1. Introduction

Globally, Europe accounted for an average of 137,479 ha, and produced around 2.4 million tons of broccoli between 2019 and 2023 [

1]. It is the second largest producer in the world after Asia. During this period, Asia produced about 20.8 million tons from 1,084,015 ha [

1]. However, Europe leads global broccoli exports. Within Europe, Spain is the largest producer (537 thousand tons) and exporter, accounting for more than 73% of European production in the period 2019–2023. The Region of Murcia is the main production area in Spain, accounting for almost 41% of Spanish broccoli production, 38% of the cultivated area, and 66% of national exports of this product [

2,

3]. This region has been identified as a national benchmark in the implementation of organic management, with 33% of the cultivated area being under this production regulation [

4,

5], following the thresholds required by the EU for the 2030 horizon in European public policies, such as the Farm to Fork strategy. However, this production system is under-represented in outdoor horticultural crops, such as broccoli. In the Region of Murcia, only 6.04% of the hectares dedicated to broccoli cultivation are cultivated organically [

6].

The Farm to Fork Strategy aims to reduce pesticide use and increase the proportion of land under organic farming, with the objective of minimizing environmental and human health impacts. In this respect, Spain, and specifically the Region of Murcia, are pioneers in the use of biological and biotechnological control, now successfully implemented in crops such as citrus fruits and greenhouse-grown peppers [

7,

8,

9,

10]. However, its use has not yet been effective in outdoor horticultural crops such as lettuce or broccoli, nor for stone fruit trees [

11]. Current research efforts are focused on developing varieties resistant to pests, diseases, and stress factors [

12,

13,

14].

The Farm-to-Fork Strategy also advocates reducing the use of synthetic inorganic fertilizers and promoting organic fertilizers instead. Likewise, Europe supports the protection of nitrate vulnerable zones, for example, through Directive 91/676/EEC. This directive aims to promote fertilization practices that are better aligned with crop nutrient requirements, in order to reduce nitrate pollution [

15,

16]. In this respect, several authors [

7,

17,

18] have demonstrated using Life Cycle Assessment (LCA) that synthetic inorganic fertilizers are among the main environmental hotspots in agri-food production. Their excessive use can trigger environmental problems, such as those occurring in the Region of Murcia within Mar Menor [

19], which is why restrictions have been implemented like those under the “Ley 3/2020, de 27 de julio” [

20]. In this context, agronomic practices—such as crop rotation with legumes and the application of organic amendments—aimed at reducing the reliance on synthetic fertilizers have become increasingly widespread [

21,

22,

23,

24,

25]. However, the high price of liquid organic fertilisers used in fertigation [

7,

26], as well as the high nutritional requirements of intensive horticultural crops, means that their application increases production costs. In this regard, it is essential to evaluate these practices economically, as they may be unviable depending on their effect on productivity and costs.

Economic and production cost studies are essential, as they provide key information for decision-making, investment planning and setting prices that cover actual production costs. In the Spanish context, the Food Chain Law [

27] establishes a legal framework aimed at preventing loss of value, ensuring fair competition and protecting the most vulnerable stakeholders (producers), guaranteeing them a decent income. However, despite its relevance, there is a notable lack of scientific literature and information published by the government that comprehensively addresses this area, which limits its availability and hinders its use for the aforementioned purposes. In this context, studies such as this one promote transparency and serve as a reference for both the government and the private sector, thus contributing to improving efficiency, competitiveness and balance in commercial relations between stakeholders in the food chain.

Given the representativeness of broccoli cultivation in the Region of Murcia within Spain, the increasing importance of more transparent production costs within the agri-food chain, and the lack of scientific literature providing a comprehensive, transparent, and up-to-date cost structure for conventional broccoli cultivation in this area, the objectives of this study are:

To establish the most representative conventional broccoli cultivation model in the Region of Murcia.

To perform an economic assessment of this model using the cost accounting method in order to determine its cost structure.

To conduct a sensitivity analysis, assigning variability to the elements identified as relevant to observe their impact on production costs.

The relevance of this study extends beyond broccoli cultivation, serving as a representative case for assessing the economic and resource challenges faced by the fruit and vegetable sector and other agricultural industries. The analyses and recommendations presented can be generalized to similar production systems, particularly in water-scarce regions such as Murcia and other arid and semiarid areas, providing valuable insights to enhance the resilience and sustainability of crop production.

2. Materials and Methods

2.1. Characterization of the Study Area

The Region of Murcia is located in the southeast of Spain (

Figure 1). This region covers a total surface of 1,131,646 hectares, of which 358,830 hectares are classified as utilized agricultural area. Irrigated crops account for 45.8% of the utilized agricultural area, and 32% of the irrigated area (53,053 hectares) is dedicated to horticultural crops [

4].

The climate in this area is semi-arid, characterized by dry, hot summers, mild winters and autumns with sporadic but abundant rain [

28]. Precipitation in the region is scarce, averaging 320 mm per year, and is both irregular and variable [

29].

Soils are usually in water deficit due to low precipitation and high evapotranspiration rates [

30]. They have a clayey loam or clayey sandy loam texture with a low amount of organic matter, high pH, and high contents of calcium carbonate and active limestone [

7,

31,

32].

2.2. Data Collection

The data on the production process for the establishment of the production model was obtained during 2025 through 15 in situ surveys conducted with producers from 3 regional companies specialized in horticulture. The technicians from these companies selected professional representative farmers who were willing to provide specific information about the production process. The established plot size corresponds to the common size reported by farmers in the surveys. The survey included all the technical and economic data described in the production cost structure: production model (planting density, productivity, non-fresh marketable production, etc.), infrastructure (irrigation network, irrigation equipment, shed, etc.), inputs, and labor and machinery performance in the different field operations. The information was collected in three stages. The first stage consisted of an open interview with the respondents; in the second, a structured questionnaire—designed by the IMIDA (Murcian Institute for Agricultural and Environmental Development and Research) research team—was administered. This questionnaire gathered detailed information on the production system and related investments, production performance indicators, labor requirements, and other production costs. Finally, once the production model had been defined, the survey information was validated through specific follow-up questions to the respondents [

33].

The Bioeconomy Team of IMIDA has published several studies on the production structure and cost analysis of multiple agricultural products in the Region of Murcia. These studies aim to establish representative cost structures for public administration purposes and, in most cases, are representative of production systems in southeastern Spain [

7,

34]. Broccoli has been one of the crops analyzed, both conventional [

35] and organic [

36]. Based on previous studies, a review and an update of the cultivation system have been carried out. Prices have been updated from the IMIDA Bioeconomy Team internal database, which includes unit prices of inputs, yields, costs, and technical and economic data for a wide range of crops, derived from in situ surveys as mentioned above.

Based on this information, a production model was established for the main broccoli production system in the Region of Murcia. The model encompasses the representative practices of broccoli cultivation in southeast of Spain. The study is limited to the production system described, which is the most widespread in the area, but it is naturally subject to market variability and socioeconomic constraints.

2.3. Establishment of Production Model

A representative system was established for conventional outdoor broccoli cultivation. A professional farm model was designed with an area of 5 hectares.

There are usually two cycles: the summer-autumn cycle with production in winter (from September to November), and the spring cycle (from March to June). They usually last approximately 90 to 110 days from transplanting to harvesting. The plantation has a spacing scheme of 1 m × 0.4 m with paired rows (50,000 plants·ha−1). The average gross production is 18,500 kg·ha−1 with around 5% of the broccoli being non-fresh marketable. The plastic mulching of the rows was also taken into account, along with the use of drip irrigation consisting of 25,000 drippers·ha−1 with a flow rate of 2 dm3·h−1 (1 dripper·plant−1). The water supply is 3250 m3·ha−1.

Table 1 shows the general descriptive information based on data collected through surveys, which were later used to define the production process and, consequently, to calculate the production cost structure.

2.4. Economic and Financial Assessment: Accounting Analysis

In order to evaluate the system described in

Table 1, an economic financial analysis was carried out from cost accounting perspective, and the cost–benefit production structure established for a single cycle of broccoli cultivation. The cost structure is based on euros (EUR) per unit of surface area (hectare) and per unit of mass (kilogram). Input prices and production resources used for the cost calculations were taken from the aforementioned database.

Costs were subdivided into fixed and variable and for each of them, opportunity cost was also taken into account [

37,

38,

39,

40]. Opportunity costs are calculated as the alternative use of money in risk-free saver bank accounts [

34,

41], in this case, 1.5%.

2.4.1. Fixed Costs

Fixed costs are those linked to the amortization of assets. The straight-line method was used to calculate amortization [

32,

34,

35,

36]. The investments associated with this crop included the infrastructure necessary for irrigation (irrigation equipment, irrigation network, and irrigation reservoir); shed for equipment; auxiliary material (tools).

For the sizing of the irrigation equipment, the flow per unit area required by the emitters and the size of the farm (5 hectares) were taken into account. The irrigation equipment has a flow rate of 50 m3·h−1, divided into five sectors (1 hectare per sector) and includes solenoid valves, filters, fertilizers tanks with agitators and a pump. The irrigation network was sized in the same way, with polyethylene pipes (with diameters of 63 mm, 50 mm in the case of distribution pipes and 16 mm in lines of droppers) with integrated self-compensating drippers (2 dm3·h−1). The reservoir was sized to store between 15 and 30 days of the water required in the month with maximum water requirements. The shed size is 80 m2. The auxiliary materials include gloves, plastic baskets, and other tools.

2.4.2. Variable Costs

Variable costs are those that can vary in the short term, in this case for a production cycle of 3 months. The following sections present the accounting categories corresponding to variable costs in each production cycle:

The preparation and planting phase involves the following operations: removal of the previous crop using a disc harrow; turning with a moldboard plow; shallow harrowing; levelling; and application of organic matter. All operations are performed using a 120 HP tractor, except for the moldboard plowing, which requires more power and a 160 HP tractor. This phase also includes installation and removal of the irrigation system, manual planting, purchased seedlings, and the placement of the plastic mulching.

A common task for various arable crops, it counts as wage labor specific to blanching (

Table 2); it is associated with the early growth stages after transplanting.

Broccoli is not usually insured, but its cost was calculated for information purposes (

Table 3). The cost of insurance was calculated using the report “Coste medio del seguro de la Comunidad Autónoma de Murcia” written by Agroseguro [

35].

This includes the use of machinery and implements in activities such as phytosanitary treatments and herbicide treatments (

Table 4). It was considered that farms hire external services. The cost of machinery was determined using the market unit cost: tractor + implement + labor.

The total fertilizer requirement for conventional broccoli production is 230-80-278-100-28 (N-P

2O

5-K

2O-CaO-MgO). These quantities are established based on information extracted from surveys and the specific technical literature on crop requirements [

35,

42].

Owing to the low quantities of organic matter of soils in the Region, it is very common for farmers to provide it in the form of manure (usually sheep–goat manure (N-P

2O

5-K

2O-CaO-MgO): 1.48-0.56-2.35-2.96-0.91) during land preparation. This is also associated with periodic soil disinfection through biosolarization. The amount of organic matter provided averages around 5000 kg per cycle and it is applied only at the beginning, with approximately 10,000 kg of organic matter distributed between the two crops grown during the two rotation cycles within the same year (e.g., broccoli–lettuce or broccoli–melon). Therefore, the total fertilization units (FU) were corrected to adjust to the contributions previously described, obtaining the following nutrient requirements: 156-52-161-0-0, which is applied by fertigation (

Table 5).

Phytosanitary treatments vary annually owing to agroclimatic factors. The main pests/pathogens on broccoli are:

Botrytis cinerea,

Brevicoryne,

Aphis,

Myzus,

Macrosyphum,

Nasonovia,

Hellix spp. and

Plutella xylostella. Currently, four treatments are applied per cycle, using a broth of 1000 dm

3·ha

−1 (

Table 6).

Only one annual pre-emergence preventive treatment is carried out with pendimethalin (

Table 7). To apply herbicide, extendable bar equipment is used.

The maintenance cost was obtained as an annual percentage (1.50%) of the cost of fixed assets: shed, irrigation equipment, irrigation reservoir, and irrigation network. It is important to note that this percentage is divided, as producers usually carry out two cycles per year.

Electricity consumption by fertigation pumps and it is based on the irrigation hours and flow mentioned above (

Table 8).

The average water requirements for the cycle have been established as 3250 m

3·ha

−1 (

Table 9). The current prices of the water resource are derived from the Comunidad de Regantes (CCRR) of Campo de Cartagena, which is the community with the largest territory and representativeness in south-eastern Spain [

43].

Harvesting includes both the labor used in harvesting and the mechanical means used in transporting the loads to the warehouse. Average yields from the harvest are obtained through surveys (

Table 10).

Farm owners typically work on management-related tasks: purchasing inputs, scheduling and controlling irrigation, hiring external services such as pruning, etc. This is reflected cost in hours per hectare and year (

Table 11). This cost is calculated as a proportion of the corresponding salary for 1 AWU·ha

−1 (1840 h); in this case, 25 hectares is the typical farm size in the region according to the surveys.

Additionally, employment per hectare (AWU·ha

−1) was calculated as an indicator of the generation of direct employment in the rural environment. The Agricultural Work Unit (AWU) corresponds to the work carried out by a person employed on a full-time basis at a farm (1 AWU = 1840 h) [

7,

44].

2.5. Sensitivity Analysis

Due to the importance of water and fertilizers, both economically and environmentally, in the production structure of broccoli, as is the case of other crops, a sensitivity analysis is carried out on these production factors.

Water supply in southeastern Spain comes from various sources (groundwater, surface water, desalinated water, the Tajo-Segura transfer, and reclaimed water) and its characteristics vary significantly between areas due to the mixing of different origins [

10,

34,

45]. Additionally, there is significant annual variability depending on climatic conditions. Furthermore, reductions in water allocations from the transfer have become increasingly frequent [

45]. Due to these challenges, the fluctuation of water prices and their impact on the economic analysis of this crop will be examined. To this end, a decrease in water supply from the Tajo-Segura transfer is simulated, compensated by desalinated water, whose share in the characterized area has increased.

Therefore, the four water mixes established for the sensitivity analysis are: (1) E0: 19.8% surface water; 23.4% groundwater; 7.6% reclaimed water; 32.2% from the Tajo-Segura transfer; 17% desalinated water (price: 0.350 EUR·m

3). It was established as the reference mix, provided by CCRR of Campo de Cartagena and described by Martin-Gorriz et al. [

45]. (2) Mix 1: 19.8% surface water; 23.4% groundwater; 7.6% reclaimed water; 21.5% from the Tajo-Segura transfer; 27.7% desalinated water (price: 0.403 EUR·m

3). The analysis also considered an intermediate scenario involving a higher input of desalinated water. (3) Mix 2: 19.8% surface water; 23.4% groundwater; 7.6% reclaimed water; 0% from the Tajo-Segura transfer; 49.2% desalinated water (price: 0.508 EUR·m

3). The most adverse scenario proposed by Martin-Gorriz et al. [

45] and García García y García García [

10] is also included, in which transfer water is completely replaced by desalinated water, while maintaining the same proportions of surface, groundwater, and reclaimed water. (4) Mix 3: 7.6% reclaimed water; 92.4% desalinated water (price: 0.592 EUR·m

3). The final scenario was the least favourable, consisting solely of desalinated and reclaimed water. For the calculation of reclaimed water costs, an estimation is used based on information provided by Martin-Gorriz et al. [

45] and Expósito et al. [

46].

As emphasized in the introduction, fertilization now is a crucial focus of public policy. Europe advocates the efficient use of fertilizers (adjusted to crop needs) and the reduction in synthetic inorganic fertilization in favour of organic alternatives, seeking to achieve more efficient production systems with the lowest possible environmental impact [

21,

23,

25]. Based on these premises, the aim was to compare various fertilization scenarios (

Table 12): (E0) Synthetic inorganic fertilization (conventional). (B1) Liquid organic fertilization. (B2) Solid organic fertilization with an organic amendment sheep–goat manure. (B3) Solid organic fertilization mix (sheep–goat manure + pelleted fertilizer). (B4) Solid organic fertilization (sheep–goat manure + pelleted fertilizer) combined with liquid organic fertilization.

The results of these analyses were evaluated using the relative difference (RD) of the irrigation costs.

RD (%) = 100 × (E0 − En)/E0, where En is the proposed scenario (Mix n or Bn depending on the analysis) and E0 is the initial scenario.

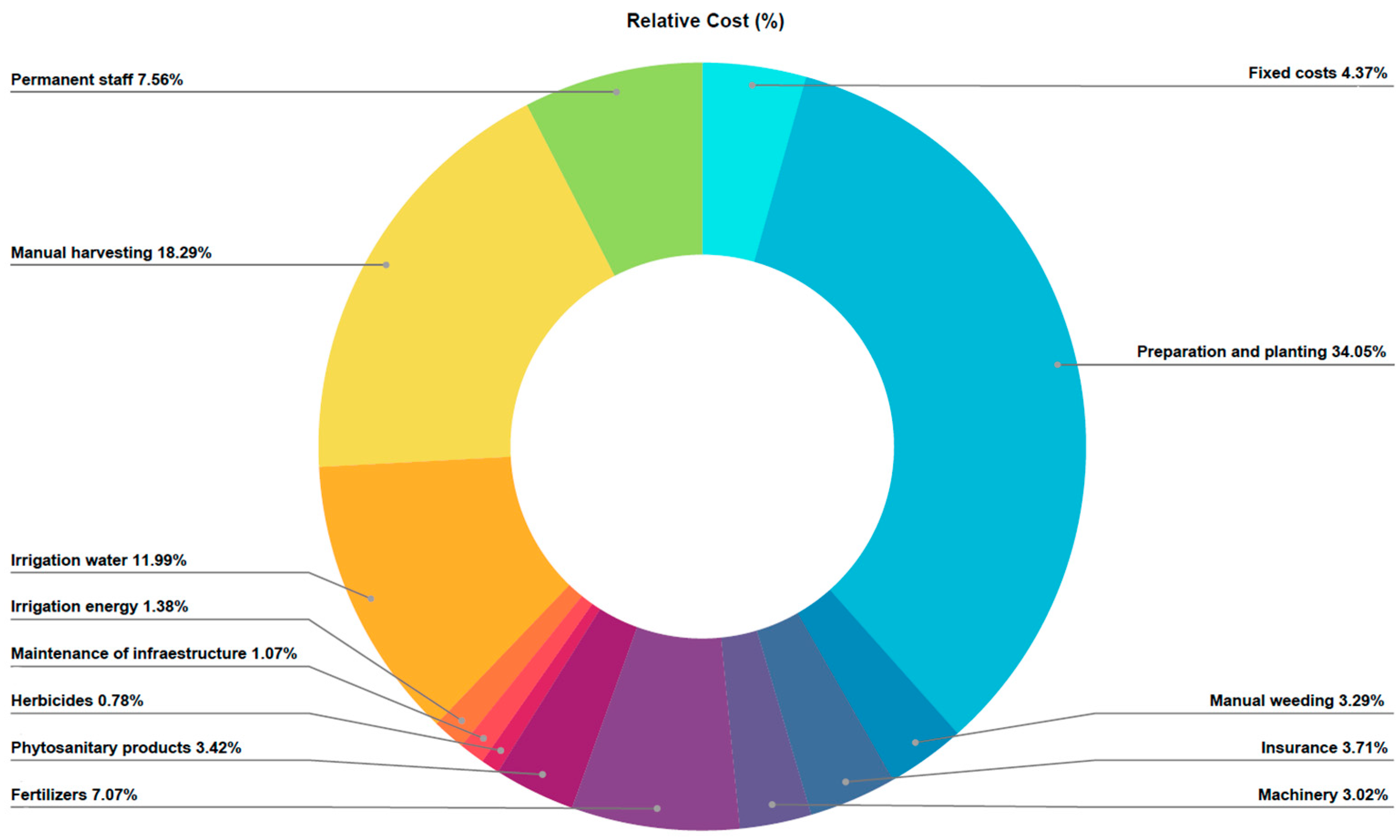

4. Conclusions

As far as cost structure is concerned, labor plays a paramount role, especially during the plantation and harvesting phases. Despite generating less employment per hectare than other more intensively farmed crops, its employment generation rate increases significantly as it is grown in combination with other crops in two cycles per year.

As for irrigation, the analysis shows the relevance that sources of water have in the current climatic situation, and, even more in a worse scenario situation, where low water availability would make costs rise as a result of the high energy demands of desalinated water. It is therefore essential to carry out research into new cultivation systems that may provide higher yields with less water input, as well as into the use of renewable energy resources that may minimize the costs involved in the process of water desalination.

Liquid organic fertilizers have shown the large impact they have on the cost structure of the crop, even making it economically unviable. The following research lines are proposed in order to obtain crops with adequate yields and reduce the use of synthetic inorganic fertilizers: the combined use of liquid and solid organic fertilizers, synthetic inorganic fertilizers in combination with organic amendments, composting strategies with the aim of achieving specific crop balances and more research focused on the formulation of more affordable liquid organic fertilizers to facilitate the transition to organic production models.

According to the information presented on the current state of crop management, and with the aim of increasing its optimization, there are open lines of research concerning plant breeding to obtain resistant varieties, and to improve biological and biotechnological control, not only of broccoli, but also of other outdoor crops.

The importance of periodic economic studies, such as the present one, lies in their role in updating crop costs and facilitating the transparency of economic information. This, in turn, simplifies decision-making processes at both the level of producers and the Public Administrations responsible for agricultural matters. Furthermore, this information is essential to help reach the goals established by the Food Chain Law.