Optimization Design and Experimentation of a Soil Covering Device for a Tree Planting Machine

Abstract

1. Introduction

2. The Overall Structure and Working Principle of Tree Planting Machine Soil Covering Device

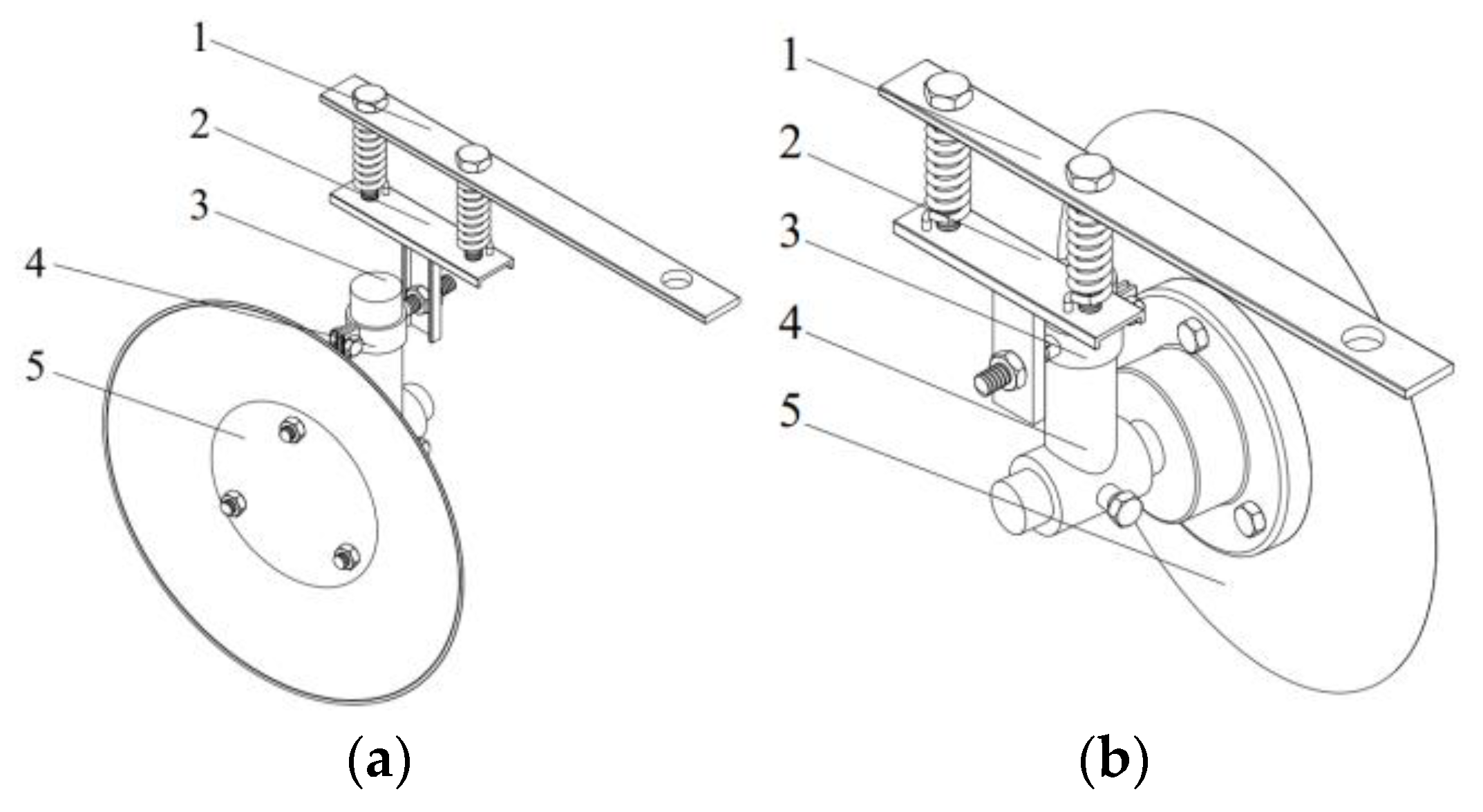

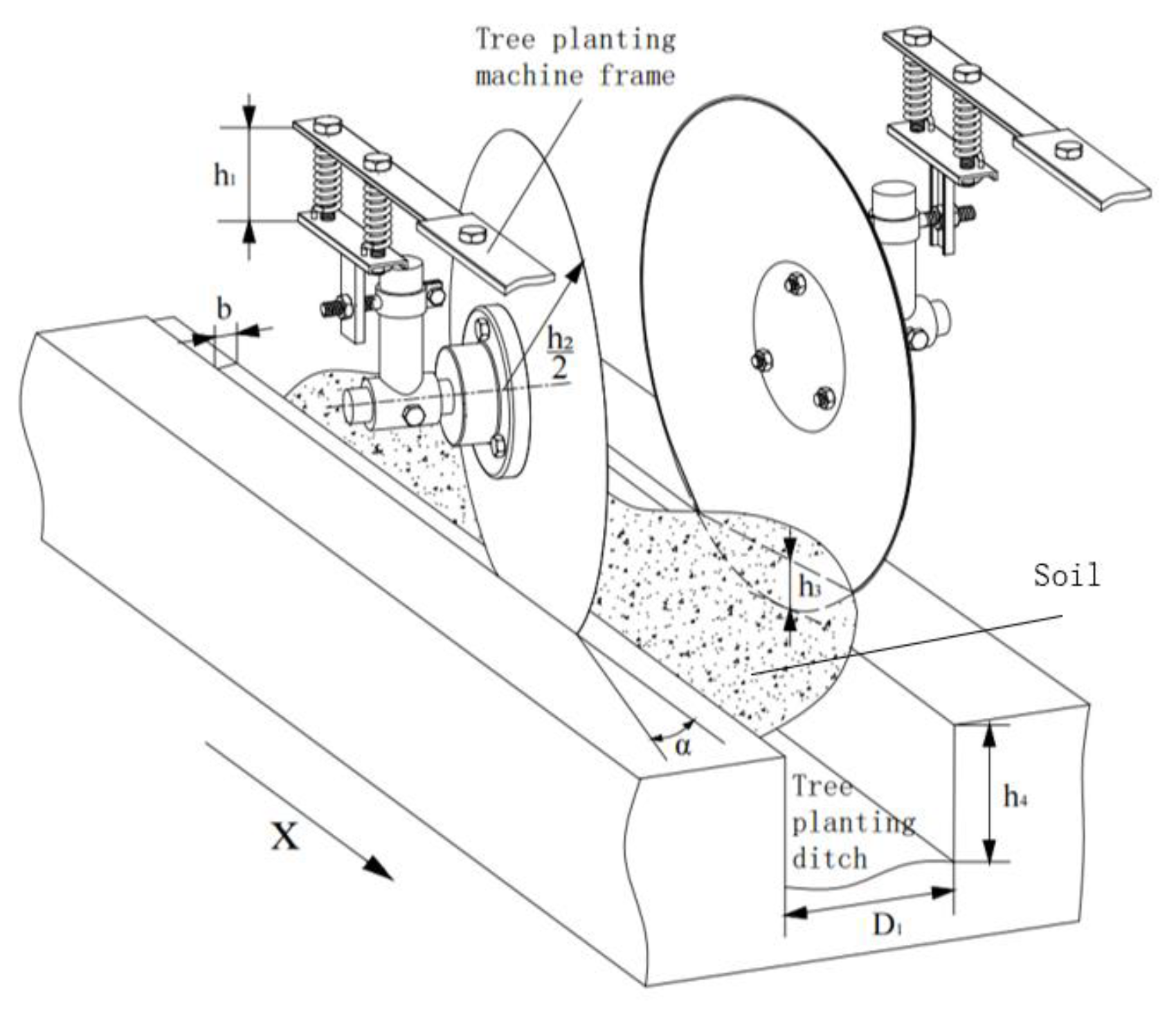

2.1. Overall Structure of Tree Planting Machine Soil Covering Device

2.2. Working Principle of Tree Planting Machine Soil Covering Device

3. Design of Key Structural Parameters of Soil Covering Device

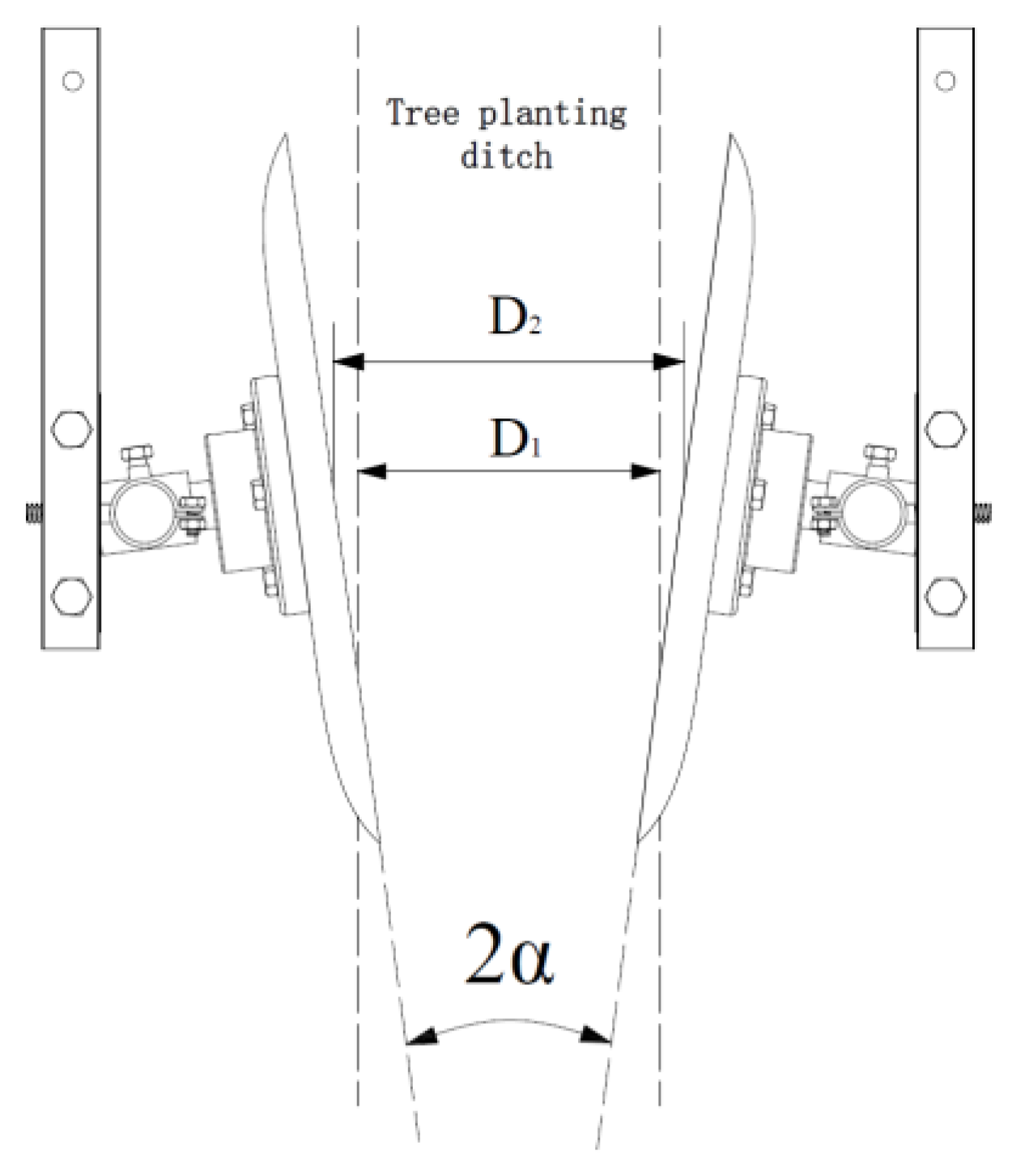

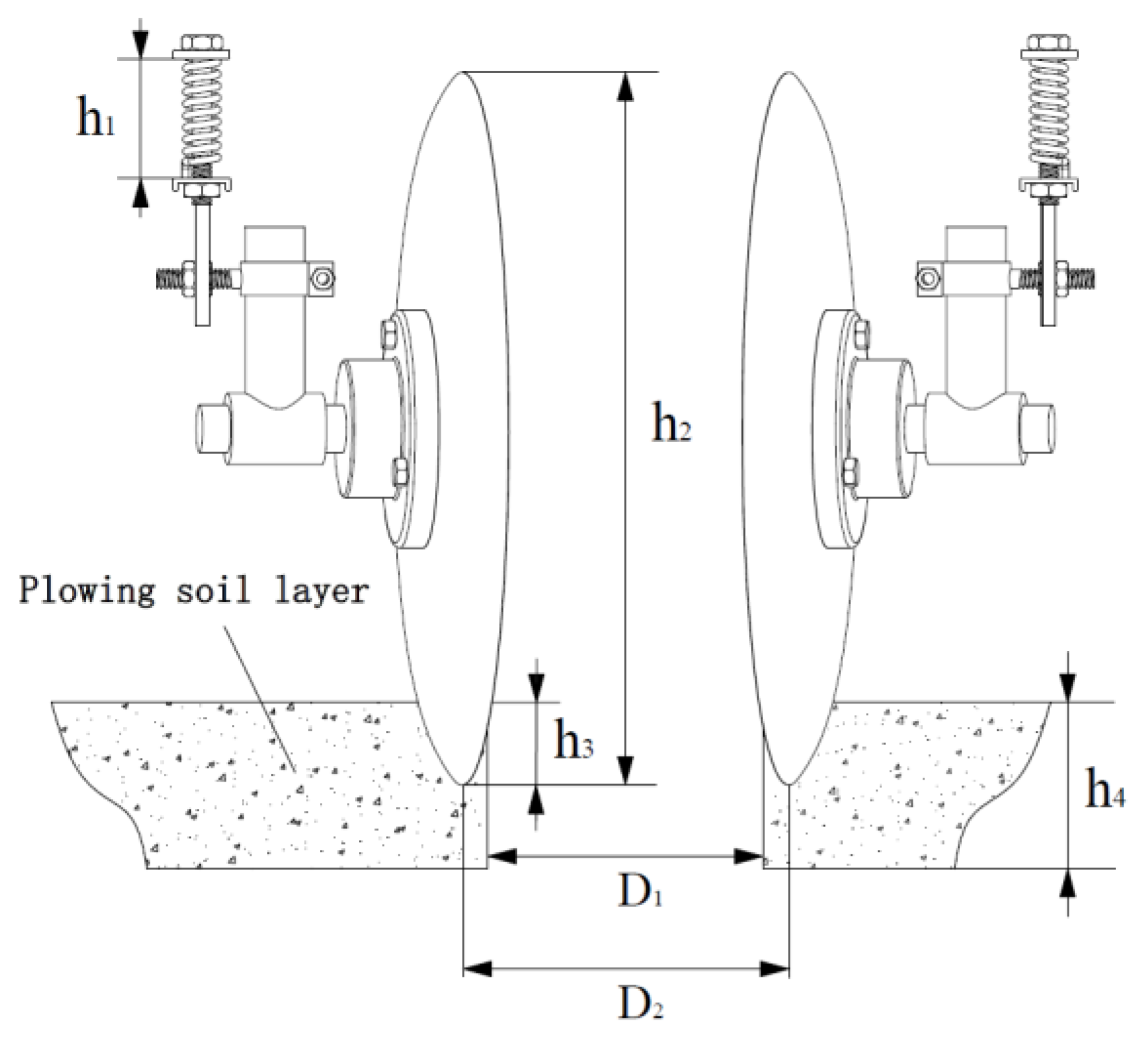

3.1. Soil Covering Width of Soil Covering Device

3.2. The Forward Angle of the Overburden Plate

3.3. The Buried Depth of Soil Covering Device

4. Simulation Test of Soil Covering Process

4.1. Simulation Model Establishment

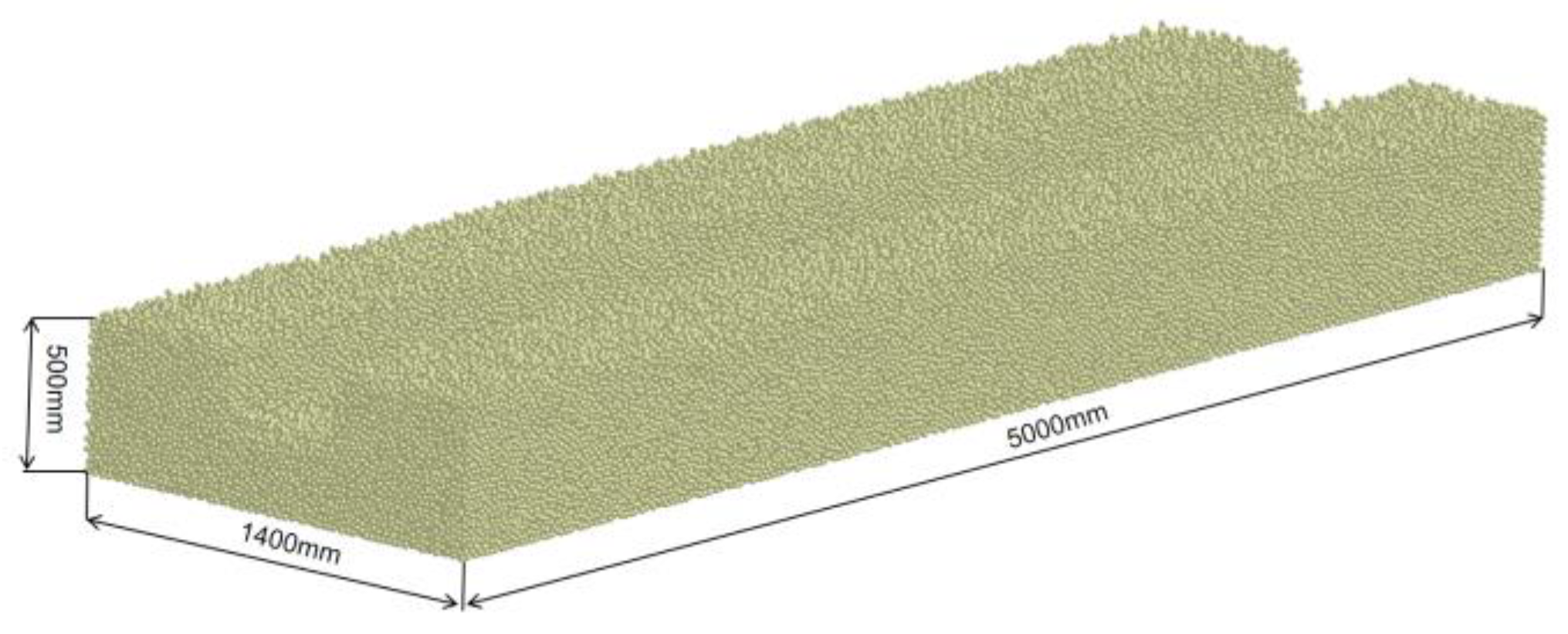

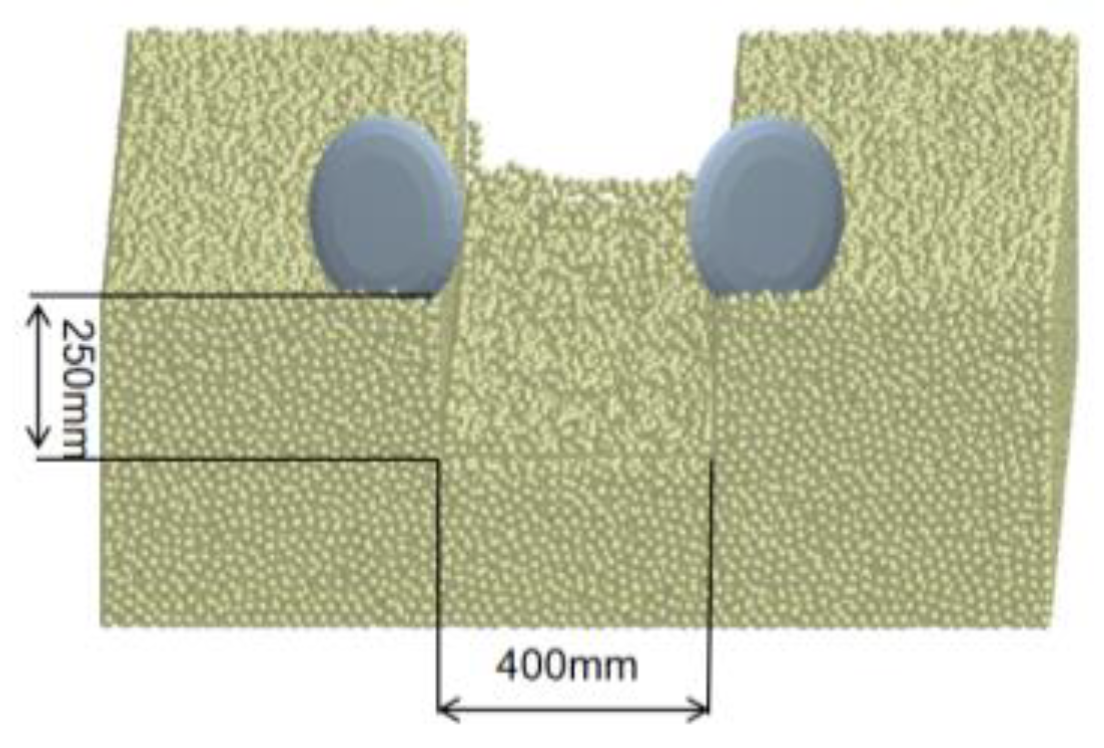

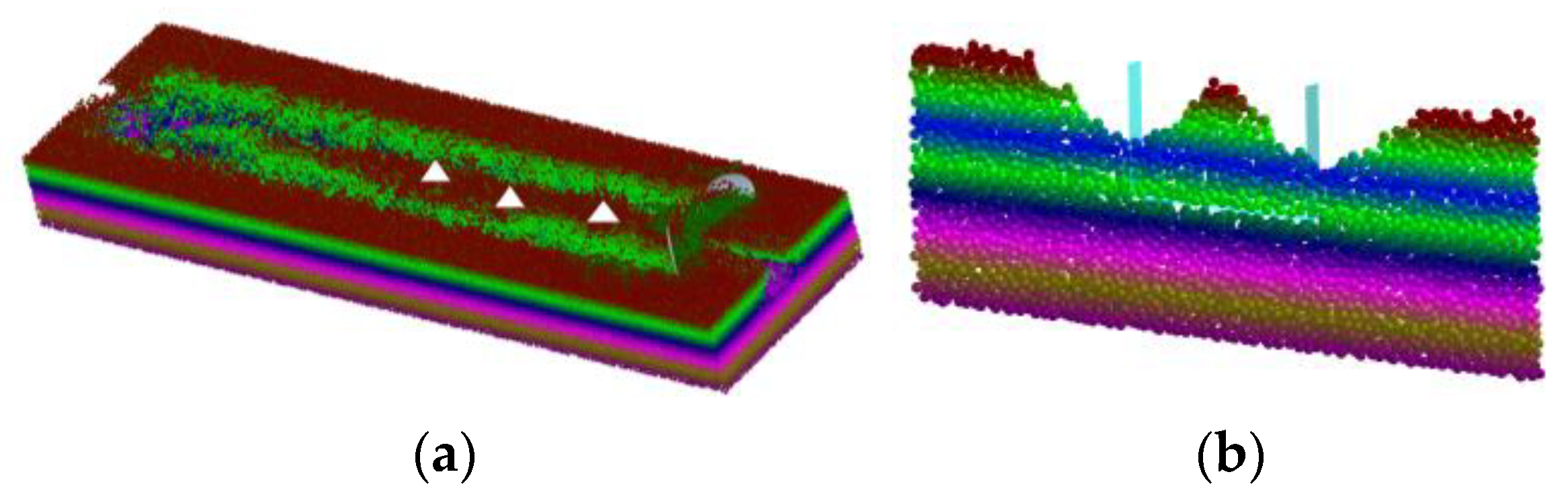

4.1.1. Establishment of Particle Model and Geometric Model

4.1.2. Simulation Parameter Setting

4.2. Experimental Design

Test Factors and Indicators

4.3. Experiment Results and Analysis

4.4. Analysis of Experimental Results

4.5. Optimization Choice for Parameters

5. Prototype Test Verification

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, H.; Chen, Z.; Jia, H.; Zheng, T.; Wang, G.; Wang, Q. Design and experiment of earth-covering ballast with conical wheel structure. Acta Agric. Eng. Sci. 2017, 33, 56–65. [Google Scholar]

- Du, W.; Yang, C.; Yang, J.; Zhang, Q.S.; Yu, J.; Liao, Q.X. Design and experiment of cigar tobacco leaf adjustable seedling bed ridging and film laying machine. J. Agric. Mach. 2023, 54, 116–126 + 295. [Google Scholar]

- Guo, Z.; Chen, H. Design and experiment of rear suspension orchard ditching and fertilizing soil covering machine. Agric. Mech. Res. 2022, 44, 120–123 + 136. [Google Scholar]

- Geng, Y.; Wang, X.; Zhong, X.; Zhang, X.; Chen, K.; Wei, Z.; Lu, Q.; Cheng, X.; Wei, M. Design and Optimization of a Soil-Covering Device for a Corn No-Till Planter. Agriculture 2022, 12, 1218. [Google Scholar] [CrossRef]

- Li, K.; Li, S.; Teng, X.; Deng, Z.; Huang, W.; Gan, F.; Ma, F. Integrated Design and Evaluation of a Soil-Covering and Film-Mulching Device for Sugarcane Transverse Planters. Agronomy 2021, 11, 1382. [Google Scholar] [CrossRef]

- Deng, X. Optimization Design of Ditching and Soil Covering Device of Sand Continuous Ditching and Tree Planting Machine. Master’s Thesis, Shihezi University, Shihezi, China, 2022. [Google Scholar]

- Tian, D.; Liu, J.; Jiao, H. Optimization and Analysis of Working Parameters of Covering Disc Based on Discrete Element Method. Agric. Mech. Res. 2018, 40, 16–22 + 59. [Google Scholar]

- Zhang, H.; Lin, C.; Chen, L.; Zhang, P.; Zheng, S. Design and experiment of ditching fertilization and soil covering machine in tea garden. Chin. J. Agric. Mach. Chem. 2022, 43, 28–35. [Google Scholar]

- Li, J.; Qi, H. Research on the design and application of soil covering roller of multifunctional cotton film mulching planter. South. Agric. Mach. 2018, 49, 28. [Google Scholar]

- Li, L.; Gong, X. Discrete Element Simulation Analysis of Soil Covering Process. Agric. Dev. Equip. 2019, 1, 109–110. [Google Scholar]

- Wang, Y.; Wei, M.; Dong, W.; Li, W.; He, J.; Han, C.; Jiang, Z. Design and Parameter Optimization of a Soil Mulching Device for an Ultra-Wide Film Seeder Based on the Discrete Element Method. Processes 2022, 10, 2115. [Google Scholar] [CrossRef]

- Niu, W.; Gao, J.; Zhao, Y.; Cui, H.; Yang, X. Design and structure analysis of corn straw gathering and returning machine. Agric. Mech. Res. 2019, 41, 50–57. [Google Scholar]

- Zheng, Z.; Fu, Z.; Wang, C.; Huang, Y.; He, J. Design and Experimental Research on Soil Covering Device with Linkage and Differential Adjustment of Potato Planter. Agriculture 2021, 11, 665. [Google Scholar] [CrossRef]

- Dong, X.; Li, H.; Gao, Z. Design of scraper conveyor overburden. Agric. Sci. Technol. Equip. 2012, 12, 19–20. [Google Scholar]

- Yang, W.; Pu, W.; Pan, W.; Zhang, X.; Zhang, L.; Zheng, J. Research design and experiment of soil covering and pressing device for Panax notoginseng seedling sowing. J. South China Agric. Univ. 2022, 43, 122–132. [Google Scholar]

- Guo, W.; Ma, R.; Fan, G.; Yang, W.; Liu, L.; Lei, X. Parameter optimization of chain-link soil covering device under intercropping mode. Agric. Eng. 2011, 27, 33–37. [Google Scholar]

- Zhang, X.; Li, Y.; Yang, J. Parameter optimization and analysis of soil-covering drum of seeder based on discrete element. Chin. J. Agric. Mach. Chem. 2020, 41, 43–48. [Google Scholar]

- Ding, S.P.; Bai, L.; Yao, Y.X.; Yue, B.; Fu, Z.; Zheng, Z.; Huang, Y. Discrete element modelling(DEM) of fertilizer dua-banding with adjustable rates. Comput. Electron. Agric. 2018, 152, 32–39. [Google Scholar] [CrossRef]

- Fang, H.; Ji, C.; Chandio, F.; Guo, J.; Zhang, Q.Y.; Chaudhry, A. Analysis of soil movement behavior in rotary tillage process based on discrete element method. Agric. Mach. J. 2016, 47, 22–28. [Google Scholar]

- Benn, D.I.; Astrom, J.; Zwinger, T.; Todd, J.O.; Nick, F.M.; Cook, S.; Hulton, N.R.; Luckman, A. Melt-under-cutting and buoyancy-driven calving from tidewater glaciers: New insights from discrete element and continuum model simulations. J. Glaciol. 2017, 63, 691–702. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielke, J.M.; Saunde, R.S.C. Three-dimensional discrete element modelling of tillage: Determination of a suitable contact model and parameters for a cohesionless soil. Biosyst. Eng. 2014, 121, 105–117. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunde, R.S.C.; Fielke, J.M. Discrete element modelling of top soil burial using a full scale mouldboard plough under field conditions. Biosyst. Eng. 2017, 160, 140–153. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielke, J.M.; Saunders, C. Three-dimensional discrete element modeling(DEM) of tillage: Accounting for soil cohesion and adhesion. Biosyst. Eng. 2015, 129, 298–306. [Google Scholar] [CrossRef]

- Solhjou, A.; Fielke, J.M.; Desbiolles, J.M. Soil translocation by narrow openers with various rake angles. Biosyst. Eng. 2012, 112, 65–73. [Google Scholar] [CrossRef]

- Tamás, K.; Jóri, I.J.; Mouazen, A.M. Modelling soil-sweep interaction with discrete element method. Soil Tillage Res. 2013, 134, 223–231. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, W.; Dai, F.; Song, X.; Qu, J.; Zhang, F. Simulation analysis and test of the suppression operation process of the whole film double ridge furrow ridge film mulching machine. Agric. Eng. 2020, 36, 20–30. [Google Scholar]

| Type | Parameters | Numerical Value |

|---|---|---|

| Soil particle | Poisson ratio | 0.3 |

| Density (kg/m3) | 1616 | |

| Shear modulus (Pa) | 5 × 107 | |

| Soil covering device (65Mn) | Poisson ratio | 0.3 |

| Density (kg/m3) | 7861 | |

| Shear modulus (Pa) | 7 × 1010 | |

| Sand-sand | Restitution coefficient | 0.279 |

| Coefficient of static friction | 0.723 | |

| Coefficient of rolling friction | 0.393 | |

| Sand—65Mn | Restitution coefficient | 0.101 |

| Coefficient of static friction | 0.847 | |

| Coefficient of rolling friction | 0.153 | |

| Other parameters | Acceleration of gravity (m/s2) | 9.8 |

| Forward speed (m/s) | 1.5 |

| Coding | Factor | ||

|---|---|---|---|

| Overburden Width D2 (mm) | Forward Angle α (°) | Operating Depth h3 (mm) | |

| −1 | 560 | 40 | 10 |

| 0 | 580 | 45 | 15 |

| 1 | 600 | 50 | 20 |

| Test Serial Number | Factor | Soil Backfill Rate y1 | ||

|---|---|---|---|---|

| X1 | X2 | X3 | ||

| 1 | −1 | −1 | 0 | 62.7 |

| 2 | 1 | −1 | 0 | 68.1 |

| 3 | −1 | 1 | 0 | 69.7 |

| 4 | 1 | 1 | 0 | 70.6 |

| 5 | −1 | 0 | −1 | 80.3 |

| 6 | 1 | 0 | −1 | 81.2 |

| 7 | −1 | 0 | 1 | 83.5 |

| 8 | 1 | 0 | 1 | 84.7 |

| 9 | 0 | −1 | −1 | 77.8 |

| 10 | 0 | 1 | −1 | 86.9 |

| 11 | 0 | −1 | 1 | 86.3 |

| 12 | 0 | 1 | 1 | 88.7 |

| 13 | 0 | 0 | 0 | 84.2 |

| 14 | 0 | 0 | 0 | 82.7 |

| 15 | 0 | 0 | 0 | 85.1 |

| 16 | 0 | 0 | 0 | 83.5 |

| 17 | 0 | 0 | 0 | 84.5 |

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 914.71 | 9 | 101.63 | 91.62 | <0.0001 |

| X1 | 8.82 | 1 | 8.82 | 7.95 | 0.0258 |

| X2 | 55.12 | 1 | 55.12 | 49.69 | 0.0002 |

| X3 | 36.12 | 1 | 36.12 | 32.56 | 0.0007 |

| X1X2 | 5.06 | 1 | 5.06 | 4.56 | 0.0700 |

| X1X3 | 0.02 | 1 | 0.02 | 0.02 | 0.8908 |

| X2X3 | 11.22 | 1 | 11.22 | 10.11 | 0.0155 |

| X12 | 369.07 | 1 | 369.07 | 332.71 | <0.0001 |

| X22 | 198.29 | 1 | 198.29 | 178.75 | <0.0001 |

| X32 | 255.34 | 1 | 255.34 | 230.19 | <0.0001 |

| Residual | 7.765 | 7 | 1.11 | ||

| Lack of Fit | 4.325 | 3 | 1.44 | 1.68 | 0.3081 |

| Pure Error | 3.44 | 4 | 0.86 | ||

| Cor Total | 922.48 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Jiang, Z.; Zhang, L.; Hu, X.; Li, W. Optimization Design and Experimentation of a Soil Covering Device for a Tree Planting Machine. Agriculture 2024, 14, 346. https://doi.org/10.3390/agriculture14030346

Wu X, Jiang Z, Zhang L, Hu X, Li W. Optimization Design and Experimentation of a Soil Covering Device for a Tree Planting Machine. Agriculture. 2024; 14(3):346. https://doi.org/10.3390/agriculture14030346

Chicago/Turabian StyleWu, Xun, Zhen Jiang, Lixin Zhang, Xue Hu, and Wenchun Li. 2024. "Optimization Design and Experimentation of a Soil Covering Device for a Tree Planting Machine" Agriculture 14, no. 3: 346. https://doi.org/10.3390/agriculture14030346

APA StyleWu, X., Jiang, Z., Zhang, L., Hu, X., & Li, W. (2024). Optimization Design and Experimentation of a Soil Covering Device for a Tree Planting Machine. Agriculture, 14(3), 346. https://doi.org/10.3390/agriculture14030346