Multi-Stage Sensitivity Analysis of the Energy Demand for the Cooling of Grain Warehouses in Cold Regions of China

Abstract

1. Introduction

2. Materials and Methods

2.1. Multi-Stage Sensitivity Analysis Method

2.1.1. Standardized Regression Coefficient (SRC) and Partial Rank Regression Coefficient (PRRC)

2.1.2. Sobol Sensitivity Analysis Approach

2.1.3. Local Sensitivity Analysis (LSA)

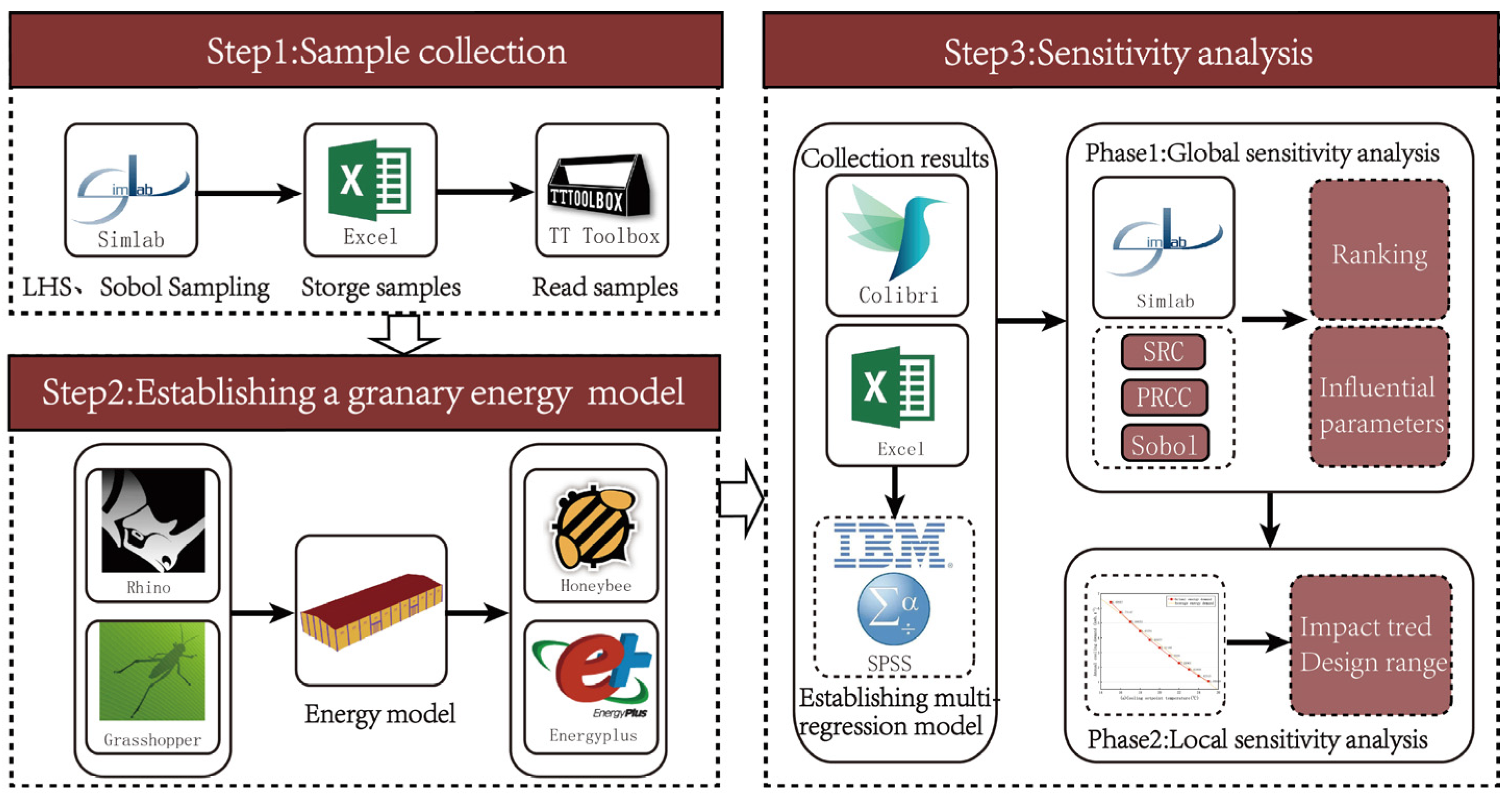

2.2. Sensitivity Analysis Process

- Step 1

- Sample collection: Simlab 2.2, a free statistical software for uncertainty and sensitivity analyses [33,34], will be used to sample variables via Sobol and LHS (Latin hypercube sampling). The collected sample data were stored in Excel, and the sample input files were read through the Toolbox plug-in.

- Step 2

- Establishment of a grain warehouse energy model: The Grasshopper plug-in for the Rhino platform was used to construct a grain warehouse energy model. This visual programming environment provides an intuitive interface and flexible components, enabling effortless parametric design and simulation analysis through plug-ins [35,36]. Honeybee [37], a plug-in, was adopted to simulate the grain warehouse energy.

- Step 3

- Sensitivity analysis: Another plug-in, Colibri, exports simulation results to Excel for further data processing and analysis [38]. LHS samples and output results were imported into SPSS 22 to establish a multiple regression model for regression analysis. In addition, LHS and Sobol samples and corresponding energy use results were entered into Simlab for sensitivity analysis. The sensitivity analysis was conducted in two steps. First, three GSA methods, namely SRC, PRCC, and Sobol method, were employed to rank the sensitivity of energy use of granary cooling. The results were compared to identify the main influence parameters. Then, LAS was performed on the top-ranked design parameters to determine the influence trend of the parameters.

3. Model Construction

3.1. Sample Collection

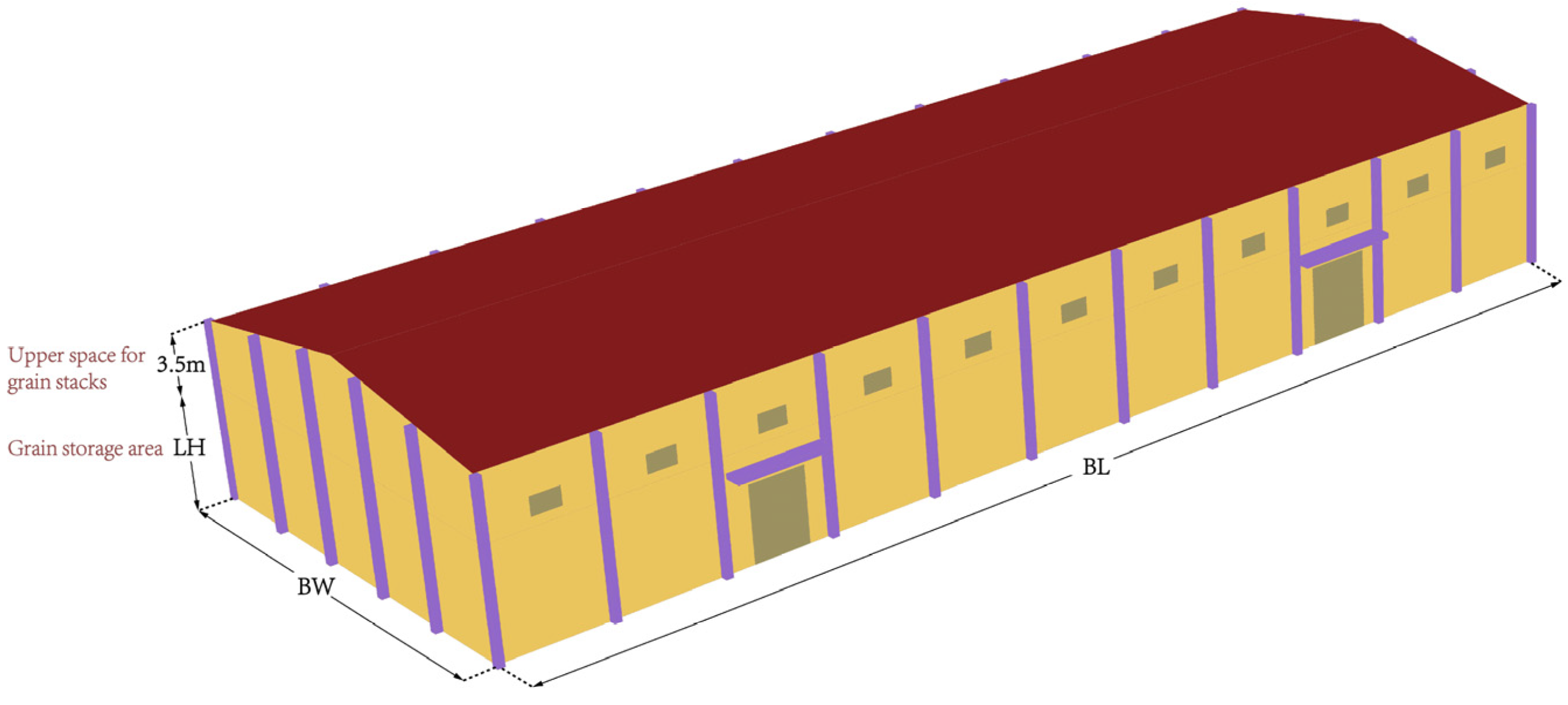

3.2. Building the Energy Use Model for the Grain Warehouse

4. Results and Discussion

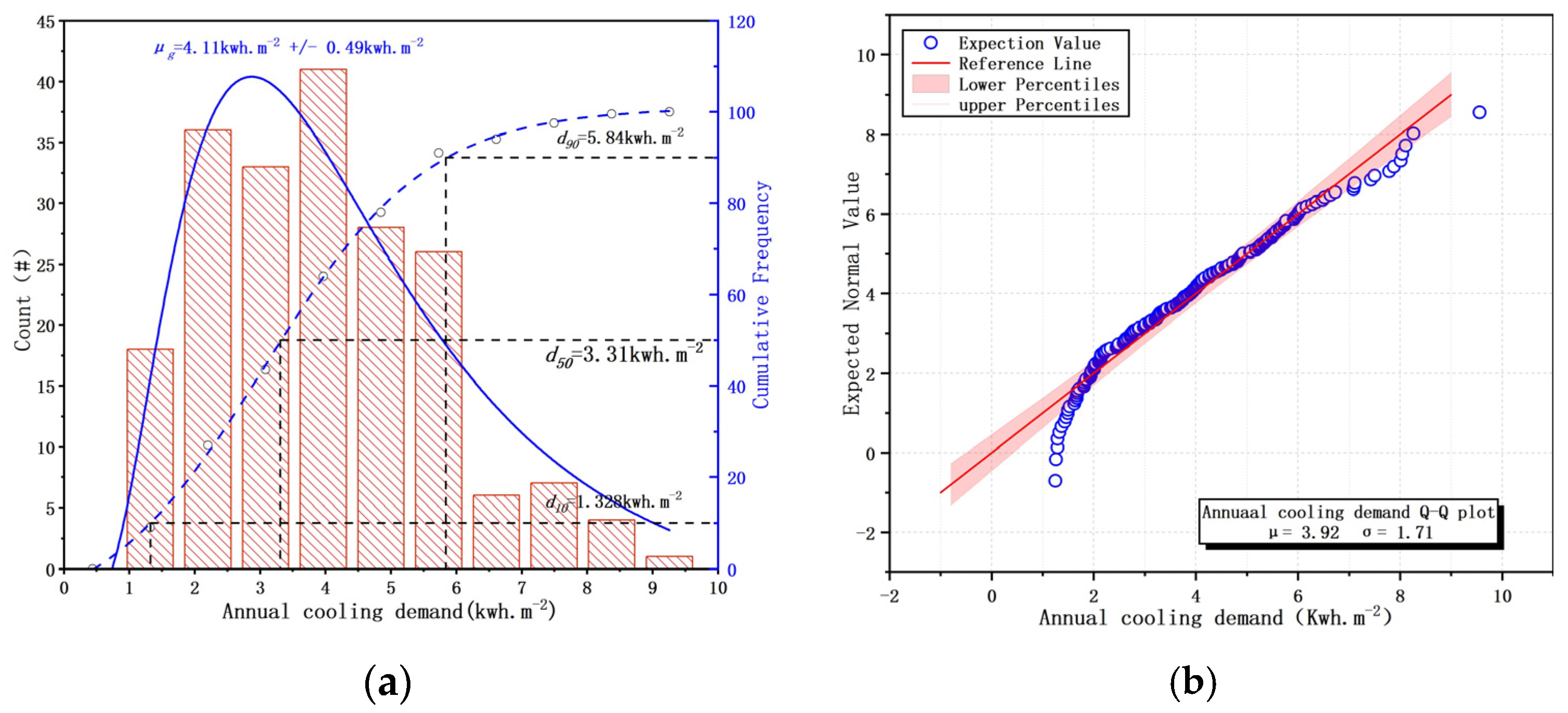

4.1. GSA Results

4.1.1. Correlation Analysis Results

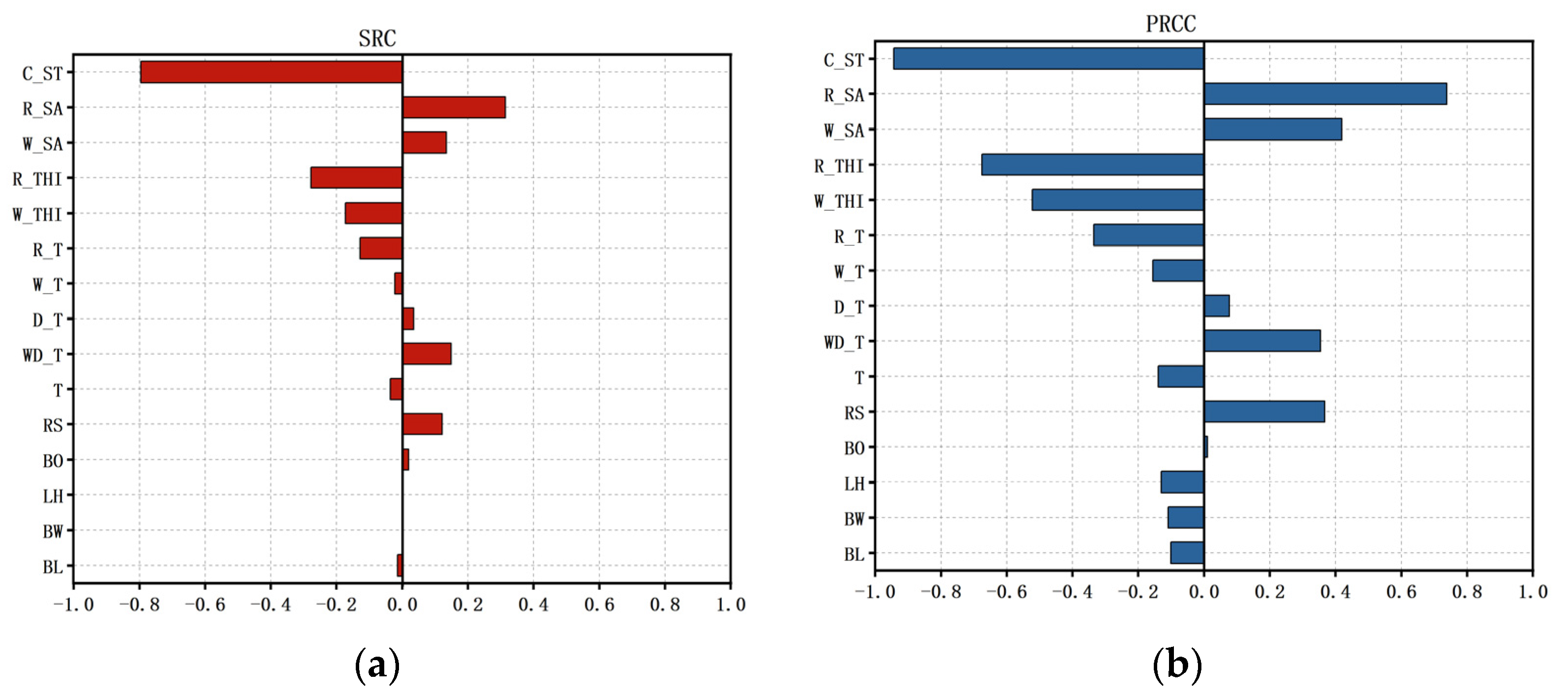

4.1.2. Sensitivity Analysis Results by SRC and PRCC

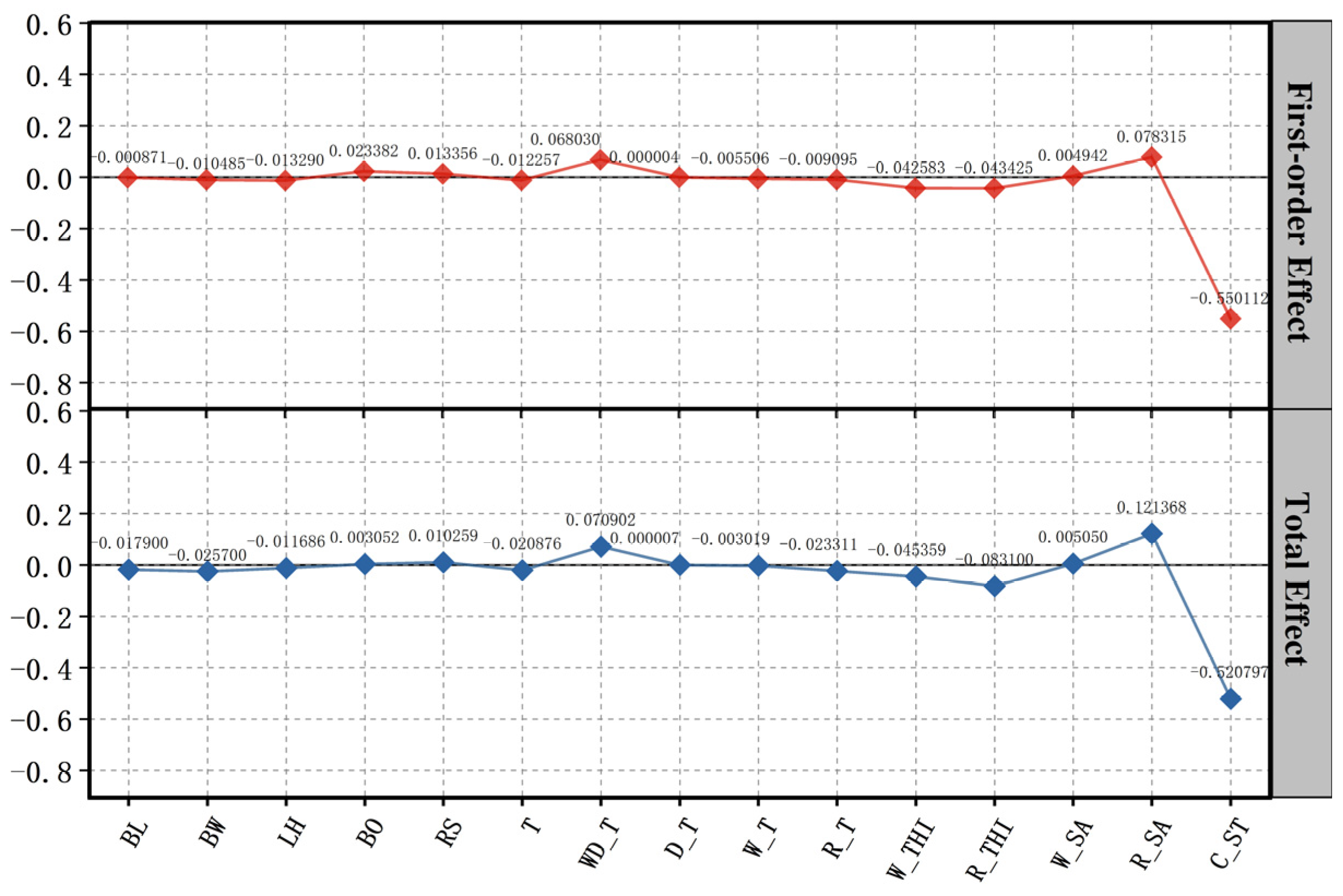

4.1.3. Sensitivity Analysis Results Based on the SOBOL Method

4.1.4. Comparison of Three GSA Results

4.2. LSA Results

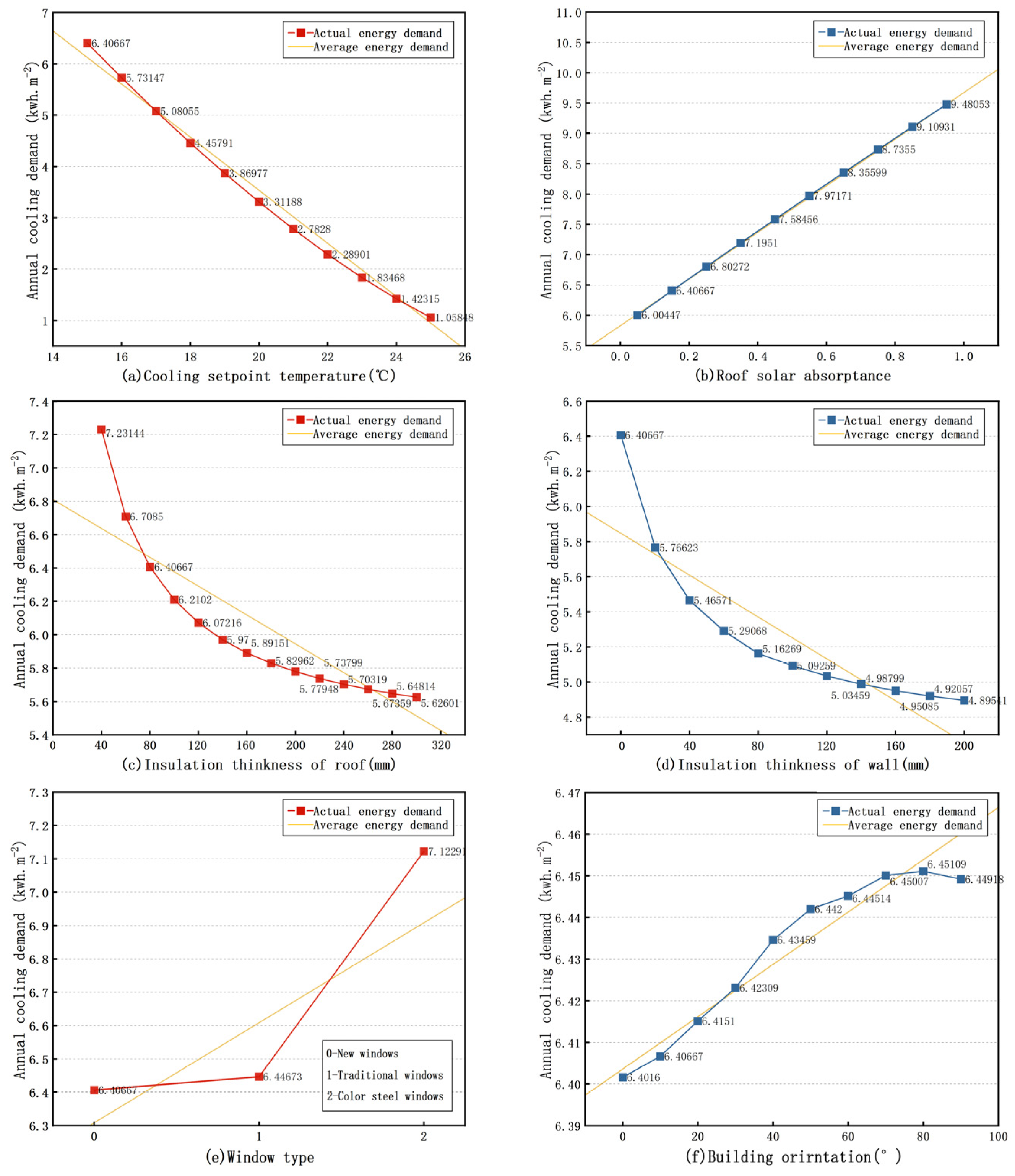

4.2.1. Comprehensive Local Sensitivity Analysis

4.2.2. Local Sensitivity Factor Analysis

4.3. Limitations and Future Works

- This study primarily examines granaries in cold regions, and the factors influencing the energy-efficient design of granary buildings in other climatic regions need to be further investigated. However, the proposed sensitivity analysis methodology is still applicable to other climate zones.

- Although sensitivity analyses have been conducted for grain warehouses, the factors influencing the energy-efficient design of other granary building types have not yet been studied, such as squat silos and silos. Given the different granary building types, the sensitivity analyses results should be different.

- The current work is based on the energy performance of granary buildings and overlooks other performance indicators. It is important to balance multiple performance criteria in practical applications [53,54,55,56]. Future research may need to consider additional performance indicators for granary buildings, such as cost and grain storage environment.

5. Conclusions

- (1)

- The GAS results indicate that the most influential parameters on cooling energy demand are cooling set-point temperature, roof solar absorptance, roof insulation thickness, exterior wall insulation thickness, window type, and orientation. Parameters such as roof and exterior wall solar absorptance are positively correlated with the cooling energy demand of the granary. In contrast, parameters including the cooling set-point temperature, roof thickness, and exterior wall insulation thickness are negatively correlated with the cooling energy demand of the granary.

- (2)

- The LAS results show that the cooling energy demand of grain warehouses increases significantly as the cooling set-point temperature decreases, with the greatest increase occurring at temperatures below 18 °C. A smaller solar absorptance of the roof leads to a greater effect on the reduction of the cooling energy demand of grain warehouses. When the thickness of the roof thermal insulation is less than 120 mm, the greatest reduction in cooling energy demand in grain warehouses is achieved. To reduce cooling energy consumption, it is recommended to use traditional or new thermal insulation with closed windows, ensuring that the long side of the granary is oriented between 10 degrees northwest and northeast.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food Security in China (White Paper) [EB/OL]. Available online: http://www.gov.cn/zhengce/2019-10/14/content_5439410.htm (accessed on 15 January 2024).

- Wang, Y.; Zeng, C.; Hu, C. Thermal Performance and Energy Conservation Effect of Grain Bin Walls Incorporating PCM in Different Ecological Areas of China. Processes 2022, 10, 2360. [Google Scholar] [CrossRef]

- Hamel, D.; Rozman, V.; Liška, A. Storage of cereals in warehouses with or without pesticides. Insects 2020, 11, 846. [Google Scholar] [CrossRef]

- Chen, G.; Hou, J.; Liu, C. A Scientometric Review of Grain Storage Technology in the Past 15 Years (2007–2022) Based on Knowledge Graph and Visualization. Foods 2022, 11, 3836. [Google Scholar] [CrossRef]

- Collins, D.A. A review on the factors affecting mite growth in stored grain commodities. Exp. Appl. Acarol. 2012, 56, 191–208. [Google Scholar] [CrossRef]

- Tang, W.; Di, Y. Ventilation technology and low temperature storage of granary in China. Appl. Mech. Mater. 2012, 204, 4372–4377. [Google Scholar] [CrossRef]

- Liu, D. Carbon Emissions Calculation of Grain Storage Process in Large Warehouse. Master’s Thesis, Henan University of Technology, Zhengzhou, China, 2020. (In Chinese). [Google Scholar]

- Samuelson, H.; Claussnitzer, S.; Goyal, A.; Chen, Y.; Romo-Castillo, A. Parametric energy simulation in early design: High-rise residential buildings in urban contexts. Build. Environ. 2016, 101, 19–31. [Google Scholar] [CrossRef]

- Gercek, M.; Arsan, Z.D. Energy and environmental performance based decision support process for early design stages of residential buildings under climate change. Sustain. Cities Soc. 2019, 48, 101580. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.; Zhang, W. Simulation-based approach to optimize passively designed buildings: A case study on a typical architectural form in hot and humid climates. Renew. Sustain. Energy Rev. 2018, 82, 1712–1725. [Google Scholar] [CrossRef]

- Tian, W. A review of sensitivity analysis methods in building energy analysis. Renew. Sustain. Energy Rev. 2013, 20, 411–419. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, N.; Wang, S. A parametric approach for performance optimization of residential building design in Beijing. Build. Simul. 2020, 13, 223–235. [Google Scholar] [CrossRef]

- Deng, Y.; Zhou, Y.; Wang, H.; Xu, C.; Wang, W.; Zhou, T.; Liu, X.; Liang, H.; Yu, D. Simulation-based Sensitivity Analysis of Energy Performance Applied to an Old Beijing Residential Neighbourhood for Retrofit Strategy Optimisation with Climate Change Prediction. Energy Build. 2023, 294, 113284. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, L.; Zheng, L.; Bi, G. A rapid evaluation method for design strategies of high-rise office buildings achieving nearly zero energy in Guangzhou. J. Build. Eng. 2021, 44, 103297. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Li, H. Sensitivity analysis of thermal performance of granary building based on machine learning. In Proceedings of the Intelligent & Informed—The 24th CAADRIA Conference, Wellington, New Zealand, 15–18 April 2019; Victoria University of Wellington: Wellington, New Zealand, 2019; Volume 1, pp. 665–674. [Google Scholar]

- Delgarm, N.; Sajadi, B.; Azarbad, K. Sensitivity analysis of building energy performance: A simulation-based approach using OFAT and variance-based sensitivity analysis methods. J. Build. Eng. 2018, 15, 181–193. [Google Scholar] [CrossRef]

- Li, H.; Wang, S.; Cheung, H. Sensitivity analysis of design parameters and optimal design for zero/low energy buildings in subtropical regions. Appl. Energy 2018, 228, 1280–1291. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, Z.; Liu, F.; Li, H.; Zhang, X.; Wang, K.; Chen, C.; Tian, C. Passive solar sunspace in a Tibetan buddhist house in Gannan cold areas: Sensitivity analysis. J. Build. Eng. 2023, 67, 105960. [Google Scholar] [CrossRef]

- Saurbayeva, A.; Memon, S.A.; Kim, J. Sensitivity analysis and optimization of PCM integrated buildings in a tropical savanna climate. J. Build. Eng. 2023, 64, 105603. [Google Scholar] [CrossRef]

- Chen, R.; Tsay, Y.S. An Integrated Sensitivity Analysis Method for Energy and Comfort Performance of an Office Building along the Chinese Coastline. Buildings 2021, 11, 371. [Google Scholar] [CrossRef]

- Gagnon, R.; Gosselin, L.; Decker, S. Sensitivity analysis of energy performance and thermal comfort throughout building design process. Energy Build. 2018, 164, 278–294. [Google Scholar] [CrossRef]

- Pianosi, F.; Beven, K.; Freer, J.; Hall, J.W.; Rougier, J.; Stephenson, D.B.; Wagener, T. Sensitivity analysis of environmental models: A systematic review with practical workflow. Environ. Model. Softw. 2016, 79, 214–232. [Google Scholar] [CrossRef]

- Goffart, J.; Woloszyn, M. EASI RBD-FAST: An efficient method of global sensitivity analysis for present and future challenges in building performance simulation. J. Build. Eng. 2021, 43, 103129. [Google Scholar] [CrossRef]

- Zhan, C.S.; Song, X.M.; Xia, J.; Tong, C. An efficient integrated approach for global sensitivity analysis of hydrological model parameters. Environ. Model. Softw. 2012, 41, 39–52. [Google Scholar] [CrossRef]

- Herrera, P.A.; Marazuela, M.A.; Hofmann, T. Parameter estimation and uncertainty analysis in hydrological modeling. Wiley Interdiscip. Rev. Water 2022, 9, e1569. [Google Scholar] [CrossRef]

- Nossent, J.; Elsen, P.; Bauwens, W. Sobol’ sensitivity analysis of a complex environmental model. Environ. Model. Softw. 2011, 26, 1515–1525. [Google Scholar] [CrossRef]

- Pudleiner, D.; Colton, J. Using sensitivity analysis to improve the efficiency of a Net-Zero Energy vaccine warehouse design. Build. Environ. 2015, 87, 302–314. [Google Scholar] [CrossRef]

- Blower, S.M.; Dowlatabadi, H. Sensitivity and uncertainty analysis of complex models of disease transmission: An HIV model, as an example. Int. Stat. Rev./Rev. Int. De Stat. 1994, 62, 229–243. [Google Scholar] [CrossRef]

- Saurbayeva, A.; Memon, S.A.; Kim, J. Integrated multi-stage sensitivity analysis and multi-objective optimization approach for PCM integrated residential buildings in different climate zones. Energy 2023, 278, 127973. [Google Scholar] [CrossRef]

- Sobol, I.M. Global sensitivity indices for nonlinear mathematical models and their Monte Carlo estimates. Math. Comput. Simul. 2001, 55, 271–280. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, R.; Heiselberg, P.K.; Johra, H. Modeling PCM phase change temperature and hysteresis in ventilation cooling and heating applications. Energies 2020, 13, 6455. [Google Scholar] [CrossRef]

- Silva, A.S.; Ghisi, E. Estimating the sensitivity of design variables in the thermal and energy performance of buildings through a systematic procedure. J. Clean. Prod. 2020, 244, 118753. [Google Scholar] [CrossRef]

- Naji, S.; Aye, L.; Noguchi, M. Sensitivity analysis on energy performance, thermal and visual discomfort of a prefabricated house in six climate zones in Australia. Appl. Energy 2021, 298, 117200. [Google Scholar] [CrossRef]

- Hopfe, C.J.; Hensen, J.L.M. Uncertainty analysis in building performance simulation for design support. Energy Build. 2011, 43, 2798–2805. [Google Scholar] [CrossRef]

- Brown, N.C.; Jusiega, V.; Mueller, C.T. Implementing data-driven parametric building design with a flexible toolbox. Autom. Constr. 2020, 118, 103252. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Liu, X.; Yang, L.; Zhang, Y.; He, J. How does future climatic uncertainty affect multi-objective building energy retrofit decisions? Evidence from residential buildings in subtropical Hong Kong. Sustain. Cities Soc. 2023, 92, 104482. [Google Scholar] [CrossRef]

- Hoseinzadeh, P.; Assadi, M.K.; Heidari, S.; Khalatbari, M.; Saidur, R.; Nejad, K.H.; Sangin, H. Energy performance of building integrated photovoltaic high-rise building: Case study, Tehran, Iran. Energy Build. 2021, 235, 110707. [Google Scholar] [CrossRef]

- Natanian, J.; Aleksandrowicz, O.; Auer, T. A parametric approach to optimizing urban form, energy balance and environmental quality: The case of Mediterranean districts. Appl. Energy 2019, 254, 113637. [Google Scholar] [CrossRef]

- Li, X.; Ding, Y.; Zhao, J.; Xu, Q. Experimental study on mechanical properties of integrated wall panels of grain warehouse with “Thermal Insulation”. Adv. Civ. Eng. 2022, 2022, 8636936. [Google Scholar] [CrossRef]

- GB/T 29890-2013; Technical Criterion for Grain and Oil-Seeds Storage. China Standard Press: Beijing, China, 2013.

- Wang, Z. Basic Theory and Design of Granary Building; Henan Science and Technology Press: Zhengzhou, China, 2015; pp. 244–250. ISBN 978-7-5349-7322-2. [Google Scholar]

- GB 50345-2012; Technical Code for Roof Engineering. China Architecture & Building Press: Beijing, China, 2012.

- Wang, H.; Huang, Y.; Yang, L. Integrated economic and environmental assessment-based optimization design method of building roof thermal insulation. Buildings 2022, 12, 916. [Google Scholar] [CrossRef]

- Manache, G.; Melching, C.S. Sensitivity of Latin hypercube sampling to sample size and distributional assumptions. In Proceedings of the 32nd Congress of the International Association of Hydraulic Engineering and Research, Venice, Italy, 1–6 July 2007. [Google Scholar]

- Ouanes, S.; Sriti, L. Regression-based sensitivity analysis and multi-objective optimisation of energy performance and thermal comfort: Building envelope design in hot arid urban context. Build. Environ. 2024, 248, 111099. [Google Scholar] [CrossRef]

- Song, J.; Peng, J.; Cao, J.; Yin, R.; He, Y.; Zou, B.; Zhao, W. Global sensitivity analysis of fan coil air conditioning demand response—A case study of medium-sized office buildings. Appl. Therm. Eng. 2023, 230, 120721. [Google Scholar] [CrossRef]

- Yildiz, Y.; Korkmaz, K.; Ozbalta, T.G.; Arsan, Z.D. An approach for developing sensitive design parameter guidelines to reduce the energy requirements of low-rise apartment buildings. Appl. Energy 2012, 93, 337–347. [Google Scholar] [CrossRef]

- Xu, W.; Gong, S.; Wang, N.; Zhao, W.; Yin, H.; Yang, R.; Yin, X.; Tan, G. Temperature reduction and energy-saving analysis in grain storage: Field application of radiative cooling technology to grain storage warehouse. Renew. Energy 2023, 218, 119272. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, J.; Gao, Y.; Tian, W.; Yan, Z.; Ye, X.; Sun, X.; Wu, C. Uncertainty and sensitivity analysis of cooling and heating loads for building energy planning. J. Build. Eng. 2022, 45, 103440. [Google Scholar] [CrossRef]

- Guo, J.; Li, M.; Jin, Y.; Shi, C.; Wang, Z. Energy Prediction and Optimization Based on Sequential Global Sensitivity Analysis: The Case Study of Courtyard-Style Dwellings in Cold Regions of China. Buildings 2022, 12, 1132. [Google Scholar] [CrossRef]

- Choi, J.H. Investigation of the correlation of building energy use intensity estimated by six building performance simulation tools. Energy Build. 2017, 147, 14–26. [Google Scholar] [CrossRef]

- Li, K.; Liu, X.; Zhang, H.; Ma, J.; He, B.J. Evaluating and improving the adaptability of commonly used indices for predicting outdoor thermal sensation in hot and humid residential areas of China. Dev. Built Environ. 2023, 16, 100278. [Google Scholar] [CrossRef]

- Liu, X.; He, J.; Xiong, K.; Liu, S.; He, B.-J. Identification of factors affecting public willingness to pay for heat mitigation and adaptation: Evidence from Guangzhou, China. Urban Clim. 2023, 48, 101405. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, B.; Caneparo, L.; Meng, Q.; Guo, W.; Liu, X. Physical Environment Study on Social Housing Stock in Italian Western Alps for Healthy and Sustainable Communities. Land 2023, 12, 1468. [Google Scholar] [CrossRef]

- Li, B.; Guo, W.; Liu, X.; Zhang, Y.; Caneparo, L. The Third Solar Decathlon China Buildings for Achieving Carbon Neutrality. Buildings 2022, 12, 1094. [Google Scholar] [CrossRef]

- Zheng, S.; He, C.; Guldmann, J.-M.; Xu, H.; Liu, X. Heat Mitigation Benefits of Urban Trees: A Review of Mechanisms, Modeling, Validation and Simulation. Forests 2023, 14, 2280. [Google Scholar] [CrossRef]

| Category | Parameter Name | Type | Ranges | References | |

|---|---|---|---|---|---|

| Shape parameters | Building length (BL) | continuous | 36~66 m | [41] | |

| Building width (BW) | continuous | 21~30 m | [41] | ||

| Loading height (LH) | continuous | 6~12 m | [41] | ||

| Building orientation (BO) | continuous | 0~90° | |||

| Roof slope (RS) | continuous | 3~45° | [42] | ||

| Envelope parameters | Wall thickness (T) | discrete | 370 mm, 490 mm, 620 mm, 740 mm | ||

| Window type (WD_T) | Color steel doors and windows | discrete | 6.6 w/(m2.k) | ||

| Door type (D_T) | Traditional insulation and airtight doors and windows | 0.5 w/(m2.k) | |||

| New thermal insulation and airtight doors and windows | 0.22 w/(m2.k) | ||||

| Wall insulation type (W_T) | EPS | discrete | 0.024 w/(m.k) | [43] | |

| Roof insulation type (R_T) | XPS | 0.032 w/(m.k) | |||

| PU | 0.039 w/(m.k) | ||||

| Wall thermal insulation thickness (W_THI) | continuous | 0~200 mm | |||

| Roof thermal insulation thickness (R_THI) | continuous | 40~300 mm | |||

| Wall solar absorptance (W_SA) | continuous | 0.05~0.95 | [21] | ||

| Roof solar absorptance (R_SA) | continuous | 0.05~0.95 | [21] | ||

| Equipmentparameter | Cooling Set-point Temperature (C_ST) | continuous | 15~25 °C | ||

| Ranking | SRC | PRCC | Sobol (First-Order Effect) |

|---|---|---|---|

| 1 | C_ST | C_ST | C_ST |

| 2 | R_SA | R_SA | R_SA |

| 3 | R_THI | R_THI | WD_T |

| 4 | W_THI | W_THI | R_THI |

| 5 | WD_T | W_SA | W_THI |

| 6 | W_SA | RS | BO |

| 7 | R_T | WD_T | RS |

| 8 | RS | R_T | LH |

| 9 | T | W_T | T |

| 10 | D_T | T | BW |

| 11 | W_T | LH | R_T |

| 12 | BO | BW | W_T |

| 13 | BL | BL | W_SA |

| 14 | LH | D_T | D_T |

| 15 | BW | BO | BL |

| C_ST | R_SA | R_THI | W_THI | WD_T | BO | |

|---|---|---|---|---|---|---|

| Sensitivity factor | 0.835 | 0.367 | 0.222 | 0.236 | 0.101 | 0.008 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Ye, J.; Li, K.; Niu, S.; Liu, X. Multi-Stage Sensitivity Analysis of the Energy Demand for the Cooling of Grain Warehouses in Cold Regions of China. Agriculture 2024, 14, 193. https://doi.org/10.3390/agriculture14020193

Zhang H, Ye J, Li K, Niu S, Liu X. Multi-Stage Sensitivity Analysis of the Energy Demand for the Cooling of Grain Warehouses in Cold Regions of China. Agriculture. 2024; 14(2):193. https://doi.org/10.3390/agriculture14020193

Chicago/Turabian StyleZhang, Hua, Junya Ye, Kunming Li, Shujie Niu, and Xiao Liu. 2024. "Multi-Stage Sensitivity Analysis of the Energy Demand for the Cooling of Grain Warehouses in Cold Regions of China" Agriculture 14, no. 2: 193. https://doi.org/10.3390/agriculture14020193

APA StyleZhang, H., Ye, J., Li, K., Niu, S., & Liu, X. (2024). Multi-Stage Sensitivity Analysis of the Energy Demand for the Cooling of Grain Warehouses in Cold Regions of China. Agriculture, 14(2), 193. https://doi.org/10.3390/agriculture14020193