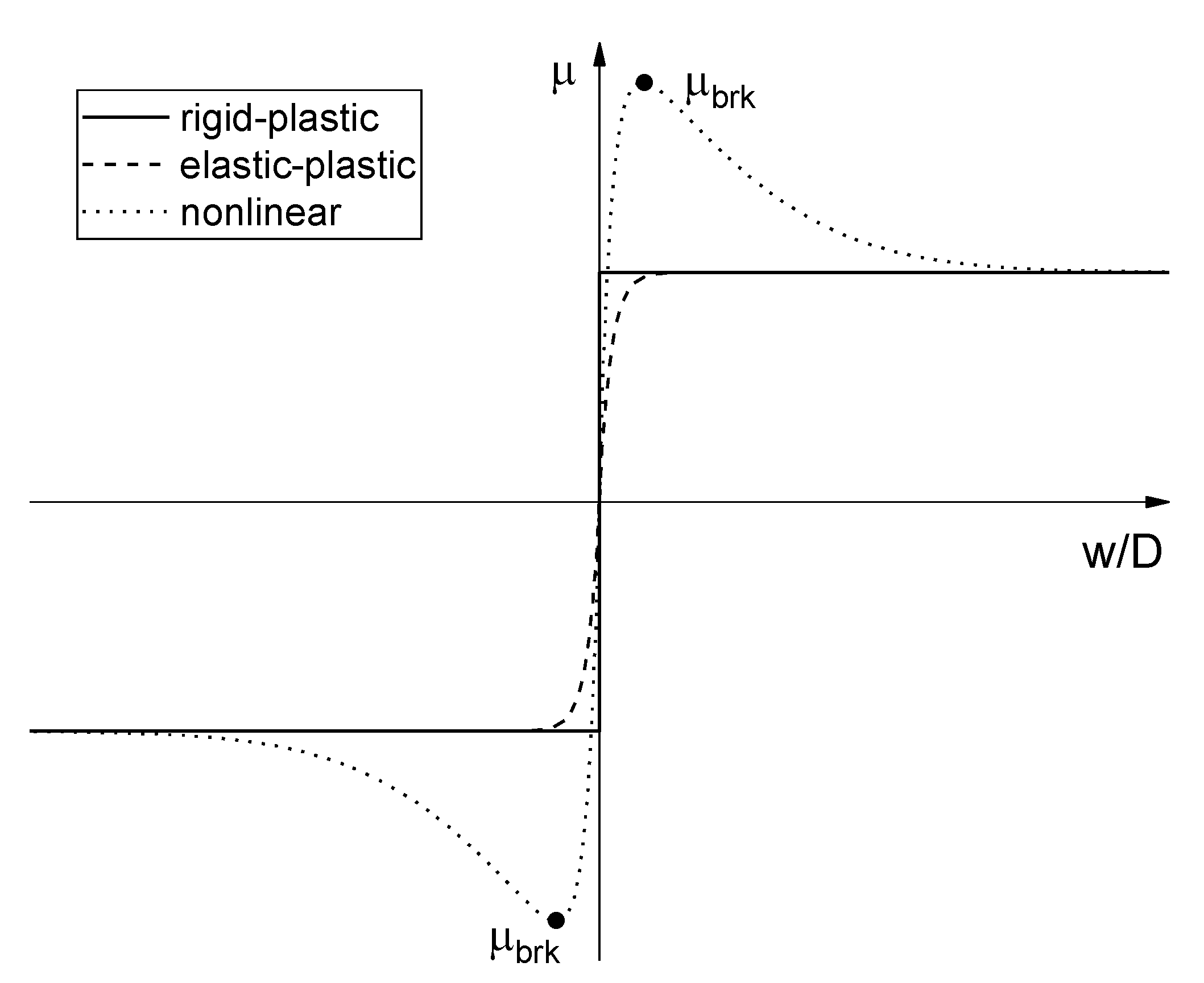

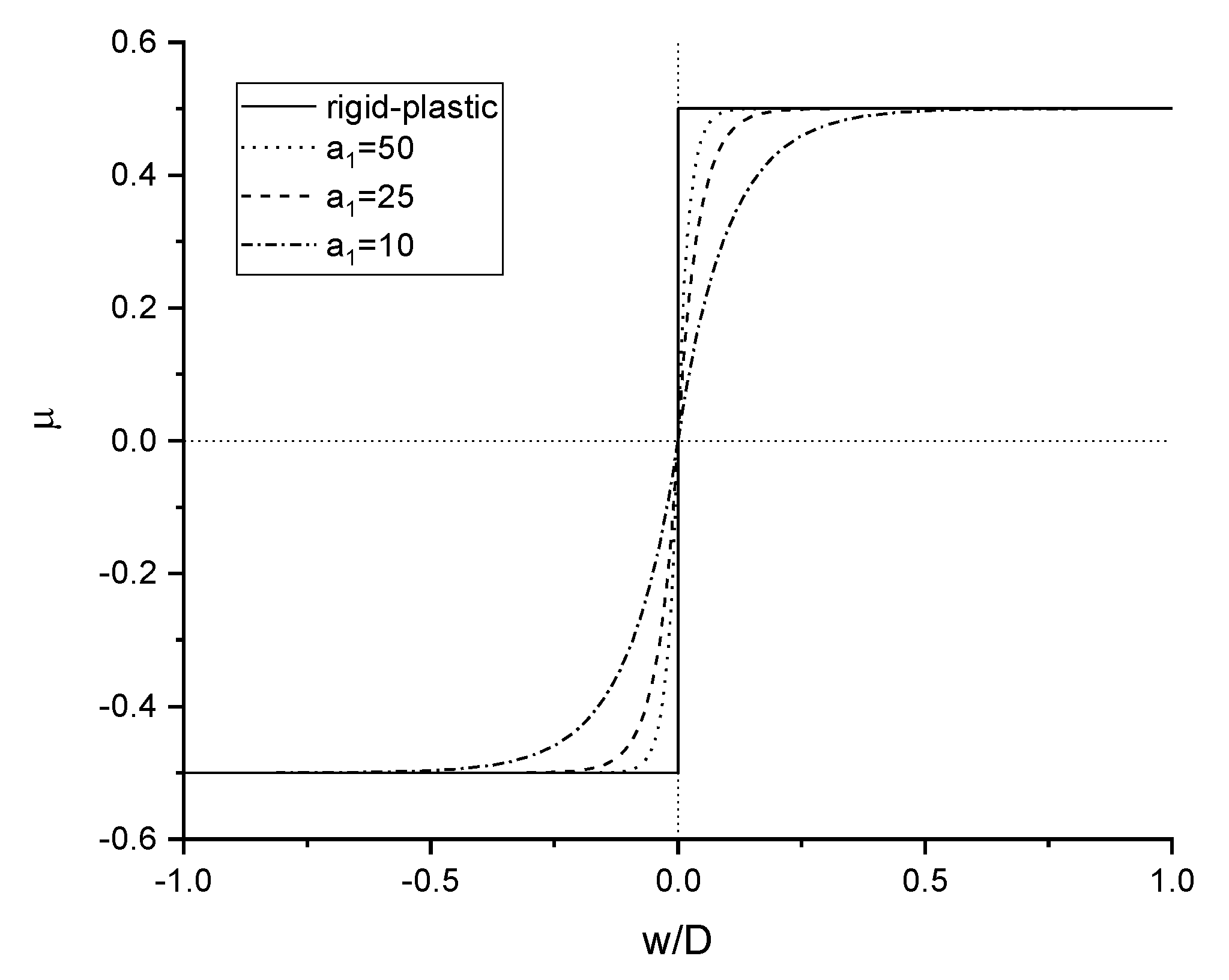

2. Mathematical Modelling

3. Results

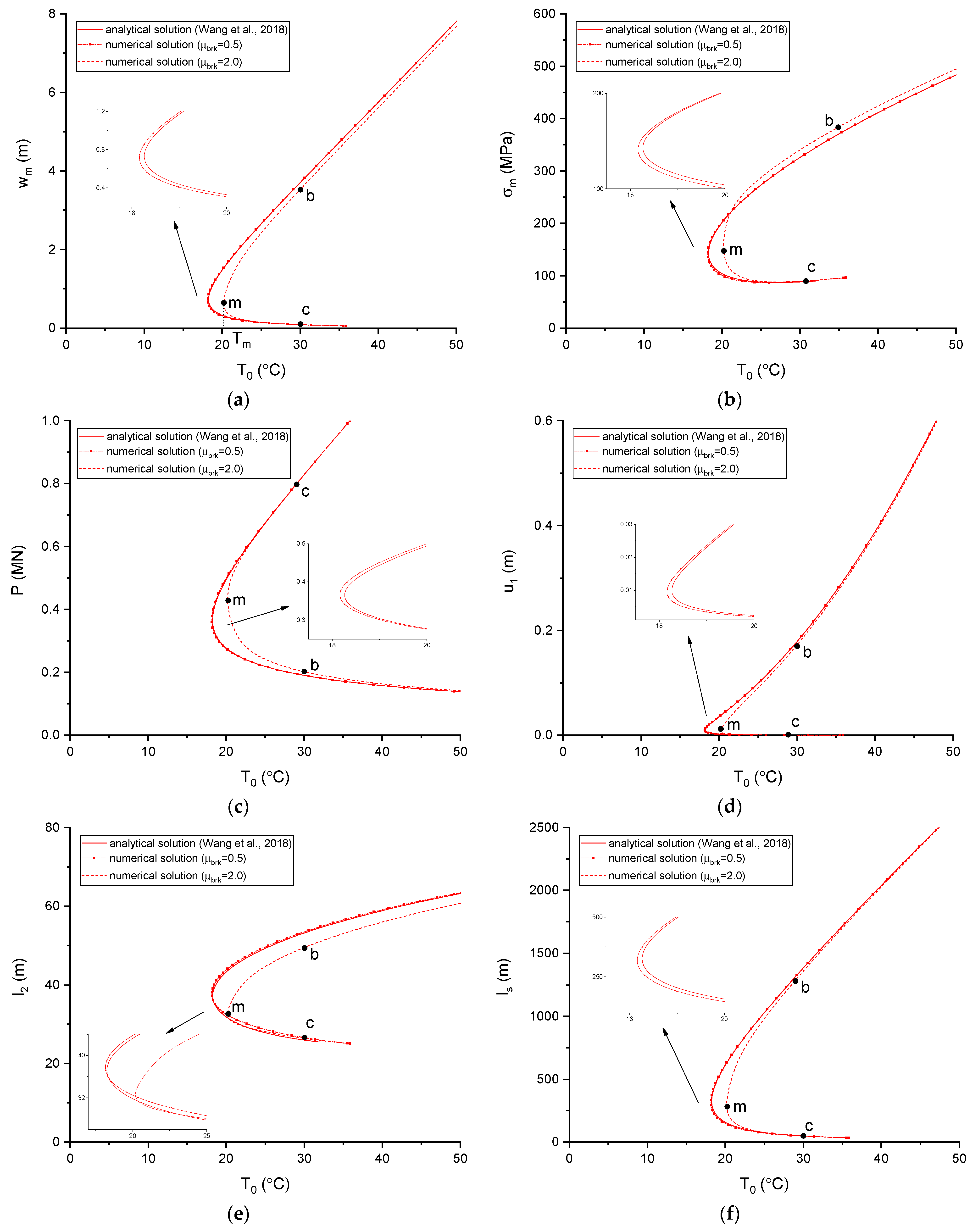

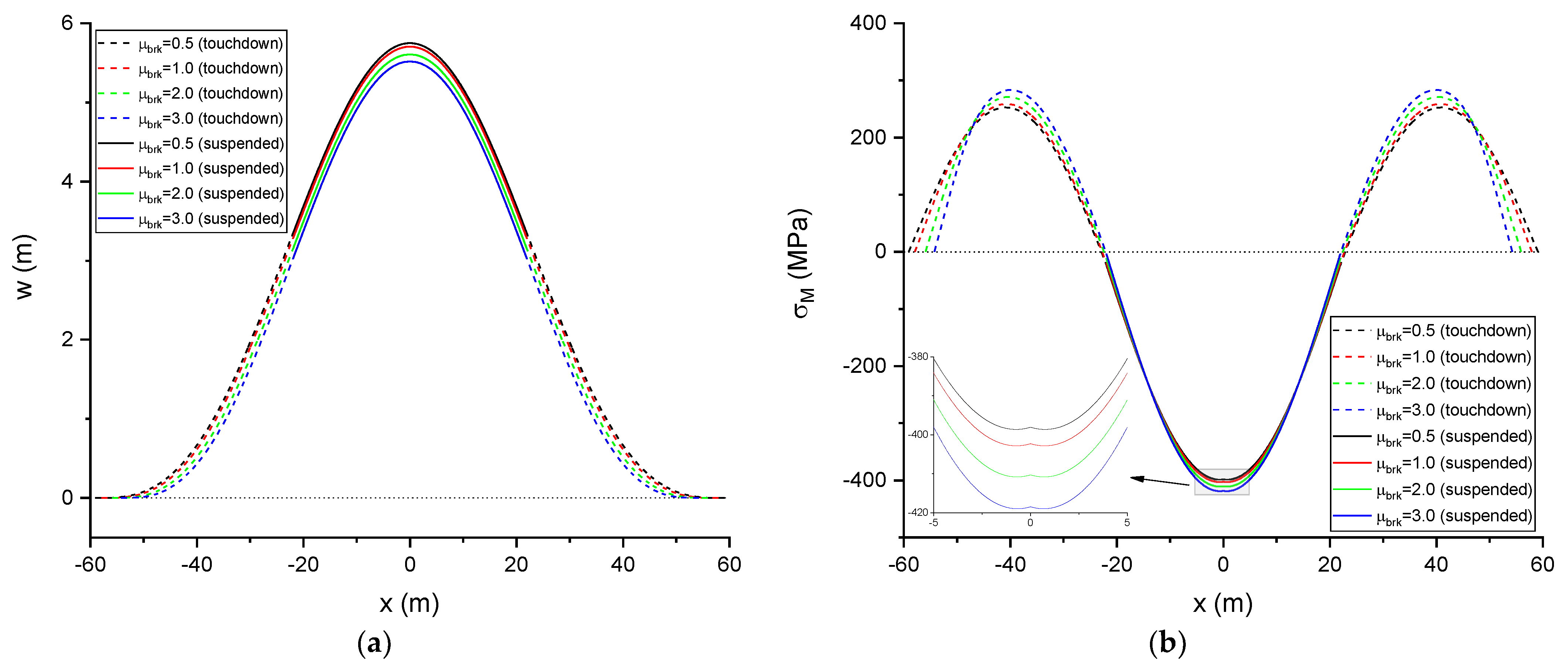

3.1. Validation

3.2. Parametric Study

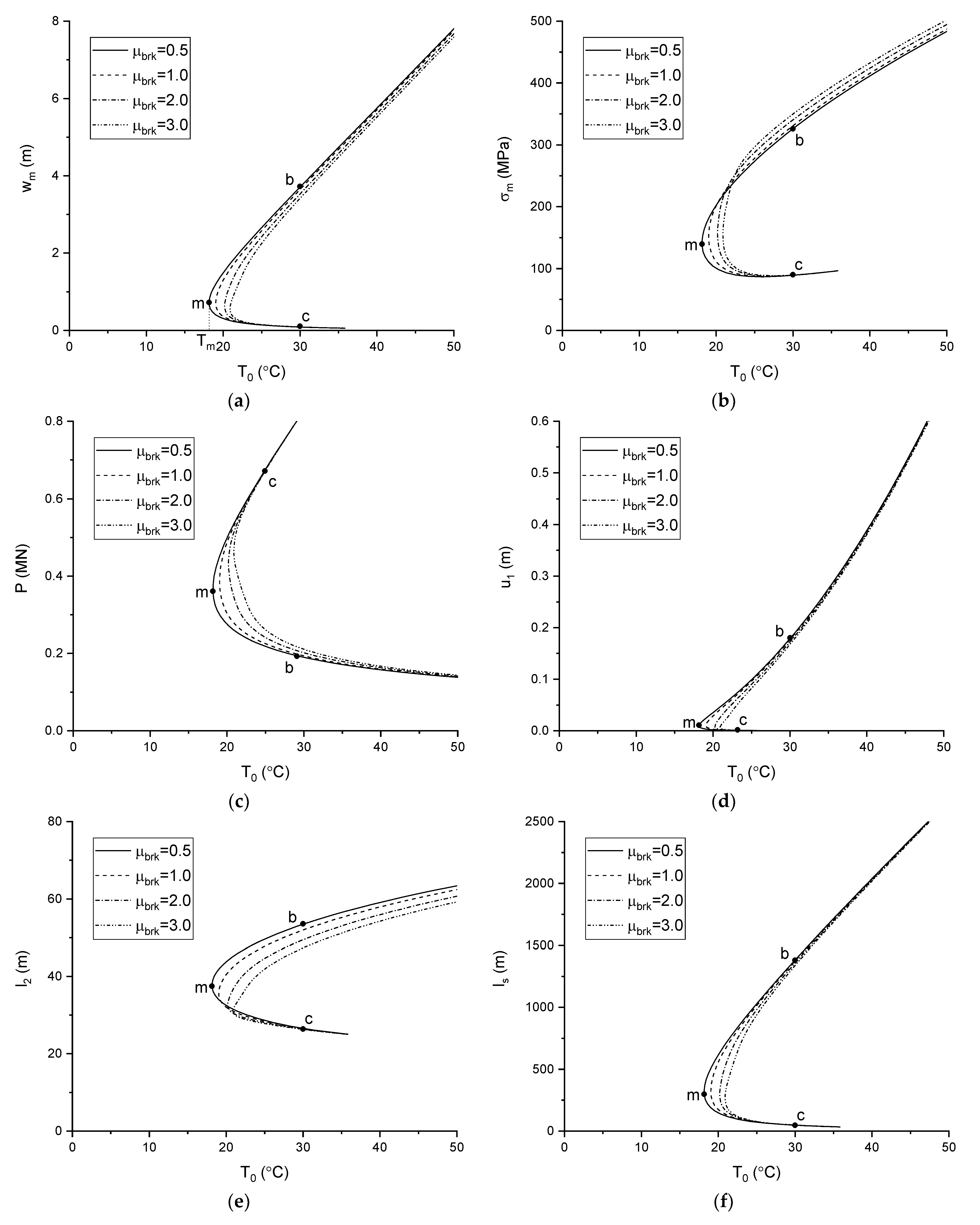

3.2.1. Influence of

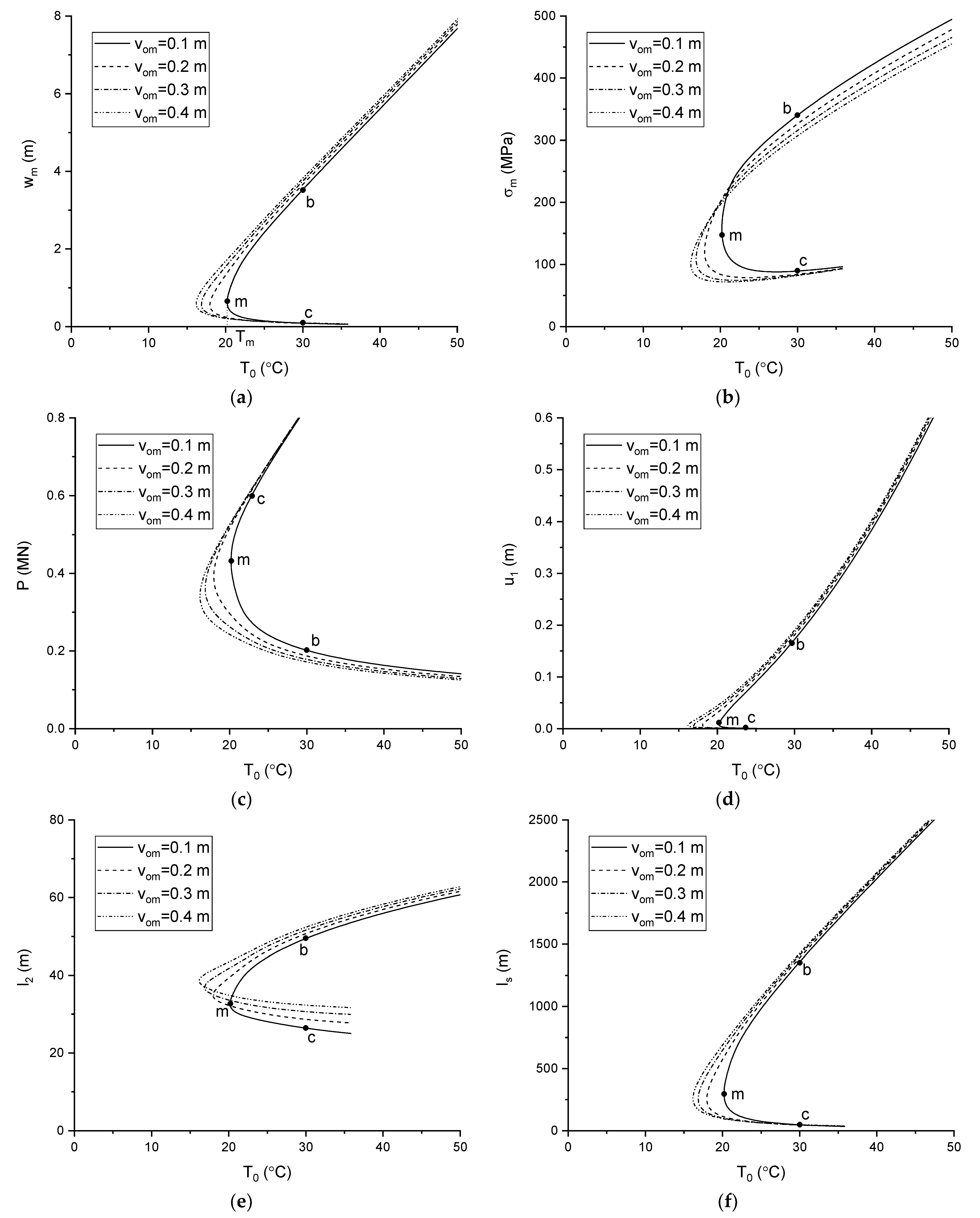

3.2.2. Influence of

3.2.3. Influence of

4. Conclusions

- (i)

- The discrepancy between the numerical and analytical solutions comes from the difference between the elastic-plastic and rigid-plastic pipe–soil interaction models, which reduces with decreasing mobilization difference in the elastic-plastic pipe–soil interaction model.

- (ii)

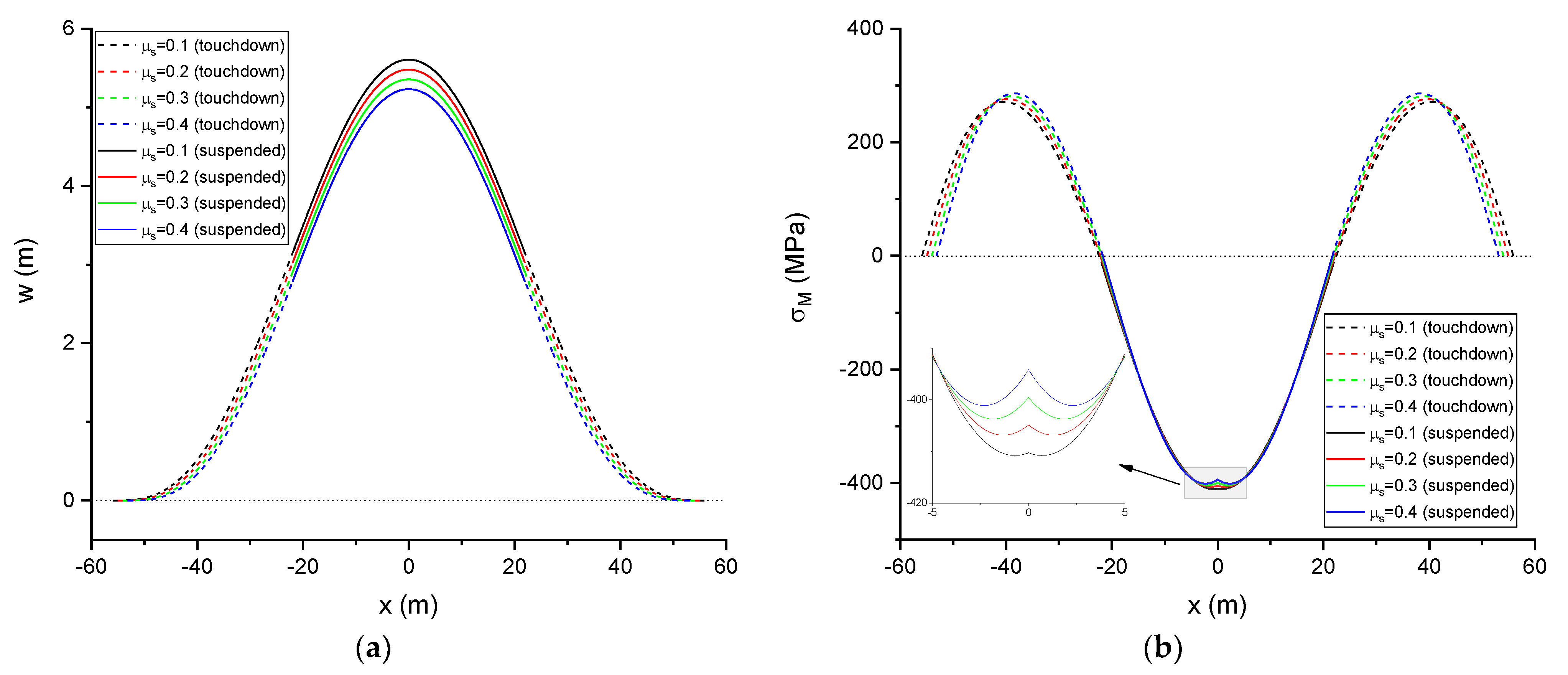

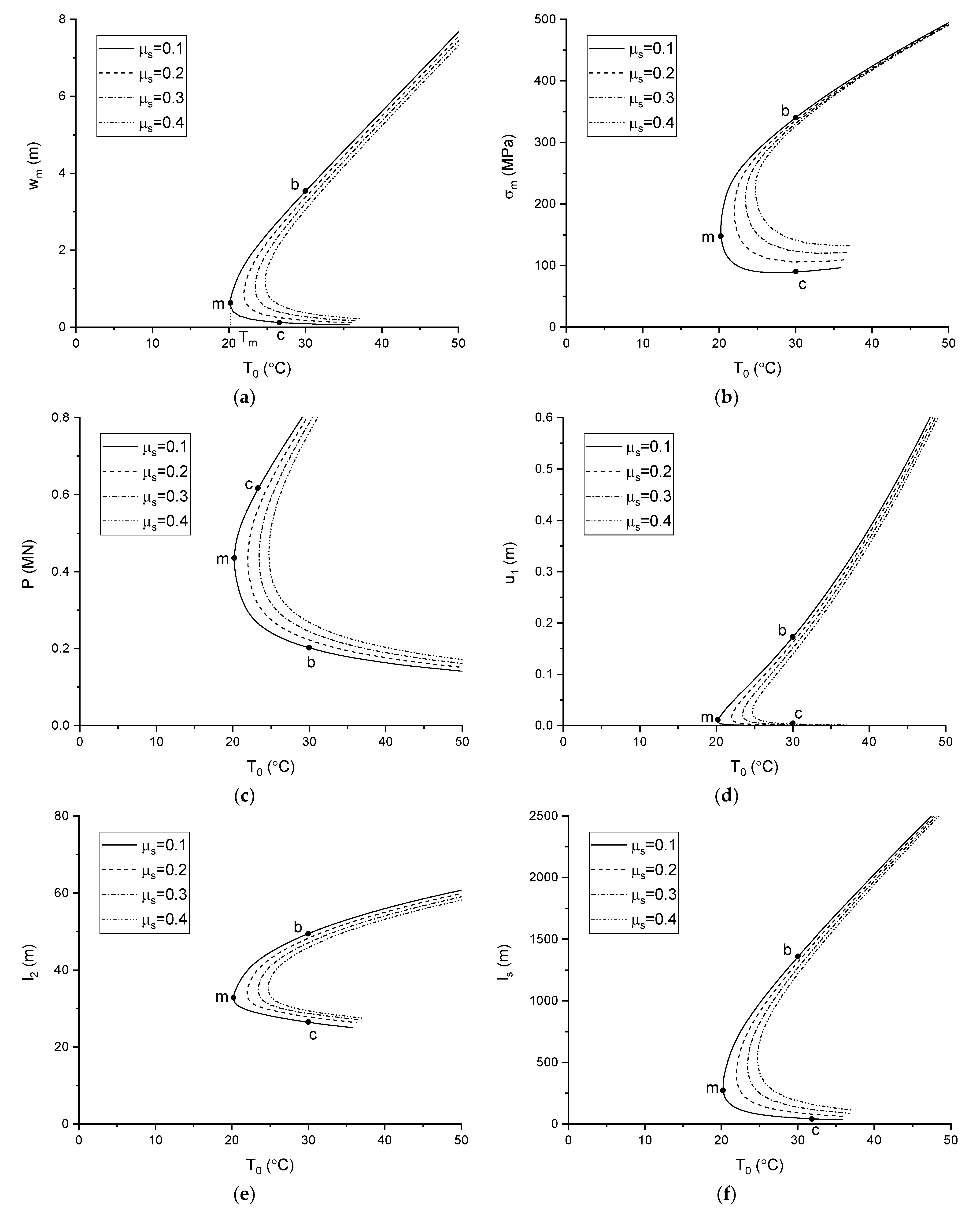

- When the nonlinear pipe–soil interaction model is taken into account, both the displacement amplitude and the buckled length reduce due to the occurrence of breakout resistance, which decreases further with increasing breakout resistance. However, both the axial force and the maximum stress, along with the buckled pipeline, increase, and increase further with increasing breakout resistance.

- (iii)

- The deflection of the buckled pipeline enlarges as the sleeper height increases and shrinks as the sleeper friction coefficient increases. The axial force decreases with increasing sleeper height and increases with increasing sleeper friction coefficient. Moreover, the maximum stress along the buckled pipeline decreases with increasing sleeper height and with decreasing sleeper friction coefficient.

- (iv)

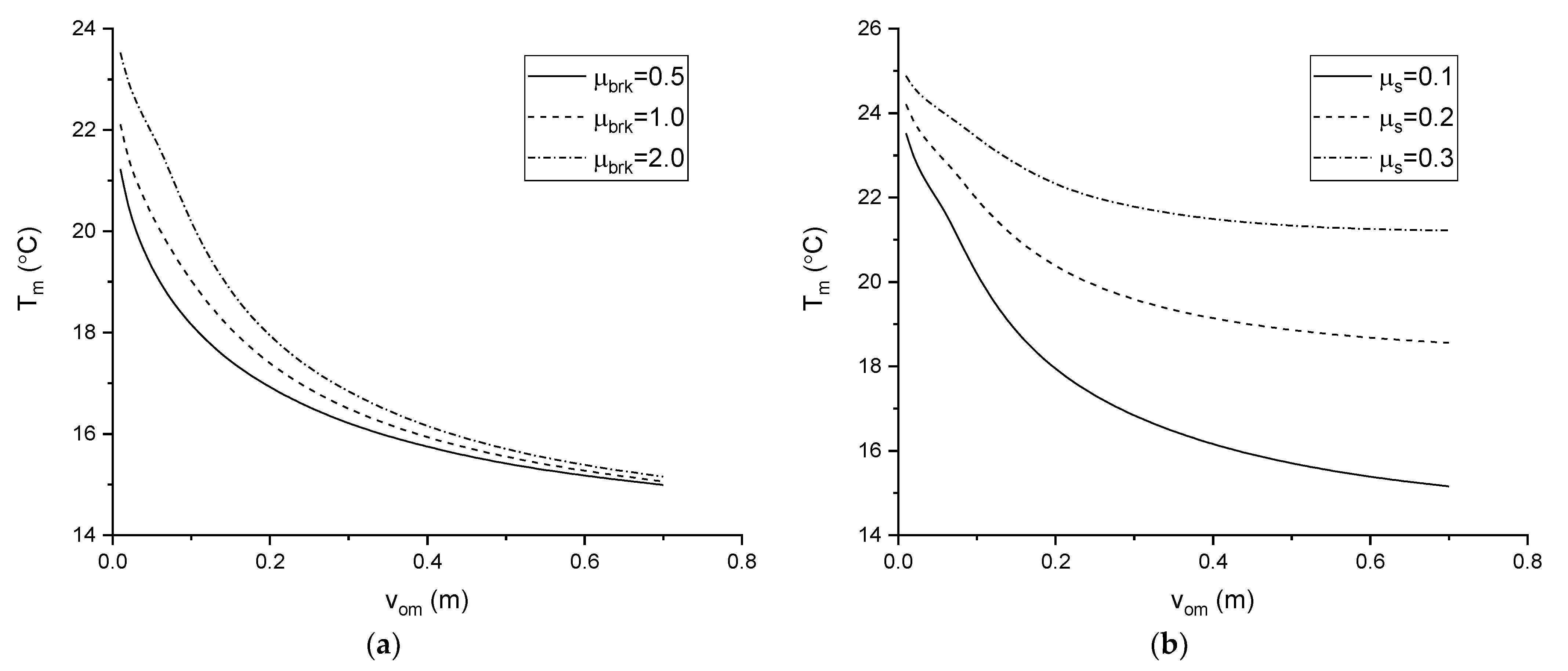

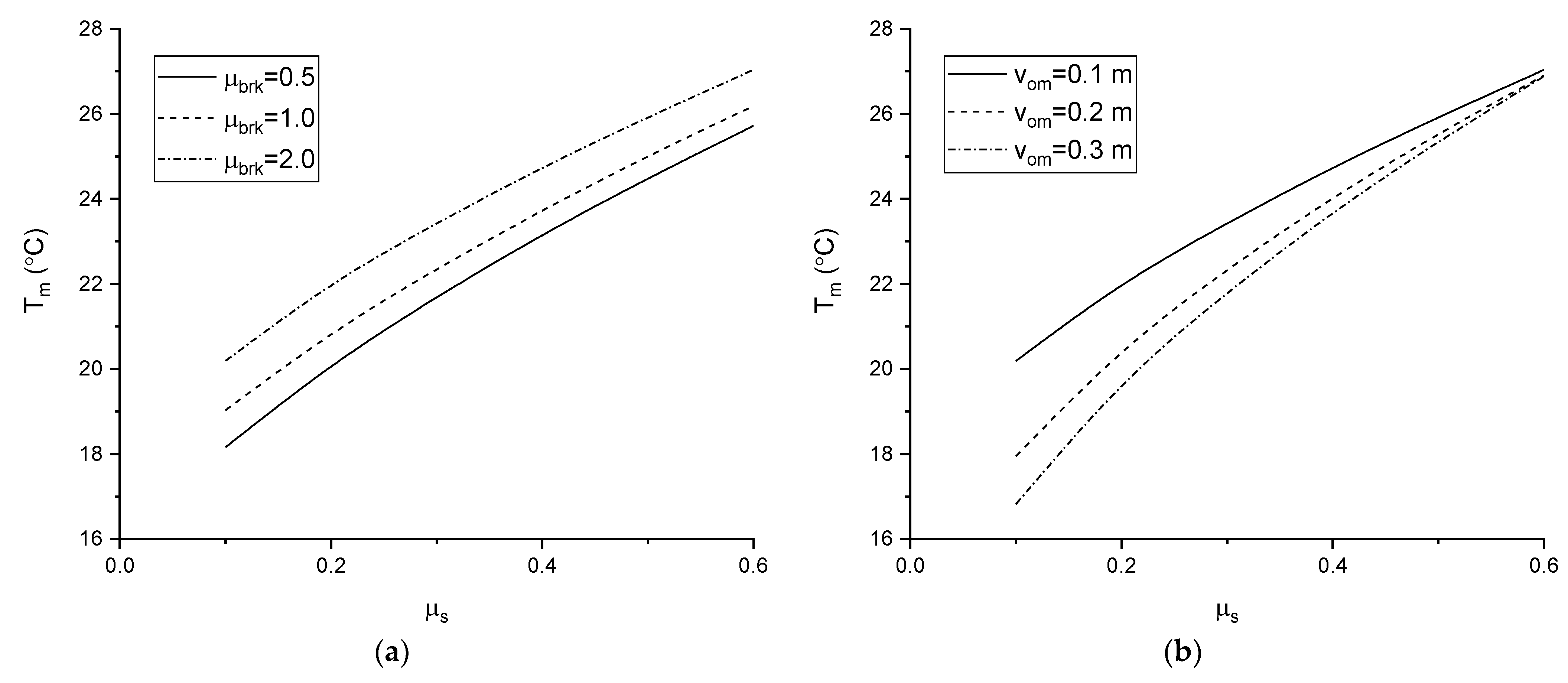

- The minimum critical temperature difference increases with increasing breakout resistance and sleeper friction coefficient, and decreases with increasing sleeper height. The influence of the breakout resistance on the minimum critical temperature difference gradually reduces with increasing sleeper height. Moreover, the sleeper height has little effect on the minimum critical temperature difference when the sleeper friction coefficient is large enough.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- DNV-RP-F110; Global Buckling of Submarine Pipelines. Det Norske Veritas: Oslo, Norway, 2019.

- Hobbs, R.E. In-service buckling of heated pipelines. J. Transp. Eng. 1984, 110, 175–189. [Google Scholar] [CrossRef]

- Taylor, N.; Gan, A.B. Submarine pipeline buckling-imperfection studies. Thin-Walled Struct. 1986, 4, 295–323. [Google Scholar] [CrossRef]

- Croll, J.G.A. A simplified model of upheaval thermal buckling of subsea pipelines. Thin-Walled Struct. 1997, 29, 59–78. [Google Scholar] [CrossRef]

- Karampour, H.; Albermani, F.; Veidt, M. Buckle interaction in deep subsea pipelines. Thin-Walled Struct. 2013, 72, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Xiong, H.; Wu, X.; Yan, S. Numerical studies on global buckling of subsea pipelines. Ocean Eng. 2014, 78, 62–72. [Google Scholar] [CrossRef]

- Hong, Z.; Liu, R.; Liu, W.; Yan, S. Study on lateral buckling characteristics of a submarine pipeline with a single arch symmetric initial imperfection. Ocean Eng. 2015, 108, 21–32. [Google Scholar] [CrossRef]

- Liu, R.; Wang, X. Lateral global buckling high-order mode analysis of a submarine pipeline with imperfection. Appl. Ocean. Res. 2018, 73, 107–126. [Google Scholar] [CrossRef]

- Konuk, I. Coupled lateral and axial soil-pipe interaction and lateral buckling Part II: Solutions. Int. J. Solids Struct. 2018, 132–133, 127–152. [Google Scholar] [CrossRef]

- Konuk, I. Coupled lateral and axial soil-pipe interaction and lateral buckling Part I: Formulation. Int. J. Solids Struct. 2018, 132–133, 114–126. [Google Scholar] [CrossRef]

- Zhang, X.; Duan, M. Prediction of the upheaval buckling critical force for imperfect submarine pipelines. Ocean Eng. 2015, 109, 330–343. [Google Scholar] [CrossRef]

- Zhang, X.; Guedes Soares, C.; An, C.; Duan, M. An unified formula for the critical force of lateral buckling of imperfect submarine pipelines. Ocean Eng. 2018, 166, 324–335. [Google Scholar] [CrossRef]

- Liu, R.; Li, C. Determinate dimension of numerical simulation model in submarine pipeline global buckling analysis. Ocean Eng. 2018, 152, 26–35. [Google Scholar] [CrossRef]

- Zeng, X.; Duan, M. Mode localization in lateral buckling of partially embedded submarine pipelines. Int. J. Solids Struct. 2014, 51, 1991–1999. [Google Scholar] [CrossRef] [Green Version]

- Chee, J.; Walker, A.; White, D. Effects of variability in lateral pipe-soil interaction and pipe initial out-of-straightness on controlled lateral buckling of pre-deformed pipeline. Ocean Eng. 2019, 182, 283–304. [Google Scholar] [CrossRef]

- Zhang, X.; Guedes Soares, C. Lateral buckling analysis of subsea pipelines on nonlinear foundation. Ocean Eng. 2019, 186, 106085. [Google Scholar] [CrossRef]

- Peek, R.; Yun, H. Flotation to trigger lateral buckles in pipelines on a flat seabed. J. Eng. Mech. 2007, 4, 442–451. [Google Scholar] [CrossRef]

- Shi, R.; Wang, L. Single buoyancy load to trigger lateral buckles in pipelines on a soft seabed. J. Eng. Mech. 2015, 141, 1–7. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, Y. Antisymmetric thermal buckling triggered by dual distributed buoyancy sections. Mar. Struct. 2020, 74, 102811. [Google Scholar] [CrossRef]

- Chee, J.; Walker, A.; White, D. Controlling lateral buckling of subsea pipeline with sinusoidal shape pre-deformation. Ocean Eng. 2018, 151, 170–190. [Google Scholar] [CrossRef] [Green Version]

- Silva-Junior, H.C.; Cardoso, C.O.; Carmignotto, M.A.P.; Zanutto, J.C. Reduced Model Device of Solutions to Control Thermal Buckling Effects in HP-HT Subsea Pipelines (OMAE2008-57637). In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Estoril, Portugal, 15 June 2008. [Google Scholar]

- de Oliveira Cardoso, C.; Solano, R.F. Performed of triggers to control thermal buckling of subsea pipelines using reduced scale model (ISOPE-I-15-445). In Proceedings of the International Offshore and Polar Engineering Conference, Honolulu, HI, USA, 21–26 June 2015. [Google Scholar]

- Bai, Q.; Qi, X.; Brunner, M. Global buckle control with dual sleepers in HP/HT pipelines (OTC-19888-MS). In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2009. [Google Scholar]

- Wang, Z.; Tang, Y. Analytical study on controlled lateral thermal buckling of antisymmetric mode for subsea pipelines triggered by sleepers. Mar. Struct. 2020, 71, 102728. [Google Scholar] [CrossRef]

- Hong, Z.; Liu, W. Modelling the vertical lifting deformation for a deep-water pipeline laid on a sleeper. Ocean Eng. 2020, 199, 107042. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, Y.; van der Heijden, G.H.M. Analytical study of lateral thermal buckling for subsea pipelines with sleeper. Thin-Walled Struct. 2018, 122, 17–29. [Google Scholar] [CrossRef] [Green Version]

- Lagrange, R.; Averbuch, D. Solution methods for the growth of a repeating imperfection in the line of a strut on a nonlinear foundation. Int. J. Mech. Sci. 2012, 63, 48–58. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, Y.; van der Heijden, G.H.M. Analytical study of distributed buoyancy sections to control lateral thermal buckling of subsea pipelines. Mar. Struct. 2018, 58, 199–222. [Google Scholar] [CrossRef] [Green Version]

- Chatterjee, S.; White, D.J.; Randolph, M.F. Numerical simulations of pipe-soil interaction during large lateral movements on clay. Géotechnique 2012, 62, 693–705. [Google Scholar] [CrossRef]

- Wolfram Mathematica, version 11.0; Wolfram Research, Inc.: Champaign, IL, USA, 2016.

| Parameter | Value | Unit |

|---|---|---|

| External diameter | 323.9 | mm |

| Wall thickness | 12.7 | mm |

| Elastic modulus | 206 | GPa |

| Steel density | 7850 | |

| Coefficient of thermal expansion | ||

| Axial friction coefficient | 0.5 | --- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Guedes Soares, C. Lateral Buckling of Subsea Pipelines Triggered by Sleeper with a Nonlinear Pipe–Soil Interaction Model. J. Mar. Sci. Eng. 2022, 10, 757. https://doi.org/10.3390/jmse10060757

Wang Z, Guedes Soares C. Lateral Buckling of Subsea Pipelines Triggered by Sleeper with a Nonlinear Pipe–Soil Interaction Model. Journal of Marine Science and Engineering. 2022; 10(6):757. https://doi.org/10.3390/jmse10060757

Chicago/Turabian StyleWang, Zhenkui, and C. Guedes Soares. 2022. "Lateral Buckling of Subsea Pipelines Triggered by Sleeper with a Nonlinear Pipe–Soil Interaction Model" Journal of Marine Science and Engineering 10, no. 6: 757. https://doi.org/10.3390/jmse10060757

APA StyleWang, Z., & Guedes Soares, C. (2022). Lateral Buckling of Subsea Pipelines Triggered by Sleeper with a Nonlinear Pipe–Soil Interaction Model. Journal of Marine Science and Engineering, 10(6), 757. https://doi.org/10.3390/jmse10060757