Non-Destructive Prediction of Apple Moisture Content Using Thermal Diffusivity Phenomics for Quality Assessment

Abstract

1. Introduction

2. Materials and Methods

2.1. Apple Samples and Experimental Design

2.2. Fabrication of the Thermal Imaging Measurement System

2.3. Thermal Diffusivity Data Collection via Heating and Cooling

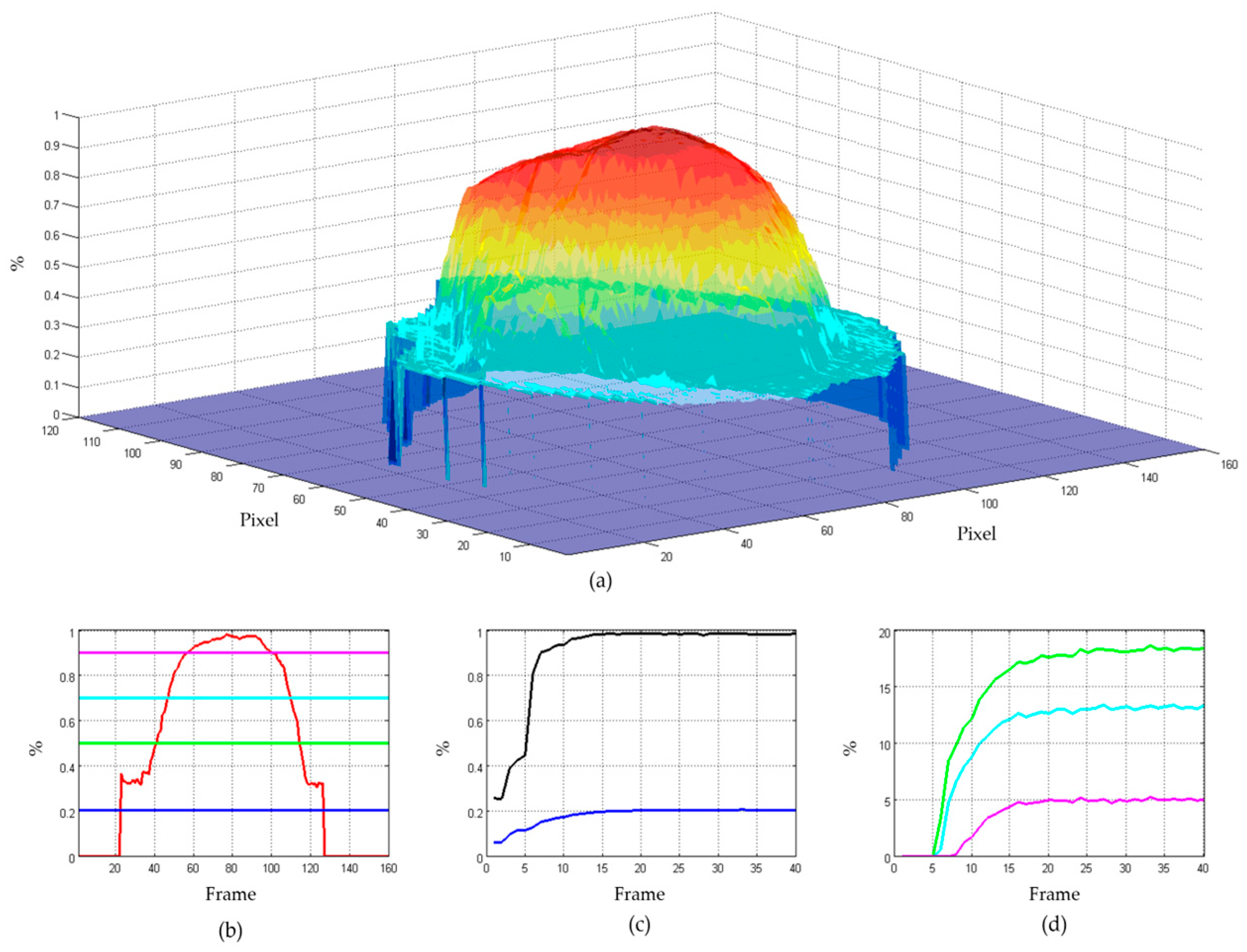

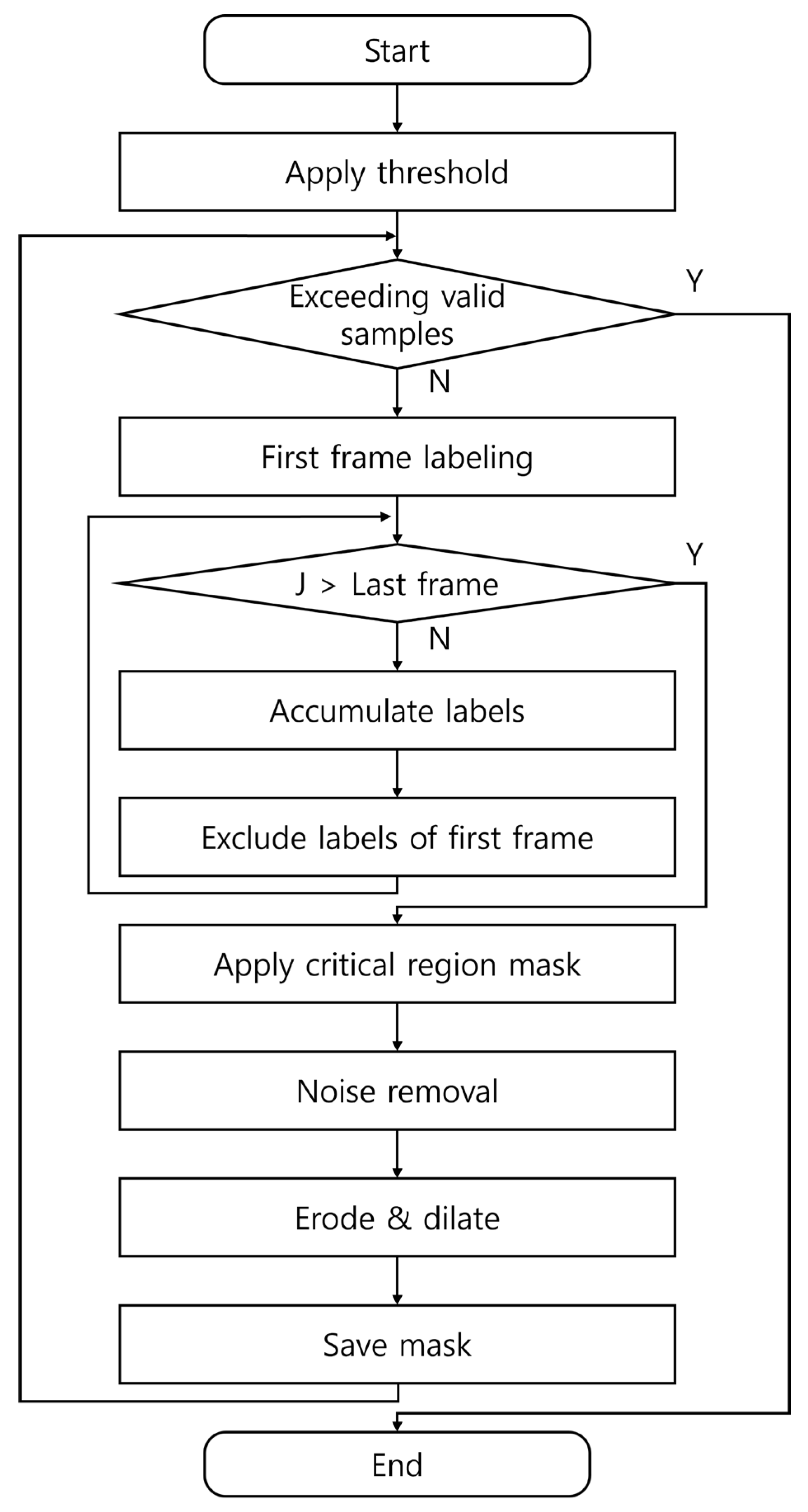

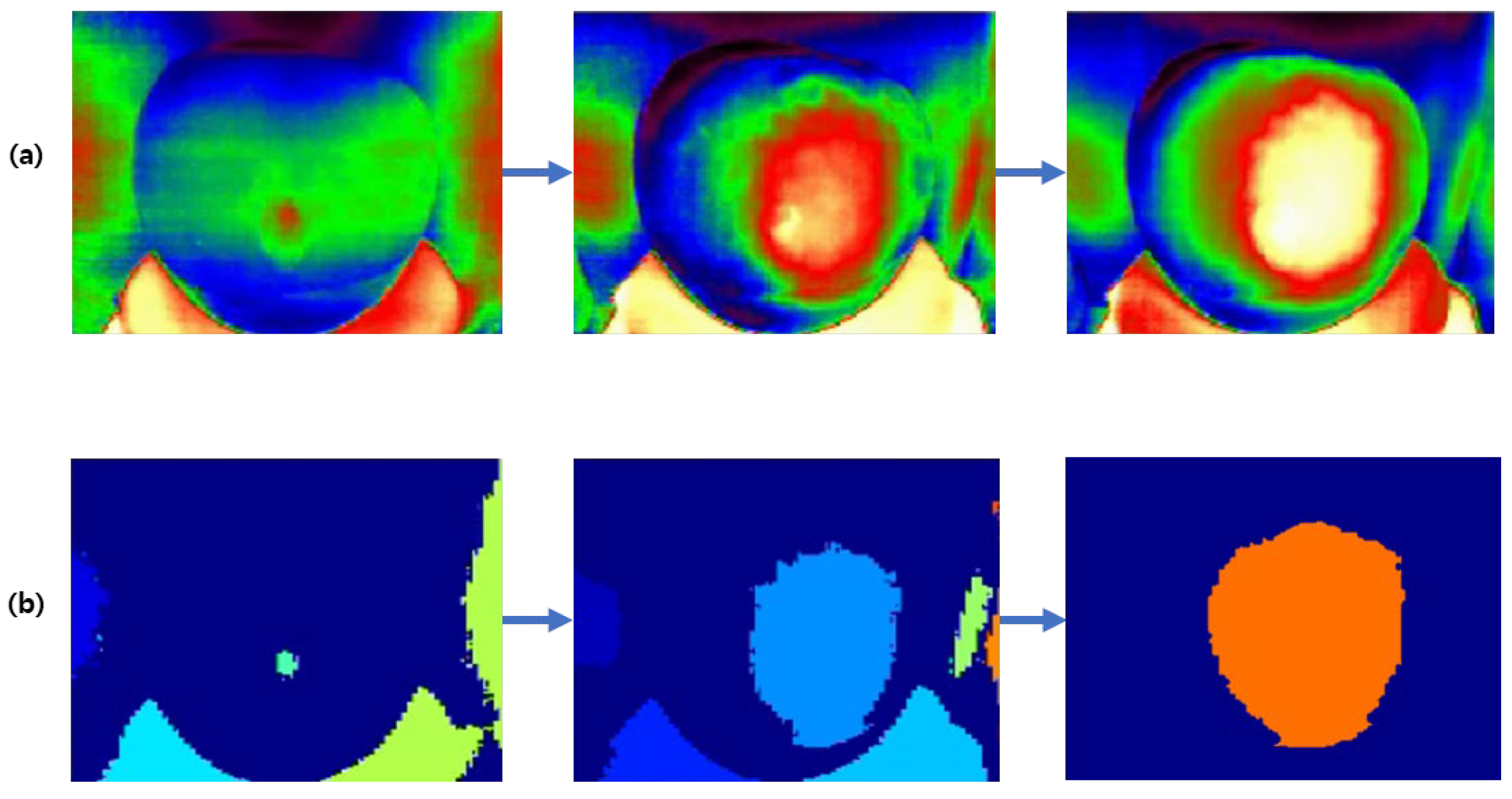

2.4. Masking and Effective Frame Selection

2.5. Moisture Content Measurement

2.6. Thermal Diffusivity Data Analysis and Regression Model Development

2.7. Application of AI Models (Supplementary Analysis)

3. Results

3.1. Distribution of Apple Moisture Content

3.2. MLR Model Results

- The mean-value-based model consistently yielded the most stable and highest coefficient of determination. For example, the model for ‘Yanggwang’ (Type 4) demonstrated high accuracy in non-destructive moisture content prediction, with and values of 0.973 and 0.904, respectively.

- The minimum-value-based analysis showed exceeding 0.9 for some varieties (e.g., ‘Aori’) but dropped below 0.3 for varieties with high variability in density and appearance (e.g., ‘Arisu’ and ‘Hongro’).

- The maximum-value-based analysis exhibited underfitting in varieties with small sample sizes (‘Yanggwang’ and ‘Fubrax’), with converging to 1.0. However, after applying frame optimization, the results stabilized within the 0.7–0.9 range.

- The max–min-value-based analysis effectively captured moisture-related temperature fluctuations in certain varieties but generally exhibited a lower coefficient of determination compared with that of the mean-value-based analysis.

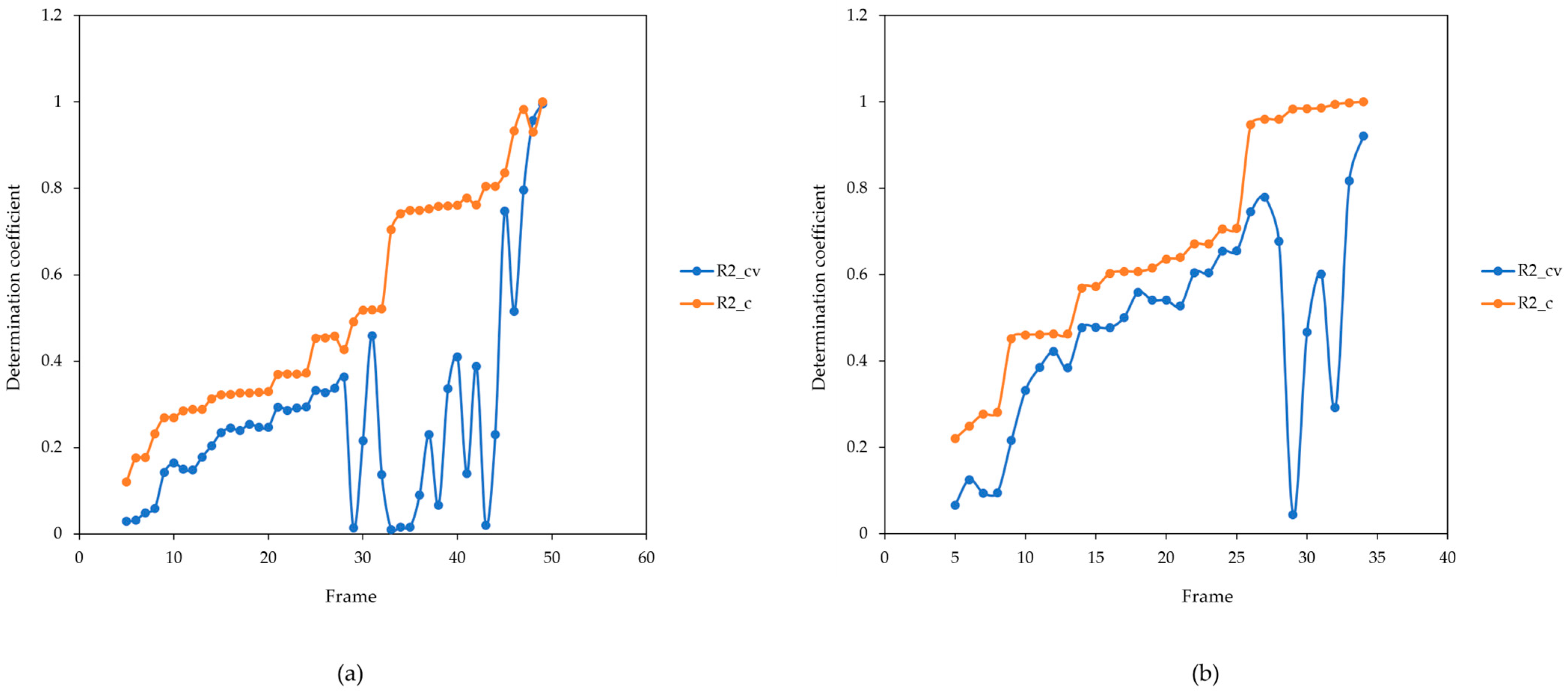

3.3. Frame Optimization and Underfitting Solution

3.4. Supplementary Analysis Using ANN

4. Discussion

- Variability in sample density and external characteristics: The lower prediction accuracy observed in certain varieties (e.g., ‘Hongro’ and ‘Arisu’) may result from differences in physical properties, including flesh density, heat capacity, and internal moisture distribution, all of which directly affect thermal diffusivity. Future studies incorporating explicit measurements of these factors and statistical outlier detection methods (e.g., Grubbs’ test) would further enhance model robustness and predictive reliability.

- Integration with additional quality indicators: expanding the model to include sugar content, acidity, and firmness would enhance its applicability.

- Multisensor fusion: combining thermal diffusivity data with NIR spectroscopy, electronic nose technology, and other sensor-based approaches could enable a more comprehensive analysis of fruit quality in future studies.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, S.; Reddy, K.S.; Bhowmick, M.K.; Srivastava, A.K.; Kumar, S.; Peramaiyan, P. Accelerating climate adaptation with big data analytics and ICTs. In Advances in Agric-Food Systems; Pathak, H., Lakra, W.S., Gopalakrishnan, A., Bansal, K.C., Eds.; Springer Nature: Singapore, 2025; Volume 1, pp. 179–196. [Google Scholar] [CrossRef]

- Bhardwaj, L.K.; Jodder, P.K.; Priya, R.; Rath, P.; Jain, H.; Thakur, S.; Yadav, P.; Purohit, S.; Sharma, B. Resilience in the digital age: Emerging technologies for climate adaptation. In Sustainable Synergy: Harnessing Ecosystems for Climate Resilience; Choudhury, M., Dixit, G., Majumdar, S., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 165–175. [Google Scholar] [CrossRef]

- Xiao, L.; Zhang, Y.; Fu, B. Exploring the moderators and causal process of trust transfer in online-to-offline commerce. J. Bus. Res. 2019, 98, 214–226. [Google Scholar] [CrossRef]

- Tong, J. AOD-Net: A lightweight real-time fruit detection algorithm for agricultural automation. J. Food Meas. Charact. 2025, 27, 1–13. [Google Scholar] [CrossRef]

- Senka, V.; Aleksandrak, T.H.; Jelena, V.; Zdravko, S.; Aleksandra, G.; Anita, V. Apple. In Valorization of Fruit Processing By-Products; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 17–42. [Google Scholar]

- Shalini, R.; Gupta, D.K. Utilization of pomace from apple processing industries: A review. J. Food Sci. Technol. 2010, 47, 365–371. [Google Scholar] [CrossRef]

- Péneau, S.; Hoehn, E.; Roth, H.R.; Escher, F.; Nuessli, J. Importance and consumer perception of freshness of apples. Food Qual. Prefer. 2006, 17, 9–19. [Google Scholar] [CrossRef]

- Hussein, M.; Silva, A.; Fraser, I. Linking intrinsic quality attributes of agricultural produce to revealed consumer preferences. Food Qual. Prefer. 2015, 41, 180–188. [Google Scholar] [CrossRef]

- Fernández-Serrano, P.; Tarancón, P.; Besada, C. Consumer information needs and sensory label design for fresh fruit packaging. An exploratory study in Spain. Foods 2020, 10, 72. [Google Scholar] [CrossRef]

- Abasi, S.; Minaei, S.; Jamshidi, B.; Fathi, D. Development of an optical smart portable instrument for fruit quality detection. IEEE Trans. Instrum. Meas. 2021, 70, 1–9. [Google Scholar] [CrossRef]

- Guan, Y.; Hua, Z.; Cheng, Y.; He, J.; Zhang, Y.; Guan, J. Monitoring of water content of apple slices using low-field nuclear magnetic resonance during drying process. J. Food Process Eng. 2023, 46, 1–10. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, M.; Agyekum, A.A.; Wu, J.; Chen, Q.; Zuo, M.; El-Seedi, H.R.; Tao, F.; Shi, J.; Ouyang, Q.; et al. Quantitative detection of apple watercore and soluble solids content by near infrared transmittance spectroscopy. J. Food Eng. 2020, 279, 109955. [Google Scholar] [CrossRef]

- Kheiralipour, K.; Jayas, D. Applications of near infrared hyperspectral imaging in agriculture, natural resources, and food in Iran. In Proceedings of the 15th National Congress and the 1st International Congress of Biosystem Mechanical Engineering and Agricultural Mechanization, Karaj, Iran, 20–22 September 2023. [Google Scholar]

- Ma, T.; Xia, Y.; Inagaki, T.; Tsuchikawa, S. Rapid and nondestructive evaluation of soluble solids content (SSC) and firmness in apple using vis–NIR spatially resolved spectroscopy. Postharvest Biol. Technol. 2021, 173, 111417. [Google Scholar] [CrossRef]

- Kavuncuoğlu, E.; Çetin, N.; Yildirim, B.; Nadimi, M.; Paliwal, J. Exploration of machine learning algorithms for pH and moisture estimation in apples using VIS-NIR imaging. Appl. Sci. 2023, 13, 8391. [Google Scholar] [CrossRef]

- Zude, M.; Herold, B.; Roger, J.M.; Bellon-Maurel, V.; Landahl, S. Non-destructive tests on the prediction of apple fruit flesh firmness and soluble solids content on tree and in shelf life. J. Food Eng. 2006, 77, 254–260. [Google Scholar] [CrossRef]

- Li, S.; Chen, Y.; Zhang, X.; Wang, J.; Gao, X.; Jiang, Y.; Chen, C. Back Propagation Neural Network model for analysis of hyperspectral images to predict apple firmness. Food Innov. Adv. 2025, 4, 1–9. [Google Scholar] [CrossRef]

- Tran, H.D.T.; Tran, A.T. The modeling of non-invasive measurement of fruit sweetness using near-infrared (NIR) spectroscopy method. J. Phys. Conf. Ser. 2025, 2949, 012024. [Google Scholar] [CrossRef]

- Butkeviciute, A.; Viskelis, J.; Viskelis, P.; Liaudanskas, M.; Janulis, V. Changes in the biochemical composition and physicochemical properties of apples stored in controlled atmosphere conditions. Appl. Sci. 2021, 11, 6215. [Google Scholar] [CrossRef]

- Tanaka, F.; Hayakawa, F.; Tatsuki, M. Flavor and texture characteristics of ‘Fuji’ and related apple (Malus domestica L.) cultivars, focusing on the rich watercore. Molecules 2020, 25, 1114. [Google Scholar] [CrossRef]

- Varith, J.; Hyde, G.M.; Baritelle, A.L.; Fellman, J.K.; Sattabongkot, T. Non-contact bruise detection in apples by thermal imaging. Innov. Food Sci. Emerg. Technol. 2003, 4, 211–218. [Google Scholar] [CrossRef]

- Kale, R.S.; Shitole, S. Non-destructive fruit quality assessment: A review on emerging trends in thermal imaging technology. J. Comput. Anal. Appl. 2024, 33, 326–341. [Google Scholar]

- Baranowski, P.; Mazurek, W.; Witkowska-Walczak, B.; Sławinski, C. Detection of early apple bruises using pulsed-phase thermography. Postharvest Biol. Technol. 2009, 53, 91–100. [Google Scholar] [CrossRef]

- Xu, T.; Wei, Z.; Li, Z.; Xu, X.; Rao, X. Bruise detection of apples based on passive thermal imaging technology. J. Food Meas. Charact. 2024, 18, 9123–9131. [Google Scholar] [CrossRef]

- Kwak, D.; Lee, H. Identification for potato plant abiotic stress through thermal-RGB imaging based on deep learning. In Proceedings of the Sensing for Agriculture and Food Quality and Safety XVI, SPIE, Bellingham, WA, USA, 13 June 2024; p. PC1306008. [Google Scholar] [CrossRef]

- Tomasz, H.; Beata, B.; Jan, G.; Klaudia, C. The Effect of Pre-Treatment on the Rehydration of Dried Apple Cube. Appl. Sci. 2025, 15, 1377. [Google Scholar] [CrossRef]

- Tepe, T.K. Convective drying of golden delicious apple enhancement: Drying characteristics, artificial neural network modeling, chemical and ATR-FTIR analysis of quality parameters. Biomass Convers. Biorefin. 2024, 14, 13513–13531. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, S.-M.; Lee, S.-J. Using the Multiple-Sensor-Based Frost Observation System (MFOS) for Image Object Analysis and Model Prediction Evaluation in an Orchard. Atmosphere 2024, 15, 906. [Google Scholar] [CrossRef]

- Yang, L.; Mu, D.; Xu, Z.; Huang, K. Apple Surface Defect Detection Based on Gray Level Co-Occurrence Matrix and Retinex Image Enhancement. Appl. Sci. 2023, 13, 12481. [Google Scholar] [CrossRef]

- Shurygin, B.; Smirnov, I.; Chilikin, A.; Khort, D.; Kutyrev, A.; Zhukovskaya, S.; Solovchenko, A. Mutual Augmentation of Spectral Sensing and Machine Learning for Non-Invasive Detection of Apple Fruit Damages. Horticulturae 2022, 8, 1111. [Google Scholar] [CrossRef]

- Agarla, M.; Napoletano, P.; Schettini, R. Quasi Real-Time Apple Defect Segmentation Using Deep Learning. Sensors 2023, 23, 7893. [Google Scholar] [CrossRef]

- Giménez-Gallego, J.; González-Teruel, J.D.; Blaya-Ros, P.J.; Toledo-Moreo, A.B.; Domingo-Miguel, R.; Torres-Sánchez, R. Automatic Crop Canopy Temperature Measurement Using a Low-Cost Image-Based Thermal Sensor: Application in a Pomegranate Orchard under a Permanent Shade Net House. Sensors 2023, 23, 2915. [Google Scholar] [CrossRef]

- Stasenko, N.; Shukhratov, I.; Savinov, M.; Shadrin, D.; Somov, A. Deep Learning in Precision Agriculture: Artificially Generated VNIR Images Segmentation for Early Postharvest Decay Prediction in Apples. Entropy 2023, 25, 987. [Google Scholar] [CrossRef]

| Type | Average MC | STD | CV |

|---|---|---|---|

| All | 85.17 | 2.28 | 2.67% |

| 1 | 84.52 | 5.07 | 6.00% |

| 2 | 84.87 | 1.44 | 1.69% |

| 3 | 85.59 | 1.87 | 2.17% |

| 4 | 86.15 | 1.01 | 1.17% |

| 5 | 85.55 | 1.50 | 1.76% |

| 6 | 84.42 | 1.76 | 2.09% |

| 7 | 83.52 | 1.59 | 1.91% |

| Type | R2C | R2CV | RMSEC | RMSECV |

|---|---|---|---|---|

| All | 0.135 | 0.120 | 2.115 | 2.134 |

| 1 | 0.986 | 0.915 | 0.597 | 1.467 |

| 2 | 0.292 | 0.300 | 1.205 | 1.199 |

| 3 | 0.307 | 0.314 | 1.550 | 1.550 |

| 4 | 1.000 | 1.000 | 0.000 | 0.000 |

| 5 | 0.696 | 0.694 | 0.924 | 0.828 |

| 6 | 1.000 | 1.000 | 0.000 | 0.000 |

| 7 | 0.828 | 0.585 | 0.657 | 1.021 |

| Type | R2C | R2CV | RMSEC | RMSECV |

|---|---|---|---|---|

| All | 0.136 | 0.119 | 2.114 | 2.135 |

| 1 | 0.976 | 0.594 | 0.782 | 3.207 |

| 2 | 0.297 | 0.317 | 1.442 | 1.184 |

| 3 | 0.337 | 0.273 | 1.516 | 1.588 |

| 4 | 1.000 | 1.000 | 0.000 | 0.000 |

| 5 | 0.737 | 0.595 | 0.767 | 0.952 |

| 6 | 1.000 | 1.000 | 0.000 | 0.000 |

| 7 | 0.847 | 0.682 | 0.620 | 0.894 |

| Type | R2C | R2CV | RMSEC | RMSECV |

|---|---|---|---|---|

| All | 0.101 | 0.072 | 2.157 | 2.192 |

| 1 | 0.997 | 0.927 | 0.260 | 1.358 |

| 2 | 0.307 | 0.269 | 1.192 | 1.225 |

| 3 | 0.263 | 0.211 | 1.598 | 1.654 |

| 4 | 1.000 | 1.000 | 0.000 | 0.000 |

| 5 | 0.701 | 0.604 | 0.818 | 0.942 |

| 6 | 1.000 | 1.000 | 0.000 | 0.000 |

| 7 | 0.900 | 0.781 | 0.502 | 0.742 |

| Type | R2C | R2CV | RMSEC | RMSECV |

|---|---|---|---|---|

| All | 0.140 | 0.106 | 2.109 | 2.151 |

| 1 | 0.797 | 0.250 | 0.732 | 8.214 |

| 2 | 0.267 | 0.270 | 1.226 | 1.224 |

| 3 | 0.365 | 0.350 | 1.483 | 1.501 |

| 4 | 1.000 | 1.000 | 0.000 | 0.000 |

| 5 | 0.650 | 0.567 | 0.886 | 0.984 |

| 6 | 1.000 | 1.000 | 0.000 | 0.000 |

| 7 | 0.893 | 0.920 | 0.518 | 0.449 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-K.; Kang, M.-K.; Lee, D.-H. Non-Destructive Prediction of Apple Moisture Content Using Thermal Diffusivity Phenomics for Quality Assessment. Agriculture 2025, 15, 869. https://doi.org/10.3390/agriculture15080869

Lee J-K, Kang M-K, Lee D-H. Non-Destructive Prediction of Apple Moisture Content Using Thermal Diffusivity Phenomics for Quality Assessment. Agriculture. 2025; 15(8):869. https://doi.org/10.3390/agriculture15080869

Chicago/Turabian StyleLee, Jung-Kyu, Moon-Kyung Kang, and Dong-Hoon Lee. 2025. "Non-Destructive Prediction of Apple Moisture Content Using Thermal Diffusivity Phenomics for Quality Assessment" Agriculture 15, no. 8: 869. https://doi.org/10.3390/agriculture15080869

APA StyleLee, J.-K., Kang, M.-K., & Lee, D.-H. (2025). Non-Destructive Prediction of Apple Moisture Content Using Thermal Diffusivity Phenomics for Quality Assessment. Agriculture, 15(8), 869. https://doi.org/10.3390/agriculture15080869