Bucket Size Optimization for Metering Device in Garlic Planter Using Discrete Element Method

Abstract

1. Introduction

2. Materials and Methods

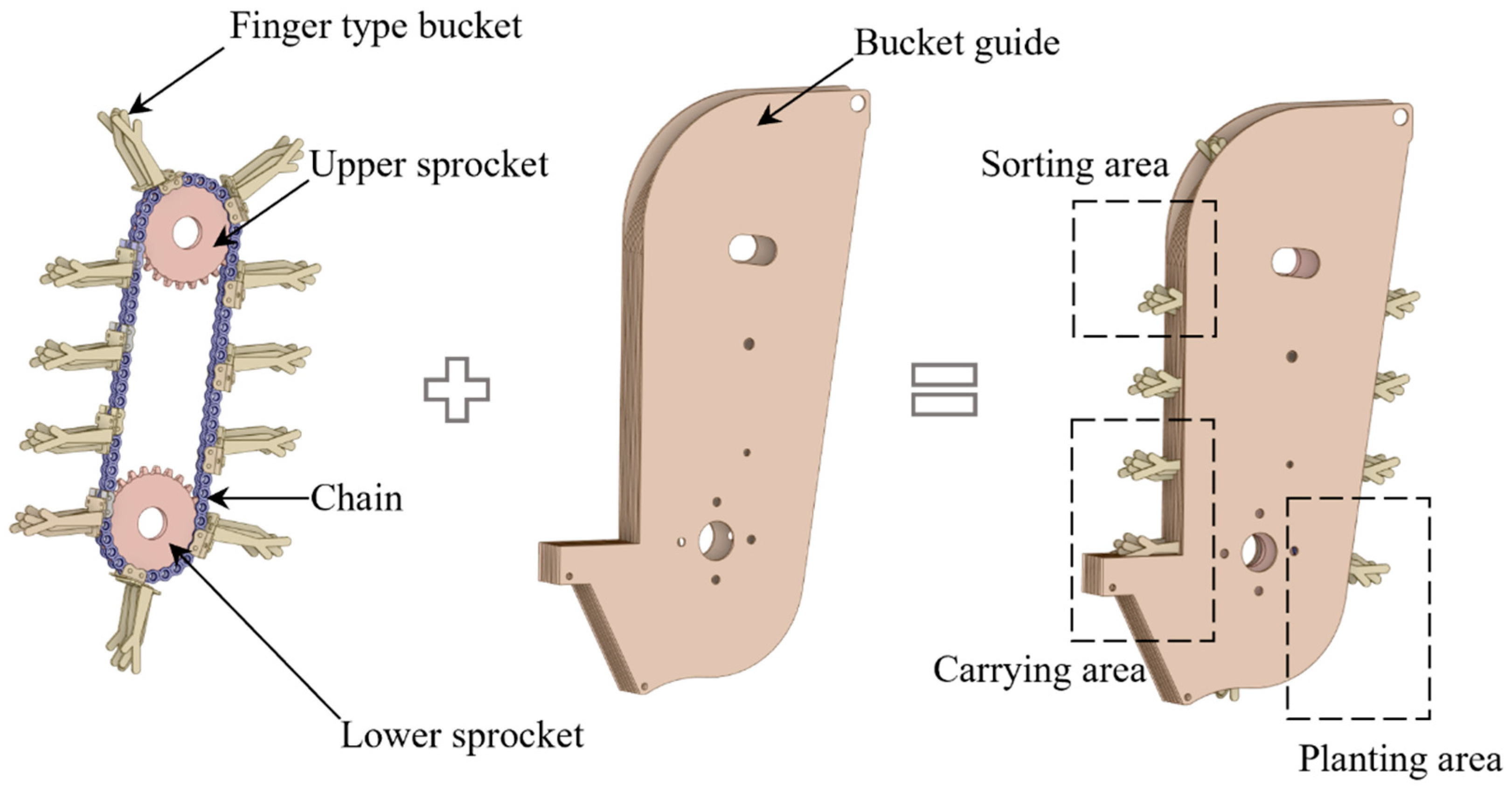

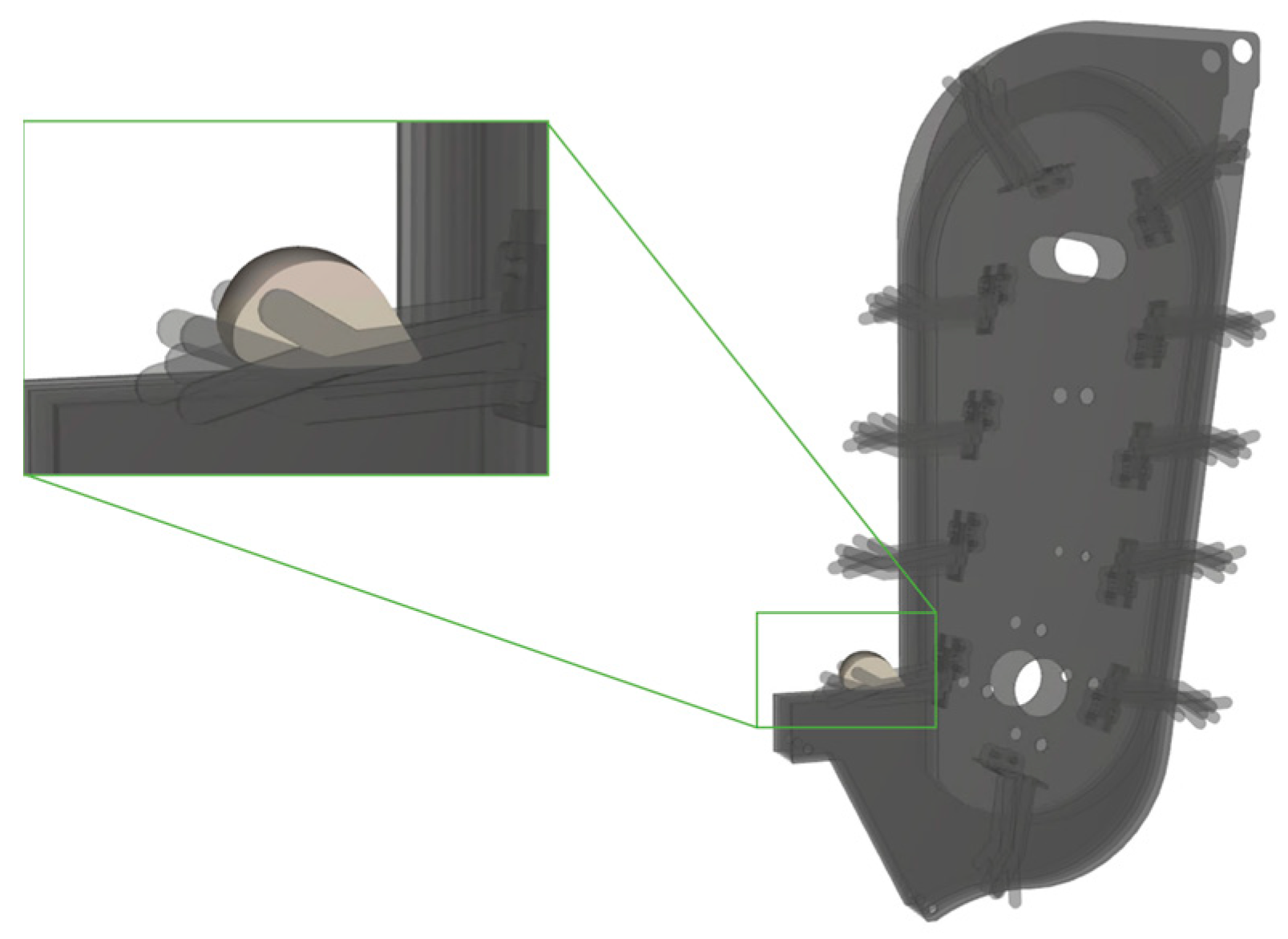

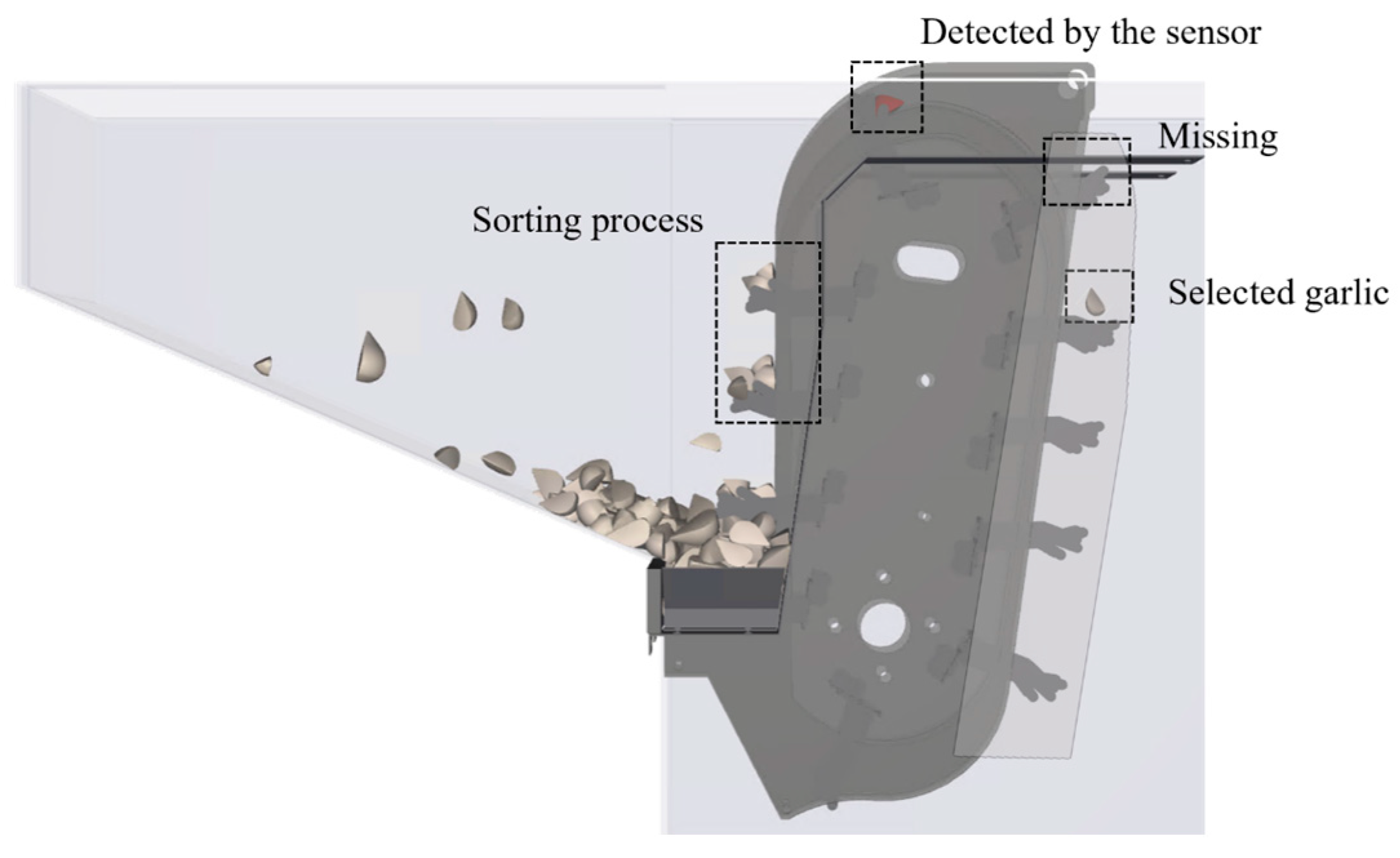

2.1. Metering Device Working Principle

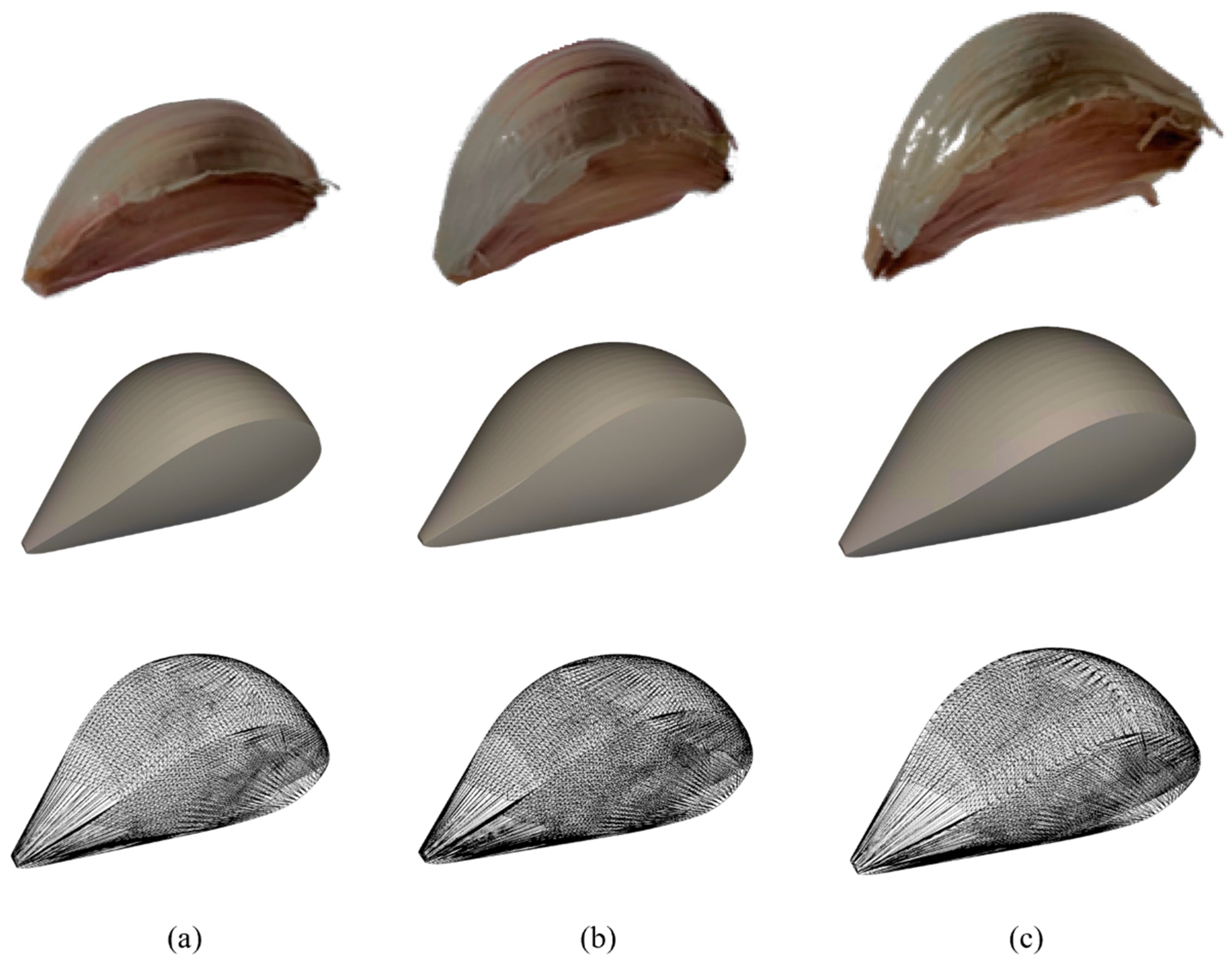

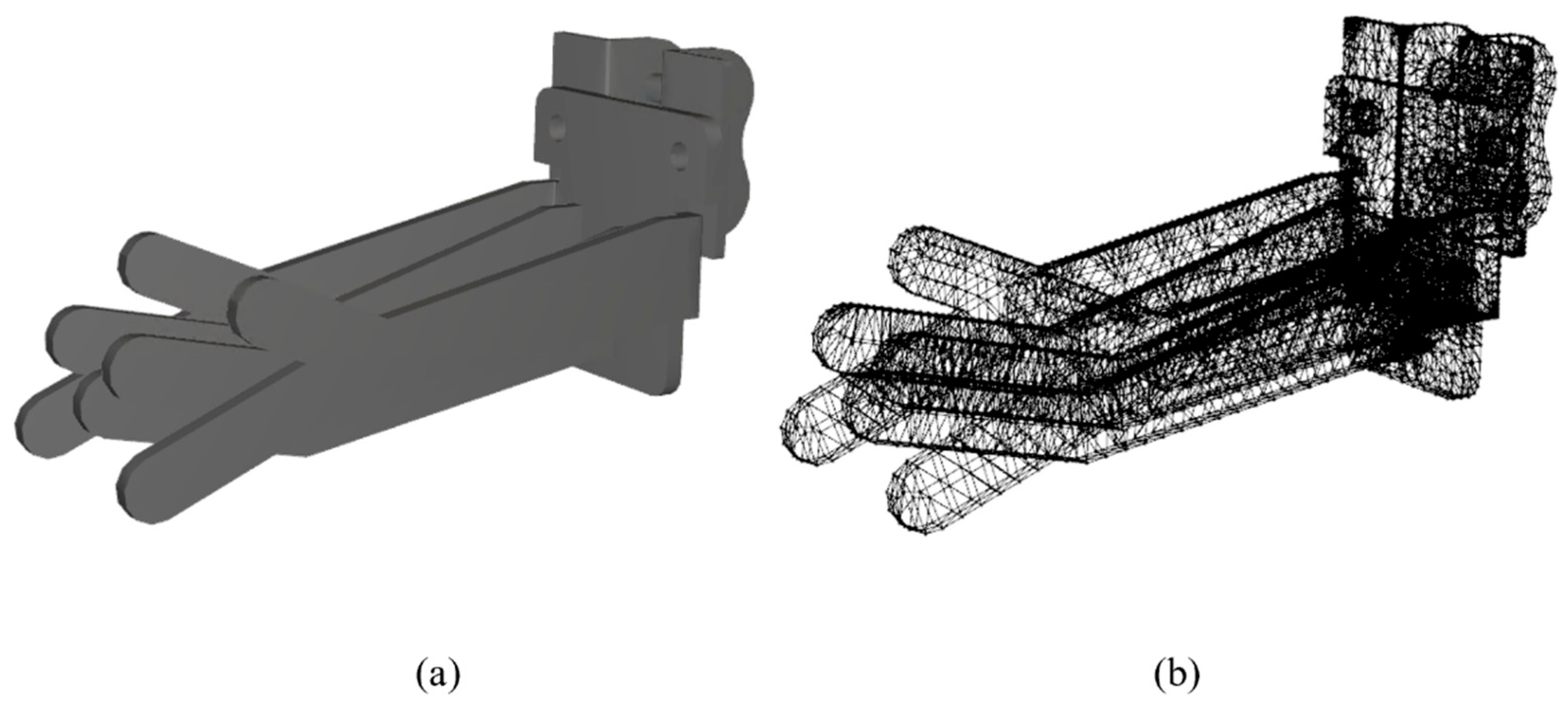

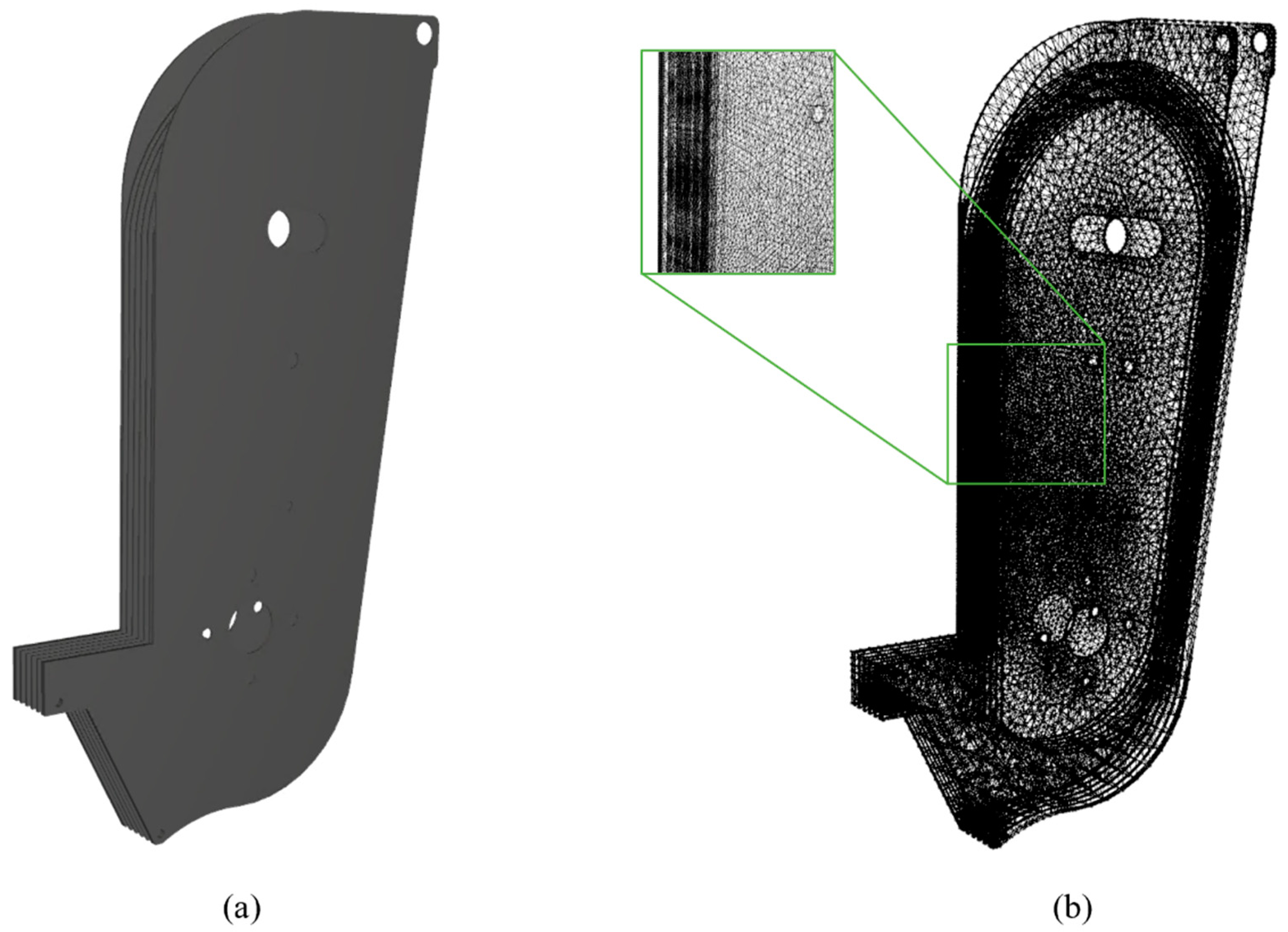

2.2. 3D Mesh Modeling

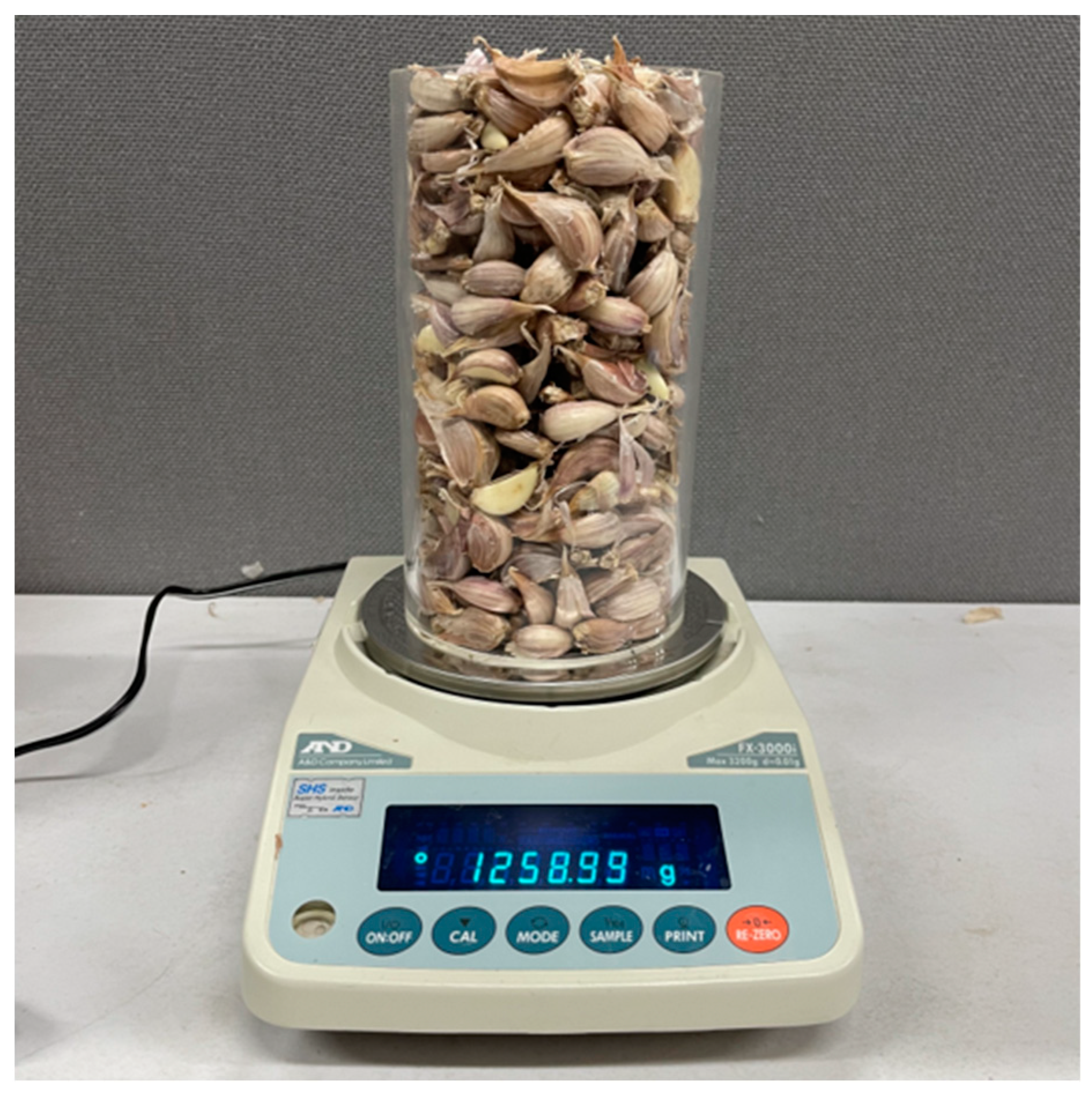

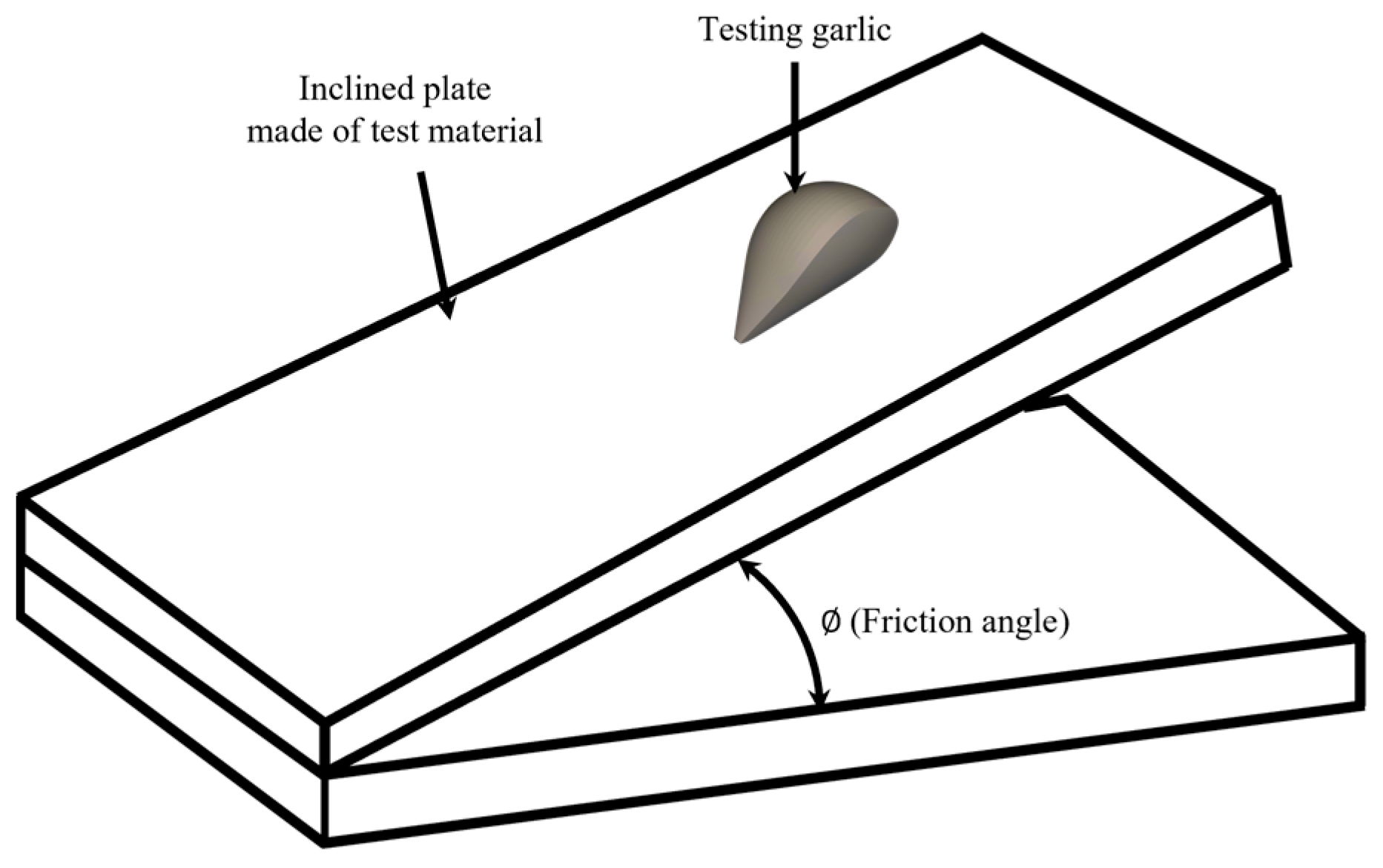

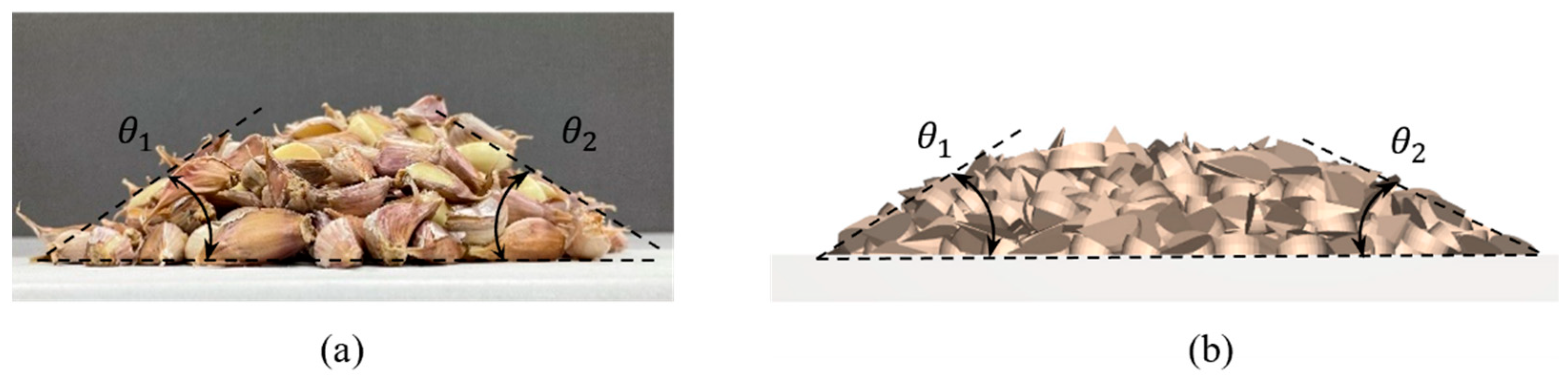

2.3. DEM Parameter Determination

2.4. DEM Contact Model

2.4.1. Normal Force Model: Hysteretic Linear Spring Model

2.4.2. Tangential Force Model: Linear Spring Coulomb Limit Model

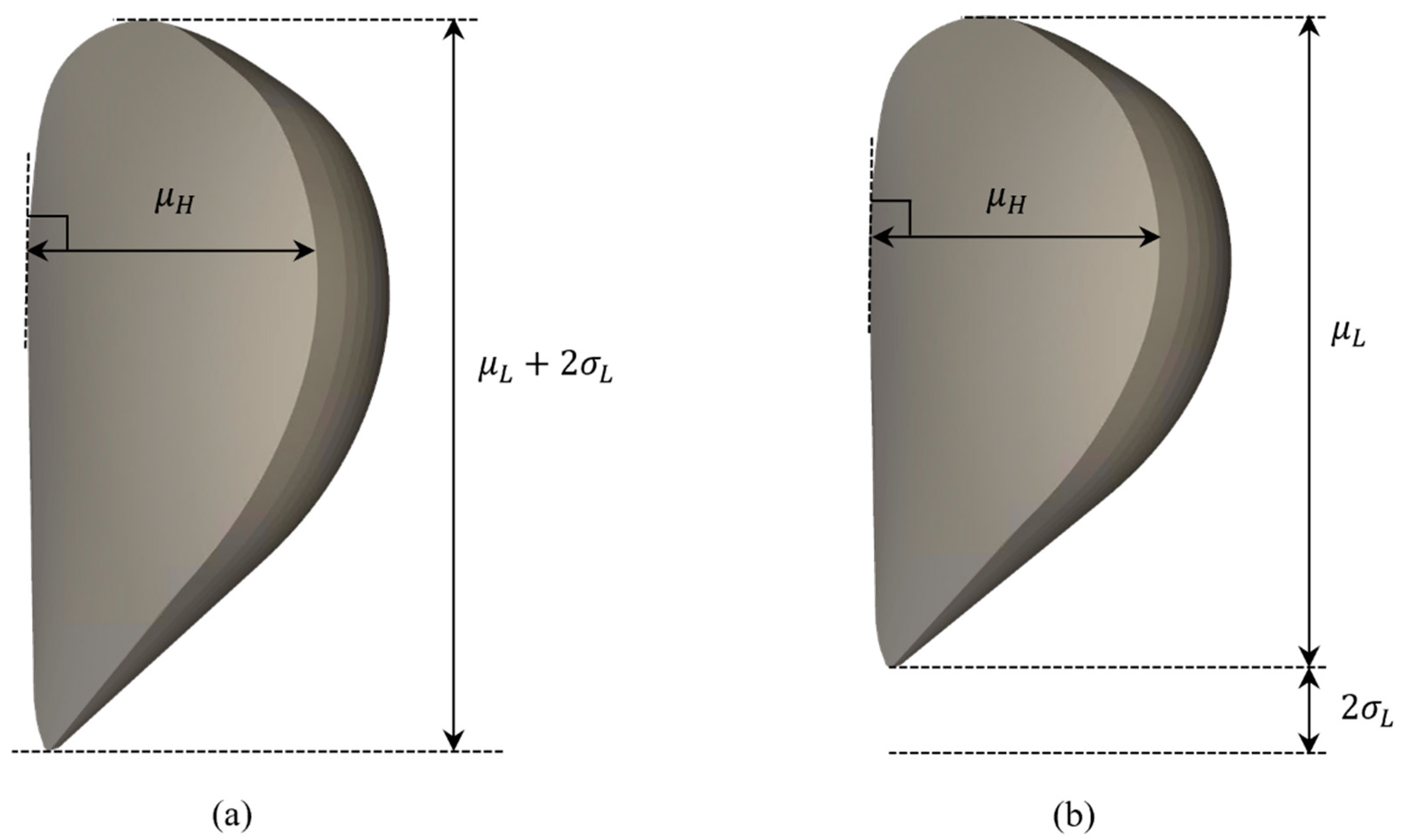

2.5. Bucket Size Optimization Using DEM

2.6. Metering Simulation Using DEM

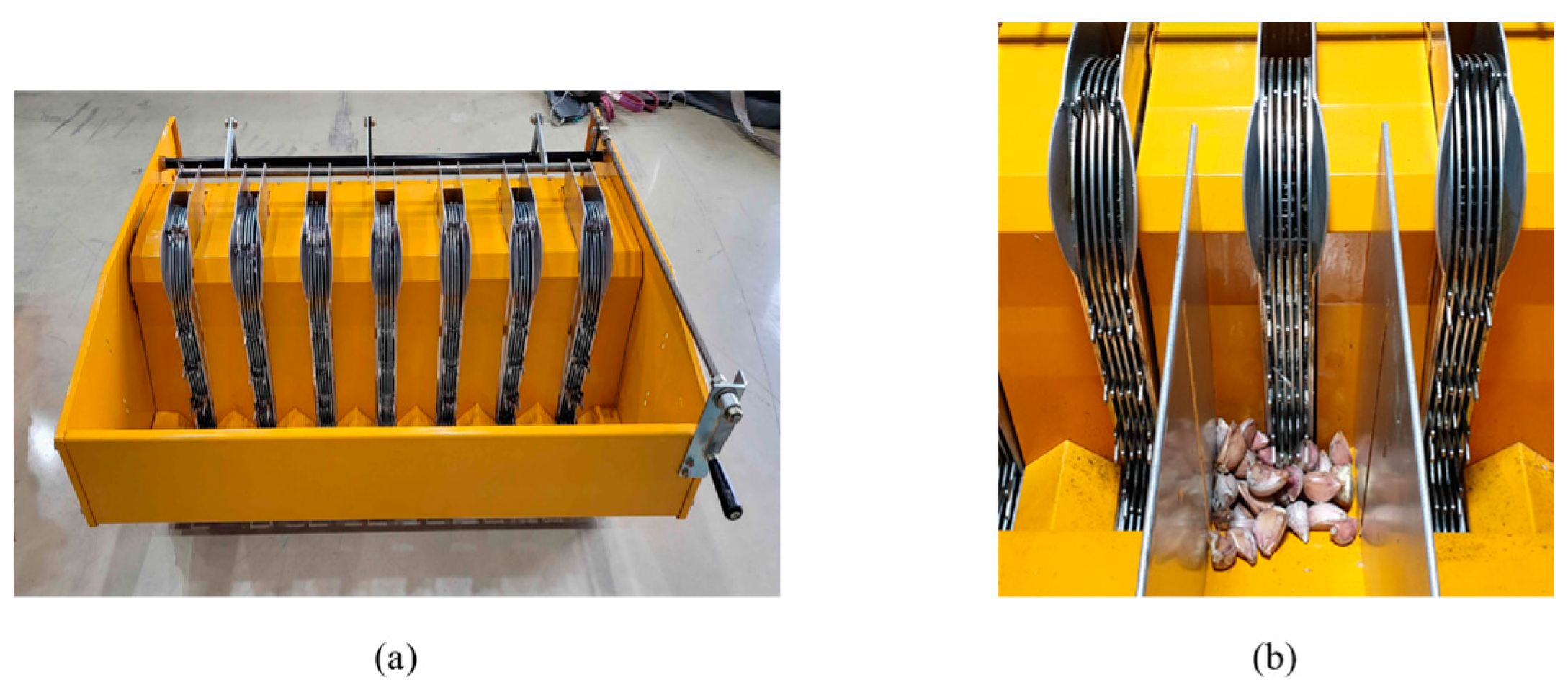

2.7. Metering Experiment

3. Results and Discussions

3.1. Bucket Size Optimization & Metering Simulation

3.2. Experimental Result

4. Conclusions

- (1)

- Calibration was executed by conducting a repose angle test to establish the garlic-garlic friction coefficient. It was ascertained that the simulation model and the test produced the same repose angle when the garlic-garlic friction coefficient was 0.46.

- (2)

- Bucket size optimization was carried out to achieve the target metering rate of 97.5%. Subsequently, it was determined that Group 1 had an optimal bucket size of 16.11 mm, Group 2 had that of 22.75 mm, and Group 3 had that of 23.64 mm.

- (3)

- To validate the reliability of the determined optimal bucket size, a metering simulation was conducted, which showed that the plant rate was 90.44% for Group 1, 97.97% for Group 2, and 94.95% for Group 3. The results indicate that Groups 2 and 3 achieved a seeding rate close to the target value of 97.5%.

- (4)

- To validate the reliability of the optimization methodology, an actual metering test was conducted under identical conditions. Upon comparing the metering performance, it was confirmed that all metering performances exhibited differences of less than 10%. Notably, in Groups 2 and 3, the difference in metering performance was within 2.8%, thus confirming the reliability of the optimization technique.

- (5)

- Regarding Group 1, as depicted in Figure 15, the garlic clove widths were relatively narrow, leading to an overlap phenomenon. Consequently, the metering performance prediction exhibits low accuracy, and the metering performance is inferior to Groups 2 and 3.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Walsh, P.P.; Murphy, E.; Horan, D. The role of science, technology and innovation in the UN 2030 agenda. Technol. Forecast. Soc. Change 2020, 154, 119957. [Google Scholar]

- Choi, D.K.; Cho, S.C.; Lee, C.S.; Park, S.H.; Kim, H.J.; Kang, T.K.; Kim, C.K.; Kwak, T.Y. Development of a Metering Device for the Garlic Planter. Biosyst. Eng. 2001, 26, 525–534. [Google Scholar]

- Kang, T.G.; Lee, S.H.; Kim, J.G.; Kim, Y.K.; Choi, Y.; Choi, I.S.; Lim, J. A factor analysis of garlic metering device for development of a garlic planter. J. Agric. Sci. 2018, 52, 143–151. [Google Scholar]

- Wang, H.; Sun, X.; Li, H.; Fu, J.; Zeng, X.; Xu, Y.; Wang, Y.; Liu, H.; Lü, Z. Design and parameter optimization of a finger clip plate garlic seed-metering device based on EDEM. Agronomy 2022, 12, 1543. [Google Scholar]

- Kang, T.G.; Lee, S.H.; Choi, Y.; Kwon, Y.S.; Kim, T.H. Study on the optimum condition of mechanical sowing of a garlic. J. Korea Acad.-Ind. Coop. Soc. 2021, 22, 360–366. [Google Scholar]

- Zilpilwar, S.; Yadav, R.; Gajjar, P.; Jakasania, R. Development and performance evaluation of metering mechanism for planting garlic cloves. Agric. Res. 2021, 10, 274–284. [Google Scholar]

- Zhang, X.; Yi, S.; Tao, G.; Zhang, D.; Chong, J. Design and experimental study of spoon-clamping type garlic precision seeding device. Wirel. Commun. Mob. Comput. 2022, 2022, 5222651. [Google Scholar]

- Im, D.; Kim, J.H.; Moon, D.J.; Moon, T.I.; Yu, S.H.; Park, Y.J. Optimization of bucket size of garlic metering device using multibody dynamics simulation. Biosyst. Eng. 2022, 47, 480–488. [Google Scholar]

- Guo, H.; Cao, Y.; Song, W.; Zhang, J.; Wang, C.; Wang, C.; Zhu, L. Design and simulation of a garlic seed metering mechanism. Agriculture 2021, 11, 1239. [Google Scholar]

- Yu, Z.; Yang, K.; Hu, Z.; Peng, B.; Gu, F.; Yang, L.; Yang, M. Parameter optimization and simulation analysis of floating root cutting mechanism for garlic harvester. Comput. Electron. Agric. 2023, 204, 107521. [Google Scholar]

- Wang, J.; Tang, H.; Wang, J.; Li, X.; Huang, H. Optimization design and experiment on ripple surface type pickup finger of precision maize seed metering device. Int. J. Agric. Biol. 2017, 10, 61–71. [Google Scholar]

- Kang, J.; Peng, Q.; Zhang, C.; Zhang, N.; Fang, H. Design and testing of a punching-on-film precision hole seeder for peanuts. Trans. ASABE 2020, 63, 1685–1696. [Google Scholar] [CrossRef]

- Singh, R.C.; Singh, G.; Saraswat, D.C. Optimisation of design and operational parameters of a pneumatic seed metering device for planting cottonseeds. Biosyst. Eng. 2005, 92, 429–438. [Google Scholar] [CrossRef]

- Wang, M.; Liu, Q.; Ou, Y.; Zou, X. Numerical simulation and verification of seed-filling performance of single-bud billet sugarcane seed-metering device based on EDEM. Agriculture 2022, 12, 983. [Google Scholar] [CrossRef]

- Ryu, I.H.; Kim, K.U. Design of roller type metering device for precision planting. Trans. ASABE 1998, 41, 923. [Google Scholar] [CrossRef]

- Han, D.; Zhang, D.; Jing, H.; Yang, L.; Cui, T.; Ding, Y.; Zhang, T. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Sun, X.; Li, H.; Qi, X.; Nyambura, S.M.; Yin, J.; Ma, Y.; Wang, J. Performance parameters optimization of a three-row pneumatic precision metering device for brassica chinensis. Agronomy 2022, 12, 1011. [Google Scholar] [CrossRef]

- ANSYS Rocky. 2023. Available online: https://www.ansys.com/products/fluids/ansys-rocky (accessed on 1 January 2023).

- Park, D.; Lee, C.G.; Park, H.; Baek, S.H.; Rhee, J.Y. Discrete element method analysis of the impact forces on a garlic bulb by the roller of a garlic harvester. Biosyst. Eng. 2019, 44, 208–217. [Google Scholar] [CrossRef]

- Yu, Z.; Hu, Z.; Peng, B.; Gu, F.; Yang, L.; Yang, M. Experimental determination of restitution coefficient of garlic bulb based on high-speed photography. Int. J. Agric. Biol. Eng. 2021, 14, 81–90. [Google Scholar] [CrossRef]

- Chen, J.; Gao, R.; Liu, Y. Numerical study of particle morphology effect on the angle of repose for coarse assemblies using DEM. Adv. Mater. Sci. Eng. 2019, 2019, 8095267. [Google Scholar] [CrossRef]

- Zeng, Y.W.; Jin, L.; Du, X.; Gao, R. Refined modeling and movement characteristics analyses of irregularly shaped particles. Int. J. Numer. Anal. Methods 2015, 39, 388–408. [Google Scholar] [CrossRef]

- Walton, O.R.; Braun, R.L. Viscosity, granular-temperature, and stress calculations for shearing assemblies of inelastic, frictional disks. J. Rheol. 1986, 30, 949–980. [Google Scholar] [CrossRef]

- ESSS Rocky, Release 2021 R2.2, DEM Technical Manual, ESSS Rocky DEM, S.R.L. 2021. Available online: https://rocky.esss.co/technical-library/ (accessed on 1 January 2023).

- Kiefer, J. Sequential minimax search for a maximum. Proc. Am. Math. Soc. 1953, 4, 502–506. [Google Scholar] [CrossRef]

| Category | Property | Value | Unit | Determination |

|---|---|---|---|---|

| Garlic | Bulk density | 605.45 | kg/m3 | Directly measured |

| Young’s modulus | 13.38 | MPa | Park et al. [19] | |

| Poisson’s ratio | 0.16 | - | Park et al. [19] | |

| Garlic-garlic | Static friction coefficient | 0.46 | - | Repose angle calibration |

| Tangential ratio | 1 | - | Default | |

| Restitution coefficient | 0.50 | - | Park et al. [19] | |

| Acryl-garlic | Static friction coefficient | 0.4 | - | Sliding test |

| Tangential ratio | 1 | - | Default | |

| Restitution coefficient | 0.65 | - | Yu et al. [20] | |

| Steel-garlic | Static friction coefficient | 0.31 | - | Sliding test |

| Tangential ratio | 1 | - | Default | |

| Restitution coefficient | 0.65 | - | Yu et al. [20] |

| Group | Optimum Bucket Size l (mm) |

|---|---|

| Group 1 | 16.11 |

| Group 2 | 22.75 |

| Group 3 | 23.64 |

| Group | No. Trials | Plant Rate (Q) | Multi-Plant Rate (M) | Missing Plant Rate (C) |

|---|---|---|---|---|

| Group 1 | 40 | 92.50% | 10.00% | 7.50% |

| Group 2 | 37 | 97.30% | 2.70% | 2.70% |

| Group 3 | 43 | 97.70% | 2.30% | 2.30% |

| Group | Test No | Plant Rate (Q) | Multi-Plant Rate (M) | Missing Plant Rate (C) |

|---|---|---|---|---|

| Group 1 | 1 | 89.29% | 0.00% | 10.71% |

| 2 | 89.09% | 1.82% | 10.91% | |

| 3 | 90.91% | 0.00% | 9.09% | |

| 4 | 89.29% | 0.00% | 10.71% | |

| 5 | 94.00% | 6.00% | 6.00% | |

| Average | 90.44% | 1.47% | 9.56% | |

| Group 2 | 1 | 100.00% | 2.04% | 0.00% |

| 2 | 97.92% | 6.25% | 2.08% | |

| 3 | 97.96% | 4.08% | 2.04% | |

| 4 | 95.92% | 2.04% | 4.08% | |

| 5 | 98.04% | 0.00% | 1.96% | |

| Average | 97.97% | 2.85% | 2.03% | |

| Group 3 | 1 | 97.56% | 2.44% | 2.44% |

| 2 | 97.62% | 0.00% | 2.38% | |

| 3 | 93.18% | 0.00% | 6.82% | |

| 4 | 93.18% | 0.00% | 6.82% | |

| 5 | 93.18% | 0.00% | 6.82% | |

| Average | 94.95% | 0.49% | 5.05% |

| Group | Index | Simulation | Experiment | Difference |

|---|---|---|---|---|

| Group 1 | Plant rate (Q) | 92.50% | 90.44% | 2.10% |

| Multi-plant rate (M) | 10.00% | 1.50% | 8.50% | |

| Missing plant rate (C) | 7.50% | 9.60% | −2.10% | |

| Group 2 | Plant rate (Q) | 97.30% | 97.97% | −0.70% |

| Multi-plant rate (M) | 2.70% | 2.90% | −0.20% | |

| Missing plant rate (C) | 2.70% | 2.00% | 0.70% | |

| Group 3 | Plant rate (Q) | 97.70% | 94.95% | 2.80% |

| Multi-plant rate (M) | 2.30% | 0.50% | 1.80% | |

| Missing plant rate (C) | 2.30% | 5.10% | −2.80% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Im, D.; Lee, H.-S.; Kim, J.-H.; Moon, D.-J.; Moon, T.-I.; Yu, S.-H.; Park, Y.-J. Bucket Size Optimization for Metering Device in Garlic Planter Using Discrete Element Method. Agriculture 2023, 13, 1199. https://doi.org/10.3390/agriculture13061199

Im D, Lee H-S, Kim J-H, Moon D-J, Moon T-I, Yu S-H, Park Y-J. Bucket Size Optimization for Metering Device in Garlic Planter Using Discrete Element Method. Agriculture. 2023; 13(6):1199. https://doi.org/10.3390/agriculture13061199

Chicago/Turabian StyleIm, Dongu, Ho-Seop Lee, Jae-Hyun Kim, Dong-Joo Moon, Tae-Ick Moon, Seung-Hwa Yu, and Young-Jun Park. 2023. "Bucket Size Optimization for Metering Device in Garlic Planter Using Discrete Element Method" Agriculture 13, no. 6: 1199. https://doi.org/10.3390/agriculture13061199

APA StyleIm, D., Lee, H.-S., Kim, J.-H., Moon, D.-J., Moon, T.-I., Yu, S.-H., & Park, Y.-J. (2023). Bucket Size Optimization for Metering Device in Garlic Planter Using Discrete Element Method. Agriculture, 13(6), 1199. https://doi.org/10.3390/agriculture13061199