Experimental Investigation of the Dynamic Behavior of Submerged Floating Tunnels under Regular Wave Conditions

Abstract

1. Introduction

2. Experimental Setup

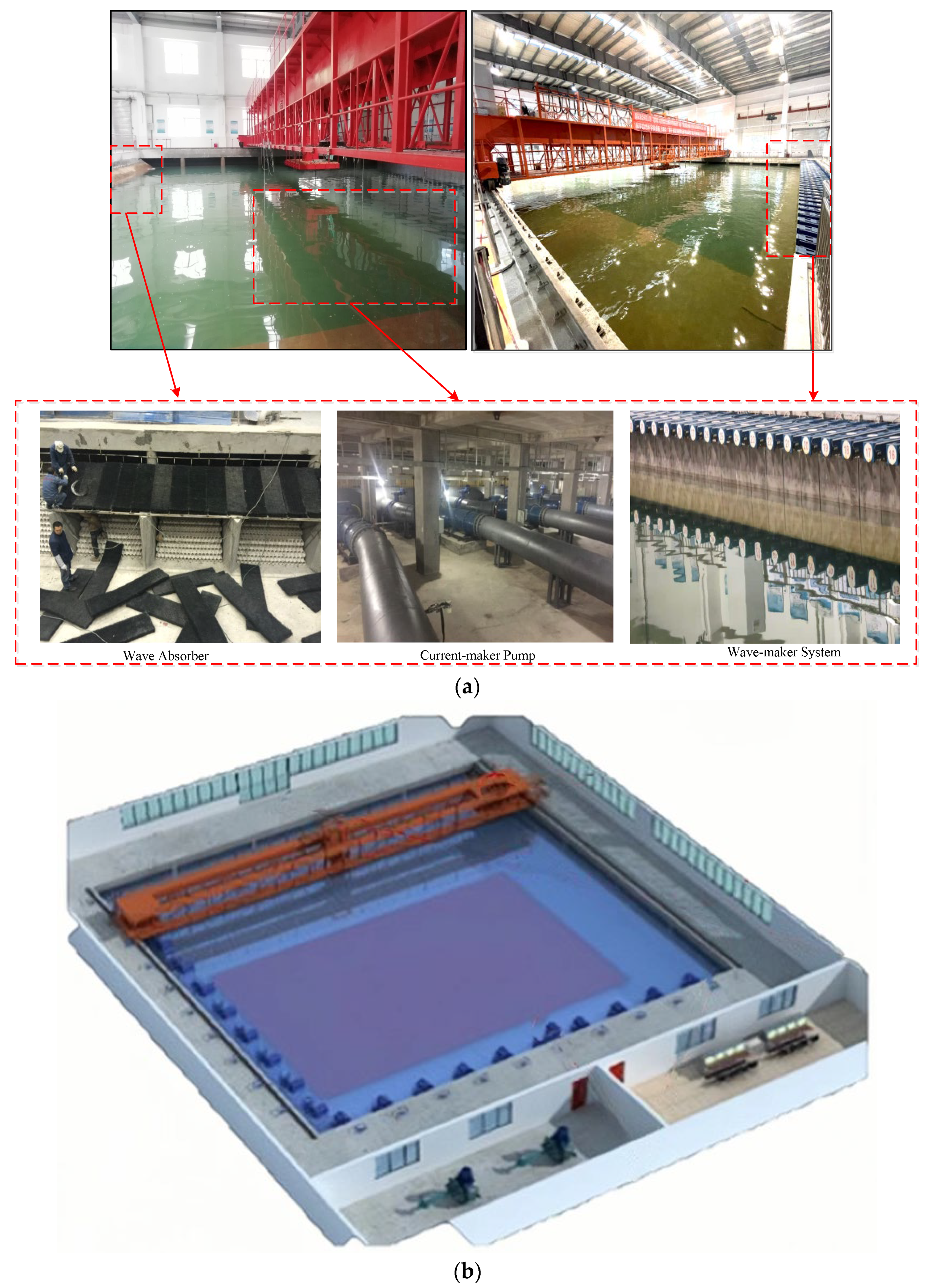

2.1. Experimental Facility

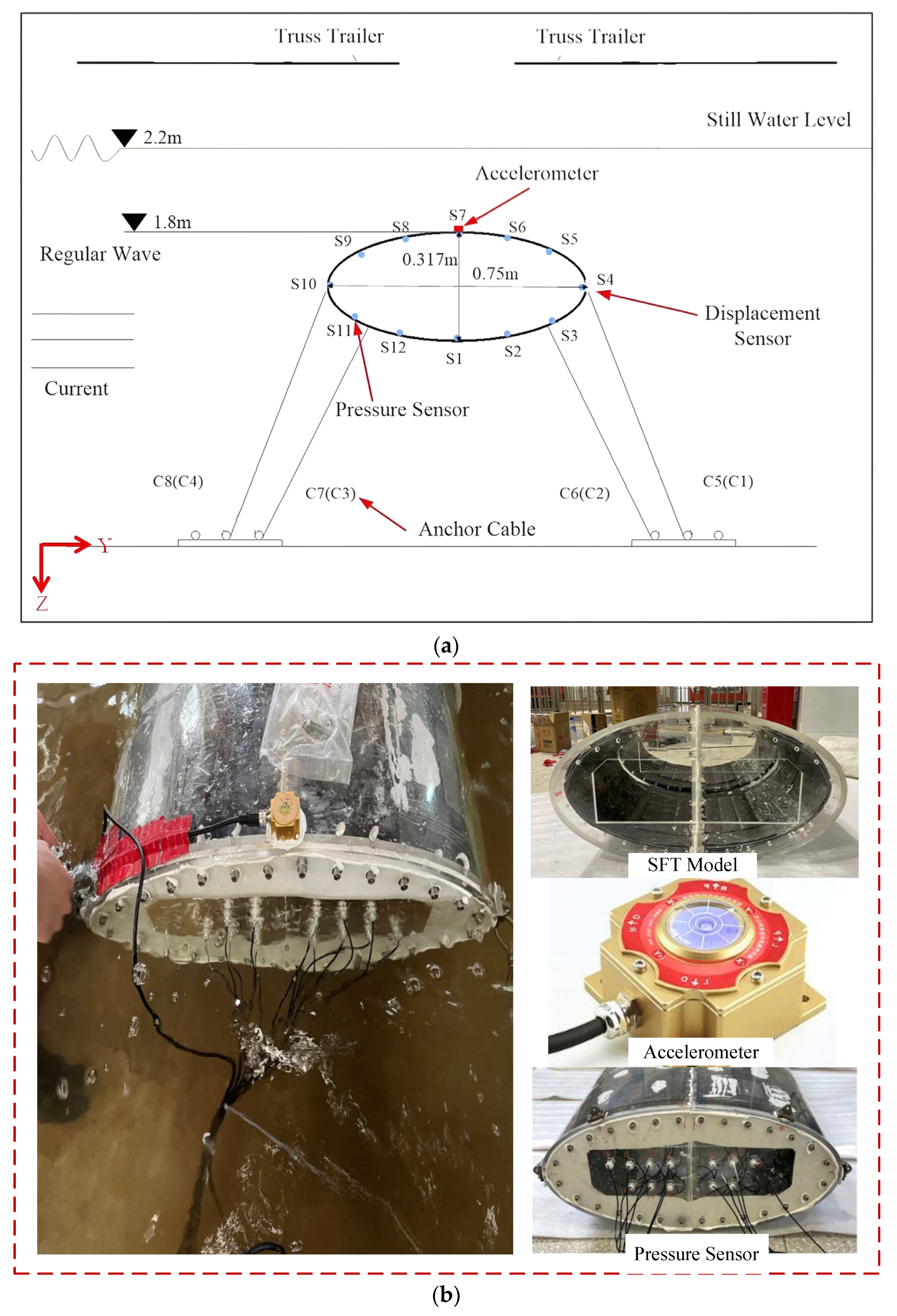

2.2. Test Model and Instrumentation

2.3. Data Acquisition

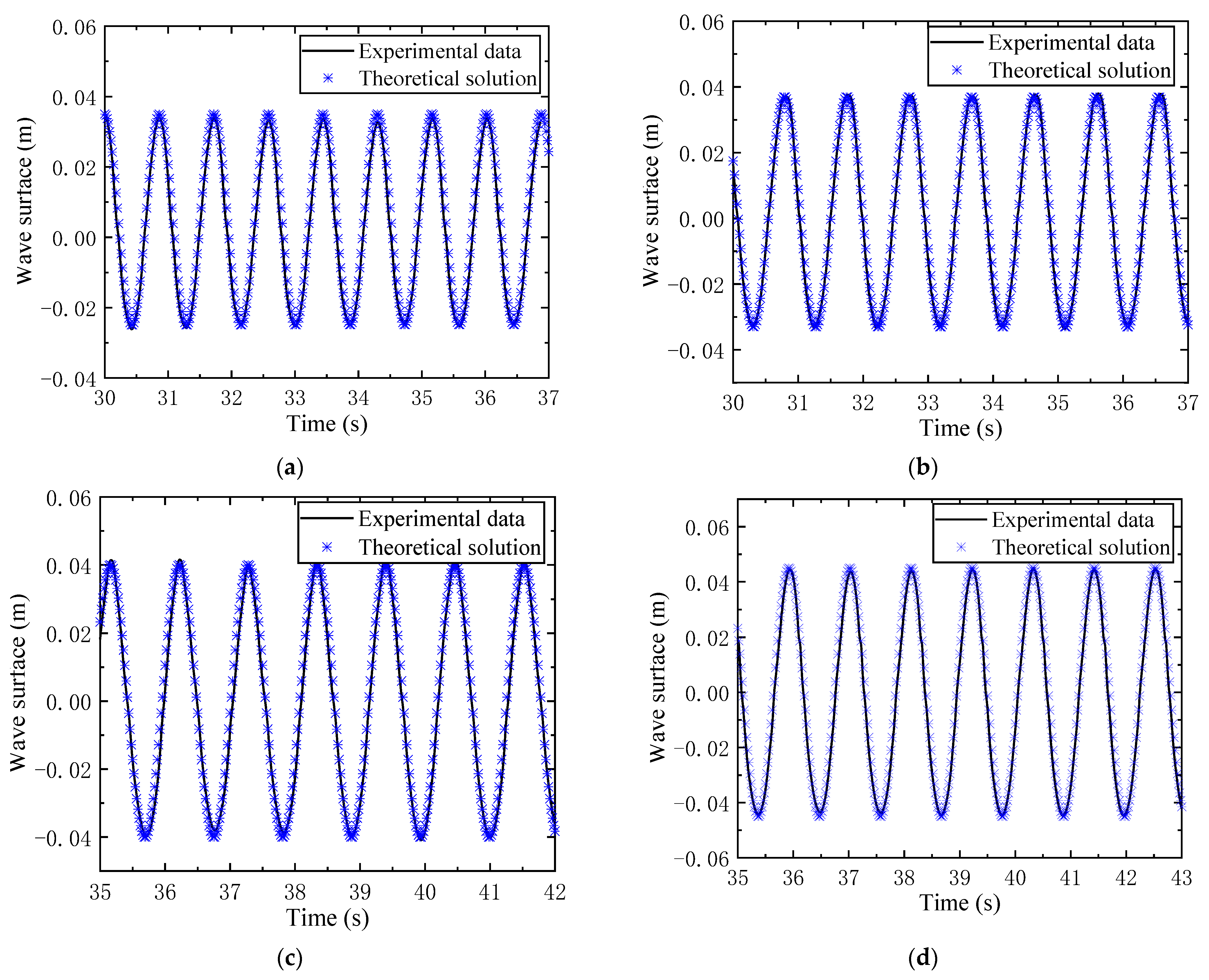

3. Reliability Analysis for the Wave Surface

4. Experimental Results and Analysis

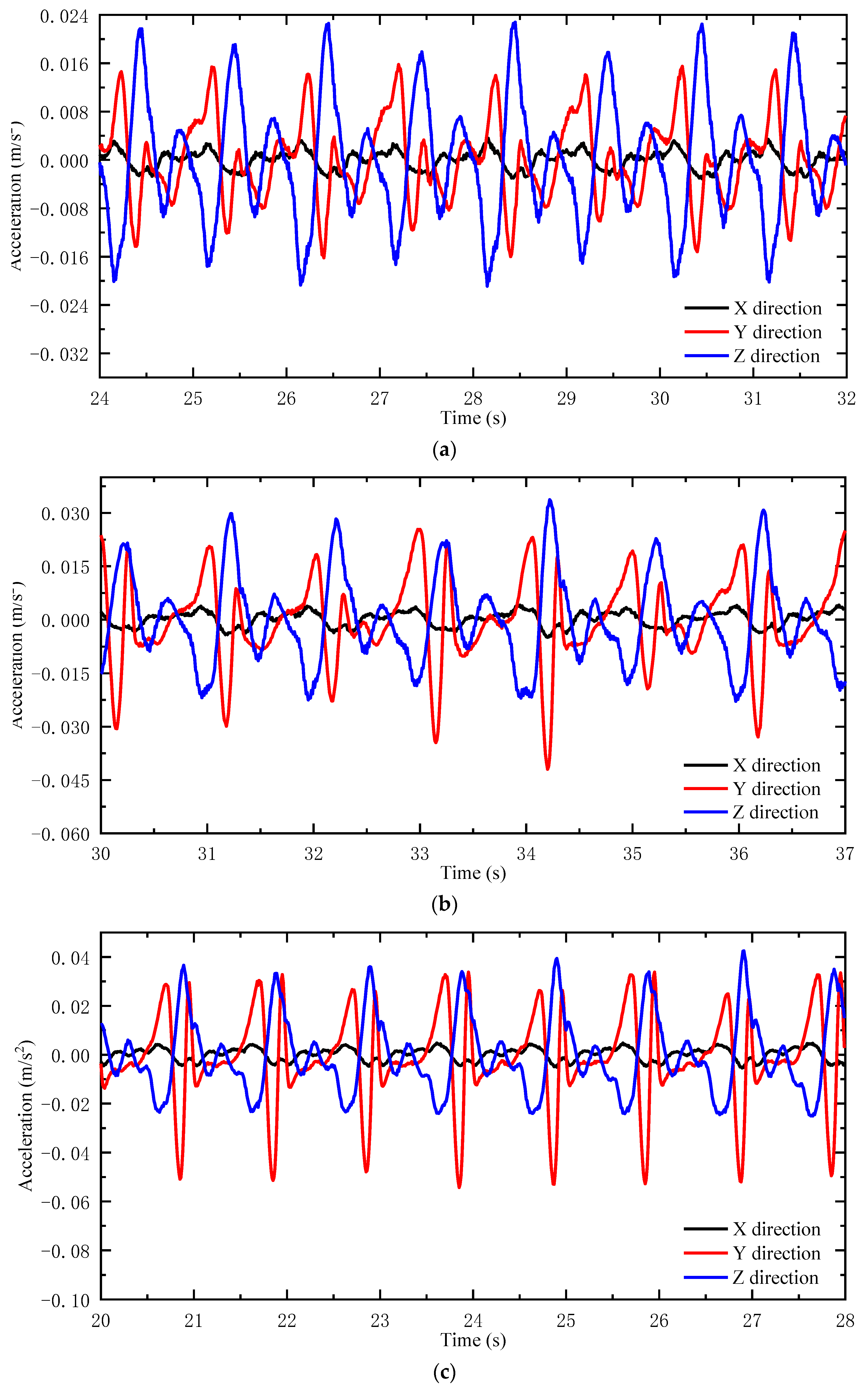

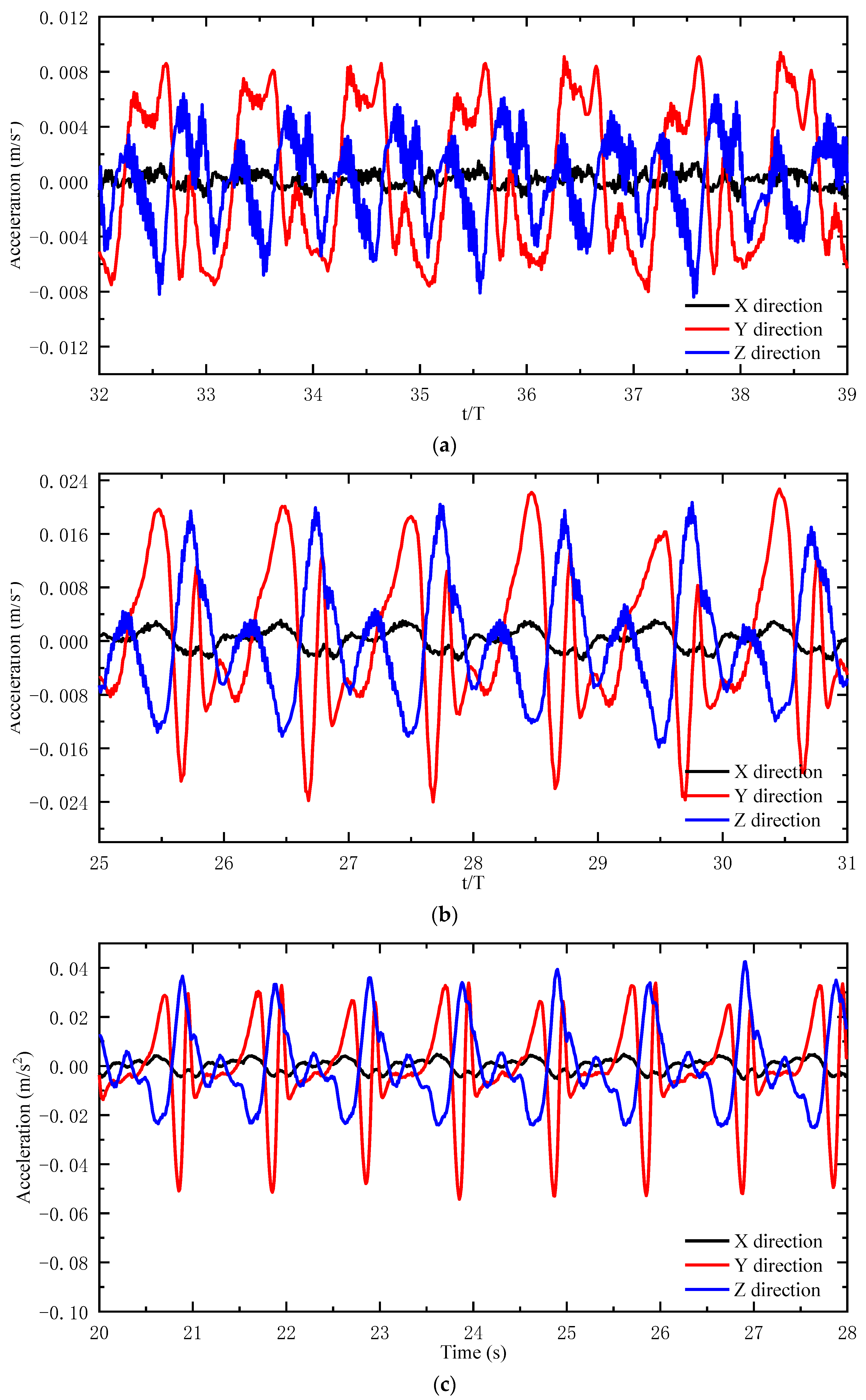

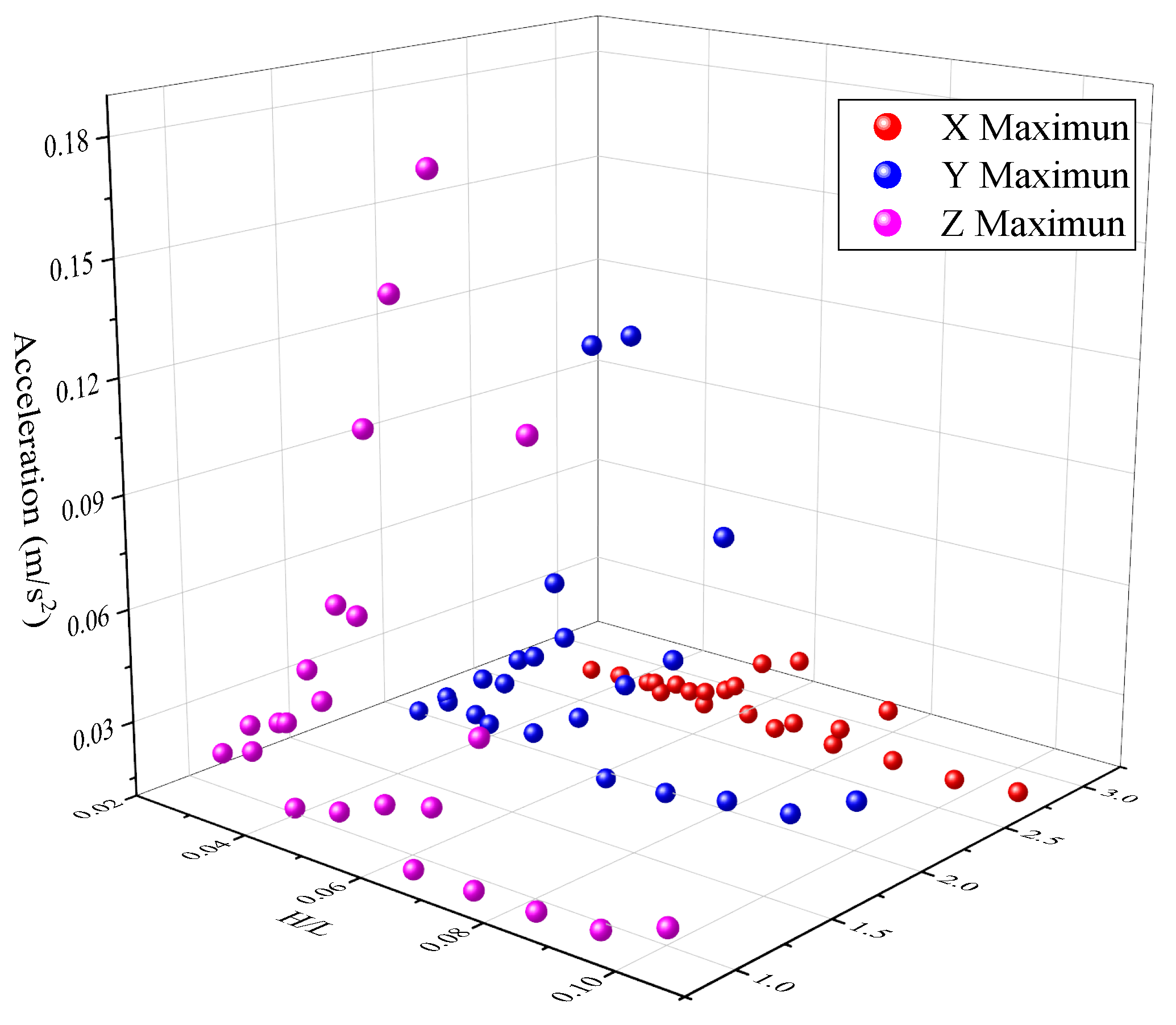

4.1. Acceleration Response of the SFT

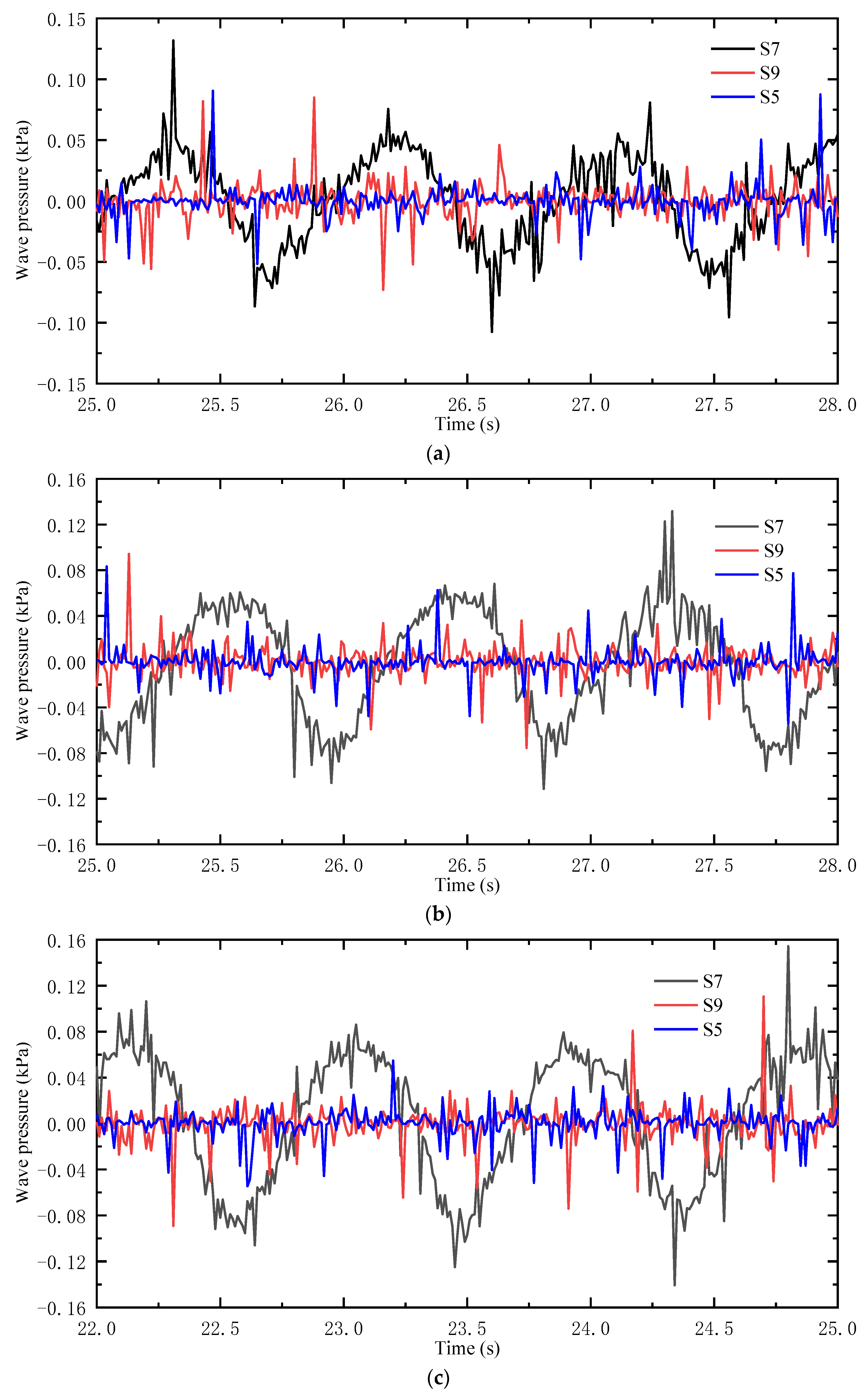

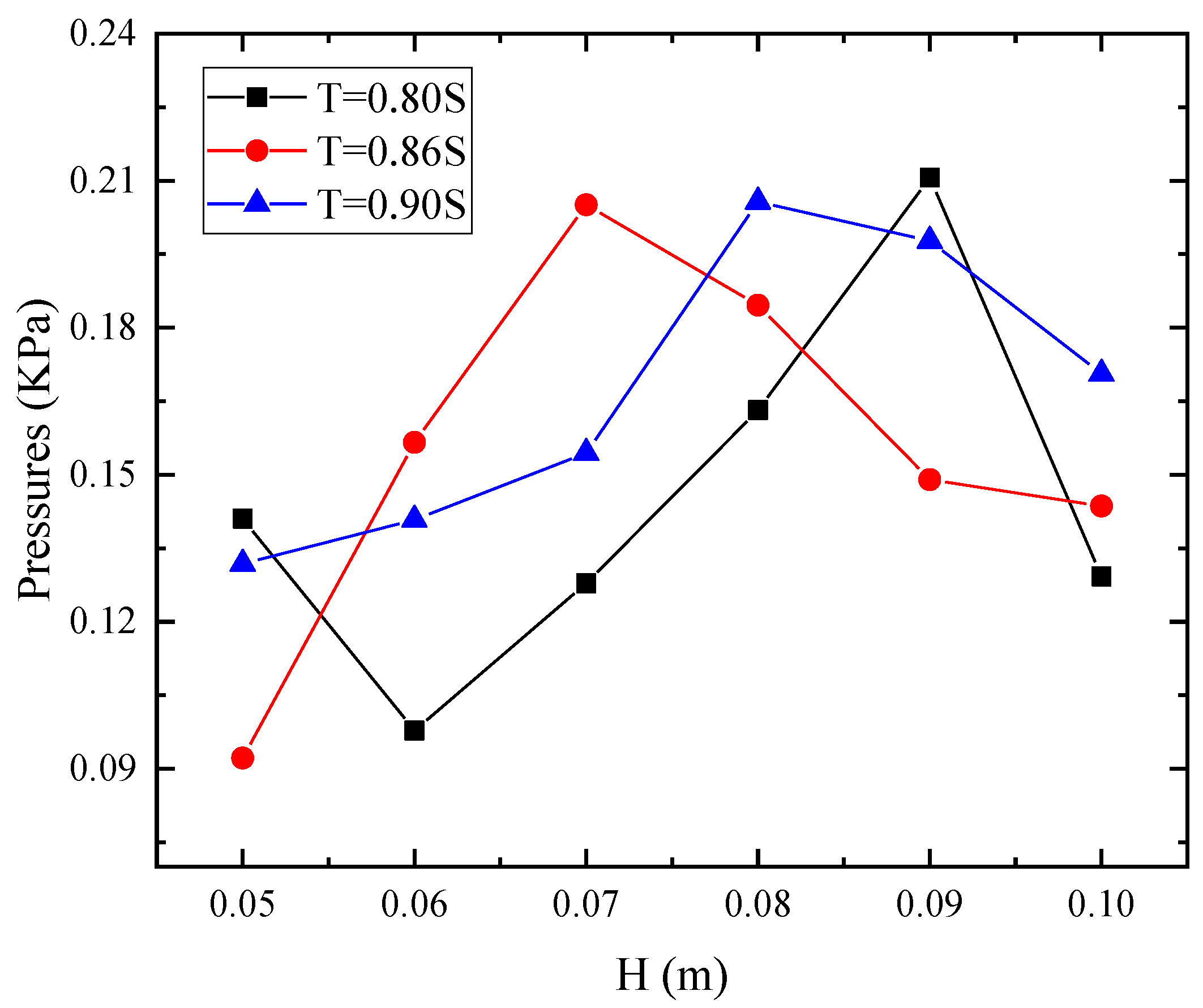

4.2. Wave Pressures on the SFT

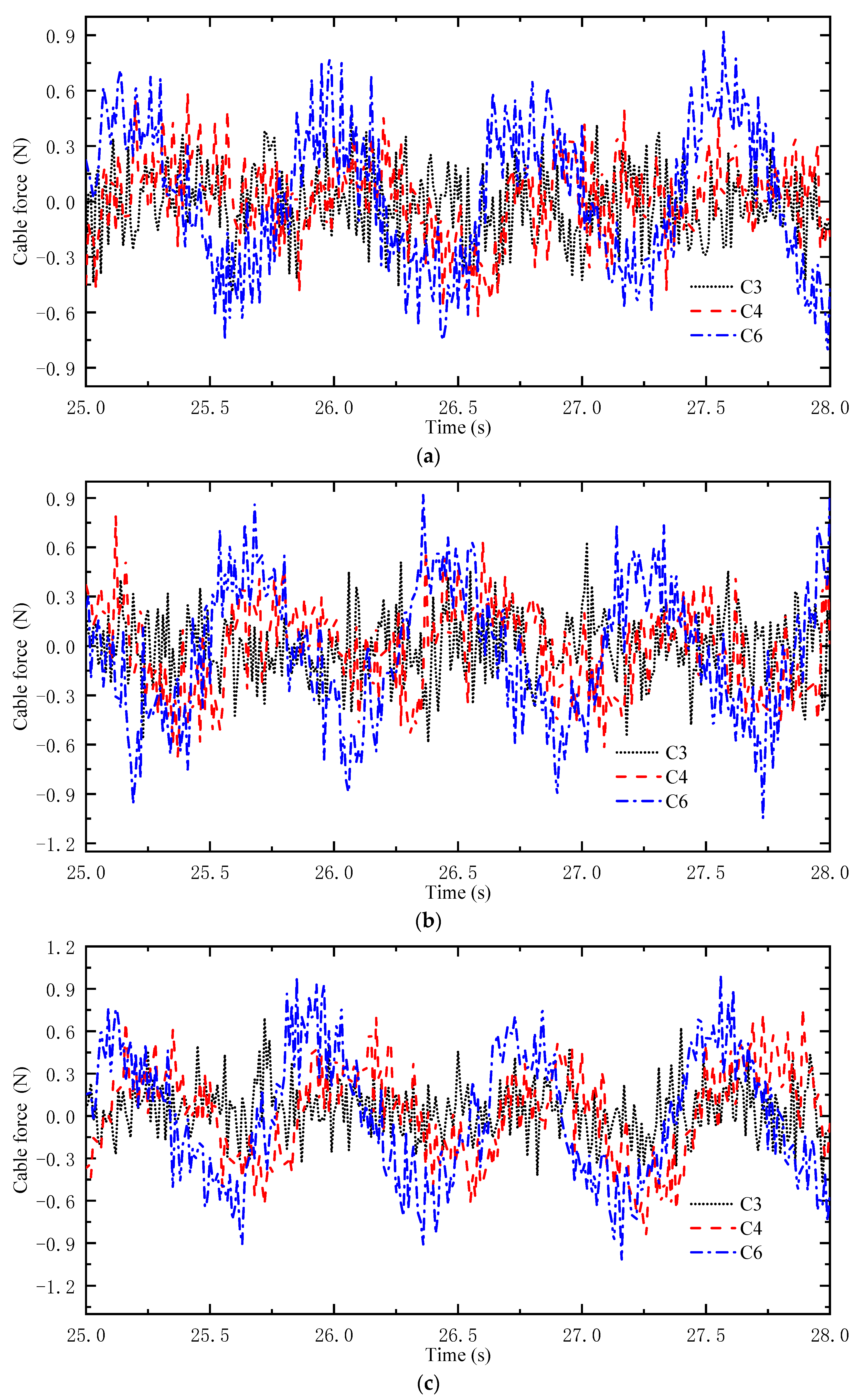

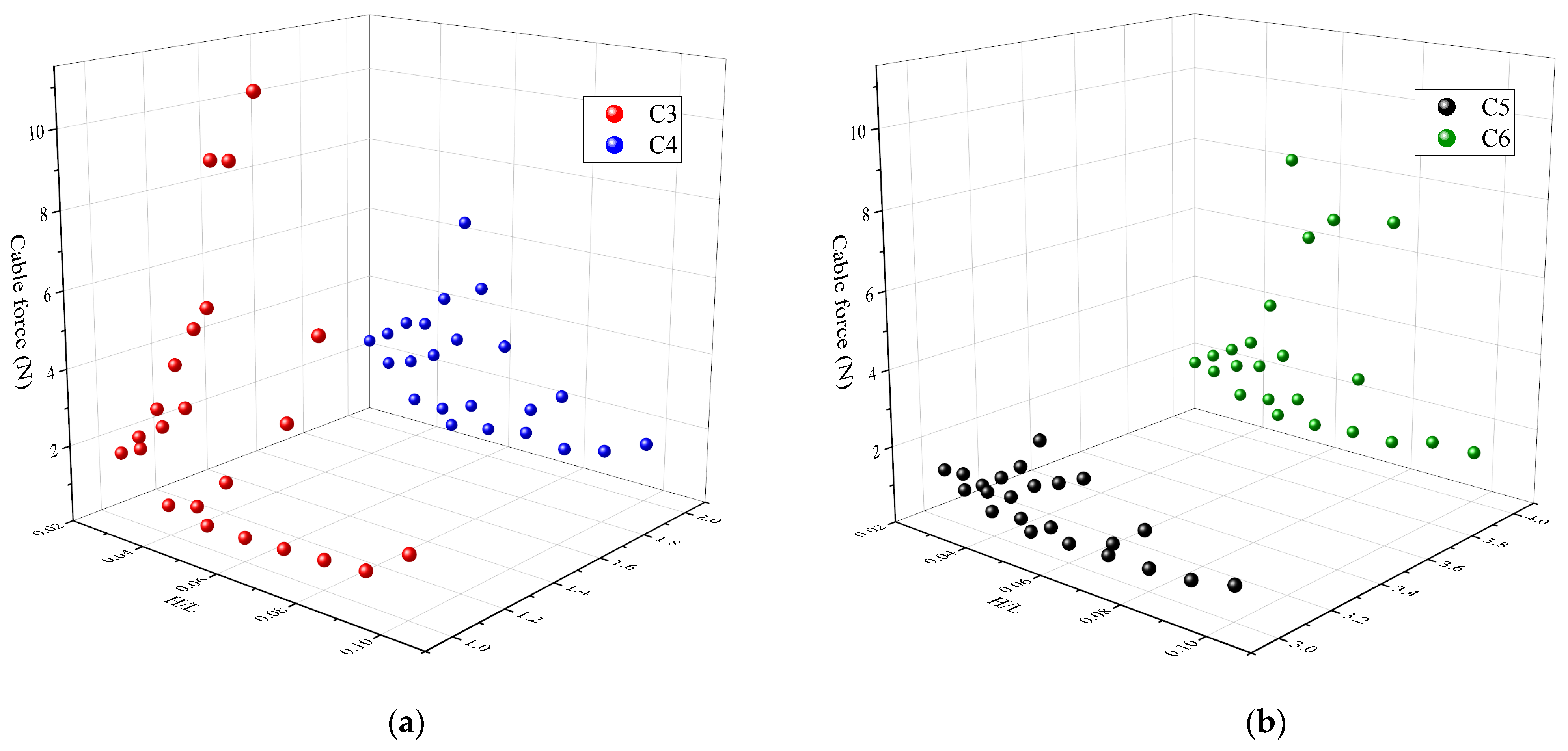

4.3. Cable Forces

4.4. Displacement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Z.; Wang, D.; Ke, W.; Qin, Y.; Lu, F.; Jiang, M. Experimental investigation for the dynamic behavior of submerged floating tunnel subjected to the combined action of earthquake, wave and current. Ocean Eng. 2021, 239, 109911. [Google Scholar] [CrossRef]

- Lin, H.; Xiang, Y.; Yang, Y.; Chen, Z. Dynamic response analysis for submerged floating tunnel due to fluid-vehicle-tunnel interaction. Ocean Eng. 2018, 166, 290–301. [Google Scholar] [CrossRef]

- Xiang, Y.; Chen, Z.; Yang, Y.; Lin, H.; Zhu, S. Dynamic response analysis for submerged floating tunnel with anchor-cables subjected to sudden cable breakage. Mar. Struct. 2018, 59, 179–191. [Google Scholar] [CrossRef]

- Ding, H.; Cheng, L.; Li, K. Research progress and prospect on dynamic response of SFT structures. Tunn. Constr. 2019, 39, 901–912. [Google Scholar]

- Jiang, S.P.; Li, Q.X. Development of conceptual design, dynamic analysis theory and model experiment of submerged floating tunnels. Tunn. Constr. 2018, 38, 352–359. [Google Scholar]

- Xiang, Y.Q.; Chen, Z.Y.; Yang, Y. Research dvevlopment of method and simulation for analyzing dynamic response of submerged floating tunnel. China J. Highw. Transp 2017, 30, 69–76. [Google Scholar] [CrossRef]

- Gao, J.L.; Ma, X.Z.; Dong, G.H.; Chen, H.; Liu, Q.; Zang, J. Investigation on the effects of Bragg reflection on harbor oscillations. Coast. Eng. 2021, 170, 103977. [Google Scholar] [CrossRef]

- Gao, J.L.; Ma, X.Z.; Zang, J.; Dong, G.; Ma, X.; Zhu, Y.; Zhou, L. Numerical investigation of harbor oscillations induced by focused transient wave groups. Coast. Eng. 2020, 158, 103670. [Google Scholar] [CrossRef]

- Lai, W. Transient dynamic response of submerged sphere shell with an opening subjected to underwater explosion. Ocean Eng. 2007, 34, 653–664. [Google Scholar] [CrossRef]

- Tariverdilo, S.; Mirzapour, J.; Shahmardani, M.; Shabani, R.; Gheyretmand, C. Vibration of submerged floating tunnels due to moving loads. Appl. Math. Model. 2011, 35, 5413–5425. [Google Scholar] [CrossRef]

- Seo, S.; Sagong, M.; Son, S. Global response of submerged floating tunnel against underwater explosion. KSCE J. Civ. Eng. 2015, 19, 2029–2034. [Google Scholar] [CrossRef]

- Jiting, M.; Baoshu, G. A preliminary calculating analysis of the wave forces on a submerged floating tunnel by applying the morison equation. J. Shijiazhuang Railw. Inst. 2003, 16, 1–4. [Google Scholar] [CrossRef]

- Mai, J.T. The Study on Responses of a Submerged Floating Tunnel Subjected to the Wave and Current. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2005. [Google Scholar]

- Mai, J.T.; Luo, Z.X.; Guan, B.S. An analytic calculation of dynamic response for a submerged floating tunnel subjected to wave and current. J. Railw. Eng. Soc. 2006, 51–54. [Google Scholar]

- Mai, J.T.; Yang, X.C.; Guan, B.S. Dynamic response analysis of the submerged floating tunnel subjected to wave. J. Railw. Eng. Soc. 2007, 102, 45–49. [Google Scholar]

- Chen, Z.Y.; Xiang, Y.Q.; Lin, H.; Yang, Y. Coupled vibration analysis of submerged floating tunnel system in wave and current. Appl. Sci. 2018, 8, 1311. [Google Scholar] [CrossRef]

- Xiang, Y.Q.; Yang, Y. Spatial dynamic response of submerged floating tunnel under impact load. Mar. Struct. 2017, 53, 20–31. [Google Scholar] [CrossRef]

- Hong, Y.S.; Ge, F. Dynamic response and structural integrity of submerged floating tunnel due to hydrodynamic load and accidental load. Procedia Eng. 2010, 4, 35–50. [Google Scholar] [CrossRef]

- Kang, L.; Ge, F.; Hong, Y. A numerical study on responses of submerged floating structures undergoing vortex-induced vibration and seismic excitation. Procedia Eng. 2016, 166, 91–98. [Google Scholar] [CrossRef]

- Long, X.; Ge, F.; Hong, Y. Feasibility study on buoyancy-weight ratios of a submerged floating tunnel prototype subjected to hydrodynamic loads. Acta Mech. Sin. 2015, 31, 750–761. [Google Scholar] [CrossRef]

- Ge, F.; Long, X.; Wang, L.; Hong, Y. Flow-induced vibrations of long circular cylinders modeled by coupled nonlinear oscillators. Sci. China Ser. G: Phys. Mech. Astron. 2009, 52, 1086–1093. [Google Scholar] [CrossRef]

- Hong, Y.; Ge, F.; Lu, W. On the two essential concepts for SFT: Synergetic buoyancy-weight ratio and slack-taut map. Procedia Eng. 2016, 166, 221–228. [Google Scholar] [CrossRef]

- Davide, L.Z. Dynamic Fluid-Structure-Vehicle Interaction Analysis for Submerged Floating Tunnels: A Comfort Assessment. Ph.D. Thesis, The Delft University of Technology, Delft, The Nertherlands, 2019. [Google Scholar]

- Papadopoulos, G. Structural Response of the Bjornefjord Submerged Floating Tunnel in Current Flow. Master’s Thesis, The Delft University of Technology, Delft, The Nertherlands, 2019. [Google Scholar]

- Hemel, M.J. Submerged Floating Tunnel: The Dynamic Response Due to Fluid Structure Interaction. Master’s Thesis, The Delft University of Technology, Delft, The Nertherlands, 2019. [Google Scholar]

- Fujita, R.; Mikami, T. Development of submerged floating tunnel in shallow water: Strait crossings. In Proceedings of the 4th Symposium on Strait Crossing, Bergen, Norway, 2–5 September 2001; Krokeborg, J., Ed.; Balkema: Leiden, The Netherlands, 2001. [Google Scholar]

- Venkataramana, K.; Yoshihara, S.; Toyoda, S.; Aikou, Y. Current-induced vibrations of submerged floating tunnels. In Proceedings of the Sixth (1996) International Offshore and Polar Engineering Conference, Los Angeles, CA, USA, 26–31 May 1996; Volume II. [Google Scholar]

- Gan, Y. There-Dimensional Analysis and Segmental Model Experimental Investigation of Submerged Floating Tunnel. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2003. [Google Scholar]

- Chao, C.F.; Xiang, Y.Q.; Yang, Y.; He, Y.L. Cables dynamic response experiment of submerged floating tunnel based on fluid-structure interaction. J. Vib. Eng. 2016, 29, 687–693. [Google Scholar] [CrossRef]

- Chao, C.F.; Xiang, Y.Q.; Yang, C. Experiments on dynamic fluid-structure coupled responses of anchor cables of submerged floating tunnel. J. Vib. Shock 2016, 35, 158–163. [Google Scholar] [CrossRef]

- Tian, X.F.; Dong, M.S.; Pang, H.P. Dynamic responses of the submerged floating tunnel under combined internal wave and sea current effect. Appl. Math. Mech. 2014, 35, 71–80. [Google Scholar]

- Qin, Y.G.; Zhou, X.J. Experimental study of dynamic behavior of submerged floating tunnel under current effect. J. Railw. Transp. Res. Dev. 2009, 26, 69–77. [Google Scholar]

- Wang, G.D. Numerical Analysis and Experiment Research of Submerged Floating Tunnel Subjected to Wave and Current Effects. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2008. [Google Scholar]

- Wei, J.Q.; Lin, M.; Yin, H.Q. Experimental study of acceleration response characteristics of submerged floating tunnel pipes under wave action. China Water Transp. 2021, 21, 124–125. [Google Scholar]

- Wang, C.C. Model experiment on the interaction between submerged floating tunnel and current. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2005. [Google Scholar]

- Yang, Z.W.; Zhang, H.Q.; Li, J.Z.; Yuan, C.G. A study on the wave-current-induced motion responses of submerged floating tunnels using longitudinal truncated model tests. Ocean Eng. 2021, 39, 44–52. [Google Scholar] [CrossRef]

- Zhao, Z.H. Experimental study on hydrodynamic response of submerged tube in wave flow field. Master’s Thesis, Dalian University of Technology, Dalian, China, 2020. [Google Scholar]

- Deng, S.; Ren, H.; Xu, Y.; Fu, S.; Moan, T.; Gao, Z. Experimental study of vortex-induced vibration of a twin-tube submerged floating tunnel segment model. J. Fluids Struct. 2020, 94, 102908. [Google Scholar] [CrossRef]

- Daniil, P. Submerged floating tunnel: Water-structure interaction. Master’s Thesis, Norwegian University of Science and Technology, Norwegian, Norway, 2019. [Google Scholar]

- Zhao, L.T. Study on reasonable cross-section type of submerged floating tunnel under wave-current coupling. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2020. [Google Scholar]

- Liu, Y.; Jin, R.J.; Geng, B.L.; Zhang, H.Q.; Ran, C. Influence of anchor cable inclination angle on motion response of submerged floating tunnel with different section. Chin. J. Hydrodyn. 2020, 35, 237–247. [Google Scholar] [CrossRef]

- Jing, S.P.; Li, Q.X. Wave characteristics of submerged floating tunnels under random irregular waves. Chin. J. Undergr. Space Eng. 2019, 15, 416–422. [Google Scholar]

- Huang, B.; Ren, Q.Y.; Cui, X.L. Wave characteristics and spectrum for Pingtan Strait Bridge location. Ocean Eng. 2021, 219, 1–15. [Google Scholar] [CrossRef]

| Structure | Parameters | Numerical Value |

|---|---|---|

| Tube body | Segment length | 120 m |

| Long axis and short axis | 45 m × 19 m | |

| Sectional area | 671.5 m2 | |

| Buoyancy (after scaling) | 373.06 kg | |

| Bending rigidity | 1456 | |

| Elastic modulus | 34.5 GPa | |

| Density | 2000 kg/m3 | |

| Buoyancy-weight ratio | 1.3 | |

| Damping factor | 0.01 | |

| Anchor cable | Length | Determined according to water depth and angle |

| Diameter | 0.346 m | |

| Mass per unit length | 1474.23 kg/m | |

| Density | 7850 kg/m3 | |

| Elastic modulus | 210 GPa | |

| Initial tension | 4.6 × 104 kN | |

| Damping factor | 0.0018 | |

| Other | Water depth | 132 m |

| Physical Parameters | Comparison Relation | Unit |

|---|---|---|

| Length | lm = λlF | m |

| Time | tm = tF | s |

| Structural mass | mm = λ3(ρm/ρF)mF | kg |

| Velocity | vm = vF | m/s |

| Acceleration | am = aF | m/s2 |

| Force | Fm = λ3(ρm/ρF)FF | N |

| Bending moment | Mm = λ4(ρm/ρF)MF | N * m |

| Tests | Experimental Serial Number | Wave Height(m) | Wave Period(s) |

|---|---|---|---|

| Reliability analysis for wave surface | 1~4 | H = 0.06 | T = 0.86, 0.96, 1.06, 1.10 |

| 5~8 | H = 0.07 | T = 0.86, 0.96, 1.06, 1.10 | |

| 9~12 | H = 0.08 | T = 0.86, 0.96, 1.06, 1.10 | |

| 13~16 | H = 0.09 | T = 0.86, 0.96, 1.06, 1.10 | |

| Regular wave test | 1~7 | H = 0.05 | T = 0.8, 0.86, 0.9, 0.96, 1.0, 1.06, 1.10 |

| 8~14 | H = 0.06 | T = 0.8, 0.86, 0.9, 0.96, 1.0, 1.06, 1.10 | |

| 15~21 | H = 0.07 | T = 0.8, 0.86, 0.9, 0.96, 1.0, 1.06, 1.10 | |

| 22~28 | H = 0.08 | T = 0.8, 0.86, 0.9, 0.96, 1.0, 1.06, 1.10 | |

| 29~35 | H = 0.09 | T = 0.8, 0.86, 0.9, 0.96, 1.0, 1.06, 1.10 | |

| 36~42 | H = 0.10 | T = 0.8, 0.86, 0.9, 0.96, 1.0, 1.06, 1.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Li, K.; Huang, B.; Cheng, L.; Ding, H. Experimental Investigation of the Dynamic Behavior of Submerged Floating Tunnels under Regular Wave Conditions. J. Mar. Sci. Eng. 2022, 10, 1623. https://doi.org/10.3390/jmse10111623

Wang F, Li K, Huang B, Cheng L, Ding H. Experimental Investigation of the Dynamic Behavior of Submerged Floating Tunnels under Regular Wave Conditions. Journal of Marine Science and Engineering. 2022; 10(11):1623. https://doi.org/10.3390/jmse10111623

Chicago/Turabian StyleWang, Fang, Ke Li, Bo Huang, Liang Cheng, and Hao Ding. 2022. "Experimental Investigation of the Dynamic Behavior of Submerged Floating Tunnels under Regular Wave Conditions" Journal of Marine Science and Engineering 10, no. 11: 1623. https://doi.org/10.3390/jmse10111623

APA StyleWang, F., Li, K., Huang, B., Cheng, L., & Ding, H. (2022). Experimental Investigation of the Dynamic Behavior of Submerged Floating Tunnels under Regular Wave Conditions. Journal of Marine Science and Engineering, 10(11), 1623. https://doi.org/10.3390/jmse10111623