Analysis of Cyclic Shear Stress–Displacement Mechanical Properties of Silt–Steel Interface in the Yellow River Delta

Abstract

:1. Introduction

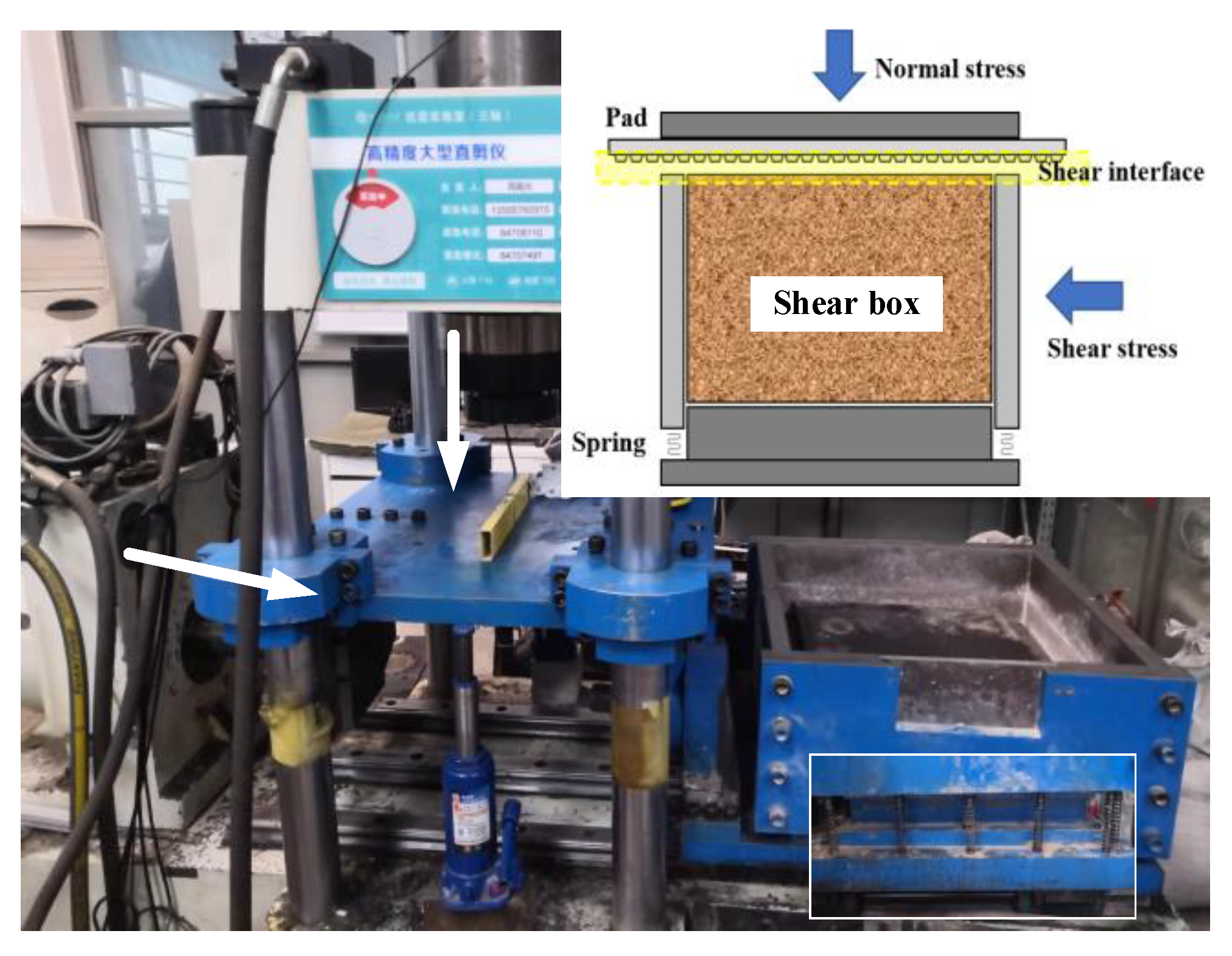

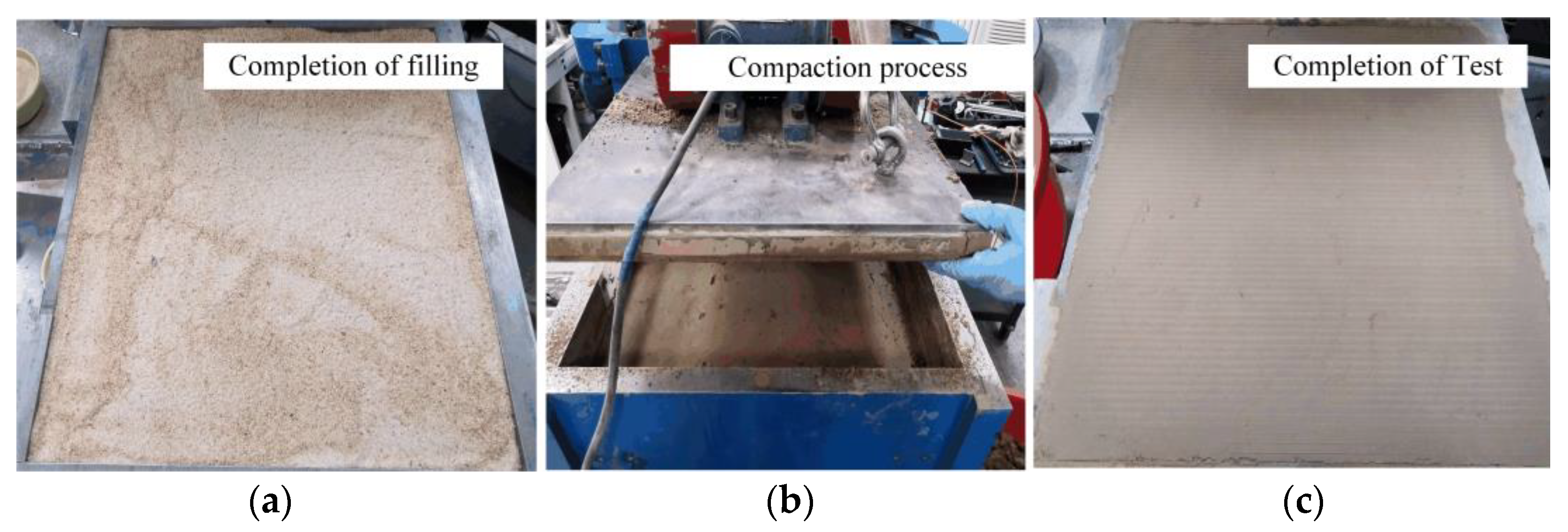

2. Materials and Methods

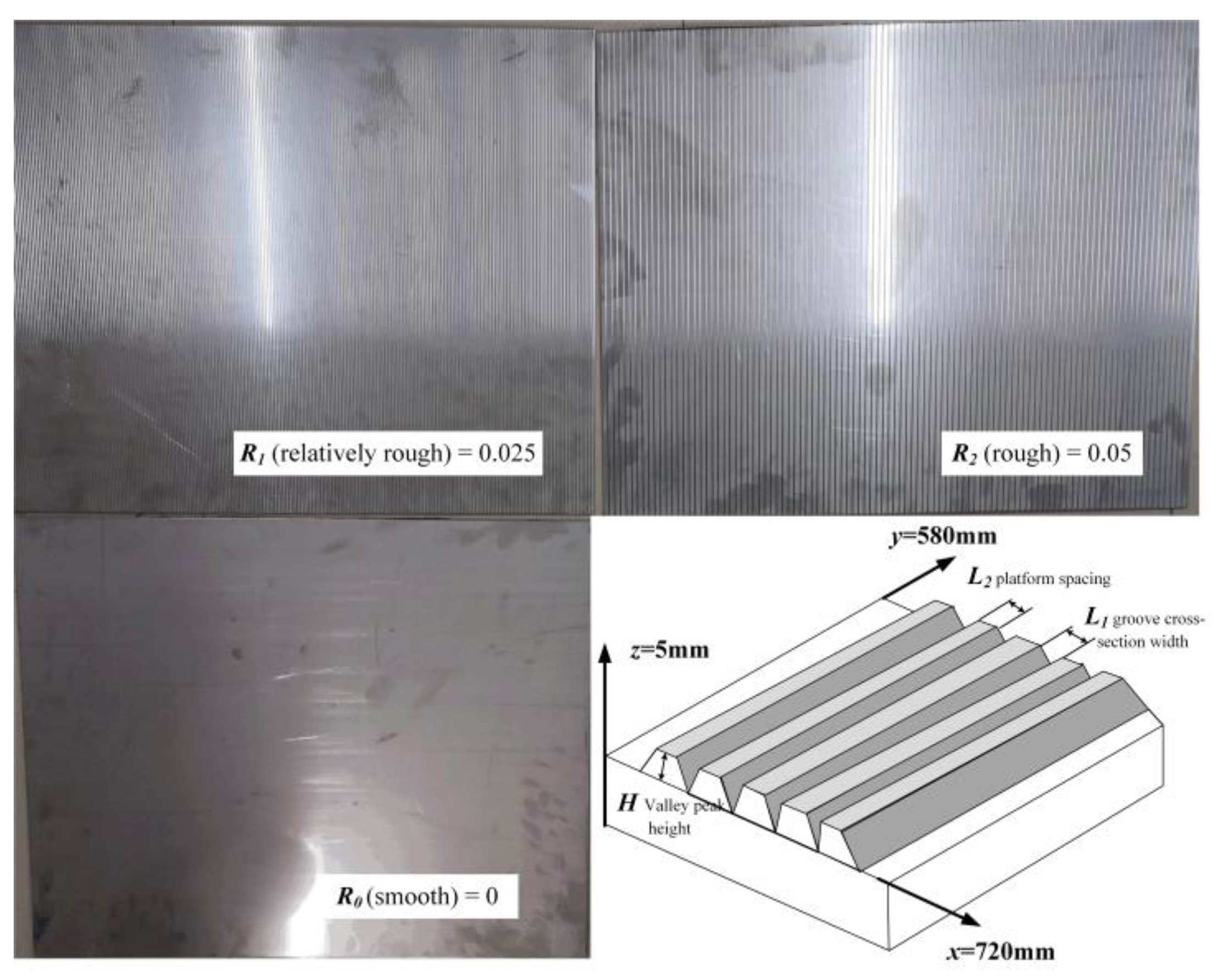

2.1. Test Instruments and Materials

2.2. Test Methods

3. Results and Discussion

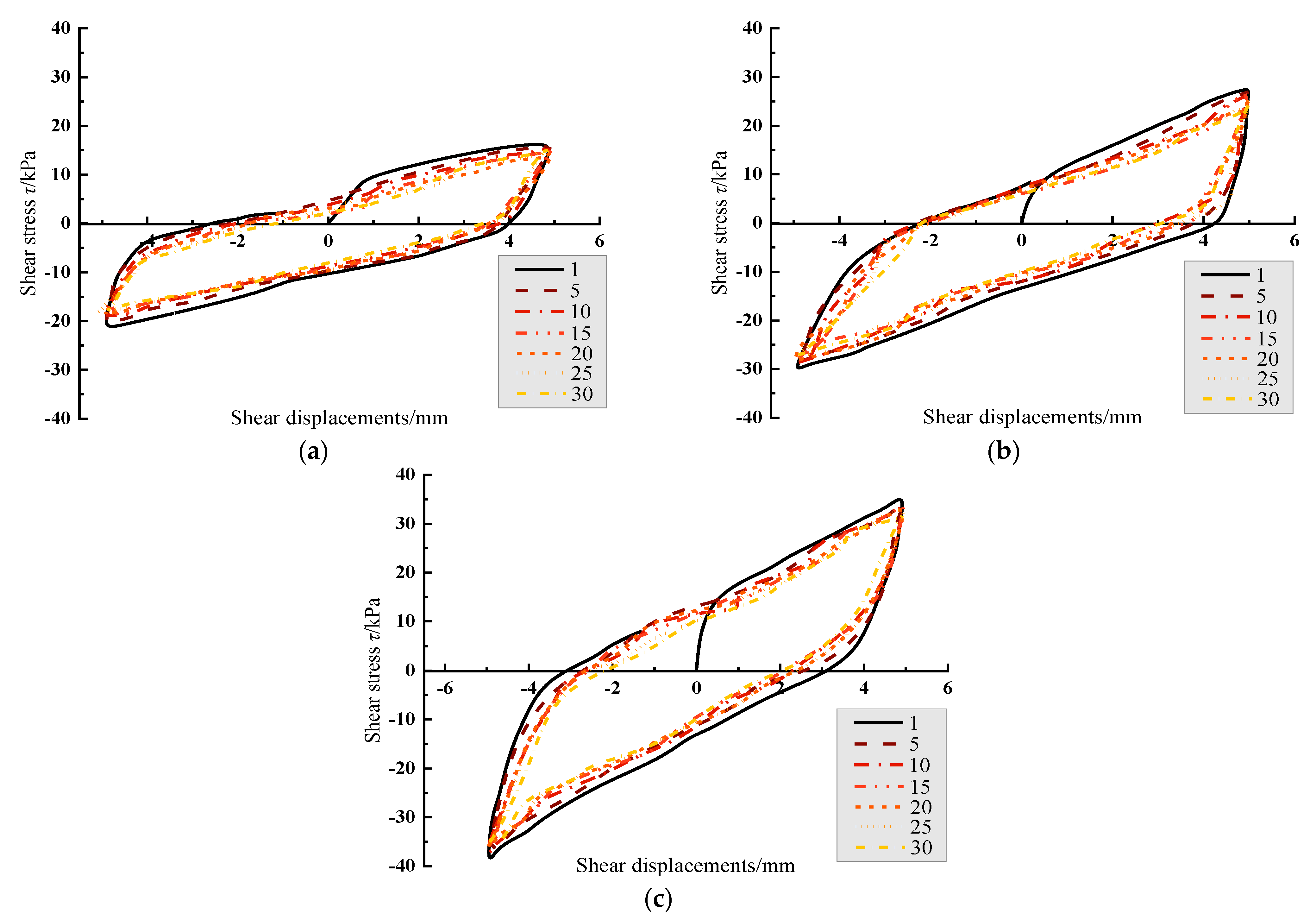

3.1. Relationship between Shear Stress and Shear Displacement

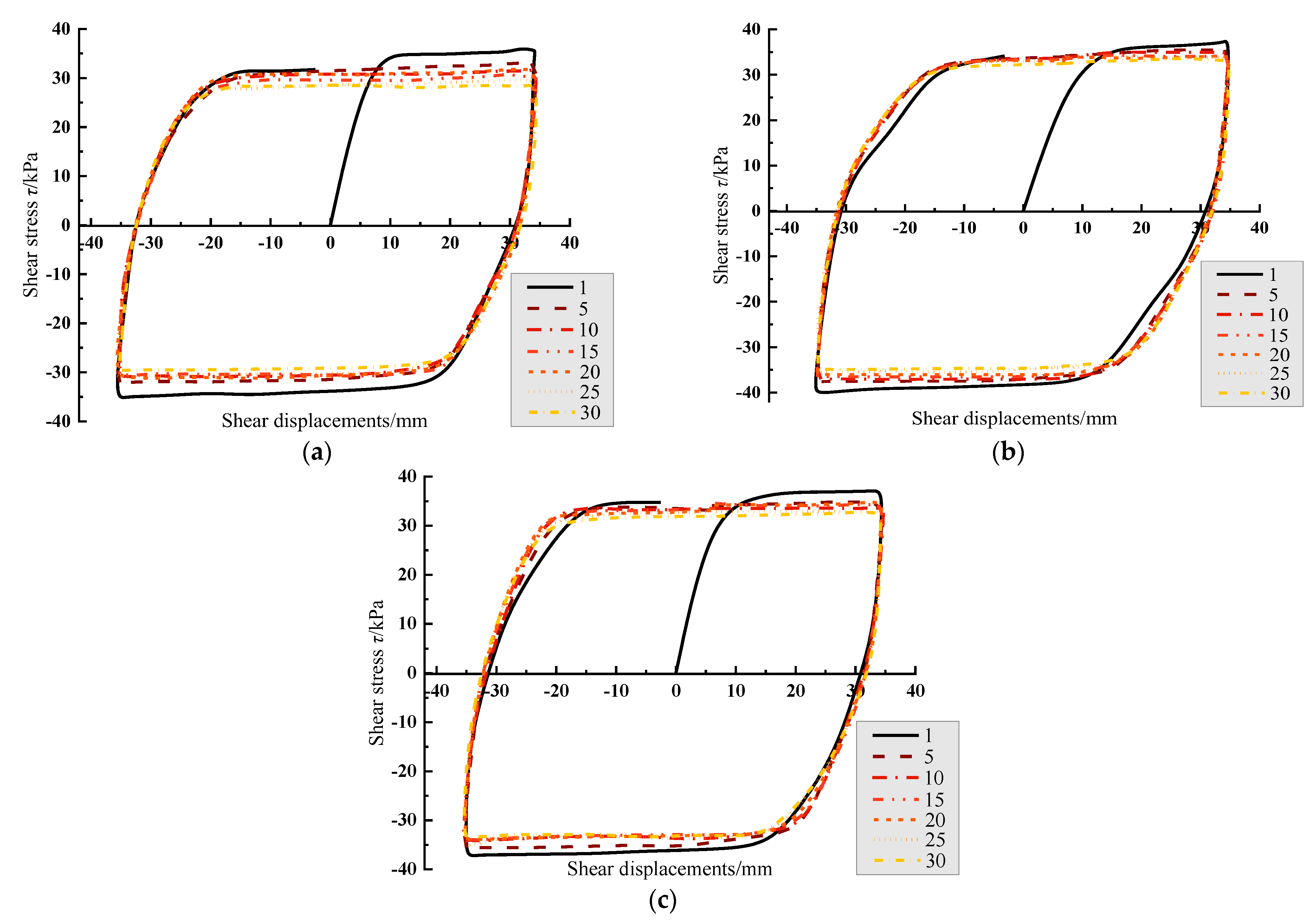

3.1.1. Effect of Normal Stress

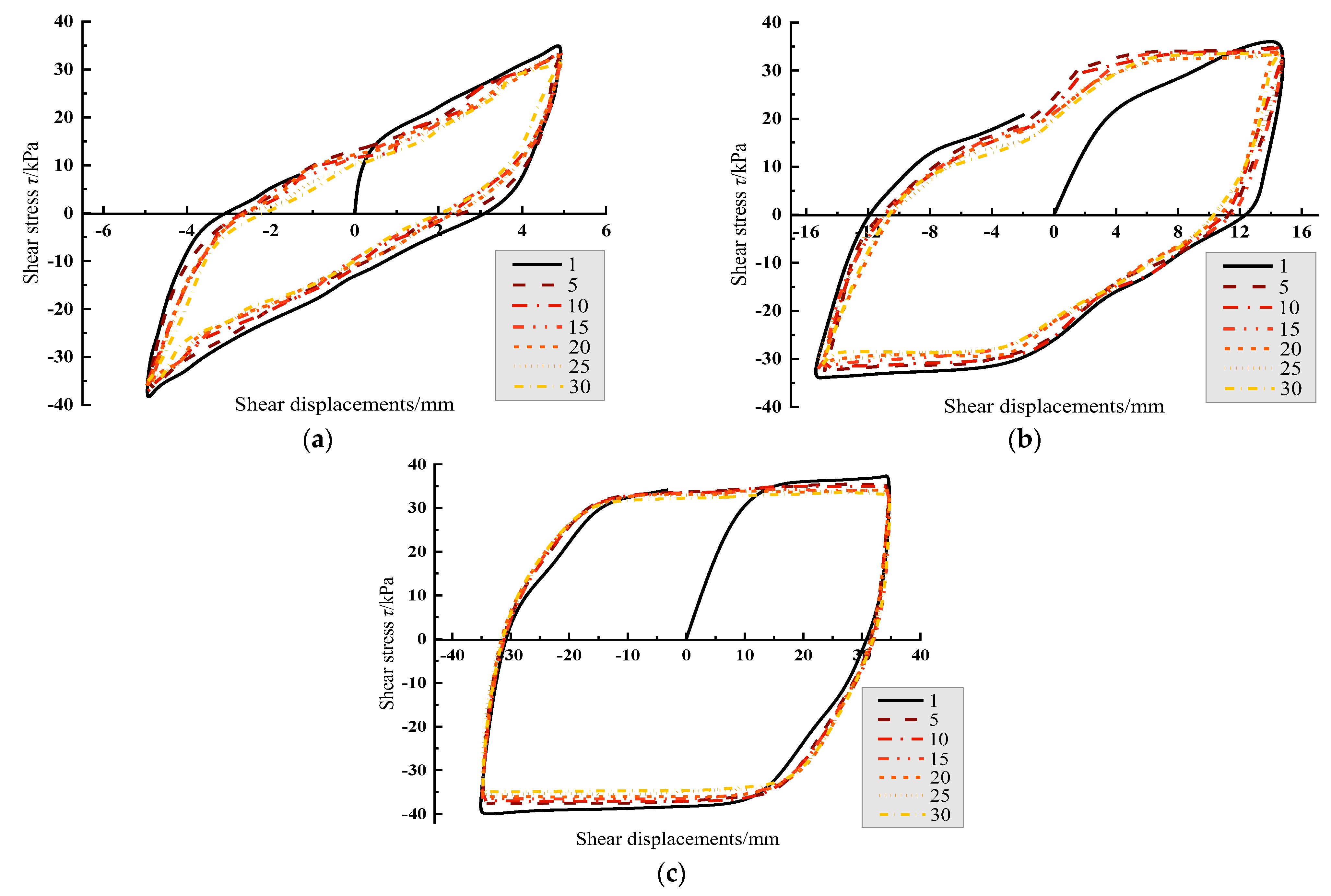

3.1.2. Effect of Shear Amplitude

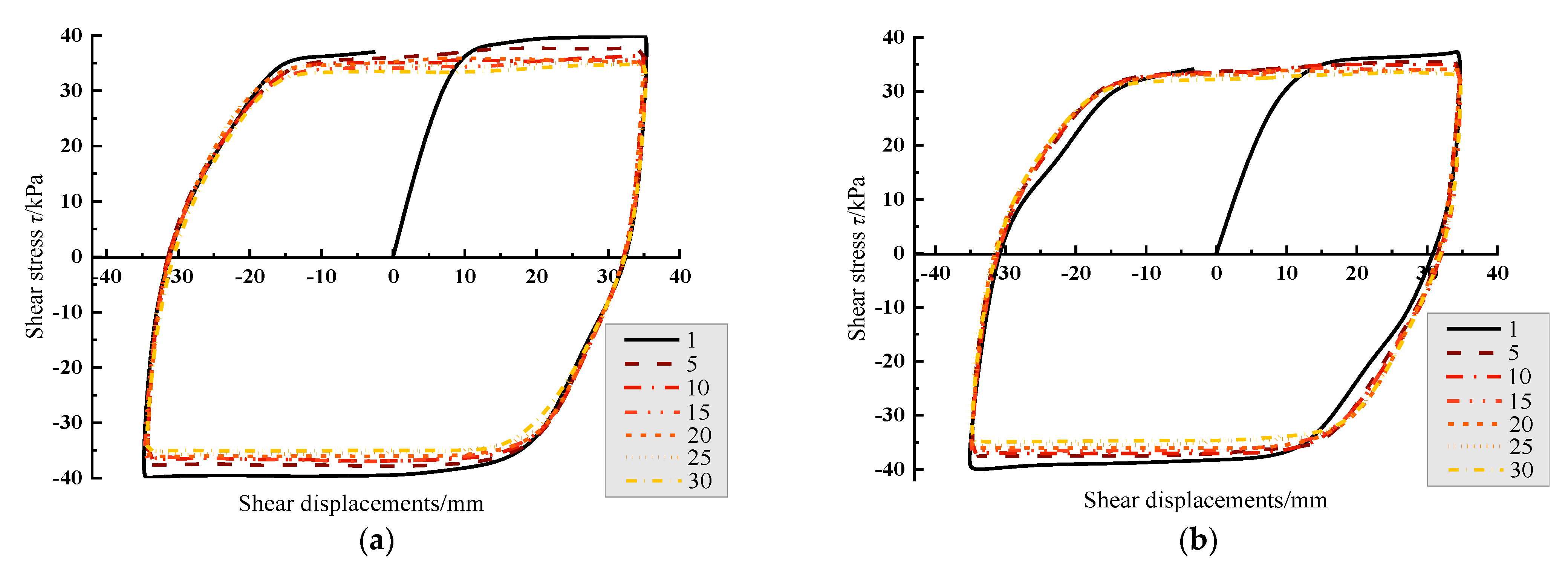

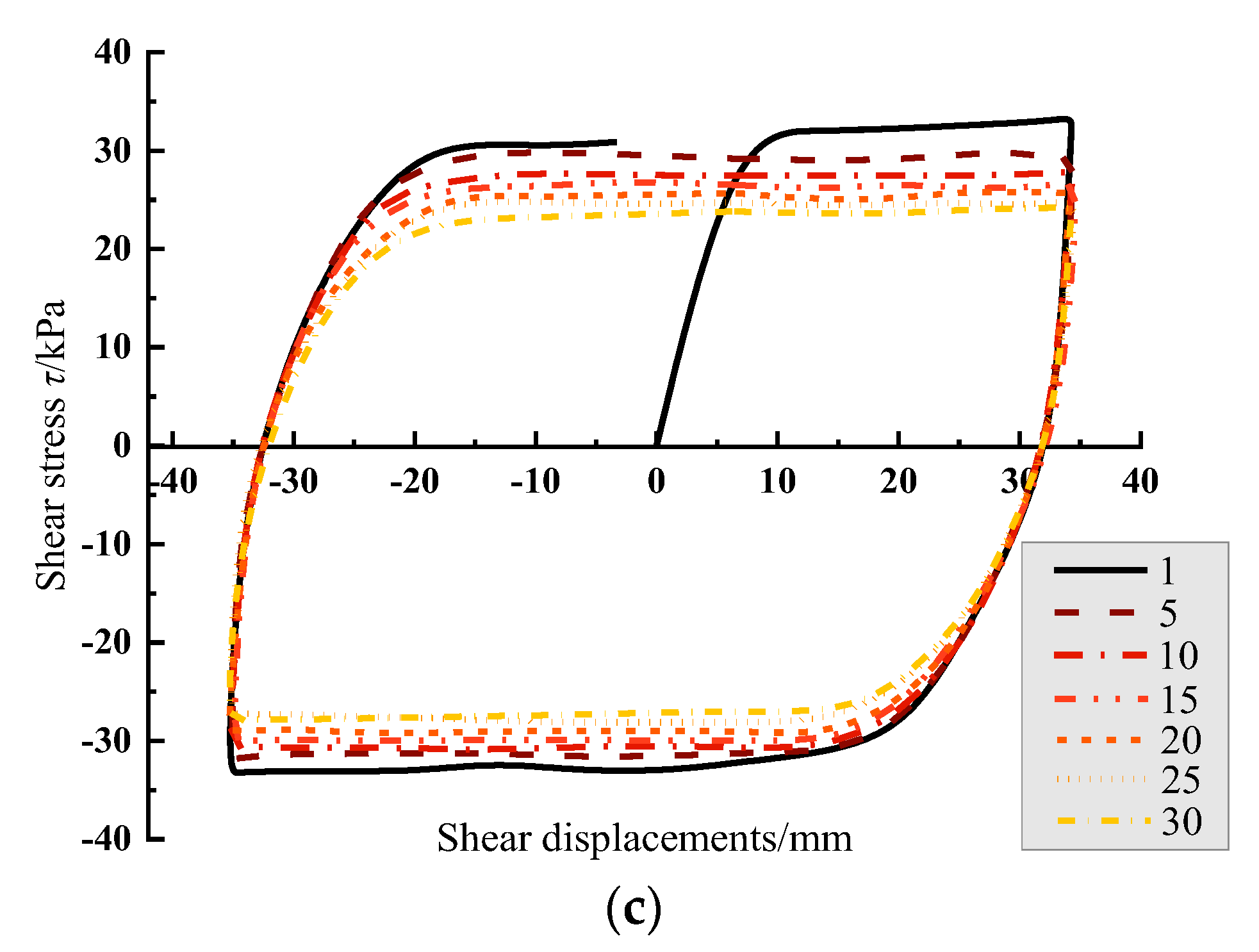

3.1.3. Effect of Roughness

3.1.4. Effect of Water Content

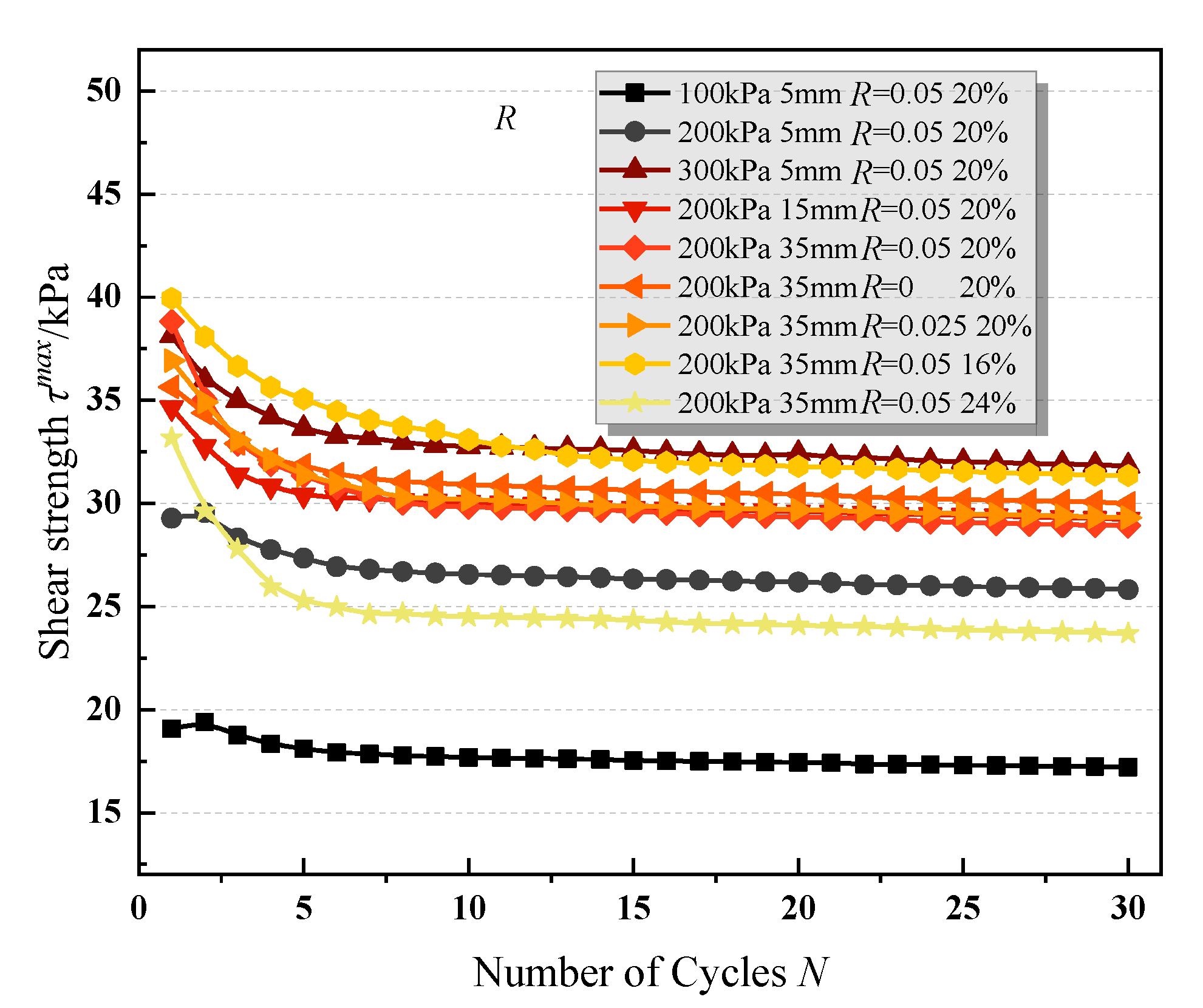

3.1.5. Shear Strength

- With the increase in the cyclic shear, the interface tended to weaken. The shear strength and residual shear strength increased with the increase in the shear amplitude.

- With the increase in the normal stress and roughness and the decrease in the water content, the interfacial shear strength and residual shear strength increased. The results were consistent with the direct shear test results for the silt–steel interface [22].

3.2. Body Change Law

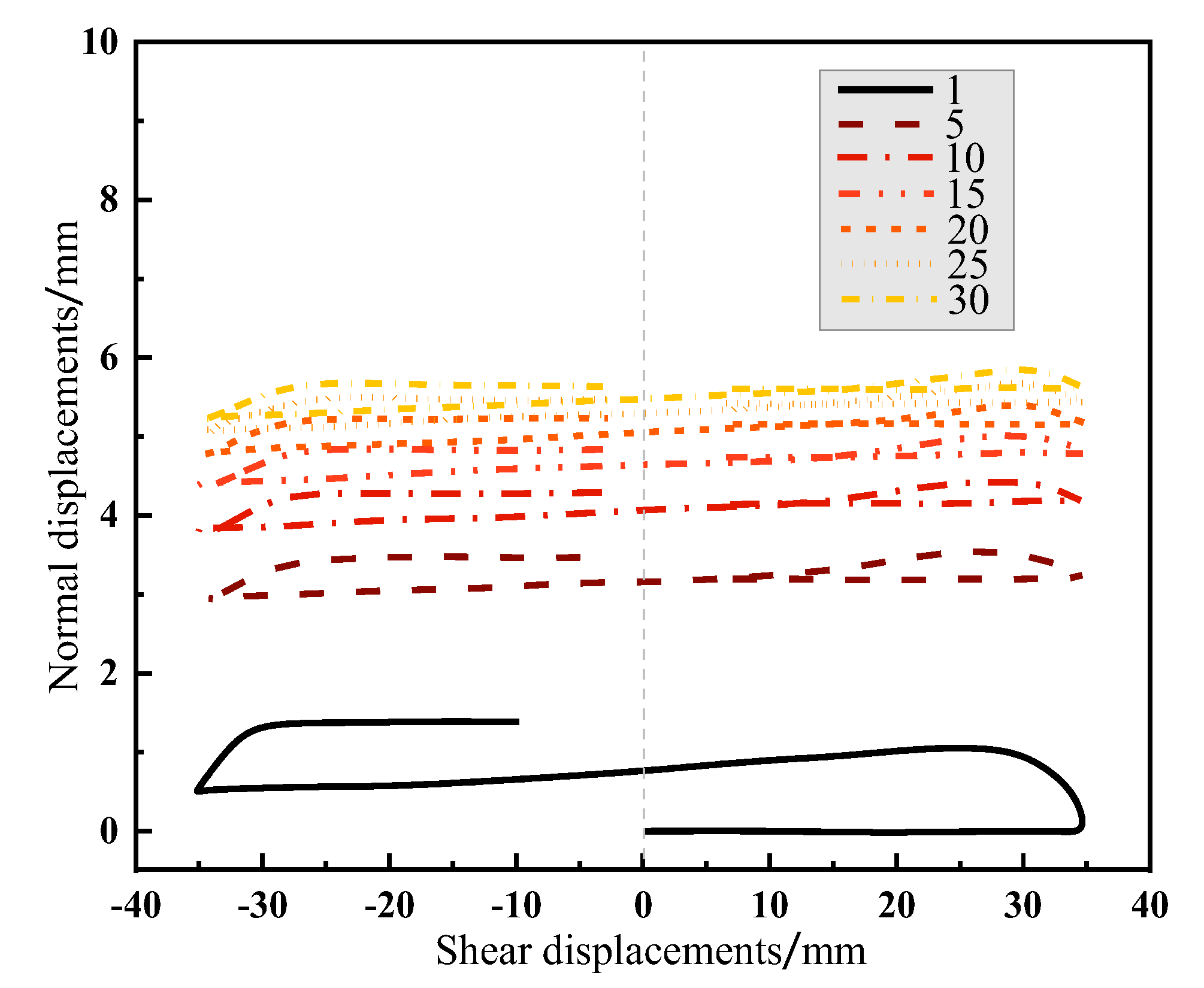

3.2.1. Typical Curve for Normal Displacement–Shear Displacement

- In the process of cyclic shear, the silt–steel interface generally presented shear shrinkage, and the shear shrinkage in the first five cycles was the largest. With the progress of the cyclic shear, the shear shrinkage increment presented a decreasing trend, but the overall shear shrinkage showed an increasing trend. This phenomenon can be explained according to the test conclusions drawn by Wang et al. [21] and Yu et al. [22]. In the process of loading and compaction, the soil body undertakes part of the compaction work. During the shearing, due to the displacement of soil particles, the accumulated cohesive potential energy and friction potential energy from compaction are released, resulting in an upward force. When the normal stress is high, the pressure difference between the upward force and the normal stress is negative and the soil particle gap is compressed, and the interface thereby shows shear shrinkage;

- In the same cycle, shear shrinkage and shear expansion occurred alternately. The shear shrinkage occurred in the loading stage, and shear expansion occurred in the unloading stage. The results show that the shear direction affected the development of the normal displacement, leading to an asymmetry in the volume change law. This phenomenon corresponds to the above conclusion on the anisotropy of shear stress. The reasons for the phenomenon are as follows. In the case of positive shear, the soil particles develop from the initial disordered arrangement to the directional arrangement, and the interface produces an apparent shear directional effect. The particle breakage and the space compression between soil particles produce shear shrinkage. In reverse shear, the stress direction of soil particles near the shear surface changes. On the one hand, the soil particles are gradually evacuated from the compaction state until they make contact again and become stable, showing shear expansion. On the other hand, the directional deformation generated during the positive shear impedes the deformation of the soil in the opposite direction, resulting in the shear expansion being less than the shear shrinkage, and a certain amount of residual deformation (shear shrinkage) occurs at the end of each cycle. When the shear direction changes, the soil particle movement is most active, resulting in apparent volume change and leading to the directivity in the macroscopic volume variation;

- Based on the comprehensive analysis of the causes of the above phenomena, the overall shear deformation in a complete shear cycle can be divided into reversible shear deformation and irreversible shear deformation. Irreversible deformation is mainly caused by stable normal stress and soil particle crushing, while reversible deformation is mainly caused by changes in the shear direction. At the initial stage of cyclic shear, the soil particles are angular and disorderedly arranged, and the irreversible body becomes dominant. However, as the shear continues, the soil particles at the shear interface slowly reach a stable state, and the amount of soil particle breakage decreases. At this time, the reversible shear deformation formed by the change in the shear direction plays a major role. Therefore, the macroscopic performance is defined by the fact that, with the increase in shear times, the volume deformation curves gradually recombine, which indicates that, during the shear test, the irreversible shear deformation of the sample becomes small, while the reversible shear deformation always exists. Zhao et al. (2019) [23] has reported that this deformation characteristic is related to the shear band.

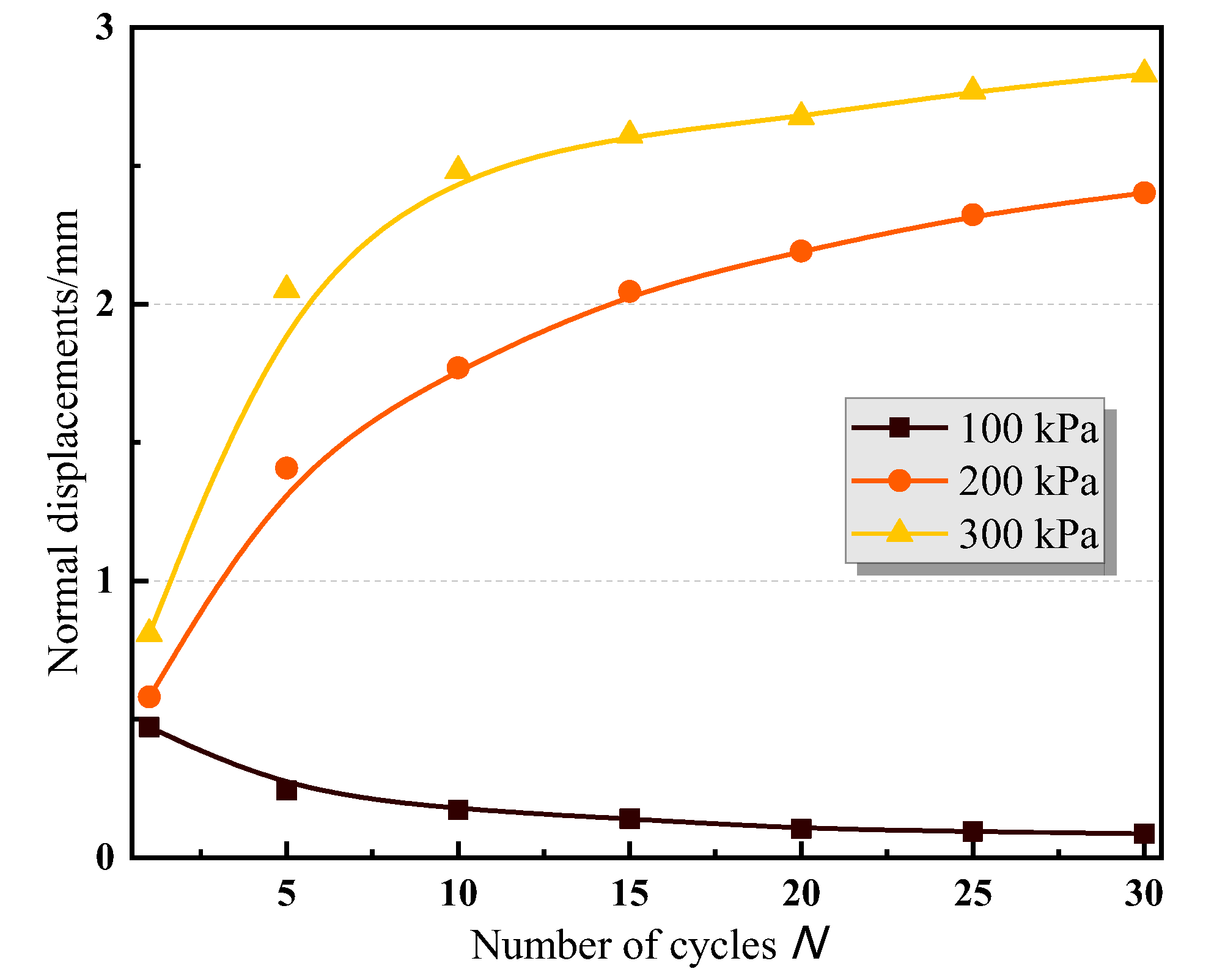

3.2.2. Effect of Normal Stress

- Under different normal stress conditions, the initial (N = 1) cyclic interface showed shear shrinkage. A larger normal stress means larger initial shear shrinkage;

- Under the action of low normal stress (100 kPa), the shear shrinkage gradually decreased with the increase in the number of cycles, showing a certain shear expansion trend. Under the action of medium-high normal stress (200 kPa and 300 kPa), with the increase in the normal stress, the effect of the steel plate’s constraint on the soil particles on the interface increased, the rate of the increase in the deformation displacement with the number of cycles grew, and the amplitude increased. The results suggest that greater normal stress indicates greater final shear shrinkage, which is consistent with the volume change rule from the direct shear test [22]. The reason for the result was that the cohesive potential energy and friction potential energy between soil particles were fully released under low normal stress and showed dilatancy characteristics. Dejong et al. (2009) [24] also reported that the increase of normal stress inhibited the shear expansion behavior;

- The volume variable in the first few shear cycles (N < 5) accounted for more than 70% of the total variation. As the shear cycle continued, the arrangement of soil particles at the interface and the volume change were also stable.

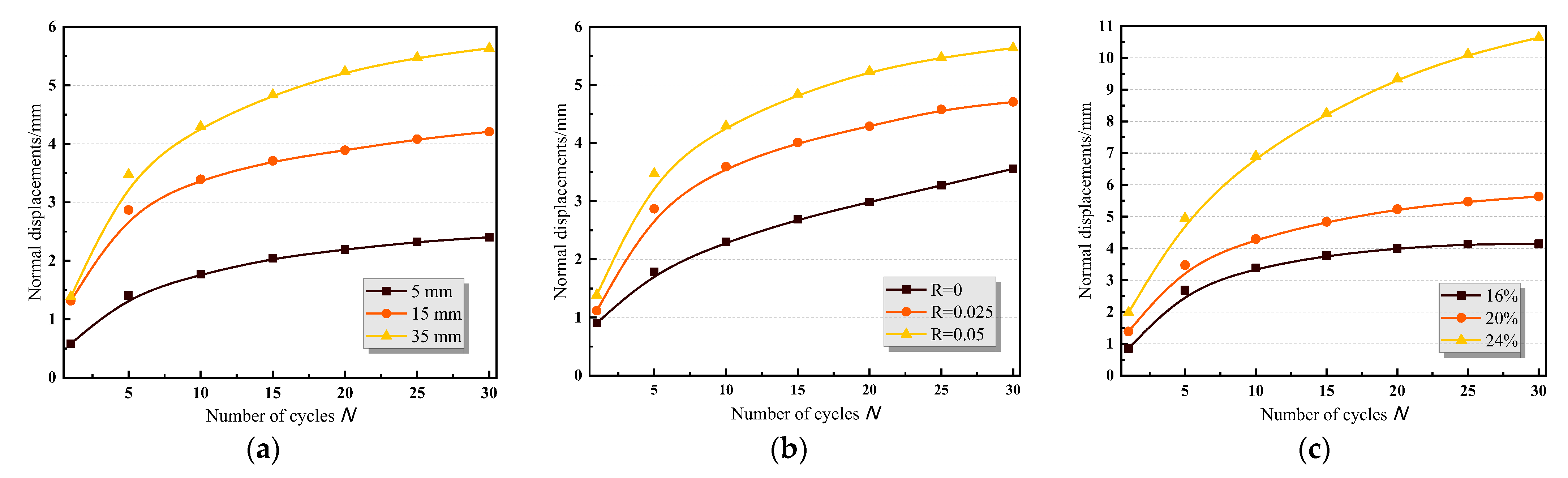

3.2.3. Effect of Other Factors

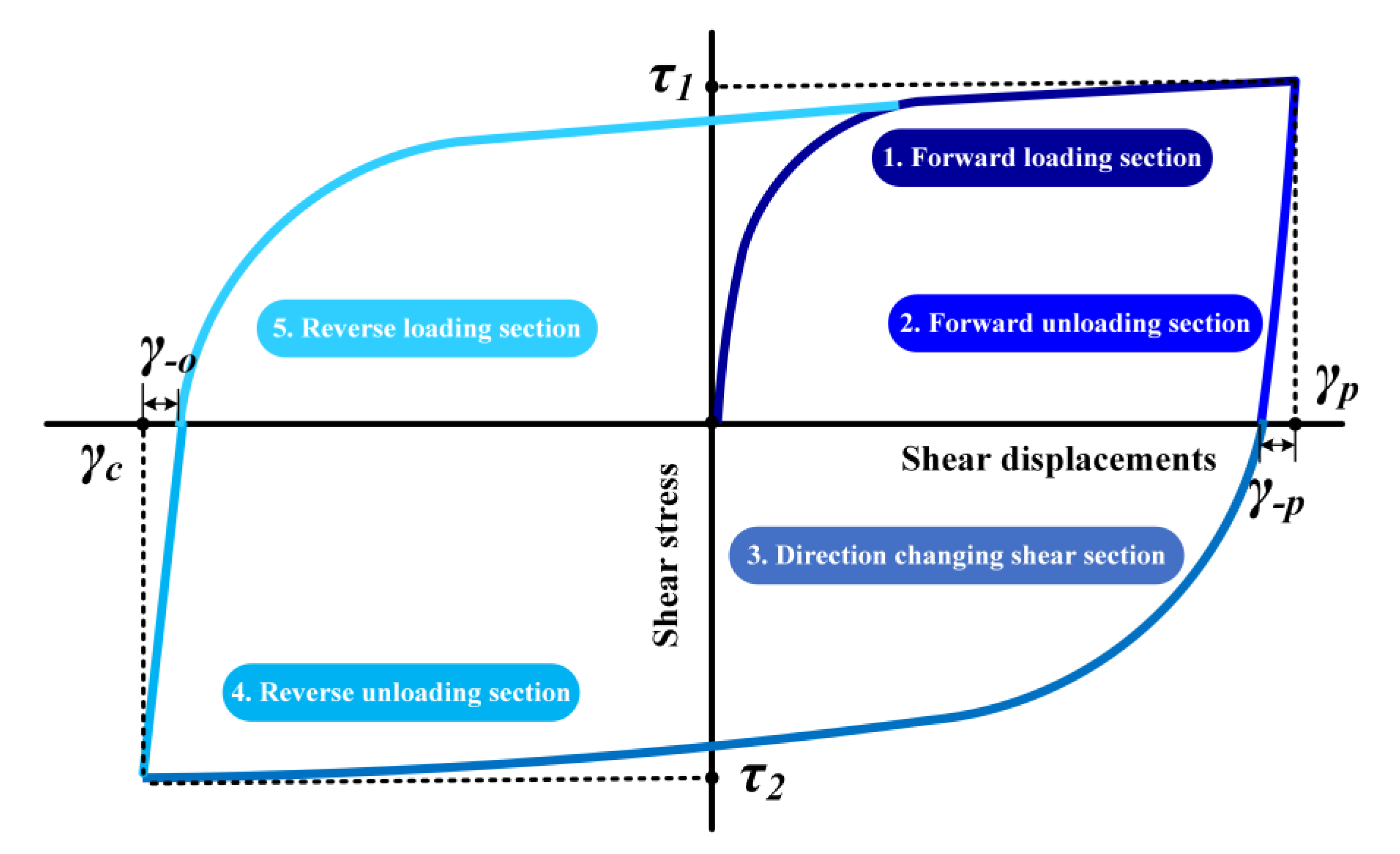

3.3. Stress–Displacement Mathematical Model for Cyclic Shear Silt–Steel interface

3.3.1. Model Derivation

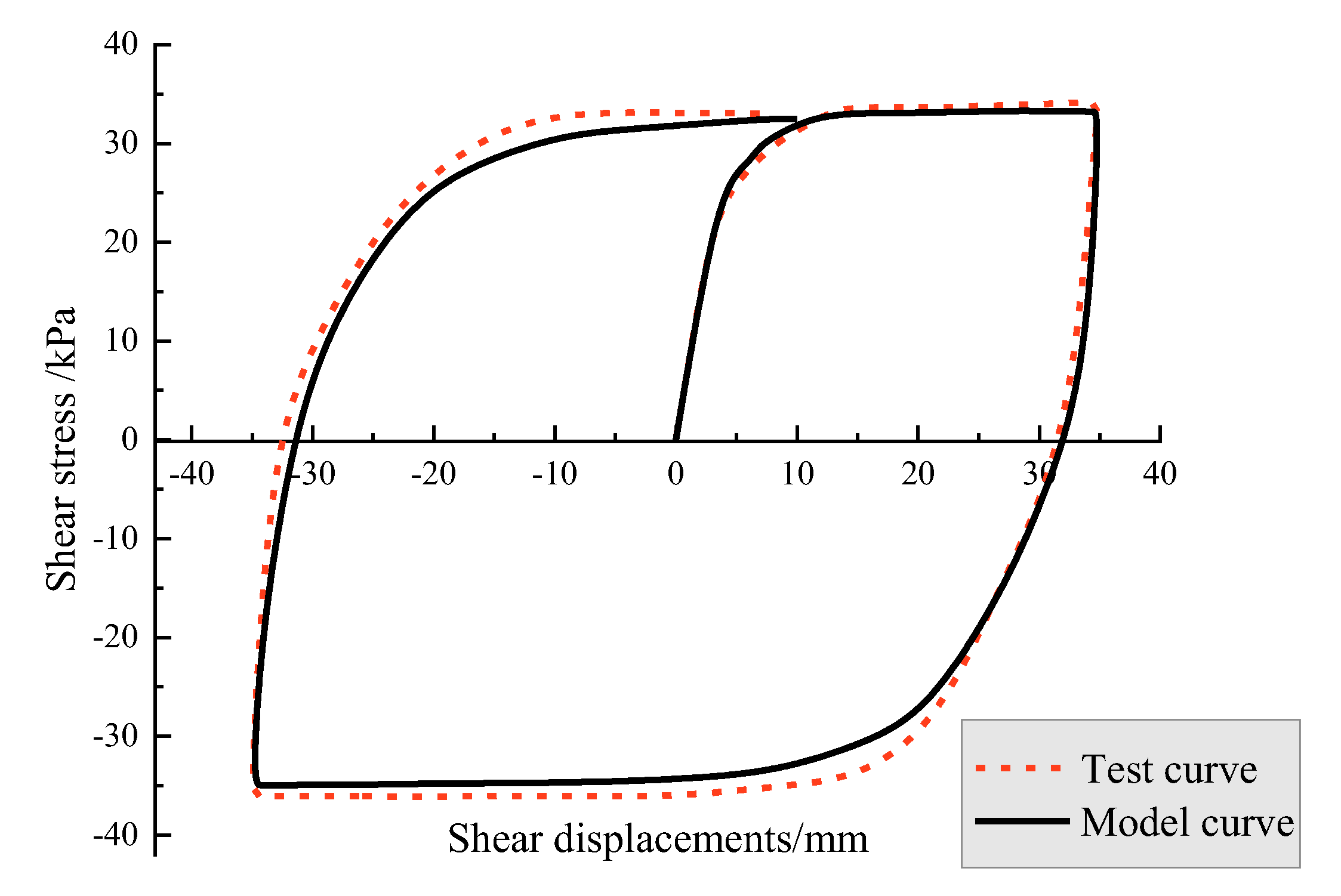

3.3.2. Parameter Determination and Model Verification

4. Conclusions

- With the increase in the the number of cycles, the hysteresis loop shrank inwards, indicating that the interfacial shear stress was softened and that the type of bulk deformation was shear shrinkage. The mechanical properties along different shear directions showed anisotropy in the same cycle;

- The change in the shear amplitude could change the shape of the hysteresis curve. With the increase in the shear amplitude, the hysteresis curve gradually developed from “parallelogram” to “shuttle” and “hysteresis cake”. At the same time, the shear strength and the volumetric displacements increased;

- The effects of normal stress, roughness, and water content on shear strength and volume change were similar to those found in the direct shear test. With the increase in the normal stress and roughness and the decrease in the water content, the shear strength, volume displacement growth rate, and growth rate increased;

- Based on the modified hyperbolic model, the cyclic shear stress–displacement relationship for the silt–steel interface in the Yellow River Delta was described. The model results were in good agreement with the test results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.M.; Feng, D.K.; Hou, W.J. An automated large-scale apparatus for 3-D cyclic testing of soil-structure interfaces. Geotech. Test. J. 2018, 41, 20170129. [Google Scholar] [CrossRef]

- Li, Y.J.; Guo, Z.; Wang, L.Z.; Li, Y.L.; Liu, Z.Y. Shear resistance of MICP cementing material at the interface between calcareous sand and steel. Mater. Lett. 2020, 274, 128009. [Google Scholar] [CrossRef]

- Jotisankasa, A.; Rurgchaisri, N. Shear strength of interfaces between unsaturated soils and composite geotextile with polyester yarn reinforcement. Geotext. Geomembr. 2018, 46, 338–353. [Google Scholar] [CrossRef]

- Li, M.J.; Fang, H.Y.; Du, M.R.; Zhang, C.; Su, Z.; Wang, F. The behavior of polymer-bentonite interface under shear stress. Constr. Build. Mater. 2020, 248, 118680. [Google Scholar] [CrossRef]

- Wang, S.J.; Liu, F.Y.; Wang, P.; Cai, Y.Q. Particle size effects on coarse soil-geogrid interface response in cyclic and post-cyclic direct shear tests. Geotext. Geomembr. 2016, 44, 854–861. [Google Scholar] [CrossRef]

- Liu, J.M.; Zou, D.K.; Kong, X.J. A three-dimensional state-dependent model of soil–structure interface for monotonic and cyclic loadings. Comput. Geotech. 2014, 61, 166–177. [Google Scholar] [CrossRef]

- Stutz, H.; Mašín, D.; Wuttke, F. Enhancement of a hypoplastic model for granular soil-structure interface behaviour. Acta Geotech. 2016, 11, 1249–1261. [Google Scholar] [CrossRef]

- Saberi, M.; Annan, C.; Konrad, J. Three-dimensional constitutive model for cyclic behavior of soil-structure interfaces. Soil Dyn. Earthq. Eng. 2020, 134, 106162. [Google Scholar] [CrossRef]

- Feng, X.L.; Wang, F.Y.; Tang, X.; Xiong, Z.H. Effects of shear box size and mean grain size on sandy soil shearing strength. Sci. Technol. Eng. 2017, 17, 1671–1815. (In Chinese) [Google Scholar]

- Jia, Y.G.; Zhang, L.P.; Zheng, J.W. Effects of wave-induced seabed liquefaction on sediment re-suspension in the Yellow River Delta. Ocean. Eng. 2014, 89, 146–156. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, X.L.; Ding, C.H.; Liu, Y.N.; Liu, T. Study of cone penetration rate effects in the Yellow River Delta silty soils with different clay contents and state parameters. Ocean. Eng. 2022, 250, 110982. [Google Scholar] [CrossRef]

- Liu, X.; Lu, Y.; Yu, H.; Ma, L.; Li, X.; Li, W.; Zhang, H.; Bian, C. In-situ observation of storm-induced wave-supported fluid mud occurrence in the subaqueous Yellow River delta. J. Geophys. Res. Ocean. 2022, 127, e2021JC018190. [Google Scholar] [CrossRef]

- Yu, H.; Liu, X.; Lu, Y.; Li, W.; Gao, H.; Wu, R.; Li, X. Characteristics of the sediment gravity flow triggered by wave-induced liquefaction on a sloping silty seabed: An experimental investigation. Front. Earth Sci. 2022, 10, 909605. [Google Scholar] [CrossRef]

- Liu, J.W.; Cui, L.; Zhu, N.; Han, B.; Liu, J. Investigation of cyclic pile-sand interface weakening mechanism based on large-scale CNS cyclic direct shear tests. Ocean. Eng. 2019, 194, 106650. [Google Scholar] [CrossRef]

- Ren, Y.; Xu, G.; Xu, X.; Zhao, T.; Wang, X. The initial wave induced failure of silty seabed: Liquefaction or shear failure. Ocean. Eng. 2020, 200, 106990. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, M.; Bai, X.; Liu, J. Experimental research on effect of shear rate on shear strength of clayey soil-concrete interface. J. Civ. Environ. Eng. 2019, 41, 48–54. (In Chinese) [Google Scholar]

- Zeghal, M.; Edil, T.B.; Plesha, M.E. Discrete element method for sand-structure interaction. In Proceedings of the 3rd International Conference on Discrete Element Methods, Santa Fe, NM, USA, 23–25 September 2010; pp. 317–322. [Google Scholar]

- Wang, J.; Ying, M.; Liu, F.; Yuan, G.; Fu, H. Experimental investigation on the stress-dilatancy response of aggregate-geogrid interface using parameterized shapes. Constr. Build. Mater. 2021, 289, 123170. [Google Scholar] [CrossRef]

- Rui, S.J.; Zhen, G.; Wang, L.Z.; Zhou, W.J.; Li, Y.J. Experimental study on cyclic shear stiffness and damping ratio of carbonate sand-steel interface. Rock Soil Mech. 2020, 41, 78–86. (In Chinese) [Google Scholar]

- Chen, H.; Wang, H.; Zhang, J.S.; Wang, Q.Y. Effects of Roughness on Cyclic Shear Behavior of Red Clay-Concrete Interface. J. South China Univ. Technol. 2018, 46, 146–152. (In Chinese) [Google Scholar]

- Wang, T.; Zhang, Z. Experimental studies of cyclic shear behavior of steel—Silt interface under constant normal stiffness condition. Chin. J. Geotech. Eng. 2019, 41, 1921–1927. (In Chinese) [Google Scholar]

- Yu, P.; Liu, C.; Liu, H.J. Large—Scale direct shear test study on the silt—Steel interface in the Yellow River Dlta. Period. Ocean. Univ. China 2021, 51, 71–79. (In Chinese) [Google Scholar]

- Zhao, C.; Xie, J.F.; Wang, W.D.; Zhou, M. Experimental Study on Shear Behavior of Interface Between Coarse Sand and Structure. J. Tongji Univ. 2019, 47, 1406–1413. (In Chinese) [Google Scholar]

- Dejong, J.T.; Westgate, Z.J. Role of initial state material properties and confinement condition on local and global soil-structure interface behavior. J. Geotech. Geoenviron. Eng. 2009, 13, 1646–1660. [Google Scholar] [CrossRef]

- Lu, X.Z. Constitutive Model of Steel-Soil Contact Interface and Its Application in the Bearing Behavior Study of Rock-Socketed Filling Pile with Steel Tube. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2015. (In Chinese). [Google Scholar]

- He, Z.J.; Mo, H.Q.; Zou, J.F. Research on the parameters of nonlinear hyperbolic model for clay-geogrid interfaces based on large scale direct shear tests. Transp. Geotech. 2019, 18, 39–45. [Google Scholar] [CrossRef]

- Fellenius, B.H. Results from long-term measurement in piles of drag load and downdrag. Can. Geotech. J. 2006, 43, 409–430. [Google Scholar] [CrossRef]

| Specific Gravity Gs | Optimum Water Content % | Void Ratio e | Plastic Limit ωp/% | Liquid Limit ωL/% |

|---|---|---|---|---|

| 2.7 | 19.60% | 0.69 | 18.3 | 30.1 |

| Specimen Numbers | 0.25~0.075 | 0.075~0.05 | 0.05~0.01 | 0.01~0.005 | <0.005 |

|---|---|---|---|---|---|

| Percentage | 6.6% | 21.6% | 51.8% | 5.9% | 14.1% |

| R | N | L1 (mm) | L2 (mm) | H (mm) |

|---|---|---|---|---|

| 0 | \ | \ | \ | \ |

| 0.025 | 200 | 0.6 | 3 | 0.3 |

| 0.05 | 100 | 1.2 | 6 | 0.6 |

| Group | Roughness | Water Content (%) | Normal Stress (kPa) | Shear Amplitude (mm) |

|---|---|---|---|---|

| 1 | 0.05 | 16 | 200 | 35 |

| 2 | 0.05 | 20 | 100 | 5 |

| 3 | 0.05 | 20 | 200 | 5 |

| 4 | 0.05 | 20 | 300 | 5 |

| 5 | 0.05 | 20 | 200 | 15 |

| 6 | 0.05 | 20 | 200 | 35 |

| 7 | 0.05 | 24 | 200 | 35 |

| 8 | 0 | 20 | 200 | 35 |

| 9 | 0.025 | 20 | 200 | 35 |

| Group | γp (mm) | γc (mm) | γ-p (mm) | γ-o (mm) | τmaxp (kPa) | τmaxc (kPa) | τmaxo (kPa) | ksip (kPa/mm) | ksic (kPa/mm) | ksio (kPa/mm) | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 35.63 | 35.06 | 3.13 | 3.84 | 39.97 | 39.96 | 39.14 | 21.26 | 21.25 | 20.81 | ∆cr= 2 mm Rp = 0.91~0.96 |

| 2 | 5.00 | 5.00 | 0.98 | 1.07 | 16.47 | 21.71 | 9.57 | 8.76 | 11.54 | 5.09 | |

| 3 | 4.98 | 5.00 | 0.66 | 1.13 | 27.92 | 30.69 | 12.37 | 14.85 | 16.32 | 6.57 | |

| 4 | 5.07 | 4.95 | 0.91 | 1.10 | 36.52 | 39.87 | 15.10 | 19.42 | 21.20 | 8.03 | |

| 5 | 15.00 | 14.97 | 1.91 | 2.51 | 36.05 | 34.08 | 25.31 | 19.17 | 18.12 | 13.46 | |

| 6 | 35.00 | 35.00 | 2.10 | 2.00 | 34.21 | 36.05 | 33.02 | 18.39 | 20.03 | 17.38 | |

| 7 | 34.45 | 35.60 | 2.43 | 3.21 | 33.39 | 33.37 | 31.90 | 17.76 | 17.75 | 16.96 | |

| 8 | 34.50 | 36.21 | 3.09 | 3.71 | 36.15 | 35.20 | 34.57 | 19.23 | 18.72 | 18.38 | |

| 9 | 34.51 | 35.21 | 2.59 | 3.43 | 37.23 | 37.40 | 35.21 | 19.80 | 19.89 | 18.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, P.; Dong, J.; Liu, H.; Xu, R.; Wang, R.; Xu, M.; Liu, H. Analysis of Cyclic Shear Stress–Displacement Mechanical Properties of Silt–Steel Interface in the Yellow River Delta. J. Mar. Sci. Eng. 2022, 10, 1704. https://doi.org/10.3390/jmse10111704

Yu P, Dong J, Liu H, Xu R, Wang R, Xu M, Liu H. Analysis of Cyclic Shear Stress–Displacement Mechanical Properties of Silt–Steel Interface in the Yellow River Delta. Journal of Marine Science and Engineering. 2022; 10(11):1704. https://doi.org/10.3390/jmse10111704

Chicago/Turabian StyleYu, Peng, Jie Dong, Haisong Liu, Rui Xu, Rujie Wang, Meijun Xu, and Hongjun Liu. 2022. "Analysis of Cyclic Shear Stress–Displacement Mechanical Properties of Silt–Steel Interface in the Yellow River Delta" Journal of Marine Science and Engineering 10, no. 11: 1704. https://doi.org/10.3390/jmse10111704

APA StyleYu, P., Dong, J., Liu, H., Xu, R., Wang, R., Xu, M., & Liu, H. (2022). Analysis of Cyclic Shear Stress–Displacement Mechanical Properties of Silt–Steel Interface in the Yellow River Delta. Journal of Marine Science and Engineering, 10(11), 1704. https://doi.org/10.3390/jmse10111704