Abstract

The effect of nitrogen and zinc treatment on quality and yield was studied to provide a theoretical basis for generating high-quality and high-yielding foxtail millet. In the years 2021–2022, ‘Jingu 21’ was utilized as the test material in a split-plot design. The main plot was subjected to nitrogen treatment, while the sub-plot was treated with zinc. An arrangement of random blocks was employed. Four levels of nitrogen application (0 kg/hm2, 120 kg/hm2, 180 kg/hm2, 240 kg/hm2) and three levels of zinc application (20 mg/L, 40 mg/L, 80 mg/L foliar spraying) were set, resulting in a total of twelve treatments. Each treatment was replicated three times, with each plot covering an area of 15 m2. (1) The findings indicated that the contents of crude fat and crude protein in foxtail millet increased initially and then decreased with the increase in nitrogen application concentration. Additionally, the protein components were found to be in the following order: gliadin > albumin > glutenin > globulin. (2) Adding an appropriate amount of nitrogen fertilizer under the same zinc level promoted the contents of amylose, total carotenoids, and flavonoids in millet to some extent. Over the course of two years, the content of flavonoids in millet was highest when treated with N180Zn40 (nitrogen 180 kg/hm2, zinc 40 mg/L), showing an increase of 50.14% and 58.67%, respectively, compared to the treatment of applying zinc fertilizer alone at the same zinc level. (3) The phytic acid content and phytic acid/zinc molar ratio exhibited a pattern of initially decreasing and then increasing with the rise in nitrogen and zinc concentrations. (4) The application of zinc fertilizer and increased nitrogen fertilizer for two consecutive years had a significant impact on the yield of millet. Additionally, the application of zinc fertilizer had a highly significant effect on both the ear weights and thousand-kernel weights of millet (p < 0.001). The results demonstrated a positive synergistic effect when nitrogen fertilizer and zinc fertilizer were applied together. This combination significantly improved millet yield and thousand-kernel weights, enhanced the nutritional quality, and increased the content of functional components. Additionally, it also improved the availability of zinc.

1. Introduction

Foxtail millet plays a crucial role in the agricultural development of Shanxi, particularly in the cultivation of ‘special’ and ‘excellent’ crops [1]. After hulling, foxtail millet is now recognized as a wholegrain food raw material that is high in nutrients, highly valued, and performs a number of physiological regulatory functions [2]. The main component of foxtail millet is starch, constituting approximately 70% [3]. The fat content ranges from 3.38% to 6.49%, with unsaturated fatty acids accounting for approximately 82.02% to 90.39% [4]. The crude protein content is estimated to be around 9.82–16.63% [5], and it consists of a significant amount of gluten and gliadin [6]. Foxtail millet is known to contain abundant mineral elements such as Fe, Mn, Se, Zn, Cu, and others [7]. Furthermore, it is high in functional active components such as total flavonoids, total carotenoids, and so on. Many factors influence the quality and yield of millet, including variety, fertilization, environment, management, and so on, and fertilization is a key element influencing millet production and quality.

Nitrogen is an essential nutrient for the growth and development of plants. Additionally, it serves as the primary component of metal transporters. It is essential for plant photosynthetic, protein, and auxin synthesis [8,9]. Cao X, Zhou T et al. demonstrated [10,11] that increasing the fertilization amount increased the apparent amylose content of rice, decreased the content of pullulan, and increased the content of gluten, essential amino acids, and trace elements. This improvement in nutritional quality and processing quality is attributed to the increased content of gluten, essential amino acids, and trace elements. Britz E. et al. [12] found that the crude protein content, mineral nutrient absorption, and crop yield of meadowsweet were significantly enhanced by increasing the nitrogen treatment. Hui Y et al. [13] found that nitrogen application increased the levels of anthocyanins, flavanols, and flavonols in plants.

Zinc is a micronutrient required by humans, animals, and plants. It plays a crucial role in various biological processes. In most crops, the typical requirement for zinc for full growth is 15–20 mg/kg dry weight. For instance, it is a component of RNA polymerase, which is necessary for protein synthesis. Zinc also affects nitrogen metabolism through its interaction with protease, and it is involved in the synthesis of glutamic acid, ribose, and protein through its interaction with glutamate dehydrogenase [14]. Zinc plays a crucial role in various biochemical processes, including photosynthesis, respiration, protein metabolism, and hormone synthesis [15]. However, zinc deficiency leading to ‘hidden hunger’ has emerged as the fifth major contributor to induced diseases in developing countries [16], particularly in low-income nations where cereals are the primary source of diet [17]. Enhancing the zinc content and bioavailability of grain is of immense importance in addressing zinc deficiency in human beings and fulfilling the zinc requirements for optimal human health. Millet, as a highly zinc-rich crop, offers a promising solution. The application of zinc fertilizer to augment the zinc content in grain has proven to be an effective approach. Notably, previous research conducted in our laboratory demonstrated that the application of zinc spray on various millet varieties significantly increased the zinc content, with the booting stage exhibiting the most favorable results [18].

The protein content of wheat grain was increased when nitrogen and zinc were applied together, compared to when the nitrogen fertilizer was applied alone [19]. This increase was mainly attributed to the effective combination of nitrogen and zinc, which facilitated the transfer of these nutrients to the grain and promoted protein synthesis [20]. In their study, Ji et al. [21] found that the supply of Zn had a significant impact on the translocation and distribution of N in rice leaves. They observed that Zn up-regulated the expression of N transporter genes (OsNRTs and OsAMTs) and induced the expression of N assimilation genes (OsNiR2 and OsGS1;1), as well as the expression levels of OsGS2 and OsFd-GOGAT. This led to an increase in the N assimilation level and the activities of NR, NiR, and GS in the shoots of rice. Zinc is transported across the membrane, then transported in the xylem, stored in vegetative organs, transported in the phloem, and ultimately unloaded in the grain [22]. The application of nitrogen has been found to significantly enhance the translocation and distribution of Zn from the root to the branches in leaves. This effect is achieved via up-regulating the expression level of Zn transporter genes (OsZIPs) [21]. According to studies conducted by Xia H et al. [23] and Zhao P et al. [24], the combined application of nitrogen and zinc has been found to significantly reduce the P/Zn molar ratio of wheat grain. This application also improves the zinc content in the grain and enhances the bioavailability of zinc in wheat. This is achieved by increasing the absorption of zinc by vegetative organs and facilitating its transfer to the grain. Furthermore, research has demonstrated that the combined application of nitrogen and zinc positively influences crop yield [25], leading to a noticeable improvement in crop productivity.

The scientific application of nitrogen and zinc in combination can enhance crop yield and quality. However, the current research primarily focuses on rice, corn, wheat, and other crops, with limited studies on millet. Additionally, the effects of combining nitrogen and zinc on millet yield and its nutritional components vary. This experiment aimed to investigate the effects of different levels of nitrogen and zinc fertilization on millet yield and its various components. This study also examined the impact of nitrogen and zinc interaction on grain crude fat, protein components, starch, mineral elements, functional substances, total carotenoids, and total flavonoids. The objective was to offer technical guidance and theoretical support for the production of high-yield and high-quality functional millet enriched with zinc.

2. Materials and Methods

2.1. Experimental Field and Phenology

The experiment was conducted at the Shenfeng Experimental Base of the College of Agriculture, Shanxi Agricultural University (112°28′ E, 37°12′ N) from May 2021 to November 2021 and from May 2022 to November 2022. The experimental base is located in a temperate continental climate with an average annual temperature of approximately 10 °C, an average annual sunshine duration of about 2500 h, and an average annual precipitation of about 400 mm. The precipitation is unevenly distributed throughout the year, with the majority occurring from July to September.

2.2. Experimental Design

The experiment followed a split-plot design, where the main zone was treated with nitrogen and the secondary zone was treated with zinc. Random blocks were arranged for the experiment. The soil used was calcareous brown soil, with the following physicochemical properties: pH = 7.9; organic matter content of 25.58 g/kg; alkaline hydrolyzable nitrogen content of 47.94 mg/kg; total nitrogen, 1.126 g/kg; available iron, 5.76 mg/kg; available manganese, 5.41 mg/kg; available phosphorus content of 23.48 mg/kg; available potassium content of 129.58 mg/kg; and a total zinc content of 94.89 mg/kg.

The variety of foxtail millet used for the experiment was ‘Jingu 21’ (Shanxi Fen du Xiang Seed Industry Technology Co., Ltd., Fenyang, China). The tested zinc fertilizer was prepared using a mixture of distilled water and analytically pure ZnSO4 7H2O. The ZnSO4 7H2O was obtained from Tianjin Zhiyuan Chemical Reagent Co., Ltd., Tianjin, China. with a purity of at least 99.5% (W). Solutions with concentrations of 20 mg/L, 40 mg/L, and 80 mg/L were prepared. The nitrogen fertilizer used was urea (with a total nitrogen content >46.0%; Shanxi Tianze Coal Chemical Group Co., Ltd., Jincheng, China). The experimental area consisted of cells measuring 15 m2 each. Four different nitrogen levels were applied: 0 kg/hm2 (N0), 120 kg/hm2 (N120), 180 kg/hm2 (N180), and 240 kg/hm2 (N240). Additionally, three different levels of zinc were used: 20 mg/L (Zn20), 40 mg/L (Zn40), and 80 mg/L (Zn80). A total of 12 treatments are shown in Table S1, each of which was repeated 3 times. Urea was applied as the base fertilizer, while the ZnSO4·7H2O solution was sprayed once during the millet booting stage until it hung without dripping.

2.3. Chemical Methods

2.3.1. Crude Fat

The crude fat content was determined using the Soxhlet extraction method [26]. Weigh 3 g of rice flour (foxtail millet seeds are shelled, crushed, and sieved using a 60 mesh sieve), put it into a filter paper bag, dry, cool, and weigh it, put it into an installed Soxhlet extractor, extract it with petroleum ether for 8 h, take out the medicine bag, dry it, cool it to room temperature and weigh it to calculate the crude fat content.

2.3.2. Crude Protein and Protein Components

The nitrogen content in foxtail millet grain was determined using the Kjeldahl nitrogen method [26]. Approximately 0.3 g of the crushed seed sample was weighed and placed in a boiling tube. Then, 5 mL of concentrated sulfuric acid was added, and the mixture was soaked overnight. The sample was heated until it became transparent, and then the nitrogen was determined using a Kjeldahl nitrogen analyzer. The crude protein content was calculated by multiplying the nitrogen content in the foxtail millet grain by a factor of 6.25.

2.3.3. Protein Components

Determination of albumin content [27]: To determine the albumin content, 0.1 g of rice flour was weighed into a 1.5 mL centrifuge tube. Then, 1 mL of distilled water was added, and the mixture was shaken and extracted on a shaker for 2 h. After that, it was centrifuged at 10,000 rpm for 10 min. The supernatant was transferred into a 10 mL graduated test tube and extracted three times. The extractive solutions were combined, and 1 mL of 0.1% Coomassie Brilliant Blue G250 colorimetric solution was added. The volume was adjusted to 10 mL. Additionally, a standard working curve of bovine serum albumin was prepared, and the albumin content was determined via the reading from the working curve.

Determination of Globulin Content: To extract globulin from the rice flour starch after albumin extraction, add 1 mL of 5% sodium chloride solution. The extraction and determination method for globulin content is the same as that used for albumin content determination.

The determination of gliadin content involved adding 1 mL of a 70% ethanol solution to the precipitation of rice flour, from which globulin was extracted. The extraction and determination procedures were the same as those used for measuring albumin content, as described above.

Determination of Glutenin Content: To determine the glutenin content, 1 mL of 0.2% sodium hydroxide solution is added to the rice flour precipitate after gliadin extraction. The mixture is then shaken on a shaking table for 2 h and centrifuged at 12,000 r/min for 10 min. The supernatant is transferred into a 50 mL volumetric flask. This extraction process is repeated three times, and the extracts are combined and adjusted to a final volume of 50 mL. From the resulting solution, 3 mL is taken and transferred to a 10 mL graduated test tube. To this, 1 mL of 0.1% Coomassie Brilliant Blue is added.

2.3.4. Straight Chain, Pullulan

The determination was conducted using the dual-wavelength method [28]. Approximately 0.1 g of skimmed foxtail millet powder was weighed and placed into a 50 mL volumetric flask. Then, 10 mL of 0.5 mol/L potassium hydroxide solution was added, and the mixture was heated in a boiling water bath for 10 min. The volume was adjusted with distilled water. In 50 mL stopper tubes, 2.5 mL of the sample assay and blank solutions were taken. Subsequently, 0.5 mL of iodine reagent was added after adjusting the pH of 1 mol/L hydrochloric acid to approximately 3.5. The blank solution was diluted to 50 mL without iodization reagent. After standing for 20 min, the content of the linear chain and pullulan was determined at a specified wavelength.

2.3.5. Total Carotenoid Content

To determine the total carotenoid content, 0.2 g of crushed skimmed foxtail millet is mixed with 10 mL of water-saturated n-butanol (1:1) and stored in a dark place. The mixture is shaken for 3 h at room temperature and then centrifuged for 10 min at 4000 g. The resulting supernatant is collected, and its absorbance value is measured at 450 nm [29].

2.3.6. Total Flavonoids

Total flavonoids were determined using the sodium nitrite–aluminum nitrate method [30]. A standard curve was prepared with rutin as the control. Then, 0.3 g of grain was weighed and dissolved in ethanol with a volume fraction of 60% (solid–liquid ratio = 1:20). The extract was subjected to ultrasonic extraction three times and then centrifuged for 10 min at 4000 r/min. The resulting extract was combined. A total of 1 mL of the extract was aspirated and mixed with 0.3 mL each of sodium nitrite and aluminum nitrate, with a 6 min interval between each reagent addition. Finally, 4 mL of 4% NaOH was added, and the volume was adjusted. After standing for 20 min, the absorbance value was measured at a wavelength of 510 nm.

2.3.7. Mineral Elements

The concentrations of Zn, Fe, Cu, Mn, and Se in foxtail millet grains were analyzed using ICP-MS. A sample weighing 0.5 g was crushed and mixed with a 10 mL solution of HNO3-H2O2 (in a ratio of 8:2). The mixture was left to soak overnight. After the pre-reaction was complete, microwave digestion was carried out using a microwave digester. The resulting acid was driven to near dryness using an acid catcher and then cooled. The volume was adjusted to 10 mL using ultrapure water. The solution was filtered using a 0.45 μm aqueous filter membrane, and the filtrate was stored in a 5 mL EP tube. The concentrations of Zn, Se, Fe, Mn, and Cu were determined using the filtered solution.

2.3.8. Phytic Acid Content

Ferric chloride colorimetry was performed [31]. The crushed sample weighing 0.25 g was placed in a 10 mL EP tube. Then, 5 mL of 0.7% hydrochloric acid solution was added, and the mixture was stirred and extracted at 25 °C for 1 h. After centrifugation for 15 min at 4000× g, the supernatant was transferred to a tube. Subsequently, 1 mL of 0.03% FeCI3·6H2O and 0.3% sulfosalicylic acid solution were added sequentially. The absorbance value at 500 nm was determined using distilled water as a reference.

2.3.9. Yield and Its Constituent Factors

After the foxtail millet reached maturity, three plants were randomly chosen from each community to measure ear characteristics, including ear length, ear weight, ear coarseness, and panicle yard. Additionally, 4 m2 ears were harvested and threshed for counting. The threshed foxtail millet was then crushed and passed through a 60-mesh sieve to determine its nutritional quality.

2.4. Data Processing

SPSS (Ver. 25.0, IBM, New York, NY, USA) software was used for ANOVA, Excel (Ver. 2019, Microsoft, Redmond, WA, USA) software was used to organize data and charts, and Origin (Ver. 2018, Origin Lab, Northampton, MA, USA) was used for plotting.

3. Results

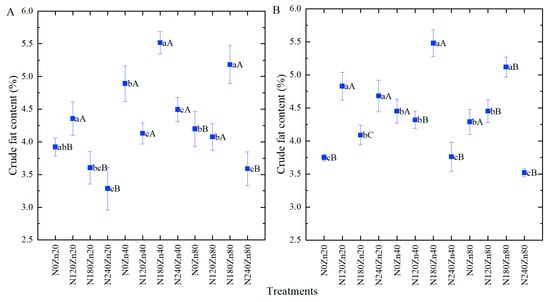

3.1. Effect of Combined Application of Zinc Nitrogen on Crude Fat Content of Foxtail Millet

The fat content of the millet grain in 2021 and 2022 exhibited a pattern of initially increasing and then decreasing with the rise in nitrogen concentration. The highest accumulation of fat content was observed under 180 kg/hm2 nitrogen fertilizer, as depicted in Figure 1. At N180Zn40, the crude fat content reached its maximum, measuring 5.52% and 5.48%, respectively. In comparison to other treatments with varying zinc levels but the same nitrogen level, the crude fat content of ‘Jingu 21’ increased by 53.3% and 6.56% in 2021 and by 33.99% and 7.03% in 2022. When the zinc concentration was 20 mg/L, the crude fat content reduced by 8.89% in 2021 compared to the single zinc fertilizer treatment under different nitrogen levels but the same zinc level. However, when the zinc concentration ranged from 40 mg/L to 80 mg/L, the crude fat content increased by 12.88% and 23.33%, respectively. In 2022, under the N180 treatment, the application of three different gradients of zinc fertilizer exhibited a significant increasing trend in comparison to the single application of zinc fertilizer under the same zinc level but different nitrogen levels. The increases were 9.07%, 23.15%, and 19.35%, respectively.

Figure 1.

Effect of combined application of zinc nitrogen on crude fat content of foxtail millet. Lowercase letters indicate significant differences at the same Zn level, and uppercase letters indicate significant differences at the same N level, p < 0.05. (A) is the measurement in 2021, and (B) is the measurement in 2022.

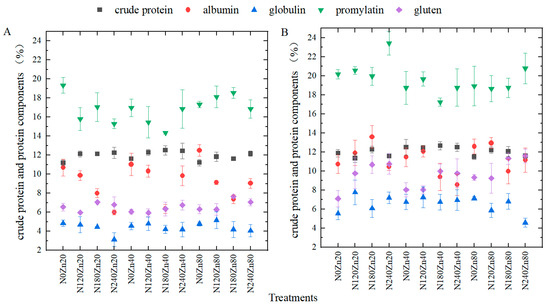

3.2. Effects of Combined Application of Zinc Nitrogen on Crude Protein and Protein Components of Foxtail Millet

The crude protein content of N180Zn40-treated seeds increased by 7.75% and 1.20% in 2021 and 2022, respectively, compared to N0Zn40 (Figure 2). In 2021, the alcohol-soluble protein content averaged 16.83%, clear protein content averaged 9.17%, gluten content averaged 6.56%, and globulin content averaged 4.42%. In 2022, the alcohol-soluble protein content of cereal grains ranged from 17.25% to 23.42% with an average of 19.64%, the clear protein content ranged from 8.57% to 13.60% with an average of 11.24%, the glutenin content ranged from 7.11% to 11.59% with an average of 9.64%, and the globulin content ranged from 4.58% to 7.77% with an average of 6.56%. The percentage of each protein fraction was slightly higher in 2022 than in 2021. Additionally, the alcohol-soluble protein content of N180Zn40-treated seeds showed a minimum value in both years, with values of 14.35% and 17.25% in 2021 and 2022, respectively. These values were reduced by 15.44% and 8.00%, respectively, compared to the treatment of zinc fertilizer alone at the same zinc level.

Figure 2.

Effects of zinc application on crude protein and protein components of foxtail millet. Lowercase letters indicate significant differences at the same Zn level, and uppercase letters indicate significant differences at the same N level, p < 0.05. (A) is the measurement in 2021, and (B) is the measurement in 2022.

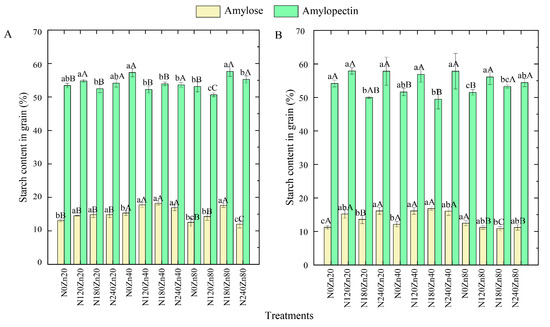

3.3. Effects of Combined Application of Zinc on Amylose and Amylopectin in Foxtail Millet

Under the same zinc level condition, the addition of a moderate amount of nitrogen fertilizer has been found to promote the content of straight-chain starch in cereals. In Figure 3, it can be observed that for two consecutive years, the N180Zn40 treatment had the highest content of straight-chain starch, showing an increase of 18.77% and 38.04% compared to the single application of the zinc fertilizer treatment at the same zinc level. In 2021, the branched starch content reached its maximum value of 57.66% in the N180Zn80 treatment, which was 8.55% higher than the single application of Zn fertilizer treatment at the same Zn level. In 2022, the branched-chain starch content in cereal grains reached its maximum value of 57.92% in the N120Zn20 treatment. This represented an increase of 6.94%, 15.86%, and 0.16% compared to other treatments under the same zinc level condition and an increase of 1.81% and 3.23% compared to other treatments under different Zn levels at the same N level.

Figure 3.

Effect of combined application of zinc on starch content of grain. Lowercase letters indicate significant differences at the same Zn level, and uppercase letters indicate significant differences at the same N level, p < 0.05. (A) is the measurement in 2021, and (B) is the measurement in 2022.

3.4. Effect of Combined Application of Zinc Nitrogen on Total Carotenoid Content of Foxtail Millet

The addition of moderate nitrogen fertilizer can promote an increase in the total carotenoid and total flavonoid content in cereal grains, as shown in Table 1. The highest overall total carotenoid content in cereal grains for both 2021 and 2022 was observed at N120. In 2021, the average total carotenoid content was 18.03 mg/kg, with the maximum observed in the N120Zn20 treatment. This represented an increase of 5.95% and 12.09% compared to other treatments under different zinc levels at the same nitrogen level. In 2022, the average total carotenoid content of cereal grains was 19.78 mg/kg. The N0Zn80 treatment showed a maximum increase of 11.25% and 5.91% compared to other treatments at the same nitrogen level. The total flavonoid content of grain was highest in the N180Zn40 treatment for two consecutive years, showing an increase of 50.14% and 58.67% compared to the treatment with a single zinc fertilizer at the same zinc level. Similarly, compared to treatments with different zinc levels but the same nitrogen level, the increases were 30.14%, 36.11%, 30.38%, and 57.28%, respectively. However, when the applied N concentration exceeded 240 kg/hm2, it had an inhibitory effect on the flavonoid content of the seeds.

Table 1.

Effects of combined application of zinc on the content (mg/kg) of total carotenoids and total flavonoids in foxtail millet.

3.5. Effect of Combined Application of Zinc on the Mineral Element Content of Foxtail Millet

Additional nitrogen fertilization at the same zinc level can effectively increase the zinc and other mineral content of grain kernels compared to zinc fertilization alone. Table 2 demonstrates that the zinc content of seeds increased by 10.89%, 11.95%, and 16.52% in all treatments after additional nitrogen fertilization, compared to treatments with the N0Zn20 treatment, respectively. Similarly, the zinc content of seeds at Zn40 increased by 5.13%, 11.12%, and 5.57% in all treatments after additional nitrogen fertilization, compared to treatments with N0Zn40, respectively. However, at Zn80, an additional nitrogen fertilizer concentration of 240 kg/hm2 actually inhibited the increase in grain zinc content, resulting in a reduction of 7.46% compared to zinc fertilizer alone. When considering different zinc levels at the same nitrogen level, the zinc content of grain kernels also exhibited a tendency to initially increase and then decrease with the increase in zinc application. Overall, the zinc content was higher than the other two treatments under the Zn40 treatment. The highest zinc content of grain kernels was observed in the N180Zn40 treatment, measuring 82.15 mg/kg.

Table 2.

Effect of nitrogen and zinc rationing on mineral content (mg/kg) of cereals.

Seed Mn content had a maximum value of 17.48 mg/kg in the N240Zn20 treatment, which increased by 26.67%, 15.30%, and 20.63% compared to other treatments at the same Zn level. Seed Fe content had a maximum value of 53.90 mg/kg in the N0Zn80 treatment, which increased by 46.55%, 44.35%, and 52.86% compared to other N treatments at the same Zn level. The Se content of seeds had a maximum value of 0.07 mg/kg in the N0Zn40 treatment, which was significantly different from the other treatments under the same Zn level conditions. In the case of seed Cu content, the maximum value of 9.08 mg/kg was observed in the N0Zn80 treatment, representing a 21.23%, 22.70%, and 17.77% increase compared to the other treatments at the same Zn level condition. On average, the contents of Mn, Fe, Se, and Cu were 14.66 mg/kg, 41.98 mg/kg, 0.05 mg/kg, and 8.10 mg/kg, respectively, for each treatment.

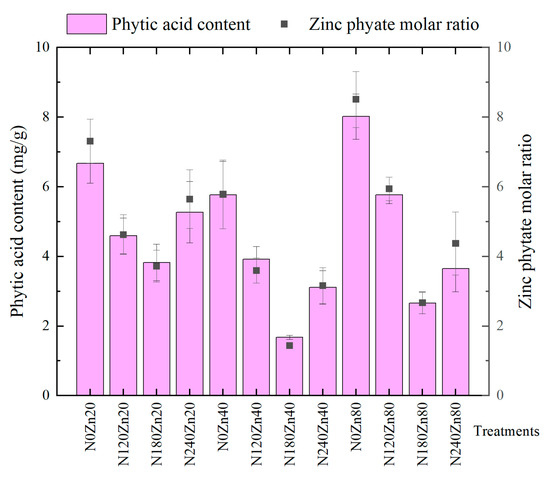

3.6. Effects of Combined Application of Zinc Nitrogen on Phytic Acid Content and Molar Ratio of Zinc Phytate in Foxtail Millet

Both the phytic acid content and the phytic acid/zinc molar ratio exhibited a fluctuating trend with increasing concentrations of zinc and nitrogen application while keeping the nitrogen and zinc levels constant. In Figure 4, the lowest value of phytic acid content was observed in the N180Zn40 treatment, measuring 1.68 mg/g. The N180Zn40 treatment resulted in a 70.88% reduction in phytic acid content compared to the N0Zn40 treatment. When different concentrations of nitrogen fertilizers were applied, the average phytate/Zn molar ratio content was 5.96, 4.66, and 7.35 at Zn20, Zn40, and Zn80, respectively. A minimum value of 2.02 was observed for the N180Zn40 treatment, indicating a 73.80% reduction in phytate/Zn molar ratio content compared to the N0Zn40 treatment. This suggests that at this particular time, the biological effectiveness of Zn content was the highest.

Figure 4.

Effects of combined application of zinc nitrogen on phytic acid content molar ratio of zinc phytate in foxtail millet grain.

3.7. Effect of Nitrogen and Zinc Rations on Grain Yield and Its Components

Spraying zinc fertilizer and increasing nitrogen fertilizer for two consecutive years (2021–2022) had a significant impact on grain yield, as shown in Table S2. Zinc application also had a highly significant effect (p < 0.001) on both spike weight and thousand-grain weight. However, neither N fertilizer alone, Zn fertilizer alone, nor N-Zn intercropping had a significant effect on the number of spike yards. The trends in grain yield and its components in 2022 were similar to those in 2021. Under the same N and Zn levels, grain spike weight, thousand-kernel weight, and yield all showed an increasing and then decreasing tendency with the increase in Zn and N concentrations. There was no significant pattern of change in spike length, spike thickness, and spike yardage. At N180Zn40, the maximum yield was observed for two consecutive years, with 4383 kg/hm2 and 4766 kg/hm2, respectively. This yield was significantly different from the other treatments, and the overall grain yield in the second year was higher than that in the first year.

In 2021, the treatments N120 and N180 resulted in a yield increase of 13.37% to 19.77%, 2.75% to 20.64%, and 10.90% to 19.87%, respectively, compared to using zinc fertilizer alone at the same zinc level. Among the three gradients of zinc fertilizer, spraying 40 mg/L of ZnSO4-7H2O at the same nitrogen level resulted in the highest overall yield. This yield increase was observed to be 766.66 kg/hm2 to 1033.33 kg/hm2, 483.33 kg/hm2 to 850.00 kg/hm2, 950.00 kg/hm2 to 1266.66 kg/hm2, and 183.33 kg/hm2 to 533.33 kg/hm2, respectively, under four different nitrogen fertilizer gradients. The N180Zn40 treatment exhibited the highest thousand-kernel weight of 2.953 g, which was a 2% increase compared to the same nitrogen treatment with zinc fertilizer alone. However, this increase was not significantly different from the other treatments at the same zinc level and different nitrogen treatment levels.

In 2022, the yield of N120 increased by 18.29%, 8.37% and 6.49% compared to each treatment of zinc fertilizer alone. At N180, the yield increased by 1300.00 kg/hm2, 583.34 kg/hm2 and 533.34 kg/hm2, respectively, compared to the treatments with zinc fertilizer alone. When dosed with Zn40, the yield increased by 13.04% and 31.80% compared to treatments with different levels of zinc at the same N level, respectively. The thousand-kernel weight of seeds showed significant differences under the same N level and different Zn levels. At N120, the thousand-kernel weight of grains increased by 1.45%, 1.84%, and 1.02%, respectively, compared to zinc fertilizer alone. The thousand-kernel weight of grains in the N180Zn40 treatment reached a maximum value of 3.027 g, but it was not significantly different from the N120Zn40 treatment.

3.8. Analysis of Principal Components of Nitrogen and Zinc Combined Application on Foxtail Millet Yield and Quality

A principal component analysis was conducted on various factors of foxtail millet, including yield, crude fat content, crude protein content, amylose content, flavonoid content, phytic acid content, and total carotenoid content, as shown in Table 3. The analysis revealed two principal components, with eigenvalues of 4.127 and 1.630, respectively, and a cumulative variance contribution rate of 82.248%. This indicates that most of the original information was explained by these components. The results of the analysis, presented in Table 4, ranked different fertilization treatments. The highest ranking was observed for the treatment with a nitrogen application concentration of 180 kg/hm2 and a zinc application concentration of 40 mg/L, followed by the N120Zn40 treatment, N240Zn40 treatment, and so on. The higher the overall ranking score, the better the comprehensive quality. Therefore, the treatment with a nitrogen concentration of 180 kg/hm2 and a zinc concentration of 40 mg/L exhibited the best comprehensive quality.

Table 3.

Principal component analysis of yield and quality.

Table 4.

Comprehensive scores and ranking of principal component analysis of yield and quality.

4. Discussion

4.1. Synergistic Effect of Nitrogen and Zinc in Foxtail Millet

Cereal proteins are classified into four groups: clear proteins, globular proteins, alcohol-soluble proteins, and gluten proteins. The composition of these fractions plays a significant role in the nutritional quality and processing characteristics of cereals. According to the findings of Shi S et al. [14], the seed protein content increases as the nitrogen application increases. Nicotinamide (NA) is a nitrogenous compound that plays a crucial role in the transportation and mobilization of zinc in the phloem. It forms a complex with zinc, known as NA-Zn, which allows it to enter the seed through the bead center protrusion. A significant quantity of zinc is absorbed in the seed in the form of NA-Zn. Moreover, the NA compound is metabolized within the seed and converted into proteins. This process may explain why the application of zinc fertilizers leads to an increase in the protein content of the seed [32]. In this study, the application of additional nitrogen (N) fertilizer for two consecutive years resulted in an increase of 7.75% and 1.20% in the crude protein content of kernels, respectively, compared to the application of zinc (Zn) fertilizer alone. The analysis also revealed that the protein fractions were present in the following order: alcohol-soluble proteins > cleansing proteins > gluten > globular proteins.

Zinc plays a crucial role in nitrogen fixation by providing electronic and energy support, as well as protecting the nitrogen fixation system [33]. It is involved in both the electron and energy supply system, as well as the protection system. The main reason why zinc affects the nutritional and processing quality of crop grains is because it promotes post-flowering assimilated nitrogen accumulation in the grain. In this experiment, the crude fat content showed a decreasing trend over two consecutive years as nitrogen application increased. This finding is consistent with the findings of Zhou Y [34]. It is likely that nitrogen fertilizer, being an essential mass element for plants, directly or indirectly affects the fat metabolism process of the plants, resulting in varying degrees of influence on the crude fat content. In this study, the average total carotenoid content was 18.03 mg/kg and 19.78 mg/kg in two consecutive years, respectively. The total flavonoid content also exhibited varying degrees of increase and decrease with increasing concentrations of zinc and nitrogen application. These findings align with the results of a previous study by [35], suggesting a potential ‘nitrogen-zinc-promoting’ effect that aids in the absorption of nitrogen and zinc in grains. Additionally, this effect enhances photosynthesis and the metabolic activity of carotenoids. Zinc plays a crucial role as an activator of aldolase, which is a key enzyme in photosynthetic carbon metabolism. It is essential for carbohydrate metabolism as many enzymes involved in this process require zinc to effectively catalyze the corresponding reactions. In our study, we observed that the treatment with N180Zn40, which had a higher concentration of straight-chain starch, showed an increase of 18.77% compared to the N0Zn40 treatment. Additionally, the branched chain starch content also increased by 8.55%. These findings are consistent with the results of a two-year field trial conducted by Gao L et al. [36].

4.2. Nitrogen–Zinc Rationing as a Good Strategy to Improve Grain Yield and Human Zinc Nutrition

The study found that applying nitrogen–zinc (NZ) dosing can enhance the biological crop yield and plant uptake of NZ [37,38]. Specifically, when spraying zinc fertilizer along with an additional 120 kg/hm2 or 180 kg/hm2 of nitrogen fertilizer, the treatments resulted in yield increases ranging from 13.37% to 19.77%, 2.75% to 20.64%, and 10.90% to 19.87%, respectively, compared to applying zinc fertilizer alone in the year 2021. The trend in 2022 remains consistent with that of 2021, with the second year of production showing higher yields compared to the first year. This observation aligns with the findings of Jalal A et al. [39], who conducted a study on the application of Zn fertilizer over a period of two years and reported a significant increase in wheat yield. The results of our study also indicate that the combination of zinc fertilizer spraying and increased nitrogen fertilizer application for two consecutive years had a highly significant effect on spike weight and thousand-grain weight of the grain. This finding aligns with the research conducted by Fongfon et al. [40], which demonstrated that rationing N and Zn can enhance crop yield via significantly increasing crop height, tiller number, spike formation rate, number of grains in a spike, and thousand-grain weight.

In this experiment, foliar zinc fertilizers were applied to cereal plants and absorbed in the leaves. The zinc was then transferred to the phloem and translocated to accumulate in the seeds. The Zn content of the seeds increased by 10.89%, 11.95%, and 16.52% when Zn20 was applied and by 5.13%, 11.12%, and 5.57% when Zn40 was applied in the treatments with additional N fertilizer. The findings of Rossi, Ahmad et al. [41,42] indicate that zinc spraying significantly increased the zinc content in wheat grains. The bioavailability of zinc is primarily assessed by the molar ratio of phytic acid to zinc. When the phytate/Zn molar ratio is greater than 15, the bioavailability of zinc is only 10% to 15%. For a phytate/Zn molar ratio between 5 and 15, the bioavailability of zinc ranges from 30% to 35%. When the phytate/Zn molar ratio is less than 5, the bioavailability of zinc falls within the range of 45% to 55% [43]. The N180Zn40 treatment had the lowest phytate/zinc molar ratio content, which was reduced by 73.80%, 59.44%, and 48.60% compared to the other treatments with the same zinc level. It was also reduced by 63.34% and 46.13% compared to the other treatments with the same nitrogen level. Previous studies have demonstrated that applying N fertilizer to the soil and foliar Zn application together effectively decrease the phytate/Zn molar ratio in wheat kernels [44]. The study by Lian J et al. [45] confirmed that applying urea to the leaves reduced the phytic acid to zinc molar ratio in semolina and increased the bioavailability of zinc. Properly balancing nitrogen and zinc levels also had a positive effect on the mineral content of cereal grains. This finding aligns with the results of Lončarić Z [46], who investigated the effects of foliar application of zinc and nitrogen treatments on mineral elements in wheat seeds. Nitrogen fertilization can influence the uptake of these elements via the root system and affect their transfer to the leaves and seeds [47].

5. Conclusions

The findings of this study indicate that optimizing soil nitrogen and foliar zinc management can enhance the health benefits of millet through the Zn biofortification of cereals. This approach not only helps maintain high yields with low nitrogen inputs but also increases the concentration and bioavailability of zinc, thereby improving the overall quality of millet. The application of N at a concentration of 180 kg/hm2 and Zn at a concentration of 40 mg/L was found to be the optimal solution for enhancing grain yield, improving quality, and increasing Zn enrichment. This research is expected to provide a theoretical basis for promoting Zn biofortification and developing high-yield and high-efficiency technologies for grains.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/agriculture13091731/s1, Table S1: Amount of fertilizer added; Table S2: Effect of nitrogen and zinc ration on grain yield and its components.

Author Contributions

Conceptualization, H.D.; methodology, H.Z., Y.D. and R.H.; Investigation, D.W., M.N. and L.Z.; Writing, original draft, G.H. and J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Research Project Supported by Shanxi Scholarship council of China, grant number 2020-060, Du, H.; Shanxi Province Modern Agricultural Industrial Technology System Construction Project, grant number 2023CYJSTX04-14, Du, H.; Major Projects of Shanxi Province Key R&D, grant number 2022ZDYF119, Du, H.; Shanxi Province Graduate Education Innovation Project, grant number 2022Y352. Wang, J.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Mineral elements were determined in the laboratory building (Shanxi Agricultural University). Here, we sincerely thank W.F.’s team for providing experiment instruments and reagents.

Conflicts of Interest

The authors declare no conflict of interests. The funders have no role in the experimental design, data collection and analysis, decision to publish, or preparation of the manuscript.

References

- Yousaf, L.; Hou, D.; Liaqat, H.; Shen, Q. Millet: A review of its nutritional and functional changes during processing. Food Res. Int. 2021, 142, 110197. [Google Scholar] [CrossRef]

- Fu, Y.; Yin, R.; Liu, Z.; Niu, Y.; Guo, E.; Cheng, R.; Diao, X.; Xue, Y.; Shen, Q. Hypoglycemic Effect of Prolamin from Cooked Foxtail Millet (Setaria italic) on Streptozotocin-Induced Diabetic Mice. Nutrients 2020, 12, 3452. [Google Scholar] [CrossRef] [PubMed]

- Mahajan, P.; Bera, M.B.; Panesar, P.S.; Chauhan, A. Millet starch: A review. Int. J. Biol. Macromol. 2021, 180, 61–79. [Google Scholar] [CrossRef] [PubMed]

- Zhang, A.; Liu, X.; Wang, G.; Wang, H.; Liu, J.; Zhao, W.; Zhang, Y. Crude Fat Content and Fatty Acid Profile and Their Correlations in Foxtail Millet. Cereal Chem. 2015, 92, 455–459. [Google Scholar] [CrossRef]

- Tian, X.; Liu, S.C.; Wang, H.G. Application of near infrared diffuse reflectance spectroscopy in rapid detection of crude protein and starch in foxtailmillet. Food Sci. 2017, 38, 140–144. [Google Scholar] [CrossRef]

- Sachdev, N.; Goomer, S.; Singh, L.R. Foxtail millet: A potential crop to meet future demand scenario for alternative sustainable protein. J. Sci. Food Agric. 2021, 101, 831–842. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Satyavathi, C.T.; Mahendrakar, M.D.; Singh, R.B.; Kumar, S.; Govindaraj, M.; Ghazi, I.A. Addressing Iron and Zinc Micronutrient Malnutrition Through Nutrigenomics in Pearl Millet: Advances and Prospects. Front. Genet. 2021, 12, 723472. [Google Scholar] [CrossRef]

- Nadeem, F.; Mahmood, R.; Sabir, M.; Khan, W.-U.; Haider, M.S.; Wang, R.; Zhong, Y.; Ishfaq, M.; Li, X. Foxtail millet [Setaria italica (L.) Beauv.] over-accumulates ammonium under low nitrogen supply. Plant Physiol. Biochem. 2022, 185, 35–44. [Google Scholar] [CrossRef]

- Zha, S.; Kuwano, K.; Shibahara, T.; Ishibashi, F. Algicidal hydroxylated C18 unsaturated fatty acids from the red alga Tricleocarpa jejuensis: Identification, synthesis and biological activity. Fitoterapia 2020, 145, 104639. [Google Scholar] [CrossRef]

- Cao, X.; Sun, H.; Wang, C.; Ren, X.; Liu, H.; Zhang, Z. Effects of late-stage nitrogen fertilizer application on the starch structure and cooking quality of rice. J. Sci. Food Agric. 2018, 98, 2332–2340. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, L.; Wang, W.; Xu, Y.; Zhang, W.; Zhang, H.; Liu, L.; Wang, Z.; Gu, J.; Yang, J. Effects of application of rapeseed cake as organic fertilizer on rice quality at high yield level. J. Sci. Food Agric. 2022, 102, 1832–1841. [Google Scholar] [CrossRef]

- Britz, E.; Cyster, L.; Samuels, I.; Cupido, C.; Masemola, L.; Ngcobo, N.; Manganyi, F.; Müller, F. Nitrogen fertilization increases the growth and nutritional quality of the forage legume, Calobota sericea—A preliminary investigation. Heliyon 2023, 9, e13535. [Google Scholar] [CrossRef]

- Hui, Y.; Wang, J.; Jiang, T.; Ma, T.; Wang, R. Effect of nitrogen regulation on berry quality and flavonoids during veraison stage. Food Sci. Nutr. 2021, 9, 5448–5456. [Google Scholar] [CrossRef]

- Shi, S.; Zhang, G.; Chen, L.; Zhang, W.; Wang, X.; Pan, K.; Li, L.; Wang, J.; Liu, J.; Cao, C.; et al. Different nitrogen fertilizer application in the field affects the morphology and structure of protein and starch in rice during cooking. Food Res. Int. 2023, 163, 112193. [Google Scholar] [CrossRef] [PubMed]

- Marschner, P. Marschner’s Mineral Nutrition of Higher Plants, 3rd ed.; Beijing Agricultural University: Beijing, China, 2012; pp. 483–643. [Google Scholar] [CrossRef]

- Cakmak, I.; McLaughlin, M.J.; White, P. Zinc for better crop production and human health. Plant Soil 2017, 411, 1–4. [Google Scholar] [CrossRef]

- Shahzad, Z.; Rouached, H.; Rakha, A. Combating Mineral Malnutrition through Iron and Zinc Biofortification of Cereals. Compr. Rev. Food Sci. Food Saf. 2014, 13, 329–346. [Google Scholar] [CrossRef]

- Cao, M.L. Effects of spraying zinc fertilizer on the physiological and photosynthetic characteristics of millet plants (Setaria italica L.) at different growth stages. Appl. Ecol. Environ. Res. 2019, 17, 8121–8138. [Google Scholar] [CrossRef]

- Gonzalez, D.; Almendros, P.; Obrador, A.; Alvarez, J.M. Zinc application in conjunction with urea as a fertilization strategy for improving both nitrogen use efficiency and the zinc biofortification of barley. J. Sci. Food Agric. 2019, 99, 4445–4451. [Google Scholar] [CrossRef] [PubMed]

- Nie, Z.; Wang, J.; Rengel, Z.; Liu, H.; Gao, W.; Zhao, P. Effects of nitrogen combined with zinc application on glutamate, glutamine, aspartate and asparagine accumulation in two winter wheat cultivars. Plant Physiol. Biochem. 2018, 127, 485–495. [Google Scholar] [CrossRef] [PubMed]

- Ji, C.; Li, J.; Jiang, C.; Zhang, L.; Shi, L.; Xu, F.; Cai, H. Zinc and nitrogen synergistic act on root-to-shoot translocation and preferential distribution in rice. J. Adv. Res. 2021, 35, 187–198. [Google Scholar] [CrossRef] [PubMed]

- Palmer, C.M.; Guerinot, M.L. Facing the challenges of Cu, Fe and Zn homeostasis in plants. Nat. Chem. Biol. 2009, 5, 333–340. [Google Scholar] [CrossRef] [PubMed]

- Xia, H.; Xue, Y.; Liu, D.; Kong, W.; Xue, Y.; Tang, Y.; Li, J.; Li, D.; Mei, P. Rational Application of Fertilizer Nitrogen to Soil in Combination with Foliar Zn Spraying Improved Zn Nutritional Quality of Wheat Grains. Front. Plant Sci. 2018, 9, 677. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Yang, F.; Sui, F.; Wang, Q.; Liu, H. Effect of nitrogen fertilizers on zinc absorption and translocation in winter wheat. J. Plant Nutr. 2016, 39, 1311–1318. [Google Scholar] [CrossRef]

- Kutman, U.B.; Kutman, B.Y.; Ceylan, Y.; Ova, E.A.; Cakmak, I. Contributions of root uptake and remobilization to grain zinc accumulation in wheat depending on post-anthesis zinc availability and nitrogen nutrition. Plant Soil 2012, 361, 177–187. [Google Scholar] [CrossRef]

- Thiex, N. Evaluation of Analytical Methods for the Determination of Moisture, Crude Protein, Crude Fat, and Crude Fiber in Distillers Dried Grains with Solubles. J. AOAC Int. 2009, 92, 61–73. [Google Scholar] [CrossRef] [PubMed]

- Thanhaeuser, S.M.; Wieser, H.; Koehler, P. Spectrophotometric and fluorimetric quantitation of quality-related protein fractions of wheat flour. J. Cereal Sci. 2015, 62, 58–65. [Google Scholar] [CrossRef]

- Li, X.; Chen, H.; Yang, B. Centrifugally spun starch-based fibers from amylopectin rich starches. Carbohydr. Polym. 2016, 137, 459–465. [Google Scholar] [CrossRef]

- Fu, B.X.; Chiremba, C.; Pozniak, C.J.; Wang, K.; Nam, S. Total Phenolic and Yellow Pigment Contents and Antioxidant Activities of Durum Wheat Milling Fractions. Antioxidants 2017, 6, 78. [Google Scholar] [CrossRef]

- Hou, M.; Hu, W.; Xiu, Z.; Jiang, A.; Men, L.; Hao, K.; Sun, X.; Cao, D. Preparative Purification of Total Flavonoids from Sophora tonkinensis Gagnep. by Macroporous Resin Column Chromatography and Comparative Analysis of Flavonoid Profiles by HPLC-PAD. Molecules 2019, 24, 3200. [Google Scholar] [CrossRef]

- Vaintraub, I.A.; Lapteva, N.A. Colorimetric determination of phytate in unpurified extracts of seeds and the products of their processing. Anal. Biochem. 1988, 175, 227–230. [Google Scholar] [CrossRef]

- Yilmaz, A.; Ekiz, H.; Torun, B.; Gultekin, I.; Karanlik, S.; Bagci, S.A.; Cakmak, I. Effect of different zinc application methods on grain yield and zinc concentration in wheat cultivars grown on zinc-deficient calcareous soils. J. Plant Nutr. 1997, 20, 461–471. [Google Scholar] [CrossRef]

- Singh, B.R.; Timsina, Y.N.; Lind, O.C.; Cagno, S.; Janssens, K. Zinc and Iron Concentration as Affected by Nitrogen Fertilization and Their Localization in Wheat Grain. Front. Plant Sci. 2018, 9, 307. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Huang, J.; Li, Z.; Wu, Y.; Zhang, J.; Zhang, Y. Yield and Quality in Main and Ratoon Crops of Grain Sorghum Under Different Nitrogen Rates and Planting Densities. Front. Plant Sci. 2022, 12, 778663. [Google Scholar] [CrossRef] [PubMed]

- Schulthess, A.; Schwember, A.R. Improving durum wheat (Triticum turgidum L. var durum) grain yellow pigment content through plant breeding. Cienc. Investig. Agric. 2013, 40, 475–490. [Google Scholar] [CrossRef]

- Gao, L.; Wang, H.; Wan, C.; Wang, P.; Eeckhout, M.; Gao, J. Suitable nitrogen fertilizer application drives the endosperm development and starch synthesis to improve the physicochemical properties of common buckwheat grain. Int. J. Biol. Macromol. 2023, 235, 123837. [Google Scholar] [CrossRef] [PubMed]

- Jha, U.C.; Nayyar, H.; Parida, S.K.; Deshmukh, R.; von Wettberg, E.J.; Siddique, K.H. Ensuring Global Food Security by Improving Protein Content in Major Grain Legumes Using Breeding and ‘Omics’ Tools. Int. J. Mol. Sci. 2022, 23, 7710. [Google Scholar] [CrossRef]

- Mazzeo, M.F.; Di Stasio, L.; D’ambrosio, C.; Arena, S.; Scaloni, A.; Corneti, S.; Ceriotti, A.; Tuberosa, R.; Siciliano, R.A.; Picariello, G.; et al. Identification of Early Represented Gluten Proteins during Durum Wheat Grain Development. J. Agric. Food Chem. 2017, 65, 3242–3250. [Google Scholar] [CrossRef]

- Jalal, A.; Oliveira, C.E.d.S.; Fernandes, G.C.; da Silva, E.C.; da Costa, K.N.; de Souza, J.S.; Leite, G.d.S.; Biagini, A.L.C.; Galindo, F.S.; Filho, M.C.M.T. Integrated use of plant growth-promoting bacteria and nano-zinc foliar spray is a sustainable approach for wheat biofortification, yield, and zinc use efficiency. Front. Plant Sci. 2023, 14, 1146808. [Google Scholar] [CrossRef]

- Fongfon, S.; Prom-U-Thai, C.; Pusadee, T.; Jamjod, S. Responses of Purple Rice Genotypes to Nitrogen and Zinc Fertilizer Application on Grain Yield, Nitrogen, Zinc, and Anthocyanin Concentration. Plants 2021, 10, 1717. [Google Scholar] [CrossRef]

- Rossi, L.; Fedenia, L.N.; Sharifan, H.; Ma, X.; Lombardini, L. Effects of foliar application of zinc sulfate and zinc nanoparticles in coffee (Coffea arabica L.) plants. Plant Physiol. Biochem. 2019, 135, 160–166. [Google Scholar] [CrossRef]

- Ahmad, P.; Alyemeni, M.N.; Al-Huqail, A.A.; Alqahtani, M.A.; Wijaya, L.; Ashraf, M.; Kaya, C.; Bajguz, A. Zinc Oxide Nanoparticles Application Alleviates Arsenic (As) Toxicity in Soybean Plants by Restricting the Uptake of as and Modulating Key Biochemical Attributes, Antioxidant Enzymes, Ascorbate-Glutathione Cycle and Glyoxalase System. Plants 2020, 9, 825. [Google Scholar] [CrossRef] [PubMed]

- Castro-Alba, V.; Lazarte, C.E.; Bergenståhl, B.; Granfeldt, Y. Phytate, iron, zinc, and calcium content of common Bolivian foods and their estimated mineral bioavailability. Food Sci. Nutr. 2015, 39, 111–119. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.-Q.; Sun, Y.-X.; Ye, Y.-L.; Karim, R.; Xue, Y.-F.; Yan, P.; Meng, Q.-F.; Cui, Z.-L.; Cakmak, I.; Zhang, F.-S.; et al. Zinc biofortification of wheat through fertilizer applications in different locations of China. Field Crop. Res. 2012, 125, 1–7. [Google Scholar] [CrossRef]

- Lian, J.; Cheng, L.; Zhai, X.; Wu, R.; Huang, X.; Chen, D.; Pan, J.; Shohag, M.; Xin, X.; Ren, X.; et al. Zinc glycerolate (Glyzinc): A novel foliar fertilizer for zinc biofortification and cadmium reduction in wheat (Triticum aestivum L.). Food Chem. 2023, 402, 134290. [Google Scholar] [CrossRef] [PubMed]

- Lončarić, Z.; Ivezić, V.; Kerovec, D.; Rebekić, A. Foliar Zinc-Selenium and Nitrogen Fertilization Affects Content of Zn, Fe, Se, P, and Cd in Wheat Grain. Plants 2021, 10, 1549. [Google Scholar] [CrossRef] [PubMed]

- Xia, H.; Riaz, M.; Zhang, M.; Liu, B.; Li, Y.; El-Desouki, Z.; Jiang, C. Biochar-N fertilizer interaction increases N utilization efficiency by modifying soil C/N component under N fertilizer deep placement modes. Chemosphere 2022, 286, 131594. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).