Unmanned Agricultural Robotics Techniques for Enhancing Entrepreneurial Competitiveness in Emerging Markets: A Central Romanian Case Study

Abstract

1. Introduction

- Understanding the link between the supply of technological agricultural products and the growing sophistication of agricultural entrepreneurs, who increasingly require innovative, efficient and adaptable technologies in a rapidly evolving agrifood context.

- Analyzing opportunities to increase the competitive advantage of agricultural entrepreneurs in Romania’s Central Region, based on the premise that competitive advantage lies at the core of strategic management research and extends beyond local markets into the regional landscape. Here, competitive advantage—as a conceptual and strategic position—translates into superior value creation compared to competitors. The first-mover advantage becomes accessible through the targeted use of scalable, innovative technologies with high potential to reinforce the precision agriculture market in the region.

- Recognizing knowledge acquisition as an implicit competitive success factor for agricultural entrepreneurs—where competitive success can be measured through increased market share, improved product quality and diversity, and greater technological adaptability. A deeper understanding of regional competition and benchmarking practices facilitates the review and adaptation of both tactical and strategic plans to emphasize the role of innovative technologies in enhancing agricultural productivity and sustainability.

- Combining and integrating new knowledge supports adaptation to the changing dynamics of competition, particularly by aligning technological innovations with the practical needs and expectations of increasingly well-informed and demanding agricultural stakeholders.

- There is currently no research that clearly outlines how KMC—namely acquisition, combination and protection—influence competitive advantage in precision agriculture. This study anticipates the importance of detecting transformation processes, designing effective organizational leverage frameworks and building superior knowledge stocks aligned with technological change and market evolution.

- The literature has limited models that examine the interconnections between KMC operational capabilities and higher-order capabilities—namely adaptive, absorptive, and innovative capacities—and their mediating role in shaping competitiveness within precision agriculture in Romania’s Central Region.

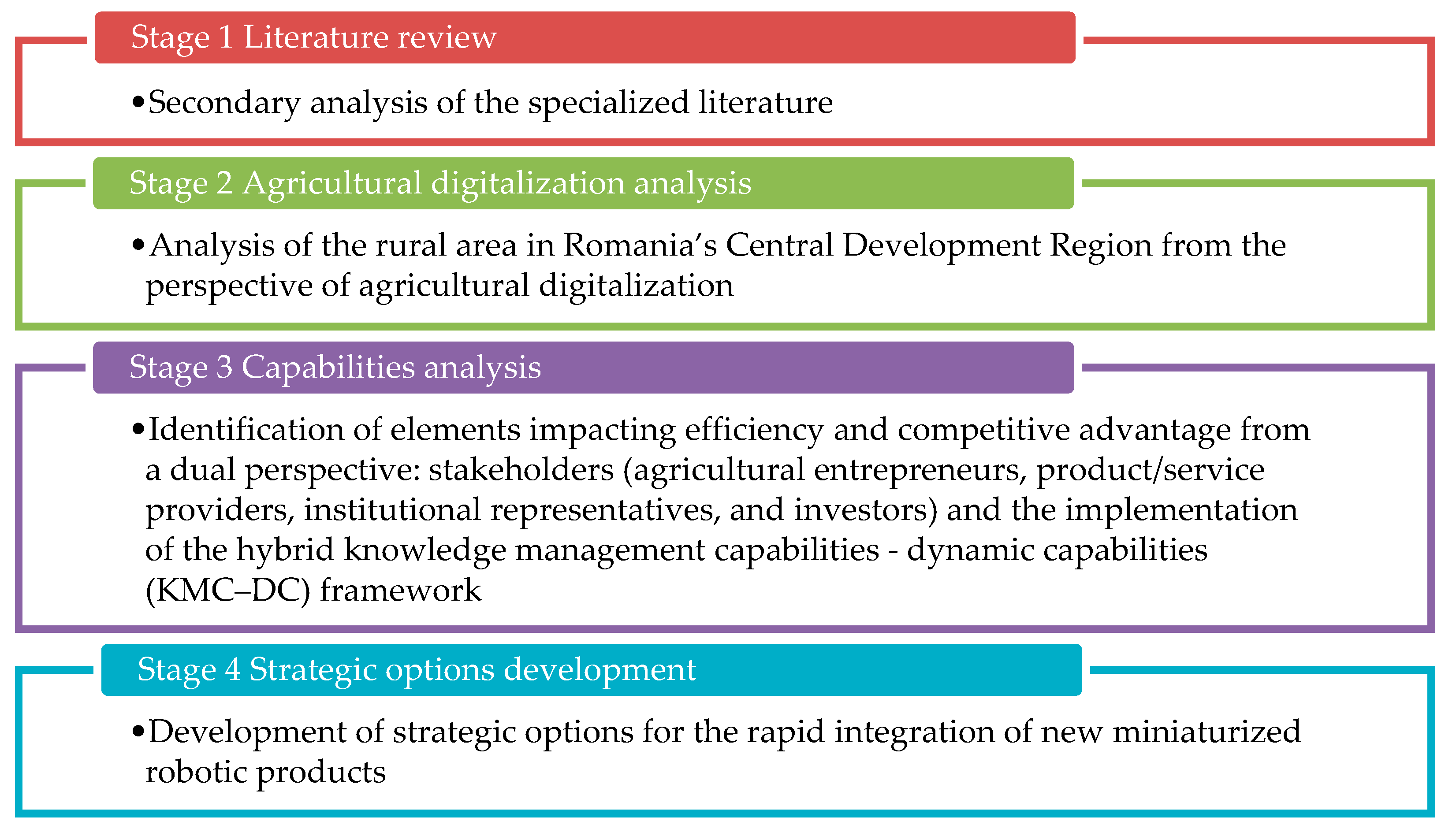

2. Materials and Methods

2.1. Research Method and Representative Sample

2.2. Statistical Analysis

3. Results

3.1. Analysis of the Issues of Interest from the Rural Area in Romania’s Central Development Region—The Perspective of Agricultural Digitalization

3.2. KMC and DC

3.2.1. KMC Operational Capabilities

3.2.2. Higher-Order Dynamic Capabilities (DC)

3.2.3. Organizational Competitiveness in the Precision Agriculture Segment

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Iagăru, R.; Șipoș, A.; Iagăru, P. Strategic thinking and its role in accelerating the transition from the linear to the circular economic model—Case study of the agri-food sector in the Sibiu depression microregion. Romania. Sustainability 2023, 15, 3109. [Google Scholar] [CrossRef]

- Nathanael, T.; Bir, C.; Widmar, D.A.; Mintert, J.R. Farmer perceptions of precision agriculture technology benefits. J. Agric. Appl. Econ. 2019, 51, 142–163. [Google Scholar] [CrossRef]

- Cheng, C.; Fu, J.; Su, H.; Ren, L. Recent Advancements in Agriculture Robots: Benefits and Challenges. Machines 2023, 11, 48. [Google Scholar] [CrossRef]

- Reddy, N.V.; Reddy, A.; Pranavadithya, S.; Kumar, J.J. A critical review on agricultural robots. Int. J. Mech. Eng. Technol. 2016, 7, 183–188. [Google Scholar]

- Moshayedi, A.J.; Khan, A.S.; Yang, Y.; Hu, J.; Kolahdooz, A. Robots in Agriculture: Revolutionizing Farming Practices. EAI Endorsed Trans. AI Robot. 2024, 3, 1–23. [Google Scholar] [CrossRef]

- Spykman, O.; Gabriel, A.; Ptacek, M.; Gandorfer, M. Farmers’ perspectives on field crop robots–evidence from Bavaria. Ger. Comput. Electron. Agric. 2021, 186, 106176. [Google Scholar] [CrossRef]

- Garlando, U.; Bar-On, L.; Avni, A.; Shacham-Diamand, Y.; Demarchi, D. Plants and Environmental Sensors for Smart Agriculture, an Overview. In Proceedings of the 2020 IEEE SENSORS, Rotterdam, The Netherlands, 25–28 October 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Shaikh, F.K.; Karim, S.; Zeadally, S.; Nebhen, J. Recent Trends in Internet-of-ThingsEnabled Sensor Technologies for Smart Agriculture. IEEE Internet Things J. 2022, 9, 23583–23598. [Google Scholar] [CrossRef]

- Wang, T.; Chen, B.; Zhang, Z.; Li, H.; Zhang, M. Applications of Machine Vision in Agricultural Robot Navigation: A Review. Comput. Electron. Agric. 2022, 198, 107085. [Google Scholar] [CrossRef]

- Ayoub Shaikh, T.; Rasool, T.; Rasheed Lone, F. Towards Leveraging the Role of Machine Learning and Artificial Intelligence in Precision Agriculture and Smart Farming. Comput. Electron. Agric. 2022, 198, 107119. [Google Scholar] [CrossRef]

- van Henten, E.J.; Tabb, A.; Billingsley, J.; Popovic, M.; Deng, M.; Reid, J. Agricultural Robotics and Automation [TC Spotlight]. IEEE Robot. Autom. Mag. 2022, 29, 145–147. [Google Scholar] [CrossRef]

- Boșcoianu, M.; Pop, S.; Iagăru, P.; Cioca, L.I.; Iagăru, R.; Petre, I.M. An Innovative Management Framework for Smart Horticulture—The Integration of Hype Cycle Paradigm. Drones 2024, 8, 291. [Google Scholar] [CrossRef]

- Albiero, D.; Pontin Garcia, A.; Kiyoshi Umezu, C.; Leme de Paulo, R. Swarm Robots in Mechanized Agricultural Operations: A Review about Challenges for Research. Comput. Electron. Agric. 2022, 193, 106608. [Google Scholar] [CrossRef]

- Atefi, A.; Ge, Y.; Pitla, S.; Schnable, J. Robotic Technologies for High-Throughput Plant Phenotyping: Contemporary Reviews and Future Perspectives. Front. Plant Sci. 2021, 12, 611940. [Google Scholar] [CrossRef]

- Emmi, L.; Gonzalez-de-Santos, P. Mobile Robotics in Arable Lands: Current State and Future Trends. In Proceedings of the 2017 European Conference on Mobile Robots (ECMR), Paris, France, 6–8 September 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Iagăru, P.; Pavel, P.; Iagăru, R. Implementation of the concept agriculture of precision a way to improve the management of agricultural enterprises. Sci. Papers. Ser. Manag. Econ. Eng. Agric. Rural. Dev. 2019, 19, 229–234. [Google Scholar]

- Ren, G.; Lin, T.; Ying, Y.; Chowdhary, G.; Ting, K.C. Agricultural Robotics Research Applicable to Poultry Production: A Review. Comput. Electron. Agric. 2020, 169, 105216. [Google Scholar] [CrossRef]

- Barth, R.; Hemming, J.; van Henten, E.J. Design of an Eye-in-Hand Sensing and Servo Control Framework for Harvesting Robotics in Dense Vegetation. Biosyst. Eng. 2016, 146, 71–84. [Google Scholar] [CrossRef]

- Zhang, Q.; Karkee, M.; Tabb, A. The Use of Agricultural Robots in Orchard Management. In Robotics and Automation for Improving Agriculture; Burleigh Dodds Science Publishing: Cambridge, MA, USA, 2019; pp. 187–214. [Google Scholar]

- Oliveira, L.F.P.; Moreira, A.P.; Silva, M.F. Advances in Forest Robotics: A Stateof-the-Art Survey. Robotics 2021, 10, 53. [Google Scholar] [CrossRef]

- Duong, L.N.K.; Al-Fadhli, M.B.; Jagtap, S.; Bader, F.; Martindale, W.; Swainson, M.; Paoli, A. A Review of Robotics and Autonomous Systems in the Food Industry: From the Supply Chains Perspective. Trends Food Sci. Technol. 2020, 106, 355–364. [Google Scholar] [CrossRef]

- Gil, G.; Casagrande, D.E.; Cortés, L.P.; Verschae, R. Why the low adoption of robotics in the farms? Challenges for the establishment of commercial agricultural robots. Smart Agric. Technol. 2023, 3, 100069. [Google Scholar] [CrossRef]

- Yang, Q.; Du, X.; Wang, Z.; Meng, Z.; Ma, Z.; Zhang, Q. A review of core agricultural robot technologies for crop productions. Comput. Electron. Agric. 2023, 206, 107701. [Google Scholar] [CrossRef]

- Al-Amin, A.K.M.A.; Lowenberg-DeBoer, J.; Franklin, K.; Behrendt, K. Economics of field size and shape for autonomous crop machines. Precis. Agric. 2023, 24, 1738–1765. [Google Scholar] [CrossRef]

- Berk, P.; Hocevar, M.; Stajnko, D.; Belsak, A. Development of alternative plant protection product application techniques in orchards, based on measurement sensing systems: A review. Comput. Electron. Agric. 2016, 124, 273–288. [Google Scholar] [CrossRef]

- Dworak, V.; Selbeck, J.; Ehlert, D. Ranging sensors for vehicle-based measurement of crop stand and orchard parameters: A review. Trans. ASABE 2011, 54, 1497–1510. [Google Scholar] [CrossRef]

- Vázquez-Arellano, M.; Griepentrog, H.W.; Reiser, D.; Paraforos, D.S. Correction: Vázquez-Arellano, M.; et al. 3-D Imaging Systems for Agricultural Applications—A Review. Sensors 2016, 16, 618. [Google Scholar] [CrossRef]

- Balsari, P.; Marucco, P.; Tamagnone, M. A crop identification system (CIS) to optimise pesticide applications in orchards. J. Hortic. Sci. Biotechnol. 2009, 84, 113–116. [Google Scholar] [CrossRef]

- Osterman, A.; Godeša, T.; Hočevar, M.; Širok, B.; Stopar, M. Real-time positioning algorithm for variable-geometry air-assisted orchard sprayer. Comput. Electron. Agric. 2013, 98, 175–182. [Google Scholar] [CrossRef]

- Saedi, S.I.; Khosravi, H. A deep neural network approach towards real-time on-branch fruit recognition for precision horticulture. Expert Syst. Appl. 2020, 159, 113594. [Google Scholar] [CrossRef]

- Delalieux, S.; Vandermaesen, J.; Vanbrabant, Y.; Wuyts, M.; Dierckx, W.; Tits, L. The uncharted territory of drone-based cross-season monitoring for precision horticulture. In Precision Agriculture; Wageningen Academic Publishers: Wageningen, The Netherlands, 2021; pp. 89–99. [Google Scholar]

- Mansingh, P.M.; Amrutha, S.V.; Roobasree, S.; Yuvarani, G. Drone Based Precision Agriculture System. Int. Res. J. Mod. Eng. Technol. Sci. 2021, 3, 2582–5208. [Google Scholar]

- Iagăru, P.; Pavel, P.; Iagăru, R.; Șipoș, A. Aerial monitorization—A vector for ensuring the agroecosystems sustainability. Sustainability 2022, 14, 6011. [Google Scholar] [CrossRef]

- Barnes, E.; Morgan, G.; Hake, K.; Devine, J.; Kurtz, R.; Ibendahl, G.; Sharda, A.; Rains, G.; Snider, J.; Maja, J.M.; et al. Opportunities for Robotic Systems and Automation in Cotton Production. AgriEngineering 2021, 3, 339–362. [Google Scholar] [CrossRef]

- Adeleke, A.A. A Review of Plastic Contamination Challenges and Mitigation Efforts in Cotton and Textile Milling Industries. AgriEngineering 2023, 5, 193–217. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and microfoundations of (sustainable) enterprise performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Easterby-Smith, M.; Prieto, I.M. Dynamic capabilities and knowledge management: An integrative role for learning? Br. J. Manag. 2008, 19, 235–249. [Google Scholar] [CrossRef]

- Yin, R. Case Study Research: Design and Methods, 2nd ed.; Sage Publishing: Thousand Oaks, CA, USA; London, UK, 1994. [Google Scholar]

- Feagin, J.; Orum, A.; Sjoberg, G. (Eds.) A Case for Case Study; University of North Carolina Press: Chapel Hill, NC, USA, 1991. [Google Scholar]

- Bolton, K.; Brace, I. Questionnaire Design. How to Plan. Structure and Write Survey Material for Effective Market Research, 5th ed.; Kogan Page: London, UK, 2022. [Google Scholar]

- Krosnick, J.A.; Presser, S. Question and questionnaire design. In Handbook of Survey Research, 2nd ed.; Marsden, P.V., Wright, J.D., Eds.; Emerald Group Publishing Limited: Bingley, UK, 2010; pp. 263–313. ISBN 978-1-84855-224-1. [Google Scholar]

- Assimakopoulos, F.; Vassilakis, C.; Margaris, D.; Kotis, K.; Spiliotopoulos, D. AI and Related Technologies in the Fields of Smart Agriculture: A Review. Information 2025, 16, 100. [Google Scholar] [CrossRef]

- Monteiro, A.; Santos, S.; Gonçalves, P. Precision Agriculture for Crop and Livestock Farming—Brief Review. Animals 2021, 11, 2345. [Google Scholar] [CrossRef]

- Plaščak, I.; Jurišić, M.; Radočaj, D.; Vujić, M.; Zimmer, D. An Overview of Precision Irrigation Systems Used in Agriculture. Teh. Glas. 2021, 15, 546–553. [Google Scholar] [CrossRef]

- Mgendi, G. Unlocking the potential of precision agriculture for sustainable farming. Discov. Agric. 2024, 2, 87. [Google Scholar] [CrossRef]

- Sanyaolu, M.; Sadowski, A. The Role of Precision Agriculture Technologies in Enhancing Sustainable Agriculture. Sustainability 2024, 16, 6668. [Google Scholar] [CrossRef]

- Vatin, N.; Joshi, S.; Acharya, P.; Sharma, R.; Nennuri, R. Precision agriculture and sustainable yields: Insights from IoT-driven farming and the precision agriculture test. BIO Web Conf. 2024, 86, 1091. [Google Scholar] [CrossRef]

- Sharma, H.; Sidhu, H.; Bhowmik, A. Remote Sensing Using Unmanned Aerial Vehicles for Water Stress Detection: A Review Focusing on Specialty Crops. Drones 2025, 9, 241. [Google Scholar] [CrossRef]

- Hundal, G.S.; Laux, C.M.; Buckmaster, D.; Sutton, M.J.; Langemeier, M. Exploring barriers to the adoption of internet of things-based precision agriculture practices. Agriculture 2023, 13, 163. [Google Scholar] [CrossRef]

- Iagăru, P.; Boșcoianu, M.; Cioca, I.L.; Petre, I.M.; Pop, S.; Sârbu, F.A.; Iagăru, R. Critical analysis of mini Unmanned Aerial Vehicles (UAV) development capabilities and perspectives of effective integration in horticultural agroecosystems in Romania. Sci. Pap. Ser. Manag. Econ. Eng. Agric. Rural. Dev. 2023, 23, 293–302. [Google Scholar]

- Sung, J. The Fourth Industrial Revolution and Precision Agriculture, in Automation in Agriculture-Securing Food Supplies for Future Generations; InTech: Rijeka, Croatia, 2018; Volume 1. [Google Scholar] [CrossRef]

- Shah, D.; Kumar, R.; Singh, P. Agriculture 4.0 adoption challenges in the emerging economies: Implications for smart farming and sustainability. J. Econ. Technol. 2024, 2, 278–295. [Google Scholar] [CrossRef]

- Grimstad, L.; From, P.J. Thorvald II: A modular and re-configurable agricultural robot. IFAC-PapersOnLine 2017, 50, 4588–4593. [Google Scholar] [CrossRef]

- Bawden, O.; Kulk, J.; Russell, R.; McCool, C.; English, A.; Dayoub, F.; Lehnert, C.; Perez, T. Robot for weed species plant-specific management. J. Field Robot. 2017, 34, 1179–1199. [Google Scholar] [CrossRef]

- Latruffe, L.; Piet, L. Does land fragmentation affect farm performance? A case study from Brittany, France. Agric. Syst. 2014, 129, 68–80. [Google Scholar] [CrossRef]

- Barnes, A.P.; Soto, I.; Eory, V.; Beck, B.; Balafoutis, A.; Sánchez, B.; Vangeyte, J.; Fountas, S.; van der Wal, T.; Gomez-Barbero, M. Exploring the adoption of precision agricultural technologies: A cross regional study of EU farmers. Land Use Policy 2019, 80, 163–174. [Google Scholar] [CrossRef]

- Klerkx, L.; Rose, D. Dealing with the game-changing technologies of Agriculture 4.0: How do we manage diversity and responsibility in food system transition pathways? Glob. Food Secur. 2020, 24, 100347. [Google Scholar] [CrossRef]

- Eastwood, C.; Klerkx, L.; Ayre, M.; Dela Rue, B. Managing socio-ethical challenges in the development of smart farming: From a fragmented to a comprehensive approach for responsible research and innovation. J. Agric. Environ. Ethics 2019, 32, 741–768. [Google Scholar] [CrossRef]

- Bronson, K. Looking through a responsible innovation lens at uneven engagements with digital farming. NJAS Wagening. J. Life Sci. 2019, 90–91, 100294. [Google Scholar] [CrossRef]

- Rose, D.C.; Wheeler, R.; Winter, M.; Lobley, M.; Chivers, C.A. Agriculture 4.0: Making it work for people, production, and the planet. Land Use Policy 2021, 100, 104933. [Google Scholar] [CrossRef]

| Variable | Category | N | M | SD | CI95% Lower | CI95% Upper | p | F | Levene Sig. |

|---|---|---|---|---|---|---|---|---|---|

| Rational use of inputs | Inactive | 5 | 2.60 | 1.14 | 1.18 | 4.02 | ≤0.001 | 3.235 | 0.009 |

| Employee | 14 | 4.86 | 0.36 | 4.65 | 5.07 | ||||

| Farmer | 79 | 4.81 | 0.55 | 4.69 | 4.93 | ||||

| Product and service provider | 11 | 4.55 | 1.50 | 3.53 | 5.56 | ||||

| Institution representative | 13 | 4.54 | 0.66 | 4.14 | 4.94 | ||||

| Investor | 8 | 4.88 | 0.35 | 4.58 | 5.17 | ||||

| Total | 130 | 4.68 | 0.81 | 4.54 | 4.82 | ||||

| PA acquisition success | Inactive | 5 | 3.20 | 1.3 | 1.58 | 4.82 | 0.007 | 3.01 | 0.013 |

| Employee | 14 | 4.86 | 0.36 | 4.65 | 5.07 | ||||

| Farmer | 79 | 4.58 | 0.79 | 4.4 | 4.76 | ||||

| Product and service provider | 11 | 4.45 | 1.5 | 3.44 | 5.47 | ||||

| Institution representative | 13 | 4.38 | 0.65 | 3.99 | 4.78 | ||||

| Investor | 8 | 4.88 | 0.35 | 4.58 | 5.17 | ||||

| Total | 130 | 4.55 | 0.87 | 4.39 | 4.7 | ||||

| PA acquisition difficulty | Inactive | 5 | 3.00 | 1.00 | 1.76 | 4.24 | ≤0.001 | 1.28 | 0.276 |

| Employee | 14 | 4.57 | 0.51 | 4.27 | 4.87 | ||||

| Farmer | 79 | 4.53 | 0.73 | 4.37 | 4.7 | ||||

| Product and service provider | 11 | 4.55 | 0.52 | 4.19 | 4.9 | ||||

| Institution representative | 13 | 4.23 | 0.59 | 3.87 | 4.59 | ||||

| Investor | 8 | 4.75 | 0.46 | 4.36 | 5.14 | ||||

| Total | 130 | 4.46 | 0.73 | 4.33 | 4.59 | ||||

| Robots use importance | Inactive | 5 | 2.6 | 1.34 | 0.09 | 4.27 | 0.009 | 0.438 | 0.821 |

| Employee | 14 | 4.21 | 0.69 | 3.81 | 4.62 | ||||

| Farmer | 79 | 4.37 | 0.98 | 4.15 | 4.59 | ||||

| Product and service provider | 11 | 4.18 | 0.98 | 3.52 | 4.84 | ||||

| Institution representative | 13 | 4.15 | 0.89 | 3.61 | 4.7 | ||||

| Investor | 8 | 4.25 | 0.88 | 3.51 | 4.99 | ||||

| Total | 130 | 4.24 | 1.00 | 4.06 | 4.41 | ||||

| Monitorization robots | Inactive | 5 | 2.6 | 1.14 | 1.18 | 4.02 | 0.009 | 1.855 | 0.107 |

| Employee | 14 | 4.07 | 0.61 | 3.72 | 4.43 | ||||

| Farmer | 79 | 4.22 | 1.08 | 3.97 | 4.46 | ||||

| Product and service provider | 11 | 4.18 | 0.98 | 3.52 | 4.84 | ||||

| Institution representative | 13 | 4.46 | 0.66 | 4.06 | 4.86 | ||||

| Investor | 8 | 4.63 | 0.51 | 4.19 | 5.06 | ||||

| Total | 130 | 4.18 | 1.02 | 4.01 | 4.36 | ||||

| Monitorization services | Inactive | 5 | 3 | 1.41 | 1.24 | 4.76 | 0.146 | 0.557 | 0.733 |

| Employee | 14 | 3.64 | 1.08 | 3.02 | 4.27 | ||||

| Farmer | 79 | 4.08 | 1.17 | 3.81 | 4.34 | ||||

| Product and service provider | 11 | 4.00 | 1.09 | 3.26 | 4.74 | ||||

| Institution representative | 13 | 3.54 | 1.39 | 2.70 | 4.38 | ||||

| Investor | 8 | 4.5 | 1.06 | 3.61 | 5.39 | ||||

| Total | 130 | 3.95 | 1.20 | 3.75 | 4.16 | ||||

| Variable rate robots | Inactive | 5 | 3.20 | 0.83 | 2.16 | 4.24 | 0.698 | 3.105 | 0.011 |

| Employee | 14 | 3.71 | 1.06 | 3.10 | 4.33 | ||||

| Farmer | 79 | 3.72 | 1.31 | 3.43 | 4.01 | ||||

| Product and service provider | 11 | 4.00 | 1.09 | 3.26 | 4.74 | ||||

| Institution representative | 13 | 3.54 | 1.26 | 2.77 | 4.30 | ||||

| Investor | 8 | 3.13 | 2.03 | 1.43 | 4.82 | ||||

| Total | 130 | 3.67 | 1.29 | 3.44 | 3.89 | ||||

| Variable rate services | Inactive | 5 | 3.00 | 1.00 | 1.76 | 4.24 | 0.199 | 1.087 | 0.371 |

| Employee | 14 | 3.64 | 1.15 | 2.98 | 4.31 | ||||

| Farmer | 79 | 3.97 | 1.12 | 3.72 | 4.23 | ||||

| Product and service provider | 11 | 3.55 | 1.57 | 2.49 | 4.60 | ||||

| Institution representative | 13 | 3.77 | 1.01 | 3.16 | 4.38 | ||||

| Investor | 4 | 4.50 | 1.06 | 3.61 | 5.39 | ||||

| Total | 130 | 3.88 | 1.16 | 3.68 | 4.08 | ||||

| Intelligent management framework | Inactive | 5 | 2.60 | 1.51 | 0.72 | 4.48 | 0.002 | 1.115 | 0.356 |

| Employee | 14 | 4.36 | 1.01 | 3.78 | 4.94 | ||||

| Farmer | 79 | 4.39 | 0.86 | 4.20 | 4.59 | ||||

| Product and service provider | 11 | 4.55 | 0.68 | 4.08 | 5.01 | ||||

| Institution representative | 13 | 4.23 | 1.09 | 3.57 | 4.89 | ||||

| Investor | 8 | 4.63 | 0.74 | 4 | 5.25 | ||||

| Total | 130 | 4.33 | 0.97 | 4.16 | 4.5 |

| Variable | Category | N | M | SD | CI95% Lower | CI95% Upper | p |

|---|---|---|---|---|---|---|---|

| KMC_acquisition_international_trends | Employee | 11 | 4.73 | 0.46 | 4.41 | 5.04 | 0.97 |

| Farmer | 76 | 4.71 | 0.48 | 4.60 | 4.82 | ||

| Product and service provider | 10 | 4.70 | 0.48 | 4.35 | 5.05 | ||

| Institution representative | 13 | 4.62 | 0.65 | 4.22 | 5.01 | ||

| Investor | 8 | 4.75 | 0.46 | 4.36 | 5.14 | ||

| Total | 118 | 4.70 | 0.49 | 4.60 | 4.79 | ||

| KMC_acquisition_partnerships | Employee | 11 | 4.82 | 0.40 | 4.55 | 5.09 | 0.85 |

| Farmer | 76 | 4.70 | 0.51 | 4.58 | 4.82 | ||

| Product and service provider | 10 | 4.60 | 0.51 | 4.23 | 4.97 | ||

| Institution representative | 13 | 4.62 | 0.65 | 4.22 | 5.01 | ||

| Investor | 8 | 463 | 0.51 | 4.19 | 5.06 | ||

| Total | 118 | 4.58 | 0.56 | 4.48 | 4.69 | ||

| KMC_acquisition_networks | Employee | 11 | 4.45 | 0.52 | 4.10 | 4.81 | 0.32 |

| Farmer | 76 | 4.66 | 0.53 | 4.54 | 4.78 | ||

| Product and service provider | 10 | 4.40 | 0.69 | 3.90 | 4.90 | ||

| Institution representative | 13 | 4.38 | 0.65 | 3.99 | 4.78 | ||

| Investor | 8 | 4.63 | 0.51 | 4.19 | 5.06 | ||

| Total | 118 | 4.58 | 0.56 | 4.48 | 4.69 | ||

| KMC_combination_experience | Employee | 11 | 4.09 | 0.53 | 3.73 | 4.45 | 0.25 |

| Farmer | 76 | 4.54 | 0.59 | 4.40 | 4.68 | ||

| Product and service provider | 10 | 4.40 | 0.69 | 3.90 | 4.90 | ||

| Institution representative | 13 | 4.46 | 0.66 | 4.06 | 4.86 | ||

| Investor | 8 | 4.50 | 0.53 | 4.05 | 4.95 | ||

| Total | 118 | 4.47 | 0.60 | 4.36 | 4.59 | ||

| KMC_combination_investments | Employee | 11 | 4.00 | 0.63 | 3.58 | 4.42 | 0.01 |

| Farmer | 76 | 4.45 | 0.66 | 4.30 | 4.60 | ||

| Product and service provider | 10 | 4.40 | 0.51 | 4.03 | 4.77 | ||

| Institution representative | 13 | 3.85 | 1.06 | 3.20 | 4.49 | ||

| Investor | 8 | 4.75 | 0.46 | 4.36 | 5.14 | ||

| Total | 118 | 4.36 | 0.72 | 4.22 | 4.49 | ||

| KMC_combination_inovative_technologies | Employee | 11 | 4.27 | 0.46 | 3.96 | 4.59 | 0.07 |

| Farmer | 76 | 4.41 | 0.65 | 4.26 | 4.56 | ||

| Product and service provider | 10 | 4.40 | 0.51 | 4.03 | 4.77 | ||

| Institution representative | 13 | 4.08 | 0.64 | 3.69 | 4.46 | ||

| Investor | 4 | 4.88 | 0.35 | 354.58 | 5.17 | ||

| Total | 114 | 4.39 | 0.62 | 4.28 | 4.50 | ||

| KMC_protection_policies | Employee | 11 | 4.09 | 0.53 | 3.73 | 4.45 | 0.04 |

| Farmer | 76 | 4.43 | 0.57 | 4.30 | 4.57 | ||

| Product and service provider | 10 | 4.30 | 0.67 | 3.82 | 4.78 | ||

| Institution representative | 13 | 4.08 | 0.64 | 3.69 | 4.46 | ||

| Investor | 8 | 4.75 | 0.46 | 4.36 | 5.14 | ||

| Total | 118 | 4.37 | 0.59 | 4.26 | 4.48 | ||

| KMC_protection_measures | Employee | 11 | 4.82 | 0.40 | 4.55 | 5.09 | 0.49 |

| Farmer | 76 | 4.58 | 0.57 | 4.45 | 4.71 | ||

| Product and service provider | 10 | 4.50 | 0.70 | 3.99 | 5.01 | ||

| Institution representative | 13 | 4.38 | 0.76 | 3.92 | 4.85 | ||

| Investor | 8 | 4.63 | 0.51 | 4.19 | 5.06 | ||

| Total | 118 | 4.58 | 0.59 | 4.47 | 4.68 | ||

| KMC_protection_priority | Employee | 11 | 4.27 | 0.90 | 3.67 | 4.88 | 0.46 |

| Farmer | 76 | 4.38 | 0.67 | 4.23 | 4.54 | ||

| Product and service provider | 10 | 4.70 | 0.67 | 4.22 | 5.18 | ||

| Institution representative | 13 | 4.54 | 0.51 | 4.22 | 4.85 | ||

| Investor | 8 | 4.63 | 0.51 | 4.19 | 5.06 | ||

| Total | 118 | 4.43 | 0.67 | 4.31 | 4.55 |

| Variable | Category | N | M | SD | CI95% Lower | CI95% Upper | p |

|---|---|---|---|---|---|---|---|

| DC_AC_new_technologies | Employee | 11 | 4.64 | 0.67 | 4.18 | 5.09 | 0.63 |

| Farmer | 76 | 4.57 | 0.63 | 4.42 | 4.71 | ||

| Product and service provider | 10 | 4.8 | 0.42 | 4.50 | 5.10 | ||

| Institution representative | 13 | 4.46 | 0.77 | 3.99 | 4.93 | ||

| Investor | 8 | 4.38 | 0.51 | 3.94 | 4.81 | ||

| Total | 118 | 4.57 | 0.63 | 4.45 | 4.68 | ||

| DC_AC_practices alignment | Employee | 11 | 4.91 | 0.30 | 4.71 | 5.11 | 0.50 |

| Farmer | 76 | 4.51 | 0.77 | 4.34 | 4.69 | ||

| Product and service provider | 10 | 4.60 | 0.51 | 4.23 | 4.97 | ||

| Institution representative | 13 | 4.62 | 0.50 | 4.31 | 4.92 | ||

| Investor | 8 | 4.63 | 0.51 | 4.19 | 5.06 | ||

| Total | 118 | 4.58 | 0.68 | 4.45 | 4.70 | ||

| DC_IC_new_capabilities | Employee | 11 | 4.64 | 0.50 | 4.30 | 4.98 | 0.75 |

| Farmer | 76 | 4.42 | 0.65 | 4.27 | 4.57 | ||

| Product and service provider | 10 | 4.50 | 0.52 | 4.12 | 4.88 | ||

| Institution representative | 13 | 4.62 | 0.65 | 4.22 | 5.01 | ||

| Investor | 8 | 4.50 | 0.75 | 3.87 | 5.13 | ||

| Total | 118 | 4.47 | 0.63 | 4.36 | 4.59 | ||

| DC_IC_competitive advantage | Employee | 11 | 4.73 | 0.64 | 4.29 | 5.16 | 0.22 |

| Farmer | 76 | 4.51 | 0.64 | 4.37 | 4.66 | ||

| Product and service provider | 10 | 4.80 | 0.42 | 4.50 | 5.10 | ||

| Institution representative | 13 | 4.23 | 0.83 | 3.73 | 4.73 | ||

| Investor | 8 | 4.38 | 0.74 | 3.75 | 5.00 | ||

| Total | 118 | 4.52 | 0.66 | 4.40 | 4.64 | ||

| DC_IC_innovations_support | Employee | 11 | 4.73 | 0.46 | 4.41 | 5.04 | 0.68 |

| Farmer | 76 | 4.53 | 0.66 | 4.37 | 4.68 | ||

| Product and service provider | 10 | 4.50 | 0.70 | 3.99 | 5.01 | ||

| Institution representative | 13 | 4.31 | 0.85 | 3.79 | 4.82 | ||

| Investor | 8 | 4.50 | 0.75 | 3.87 | 5.13 | ||

| Total | 118 | 4.52 | 0.67 | 4.39 | 4.64 | ||

| DC_AbC_collaborations | Employee | 11 | 4.73 | 0.46 | 4.41 | 5.04 | 0.04 |

| Farmer | 76 | 4.64 | 0.55 | 4.52 | 4.77 | ||

| Product and service provider | 10 | 4.10 | 0.99 | 3.39 | 4.81 | ||

| Institution representative | 13 | 4.31 | 0.75 | 3.85 | 4.76 | ||

| Investor | 8 | 4.38 | 0.74 | 3.75 | 5.00 | ||

| Total | 118 | 4.55 | 0.64 | 4.43 | 4.67 | ||

| DC_AbC_training | Employee | 11 | 4.73 | 0.46 | 4.41 | 5.04 | 0.46 |

| Farmer | 76 | 4.63 | 0.65 | 4.48 | 4.78 | ||

| Product and service provider | 10 | 4.50 | 0.70 | 3.99 | 5.01 | ||

| Institution representative | 13 | 4.85 | 0.37 | 4.62 | 5.07 | ||

| Investor | 8 | 4.38 | 0.74 | 3.75 | 5.00 | ||

| Total | 118 | 4.64 | 0.62 | 4.52 | 4.75 |

| Variable | N | % |

|---|---|---|

| Adopting new technologies (e.g., drones, sensors, GPS) | 46 | 39 |

| Creating strategic partnerships with other farmers or organizations | 21 | 17.8 |

| Protecting and leveraging internal knowledge (cultivation techniques, soil data) | 13 | 11 |

| Digitalizing farm management processes | 19 | 16.1 |

| Investing in employee training and development | 15 | 16.1 |

| Total | 114 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petre, I.M.; Boșcoianu, M.; Iagăru, P.; Iagăru, R. Unmanned Agricultural Robotics Techniques for Enhancing Entrepreneurial Competitiveness in Emerging Markets: A Central Romanian Case Study. Agriculture 2025, 15, 1910. https://doi.org/10.3390/agriculture15181910

Petre IM, Boșcoianu M, Iagăru P, Iagăru R. Unmanned Agricultural Robotics Techniques for Enhancing Entrepreneurial Competitiveness in Emerging Markets: A Central Romanian Case Study. Agriculture. 2025; 15(18):1910. https://doi.org/10.3390/agriculture15181910

Chicago/Turabian StylePetre, Ioana Madalina, Mircea Boșcoianu, Pompilica Iagăru, and Romulus Iagăru. 2025. "Unmanned Agricultural Robotics Techniques for Enhancing Entrepreneurial Competitiveness in Emerging Markets: A Central Romanian Case Study" Agriculture 15, no. 18: 1910. https://doi.org/10.3390/agriculture15181910

APA StylePetre, I. M., Boșcoianu, M., Iagăru, P., & Iagăru, R. (2025). Unmanned Agricultural Robotics Techniques for Enhancing Entrepreneurial Competitiveness in Emerging Markets: A Central Romanian Case Study. Agriculture, 15(18), 1910. https://doi.org/10.3390/agriculture15181910