1. Introduction

Although the concept of sustainable development has undergone various developmental phases since its introduction [

1,

2], ensuring basic needs and the quality of life for all is now widely recognized as one of the key elements or core principles of this concept [

2]. Hence, achieving food security and promoting sustainable agriculture are among the main targets of sustainable development goals worldwide [

3]. Cropland resources are crucial for ensuring food security and promoting the development of sustainable agriculture [

4,

5]. In particular, how to utilize the limited cropland to produce sufficient agricultural products and feed a large population is a grand challenge for China. On the other hand, within the context of large-scale emigration of rural labor, how to cope with the resulting seasonal shortage of agricultural labor, rising wages, and soaring agricultural production costs is another major challenge for China’s goal to achieve sustainable agriculture.

It is well known that displacing scarce and costly labor with mechanical technology is an effective way to tackle the latter challenge [

6]. As a result, the productivity impact of agricultural mechanization in terms of labor savings has long been thoroughly discussed by economists [

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20]. However, few scholars have recognized that the use of labor-displacing machinery in agriculture can also help address the previous challenge by augmenting aggregate area [

21,

22]. This suggests that agricultural mechanization has become an important lever for the sustainable development of agriculture in China and other developing countries.

1.1. Literature Review

The current literature discovers three specific paths for agricultural mechanization to increase aggregate area (see

Table 1). The first path involves farms/farmers extending into fallow/abandoned/reclaimed land with the adoption of machinery technology (Pingali, 2007) [

21]. Two empirical studies suggest that agricultural machinery operation services significantly decrease both farmers’ probability of cropland abandonment and the proportion of the area of abandoned cropland in rural China [

23,

24]. The second path stems from replacing draft animals with machinery. Olmstead and Rhode (2001) [

22] point out that the adoption of tractors essentially leads to land augmentation by enabling farmers to convert land previously used to feed draft animals into land for producing food and fiber for human consumption. The USDA (1962) [

25] estimates that during the 1880 to 1920 period, the released land in the USA in the process of displacing draft animals (horses, mules, etc.) with tractors was roughly equal to two-thirds of the total cropland harvested in 1920 in the territory of the Louisiana Purchase. The last path involves increased farming intensification, where joint mechanization helps farmers optimize their farming time by ensuring that harvesting the previous crop and preparing for the next crop are completed within a narrow time window (Pingali, 2007) [

21]. Juarez and Pathnopas (1983) [

26] find evidence that rice cropping intensities have increased significantly from the joint mechanization of land preparation and threshing, especially in humid, tropical Southeast Asia.

To sum up, the previous research has detected two general paths for agricultural mechanization to augment aggregate area, namely increases in the effective stock of cropland and increases in farming intensity. The former includes the specific path 1 and path 2 and refers to increasing the area of farmland that actually yields products for human consumption. The latter only includes the specific path 3 and represents the increase in total crop cultivation area by intensified farming. These findings highlight and prove the positive and significant role of agricultural mechanization in enhancing agricultural productivity through aggregate area augmentation.

1.2. Research Questions and Contributions

Agricultural mechanization is a dynamic process accompanied by an increasing number of production stages involved in mechanical technology adoption and by increasing varieties of machinery being harnessed. Hence, in this process, some fresh aggregate area-expanding paths may emerge. Within the current process of agricultural mechanization in China, machinery rice transplanting (MRT) is one of the fastest progressing links. Over a long period in the past, MRT has been a limitation in China’s agricultural mechanization. In this context, the Chinese government has paid great attention to this issue and promulgated a series of policies. For example, the “14th Five Year Plan for National Agricultural Mechanization Development” emphasized the importance and urgency of the mechanization of rice cultivation and proposed a goal that the mechanization rate of rice cultivation achieves 65% by 2025. The “National Plan for Modern Facility Agriculture Construction (2023–2030)” specifies that in the Yangtze River Basin and major double-cropping rice-producing counties in southern China, about 6000 early rice CRSC centers will be built. Thanks to these supporting policies, the national adoption level of MRT technology has reached a higher stage recently. According to the data published in the China Agricultural Machinery Industry Yearbook, the inventory of rice transplanters increased to about one million units, and the proportion of the sown area of rice transplanted by machinery amounted to 55.8% in 2022.

Production implementation has shown that the transformation of seedling cultivation methods brought about by MRT has a positive significance in increasing aggregate area. The following quote is taken from a recent government news report (

https://www.moa.gov.cn/xw/qg/202304/t20230428_6426565.htm) (accessed on 30 September 2024). The excerpt from the report describes the situation we want to discuss and is typical of the southern rice-cultivating region.

In Santai County, Mianyang City, Sichuan Province, the traditional decentralized rice seedling cultivation used to occupy a large amount of arable land. While after the adoption of modern centralized rice seedling cultivation matched with machinery rice transplanting, the county has saved about 10% of the arable land for rice field production, achieved an expansion of nearly 2.7 thousand hectares of planting area for summer crops, and increased grain and rapeseed production capacity by more than 15 thousand tons.

This case demonstrates that centralized rice seedling cultivation (CRSC) can increase aggregate area by replacing and saving traditional seedling fields. This is a fresh aggregate area-expanding path spurred by a new type of machinery in a new production stage that has never been discussed in the extant literature. However, the aggregate area expansion mechanism of machinery rice transplanting and centralized rice seedling cultivation (MRT and CRSC) in practice is still a black box to be uncovered. In addition, determining the extent to which promoting this mechanical technology can increase the macro total crop cultivation area and production capacity is another issue that needs to be addressed. Answering these questions is of great significance for ensuring food security and promoting sustainable agriculture. This article focuses on tackling the above two issues.

Compared with the previous studies, there are mainly three marginal contributions of our study. First, we find the fourth specific path for agricultural mechanization to increase aggregate area. That is seedling field saving and farming time releasing in that saved field. This specific path belongs to the second general path and is different from the previous third specific path. This fresh path is triggered by a new process of mechanization in rice production, namely MRT and CRSC. Second, we propose several innovative concepts, such as the supply efficiency of seedlings, the space utilization efficiency of seedling field, the land use coefficient, and the seedling field saving rate, which are significant for detecting MRT and CRSC’s aggregate area expansion mechanism and estimating aggregate area expansion effects. Third, we put forward specific methods and steps for estimating the aggregate area expansion effects of MRT and CRSC.

The main objective of this study is twofold: unveiling the aggregate area expansion mechanism of MRT and CRSC and estimating their aggregate area expansion effects. This article is organized as follows.

Section 2 describes the research method and data.

Section 3 presents a technical comparison of two rice seedling cultivation methods.

Section 4 discusses the aggregate area expansion mechanism of MRT and CRSC.

Section 5 and

Section 6 present the estimation of the micro and macro aggregate area expansion effects of MRT and CRSC.

Section 7 concludes.

2. Materials and Methods

This article uses the case study approach. This approach lends itself to an in-depth dissection of the intermediate mechanism for MRT and CRSC to augment aggregate area through in-depth interviews and actual observation. Additionally, it helps to accurately estimate the micro land-augmenting effect. The steps of the approach are as follows:

Step 1: Define the research questions. To achieve the main research goal, we defined the following four open-ended questions: (1) What are the technical specifications (including related facilities and equipment) of the specific rice seedling cultivation method? (2) How much is the efficiency of rice seedling cultivation in terms of seedling field utilization? (3) How can CRSC lead to aggregate area expansion when displacing the traditional seedling method? (4) To what extent can a CRSC center bring about aggregate area expansion within a year?

Step 2: Case selection. We chose two cases in Jiangxi Province, characterizing two different rice seedling cultivation methods, namely the traditional rice seedling method and CRSC. These two methods are suitable for manual rice transplanting and MRT, respectively. Jiangxi Province is currently one of the most important provinces in China producing double-cropping rice. According to statistical data, the proportion of machinery rice transplanting area in Jiangxi Province reached 41% in 2022. According to an official news report, Jiangxi Province had built 827 CRSC centers by 2023 (

http://nync.jiangxi.gov.cn/art/2024/3/5/art_27873_4804947.html) (accessed on 7 October 2024). As a result, Jiangxi Province has the typicality for our research.

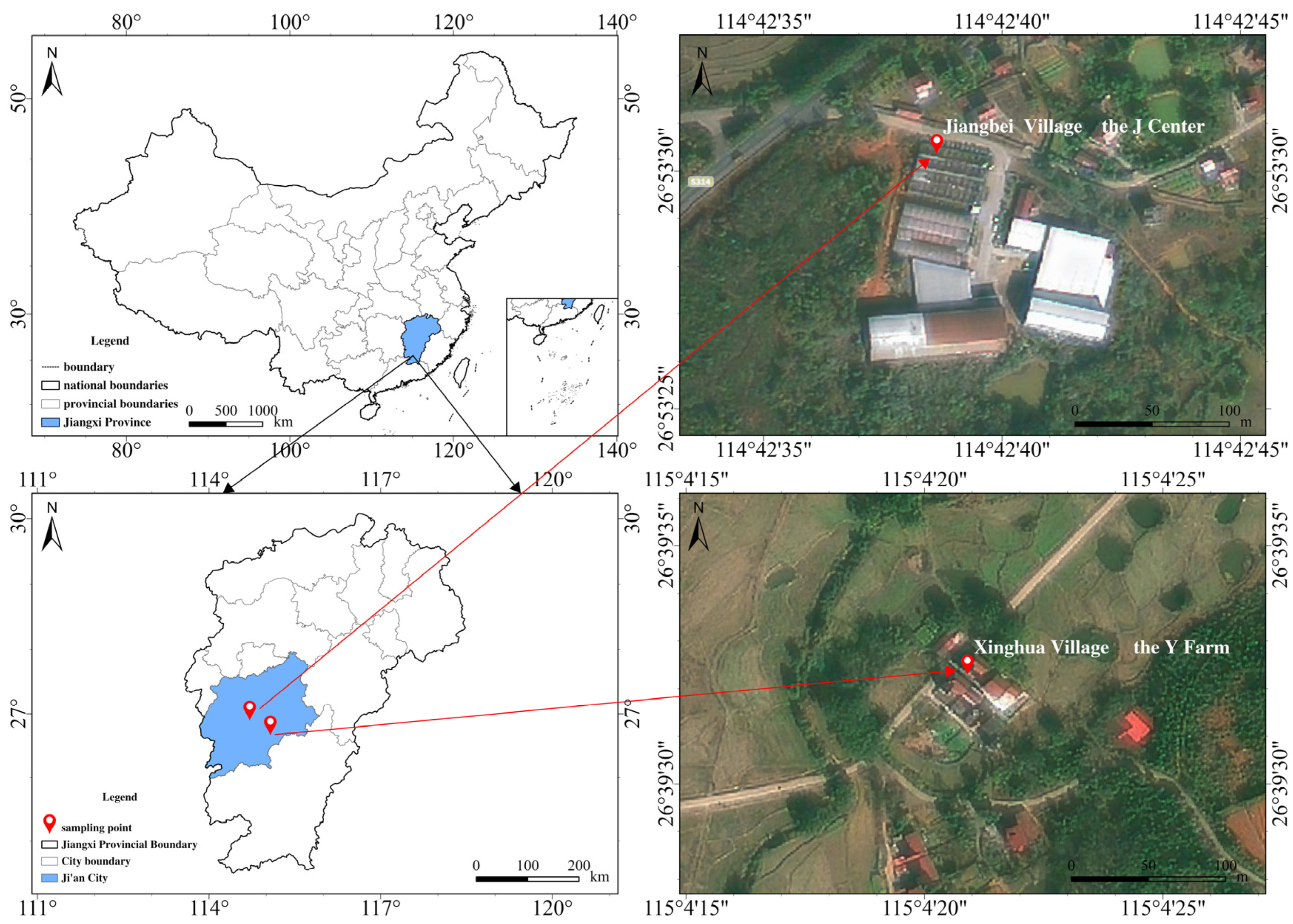

We chose the J CRSC Center (hereinafter referred to as the J Center) and the Y Farm as our specific cases (see

Figure 1). They are both located in Taihe County, a National Commercial Grain Base County. The J Center was established in 2017 and belonged to the J Agricultural Machinery Professional Cooperative, which was previously awarded the title of National Excellent Demonstration Cooperative. The J Center is one of the representative CRSC centers because of its relatively mature technique and large service scale. The person in charge went to Guangdong province in 2015 to study the CRSC technique and has been providing local CRSC services in Taihe County since 2017 with continuously upgraded equipment and constantly improving management experience. Until now, this center has constructed two semi-automatic seedling cultivation and sowing production lines. It has also been equipped with other essential sophisticated facilities, such as darkening germination rooms, enabling it to provide CRSC services to large-scale farms located in over 10 surrounding towns. In 2023, the sown area of rice served by the J Center amounted to 815 hectares. Hence, the J Center can provide us with technological details for land utilization in MRT and CRSC.

Currently, the main adopters of MRT technology in China are large-scale farms, and they are the primary customers of the CRSC centers. In other words, the targets displaced by CRSC technology are traditional seedling techniques used on large-scale rice planting farms. The Y Farm is one of the representative farms because of its farming scale and long practices in traditional rice seedling cultivation. The Y Farm was established in 2011 in another town, which is 36 km in terms of straight-line distance away from the town where the J center is located. In 2023, the Y Farm managed 143 hectares of arable land, most of which was used for rice plantation. Since a decade ago, the Y farm has been using the traditional seedling cultivation method and manual transplanting methods in its rice production. This allowed us to detect the land occupation parameters of the traditional way of rice seedling cultivation and transplantation. As a result, the Y Farm has typicality for the traditional seedling model in Jiangxi Province, as well as the southern rice growing regions.

Step 3: Data collection. In brief, there were three main ways to collect data for this study. First, we mainly interviewed the persons in charge of the J Center and the Y Farm through in-depth interviews about the primary information we needed. This information includes the supplied field area, the process of rice seedling cultivation, the corresponding facilities and equipment, and the land use of rice seedlings. Second was direct on-site observation. Specifically, participatory observation—the surveyors participated in the J Center’s and the Y Farm’s rice seedling cultivation production activities—was used to gather supplementary information. Third, for typical rice seedling cultivation plots, we used a tape measure to gauge their lengths and widths. In March and April 2024, we conducted two specialized field surveys at the J Center and the Y Farm.

Step 4: Case studies. Based on the above data and materials, we first compared these two typical cases and identified the technical differences between the two seedling cultivation methods. Then, we detected the intermediate mechanism for MRT and CRSC to augment aggregate area and estimate the aggregate area expansion effect of MRT and CRSC. As for the estimation method of aggregate area augmentation effects, a detailed description is provided in

Section 5 and

Section 6.

3. Comparison of Technical Levels of Two Rice Seedling Cultivation Methods

The technical difference between the two rice seedling cultivation methods mainly lies in the types of seedlings, seedling cultivation stages, the field of production activity, facilities and equipment, and the specific seedling cultivation technique (see

Figure 2).

First, the type of seedlings is different. Traditional seedling cultivation mainly cultivates relatively strong seedlings suitable for manual transplanting or throwing, with relatively long seedling ages generally requiring 30 to 40 days. CRSC is a typical model of the integration of agricultural machinery and agronomy. It mainly cultivates seedlings suitable for mechanical transplanting. The age of mechanically transplanted seedlings is relatively shorter than their traditional counterpart, and the required time of mechanically transplanted seedlings is generally 18 to 25 days.

Second, there are slight variations in the seedling cultivation stages. Although the entire physiological processes from rice seeds to seedlings between the two methods are almost the same, there are still certain discrepancies in their seedling stages. For instance, the Y Farm divides seedling cultivation into five major stages: soaking, germination, sowing, seedling care, and seedling lifting. At the J Center, there are relatively more seedling stages, including soaking, breast breaking, sowing, germination, seedling training, and seedling lifting. Among them, the three stages of soaking, sowing, and seedling lifting have the same meaning in both methods. The breast-breaking stage of CRSC is equivalent to the germination stage of the traditional method, while the germination stage of CRSC is an independent stage immediately after breast breaking and sowing. The stage of seedling training after germination (a specialized term for CRSC) has a similar meaning to the stage of seedling care for the traditional method.

Third, the venues for seedling production activity are varied. Traditional seedling cultivation does not require dedicated sites for soaking and germination and can be carried out in places such as the farmers’ courtyards. When the germination is completed, the Y Farm sows the germinated rice seeds into the seedling tray that has been placed in the seedling field in advance. Then, the subsequent seedling care and seedling lifting will be carried out in the seedling field. Due to the large scale and the need for a series of supporting facilities and equipment, the J Center has invested in the construction of a dedicated sowing and emergence workshop, where soaking, breast breaking, sowing, and germination operations are conducted. To ensure the smooth and precise operation of facilities and equipment, the ground of the sowing and seedling workshop needs to be hardened (damaging the surface layer of the land). When germination is completed, the seedling tray is sent to the seedling field to be placed and trained until seedling lifting.

The biggest difference between these two methods is their divergencies in facilities, equipment, and production techniques. In the entire production process, traditional seedling cultivation is mainly carried out manually, supplemented by several low-cost and simple facilities. The Y Farm uses simple containers such as plastic buckets to soak and package rice seeds in breathable special bags. After soaking, the rice seeds are placed in a warm and humid place in the courtyard for germination. In early rice seedling cultivation, to cope with the shock of low-temperature freezing weather, the Y Farm sets up simple plastic sheds in the seedling fields. In contrast, the J Center displaces a large amount of manual labor with high-tech and costly equipment. Only a few operations need supplementary hand labor. The soaking pool, darkening germination room, sowing production line, and forklift are supporting facilities and equipment for the sowing and emergence workshop. To improve the seedling training efficiency and reduce labor costs, the J Center modernizes the seedling fields by laying sprinkler pipes and nozzles, transporting seedling trays in the seedling plots, and setting up plastic greenhouses for early rice seedling cultivation as well.

4. The Intermediate Mechanism by Which MRT and CRSC Increases Aggregate Area

4.1. The Mechanism for CRSC to Replace and Save Traditional Scattered Seedling Fields

Compared with the Y Farm, the J Center’s CRSC technology substitutes and saves a number of traditional seedling fields through two separate paths. The first path is to improve the supply efficiency of seedlings. Compared with the traditional method, the number of seedling trays per unit supplied paddy field required by CRSC decreases dramatically, and so does the corresponding occupied seedling field area. The second path is to improve the space utilization efficiency of seedling fields, that is, to increase the number of standardized seedling trays placed in the same area of the seedling field.

CRSC enhances the supply efficiency of seedlings through two subpaths: increasing sowing density and improving the germination and survival rate of rice seeds. The root cause of an increase in sowing density for CRSC lies in the transition of seedling type. Compared with the traditional method, the higher seeding density in CRSC is due to the shorter age and specifications of mechanically transplanted seedlings. The seeding density of the two methods can be reflected by the amounts of seeds per seedling tray. At the J Center, 30 seedling trays can be sown with 1.5 kg early hybrid rice seeds and 35 seedling trays with 4–5 kg early conventional rice seeds. Meanwhile, at the Y Farm, 65 seedling trays can be sown with 1.5 kg early hybrid rice seeds or 4–5 kg early conventional rice seeds. The intelligent temperature and humidity control technology used in the darkened germination room and the precise sowing technology of the sowing production line work together to greatly improve the germination and survival rate of rice seeds. The germination and survival rate of rice seeds at the J Center is generally above 90%, while at the Y Farm, it is usually only 70%. The increase in sowing density enables the unit seedling tray to embrace greater seedling supply potential. The increase in germination and survival rate of rice seeds results in a greater proportion of conversion from the seedling supply potential of every seedling tray into the actual seedling supply capacity. Therefore, compared with the traditional method, every paddy field supplied by CRSC requires fewer seedling trays and occupies less seedling field area.

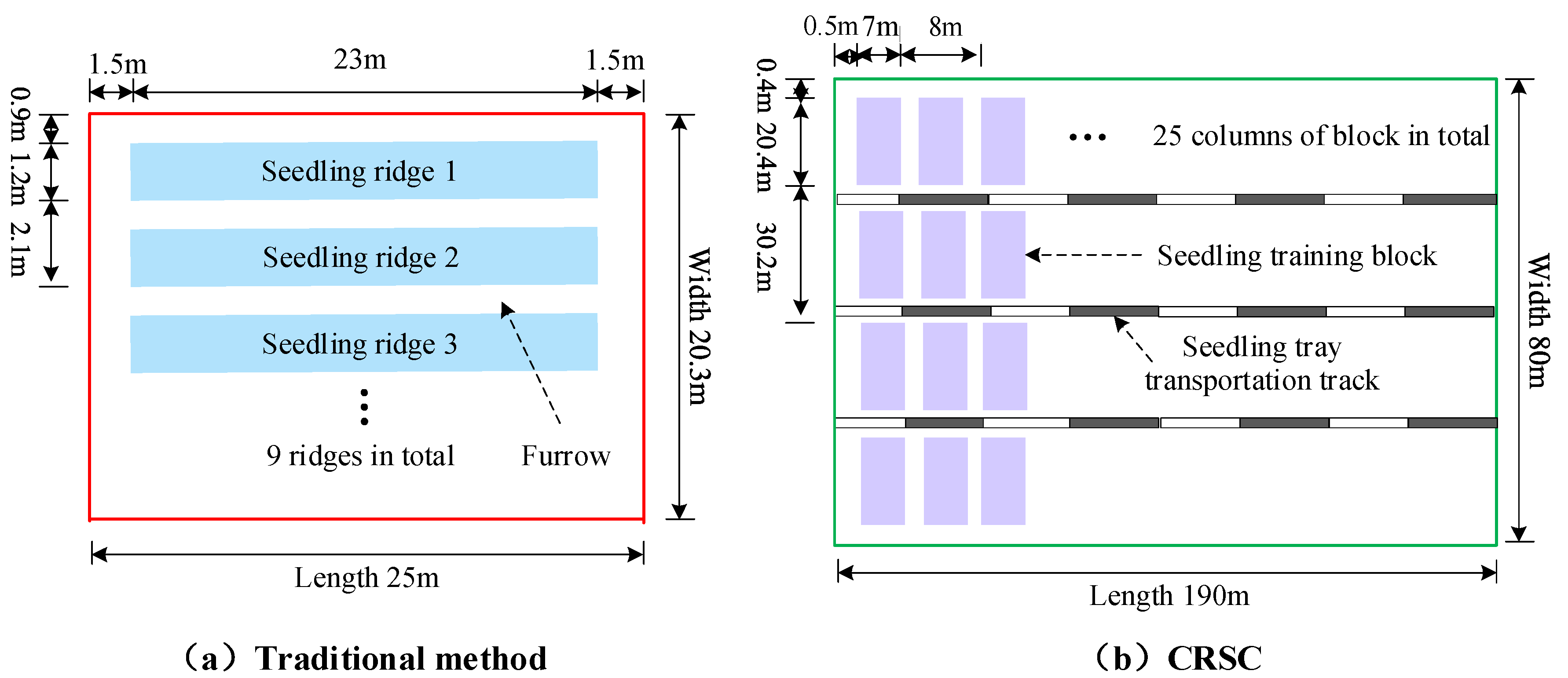

With the introduction of advanced facilities and equipment, as well as the adjustment of operation venues, CRSC effectively improves the space utilization efficiency of seedling field. In order to facilitate the laborer’s entry into the seedling field and ensure water storage management, the Y Farm leaves a 0.9-m-wide furrow between every two seedling ridges in the seedling field (see

Figure 3a). The ridges, ditches, and other unavoidable empty spaces reduce the actual area to place seedling trays, thereby lowering the space utilization efficiency of seedling fields. At the J Center, the stages from soaking to germination are completed in the sowing and emergence workshop. During the later stage of seedling training, the J Center mainly relies on automated sprinkler irrigation equipment to transport water, fertilizer, and medicine. This eliminates the separate manual workspace. The J Center has installed sprinkler irrigation pipes and seedling tray transportation tracks in the seedling fields (see

Figure 3b). However, the area occupied by these facilities is much smaller than the furrow area at the Y Farm.

In summary, CRSC significantly improves the supply efficiency of seedlings and the space utilization efficiency of seedling fields. This, in turn, substitutes and saves a large number of traditional dispersed seedling fields with relatively fewer modern seedling fields when large-scale farms abandon the traditional seedling method and switch to purchasing mechanically transplanted seedlings from the local CRSC centers.

4.2. The Transmission Mechanism from Seedling Field Saving to Aggregate Area Expansion

Both seedling cultivation methods require a certain amount of vegetal time to ensure the ultimate seedlings meet the transplanting standards. The seedling field can normally have the seasonal rice planted when seedling cultivation is complete, although the seedling cultivation activities inhibit the plantation of the previous crops in the same plot. This is because the farming time of the potential previous crop conflicts with that of rice seedling cultivation. In other words, if a plot is used for rice seedling cultivation, the potential previous crops (such as wheat, oilseed rape, etc.) on it cannot be normally harvested since the crops are not yet mature when the seedling cultivation activities begin. As a result, rice seedling cultivation occupies both the space and the farming time for the potential previous crops.

Under multiple cropping circumstances, when a traditional seedling plot is displaced and saved by CRSC, the previously occupied farming time is released, and farmers can plant the previous crop on it thereafter. This increases the farming intensity of the saved traditional seedling field and thus broadens the farmers’ total planting area. Since CRSC can supply the same area of paddy field at the cost of occupying less seedling field, the development of MRT and the substitution of the traditional seedling method with CRSC results in aggregate area augmentation by increasing the net total area of the previous crop(s). The augmented aggregate area is equal to the subtraction of the area of modern seedling fields from the total area of saved traditional seedling fields.

If rice–wheat (oilseed rape) rotation or double-cropping rice is implemented locally, the traditional seedling fields saved by CRSC can be planted with wheat, oilseed rape, or early rice as the previous crop(s), without delaying the planting of the current-season rice, whereas under the monoculture planting system of rice in one season, there is no potential previous crop in the seedling field plot. Under such circumstances, CRSC poses no effect on increasing the net total planting area of the previous crop(s), even though it saves a lot of seedling fields. Therefore, aggregate area expansion only takes place with the combination of saving the traditional seedling fields by CRSC and the implementation of a multi-crop rotation system on the saved plots.

In summary, we find the fourth specific path for agricultural mechanization to augment aggregate area. That is, the adoption of MRT and CRSC technology displaces and saves a large number of traditional seedling fields. This specific path belongs to the second general path since the farming intensities of the saved traditional seedling fields are enhanced, thanks to the release of farming time for the previous crop(s) by CRSC.

5. Microscopic Measurement of Aggregate Area Expansion Effect of MRT and CRSC

5.1. Measurement Methods

The supply efficiency of seedlings for the two methods can be expressed by the footprint of the seedling tray required per unit of paddy field:

where

represents the seedling cultivation method, and 1 for the traditional way, 2 for CRSC. The type of rice is indexed by

, and 1, 2, 3 are for early rice, middle rice, and late rice, respectively.

represents the required area of seedling trays per unit of paddy field. The smaller the value of

, the higher the supply efficiency of seedlings.

and

represent the length and width of a single seedling tray, respectively.

represents the number of seedling trays required per unit of paddy field.

The space utilization efficiency of seedling fields for the two methods can be expressed by the proportion of the actual area occupied by seedling trays to the total area of the seedling field:

where

represents the space utilization efficiency of seedling fields.

represents the actual number of seedling trays that can be placed in the seedling field.

represents the area of the seedling field.

represents the area occupied or left vacant by other facilities. The area of the seedling field plot

is equal to the sum of the area occupied by the seedling tray and the area occupied by other facilities or vacant area.

The land use coefficient of the two methods is defined as the required seedling field area per unit of paddy field in a single season. It can be expressed as the ratio of the supply efficiency of seedlings to the space utilization efficiency of seedling fields:

where

represents the land use coefficient (between 0 and 1). The larger the value of

, the larger the required area of the seedling field per unit of paddy field. The expected land use coefficient of CRSC is lower than that of the traditional method. The seedling field saving effect of CRSC (referred to as seedling field saving rate) can be expressed as

where

represents the seedling field saving rate of CRSC. Its specific meaning is the net area of the seedling field saved by CRSC per unit served paddy field.

represents the land use coefficient of traditional seedling cultivation, while

represents that of CRSC. The total area of seedling field saved by a single CRSC center during a single season can be expressed as

where

represents the total area of the saved seedling fields.

represents the total area of paddy field served by a CRSC center in the current season. The aggregate area expansion effect can be expressed as

where

represents the augmented aggregate area.

represents the land adjustment coefficient for the

j-th type of rice, that is, whether the current-season seedling cultivation activities prohibit the plantation of the potential previous crop. For early rice,

= 0 (the plots are generally winter fallow before plantation of early rice), and for both mid rice and double late rice,

= 1 (the plots can theoretically plant other crops before the current-season rice).

represents the expected direction of cropping patterns in the saved traditional seedling plot when it is no longer used for rice seedling cultivation.

is equal to 0 when the expected cropping pattern is monoculture and is equal to 1 for the rotation cropping pattern. The expanded crop production capacity by CRSC can be expressed as

where

represents the expanded crop production capacity,

represents the potential average yield of the previous crop(s).

5.2. Measurement Results

Based on the survey data of the J Center and the Y Farm, this article estimates the aggregate area expansion effect of CRSC at the J Center.

Table 2 shows that the number of seedling trays required per unit of paddy field at the J Center is more than half that of the Y Farm, resulting in a significant improvement in the supply efficiency of seedlings. For early rice, the total area of seedling trays required per hectare of paddy field at the J Center is only 67.5 m

2, which is one-third of that of the Y Farm. For mid and late rice, this indicator at the J Center decreases to 60.75 m

2, while for the Y Farm, it is as high as 180.90 m

2. Compared with the traditional method, CRSC increases the supply efficiency of seedlings by 2/3.

According to the various indicators of the plot depicted in

Figure 2, the space utilization efficiency of the typical seedling plot at the J Center reaches 89.47%, while the Y Farm is only 48.95%.

For typical plots, the land use coefficient for early rice at the J Center is 0.008, suggesting that the required seedling field area for every hectare paddy field is 0.008 hm2. This indicator at the Y Farm is 0.040, indicating that 0.040 hm2 of seedling field is needed when supplying 1 hm2 paddy field. The average land use coefficients for early rice, middle rice, and late rice at the J Center are 0.010, 0.009, and 0.009, respectively, while for the Y Farm, they are 0.050, 0.047, and 0.047, respectively. Therefore, if the Y Farm chooses to abandon traditional seedling cultivation and purchase mechanically transplanted seedlings from the J Center, they can save about 80% of the total seedling fields all together.

Table 2 further calculates the seedling field saving rates of CRSC based on Formula (4). The results show that the seedling field saving rates for early rice, mid rice, and late rice at the J Center are 0.040, 0.038, and 0.038, respectively. This indicates that CRSC can save 0.038 to 0.040 hm

2 of traditional seedling fields when serving 1 hm

2 paddy field for a single season of rice.

The market order for CRSC for early rice, middle rice, and late rice at the J Center in 2023 is 154 hm2, 487 hm2, and 174 hm2, respectively. It can be further calculated that the total area of seedling fields saved by CRSC in early rice, middle rice, and late rice production is 6.16 hm2, 18.51 hm2, and 6.61 hm2, respectively. If the released traditional middle rice seedling plots implement a rice–rapeseed rotation system thereafter, and late rice seedling plots the double rice cropping system, then the J Center can increase by 18.51 hm2 and 6.61 hm2 the aggregate area by CRSC in middle rice and late rice production, respectively. This is equivalent to increasing the production capacity of previous crops, oilseed rape and early rice, by 26.94 tons and 37.65 tons, respectively.

One can observe that under the rotation cropping system, increasing the land use coefficient of CRSC and expanding the service scale can release more traditional seedling plots, thereby augmenting more aggregate area for planting previous crops (especially grain) locally. This, in turn, brings about a further chain effect of expanding the production capacity of the previous crops and thus increasing the farmers’ income.

6. Macroscopic Simulation of Aggregate Area Augmenting Effect of MRT and CRSC

6.1. Indicators and Data

One of the basic indicators required to predict and simulate the macro aggregate area expansion effect of MRT and CRSC is the area of cropland implementing different cropping patterns. These patterns include rice–wheat rotation systems, rice–other crop (including oilseed rape) rotation systems, and double-cropping of rice, among others. A previous study shows that the area of cropland implementing rice–wheat rotation system in China is approximately 6 million hectares [

27]. These croplands mainly concentrate in such provinces as Jiangsu, Anhui, Hubei, Sichuan, and Henan. According to the data reported in the China Rural Statistical Yearbook, the area of cropland implementing continuous cropping of double-season rice in China in 2022 was 5.1 million hectares, mainly concentrated in Jiangxi, Hunan, Guangdong, and Guangxi Provinces.

There is no direct statistical data for the area of cropland implementing rice and other crop rotation systems in southern China. We use relevant indicators to estimate it. In theory, we assume most of the paddy fields in southern China can implement rice-centered rotation systems. We then take the difference between the sowing area of middle rice and single-season late rice in the southern region in 2022 and the area of cropland implementing rice–wheat rotation as an estimate of the potential area implementing a rice–other crop rotation system.

The second basic indicator required is the average yields of the previous potential crops. We estimate them by dividing the total production of the crop by its total sown area. The relevant provincial-level data are gathered from the 2023 China Rural Statistical Yearbook. The results of the corresponding indicators are listed in

Table 3.

6.2. Simulation Method

We can simply simulate the aggregate area expansion effect of MRT and CRSC by sequentially changing the values of two key indicators at the national level. They are the seedling field saving rate and the adoption rate of MRT technology (equals the proportion of paddy field served by CRSC). The latter indicator ranges from 0 to 1, and the larger the value, the higher the adoption rate. We use the following formula to simulate the aggregate area expansion effect under a given planting system:

where

c represents the type of cropping patterns, and specifically, 1 denotes rice–wheat rotation, 2 rice and other crop rotation, and 3 double-cropping rice.

represents augmented aggregate area brought about by CRSC.

represents the area of cropland implementing relative cropping patterns (corresponding to column 2 of

Table 3).

represents the seedling field saving rate of CRSC.

represents the adoption rate of MRT technology. The crop production capacity expansion effect of CRSC can be expressed as

where

represents the expected increased amount of production of previous crops.

represents the average yield of the previous crops (corresponding to column 3 of

Table 3).

According to the typical case in Sichuan Province introduced earlier, CRSC in a rice–wheat (oilseed rape) rotation system can save 10% of the paddy field, suggesting a seedling field saving rate of 0.1. In this situation, the land use coefficient of the traditional seedling method is above 0.1. Our estimation on this indicator for the J Center is around 0.04. In view of this, we set the range of variation for the seedling field saving rate between 0.01 and 0.10 and set the range of variation for the adoption rate of MRT technology between 0.1 and 1.0. When the adoption rate is equal to 1, all paddy fields are mechanically transplanted with CRSC seedlings.

6.3. Simulation Results

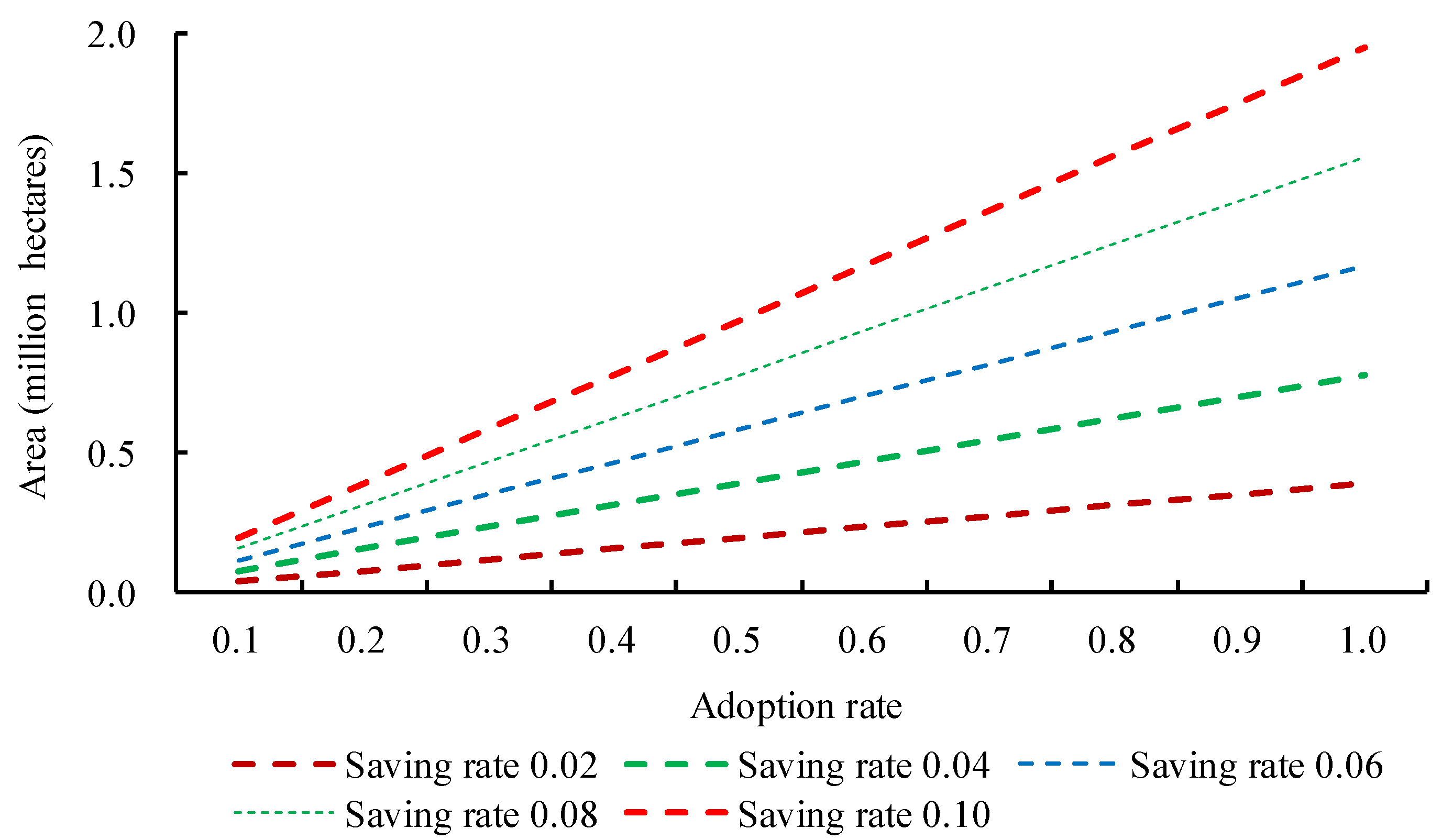

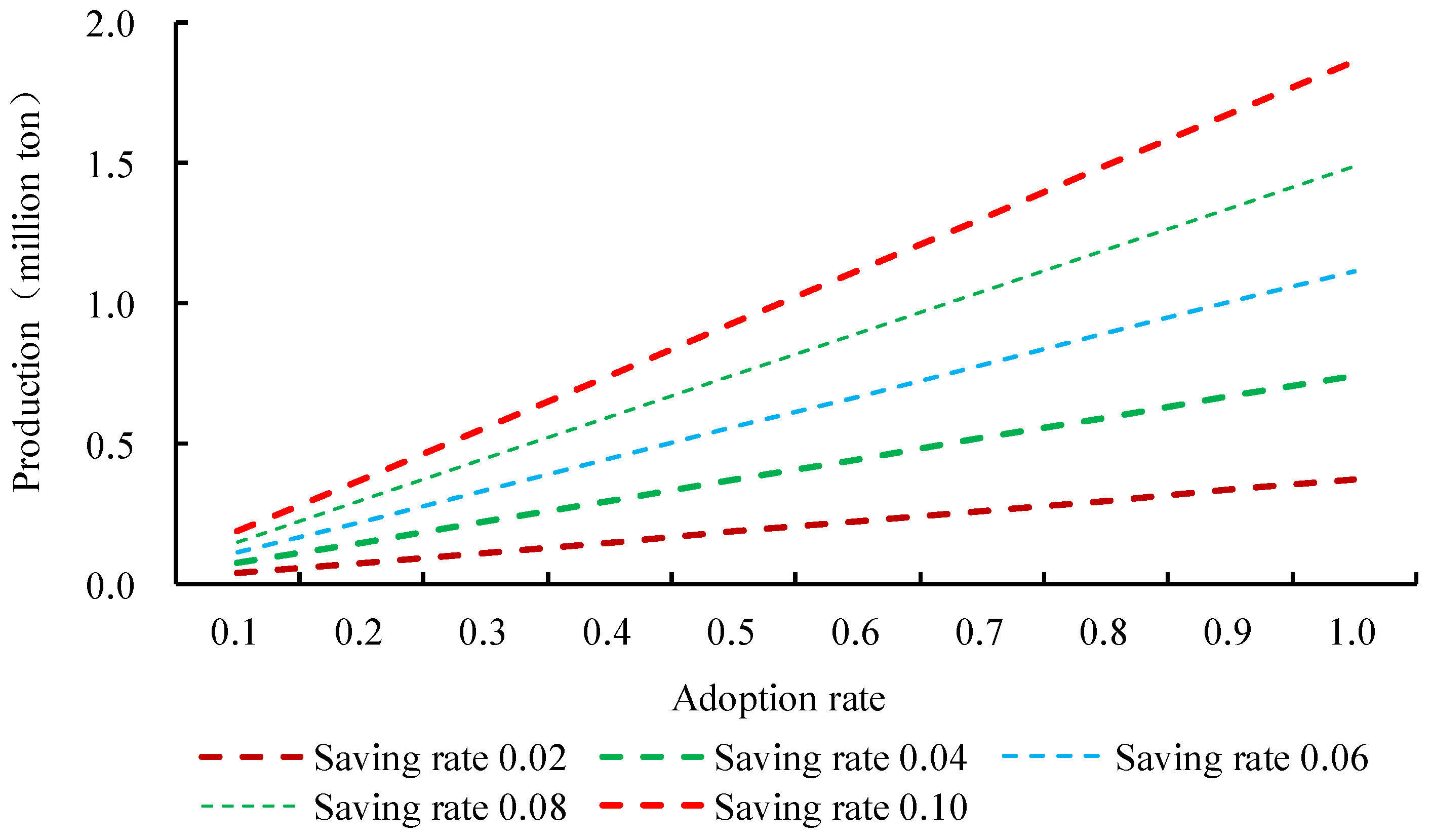

Figure 4,

Figure 5 and

Figure 6 report the simulation results. The results suggest the following pattern: First, if the seedling field saving rate remains unchanged, the increasing adoption of MRT significantly enhances aggregate area expansion effects. Second, the higher the seedling field saving rate, the greater the marginal increase in aggregate area and crop production capacity brought about by each unit increase in the adoption rate of MRT. Third, if the adoption rate of MRT remains unchanged, the increase in seedling field saving rate will promote a surge in aggregate area expansion effects. Fourth, the higher the adoption rate of MRT, the greater the marginal increase in aggregate area expansion effect caused by each unit increase in seedling field saving rate.

We then define two scenarios. In the high-value scenario, we assume all paddy fields adopt the MRT technology (the adoption rate of MRT amounts to 1.0), and the seedling field saving rate is as high as 0.1, whereas in the middle-value scenario, we assume the adoption rate of MRT and seedling field saving rate equals 0.5 and 0.05, respectively.

Figure 4 shows that under the high-value scenario, CRSC can increase aggregate area by 1.9 million hectares nationwide, equivalent to 1.62% of the total farmland in China. Within the middle-value scenario, CRSC can lead to an increase in aggregate area by 0.5 million hectares.

Figure 5 indicates that under the high-value scenario, CRSC can increase the previous grain production capacity by 6.21 million tons nationwide. If the middle-value scenario is achieved, CRSC can increase the production of previous grain by 1.55 million tons nationwide.

According to

Figure 6, under the high-value scenario, CRSC has the potential to increase the national production of rapeseed by 1.86 million tons, equivalent to an 11.98% increase on the basis of 2022. If the middle-value scenario becomes a reality, CRSC can help to expand rapeseed production by 0.5 million tons nationwide, equivalent to increasing rapeseed production by 2.99% based on 2022.

7. Discussion and Conclusions

Previous studies have found three specific and two general paths for agricultural mechanization to augment aggregate area [

21,

22,

23,

24,

25,

26]. The first general path is an increase in the effective stock of cropland, which includes two specific paths, namely farms or farmers extending into fallow/abandoned/reclaimed land and farmers converting land used to feed draft animals into the production of products for human consumption. The second general path is an increase in cropping intensity, and it covers the third specific path, namely farmers optimizing farming time by finishing harvesting the previous crop timeously and preparing for the next crop within a narrow time window.

To supplement these studies, this article detects a fresh specific path: MRT and CRSC save lots of seedling fields and release the farming time on them for the previous crop(s). This specific path belongs to the second general path because the MRT and CRSC‘s eventual result is an increase in cropping intensity. However, compared with the third specific path, this path only enhances the cropping intensity on those plots previously used for traditional rice seedling cultivation. Besides, compared with the tractor and combined harvester-centered mechanization, this study focuses on the rice transplanter and the CRSC technology. The research results can provide a theoretical reference for the government to promote agricultural mechanization in rice production, to promote aggregate crop cultivation area, and to achieve food security.

Employing and contrasting case materials from the J Center and the Y Farm in Jiangxi Province, this study identifies the intermediate mechanisms of MRT and CRSC to augment aggregate area and promote crop production capacity. During this process, we propose several key indicators, such as the supply efficiency of seedlings, the space utilization efficiency of seedling fields, the land use coefficient, and the seedling field saving rate. We also measure and simulate the aggregate area expansion effects at both micro and macro levels.

Our results indicate that CRSC, compared with the traditional method, brings about multiple technological advancements. They include the transformation of seedling type (manual transplanted seedlings to mechanically transplanted ones), the introduction of a series of specialized facilities and equipment (seeding production lines and darkened germination rooms), the adoption of precision seeding and intelligent temperature and humidity control technologies, the construction of specialized seeding and emergence workshops, and the modernization of seedling fields. The technological progress significantly reduces the required area of seedling field per unit of paddy field by improving the supply efficiency of seedlings and improving the space utilization efficiency of seedling fields. Therefore, CRSC can substitute and release a large amount of traditional scattered seedling fields at the cost of fewer modern seedling fields. However, only under the rotations cropping system can CRSC release the farming time of the previous crops in the saved traditional seedling fields. The released farming time makes it possible to cultivate the previous crops. This, in turn, leads to an increase in farming intensity and aggregate area.

In the micro cases, CRSC can save about 0.04 hectares of seedling fields by serving 1 hectare of paddy field in a single season. In macro simulations, CRSC can increase aggregate area by up to 1.95 million hectares nationwide, corresponding to an increase of 6.21 million tons of grain and 1.86 million tons of rapeseed.

There are two theoretical implications of this study. First, our findings suggest that the productivity impacts of agricultural mechanization are characterized by diversity and multi-path. This is largely due to the dynamic characteristic of agricultural mechanization, where production stages increasingly involve the use of machinery, and an increasing variety of new agricultural machinery is being utilized as economic development progresses. Second, this study sheds new light on the complex relationship between capital factors and land factors in agricultural production. The literature on endogenous technology adoption mainly discusses the impacts of land endowments on the adoption of mechanical technology [

28], while few other studies find that the adoption of agricultural machinery technology can, conversely, affect the degree of land use by farmers, namely farming intensity [

21,

26]. Our findings identify a new path to farming intensity by agricultural mechanization.

Under the dual constraints of population pressure and scarce cropland, increasing aggregate crop cultivation area is of great significance for achieving the first and the second Sustainable Development Goals (SDGs), namely “no poverty” and “zero hunger”, in developing countries. Our findings provide a new path to aggregate area expansion and a potential way to battle poverty and hunger as well. In order to convert the aggregate area expansion effects of MRT and CRSC into actual productivity and thus contribute to fulfilling the Sustainable Development Goals, it is necessary to promote MRT and CRSC technology, to resolve the bottleneck problems that restrict its adoption, and to gradually displace the traditional seedling cultivation model. Hence, we propose several policy implications.

First, multiple measures should be taken to promote the dissemination of CRSC in southern rice-growing areas. Based on the subsidy policy for the purchase of agricultural machinery, policymakers can increase the funding support for the construction of CRSC centers and the purchase of corresponding equipment. Besides, it is reasonable to explore cross-regional CRSC technology “transmission and assistance” mechanisms through mutually beneficial cooperation between technologically mature areas and technologically backward areas. The government can encourage service providers in technologically mature areas to take advantage of farming time difference to go out and provide free technology guidance for CRSC in technologically backward areas. In return, those external technical mentors can take over the local MRT service market and obtain corresponding service revenue. In addition, increasing subsidies for MRT and improving the quality of MRT could be beneficial for incentivizing more farms/farmers to purchase MRT services and CRSC services.

Second, it is of great significance to support CRSC centers to expand their service scale, improve their technical and management levels, and thus acquire sustainable business capabilities. At the policy level, it is possible to explore the establishment of precise support projects by targeting the weakest technical link and implementing individual financial support schedules. It is also beneficial to establish a regional agricultural socialized service federation at the county level. This can create a platform for the exchange of operational technology and management experience among CRSC centers and then promote the dissemination and implementation of advanced technologies and management experience.

This study mainly has two limitations, as follows:

- (1)

At the micro level, this study only investigates two cases, and thus, we cannot detect the variations in the land use coefficients between different CRSC centers and between different farms adopting traditional rice seedling cultivation methods as well. Thus, future large-scale field surveys and research based on this foundation are required to explore the local average seedling field saving rate so as to provide a more comprehensive reference for the developing MRT and CRSC technology.

- (2)

At the macro level, our simulation results of aggregate area expansion effects are relatively rough. This is because our parameters, namely the actual adoption rate of CRSC technology and the seedling field saving rate, are generally not precise enough due to data availability. In addition, our simulation method also assumes that all of the paddy fields served by CRSC originally used traditional manual transplanting instead of the direct seeding method. However, in reality, many farms/farmers adopt the direct seeding method to save production costs. This leads to an overestimation of our simulation results. In the future, we need more detailed statistical data on the parameters of MRT and CRSC, as well as the adoption rate of every rice planting method.