Study on the Estimation of Greenhouse Sensible Heat Flux Based on the Surface Renewal Method: Validation and Calculation Results

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site and Climate

2.2. Micrometeorological Data Collection

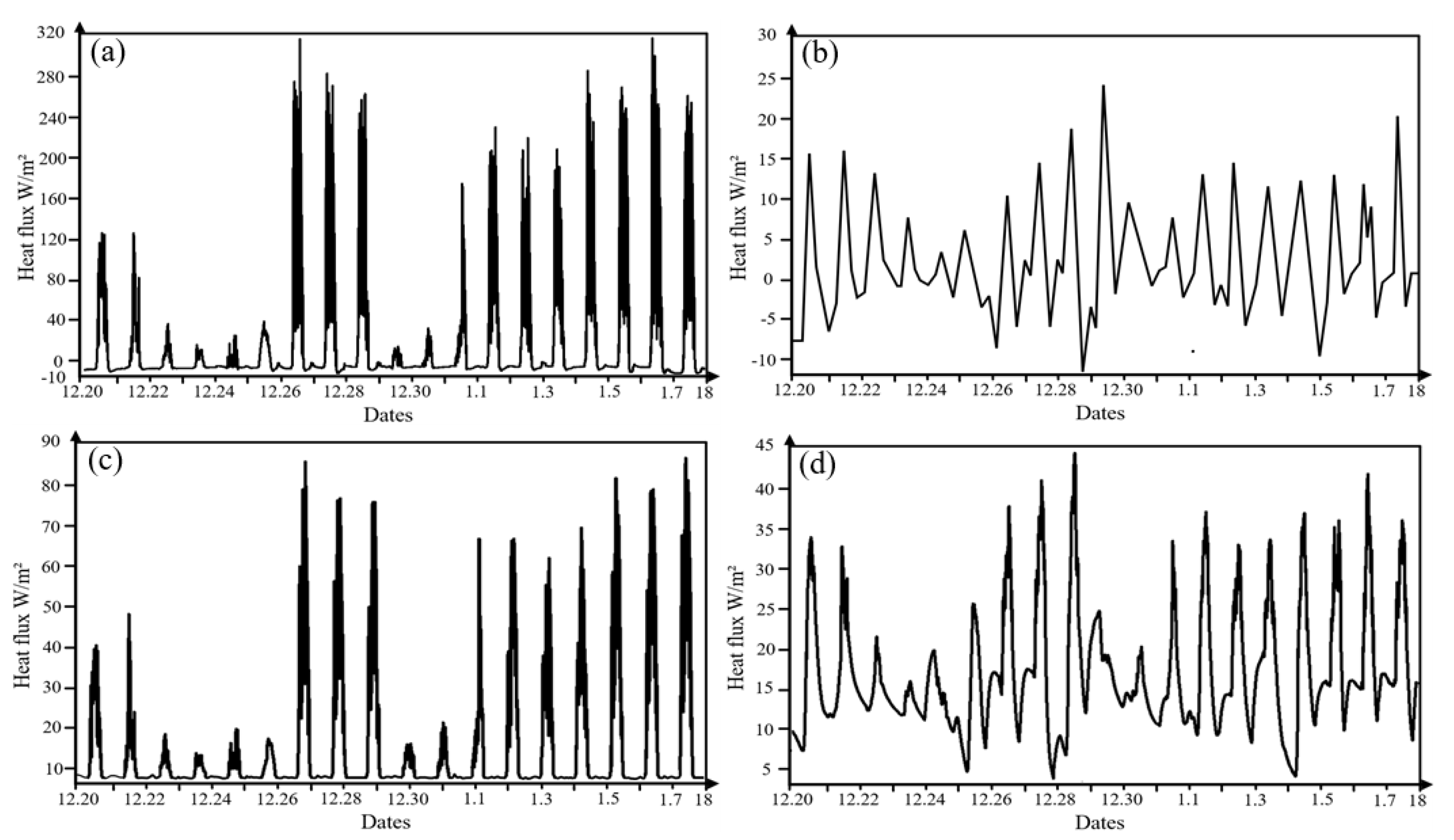

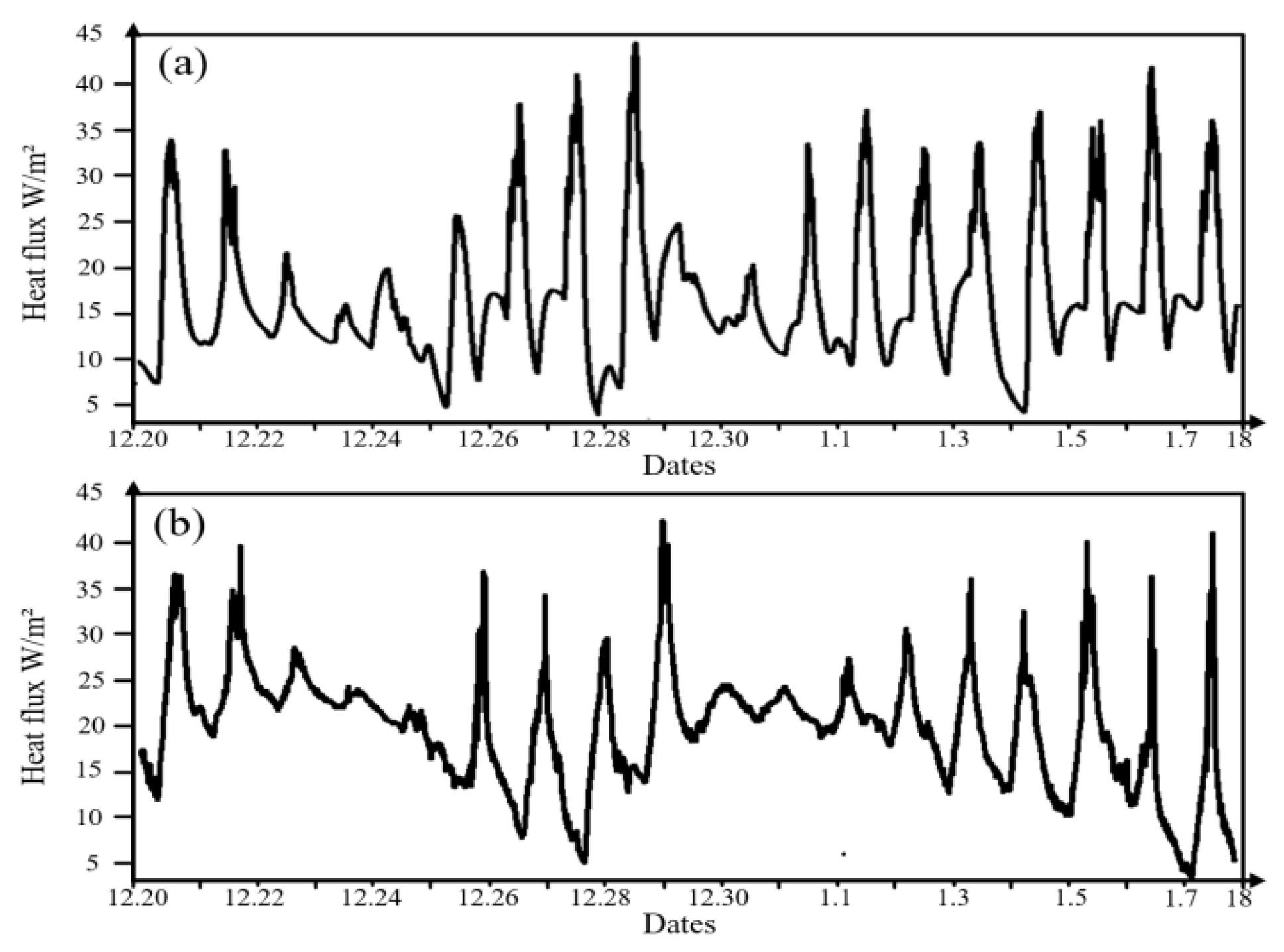

2.3. Dynamic Changes in Heat Flux in the Greenhouse

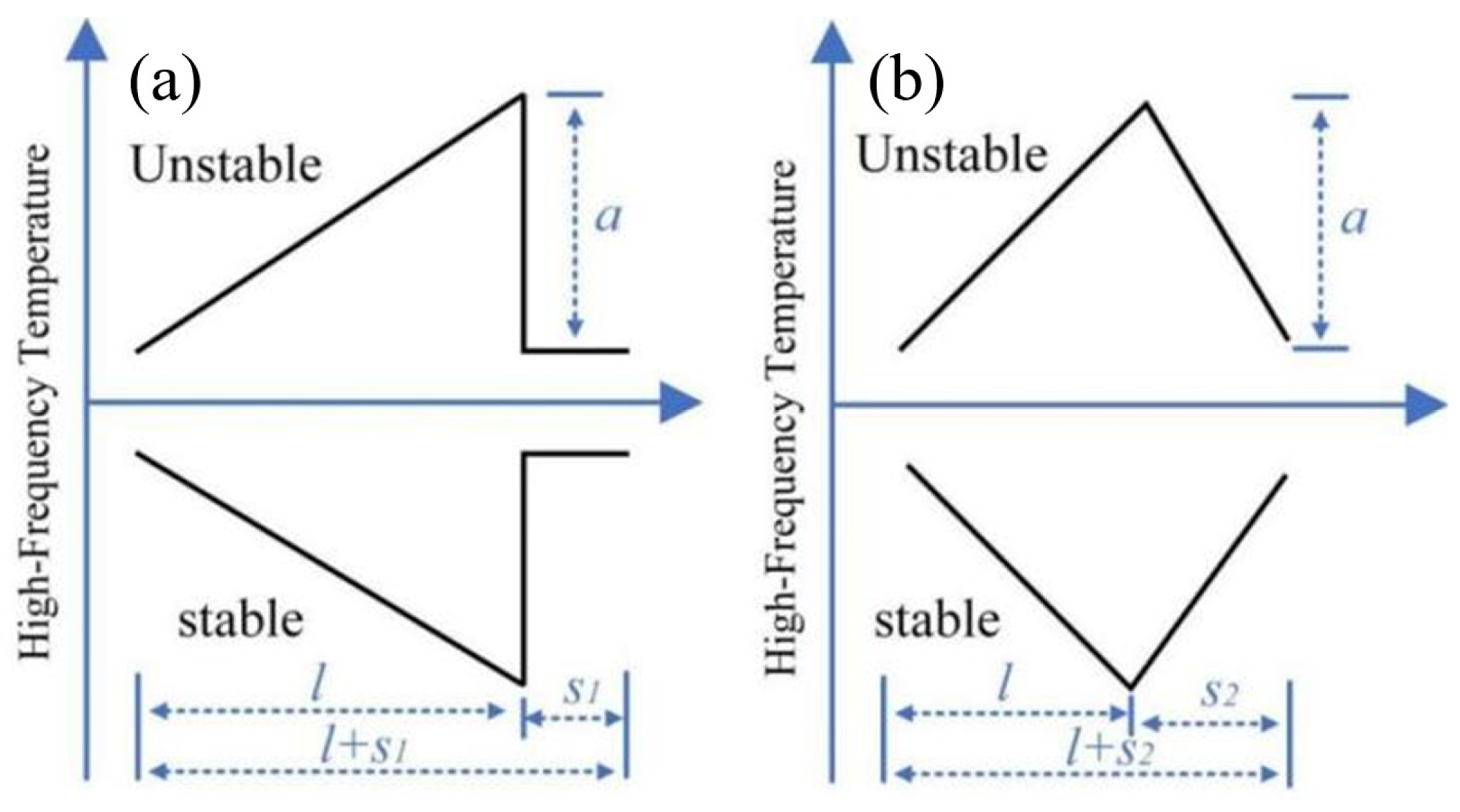

2.4. Calculation of H Using the Surface Renewal Method

2.5. Calculation of H Using the Improved Surface Renewal Method

2.6. Evaluation Criteria

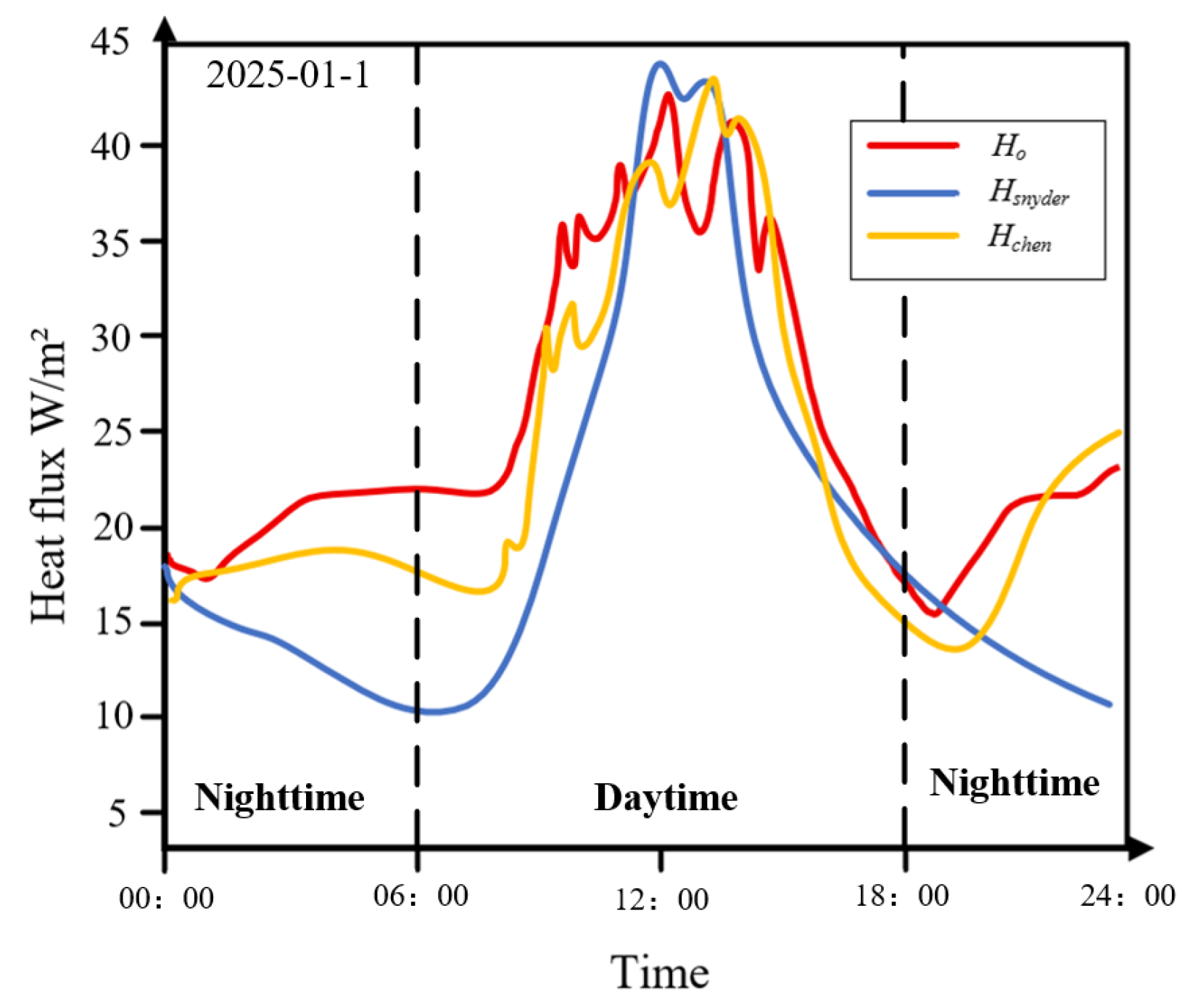

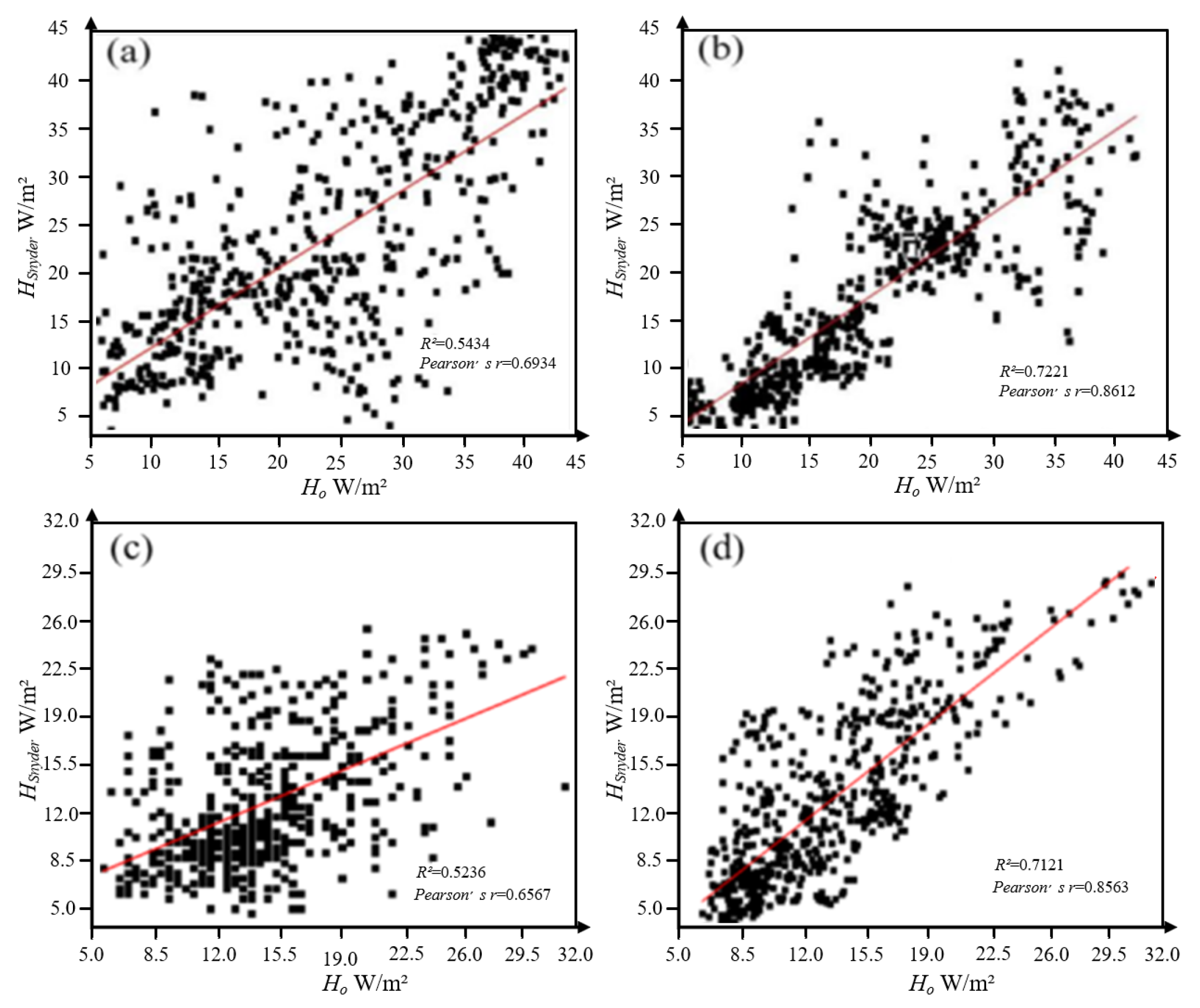

3. Results and Analysis

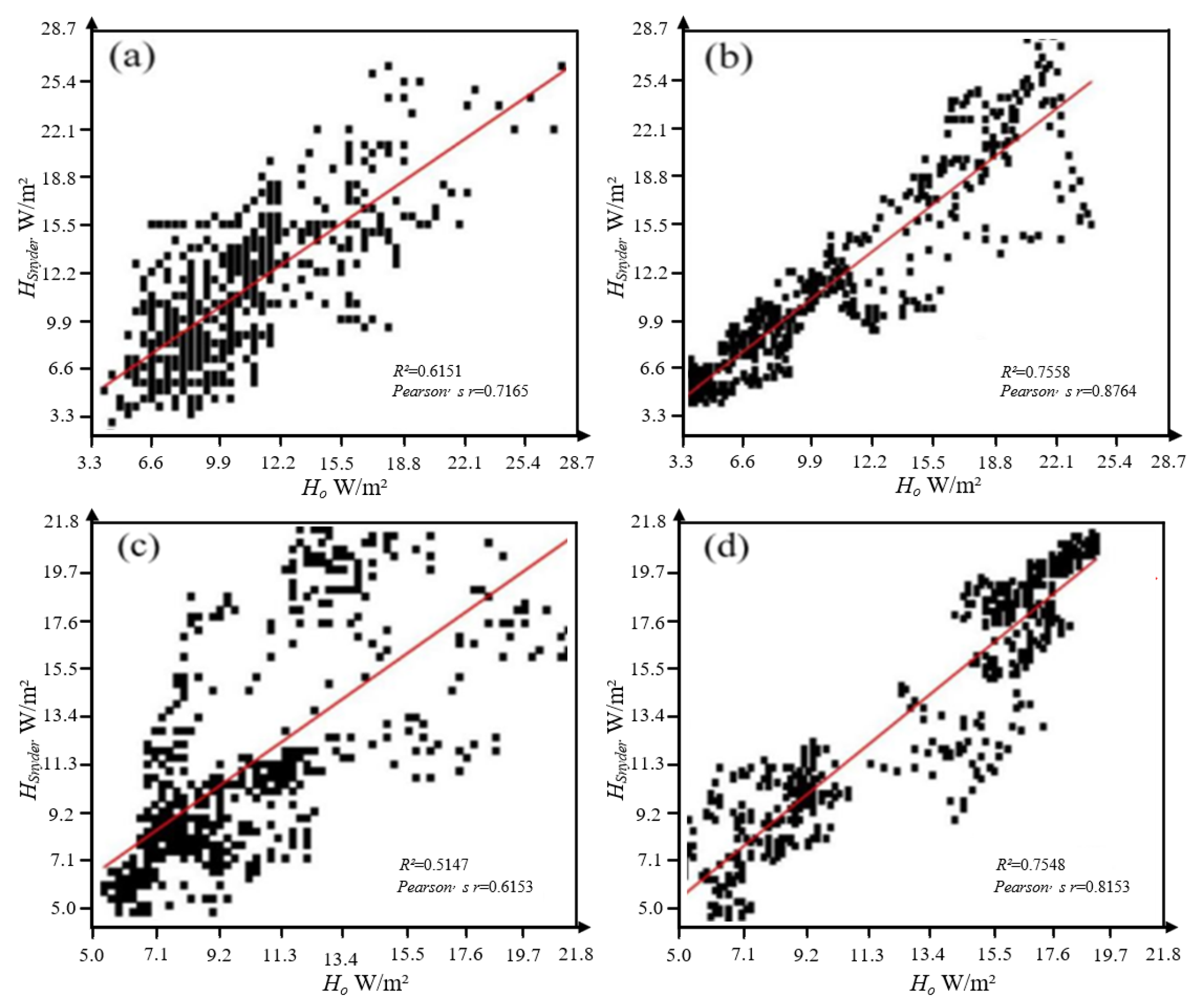

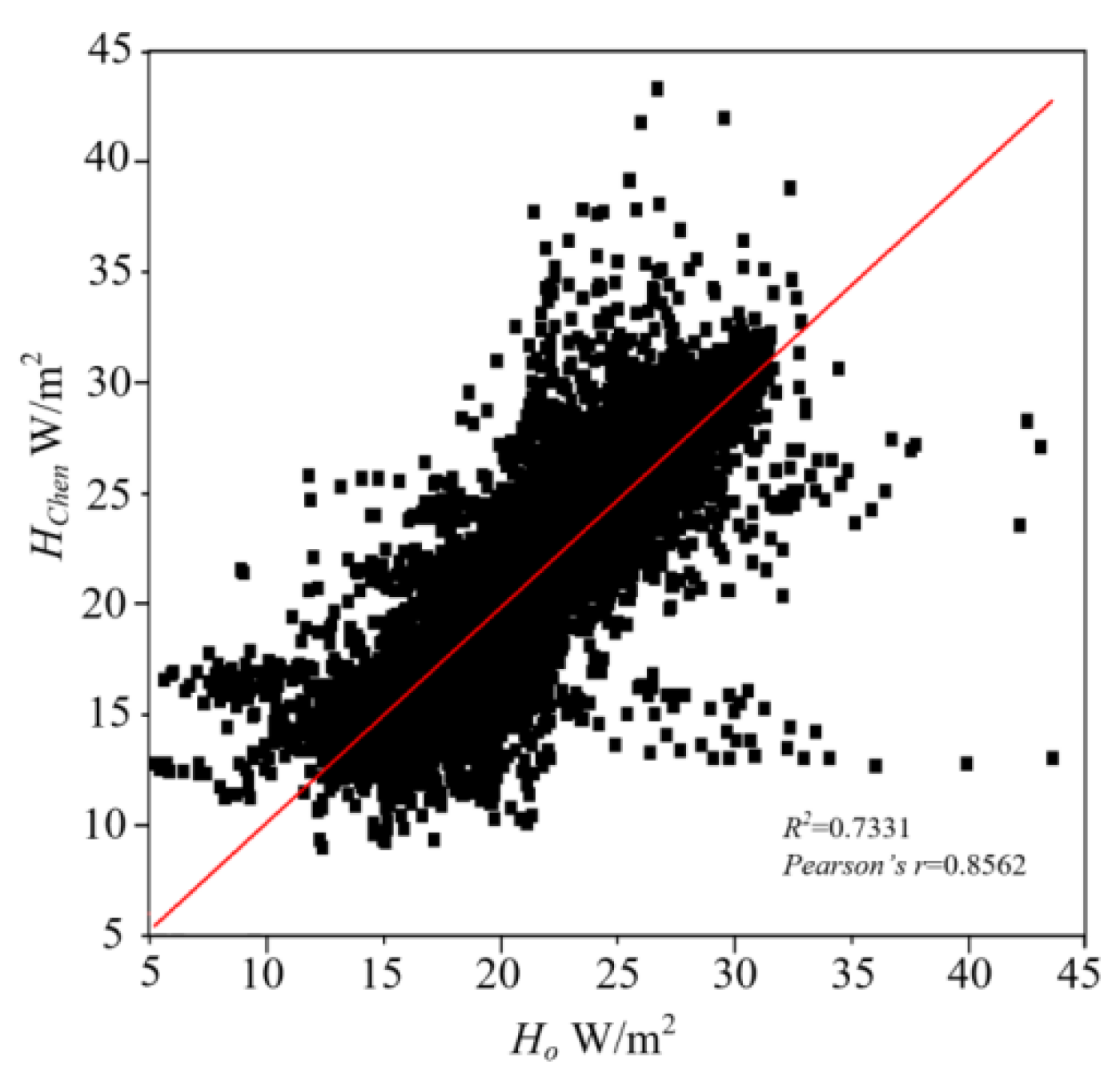

Evaluation of Two SR Models

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, D.Z.; Cheng, M.; Yuan, H.B.; Cai, Z.J. Review of irrigation control strategy for greenhouse. J. Chin. Agric. Mech. 2022, 43, 63–72. [Google Scholar] [CrossRef]

- Sun, Y.X.; Ma, L.L.; Miao, L.L.; He, J.X.; Li, J.M. Construction of greenhouse tomato transpiration model based on light radiation time-lag effect. J. Northwest AF Univ. (Nat. Sci. Ed.) 2023, 51, 83–92. [Google Scholar] [CrossRef]

- Xu, L.H.; Xiao, K.J.; Wei, R.H. Irrigation models for the tomatoes cultivated in organic substrate based on greenhouse environment and crop growth. Trans. Chin. Soc. Agric. Mach. 2020, 36, 189–196. [Google Scholar] [CrossRef]

- Li, F.; Yan, H.F.; Chuan, Z.; Zhang, J.Y.; Wang, G.Q.; Acquah, S.J. Current deficiencies and needed enhancements on greenhouse crop evapotranspiration models. J. Drain. Irrig. Mach. Eng. 2024, 42, 57–63. [Google Scholar] [CrossRef]

- Rouphael, Y.; Colla, G. Modelling the transpiration of a greenhouse zucchini crop grown under a Mediterranean climate using the Penman-Monteith equation and its simplified version. Aust. J. Agric. Res. 2004, 55, 931–937. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, C.; Gerrits, M.C.; Acquah, S.J.; Zhang, H.; Wu, H.; Zhao, B.; Huang, S.; Fu, H. Parametrization of aerodynamic and canopy resistances for modeling evapotranspiration of greenhouse cucumber. Agric. For. Meteorol. 2018, 262, 370–378. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, C.; Hiroki, O. Parameterization of canopy resistance for modeling the energy partitioning of a paddy rice field. Paddy Water Environ. 2018, 16, 109–123. [Google Scholar] [CrossRef]

- Jolliet, O.; Bailey, B. The effect of climate on tomato transpiration in greenhouses: Measurements and models comparison. Agric. For. Meteorol. 1992, 58, 43–62. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Zhuang, H.R.; Xu, D.H.; Ma, G.R.; Ma, Y.C.; Feng, K.P. Hydrogen and oxygen stable isotope characteristics of maize fields in arid and semi-arid oasis irrigation areas with SPAC system: Variability traits and influencing factors. Chin. J. Plant Ecol. 2025, 49, 256–267. [Google Scholar] [CrossRef]

- Gong, X.; Liu, H.; Sun, J.; Gao, Y.; Zhang, X.; Jha, S.K.; Zhang, H.; Ma, X.; Wang, W. A proposed surface resistance model for the Penman-Monteith formula to estimate evapotranspiration in a solar greenhouse. J. Arid Land 2017, 9, 530–546. [Google Scholar] [CrossRef]

- Qiu, R.; Kang, S.; Du, T.; Tong, L.; Hao, X.; Chen, R.; Chen, J.; Li, F. Effect of convection on the Penman–Monteith model estimates of transpiration of hot pepper grown in solar greenhouse. Sci. Hortic. 2013, 160, 163–171. [Google Scholar] [CrossRef]

- Liu, H.; Duan, A.W.; Sun, J.S.; Liu, Z.G. Estimating model of transpiration for greenhouse tomato based on Penman-Monteith equation. Trans. Chin. Soc. Agric. Mach. 2011, 27, 208–213. [Google Scholar] [CrossRef]

- Gong, X.W.; Li, Y.; Ge, J.K.; Liu, H.; Li, H.H.; Qiang, X.W.; Zhang, L. Calculation Model of Reference Crop Evapotranspiration in Greenhouse Based on Outdoor Meteorological Data during Ventilation. Trans. Chin. Soc. Agric. Mach. 2025, 56, 649–659. [Google Scholar] [CrossRef]

- Niu, M.L.; Li, H.J.; Li, X.X. A CatBoost Model for Simulating the Daily Reference Evapotranspiration in Greenhouse. Water Sav. Irrig. 2022, 31, 14–19. [Google Scholar] [CrossRef]

- Duan, M.; Mao, X.M.; Xu, Z.Q.; Zhao, Y.; Chen, S.; Bo, L.Y. Effects of water deficit and mulching on leaf gas exchange parameters and yield in seed-maize grain filling stage. J. Drain. Irrig. Mach. Eng. 2018, 36, 1065–1070. [Google Scholar]

- Li, H.H.; Lu, H.; Sun, J.S.; Ma, X.J.; Cui, Y.S.; Ma, Y.C. Effects of water and fertilizer coupling on yield, water use efficiency and quality of tomato in greenhouse. J. Drain. Irrig. Mach. Eng. 2018, 36, 886–891. [Google Scholar] [CrossRef]

- Fu, Y.H.; Shen, X.J.; Li, W.C.; Xu, W.; Zhang, Q.Q. Applicability of reference crop evapotranspiration calculation based on Hargreaves-Samani regression correction. Arid Land Geogr. 2022, 45, 1752–1760. [Google Scholar]

- Yan, H.F.; Wu, H.M.; Zhang, C.; Acquah, S.J.; Zhao, B.S.; Huang, S. Estimation of greenhouse cucumber evapotranspiration in different seasons based on modified dual crop coefficient model. Trans. Chin. Soc. Agric. Mach. 2018, 34, 117–125. [Google Scholar] [CrossRef]

- Chuan, Z.; Fang, Y.H.; Da Shang, B.J.; Shi, H.B.; Wang, G.Q. Parameterization of surface soil available moisture and simulation of soil evaporation beneath canopy. Trans. Chin. Soc. Agric. Mach. 2015, 31, 102–107. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, C.; Oue, H.; Wang, G.; He, B. Study of evapotranspiration and evaporation beneath the canopy in a buckwheat field. Theor. Appl. Clim. 2015, 122, 721–728. [Google Scholar] [CrossRef]

- Yan, H.; Oue, H. Application of the two-layer model for predicting transpiration from the rice canopy and water surface evaporation beneath the canopy. J. Agric. Meteorol. 2011, 67, 89–97. [Google Scholar] [CrossRef]

- Yan, H.F.; Acquah, S.J.; Zhang, J.Y.; Wang, G.Q.; Chuan, Z.; Darko, R.O. Overview of modelling techniques for greenhouse microclimate environment and evapotranspiration. Agric. Eng. Technol. 2022, 42, 100. [Google Scholar] [CrossRef]

- Paw, U.K.T.; Qiu, J.; Su, H.-B.; Watanabe, T.; Brunet, Y. Surface renewal analysis: A new method to obtain scalar fluxes. Agric. For. Meteorol. 1995, 74, 119–137. [Google Scholar] [CrossRef]

- Snyder, R.; Spano, D.; Pawu, K. Surface renewal analysis for sensible and latent heat flux density. Bound. Layer Meteorol. 1996, 77, 249–266. [Google Scholar] [CrossRef]

- Paw, U.K.T.; Snyder, R.L.; Spano, D.; Su, H.B. Surface renewal estimates of scalar exchange. Micrometeorol. Agric. Syst. 2005, 47, 455–483. [Google Scholar] [CrossRef]

- Liu, H.J.; Cohen, S.; Lemcoff, J.H.; Israeli, Y.; Tanny, J. Sap flow, canopy conductance and microclimate in a banana screenhouse. Agric. For. Meteorol. 2015, 201, 165–175. [Google Scholar] [CrossRef]

- Qi, Y.H.; Wang, X.D. Challenges and opportunities for measuring carbon fluxes in terrestrial ecosystems by eddy covariance. Acta Ecol. Sin. 2023, 43, 2979–2994. [Google Scholar] [CrossRef]

- Yang, L.; Jiang, X.W.; Zhang, Z.Y.; Han, P.F.; Ouyang, K.L.; Gao, B.; Zhang, Y.; Li, H.T. Study on Evapotranspiration Rate of Baiyangdian Wetland Based on Eddy Covariance Technique. J. Lake Sci. 2025, 37, 1024–1034. [Google Scholar] [CrossRef]

- Wei, S.Y.; Li, P.G.; Chu, X.J.; Song, W.M.; Wang, X.J.; Zhao, M.L.; Zhang, X.S.; Han, G.X. Dataset of Carbon and Water Flux Observations in Reed Wetland Ecosystem of the Yellow River Delta from 2011 to 2018. China Sci. Data 2023, 9, 23–35. [Google Scholar] [CrossRef]

- Tang, Y.M. Applicability and Comparative Study of Penman-Monteith Formula and Dual-Source Evapotranspiration Model in the Upper Reaches of Huaihe River Basin. Water Resour. Power 2016, 34, 15–18. [Google Scholar] [CrossRef]

- Wang, X.X.; Kong, J.L.; Zhang, Q.T.; Zhang, Z.Y.; Wang, L.Z. Remote Sensing Estimation of Regional Continuous Daily Evapotranspiration Based on Richards Equation. Hydrogeol. Eng. Geol. 2024, 51, 35–44. [Google Scholar] [CrossRef]

- Xiong, Y.J.; Wang, X.; Wu, C.B. Review of surface renewal, a new method for measuring evapotranspiration based on high frequency temperature. Adv. Earth Sci. 2023, 38, 1097–1106. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, Y.; Tanaka, H.; Hiyama, T. A comparison of flux variance and surface renewal methods with eddy covariance. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2010, 3, 345–350. [Google Scholar] [CrossRef]

- Parry, C.K.; Kustas, W.P.; Knipper, K.R.; Anderson, M.C.; Alfieri, J.G.; Prueger, J.H.; McElrone, A.J. Comparison of vineyard evapotranspiration estimates from surface renewal using measured and modelled energy balance components in the GRAPEX project. Irrig. Sci. 2019, 37, 333–343. [Google Scholar] [CrossRef]

- Chen, W.; Novak, M.D.; Black, T.A.; Lee, X. Coherent eddies and temperature structure functions for three contrasting surfaces. Part II: Renewal model for sensible heat flux. Bound. Layer Meteorol. 1997, 84, 125–147. [Google Scholar] [CrossRef]

- Hu, Y.; Buttar, N.A.; Tanny, J.; Snyder, R.L.; Savage, M.J.; Lakhiar, I.A. Surface renewal application for estimating evapotranspiration: A review. Adv. Meteorol. 2018, 2018, 1690714. [Google Scholar] [CrossRef]

- Doorenbosj, P. Crop Water Requirements; FAO: Rome, Italy, 1977. [Google Scholar]

- Wang, D.D.; Wang, W.; Liu, S.D.; Qiu, X.F.; Mu, J.Y.; Mo, H.Y.; Cui, C.X.; Tao, P.H.; Jie, Q.Y.; Yu, L.; et al. Characteristics of modelling hourly water surface evaporation in Lake Taihu and comparison of simulation results by three models. J. Lake Sci. 2017, 29, 1538–1550. [Google Scholar] [CrossRef]

- Li, N.; Zhan, P.; Pan, Y.; Zhu, X.; Li, M.; Zhang, D. Comparison of remote sensing time-series smoothing methods for grassland spring phenology extraction on the Qinghai–Tibetan Plateau. Remote Sens. 2020, 12, 3383. [Google Scholar] [CrossRef]

- Hu, H.; Lu, Y.; Hu, Y.; Ding, R. Evaluation of two surface renewal methods for calculating the sensible heat flux over a tea field ecosystem in hilly terrain. Agronomy 2023, 13, 1302. [Google Scholar] [CrossRef]

- Suvočarev, K.; Castellví, F.; Reba, M.; Runkle, B.R.K. Surface renewal measurements of H, λE and CO2 fluxes over two different agricultural systems. Agric. For. Meteorol. 2019, 279, 107763. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, H.B.; Xu, L.S.; Wu, Y.F.; Su, Y.L. An overview of applications of cryogenic temperature sensors. Cryog. Supercond. 2013, 41, 10–14+58. [Google Scholar] [CrossRef]

- Gao, Z.J.; Li, S.L.; Si, C.Q.; Ding, X.M.; Batkhuu, N.-O.; Li, H. Analysis of cooling effect on the Venlo greenhouse depending on the installation height of wet curtain and fan. Trans. Chin. Soc. Agric. Mach. 2022, 38, 257–264. [Google Scholar] [CrossRef]

- Hong, Y.J.; Wang, X.Z.; Li, L.L.; Chen, J.; Lu, Q. CFD Simulation for Effect of Circulation Fans Arrangement on Flow Field in Greenhouse. J. Agric. Mech. Res. 2019, 41, 180–185. [Google Scholar] [CrossRef]

- Feng, F.G. Comparing Evapotranspiration Estimates by the Bowen Ratio Energy Balance and Surface Renewal Methods. Master’s Degree, Sun Yat-sen University, Guangzhou, China, 2021. [Google Scholar]

- Castellví, F.; Snyder, R. A comparison between latent heat fluxes over grass using a weighing lysimeter and surface renewal analysis. J. Hydrol. 2010, 381, 213–220. [Google Scholar] [CrossRef]

- Castellvi, F.; Martínez-Cob, A.; Pérez-Coveta, O. Estimating sensible and latent heat fluxes over rice using surface renewal. Agric. For. Meteorol. 2006, 139, 164–169. [Google Scholar] [CrossRef]

- Castellví, F.; Snyder, R. Sensible heat flux estimates using surface renewal analysis: A study case over a peach orchard. Agric. For. Meteorol. 2009, 149, 1397–1402. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Hu, Y.; Lu, Y.; Wang, J. Study on the Estimation of Greenhouse Sensible Heat Flux Based on the Surface Renewal Method: Validation and Calculation Results. Agriculture 2025, 15, 2439. https://doi.org/10.3390/agriculture15232439

Li Y, Hu Y, Lu Y, Wang J. Study on the Estimation of Greenhouse Sensible Heat Flux Based on the Surface Renewal Method: Validation and Calculation Results. Agriculture. 2025; 15(23):2439. https://doi.org/10.3390/agriculture15232439

Chicago/Turabian StyleLi, Yang, Yongguang Hu, Yongzong Lu, and Jizhang Wang. 2025. "Study on the Estimation of Greenhouse Sensible Heat Flux Based on the Surface Renewal Method: Validation and Calculation Results" Agriculture 15, no. 23: 2439. https://doi.org/10.3390/agriculture15232439

APA StyleLi, Y., Hu, Y., Lu, Y., & Wang, J. (2025). Study on the Estimation of Greenhouse Sensible Heat Flux Based on the Surface Renewal Method: Validation and Calculation Results. Agriculture, 15(23), 2439. https://doi.org/10.3390/agriculture15232439