Current Status and Future Prospects of Key Technologies in Variable-Rate Spray

Abstract

1. Introduction

2. Materials and Methods

3. Information Detection

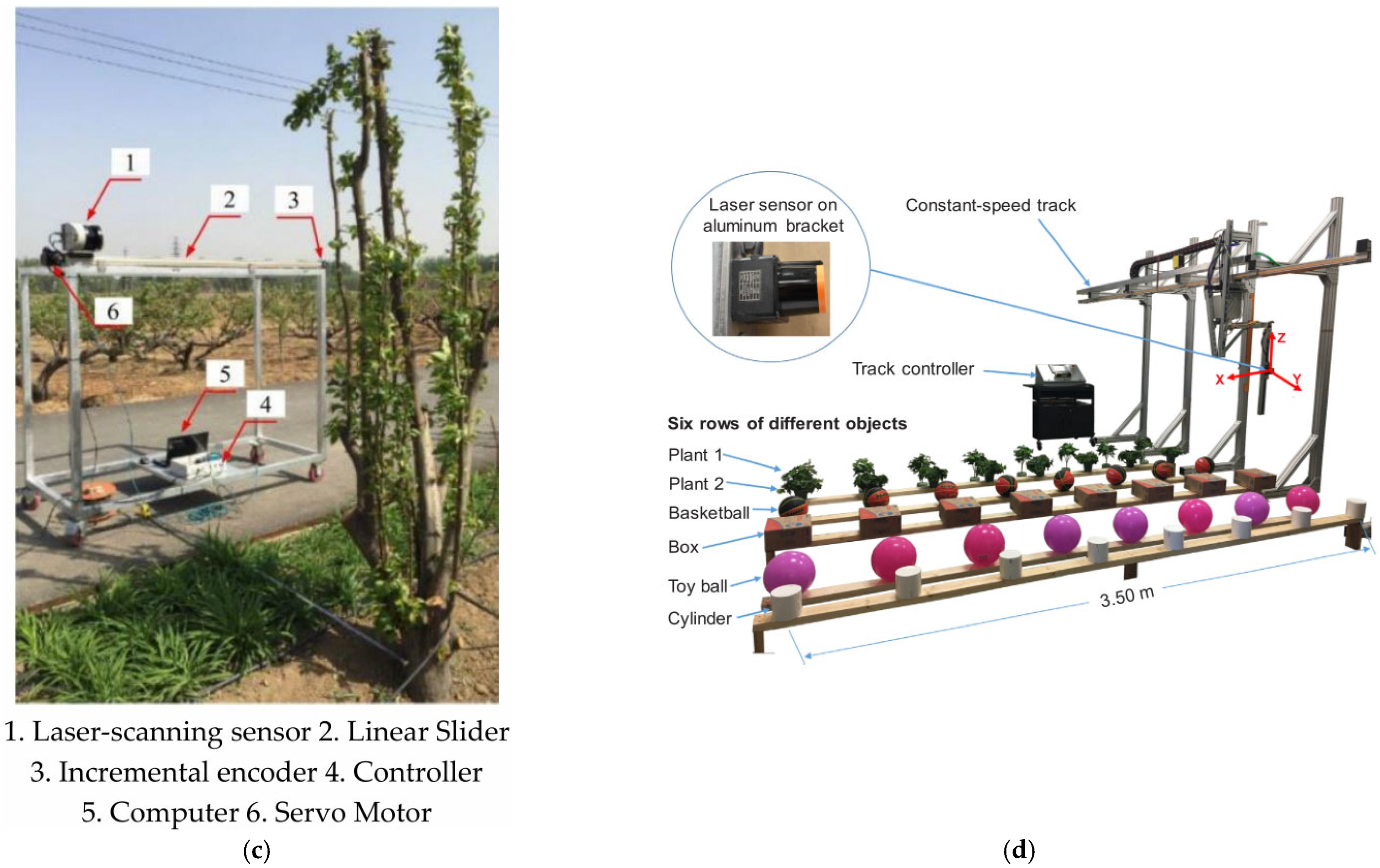

3.1. Laser Scanning Sensor

3.2. Infrared Sensor

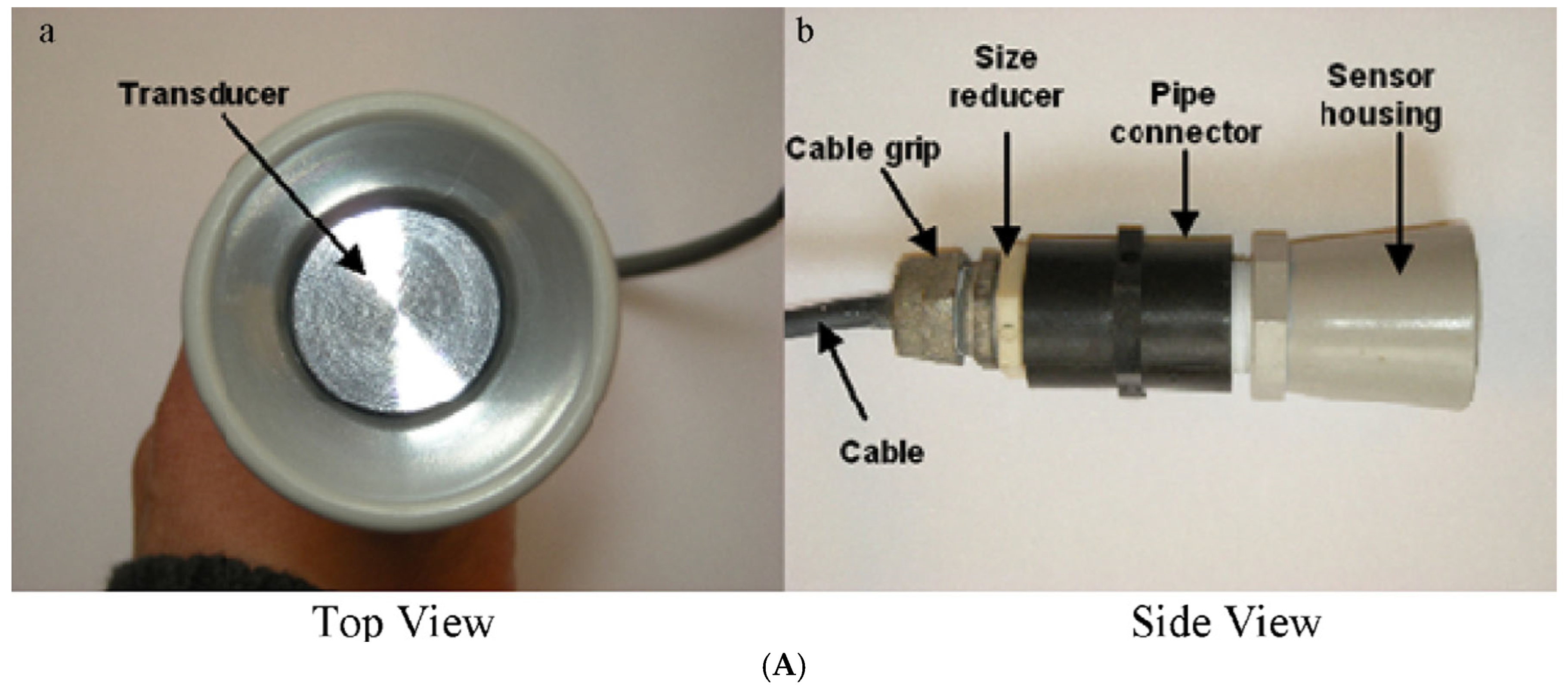

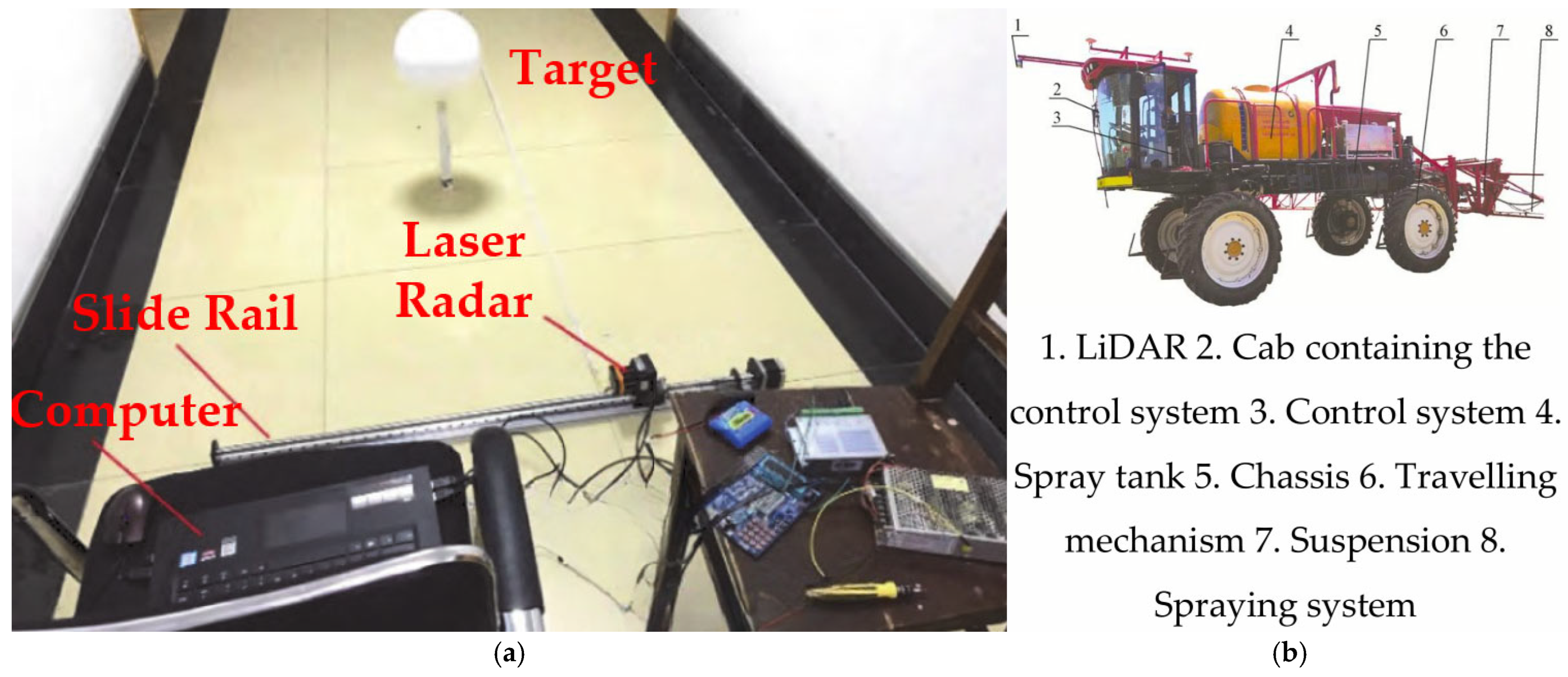

3.3. Ultrasonic Sensor

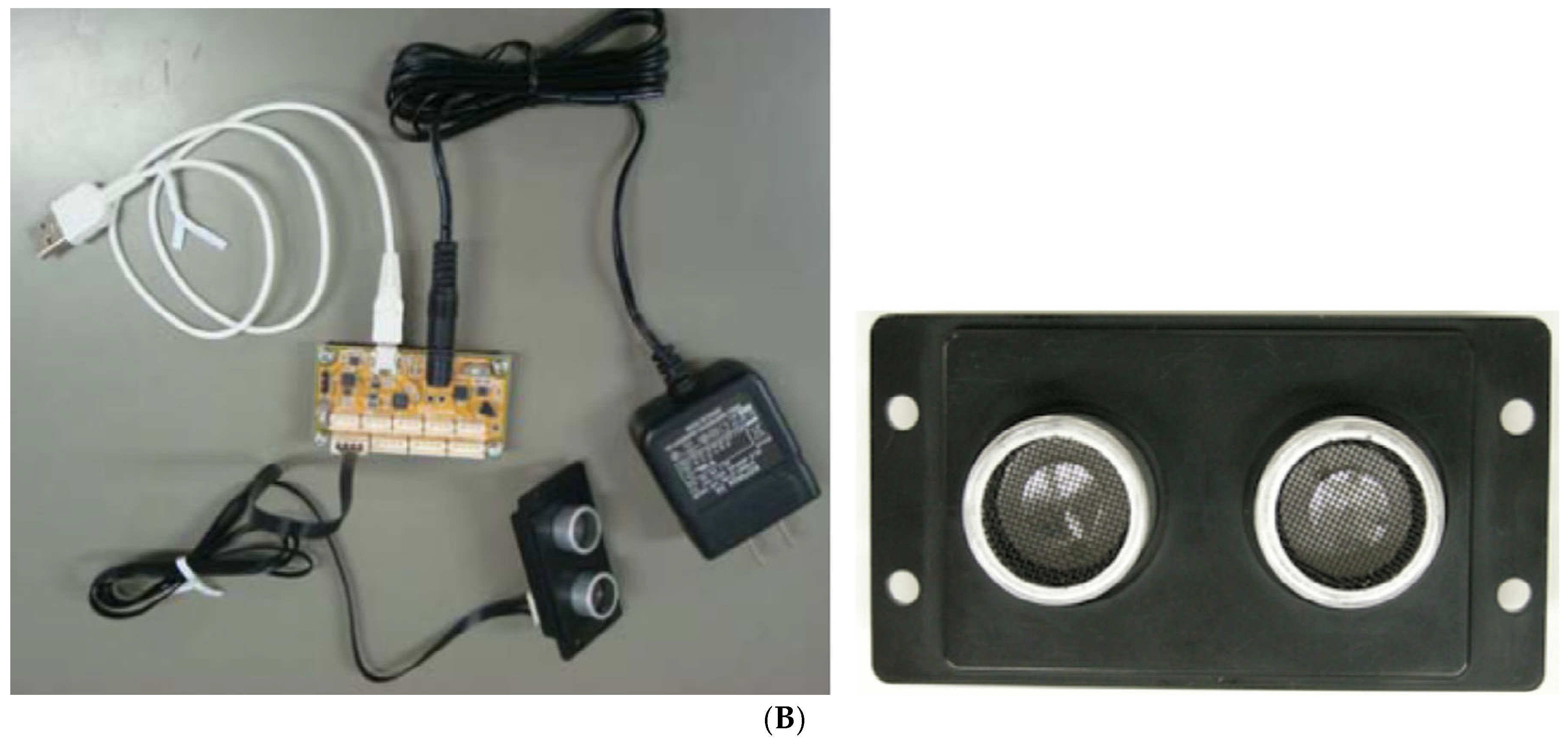

3.4. Radar

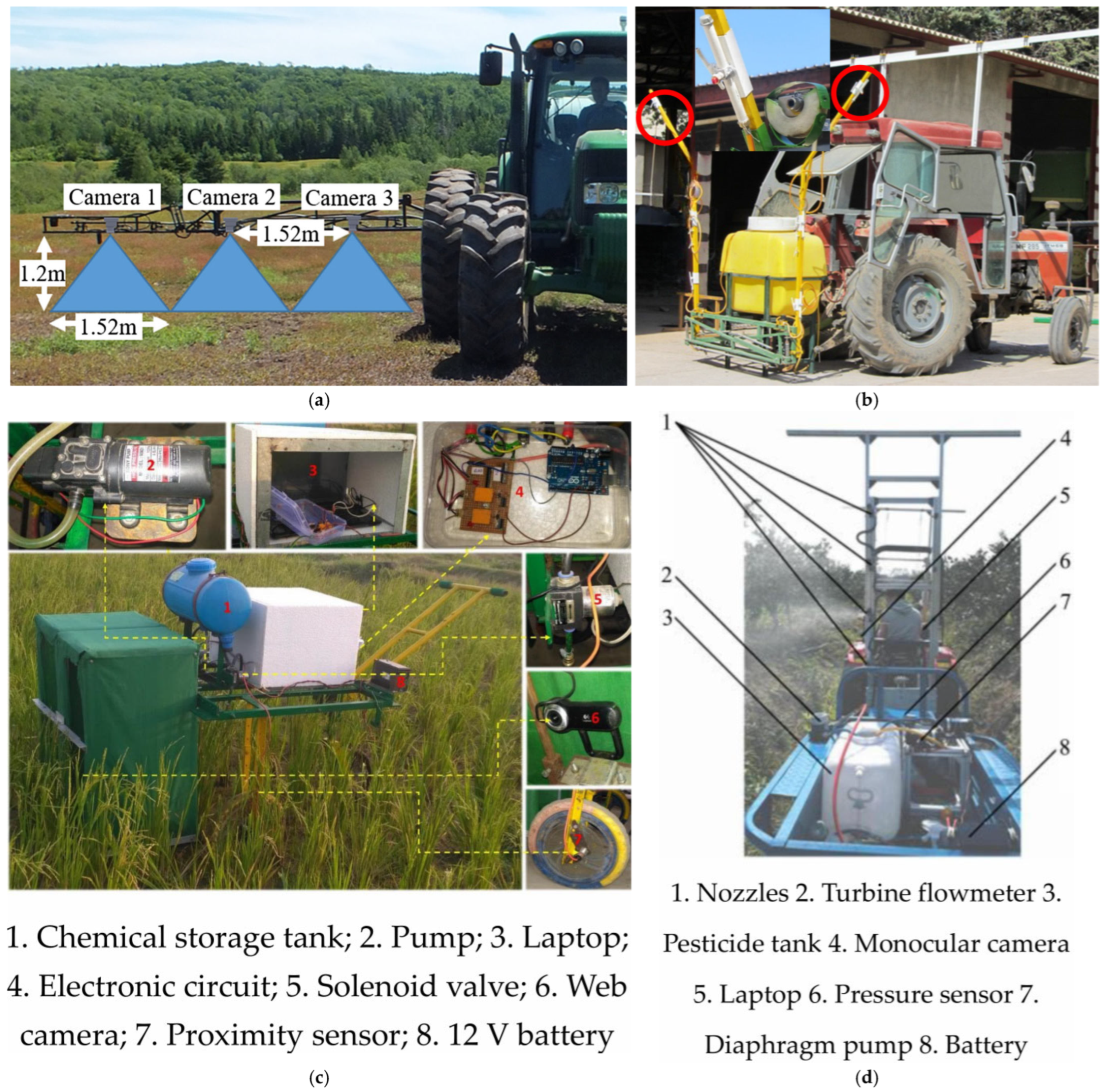

3.5. Machine Vision

3.6. Multi-Sensor Fusion

4. Spray Volume Model

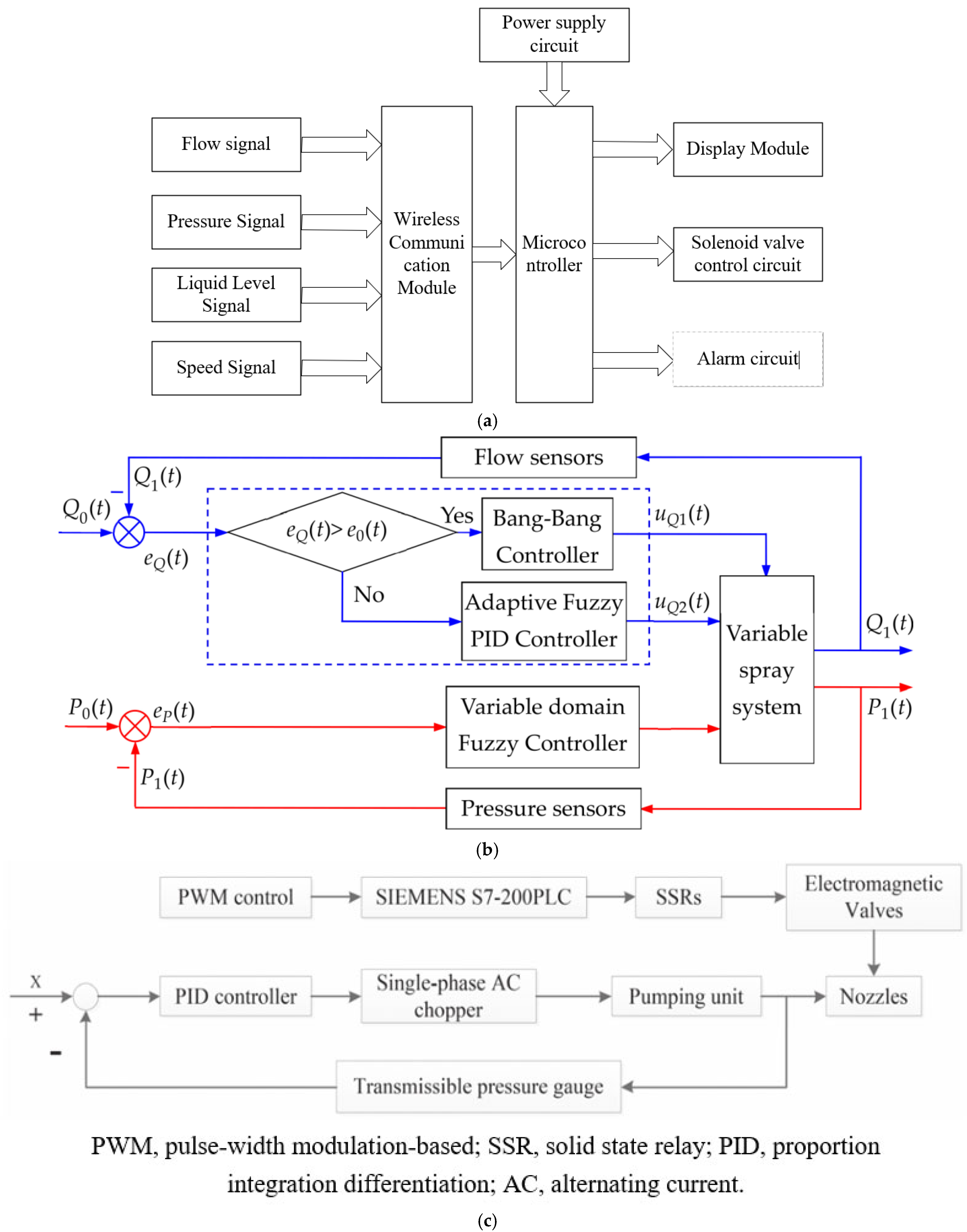

5. Control System

6. Discussion

7. Conclusions and Prospect

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wisnujati, N.S. Unveiling the epoch: Exploring pesticide utilization and trade trends globally and regionally from 1990 to 2020. Sci. J. Multi Discip. Sci. 2023, 2, 108–121. [Google Scholar] [CrossRef]

- Liao, L.Y.; Ge, L.Q.; Han, Q.L. How to view pesticides correctly based on the pesticide dosage in the past 30 years. Agrochemicals 2023, 62, 703–707. (In Chinese) [Google Scholar]

- Warneke, B.W.; Zhu, H.; Pscheidt, J.W.; Nackley, L.L. Canopy spray application technology in specialty crops: A slowly evolving landscape. Pest. Manag. Sci. 2021, 77, 2157–2164. [Google Scholar] [CrossRef]

- News Office of the Ministry of Agriculture and Rural Affairs of China. China’s three major food crops fertilizer and pesticide utilization rate of both more than 40% of fertilizers and pesticides to achieve the goal of zero growth of fertilizers and pesticides. Agric. Prod. Mark. 2021, 34. (In Chinese) [Google Scholar]

- Tudi, M.; Daniel Ruan, H.; Wang, L.; Lyu, J.; Sadler, R.; Connell, D.; Chu, C.; Phung, D.T. Agriculture development, pesticide application and its impact on the environment. Int. J. Environ. Res. Public Health 2021, 18, 1112. [Google Scholar] [CrossRef]

- Akhter, S.; Naik, V.K.; Naladi, B.J.; Rathore, A.; Yadav, P.; Lal, D. The Ecological Impact of Pesticides on Non-Target Organisms in Agricultural Ecosystems. Adv. Biores. 2024, 15, 322–334. [Google Scholar]

- Gebbers, R.; Adamchuk, V.I. Precision agriculture and food security. Science 2010, 327, 828–831. [Google Scholar] [CrossRef] [PubMed]

- Karunathilake, E.; Le, A.T.; Heo, S.; Chung, Y.S.; Mansoor, S. The path to smart farming: Innovations and opportunities in precision agriculture. Agriculture 2023, 13, 1593. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, X.; Chen, X.; Liu, D.; Gong, Y. Current research status and prospects of precision pesticide application technology and device. J. Chin. Agric. Mech. 2023, 44, 68–73. (In Chinese) [Google Scholar] [CrossRef]

- Guan, Y.; Chen, D.; He, K.; Liu, Y.; Li, L. Review on research and application of variable rate spray in agriculture. In Proceedings of the 2015 IEEE 10th Conference on Industrial Electronics and Applications (ICIEA), Auckland, New Zealand, 15–17 June 2015; pp. 1575–1580. [Google Scholar]

- Song, Y.; Sun, H.; Li, M.; Zhang, Q. Technology application of smart spray in agriculture: A review. Intell. Autom. Soft Comput. 2015, 21, 319–333. [Google Scholar] [CrossRef]

- Dou, H.; Zhang, C.; Li, L.; Hao, G.; Ding, B.; Gong, W.; Huang, P. Application of variable spray technology in agriculture. IOP Conf. Ser. Earth Environ. Sci. 2018, 186, 012007. [Google Scholar] [CrossRef]

- Yang, G.Y.; Kong, H.; Lan, Y.B.; Yi, L.L.; Han, X. Key technologies and application status of precise variable application. Agric. Technol. Equip. 2022, 1, 96–97. [Google Scholar]

- He, L. Variable rate technologies for precision agriculture. In Encyclopedia of Smart Agriculture Technologies; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–9. [Google Scholar]

- Zhou, H.W.; Ding, S.M.; Xue, X.X.; Sun, Z.; Xu, Y. Current Situation and Prospect in Research of Variable Pesticide Application Technology. J. Ningxia Agric. For. Sci. Technol. 2024, 65, 11–18. [Google Scholar]

- Zhang, Z.; Wang, X.; Lai, Q.; Zhang, Z. Review of variable-rate sprayer applications based on real-time sensor technologies. In Automation in Agriculture-Securing Food Supplies for Future Generations; InTech: Rijeka, Croatia, 2018; Volume 13. [Google Scholar]

- Abbas, I.; Liu, J.; Faheem, M.; Noor, R.S.; Shaikh, S.A.; Solangi, K.A.; Raza, S.M. Different sensor based intelligent spraying systems in Agriculture. Sens. Actuators A Phys. 2020, 316, 112265. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, H.; Ozkan, H.E. Development of a variable-rate sprayer with laser scanning sensor to synchronize spray outputs to tree structures. Trans. ASABE 2012, 55, 773–781. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, H. Evaluation of a laser scanning sensor in detection of complex-shaped targets for variable-rate sprayer development. Trans. ASABE 2016, 59, 1181–1192. [Google Scholar]

- Cai, J.C.; Wang, X.; Song, J.; Wang, S.L.; Yang, S.; Zhao, C.J. Development of real-time laser-scanning system to detect tree canopy characteristics for variable-rate pesticide application. Int. J. Agric. Biol. Eng. 2017, 10, 155–163. [Google Scholar]

- Yan, T.; Zhu, H.; Sun, L.; Wang, X.; Ling, P. Detection of 3-D objects with a 2-D laser scanning sensor for greenhouse spray applications. Comput. Electron. Agric. 2018, 152, 363–374. [Google Scholar] [CrossRef]

- Yan, T.; Zhu, H.; Sun, L.; Wang, X.; Ling, P. Investigation of an experimental laser sensor-guided spray control system for greenhouse variable-rate applications. Trans. ASABE 2019, 62, 899–911. [Google Scholar] [CrossRef]

- Zou, J.J.; Zeng, A.J.; He, X.K.; Liu, Y.J.; Song, X.G.; Guo, Y.B. Research and development of infrared detection system for automatic target sprayer used in orchard. Trans. Chin. Soc. Agric. Eng. 2007, 23, 129–132. [Google Scholar]

- He, X.K.; Zeng, A.J.; Liu, Y.J.; Song, J.L. Precision orchard sprayer based on automatically infrared target detecting and electrostatic spraying techniques. Int. J. Agric. Biol. Eng. 2011, 4, 35–40. [Google Scholar]

- Liu, J.L.; Ding, W.M.; Deng, W. Design and test of infrared detection system for target spraying in orchards. Jiangsu Agric. Sci. 2012, 40, 370–372. [Google Scholar]

- Zou, W.; Wang, X.; Deng, W.; Su, S.; Wang, S.L.; Fan, P.F. Design and test of automatic toward-target sprayer used in orchard. In Proceedings of the 2015 IEEE International Conference on Cyber Technology in Automation, Control, and Intelligent Systems (CYBER), Shenyang, China, 8–12 June 2015; pp. 697–702. [Google Scholar]

- Zou, W.; Wang, X.; Gao, B.; Fan, P.F.; Su, S. Design and Test of Control System for Automatic Variable Target Sprayer Used in Orchard. J. Agric. Mech. Res. 2019, 41, 177–182. [Google Scholar]

- Jeon, H.Y.; Zhu, H.; Derksen, R.; Ozkan, E.; Krause, C. Evaluation of ultrasonic sensor for variable-rate spray applications. Comput. Electron. Agric. 2011, 75, 213–221. [Google Scholar] [CrossRef]

- Maghsoudi, H.; Minaei, S.; Ghobadian, B.; Masoudi, H. Ultrasonic sensing of pistachio canopy for low-volume precision spraying. Comput. Electron. Agric. 2015, 112, 149–160. [Google Scholar] [CrossRef]

- Zou, W.; Wang, X.; Feng, Q.C.; Fan, P.F.; Jiang, K. Design of Variable Spraying Control System Based on Ultrasonic Target Detection. J. Agric. Mech. Res. 2021, 43, 58–63+70. [Google Scholar]

- Nan, Y.; Zhang, H.; Zheng, J.; Yang, K.; Ge, Y. Low-volume precision spray for plant pest control using profile variable rate spraying and ultrasonic detection. Front. Plant Sci. 2023, 13, 1042769. [Google Scholar] [CrossRef]

- Shu, Y.P.; Li, Q.J.; Zhou, H.P.; Tao, R.; Xu, L.Y. Design of variable rate spray control system based on LiDAR detection. J. For. Eng. 2020, 5, 139–147. [Google Scholar]

- Yuan, P.C.; Li, Q.J.; Deng, X.; Zhou, H.P.; Ru, Y.; Zhou, M.F. Design and Experiment of Real-time Control System for Target Spraying Based on LiDAR. Trans. CSAM 2020, 51, 273–280. [Google Scholar]

- Zhou, L.F.; Song, H.C.; Zhou, B.B.; Yu, P.; Dai, X. Research on the detection method of fruit tree canopy structure information based on two-dimensional LiDAR. J. Chin. Agric. Mech. 2024, 45, 147–153+2. [Google Scholar]

- Qiao, B.; He, X.; Wang, Z.; Han, L.; Liu, W.; Dong, X.; Liang, W. Development of variable-rate spraying system for high clearance wide boom sprayer based on LiDAR scanning. Trans. Chin. Soc. Agric. Eng. 2020, 36, 89–95. [Google Scholar]

- Liu, L.; Liu, Y.; He, X.; Liu, W. Precision variable-rate spraying robot by using single 3D LIDAR in orchards. Agronomy 2022, 12, 2509. [Google Scholar] [CrossRef]

- Qiao, B.; Han, L.; Wang, Z.; Li, Y.; Wang, L.; Han, H.; He, X. Design and testing of an intelligent variable-rate spraying system based on LiDAR-guided application. Crop. Prot. 2024, 184, 106874. [Google Scholar] [CrossRef]

- Esau, T.; Zaman, Q.; Groulx, D.; Farooque, A.; Schumann, A.; Chang, Y. Machine vision smart sprayer for spot-application of agrochemical in wild blueberry fields. Precis. Agric. 2018, 19, 770–788. [Google Scholar] [CrossRef]

- Asaei, H.; Jafari, A.; Loghavi, M. Site-specific orchard sprayer equipped with machine vision for chemical usage management. Comput. Electron. Agric. 2019, 162, 431–439. [Google Scholar] [CrossRef]

- Tewari, V.K.; Pareek, C.M.; Lal, G.; Dhruw, L.K.; Singh, N. Image processing based real-time variable-rate chemical spraying system for disease control in paddy crop. Artif. Intell. Agric. 2020, 4, 21–30. [Google Scholar] [CrossRef]

- Yan, C.G.; Xu, L.M.; Yuan, Q.C.; Ma, S.; Niu, C.; Zhao, S.J. Design and experiments of vineyard variable spraying control system based on binocular vision. Trans. Chin. Soc. Agric. Eng. 2021, 37, 13–22. [Google Scholar]

- Sun, D.; Liu, W.; Luo, R.; Zhan, X.; Chen, Z.; Wei, T.; Wang, X.; Xue, X.; Li, Z.; Song, S. Monocular vision for variable spray control system. Int. J. Agric. Biol. Eng. 2022, 15, 206–215. [Google Scholar] [CrossRef]

- Yang, R.; Lu, X.; Huang, J.; Zhou, J.; Jiao, J.; Liu, Y.; Liu, F.; Su, B.F.; Gu, P.W. A multi-source data fusion decision-making method for disease and pest detection of grape foliage based on ShuffleNet V2. Remote Sens. 2021, 13, 5102. [Google Scholar] [CrossRef]

- Zhao, X.; Zheng, S.; Yi, K.; Wang, X.; Zou, W.; Zhai, C. Design and experiment of the target-oriented spraying system for field vegetable considering spray height. Trans. Chin. Soc. Agric. Eng. 2022, 38, 1–11. [Google Scholar]

- Wang, X.R.; Wu, P.R.; Zhuang, C.C.; Liu, W.K.; Wei, T.; Xue, X.Y.; Wang, W.X.; Sun, D.Z. Application of LiDAR and binocular sensing data in fruit trees variable spray. Laser Infrared 2023, 53, 346–354. (In Chinese) [Google Scholar]

- Navaneethan, S.; Sampath, J.L.; Kiran, S.S. Development of a multi-sensor fusion framework for early detection and monitoring of corn plant diseases. In Proceedings of the 2023 2nd International Conference on Automation, Computing and Renewable Systems (ICACRS), Pudukkottai, India, 13–15 December 2023; pp. 856–861. [Google Scholar]

- Li, H.; Tan, B.; Sun, L.; Liu, H.; Zhang, H.; Liu, B. Multi-Source Image Fusion Based Regional Classification Method for Apple Diseases and Pests. Appl. Sci. 2024, 14, 7695. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Gallart, M. Use of a terrestrial LIDAR sensor for drift detection in vineyard spraying. Sensors 2013, 13, 516–534. [Google Scholar] [CrossRef]

- Zhang, M.N.; Lv, X.L.; Qiu, W.; Lei, X.H.; Yang, Q.S.; Zhang, D.X. Calculation method of leaf area density based on three-dimensional laser point cloud. Trans. CSAM 2017, 48, 172–178. [Google Scholar]

- Xue, X.Y. Research on Orchard Canopy Construction and Variable Spray Technology Based on LiDAR. Ph.D. Thesis, South China Agricultural University, Guangzhou, China, 2021. [Google Scholar]

- Qi, Y.C.; Chen, Y.F.; Yang, H.M.; Wang, X.N. Research and test on target detection system based on three-dimensional laser point cloud. Xinjiang Agric. Sci. 2023, 60, 2833–2841. [Google Scholar]

- Zhang, R.; Song, L. Study of variable spray control system based on machine vision. In Proceedings of the 2014 IEEE 13th International Conference on Cognitive Informatics and Cognitive Computing, London, UK, 18–20 August 2014; pp. 455–458. [Google Scholar]

- Zhou, H.P.; Zhang, C.; Xu, L.Y.; Ru, Y.; Zheng, J.Q.; Li, Q.J. Research and progress of precision spraying technology and equipment for trees. J. For. Eng. 2022, 7, 12–22. (In Chinese) [Google Scholar]

- Shen, Y.; Xia, W.; Liu, H.; Li, N. Application of laser scanning sensor for spray targets detection. Res. Agric. Mod. 2017, 38, 335–342. [Google Scholar]

- Li, L.L.; He, X.K.; Song, J.L.; Liu, Y.J.; Zeng, A.J.; Liu, Y.; Liu, C.H.; Liu, Z.X. Design and experiment of variable rate orchard sprayer based on laser scanning sensor. Int. J. Agric. Biol. Eng. 2018, 11, 101–108. [Google Scholar] [CrossRef]

- Cai, J.C.; Wang, X.; Gao, Y.Y.; Yang, S.; Zhao, C.J. Design and performance evaluation of a variable-rate orchard sprayer based on a laser-scanning sensor. Int. J. Agric. Biol. Eng. 2019, 12, 51–57. [Google Scholar]

- Nair, U.; Ling, P.P.; Zhu, H. Improved canopy characterization with laser scanning sensor for greenhouse spray applications. Trans. ASABE 2021, 64, 2125–2136. [Google Scholar] [CrossRef]

- Xu, L.Y.; Zhang, H.T.; Zhang, H.F.; Xu, Y.Y.; Xu, M.M.; Jiang, X.S.; Zhang, H.C.; Jia, Z.C. Development and experiment of automatic target spray control system used in orchard sprayer. Trans. Chin. Soc. Agric. Eng. 2014, 30, 1–9. (In Chinese) [Google Scholar]

- Ke, X.I.A.O.; Yi, H.A.O.; Guandong, G.A.O. Design and Experiment of Automatic Variable-distance Precison Spraying System in Orchard. Trans. CSAM 2022, 53, 137–145. (In Chinese) [Google Scholar]

- Stajnko, D.; Berk, P.; Lešnik, M.; Jejčič, V.; Lakota, M.; Štrancar, A.; Hočevar, M.; Rakun, J. Programmable ultrasonic sensing system for targeted spraying in orchards. Sensors 2012, 12, 15500–15519. [Google Scholar] [CrossRef] [PubMed]

- Bhalekar, D.G.; Parray, R.A.; Mani, I.; Kushwaha, H.; Khura, T.K.; Sarkar, S.K.; Lande, S.D.; Verma, M.K. Ultrasonic sensor-based automatic control volume sprayer for pesticides and growth regulators application in vineyards. Smart Agric. Technol. 2023, 4, 100232. [Google Scholar] [CrossRef]

- Liu, H.; Xia, W.; Shen, Y.; Li, N.; Xu, H. Development overview of precision variable spraying based on real-time sensor technology. J. Chin. Agric. Mech. 2016, 37, 238–244. (In Chinese) [Google Scholar]

- Jiang, H.H.; Liu, L.M.; Liu, P.Z.; Wang, J.Y.; Zhang, X.H.; Gao, D.S. Online calculation method of fruit trees canopy volume for precision spray. Trans. CSAM 2019, 50, 120–129. (In Chinese) [Google Scholar]

- Zhou, L.F.; Xue, X.Y.; Zhou, L.X.; Zhang, L.; Ding, S.M.; Chang, C.; Zhang, X.J.; Chen, C. Research situation and progress analysis on orchard variable rate spraying technology. Trans. Chin. Soc. Agric. Eng. 2017, 33, 80–92. (In Chinese) [Google Scholar]

- Gil, E.; Escolà, A. Design of a decision support method to determine volume rate for vineyard spraying. Appl. Eng. Agric. 2009, 25, 145–151. [Google Scholar] [CrossRef]

- Llorens, J.; Gil, E.; Llop, J.; Escolà, A. Variable rate dosing in precision viticulture: Use of electronic devices to improve application efficiency. Crop. Prot. 2010, 29, 239–248. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Landers, A.; Llop, J.; Giralt, L. Field validation of DOSAVIÑA, a decision support system to determine the optimal volume rate for pesticide application in vineyards. Eur. J. Agron. 2011, 35, 33–46. [Google Scholar] [CrossRef]

- Gao, G.; Zhou, H.; Niu, X. An intelligent variable spraying decision-making system based on fuzzy neural network for greenhouse mobile robot. In International Conference on Intelligent Computing for Sustainable Energy and Environment; Springer: Berlin/Heidelberg, Germany, 2012; pp. 257–265. [Google Scholar]

- Gao, G.Q.; Zhou, H.Y.; Niu, X.M.; Fang, Z.M. Research on intelligent decision-making system of variable spraying for mobile robot in greenhouse. Appl. Mech. Mater. 2013, 241, 1835–1838. [Google Scholar] [CrossRef]

- Cai, J.; Wang, X.; Wang, S.; Yang, S.; Zhao, C. Research on spray delay control of a variable-rate orchard sprayer based on a laser-scanning system. In Proceedings of the 2017 ASABE Annual International Meeting, Washington, DC, USA, 16–19 July 2017; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017; p. 1. [Google Scholar]

- Liu, Y.; Ru, Y.; Duan, L.; Qu, R. Model and design of real-time control system for aerial variable spray. PLoS ONE 2020, 15, e0235700. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.; Wen, S.; Zhang, L.; Lan, Y.; Chen, X. Extraction of crop canopy features and decision-making for variable spraying based on unmanned aerial vehicle LiDAR data. Comput. Electron. Agric. 2024, 224, 109197. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Fu, M.; Fu, W.; Wang, J.; Zhang, B.; Fu, Y.; Zeng, T. Design and experimental evaluation of a variable pesticide application control system for the air-assisted rubber tree powder sprayer. Pest. Manag. Sci. 2024, 80, 5186–5199. [Google Scholar] [CrossRef] [PubMed]

- Fedele, G.; Salotti, I.; Caffi, T.; Rossi, V. Multi-modelling approach to support decision making in crop protection. Plant Health Cases 2024, phcs20240004. [Google Scholar] [CrossRef]

- Feng, Y.N.; Pei, L.; Chen, X.; Chen, X.B.; Liu, Y.; Chen, B. Summary of the key technology of variable rate application. J. Chin. Agric. Mech. 2021, 42, 65–71. (In Chinese) [Google Scholar]

- Cerruto, E.; Manetto, G.; Papa, R.; Longo, D. Modelling spray pressure effects on droplet size distribution from agricultural nozzles. Appl. Sci. 2021, 11, 9283. [Google Scholar] [CrossRef]

- Sun, D.; Huang, X.; Hu, J.; Jiang, H.; Song, S.; Xue, X. Multifactorial analysis and experiments affecting the effect of fog droplet penetration in fruit tree canopies. Front. Plant Sci. 2024, 15, 1351525. [Google Scholar] [CrossRef]

- Mashhadi, H.; Raeini, M.G.N.; Asoodar, M.A.; Mehdizadeh, S.A. Effect of pressure and nozzle diameter on spray quality and droplet size in handheld gun sprayers. Results Eng. 2025, 26, 104709. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, L.; Shi, W. Effects of operating parameters for dynamic PWM variable spray system on spray distribution uniformity. IFAC-Pap. 2016, 49, 216–220. [Google Scholar] [CrossRef]

- Silva, J.E.; Zhu, H.; da Cunha, J.P.A.R. Spray outputs from a variable-rate sprayer manipulated with PWM solenoid valves. Appl. Eng. Agric. 2018, 34, 527–534. [Google Scholar] [CrossRef]

- Grella, M.; Gioelli, F.; Marucco, P.; Zwertvaegher, I.; Mozzanini, E.; Mylonas, N.; Balsari, P. Field assessment of a pulse width modulation (PWM) spray system applying different spray volumes: Duty cycle and forward speed effects on vines spray coverage. Precis. Agric. 2022, 23, 219–252. [Google Scholar] [CrossRef]

- Luck, J.D.; Shearer, S.A.; Sama, M.P.; Pitla, S.K. Control system development and response analysis of an electronically actuated variable-orifice nozzle for agricultural pesticide applications. Trans. ASABE 2015, 58, 997–1008. [Google Scholar] [CrossRef]

- Sun, W.F.; Liu, H.Y.; Wang, R.T.; Fu, T.P.; Lü, J.Q.; Wang, F.L. Design and experiment of PID control variable application system based on neural network tuning. Trans. CSAM 2020, 51, 55–64+94. (In Chinese) [Google Scholar]

- Xu, Y.; Wang, X.; Zhai, Y.; Li, C.; Gao, Z. Precise variable spraying system based on improved genetic proportional-integral-derivative control algorithm. Trans. Inst. Meas. Control 2021, 43, 3255–3266. [Google Scholar] [CrossRef]

- Wang, D.K.; Yu, F.H.; Xu, T.Y.; Chen, C.L.; Yao, W.X. Research on precision control method of variable spray system based on single neuron PID. J. Chin. Agric. Mech. 2022, 43, 61–66. (In Chinese) [Google Scholar]

- Chowdhury, M.; Thomas, E.V.; Jha, A.; Kushwah, A.; Kurmi, R.; Khura, T.K.; Sarkar, P.; Patra, K. An automatic pressure control system for precise spray pattern analysis on spray patternator. Comput. Electron. Agric. 2023, 214, 108287. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Hu, J.; Liu, C.X.; Li, Y.F.; Wang, S.; Wu, Z.K.; Zhang, W. Design and Experiment of Variable Spray Control System Based on ABC-PID Algorithm. J. Agric. Mech. Res. 2024, 46, 57–63. (In Chinese) [Google Scholar]

- Zaman, Q.U.; Esau, T.J.; Schumann, A.W.; Percival, D.C.; Chang, Y.K.; Read, S.M.; Farooque, A.A. Development of prototype automated variable rate sprayer for real-time spot-application of agrochemicals in wild blueberry fields. Comput. Electron. Agric. 2011, 76, 175–182. [Google Scholar] [CrossRef]

- Jeon, H.Y.; Zhu, H. Development of a variable-rate sprayer for nursery liner applications. Trans. ASABE 2012, 55, 303–312. [Google Scholar] [CrossRef]

- Song, L.; Huang, J.; Liang, X.; Yang, S.X.; Hu, W.; Tang, D. An intelligent multi-sensor variable spray system with chaotic optimization and adaptive fuzzy control. Sensors 2020, 20, 2954. [Google Scholar] [CrossRef]

- Deng, W.; Zhao, C.; Chen, L.; Wang, X. Constant pressure control for variable-rate spray using closed-loop proportion integration differentiation regulation. J. Agric. Eng. 2016, 47, 148–156. [Google Scholar] [CrossRef]

- Xu, Y.; Gao, Z.; Khot, L.; Meng, X.; Zhang, Q. A real-time weed map** and precision herbicide spraying system for row crops. Sensors 2018, 18, 4245. [Google Scholar] [CrossRef] [PubMed]

- Lian, Q.; Tan, F.; Fu, X.; Zhang, P.; Liu, X.; Zhang, W. Design of precision variable-rate spray system for unmanned aerial vehicle using automatic control method. Int. J. Agric. Biol. Eng. 2019, 12, 29–35. [Google Scholar] [CrossRef]

- Qi, Y.C.; Chen, Y.F.; Yang, H.M.; Yu, C.; Wang, X.N. Design and Test of Variable Spray System Based on PLC. J. Agric. Mech. Res. 2024, 46, 162–168. (In Chinese) [Google Scholar]

- Padhiary, M.; Tikute, S.V.; Saha, D.; Barbhuiya, J.A.; Sethi, L.N. Development of an IOT-based semi-autonomous vehicle sprayer. Agric. Res. 2025, 14, 229–239. [Google Scholar] [CrossRef]

- Fessler, L.; Fulcher, A.; Lockwood, D.; Wright, W.; Zhu, H. Advancing sustainability in tree crop pest management: Refining spray application rate with a laser-guided variable-rate sprayer in apple orchards. HortScience 2020, 55, 1522–1530. [Google Scholar] [CrossRef]

- Pagliai, A.; Sarri, D.; Perna, C.; Vieri, M. Can a variable-rate sprayer be efficient and economic? Testing and economic analysis in viticulture. In Conference of the Italian Society of Agricultural Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 805–815. [Google Scholar]

- Berenstein, R.; Edan, Y. Automatic adjustable spraying device for site-specific agricultural application. IEEE Trans. Autom. Sci. Eng. 2017, 15, 641–650. [Google Scholar] [CrossRef]

- Koo, Y. Nozzle pressure response characteristics of variable rate system for unmanned aerial applications. J. Biosyst. Eng. 2019, 44, 1–11. [Google Scholar] [CrossRef]

- Jeon, D.; Jung, H.J.; Lee, K.D.; Han, J.; Park, C.; Han, S.; Kim, H. A Study of Spray Volume Prediction Techniques for Variable Rate Pesticide Application using Unmanned Aerial Vehicles. J. Biosyst. Eng. 2025, 50, 21–32. [Google Scholar] [CrossRef]

- Rovira-Más, F.; Saiz-Rubio, V.; Cuenca, A.; Ortiz, C.; Teruel, M.P.; Ortí, E. Open-Format prescription maps for variable rate spraying in orchard farming. J. ASABE 2024, 67, 243–257. [Google Scholar] [CrossRef]

- Henderson, S. What motivates top fruit growers to adopt precision variable rate spray systems? An application of Q methodology. In Proceedings of the 99th Annual Conference, Bordeaux, France, 14–16 April 2025. [Google Scholar]

- Baio, F.H.R.; Neves, D.C.; Souza, H.B.; Leal, A.J.F.; Leite, R.C.; Molin, J.P.; Silva, S.P. Variable rate spraying application on cotton using an electronic flow controller. Precis. Agric. 2018, 19, 912–928. [Google Scholar] [CrossRef]

- Nauman, H.M.; Ghafoor, A.; Khan, M.A.; Tanveer, A. Real time variable rate sprayer: Its development and comparative analysis of spray coverage with conventional orchard sprayer. Pak. J. Agric. Sci. 2022, 59. [Google Scholar]

- Aryal, J.P.; Sapkota, T.B.; Khurana, R.; Khatri-Chhetri, A.; Rahut, D.B.; Jat, M.L. Climate change and agriculture in South Asia: Adaptation options in smallholder production systems. Environ. Dev. Sustain. 2020, 22, 5045–5075. [Google Scholar] [CrossRef]

| Reference | Year | Model | Detection Performance |

|---|---|---|---|

| [18] | 2012 | LMS291 (SICK, Inc., Waldkirch, Germany), 0–180° scanning angle, angular resolution 0.5°, detection cycle 26 ms. | The model was used to detect the canopy structure of four tree species, including Douglas fir and western hemlock. When the machine is traveling at a speed of 0.89–1.78 m/s, the detection width is 0.023–0.046 m. Increasing the speed will result in a decrease in detection accuracy. |

| [19] | 2016 | UTM-30LX (Hokuyo Automatic Co., Ltd., Osaka, Japan), 0–270° scanning angle, angular resolution 0.25°, detection cycle 25 ms, maximum detection distance 30 m. | Within a detection range of 0.58–2.94 m, the average coefficient of variation for detecting spheres in the X/Y/Z directions is 6.1/8.6/5.3%, respectively, and the image similarity between the sensor and the camera is greater than 0.85. The detection error of the sensor in the Z direction increases with the detection distance, the resolution in the X direction is affected by the travel speed of the sprayer, and the sensor has a 90° blind spot on the ground. |

| [20] | 2017 | LMS511 (SICK, Inc., Germany), scanning angle 30–150°, angular resolution 0.5°, detection cycle 20 ms. | The maximum relative errors for detecting the cross-sectional volumes of rectangular prisms, triangular prisms, and cylinders were 3.3%, 7.9%, and 9.4%, respectively. The coefficients of variation for detecting the total volumes of pine trees and apple trees were 0.078 and 0.041, respectively. The sensor had a high detection error for irregular shapes (cylinders, triangular prisms) and was dependent on the preset tree row plane distance parameters. |

| [21] | 2018 | UST-10LX (Hokuyo Automatic Co., Ltd., Japan), 0–270° scanning angle, angular resolution 0.25°, detection cycle 25 ms, maximum detection distance 10 m. | The average root mean square error (RMSE) and coefficient of variation (CV) of the sensor in the X direction were 0.083 m/35.8% (toy ball), 0.081 m/44.4% (basketball), 0.057 m/25.3% (cardboard box), and 0.0606 m/51.5% (cylinder), respectively. The RMSEs of the two artificial plants (0.231 m and 0.254 m wide) in the X-direction were 0.075 m and 0.07 m, respectively; the average RMSEs in the Y-direction and Z-direction were 0.023 m/9.3% and 0.008 m/6.2% (toy ball), respectively. The measurement accuracy of the sensor in the X direction is generally low and decreases significantly with increasing target distance. Object color and texture do not significantly affect accuracy, but complex canopy structures may increase the difficulty of edge detection. |

| [22] | 2019 | UST-10LX (Hokuyo Automatic Co., Ltd., Japan), 0–270° scanning angle, angular resolution 0.25°, detection cycle 25 ms, maximum detection distance 10 m. | Used to detect objects of different shapes (toy balls, basketballs, rectangular boxes, cylinders) and two types of artificial plants with different canopy structures. The detection range is 0.033 to 0.083 m before reaching the target object and 0.013 to 0.084 m after passing the object. When moving at high speed, the spatial sampling density of the sensor decreases, affecting the recognition accuracy of small targets. |

| Reference | Year | Model | Detection Performance |

|---|---|---|---|

| [23] | 2007 | Composed of integrated circuits BA5104, BA5204, and integrated infrared receiver HS0038B. | The average detection distance was 6.15 m (white paper) and 4.33 m (simulated peach tree), and the average identification distance was 0.216 m. The detection distance was affected by the angle and density of the branches and leaves. The experiment was conducted under ideal laboratory conditions and has not been verified in an actual orchard environment. |

| [24] | 2011 | HS0038B, capable of emitting 38 kHz modulated infrared pulse signals. Maximum detection distance of 10 m, minimum detectable gap of 0.3 m. | The sensor can adapt to the detection of tree crowns with different row spacings, but detection accuracy depends on the stability of target reflectance, which is easily affected by complex tree crown shapes or environmental factors, and has limited adaptability to unstructured planting scenarios. |

| [25] | 2012 | The model consists of a receiving unit composed of a Wennerworth bridge sine wave oscillation circuit, a high-power LED emitting unit driven by a Darlington tube TIP142, and a silicon photovoltaic cell and CA3140 operational amplifier. | The detection distance for the Chinese scholar tree is 3.2 to 4.4 m, with an average detection interval of 0.22 m. However, the detection distance is greatly affected by lighting conditions, and the detection interval is greatly affected by the reflective properties of the target branches and leaves. |

| [26] | 2015 | E3F3-DS50N1 (Yueqing Gaode Electric Co., Ltd., Yueqing, China), maximum detection distance 70 cm, response time < 2.5 ms. | When detecting green leaves, the maximum distance can reach 0.65 m, and the target recognition rate is 100% at speeds of ≤ 1.5 m/s. However, there are significant differences in detection distances for different colored targets (white 0.70 m, gray 0.26 m, black 0.14 m). |

| [27] | 2019 | E3K80-DS5M1 (Shanghai Senzheng Electric Co., Ltd., Shanghai, China), maximum detection distance of 150 cm, response time ≤ 1 ms. | When the driving speed is ≤1.16 m/s, the cherry tree recognition rate is 100% and the detection error is <0.04 m. When the tree crown exceeds the 1.5 m detection radius, the sensor measures a width that is smaller than the actual tree crown width, with an error range of 3.8–7.9%. |

| Reference | Year | Model | Detection Performance |

|---|---|---|---|

| [28] | 2011 | LV-MaxSonar-WR1 (Maxbotix Inc., Brainerd, MN, USA), detection beam angle of approx. 10°, minimum detection distance 30.48 cm, resolution 0.32 cm, sampling frequency 20 Hz. | The sensor performs stably under harsh conditions such as low temperatures, dust, and strong winds, but the detection distance decreases by 0.05 m at high temperatures of 41.6 °C. Additionally, irregular tree crown shapes may cause ultrasonic multipath reflection errors. After artificial filtering, the root mean square error range decreases from 0.101 m (8.3% of the detection distance) to 0.194 m (15.9%) to 0.064 m (5.2%) to 0.079 m (6.5%). |

| [29] | 2015 | USS3 (Best Technology Ltd., Kyoto, Japan), output accuracy 1 cm, detection distance 0.04–10 m. | The surface of the pistachio tree canopy is composed of randomly distributed leaves, causing ultrasonic waves to produce diffuse reflection rather than specular reflection, which affects ranging accuracy. The sensor beam angle changes with the detection distance, resulting in reduced measurement consistency and stability. |

| [30] | 2021 | MB7060 (Maxbotix Inc., USA), detection distance 0.05–7 m. | The sensor’s accuracy is significantly affected by the target volume, density, and surface smoothness. The detection distance is generally greater than the actual closest distance, with a maximum error of 17.7%. In complex orchard environments, leaves and branches may obstruct the view and reduce the reliability of target identification. |

| [31] | 2023 | 8-channel ultrasonic array, model unknown. | The overall average tracking error is reduced by 35%. Random variations in actual canopy morphology cause large fluctuations in single-measurement-angle values, requiring stabilization of data through the mean of four adjacent measurements. Complex canopy structures or high-density foliage affect the accuracy of ultrasonic echo signals. |

| Reference | Year | Model | Detection Performance |

|---|---|---|---|

| [32] | 2020 | 2D laser radar UTM-30LX, 0–270° scanning angle, angular resolution 0.25°, scanning cycle 25 ms. | Within a detection distance of 1–2 m, the maximum relative errors for detecting the volumes of spheres, cylinders, and cuboids are 9.32%, 8.84%, and 8.53%, respectively. The accuracy of volume calculations decreases as the detection distance increases, mainly due to the accumulation of discretization calculation errors caused by sparse point clouds at long distances. |

| [33] | 2020 | UTM-30LX 2D laser radar. | The minimum identifiable target spacing is 0.08–0.18 m. When the sprayer vehicle speed exceeds 0.9 m/s, the minimum identifiable spacing exceeds 0.18 m, and the identification capability decreases linearly with increasing speed. There is a fixed response delay of 160 ms, and insufficient dynamic compensation at high speeds can easily lead to target deviation. |

| [34] | 2024 | SICK LMS5100 2D laser radar (SICK, Inc., Waldkirch, Germany), −5–185° scanning angle, 0.167–1° angular resolution, 25–100 Hz scanning frequency, 12 mm measurement accuracy. | The measurement errors for tree height and width were 2.22% and 4.11%, respectively, with a model fit > 0.9; however, the error in tree thickness increased with LAI (reaching 41.1% when LAI = 3.68), limited by the “shadow effect” caused by the characteristics of two-dimensional scanning (unable to penetrate a dense canopy). |

| [35] | 2020 | R-Fans-16 3D Laser Radar (Beijing Beike Tianhui Technology Co., Ltd., Beijing, China), 360° horizontal scanning and 30° vertical scanning angle (−15° to +15°, single-line vertical angle interval of 2°), maximum detection distance of 200 m, and ranging accuracy of 2 cm. | The maximum height identification error for sugarcane reached 8.42%, with an average error of 4.59%. Point cloud data processing relies on Python 3.8 programming to convert polar coordinates to rectangular coordinates, which is relatively complex. Its adaptability to low-growing crops or scenarios with significant differences in plant density has not been verified. |

| [36] | 2022 | RoboSense 16-line 3D laser radar (Sure Star Technology Co., Beijing, China), 360° horizontal scanning and 30° vertical scanning angle (−15° to +15°, single line vertical angle interval 2°), maximum detection distance 150 m, accuracy 2 cm. | It can achieve high-precision navigation (lateral deviation < 0.22 m, heading deviation < 4.02°), but data processing is complex, and canopy volume calculations are based on the linear assumption of leaf area index (LAI) and volume, which may introduce errors when fruit trees change during their growing season. |

| [37] | 2024 | R-Fans-16 3D Laser Radar (Beijing Beike Tianhui Technology Co., Ltd.). | A three-dimensional model of corn plants was successfully constructed, with a height prediction error of less than 10% and a leaf area prediction model R2 of over 0.9. Increasing the driving speed during dynamic scanning reduces point cloud density, affecting detection accuracy. Leaf area prediction accuracy decreases under complex canopy conditions (R2 as low as 0.74). |

| Reference | Year | Model | Detection Performance |

|---|---|---|---|

| [38] | 2018 | UI-1220SE/C Digital Color Camera (IDS Imaging Development System Inc., Obersulm, Germany). 752 × 128-pixel resolution, 24-bit RGB color mode, a 3.5 mm focal length lens, and a 2 ms maximum auto exposure time. | At a height of 1.2 m, the field of view covers an area of 1.52 m × 0.28 m. In a mixed-vegetation canopy (e.g., when weeds and blueberries are similar in color), the resolution capability is limited and relies on texture analysis for assistance. Changes in lighting conditions (e.g., shadows or reflections) may lead to misjudgments. |

| [39] | 2019 | Camera model unknown. The image format grabbed by this camera is (TSCO, VGA (640 × 480), 30 fps, 10 megapixels). | In a laboratory environment, the average response delay was 0.55 s for start-up (corresponding to a spatial lag of 0.30–0.83 m) and 0.85 s for stop (corresponding to a lag of 0.55–1.32 m). Light sensitivity increases the risk of misidentification in complex backgrounds. A fixed threshold strategy is insufficiently adaptive to changes in olive tree canopy density. The spatial offset caused by mechanical delay increases linearly with speed. |

| [40] | 2020 | Logitech Pro 9000 webcam (Logitech Inc., San Jose, CA, USA), 640 × 480-pixel resolution. | Used to detect leaf lesions caused by rice blast disease. At an operating speed of 0.25 m/s, a processing delay of 800 ms can be achieved, but this relies on a green background cloth to eliminate light interference (limited field adaptability), and the trigger mechanism based on the travel sensor is easily affected by variations in plant spacing. |

| [41] | 2021 | XiaoMi Intelligent S1030-IR-120 Dual-Camera System (Slightech (Jiangsu) Co., Ltd., Jiangsu, Wuxi, China), pixel pitch 6.0 μm, focal length 2.1 mm, field of view 146° × 122° × 76°, 752 × 480-pixel resolution, detection range 0.8~5 m. | Used to detect canopy depth information and calculate canopy volume. After calibration compensation of 0.15 m, the linear correlation coefficient between the canopy volume detection results and manual measurement values reaches 0.933. In static tests, when the canopy volume exceeds 0.036 m3, the coefficient of determination between actual flow rate and theoretical flow rate is 0.990. Outdoor lighting conditions can interfere with the depth detection accuracy of the stereo camera, requiring calibration compensation values for correction. Additionally, the error characteristics at different detection distances must be calibrated separately. |

| [42] | 2022 | Microsoft LifeCam HD-3000 monocular camera (Microsoft, Redmond, WA, USA), 30 fps | Used to detect the leaf wall area of citrus tree canopies. The error in calculating LWA is only 0.5%, with a camera response time of 40 ms. The flow model constructed within a duty cycle range of 15% to 65% has a coefficient of determination R2 > 0.94. However, monocular vision lacks depth information, which limits the acquisition of three-dimensional canopy features. |

| Reference | Year | Model | Detection Performance |

|---|---|---|---|

| [43] | 2021 | RGB camera (LRCP Luoke USB, ShenZhen ZWAK LRCP Technology Co., LTD, Shenzhen, China, resolution 2592 × 1944, 3 channels), multispectral camera (XIMEA MQ022HG-IM-SM5 × 5 NIR, XIMEA GmbH, Am Mittelhafen, Münster, Germany, resolution 409 × 216, 25 bands) and thermal infrared camera (FILR Tau2-640, Flir Systems, Inc., Wilsonville, OR, USA, resolution 640 × 512, 3 channels). | Used to detect pests and diseases on grape leaves. The RGB model performed best in independent testing, with an overall accuracy rate of 93.77%. Through the proposed multi-source data fusion decision-making method, the accuracy rate was improved to 96.05%. However, thermal infrared images are easily affected by fluctuations in ambient temperature, and the high dimensionality of multispectral data leads to feature redundancy. During the fusion process, some correct samples may be misjudged due to the confidence threshold. |

| [44] | 2022 | Industrial camera (MER-131-210U3M/C, China Daheng Co., Ltd., Beijing, China, resolution 1280 × 1024 pixels, frame rate 210 frames/s), ultrasonic sensor (MB7155, MaxBotix Inc., Brainerd, MN, USA, detection range 20–765 cm, frequency 10 Hz, accuracy ±0.7 cm), pressure sensor (131-B, Beijing Aosheng Automation Technology Co., Ltd., Beijing, China, range 0–2.5 MPa) and flow sensor (HI2144, Yueqing Ponai Sensing Technology Co., Ltd., Yueqing, China, 1–30 L/min) | Used to detect field vegetables such as cabbage. The target error (mean absolute error ≤ 0.0363 m, root mean square error ≤ 0.0426 m) is significantly reduced compared to when not fused. However, industrial cameras have limited recognition stability in complex lighting or high-speed scenarios, and the low-frequency characteristics of ultrasonic sensors may cause data update delays during high-speed operations. |

| [45] | 2023 | LiDAR (SICK LMS291-S05, SICK, Inc., Waldkirch, Germany), stereo vision camera (Microsoft AzureKinectDK, Microsoft, Redmond, WA, USA, resolution 2560 × 1440, field of view 90° × 59°). | LiDAR was used to analyze the density distribution of the vertical layering of simulated fruit tree canopies, with a two-dimensional reconstruction accuracy error of 0.633% ± 0.0276%. The stereo camera calculates leaf wall area through reference calibration, with an area detection error of 1.525% compared to lidar. However, lidar point cloud accuracy and complex canopy segmentation algorithms still require optimization, and stereo vision faces the risk of mis-segmentation in scenarios with strong light interference and multiple overlapping trees. |

| [46] | 2023 | Visible-light and near-infrared camera, thermal imaging sensor, hyperspectral imaging sensor, model unknown | By integrating data through weighted averaging and principal component analysis algorithms, the model ultimately achieved an accuracy rate of 95%, a sensitivity of 96%, and a specificity of 94%, with detection accuracies of 92%, 96%, and 94% in the early, middle, and late stages of corn growth, respectively. The model’s performance is limited by environmental conditions and training data diversity, and insufficient data on specific diseases or regions may affect generalization capabilities. |

| [47] | 2024 | The DJI Phantom 4 Pro multispectral drone (SZ DJI Technology Co., Ltd., Shenzhen, China) is equipped with an RGB camera (red, green, and blue bands) and a multispectral camera (five bands: 450 nm, 560 nm, 650 nm, 730 nm, and 840 nm) for multi-source image fusion. | The five common pests and diseases identified in apple tree canopies are aphids, Alternaria leaf spot, mosaic virus, brown spot disease, and gray spot disease. For the self-built dataset, the model achieved a subset accuracy of 92.92%, a sample accuracy of 85.43%, and an F1 score of 86.21%, representing improvements of 8.93% and 10.9% over single-source RGB/multispectral models, respectively. The accuracy for single-disease identification exceeded 97%. However, data collection relies on clear, windless weather, and the model requires high-resolution images to distinguish between complex backgrounds and similar-symptom pests and diseases. Vegetation index calculations depend on manual experience-based screening, and model training requires a large amount of precisely annotated canopy region data. |

| Reference | Year | Model Introduction | Model Effects |

|---|---|---|---|

| [65] | 2009 | Based on multidimensional data such as crop parameters, pesticide characteristics, equipment parameters, and environmental conditions, the system quantifies efficiency factors to correct for losses during the spraying process (such as canopy obstruction and meteorological interference), and ultimately outputs the optimized spray volume. | The model can reduce traditional spray volume by approximately 30%, but it is highly parameter-dependent (requiring precise input of data such as LAI and canopy volume that is difficult to obtain in real time). Simplified assumptions affect accuracy (such as the assumption of uniform droplet coverage ignoring heterogeneity of deposition within the canopy), efficiency factor weights lack dynamic verification (some sub-factor scores rely on empirical values), and its universality is limited (mainly suitable for vineyard scenarios). |

| [66] | 2010 | Based on canopy width, height, tractor travel speed, and a preset unit volume spray coefficient, the nozzle flow rate is dynamically adjusted to achieve a linear match between canopy volume and spray volume. | The model achieved an average reduction of 58% in pesticide usage across three grape varieties and different growth stages, while normalized leaf deposition and leaf recovery rates were comparable to or better than those of traditional spraying, with no significant decrease in deposition uniformity. However, when the canopy volume was low, the system’s minimum pressure limit caused the spray coefficient to deviate from the theoretical value, resulting in localized over-spraying. Additionally, the model does not incorporate parameters such as leaf density or leaf area index, which may affect its adaptability to complex canopy structures. |

| [67] | 2011 | The optimal spray volume is calculated based on crop canopy characteristics, spray equipment parameters, environmental conditions, and pest characteristics. By setting the target droplet density and droplet volume, the spray volume is dynamically adjusted in combination with a leaf area database, and an efficiency factor is introduced to quantify spray loss. | The model reduced spray volume by an average of 39.9% and pesticide use by 53%, with leaf surface deposition uniformity superior to that of traditional methods. Its efficacy in controlling diseases such as powdery mildew and gray mold was comparable to that of traditional high-dose treatments. However, the model relies on a pre-established crop parameter database and does not account for synergistic effects of multiple pesticides. Under high-density canopies, traditional methods achieve higher recovery rates. |

| [68] | 2012 | The model is based on a fuzzy neural network and includes parameters such as crop area, target distance, and pest and disease severity. It adopts a five-layer fuzzy neural network structure, which uses Gaussian membership functions to fuzzy the input parameters, combines 18 fuzzy rules for inference, and utilizes the BP algorithm to dynamically adjust the weights, membership function centers, and width parameters to achieve self-learning. | After 191 training sessions, the model achieved a target error of 0.001. The decision error of the test samples was significantly lower than that of traditional fuzzy systems, and the model demonstrated stronger generalization capabilities for samples that were not included in the training, enabling real-time response to uncertain greenhouse environments. However, the model did not explicitly consider dynamic interference factors such as environmental parameters and robot movement speed, and model verification relied on laboratory simulation data. |

| [69] | 2013 | Based on fuzzy neural networks, input parameters include the area of the spraying target, target distance, and pest and disease severity. The model learns from operational experience data through offline training and outputs pesticide flow rates. | The model has a small average decision error on the test set, with an error reduction of approximately 30–40% compared to traditional fuzzy decision systems. However, the model’s pest and disease severity ratings depend on manual input and do not yet support automated real-time detection. The model does not consider the potential impact of other environmental factors such as temperature and humidity on pesticide application rates, and the experimental data was collected in a specific greenhouse scenario. |

| [70] | 2017 | The model is based on the canopy grid volume algorithm, with key parameters including canopy grid height, width, depth, single-point height, sprayer travel speed, vertical distance from the sensor to the tree row, and nozzle flow coefficient. The model calculates the grid volume and converts it into PWM duty cycle to control the nozzle flow, achieving variable-rate spray that matches the canopy volume and speed. | The model shows a small range of spray position distance errors at different speeds (0–0.14 m), with the lowest error occurring at fine grid settings, validating the effectiveness of the delay control method. However, the model’s accuracy is limited by the grid width setting; as the grid size increases, the error significantly increases. Additionally, the model does not account for the potential impact of dynamic factors such as environmental wind speed. |

| [71] | 2020 | The model mainly integrates four parameters: flight altitude, flight speed, nozzle voltage, and solenoid valve opening angle. It achieves stable spray volume per unit area through dynamic adjustment of the solenoid valve opening angle. | In single-factor tests, the model control deviation range was 0.11–9.79%, and in multi-factor orthogonal tests, the maximum deviation was 9.46%, both of which met agricultural aviation spraying requirements (<10%). However, the droplet movement model only considers gravity and ignores complex factors such as air resistance, and the spray width prediction is based on an approximate sine curve for a specific centrifugal spray nozzle (Auz900), which may affect the model’s universality. |

| [31] | 2023 | The core parameters of the model include crown unit volume, leaf area density, and spray volume per unit volume, with maximum theoretical leaf area density as the benchmark parameter. Spray flow is dynamically adjusted based on crown volume and leaf area density parameters. | The spray variability coefficient of the contour variable-rate spray was reduced by 25.9% and 21.9% in the inner and outer layers of the tree canopy, respectively, with spray uniformity significantly superior to traditional methods. While achieving a 32.1% reduction in flow rate, key indicators such as droplet coverage and volume median diameter (VMD) showed no significant difference from traditional spraying methods. However, ground deposition coverage decreased from 33.2% to 13.0%. However, the complexity of canopy morphology causes significant fluctuations in single contour angle calculations, necessitating smoothing through the average of four measurements. Leaf area density estimation relies on ultrasonic echo characteristics, which are susceptible to environmental noise and extreme conditions of branch and leaf density. |

| [72] | 2024 | Based on the dynamic adjustment of spray flow according to cotton canopy volume, the main parameters include drone flight parameters, canopy volume, nozzle duty cycle, and geographic coordinate information. The model establishes a linear relationship between flight parameters, canopy volume, and duty cycle, and combines polygon prescription maps to decode geographic coordinates and flow information in real time, thereby achieving variable-rate spray. | The model-calculated canopy volume showed a coefficient of determination (R2) of 0.89 compared to manually measured values, confirming a high correlation. The variable-rate spray system saved 43.37% of the pesticide compared to the constant-rate spray system. The deposition efficiency (average 0.31 μL/cm2) and coverage rate (7.78%) met operational requirements, and no over-spraying occurred. However, the model is limited by the PWM duty cycle adjustment range at low flow rates, and the onboard processor’s ability to process large-scale point cloud data in real time may affect the dynamic response speed under complex canopy conditions. |

| [73] | 2024 | The model is based on the rubber tree powdery mildew control standard and integrates parameters such as leaf area index (LAI), individual tree height, canopy volume, powdery mildew severity, and the distance from the powder spray nozzle to the canopy center. The model dynamically adjusts the application rate of sulfur powder based on LAI values, calculates the initial wind speed using jet decay theory, and adjusts the spray angle in real time based on the canopy center height. | The accuracy of the model-controlled actuator exceeds 95.9%. Compared to the quantitative mode, the coefficient of variation (CV) of canopy deposition in the variable mode is reduced to 35.38–36.90%, and the effective utilization rate of sulfur powder is improved by 20.03%. However, the model wind speed is fixed at 2 m/s and is not dynamically optimized based on spray volume, resulting in an actual deposition growth trend below the theoretical value at high spray volumes. Additionally, the model does not account for the influence of natural wind on airflow, limiting its applicability under high-wind conditions, and further integration of meteorological parameters is required. |

| Reference | Year | System Principle | Control Performance |

|---|---|---|---|

| [82] | 2015 | Comprising an electronic linear actuator, a variable orifice nozzle (VariTarget), a pressure sensor, an electromagnetic flowmeter, and a data acquisition module, the control algorithm employs proportional control (variable gain P control) based on dynamic adjustment of the system pressure gain, with gain adaptation achieved through a pressure polynomial equation. | Within the pressure range of 138–414 kPa, the step response settling time is <1 s (as fast as 0.63 s), overshoot is ≤7.2%, and the steady-state error is <2%. The ramp response has an average absolute error of <5% at an input of 0.07 Hz, a hysteresis time of <0.38 s, and a maximum flow rate change rate of 6.39 mL/s2 (414 kPa). However, system gain requires adjustment based on pressure experience, and laboratory conditions do not account for field vibrations/temperature effects. |

| [83] | 2020 | The system consists of a multi-sensor data acquisition module (including speed, flow, pressure, and liquid level sensors), an STC12C5A60S2 microcontroller, and an electrically controlled regulating valve actuator. The system employs a PID control algorithm tuned using a BP neural network, leveraging the neural network’s self-learning capabilities to dynamically adjust PID parameters, thereby achieving precise control of the drug solution return flow. | When the vehicle speed randomly varies between 1.11 and 3.06 m/s, the spray volume control error remains stable within ±3%, with an average adjustment time of 0.72 s, an overshoot of only 2.1%, a coefficient of variation for longitudinal spray uniformity below 6%, and a standard deviation of droplet deposition density < 1.4 per cm2, significantly outperforming traditional PID and fuzzy PID control. However, the system still has limitations such as the manual pressure regulating valve affecting automation levels, pressure regulation potentially disrupting spray atomization stability, and the complexity of neural network parameter training. |

| [82] | 2021 | The system consists of an STM32 processor, electric valve control circuit, flow sensor, pressure sensor, liquid level sensor, and actuators (electric control valve and anti-drip nozzle). The system uses an improved genetic PID (IGA-PID) control algorithm, which optimizes population selection through mean selection operators, and combines adaptive crossover and mutation operators to improve parameter optimization efficiency. | The algorithm outperforms traditional PID, fuzzy PID, and standard genetic PID in terms of overshoot (1.25%), steady-state error (1.21%), and settling time (0.157 s). The field test response time is 3.84 s, with a spray volume error of 2.59%. However, the system relies on electric valves to regulate flow, and pressure changes may affect atomization efficiency. |

| [83] | 2022 | The system consists of an STM32H743VIT6 processor, a diaphragm pump drive module, a flow/pressure sensor, a PWM drive module, and a wireless communication module. It uses a single-neuron PID control algorithm based on the Hebb learning rule to achieve precise control of the spray flow by dynamically adjusting the PID parameters. | Single-neuron PID control demonstrates significantly higher accuracy than traditional PID control. Simulation results show that the rise time is reduced to 0.054 s with no steady-state error. In indoor tests, the maximum overshoot is 3.88%, and the average response time is 0.85 s. In field tests, the flow error is less than 5%, and the droplet deposition rate is positively correlated with the flow rate. However, overshoot still requires optimization during sudden changes in system flow (reaching a maximum of 9.1% in field tests), and single-neuron parameters (such as learning rate and proportional coefficient) still require manual tuning. |

| [84] | 2023 | The system consists of a microcontroller (ATmega328), pressure sensor, PWM controller, precision potentiometer, buck module, and diaphragm pump. The system employs a PWM-based open-loop control strategy, where the target pressure value is set via the potentiometer. The microcontroller continuously monitors the pressure sensor signal and adjusts the PWM duty cycle to control the pump speed. | The system control accuracy can reach ±0.1 kg/cm2 (±9.81 kPa) of the target pressure value, significantly outperforming the ±0.3 kg/cm2 fluctuation of the traditional pressure relief valve + gate valve combination. Experiments show that this system keeps the coefficient of variation (CV) of nozzle flow below 1%, while traditional methods often exceed 1%. However, this system has only been validated in a laboratory single-nozzle scenario and has not yet been adapted to the complex operating conditions of multi-nozzle spray bar sprayers. |

| [85] | 2024 | The S7-200 PLC serves as the central controller, equipped with Hall effect speed sensors, flow sensors, and pressure sensors to collect real-time operational parameters. Flow is regulated via proportional electric control valves, and the power source uses a diaphragm pump to drive the delivery of the solution. The system employs an ABC-optimized PID control algorithm (ABC-PID), utilizing swarm intelligence to dynamically adjust PID parameters. | In the simulation, the overshoot of the ABC-PID control was only 1.7% (compared to 24.5% for conventional PID), the rise time was reduced to 0.17 s (compared to 0.3 s for conventional PID), the average error in spray volume during the indoor constant-speed test was 1.3% (compared to 3.1% for fuzzy PID), and the error in the variable test was 2.1%; it outperformed the comparison algorithms in all these areas. However, the experiments were conducted solely in a laboratory environment and have not been validated in actual field operation scenarios. The number of iterations and population size of the ABC algorithm have not been optimized, which may increase the computational burden in real-time applications. |

| [86] | 2011 | The system is composed of an 8-channel variable controller, solenoid valve, LandManager II controller, flow valve, and nozzles. The control algorithm is based on real-time threshold judgment. When the height of weeds exceeds the preset threshold, the variable controller immediately activates the corresponding nozzles using open-loop control logic. | The system response time is 0.05 ± 0.003 s, with a flow control error of ≤2.5%. A t-test of water-sensitive paper coverage in field trials showed no significant difference between variable-rate spray (10.01–81.22%) and uniform spray (5.39–72.67%). However, the system is only applicable for weed detection between 0.3 and 0.55 m in height and is ineffective for short weeds (<0.3 m) and early growth stages. Spray coverage is significantly dependent on weed height, with coverage decreasing for weeds over 0.55 m in height, necessitating spraying during specific growth stages. |

| [87] | 2012 | The system consists of a PWM solenoid valve nozzle assembly, a microcontroller (PIC18F4523), and a speed sensor. Each nozzle is independently controlled by a PWM solenoid valve to regulate flow. The microcontroller adjusts the PWM duty cycle of each nozzle based on sensor data and travel speed, and uses a pre-trigger mechanism to ensure that the spraying timing is synchronized with the canopy position. | At a speed of 0.89 m/s, the system achieves an average response time of 296 ms, with a trigger error of 0.045–0.125 m. The coefficient of variation for spray coverage and deposition rate ranges from 44.5% to 59.2%. However, there were no significant differences in average coverage (12.0–14.7%) and deposition rate (0.72–0.90 μL/cm2) across different speeds (0.89–2.22 m/s). Nevertheless, the simplification of the canopy volume using a rectangular assumption may affect the accuracy of detecting complex shapes, and the sensor is susceptible to interference from path deviations and mechanical vibrations. |

| [88] | 2020 | The system uses three pressure sensors and two flow sensors to monitor the main pipeline pressure and spray flow in real time. The actuator includes an electric control valve and a return flow control valve. The control algorithm uses a composite control strategy based on chaos optimization: the outer loop flow control combines Bang-Bang relay control with adaptive fuzzy nonlinear PID, while the inner loop pressure control uses variable domain fuzzy control, and the controller parameters are globally optimized through a chaos algorithm. | The simulation results show that the optimized controller’s rise time (0.9 s), settling time (1.5 s), and overshoot (2.67%) are all better than the traditional PID (2.2 s, 5 s, and 6%). Experimental verification shows that the effective droplet rate reaches 89.4% at a pressure of 300 kPa and a flow rate of 0.08 m3/h, which is an 8.1% improvement over the PID. However, the system’s reliance on multiple sensors increases complexity, and the significant computational load of chaotic optimization may impact real-time performance. |

| [89] | 2016 | The system consists of a closed-loop PID controller, a single-phase AC chopper voltage regulator, an electric impeller pump, a pressure transmitter, a PLC controller, solid-state relays, solenoid valves, and hollow conical nozzles. Pressure sensors provide real-time feedback on pipeline pressure, which is used by the PID algorithm to calculate deviation signals. The single-phase AC chopper then dynamically adjusts the speed of the pump motor to achieve closed-loop pressure control. | Within the set pressure range of 100–400 kPa, the maximum relative error of closed-loop control is 8.36% (400 kPa/three-nozzle condition), while the error of open-loop control is as high as 40%. The system performs optimally in the medium-pressure range of 200–300 kPa, with a spray angle deviation of less than 0.87°. However, the error increases at high pressure (400 kPa) due to the limitations of the pump’s maximum head. The AC chopping voltage regulation technology used has a narrower speed control range and lower precision compared to the variable-frequency speed control scheme. |

| [90] | 2018 | The system consists of a DSP controller (TMS320F2812 chip), a multi-nozzle solenoid valve drive circuit, a network of flow/level/pressure sensors, a WiFi communication module, and an alarm circuit. The system uses an improved particle swarm optimization algorithm (IPSO) for weed image segmentation, combined with a lateral histogram algorithm to quickly extract weed distribution maps, and implements multi-nozzle combination control based on weed density through the DSP. | The system has high control accuracy, with a spray response time of 1.562 s and a flow rate adjustment range of 84–674.4 L/hm2, which is eight times greater than that of traditional single-nozzle systems. However, at low pressures (200 kPa), small flow rates cannot be detected by the sensor, and the system has only been verified during the early stages of corn seedling growth (3–4 leaf stage). Its applicability under complex canopy conditions has not been tested. |

| [91] | 2019 | The system consists of a core control board (based on the NXPKinetisK60 microcontroller), a miniature diaphragm pump, a flow sensor, a pump motor speed controller, and a spray nozzle. The system employs a closed-loop PID control algorithm, which continuously collects real-time flight speed and altitude parameters. These are combined with pre-set nozzle spacing, target spray volume, and other parameters to dynamically calculate the target flow rate and adjust the PWM duty cycle of the diaphragm pump. Additionally, feedback from the flow sensor is utilized to form a closed-loop correction mechanism. | The system’s average control response time is 0.18 s, with a flow stabilization time of 0.75 s, enabling rapid tracking of changes in flight status to achieve flow regulation. However, insufficient GPS positioning accuracy may lead to speed calculation errors; the acceleration integration method for speed measurement carries the risk of cumulative errors; the mechanical inertia of the diaphragm pump causes startup/shutdown delays (average stabilization time of 0.54 s), affecting precision in high-frequency speed-changing scenarios; and parameter settings rely on manual input (nozzle type, spacing, etc.) and lack intelligent adaptation capabilities. |

| [92] | 2024 | The Xinjie XD3-16RT-C PLC is used to implement pulse width modulation control of the solenoid valve opening through a time relay, which essentially belongs to an open-loop time proportional control algorithm. | Test results indicate that the system achieves a maximum variable capacity of 9.91 times within the pressure range of 100–200 kPa. The coefficient of determination for the exponential/polynomial fit between the solenoid valve opening and spray volume exceeds 0.99, with relative error controlled within 4%, demonstrating high-control precision. However, the system lacks a closed-loop feedback mechanism, relies on a constant-pressure pipeline environment, and requires manual intervention for pressure adjustments. Additionally, the system does not integrate a flow sensor for real-time correction, which may result in cumulative errors during long-term operation. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, Y.; Sun, Z.; Jin, Y.; Cui, L.; Zhang, X.; Wang, S.; Zhang, S.; Chang, C.; Ding, S.; Xue, X. Current Status and Future Prospects of Key Technologies in Variable-Rate Spray. Agriculture 2025, 15, 2111. https://doi.org/10.3390/agriculture15202111

Jiao Y, Sun Z, Jin Y, Cui L, Zhang X, Wang S, Zhang S, Chang C, Ding S, Xue X. Current Status and Future Prospects of Key Technologies in Variable-Rate Spray. Agriculture. 2025; 15(20):2111. https://doi.org/10.3390/agriculture15202111

Chicago/Turabian StyleJiao, Yuxuan, Zhu Sun, Yongkui Jin, Longfei Cui, Xuemei Zhang, Shuai Wang, Songchao Zhang, Chun Chang, Suming Ding, and Xinyu Xue. 2025. "Current Status and Future Prospects of Key Technologies in Variable-Rate Spray" Agriculture 15, no. 20: 2111. https://doi.org/10.3390/agriculture15202111

APA StyleJiao, Y., Sun, Z., Jin, Y., Cui, L., Zhang, X., Wang, S., Zhang, S., Chang, C., Ding, S., & Xue, X. (2025). Current Status and Future Prospects of Key Technologies in Variable-Rate Spray. Agriculture, 15(20), 2111. https://doi.org/10.3390/agriculture15202111