Measurement of Production Efficiency and Analysis of Influencing Factors in Major Sugarcane-Producing Regions of China

Abstract

1. Introduction

2. Materials and Methods

2.1. Sources of Data

2.2. Research Techniques

2.2.1. DEA Model

2.2.2. Malmquist Index

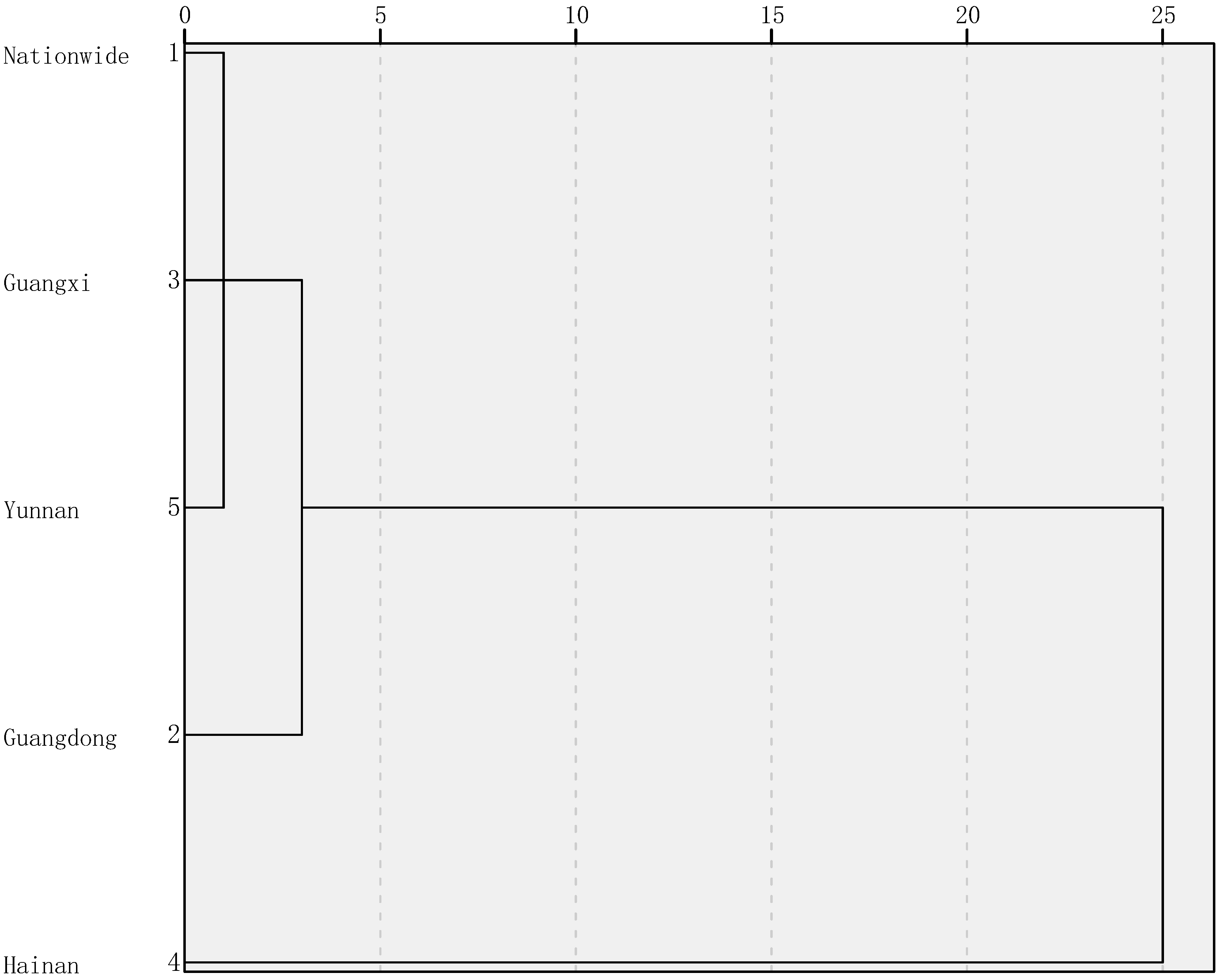

2.2.3. Cluster Analysis

2.2.4. Tobit Model

3. Results and Analysis

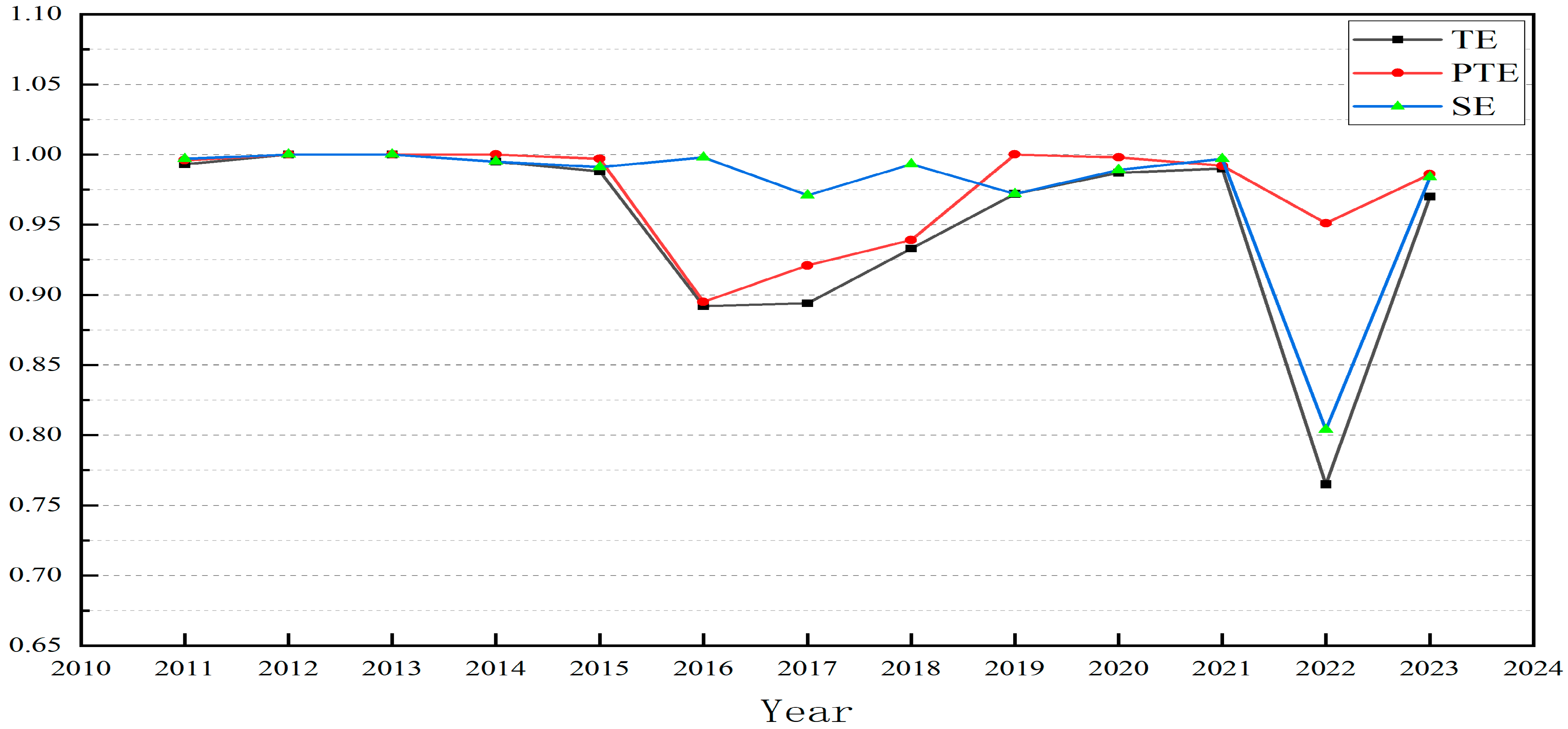

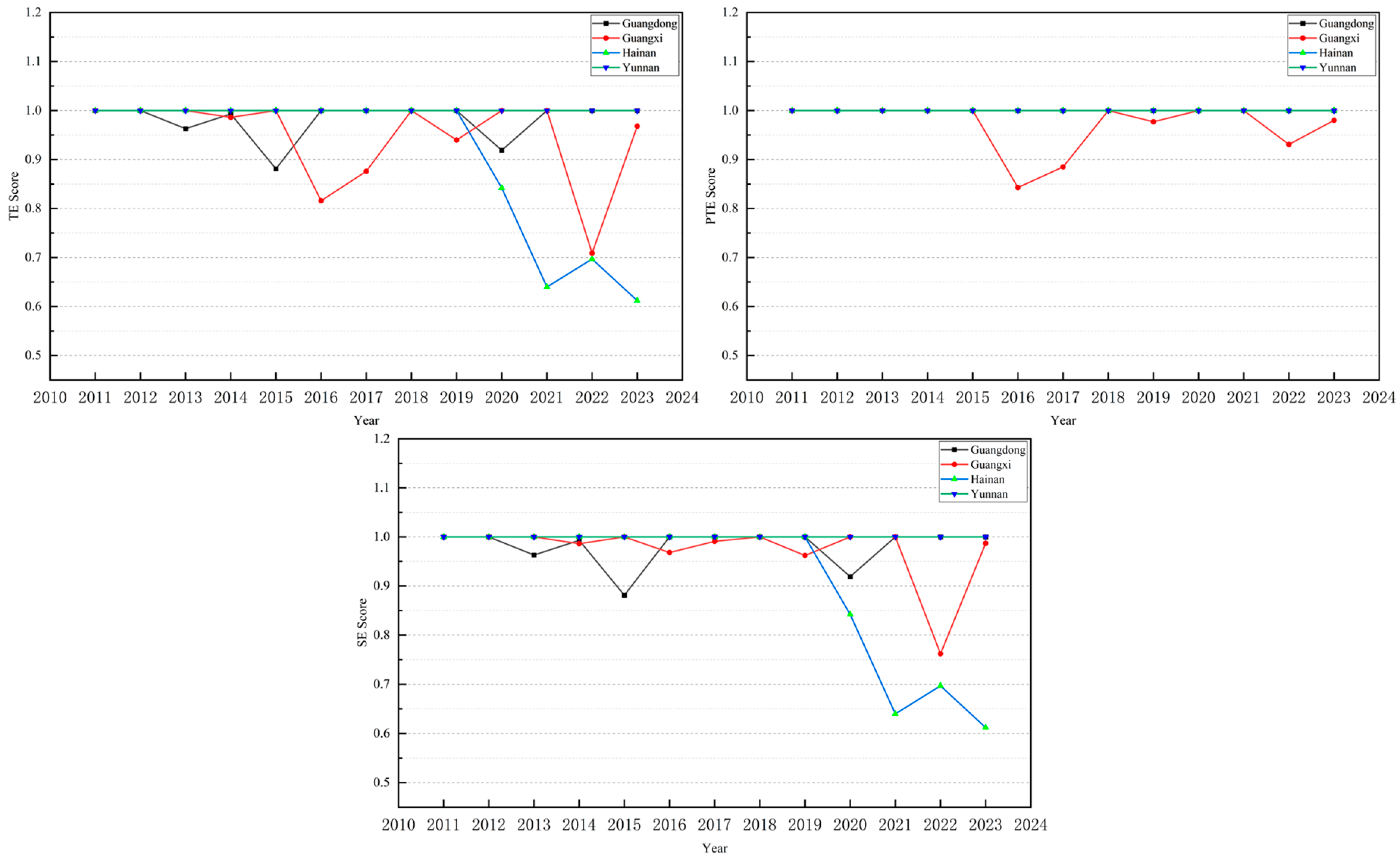

3.1. Analysis of DEA Model Results

3.2. Comparative Analysis of Malmquist Indices

3.2.1. Holistic Analysis

3.2.2. Decomposition Analysis

3.3. Analysis of Influencing Factors

4. Discussions

4.1. Production Efficiency Variations Among China’s Principal Sugarcane-Producing Regions

4.2. Empirical Findings for Additional Crops in the Same Areas

4.3. Comparison of the World’s Principal Sugarcane-Producing Regions

4.4. Limitations

5. Conclusions and Recommendations

5.1. Conclusions

5.2. Recommendations

5.2.1. Encourage Technological Innovation, Improve Integrated Technical Efficiency, and Practice Optimal Resource Management

5.2.2. Differentiated Regional Policymaking to Support District Development Based on Local Circumstances

5.2.3. Increasing the Income and Educational Attainment of Rural Residents by Fortifying External Environmental Support

5.2.4. Encourage Cooperation Among Industry Chains and Marketization to Boost Industrial Competitiveness

5.2.5. Enhancing Readiness and Reaction to Disasters to Guarantee Consistent Output

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, H.X. Research on the Impact of the Surge in Sugar Imports on China’s Sugar Industry. Master’s Thesis, Heilongjiang University, Harbin, China, 2023. [Google Scholar]

- Zhang, X.Y. Research on the Impact of Sugar Price Fluctuations in China from the Perspective of Import Security. Master’s Thesis, Heilongjiang University, Harbin, China, 2023. [Google Scholar]

- Shu, D.Z. Dilemmas and countermeasures for high-quality development of Guangxi sugar industry. Guangxi Sugar Ind. 2022, 42, 35–38. [Google Scholar]

- Li, S.; Feng, X.F. A Study on Market Power in China’s Sugar Import Trade; Price Monthly: Jiangxi Province, China, 2021; pp. 40–47. [Google Scholar]

- Wei, J.N. Analysis on changes and influencing factors of sugarcane production layout in Guangxi. Chin. J. Trop. Agric. 2023, 43, 126–131. [Google Scholar]

- Xie, G.X.; Su, Q.Q.; Yang, N.; Yang, S.; Huang, Q.; Qu, T. Analysis of changes in Guangxi’s leading agricultural economic industries and countermeasure suggestions. J. Anhui Agric. Sci. 2024, 52, 255–259. [Google Scholar]

- Lu, P. Investigation on the Current Development and Influencing Factors of Mechanized Sugarcane Harvesting in Guangxi. Master’s Thesis, Guangxi University, Nanning, China, 2023. [Google Scholar]

- Hu, Z.H.; Yin, Y.L.; Zhang, T.F.; Li, J.Q.; Wei, X.; Yan, Q.Y. Feasibility and economic benefit analysis of sugarcane step-by-step mechanical harvesting. Sugar Crops China 2023, 45, 70–80. [Google Scholar]

- Liu, X.X.; Yan, C.Y.; Li, T.H. Investigation and analysis on influencing factors and cost-benefit of sugarcane planting behavior in Guangxi. Sugar Crops China 2020, 42, 59–66. [Google Scholar]

- Zhang, J.Y.; Li, F.N.; Wei, L. Analysis of Strategies for the Brand Development of the Sugar Industry in Guangxi. Guangxi Sugar Ind. 2023, 43, 28–31. [Google Scholar]

- Lei, C.B. Building a New Ecological Model of Harmonious and Win-Win Development for China’s Sugar Industry—Research on the Development of China’s Sugar Industry during the 14th Five-Year Plan Period. Guangxi Sugar Ind. 2021, 42, 38–44. [Google Scholar]

- Du, Z.X.; Zhang, H.Y.; Zhu, J.; Lin, W.; Luo, B. Further Deepening Rural Reform and Improving the Support System for Strengthening, Benefiting, and Enriching Agriculture—Explanations by Authoritative Experts on the 2024 Central Economic Work Conference and the Central Rural Work Conference. China Rural Econ. 2025, 3–19. [Google Scholar] [CrossRef]

- National Sugarcane Industry Technology System. Chinese Modern Agricultural Industry Sustainable Development Strategy Research: Sugarcane Volume; Agriculture Press: Beijing, China, 2018. [Google Scholar]

- Liu, Z.X. Evaluation and international comparison of China’s sugar industry security under open conditions. Issues Agric. Econ. 2012, 33, 77–84. [Google Scholar]

- Wei, J.P.; Zhou, X.R.; Huang, Y.Z. Development Status and Strategies of Guangxi Sugar Industry from the Perspective of Strategic Reserve Security. Guangxi Sugar Ind. 2024, 44, 61–66. [Google Scholar]

- Chen, Y.H. Analysis of Influencing Factors of Farmers’ Willingness to Plant Sugarcane in Binyang County, Guangxi. Master’s Thesis, Zhongkai University of Agriculture and Engineering, Guangzhou, China, 2018. [Google Scholar]

- Li, H. Investigation and analysis of sugarcane planting behaviors of farmers in Longchuan County Yunnan. Sugarcane Canesugar 2022, 51, 34–39. [Google Scholar]

- Rossetto, R.; Ramos, N.P.; de Matos Pires, R.C.; Xavier, M.A.; Cantarella, H.; de Andrade Landell, M.G. Sustainability in sugarcane supply chain in Brazil: Issues and way forward. Sugar Tech 2022, 24, 941–966. [Google Scholar] [CrossRef]

- Hiban, I.D.; Nugraha, D.; Dwirayani, D. Analysis of Factors Affecting Sugarcane Farmers’ Income (Case Study: PT. PG Rajawali II Unit PG. Sindanglaut). Asian J. Manag. Entrep. Soc. Sci. 2024, 4, 73–83. [Google Scholar]

- Picoli, M.C.A.; Machado, P.G. Land use change: The barrier for sugarcane sustainability. Biofuels Bioprod. Biorefin. 2021, 15, 1591–1603. [Google Scholar] [CrossRef]

- da Silva, G.J.; Berg, E.C.; Calijuri, M.L.; dos Santos, V.J.; Lorentz, J.F.; do Carmo Alves, S. Aptitude of areas planned for sugarcane cultivation expansion in the state of São Paulo, Brazil: A study based on climate change effects. Agric. Ecosyst. Environ. 2021, 305, 107164. [Google Scholar] [CrossRef]

- Bahati, I.; Martiniello, G.; Abebe, G.K. The implications of sugarcane contract farming on land rights, labor, and food security in the Bunyoro sub-region, Uganda. Land Use Policy 2022, 122, 106326. [Google Scholar] [CrossRef]

- Fischer, G.; Teixeira, E.; Hizsnyik, E.T.; Van Velthuizen, H. Land Use Dynamics and Sugarcane Production//Sugarcane Ethanol; Wageningen Academic: Wageningen, The Netherlands, 2008; pp. 29–62. [Google Scholar]

- Dubb, A. Commodity Study: Small-Scale Sugar Production. 2020. Available online: http://hdl.handle.net/10566/5214 (accessed on 13 January 2025).

- Zheng, J. Current Status of China’s Sugarcane (Sugar) Industry and Prospects for Cooperation with Thailand. EDP Sci. 2024, 142, 01011. [Google Scholar] [CrossRef]

- Upreti, P.; Singh, A. An economic analysis of sugarcane cultivation and its productivity in major sugar producing states of Uttar Pradesh and Maharashtra. Econ. Aff. 2017, 62, 711–718. [Google Scholar] [CrossRef]

- Naeem, M.K.; Bashir, M.K.; Hussain, B.; Abbas, M. Assessment of profitability of sugarcane crop in Faisalabad district. Pak. J. Life Soc. Sci. 2007, 5, 30–33. [Google Scholar]

- Abnave, V.B. Economic viability of sugarcane cultivation: A comparative analysis. J. Sugarcane Res. 2021, 10, 158–173. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Lin, L.; Huang, H.R. Technological progress, scale operation, and production efficiency in major sugarcane-producing regions of China. China Agric. Resour. Reg. Plan. 2021, 42, 251–259. [Google Scholar]

- Ye, J.; Xu, L.P. Empirical study on production efficiency of sugarcane advantageous regions in China based on DEA. Jiangsu Agric. Sci. 2015, 43, 476–480. [Google Scholar]

- Xie, Y.; Chen, R.K.; Chen, N.; Que, Y. An empirical investigation on the relationship between fertilizer inputs and production efficiency in the main sugarcane planting areas in China. Sugar Tech 2024, 26, 376–386. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Sun, L.X.; Liang, J.J. Analysis of Fiscal Investment Efficiency and Its Influencing Factors in Senior Education under the Context of High-Quality Development. Res. Educ. Dev. 2025, 45, 19–27. [Google Scholar]

- Lan, Y. Evaluation of Public Health Fiscal Expenditure Efficiency—An Empirical Study of 12 Provinces in Western China. Stat. Decis. 2023, 39, 147–151. [Google Scholar]

- An, H.; Zhang, F. Innovation-Driven, Interest Rate Liberalization, and Efficiency Improvement in the Banking Industry. Reform 2017, 139–149. [Google Scholar]

- Yang, S.Y. Theory and Empirical Research on Total Factor Productivity. Master’s Thesis, Tianjin University, Tianjin, China, 2006. [Google Scholar]

- Gu, H.; Meng, L.J. Growth and Composition of Agricultural TFP in China. Quant. Econ. Tech. Econ. Res. 2002, 1518. [Google Scholar]

- Han, Y.H.; Zhang, F.; Zhu, C.W. Re-estimation and Dynamic Evolution Analysis of Total Factor Productivity in Chinese Cities—Based on the Perspectives of Common Frontier and Regional Production Technology Heterogeneity. Sci. Sci. Manag. ST 2025, 46, 62–75. [Google Scholar]

- Yan, C.Z.; Yin, L.J.; He, B. Logistics Industry Agglomeration, Spatial Spillover Effects, and Agricultural Green Total Factor Productivity—An Empirical Analysis Based on Provincial Data. China Circ. Econ. 2022, 36, 3–16. [Google Scholar]

- Min, C.; Xinjie, P. Evaluation on the spatial differences and temporal changes of infrastructure investment efficiency of cities at prefecture level or above in China based on DEA and malmquist index. Manag. Rev. 2017, 29, 225. [Google Scholar]

- Guan, L.J.; Zhao, W. Evaluation of Rural Infrastructure Supply Efficiency Based on DEA-Malmquist. Stat. Decis. 2020, 36, 172–175. [Google Scholar]

- Zhang, C.X.; Shang, Y.; Aubli, T. Dynamic comparison of wheat production efficiency between Xinjiang and major wheat-producing areas in China based on DEA-Malmquist method. Sci. Technol. Cereals Oils Foods 2024, 32, 227–234. [Google Scholar]

- Zhang, Y.L.; Zhou, Y.J. A review of clustering algorithms. J. Comput. Appl. 2019, 39, 1869–1882. [Google Scholar]

- Yao, J.; Liao, Y.H.; Zhang, H.D.; He, J.P.; Wang, Z.Q. Evaluation of passenger check-in efficiency in railway transit operations based on DEA-Malmquist-Tobit model. Railw. Transp. Econ. 2025, 47, 156–164+190. [Google Scholar] [CrossRef]

- Xia, C.F. Research on the Green Economic Development Efficiency of Various Prefectures in Xinjiang Based on DEA-Tobit Model. Master’s Thesis, Kashgar University, Kashgar, China, 2022. [Google Scholar]

- Liao, Q.H.; Chen, T.; Sun, Y.; Tao, Z.M. Generalized Additive Fuzzy DEA-BCC Efficiency Evaluation Model and Its Application. Stat. Decis. 2016, 24, 74–76. [Google Scholar]

- Gomes, E.G.; Meza, L.A.; Neto, L.B. Alguns paradoxos em modelos dea-bcc: Eficiências negativas e inexistência de retornos de escala. In Proceedings of the XXVIII ENCONTRO NACIONAL DE ENGENHARIA DE PRODUÇÃO, Rio de Janeiro, Brazil, 13–16 October 2008. [Google Scholar]

- Ni, P.; Shi, L.G.; Ren, X.H.; Wang, J.; Tang, Z.; Xu, L. Evaluation of Surgical Department Operational Efficiency Based on DEA-BCC and Malmquist Index Models. Chin. J. Health Stat. 2024, 41, 901–904. [Google Scholar]

- Shan, B.; Zhou, H.L.; Tang, H.W.; Qin, Q.; Tang, X.; Pang, X.; Tang, S.; Zhou, Q. Impact of COVID-19 epidemic on Guangxi sugarcane industry and corresponding countermeasures. Chin. J. Trop. Agric. 2020, 21–24. [Google Scholar]

- Yang, J. Promoting Mechanized Harvesting of Sugarcane Through Diversified Strategies; China Agricultural Mechanization Herald: Beijing, China, 2024. [Google Scholar]

- Zhang, Y.; Liu, Y.Q.; Xiao, G.J.; Wan, Z.; Xie, J. Development status and policy suggestions for Guangdong sugarcane industry in 2014. Guangdong Agric. Sci. 2015, 42, 4–8. [Google Scholar]

- Liu, X.X.; Wang, J.; Zhou, J.Y. Dynamic evolution and influencing factors of sugarcane cost-benefit in China from 2001 to 2020. Sugarcane Canesugar 2023, 52, 55–70. [Google Scholar]

- Cen, Q. Guangxi Sugar Output Accounts for 60% of the National Total for 20 Consecutive Sugar Seasons, with an Estimated Sugarcane Planting Area of over 11.3 Million mu in 2024. Guangxi Daily. 2024; p. 20. Available online: http://nynct.gxzf.gov.cn/xwdt/ywkb/t18581478.shtml (accessed on 6 April 2025).

- Zhao, R.F.; Wang, W.; Liu, H.M.; Xue, W. Analysis on independent innovation capacity of Guangxi sugar industry. China Mark. 2011, 171–173. [Google Scholar]

- Chen, H.J.; Qin, D.S.; Yuan, S.H.; Huang, M.; Liang, J.; Wei, H.; Li, B.; Zhu, W. Analysis of planting efficiency of sugarcane, eucalyptus, and citrus in Guigang. Guangxi Sugar Ind. 2024, 44, 16–21. [Google Scholar]

- Gan, J.W.; Zhou, Y.F.; Mo, S.F. Implementation of farmland chief system and stabilization of sugarcane base in Laibin City. South China Nat. Resour. 2023, 12–15. [Google Scholar]

- Cen, Q.; Xiong, M.Z. Guangxi promotes comprehensive development of sugar industry through multi-point efforts. China Food Saf. Newsp. 2024. [Google Scholar] [CrossRef]

- He, F.; Fu, X.Y. Development situation and strategies of sugarcane in Hainan. Sugarcane 1998, 32–34. [Google Scholar]

- Zhong, Y.K.; Ou, B.; Deng, J. Current situation and countermeasures of sugarcane industry in Hainan Province. Sugar Crops China 2016, 38, 74–76. [Google Scholar]

- Wu, D.G.; Wu, J.T.; Xie, J.; Wang, Q.; Qiu, Y. Analysis on development trend of sugarcane production in China. Guangdong Agric. Sci. 2017, 44, 154–160. [Google Scholar]

- Zhan, L.; Xu, Z.H.; Huang, Z.G. Analysis on regional comparative advantages of sugarcane industry in China. Chin. J. Trop. Agric. 2025, 45, 132–139. [Google Scholar]

- Yu, H.X.; Tian, C.Y.; Jing, Y.F.; An, R.D.; Lang, R.B.; Dong, L.H.; Tao, L.A.; Sun, Y.F.; Yang, L.H.; Bian, X.; et al. SWOT analysis of sugar industry development in Yunnan. Sugar Crops China 2022, 44, 81–88. [Google Scholar]

- Zou, X.; Fu, M.; Wang, X.; Chen, F. Spatio-temporal changes and regional advantage analysis of sugarcane production in China from 1985 to 2018. J. China Agric. Univ. 2022, 27, 120–131. [Google Scholar]

- Qin, L.J. Research on the Development of Sugarcane Industry in Yunnan. Master’s Thesis, Guangdong Ocean University, Zhanjiang, China, 2021. [Google Scholar]

- Li, D.X.; Yin, Q.; Fang, W. Analysis on the production situation of Guangdong sugarcane industry in 2023. Sugarcane Canesugar 2024, 53, 66–74. [Google Scholar]

- Wan, C.X.; Hu, Z.D. Discussion on promoting modernization of sugarcane industry through agricultural science and technology innovation. Countrys. Agric. Farmers 2023, 35–37. [Google Scholar]

- Zhang, X.D. Analysis of Agricultural Production Efficiency and Its Influencing Factors in Hebei Province. Master’s Thesis, Hebei University, Baoding, China, 2008. [Google Scholar]

- He, X.L. Empirical Study on Agricultural Carbon Emissions, Agricultural Production Efficiency, and Economic Development in China. Master’s Thesis, Lanzhou University, Lanzhou, China, 2018. [Google Scholar]

- Mei, X.Y. The Importance of Ensuring and Expanding Effective Irrigation Area for Food Security. People’s Forum Acad. Front. 2022, 87–95. [Google Scholar]

- Hua, L. Analysis of the Influencing Factors of Agricultural Production Efficiency in Six Provinces of Central China. Guangxi Qual. Superv. Bull. 2021, 75–76. [Google Scholar]

- Zeng, M.Y.; Song, S.M. Can Farmers’ Income Promote Agricultural Production Technical Efficiency?—Path Analysis Based on Labor Price Distortion and Technological Innovation. Xinjiang Agric. Reclam. Econ. 2023, 1–12+77. [Google Scholar]

- Bin, L.H.; Liu, C.Y. Analysis of Sugarcane Production Efficiency and Its Influencing Factors in Guigang City. Hunan Agric. Sci. 2017, 105–109. [Google Scholar]

- Wang, L.N. Measurement and Analysis of the Influencing Factors of Agricultural Green Production Efficiency in China. Technol. Econ. Manag. Res. 2022, 37–41. [Google Scholar]

- Deng, J.M.; Dong, K.J.; Wang, X. Study on the Impact of Agricultural Meteorological Disasters on Food Production Efficiency. South. Metrop. J. 2023, 43, 101–108. [Google Scholar]

- Huang, J.Q.; Ding, P.F. Research on the Coordination of Agricultural Production Efficiency in Jiangsu Province under the Background of New-Type Urbanization. Jiangsu Bus. Rev. 2024, 99–102. [Google Scholar]

- Chen, C.B.; Han, Z.B. Rural Hollowing, Farmers’ Drought, and the Cultivation of Professional Farmers. J. China Univ. Geosci. 2013, 13, 7. [Google Scholar]

- Tian, H.Y.; Zhu, Z.Y. Analysis of China’s Grain Production Efficiency and Influencing Factors—Based on DEA-Tobit Two-Step Method. China Agric. Resour. Zoning 2018, 39, 161–168. [Google Scholar]

- Ju, L.P. Study on Wheat Production Efficiency and Its Influencing Factors in Hebei Province. Master’s Thesis, Jilin Agricultural University, Changchun, China, 2023. [Google Scholar]

- Wang, M.Y. Study on the Impact of Agricultural Industry Clustering on Agricultural Green Total Factor Productivity. Master’s Thesis, Shanxi University of Finance and Economics, Taiyuan, China, 2024. [Google Scholar]

- Wang, H.; Gao, M. Regional Differences and Spatio-Temporal Variation of Rice Production Efficiency in China—An Empirical Analysis Based on Major Rice-Producing Areas. China Agric. Sci. Technol. Bull. 2020, 22, 1–11. [Google Scholar]

- Bai, L.; Liu, L. Study on Total Factor Productivity of Fruit Production in China—Analysis Based on DEA-Malmquist Index Method. Product. Res. 2021, 106–109. [Google Scholar]

- Solomon, S. The Indian sugar industry: An overview. Sugar Tech 2011, 13, 255–265. [Google Scholar] [CrossRef]

- Tan, J.J. Analysis of Sugarcane Production Cost Structure and International Competitiveness Comparison in China. Agric. Technol. 2018, 38, 161–164. [Google Scholar]

- Qian, Y.L.; Kuang, Z.M.; Zhao, X.F.; Zhang, Y.H.; He, Y.B. Evolution of Global Sugarcane Planting and Sugar Production Circulation. Sugarcane Ind. 2024, 53, 68–81. [Google Scholar]

- Liu, X.X.; Li, W.; Meng, W.Y. Investigation of Global Sugar Production Layout Characteristics and Evolution of Major Producing Countries. Sugarcane Ind. 2024, 53, 49–65. [Google Scholar]

| Year | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nationwide | TE | 0.993 | 1.000 | 1.000 | 0.995 | 0.988 | 0.892 | 0.894 | 0.933 | 0.972 | 0.987 | 0.990 | 0.765 | 0.970 |

| PTE | 0.996 | 1.000 | 1.000 | 1.000 | 0.997 | 0.895 | 0.921 | 0.939 | 1.000 | 0.998 | 0.992 | 0.951 | 0.986 | |

| SE | 0.997 | 1.000 | 1.000 | 0.995 | 0.991 | 0.998 | 0.971 | 0.993 | 0.972 | 0.989 | 0.997 | 0.804 | 0.984 | |

| DRS | - | - | DRS | IRS | DRS | IRS | DRS | DRS | IRS | IRS | IRS | IRS | ||

| Guangdong | TE | 1.000 | 1.000 | 0.963 | 0.993 | 0.881 | 1.000 | 1.000 | 1.000 | 1.000 | 0.919 | 1.000 | 1.000 | 1.000 |

| PTE | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | |

| SE | 1.000 | 1.000 | 0.963 | 0.993 | 0.881 | 1.000 | 1.000 | 1.000 | 1.000 | 0.919 | 1.000 | 1.000 | 1.000 | |

| - | - | DRS | IRS | IRS | - | - | - | - | IRS | - | - | - | ||

| Guangxi | TE | 1.000 | 1.000 | 1.000 | 0.986 | 1.000 | 0.816 | 0.876 | 1.000 | 0.940 | 1.000 | 1.000 | 0.709 | 0.968 |

| PTE | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.843 | 0.885 | 1.000 | 0.977 | 1.000 | 1.000 | 0.931 | 0.980 | |

| SE | 1.000 | 1.000 | 1.000 | 0.986 | 1.000 | 0.968 | 0.991 | 1.000 | 0.962 | 1.000 | 1.000 | 0.762 | 0.987 | |

| - | - | - | DRS | - | IRS | IRS | - | DRS | - | - | IRS | IRS | ||

| Hainan | TE | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.842 | 0.640 | 0.697 | 0.612 |

| PTE | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | |

| SE | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.842 | 0.640 | 0.697 | 0.612 | |

| - | - | - | - | - | - | - | - | - | IRS | IRS | IRS | IRS | ||

| Yunnan | TE | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| PTE | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | |

| SE | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | |

| - | - | - | - | - | - | - | - | - | - | - | - | - |

| Technical Efficiency Change (Effch) | Technical Progress Change (Techch) | Pure Technical Efficiency Change (Pech) | Scale Efficiency Change (Sech) | Total Factor Productivity Change (Tfpch) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Area | Index Value | Rank | Index Value | Rank | Index Value | Rank | Index Value | Rank | Index Value | Rank |

| Nationwide | 0.998 | 2 | 0.979 | 2 | 0.999 | 2 | 0.999 | 2 | 0.977 | 3 |

| Guangdong | 1.000 | 1 | 0.988 | 1 | 1.000 | 1 | 1.000 | 1 | 0.988 | 1 |

| Guangxi | 0.997 | 3 | 0.979 | 2 | 0.998 | 3 | 0.999 | 2 | 0.977 | 3 |

| Hainan | 0.960 | 4 | 0.922 | 3 | 1.000 | 1 | 0.960 | 3 | 0.885 | 4 |

| Yunnan | 1.000 | 1 | 0.979 | 2 | 1.000 | 1 | 1.000 | 1 | 0.979 | 2 |

| Average | 0.991 | 0.969 | 1.000 | 0.991 | 0.961 | |||||

| Time | Area | Technical Efficiency Change (Effch) | Technical Progress Change (Techch) | Pure Technical Efficiency Change (Pech) | Scale Efficiency Change (Sech) | Total Factor Productivity Change (Tfpch) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Index Value | Rank | Index Value | Rank | Index Value | Rank | Index Value | Rank | Index Value | Rank | ||

| 12th Five-Year Plan | Nationwide | 0.999 | 2 | 0.931 | 3 | 1.000 | 1 | 0.999 | 2 | 0.930 | 3 |

| Guangdong | 0.969 | 3 | 0.897 | 5 | 1.000 | 1 | 0.969 | 3 | 0.869 | 5 | |

| Guangxi | 1.000 | 1 | 0.926 | 4 | 1.000 | 1 | 1.000 | 1 | 0.926 | 4 | |

| Hainan | 1.000 | 1 | 0.983 | 1 | 1.000 | 1 | 1.000 | 1 | 0.983 | 1 | |

| Yunnan | 1.000 | 1 | 0.966 | 2 | 1.000 | 1 | 1.000 | 1 | 0.966 | 2 | |

| Average | 0.993 | 0.940 | 1.000 | 0.993 | 0.934 | ||||||

| 13th Five-Year Plan | Nationwide | 1.025 | 2 | 0.961 | 2 | 1.028 | 2 | 0.998 | 3 | 0.985 | 3 |

| Guangdong | 0.979 | 4 | 0.931 | 4 | 1.000 | 3 | 0.979 | 4 | 0.911 | 4 | |

| Guangxi | 1.052 | 1 | 0.955 | 3 | 1.044 | 1 | 1.008 | 1 | 1.004 | 1 | |

| Hainan | 0.958 | 5 | 0.858 | 5 | 1.000 | 3 | 0.958 | 5 | 0.822 | 5 | |

| Yunnan | 1.000 | 3 | 0.996 | 1 | 1.000 | 3 | 1.000 | 2 | 0.996 | 2 | |

| Average | 1.002 | 0.939 | 1.014 | 0.988 | 0.941 | ||||||

| 14th Five-Year Plan | Nationwide | 0.990 | 2 | 1.017 | 2 | 0.997 | 2 | 0.993 | 2 | 1.007 | 2 |

| Guangdong | 1.000 | 1 | 1.015 | 3 | 1.000 | 1 | 1.000 | 1 | 1.015 | 1 | |

| Guangxi | 0.984 | 3 | 1.020 | 1 | 0.990 | 3 | 0.993 | 2 | 1.004 | 3 | |

| Hainan | 0.977 | 4 | 0.965 | 5 | 1.000 | 1 | 0.977 | 3 | 0.943 | 5 | |

| Yunnan | 1.000 | 1 | 1.003 | 4 | 1.000 | 1 | 1.000 | 1 | 1.003 | 4 | |

| Average | 0.990 | 1.004 | 0.997 | 0.993 | 0.994 | ||||||

| Norm | Indicator Symbols | |

|---|---|---|

| Implicit Variable | Integrated technical efficiency of sugarcane (TE) | y |

| Independent Variable | Effective irrigated area of sugarcane (thousands of hectares) | x1 |

| Per capita disposable income of rural residents (CNY) | x2 | |

| Average years of schooling in rural areas (year) | x3 | |

| Disaster rate (%) | x4 | |

| Urbanization rate (%) | x5 |

| Variable | VIF | 1/VIF |

|---|---|---|

| Effective irrigated area of sugarcane (thousands of hectares) | 1.03 | 0.968688 |

| Per capita disposable income of rural residents (CNY) | 3.10 | 0.322423 |

| Average years of schooling in rural areas (year) | 2.08 | 0.480392 |

| Disaster rate (%) | 1.37 | 0.728967 |

| Urbanization rate (%) | 3.53 | 0.283603 |

| Mean VIF | 2.22 | 0.5568146 |

| Variable | Coefficient | Std. Err. | z | p > |z| |

|---|---|---|---|---|

| x1 | −0.00002 | 0.00004 | −0.46000 | 0.64800 |

| x2 | −0.00001 | 0.00000 | −2.85000 | 0.00400 ** |

| x3 | −0.09271 | 0.02714 | −3.42000 | 0.00100 *** |

| x4 | 0.02404 | 0.09464 | 0.25000 | 0.80000 |

| x5 | 0.54863 | 0.17934 | 3.06000 | 0.00200 ** |

| C | 1.49714 | 0.17319 | 8.64000 | 0.00000 *** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, C.; Li, X.; Zhan, L.; Li, Z.; Wen, J. Measurement of Production Efficiency and Analysis of Influencing Factors in Major Sugarcane-Producing Regions of China. Agriculture 2025, 15, 885. https://doi.org/10.3390/agriculture15080885

Yan C, Li X, Zhan L, Li Z, Wen J. Measurement of Production Efficiency and Analysis of Influencing Factors in Major Sugarcane-Producing Regions of China. Agriculture. 2025; 15(8):885. https://doi.org/10.3390/agriculture15080885

Chicago/Turabian StyleYan, Chuanmin, Xingqun Li, Lei Zhan, Zhizhuo Li, and Jun Wen. 2025. "Measurement of Production Efficiency and Analysis of Influencing Factors in Major Sugarcane-Producing Regions of China" Agriculture 15, no. 8: 885. https://doi.org/10.3390/agriculture15080885

APA StyleYan, C., Li, X., Zhan, L., Li, Z., & Wen, J. (2025). Measurement of Production Efficiency and Analysis of Influencing Factors in Major Sugarcane-Producing Regions of China. Agriculture, 15(8), 885. https://doi.org/10.3390/agriculture15080885