Environmental and Economic Sustainability Assessment for Two Different Sprinkler and A Drip Irrigation Systems: A Case Study on Maize Cropping

Abstract

1. Introduction

2. Materials and Methods

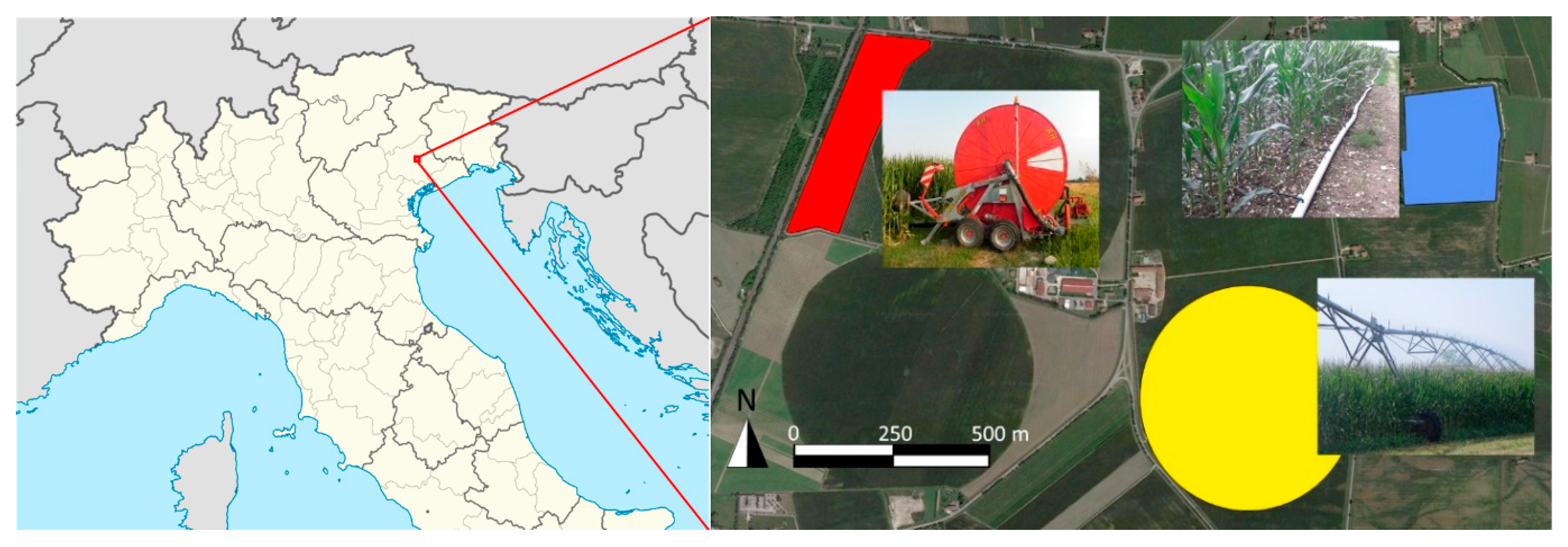

2.1. Study Area and Field Management

2.2. Irrigation

2.3. Water-Based Indicators

2.4. Biomass and Yield Analysis

2.5. Economic Balance and Related Indexes of Performance

2.6. Energetic Balance and Related Indexes

3. Results and Discussion

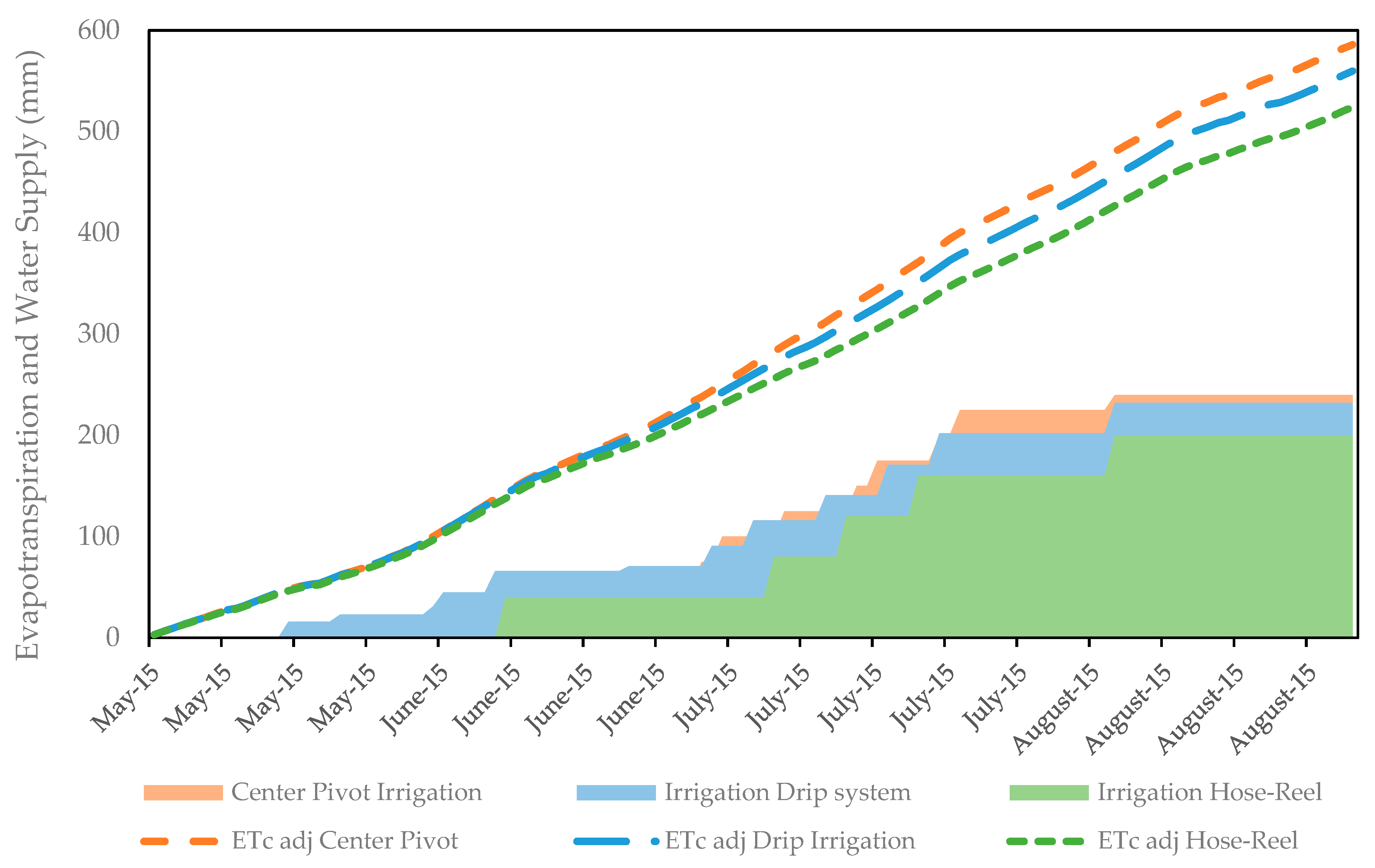

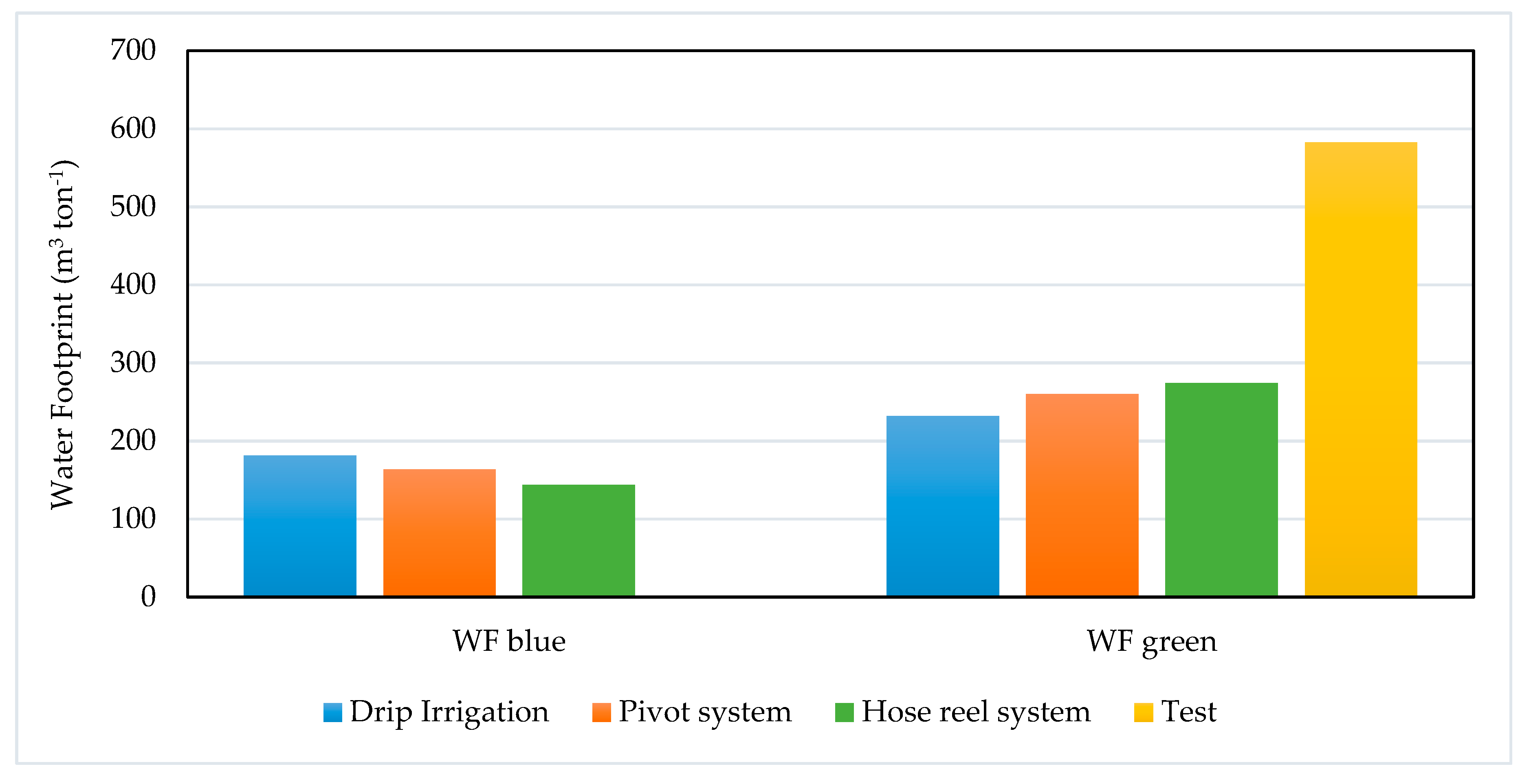

3.1. Water Based Indicators

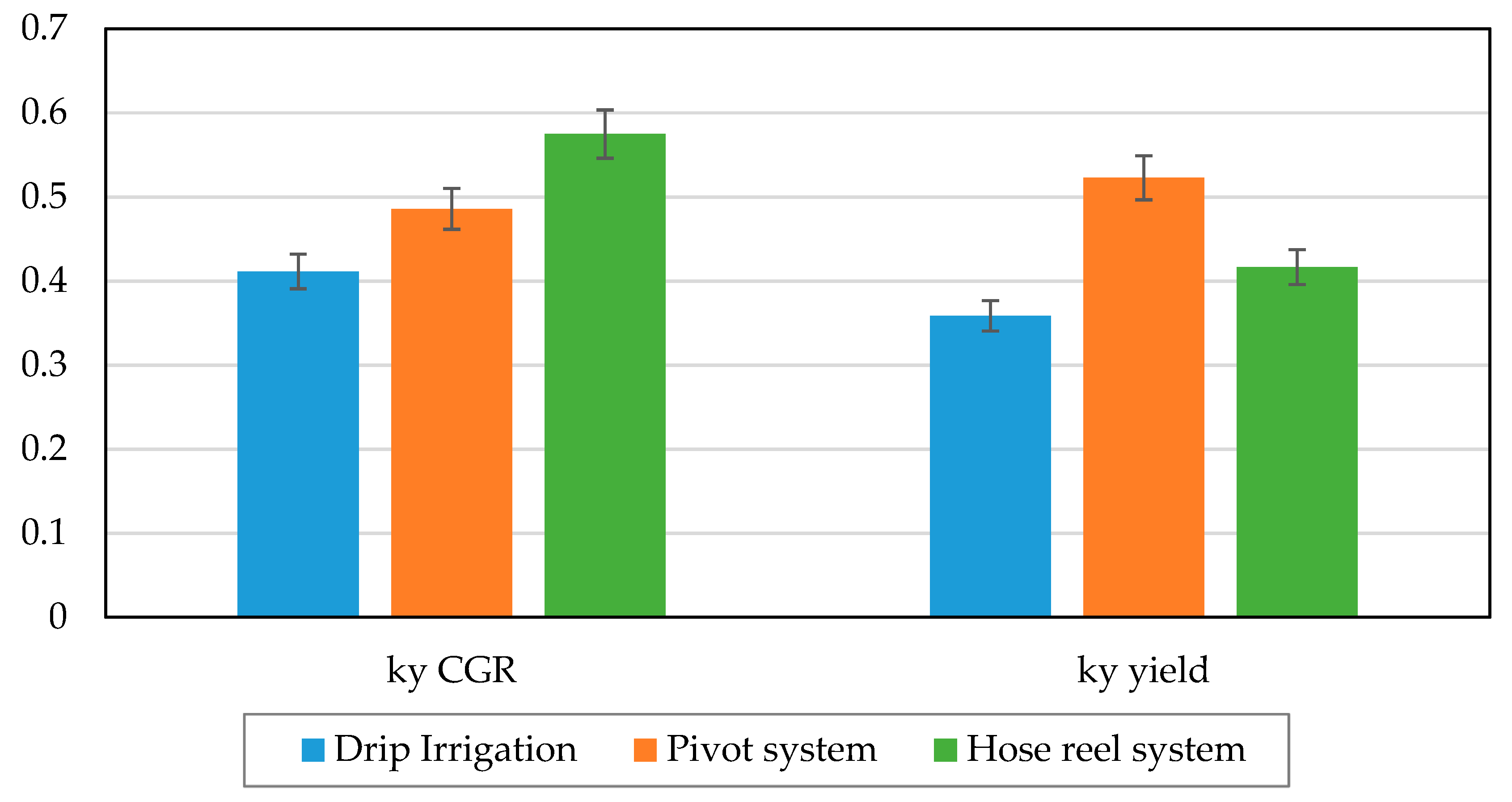

3.2. Indicator for Biomass and Yield Evaluation

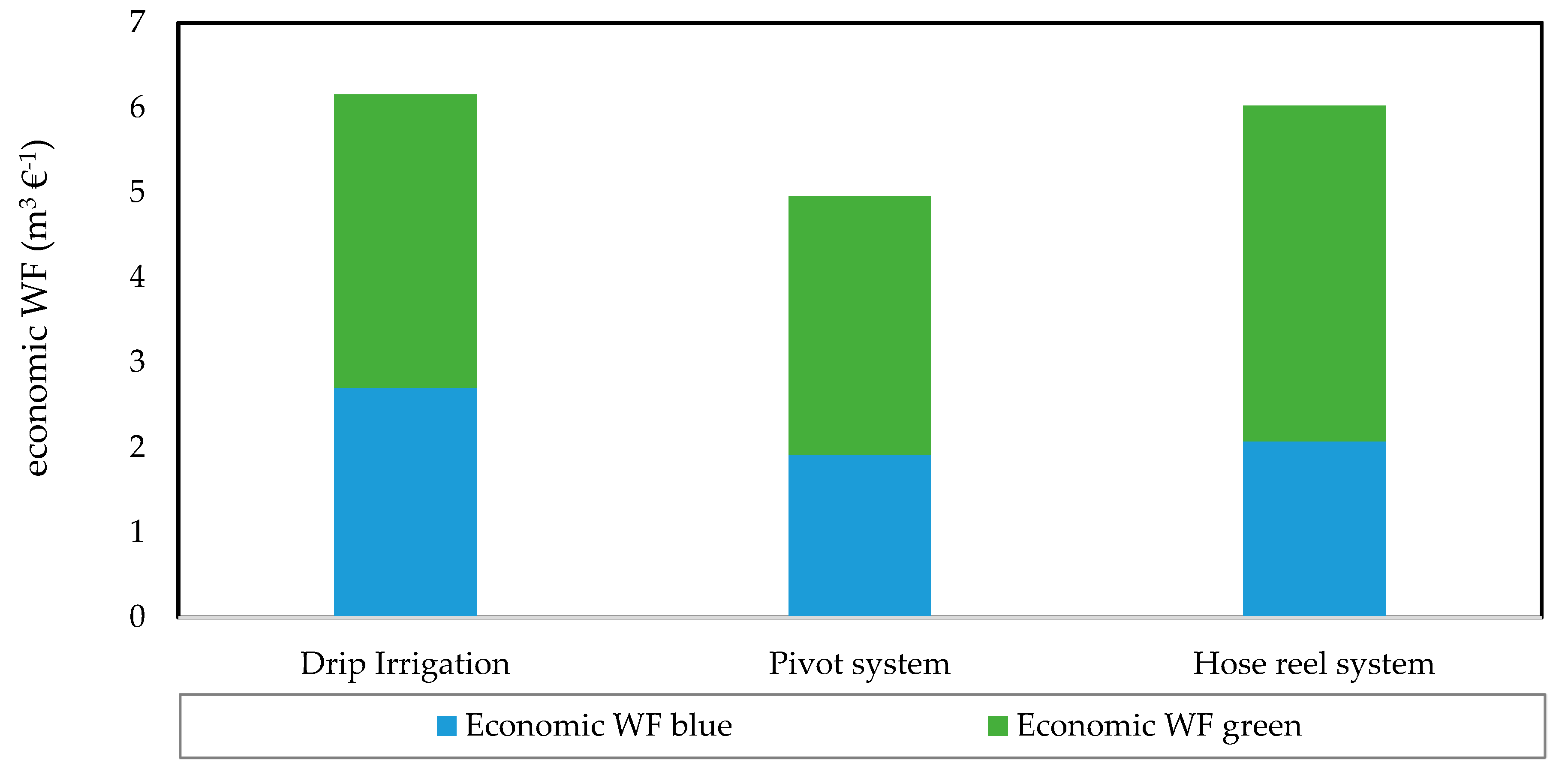

3.3. Economic Indicators

3.4. Energetic Indicators

4. Conclusions

Author Ccontributions

Funding

Conflicts of Interest

References

- Rockström, J.; Williams, J.; Daily, G.; Noble, A.; Matthews, N.; Gordon, L.; Wetterstrand, H.; DeClerck, F.; Shah, M.; Steduto, P.; et al. Sustainable intensification of agriculture for human prosperity and global sustainability. Ambio 2017, 46, 4–17. [Google Scholar] [CrossRef]

- Chartzoulakis, K.; Bertaki, M. Sustainable Water Management in Agriculture under Climate Change. Agric. Agric. Sci. Procedia 2015, 4, 88–98. [Google Scholar] [CrossRef]

- Alcamo, J.; Döll, P.; Henrichs, T.; Kaspar, F.; Lehner, B.; Rösch, T.; Siebert, S. Global estimates of water withdrawals and availability under current and future “business-as-usual” conditions. Hydrol. Sci. J. 2003, 48, 339–348. [Google Scholar] [CrossRef]

- Directorate-General for Environment. Ecological Flows in the Implementation of the Water Framework Directive: Guidance Document N°31; European Commission: Bruxelles, Belgium, 2016; ISBN 978-92-79-45758-6. [Google Scholar]

- Smakhtin, V.; Revenga, C.; Döll, P. A pilot global assessment of environmental water requirements and scarcity. Water Int. 2004, 29, 307–317. [Google Scholar] [CrossRef]

- Sullivan, C. Calculating a Water Poverty Index. World Dev. 2002, 30, 1195–1210. [Google Scholar] [CrossRef]

- Rosa, L.; Rulli, M.C.; Davis, K.F.; Chiarelli, D.D.; Passera, C.; D’Odorico, P. Closing the yield gap while ensuring water sustainability. Environ. Res. Lett. 2018, 13, 104002. [Google Scholar] [CrossRef]

- D’Odorico, P.; Davis, K.F.; Rosa, L.; Carr, J.A.; Chiarelli, D.; Dell’Angelo, J.; Gephart, J.; MacDonald, G.K.; Seekell, D.A.; Suweis, S.; et al. The Global Food-Energy-Water Nexus. Rev. Geophys. 2018, 56, 456–531. [Google Scholar] [CrossRef]

- Unver, O.; Bhaduri, A.; Hoogeveen, J. Water-use efficiency and productivity improvements towards a sustainable pathway for meeting future water demand. Water Secur. 2017, 1, 21–27. [Google Scholar] [CrossRef]

- Grafton, R.Q.Q.; William, J.; Perry, C.J.J.; Molle, F.; Ringler, C.; Steduto, P.; Udall, B.; Wheeler, S.A.A.; Wang, Y.; Garrick, D.; et al. The paradox of irrigation efficiency. Science 2018, 361, 748–750. [Google Scholar] [CrossRef]

- Falkenmark, M. Society’s interaction with the water cycle: A conceptual framework for a more holistic approach. Hydrol. Sci. J. 1997, 42, 451–466. [Google Scholar] [CrossRef]

- Tuninetti, M.; Tamea, S.; Dalin, C. Water Debt Indicator Reveals Where Agricultural Water Use Exceeds Sustainable Levels. Water Resour. Res. 2019, 55, 2464–2477. [Google Scholar] [CrossRef]

- Borsato, E.; Galindo, A.; Tarolli, P.; Sartori, L.; Marinello, F. Evaluation of the grey water footprint comparing the indirect effects of different agricultural practices. Sustainability 2018, 10, 3992. [Google Scholar] [CrossRef]

- Mejía, A.; Hubner, M.N.; Sánchez, E.R.; Doria, M. Water and Sustainability: A Review of Targets, Tools and Regional Cases; UNESCO: Paris, France, 2012; ISBN 9789230010942. [Google Scholar]

- Gómez-Limón, J.A.; Riesgo, L. Alternative approaches to the construction of a composite indicator of agricultural sustainability: An application to irrigated agriculture in the Duero basin in Spain. J. Environ. Manag. 2009, 90, 3345–3362. [Google Scholar] [CrossRef] [PubMed]

- Bubb, R.; Kaur, S.; Mullainathan, S. Barriers to contracting in village economies: A test for enforcement constraints. Unpublished work. 2016. [Google Scholar]

- Pellegrini, E.; Bortolini, L.; Defrancesco, E. Coordination and Participation Boards under the European Water Framework Directive: Different approaches used in some EU countries. Water 2019, 11, 833. [Google Scholar] [CrossRef]

- Vanham, D.; Hoekstra, A.Y.; Wada, Y.; Bouraoui, F.; de Roo, A.; Mekonnen, M.M.; van de Bund, W.J.; Batelaan, O.; Pavelic, P.; Bastiaanssen, W.G.M.; et al. Physical water scarcity metrics for monitoring progress towards SDG target 6.4: An evaluation of indicator 6.4.2 “Level of water stress”. Sci. Total Environ. 2018, 613–614, 218–232. [Google Scholar] [CrossRef] [PubMed]

- Chaves, H.M.L.; Alipaz, S. An integrated indicator based on basin hydrology, environment, life, and policy: The watershed sustainability index. Water Resour. Manag. 2007, 21, 883–895. [Google Scholar] [CrossRef]

- Galli, A.; Wiedmann, T.; Ercin, E.; Knoblauch, D.; Ewing, B.; Giljum, S. Integrating Ecological, Carbon and Water footprint into a “footprint Family” of indicators: Definition and role in tracking human pressure on the planet. Ecol. Indic. 2012, 16, 100–112. [Google Scholar] [CrossRef]

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. A review of footprint analysis tools for monitoring impacts on sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- Rennings, K.; Wiggering, H. Steps towards indicators of sustainable development: Linking economic and ecological concepts. Ecol. Econ. 1997, 20, 25–36. [Google Scholar] [CrossRef]

- Galindo, A.; Collado-González, J.; Griñán, I.; Corell, M.; Centeno, A.; Martín-Palomo, M.J.; Girón, I.F.; Rodríguez, P.; Cruz, Z.N.; Memmi, H.; et al. Deficit irrigation and emerging fruit crops as a strategy to save water in Mediterranean semiarid agrosystems. Agric. Water Manag. 2018, 202, 311–324. [Google Scholar] [CrossRef]

- Herva, M.; Franco, A.; Carrasco, E.F.; Roca, E. Review of corporate environmental indicators. J. Clean. Prod. 2011, 19, 1687–1699. [Google Scholar] [CrossRef]

- Marino, G.; Zaccaria, D.; Snyder, R.L.; Lagos, O.; Lampinen, B.D.; Ferguson, L.; Grattan, S.R.; Little, C.; Shapiro, K.; Maskey, M.L.; et al. Actual Evapotranspiration and Tree Performance of Mature Micro-Irrigated Pistachio Orchards Grown on Saline-Sodic Soils in the San Joaquin Valley of California. Agriculture 2019, 9, 76. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration. In FAO Irrigation and Drainage Paper No. 56; FAO: Rome, Italy, 1998; Volume 56, p. 333. ISBN 92-5-104219-5. [Google Scholar]

- Lovelli, S.; Perniola, M.; Ferrara, A.; Di Tommaso, T. Yield response factor to water (Ky) and water use efficiency of Carthamus tinctorius L. and Solanum melongena L. Agric. Water Manag. 2007, 92, 73–80. [Google Scholar] [CrossRef]

- Steduto, P.; Albrizio, R. Resource use efficiency of field-grown sunflower, sorghum, wheat and chickpea: II. Water use efficiency and comparison with radiation use efficiency. Agric. For. Meteorol. 2005, 130, 269–281. [Google Scholar] [CrossRef]

- Molden, D.; Oweis, T.; Steduto, P.; Bindraban, P.; Hanjra, M.A.; Kijne, J. Improving agricultural water productivity: Between optimism and caution. Agric. Water Manag. 2010, 97, 528–535. [Google Scholar] [CrossRef]

- Morillo, J.G.; Díaz, J.A.R.; Camacho, E.; Montesinos, P. Linking water footprint accounting with irrigation management in high value crops. J. Clean. Prod. 2015, 87, 594–602. [Google Scholar] [CrossRef]

- Playán, E.; Mateos, L. Modernization and optimization of irrigation systems to increase water productivity. Agric. Water Manag. 2006, 80, 100–116. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual; Earthscan: London, UK, 2011; ISBN 9781849712798. [Google Scholar]

- Chukalla, A.D.; Krol, M.S.; Hoekstra, A.Y. Green and blue water footprint reduction in irrigated agriculture: Effect of irrigation techniques, irrigation strategies and mulching. Hydrol. Earth Syst. Sci. 2015, 19, 4877–4891. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. National water footprint accounts: The green, blue and grey water footprint of production and consumption. In Value of Water Research Report Series No. 50; UNESCO-IHE: Delft, The Netherlands, 2011. [Google Scholar]

- Bonamente, E.; Scrucca, F.; Rinaldi, S.; Merico, M.C.; Asdrubali, F.; Lamastra, L. Environmental impact of an Italian wine bottle: Carbon and water footprint assessment. Sci. Total Environ. 2016, 560, 274–283. [Google Scholar] [CrossRef]

- Lamastra, L.; Suciu, N.A.; Novelli, E.; Trevisan, M. A new approach to assessing the water footprint of wine: An Italian case study. Sci. Total Environ. 2014, 490, 748–756. [Google Scholar] [CrossRef] [PubMed]

- Zhuo, L.; Mekonnen, M.M.; Hoekstra, A.Y. Sensitivity and uncertainty in crop water footprint accounting: A case study for the Yellow River basin. Hydrol. Earth Syst. Sci. 2014, 18, 2219–2234. [Google Scholar] [CrossRef]

- Borsato, E.; Giubilato, E.; Zabeo, A.; Lamastra, L.; Criscione, P.; Tarolli, P.; Marinello, F.; Pizzol, L. Comparison of Water-focused Life Cycle Assessment and Water Footprint Assessment: The case of an Italian wine. Sci. Total Environ. 2019, 666, 1220–1231. [Google Scholar] [CrossRef] [PubMed]

- Castellanos, M.T.; Cartagena, M.C.; Requejo, M.I.; Arce, A.; Cabello, M.J.; Ribas, F.; Tarquis, A.M. Agronomic concepts in water footprint assessment: A case of study in a fertirrigated melon crop under semiarid conditions. Agric. Water Manag. 2016, 170, 81–90. [Google Scholar] [CrossRef]

- Toniolo, L.; Mosca, G.; Sattin, M. Crop physiology aspects of soybean versus maize in north-eastern Italy. Rivista di Agronomia 1985, 19, 251–257. [Google Scholar]

- Hunt, R.; Causton, D.R.; Shipley, B.; Askew, A.P. A Modern Tool for Classical Plant Growth Analysis. Ann. Bot. 2002, 90, 484–488. [Google Scholar] [CrossRef] [PubMed]

- Haghverdi, A.; Leib, B.; Washington-Allen, R.; Wright, W.; Ghodsi, S.; Grant, T.; Zheng, M.; Vanchiasong, P. Studying Crop Yield Response to Supplemental Irrigation and the Spatial Heterogeneity of Soil Physical Attributes in a Humid Region. Agriculture 2019, 9, 43. [Google Scholar] [CrossRef]

- Doorenbos, J.; Pruitt, W.O. Guidelines for predicting crop water requirements. In FAO Irrigation and Drainage Paper 24; FAO: Rome, Italy, 1977. [Google Scholar]

- Handa, D.; Frazier, R.; Taghvaeian, S.; Warren, J. The Efficiencies, Environmental Impacts and Economics of Energy Consumption for Groundwater-Based Irrigation in Oklahoma. Agriculture 2019, 9, 27. [Google Scholar] [CrossRef]

- Borsato, E.; Tarolli, P.; Marinello, F. Sustainable patterns of main agricultural products combining different footprint parameters. J. Clean. Prod. 2018, 179, 357–367. [Google Scholar] [CrossRef]

- Carnovale, E.; Marletta, L. Tabelle di Composizione Degli Alimenti. Available online: http://nut.entecra.it/646/tabelle_di_composizione_degli_alimenti.html (accessed on 28 August 2019).

- Hess, M.; Barralis, G.; Bleiholder, H.; Buhr, L.; Eggers, T.H.; Hack, H.; Stauss, R. Use of the extended BBCH scale—general for the descriptions of the growth stages of mono; and dicotyledonous weed species. Weed Res. 1997, 37, 433–441. [Google Scholar] [CrossRef]

| Center Pivot System | Drip Irrigation | Hose-reel System | TEST | |

|---|---|---|---|---|

| Total gross income | 2054 | 2300 | 1949 | 917 |

| Amortization value | 131 | 62 | 111 | - |

| Labor and maintenance | 30 | 125 | 75 | - |

| Energy | 99 | 104 | 171 | - |

| Cost for drip line | - | 320 | - | - |

| Total Irrigation costs | 260 | 610 | 357 | - |

| Net income | 1794 | 1690 | 1592 | 917 |

| Inventory List | Metric | Drip Irrigation | Center Pivot | Hose-Reel |

|---|---|---|---|---|

| Number of irrigations | n° | 12 | 10 | 5 |

| Electricity consumption single irrigation per hectare | kWh (*) | 48 | 55 | 52.5 |

| Energy cost | € ha−1 | 104 | 99 | 171 |

| Electricity price | € kWh−1 (**) | 0.18 | 0.18 | 0.65 |

| Irrigation Plot | WUE 22-June kg m−3 | WUE 28-July kg m−3 | IWUE kg m−3 | RIS |

|---|---|---|---|---|

| Drip irrigation | 1.251 | 1.875 | 2.981 | 0.79 |

| Center Pivot | 1.349 | 2.040 | 2.370 | 0.75 |

| Hose-reel system | 0.972 | 1.541 | 2.580 | 0.78 |

| Non-irrigated test | 1.319 | 1.627 |

| Irrigation System | HI at Hard Dough Phase kgharvest·kgbiomass−1 | CGR Maize Biomass g day−1 | CGR Maize Ear g day−1 | RGR Maize Biomass g g−1 day−1 | RGR Maize Ear g g−1 day−1 |

|---|---|---|---|---|---|

| Drip irrigation | 0.521 | 13.5 | 21.5 | 0.031 | 0.031 |

| Center pivot | 0.478 | 15.9 | 17.5 | 0.033 | 0.026 |

| Hose-reel | 0.533 | 10.4 | 18.9 | 0.032 | 0.033 |

| Test | 0.416 | 6.4 | 7.3 | 0.019 | 0.024 |

| Energetic Footprint m3 MJ−1 | Energetic Cost Footprint m3 €−1 | Energy Performance MJ m3 kgCO2−eq−1 | GHG Emission Per Irrigation kgCO2−eq ha−1 | |

|---|---|---|---|---|

| Drip irrigation | 1.00 | 22.3 | 0.21 | 26 |

| Center pivot system | 0.85 | 24.2 | 0.15 | 29 |

| Hose-reel system | 0.12 | 11.7 | 0.35 | 29 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borsato, E.; Martello, M.; Marinello, F.; Bortolini, L. Environmental and Economic Sustainability Assessment for Two Different Sprinkler and A Drip Irrigation Systems: A Case Study on Maize Cropping. Agriculture 2019, 9, 187. https://doi.org/10.3390/agriculture9090187

Borsato E, Martello M, Marinello F, Bortolini L. Environmental and Economic Sustainability Assessment for Two Different Sprinkler and A Drip Irrigation Systems: A Case Study on Maize Cropping. Agriculture. 2019; 9(9):187. https://doi.org/10.3390/agriculture9090187

Chicago/Turabian StyleBorsato, Eros, Marco Martello, Francesco Marinello, and Lucia Bortolini. 2019. "Environmental and Economic Sustainability Assessment for Two Different Sprinkler and A Drip Irrigation Systems: A Case Study on Maize Cropping" Agriculture 9, no. 9: 187. https://doi.org/10.3390/agriculture9090187

APA StyleBorsato, E., Martello, M., Marinello, F., & Bortolini, L. (2019). Environmental and Economic Sustainability Assessment for Two Different Sprinkler and A Drip Irrigation Systems: A Case Study on Maize Cropping. Agriculture, 9(9), 187. https://doi.org/10.3390/agriculture9090187