This section applies IWOA-ACO to solve the problem and analyzes the simulation results of flat and bump environment by the three algorithms so as to verify the performance of IWOA-ACO.

3.1. Simulation of Flat Environment

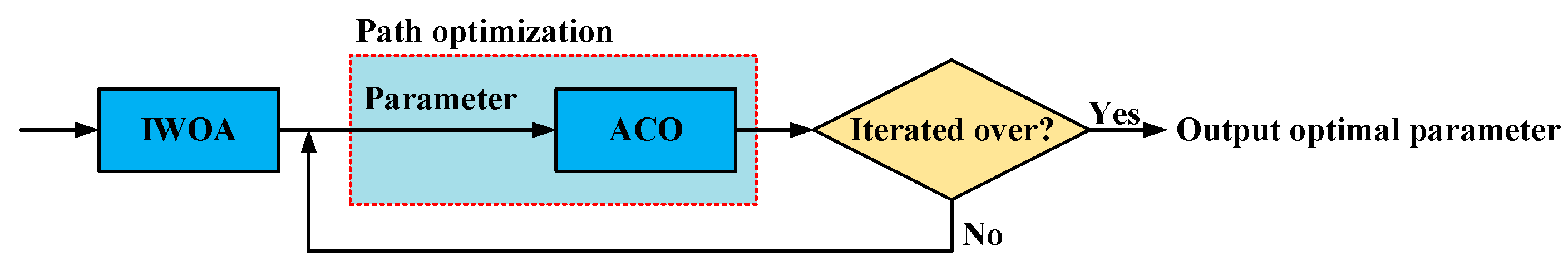

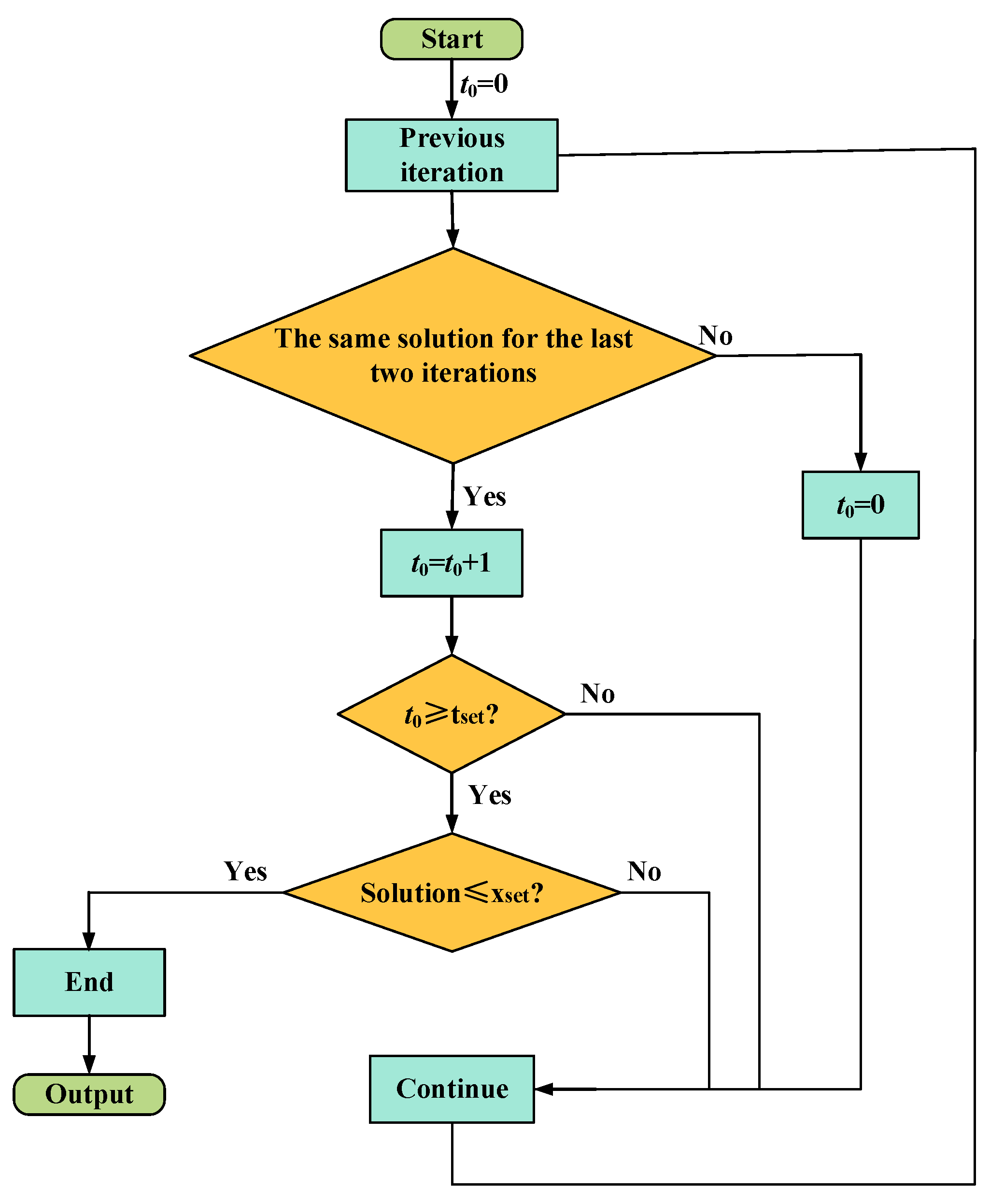

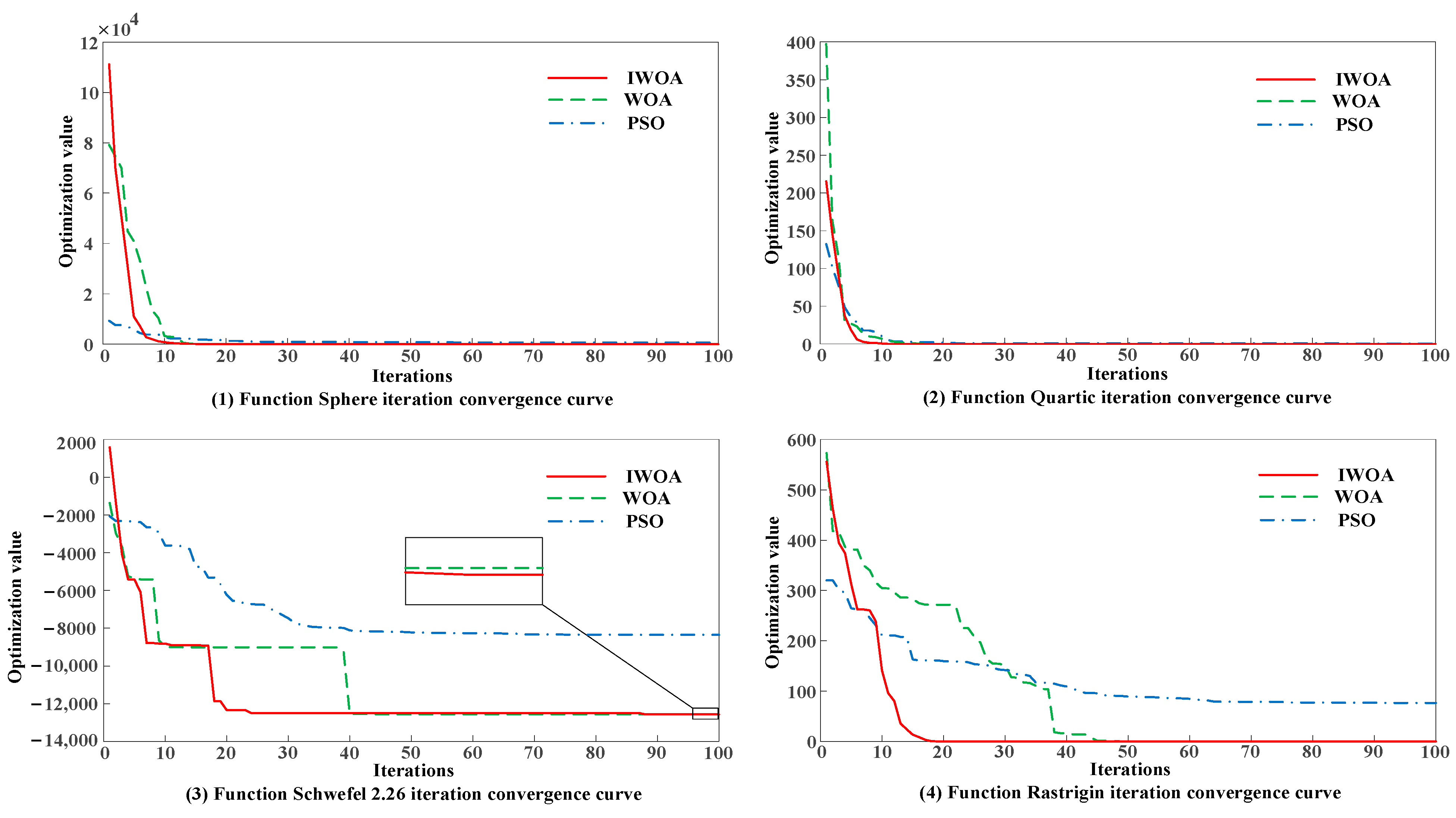

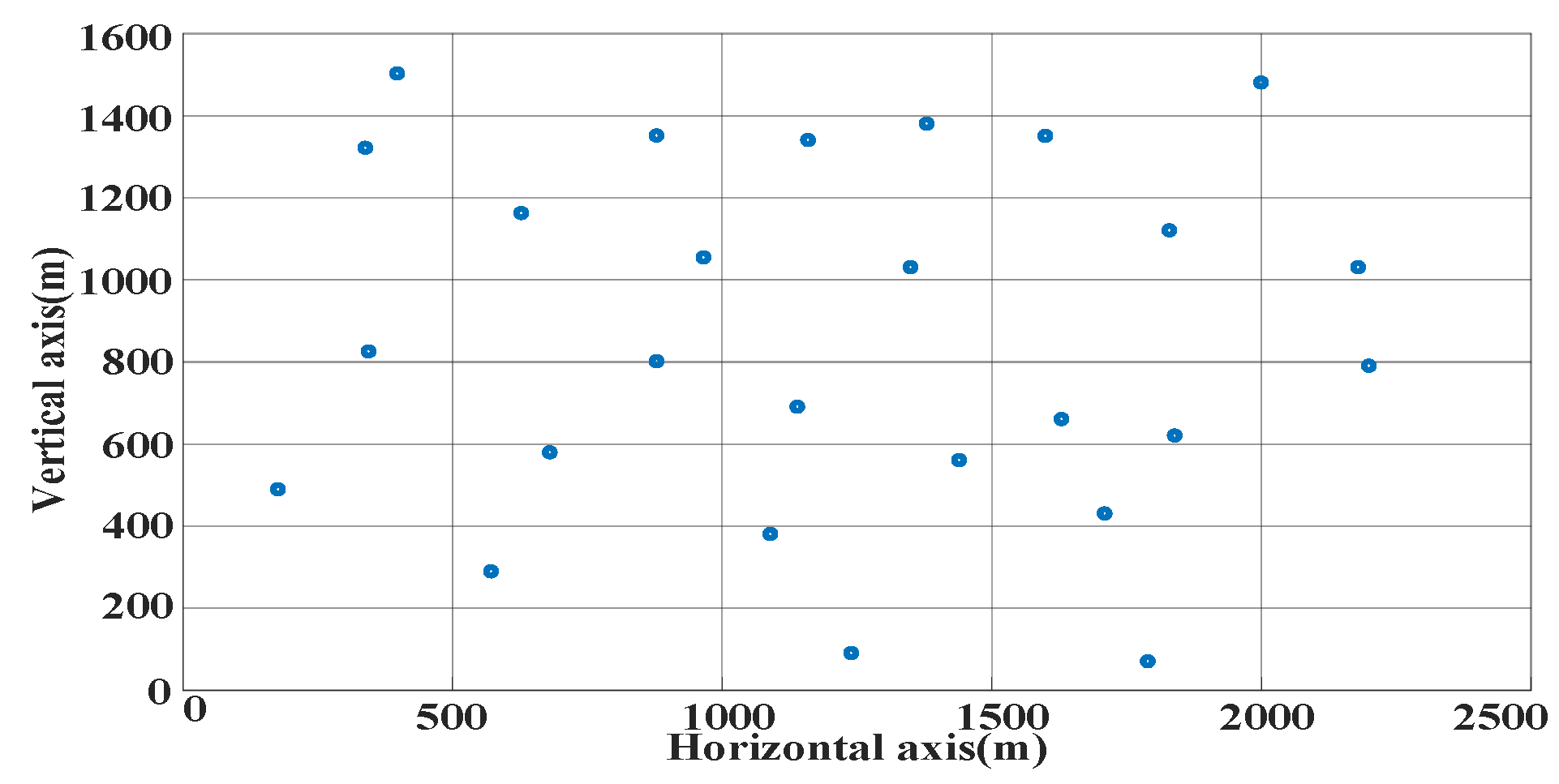

First, according to the analysis in

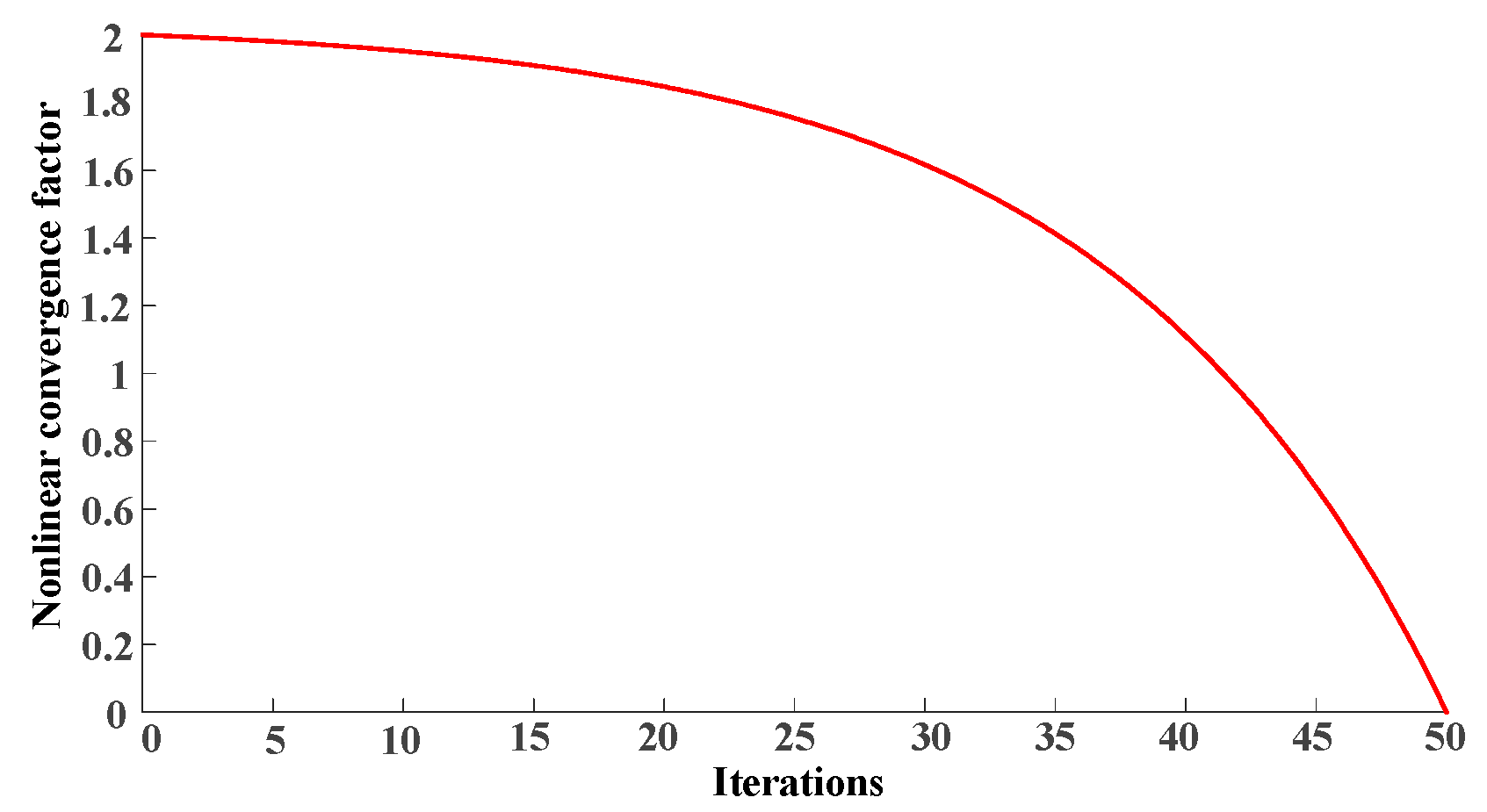

Section 2.3.1, we need to extract the node data from the test field, and the experiment needs a planned optimal path for the electric tractor to traverse all nodes. Second, we need to set the relevant parameters of the electric tractor as follows: the friction coefficient of traveling road surface is 0.07, the gravity of electric tractor is 10,700, and the transmission efficiency is 0.85. Then, we need to unify the evaluation functions of the three algorithms into Equation (25), and unify the setting parameters as follows: the variable dimension is 4, the number of individuals in the population is 30, the maximum number of iterations is 50. Finally, in order to eliminate the impact of algorithm simulation environment on algorithm performance, we unify the simulation environment of the three algorithms as follows: Windows10 (64 bit), Core (TM) i7-8550U, CPU 1.80 GHz, 16 GB, MatlabR2017a.

In order to better analyze the operational performance of IWOA-ACO, this paper solves the node path planning problem as shown in

Figure 5 with IWOA-ACO, WOA-ACO and PSO-ACO, compares the iteration curves of the evaluation functions of the three algorithms, and records the operation parameters of ACO algorithm, respectively.

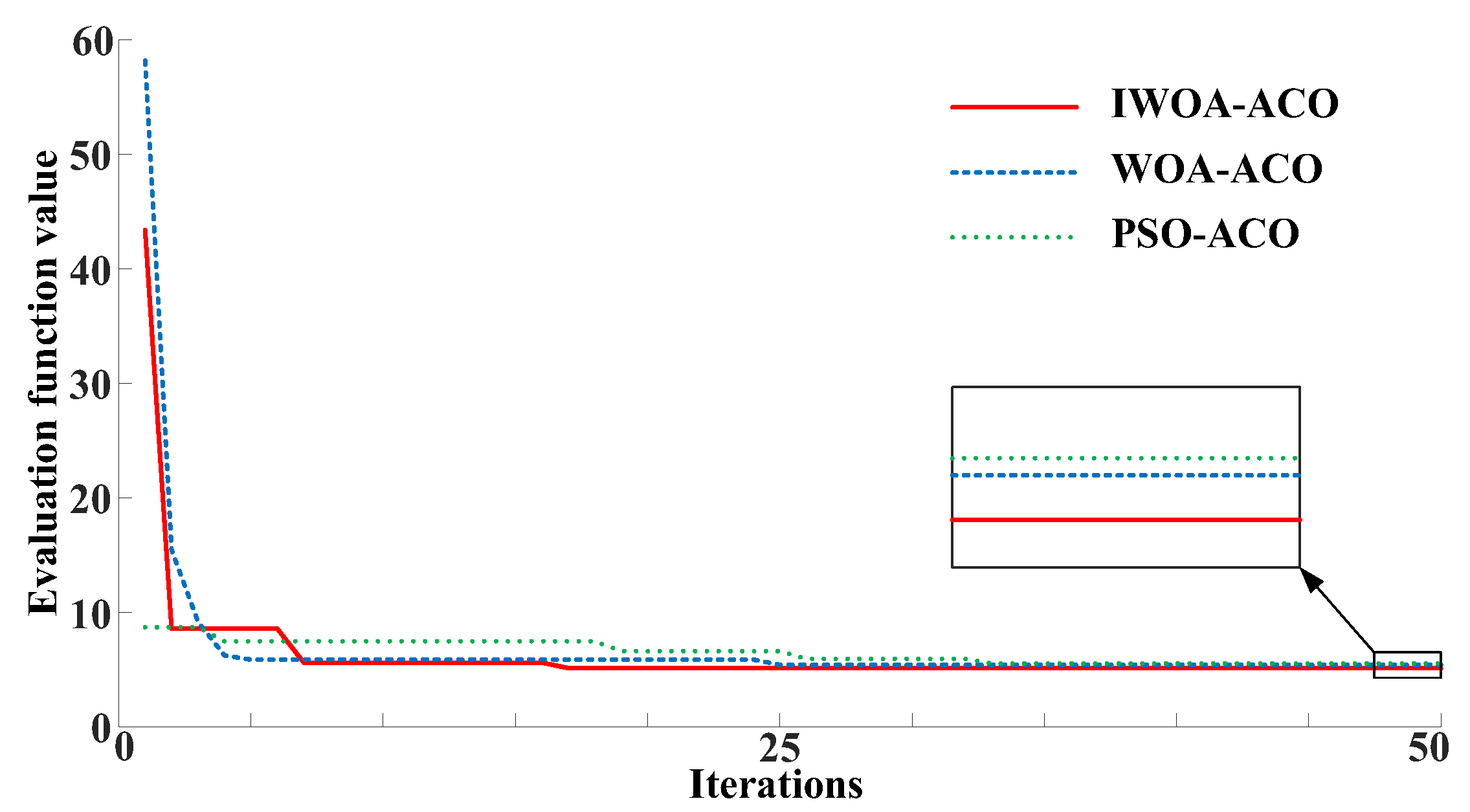

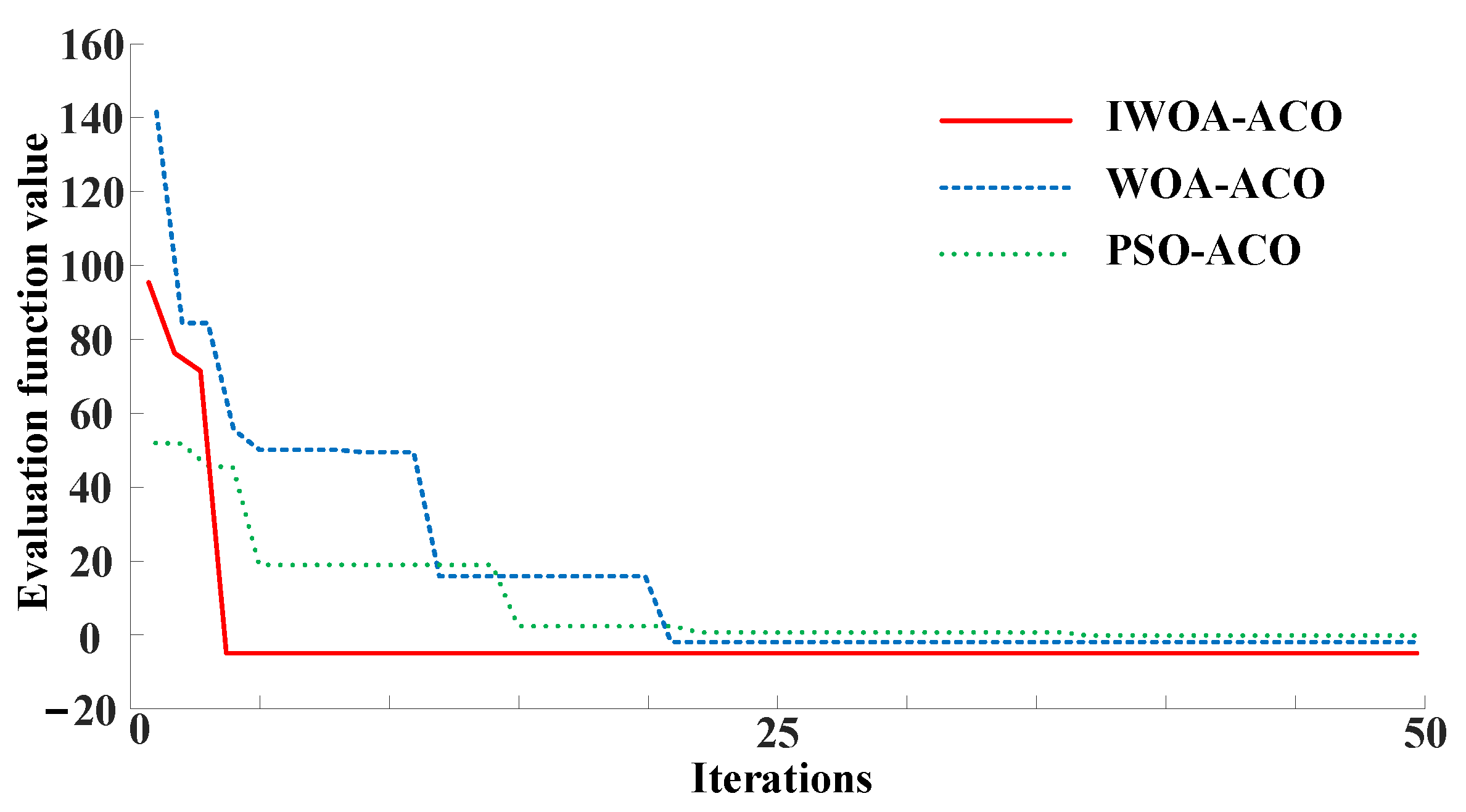

The convergence curve of the evaluation function corresponding to the three algorithms is shown in

Figure 8. The parameter values of ACO obtained by convergence of three functions are shown in

Table 3. The convergence value of the evaluation function of IWOA-ACO is better than that of WOA-ACO and PSO-ACO.

Ref. [

24] referred to the scheme of determining the parameter values of standard ACO algorithm by empirical method. In order to better verify the convergence performance of the IWOA-ACO algorithm, we employ the optimization scheme of the standard ACO algorithm as the control group in the comparison simulation. The parameter values of the algorithm are set according to Ref. [

24]:

m = 50,

α = 1,

β = 7 and

rh = 0.3.

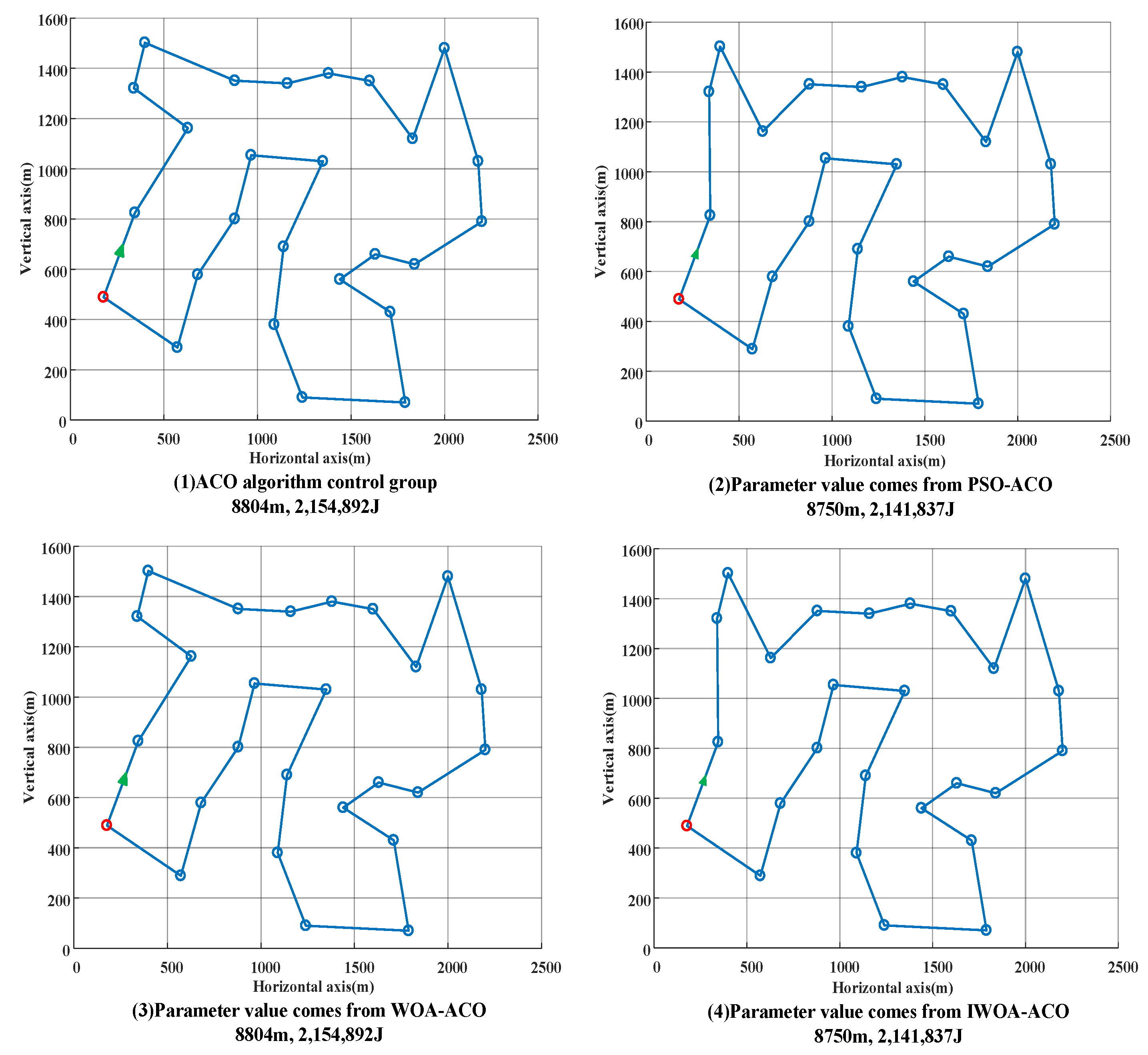

ACO plans the 26 node paths of the electric tractor according to the operation parameters in

Table 3 and experience parameters. The generated path planning diagram is shown in

Figure 9. This paper uses the iteration path length convergence curve to compare the convergence performance of ACO under different parameters, as shown in

Figure 10.

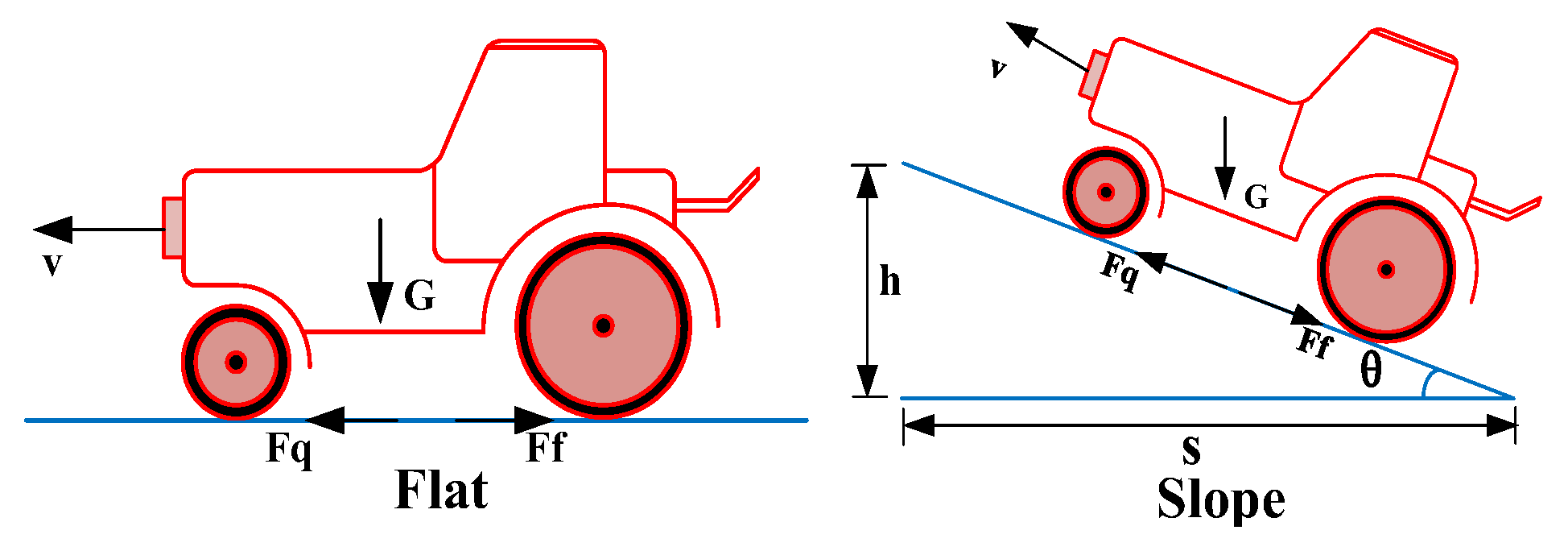

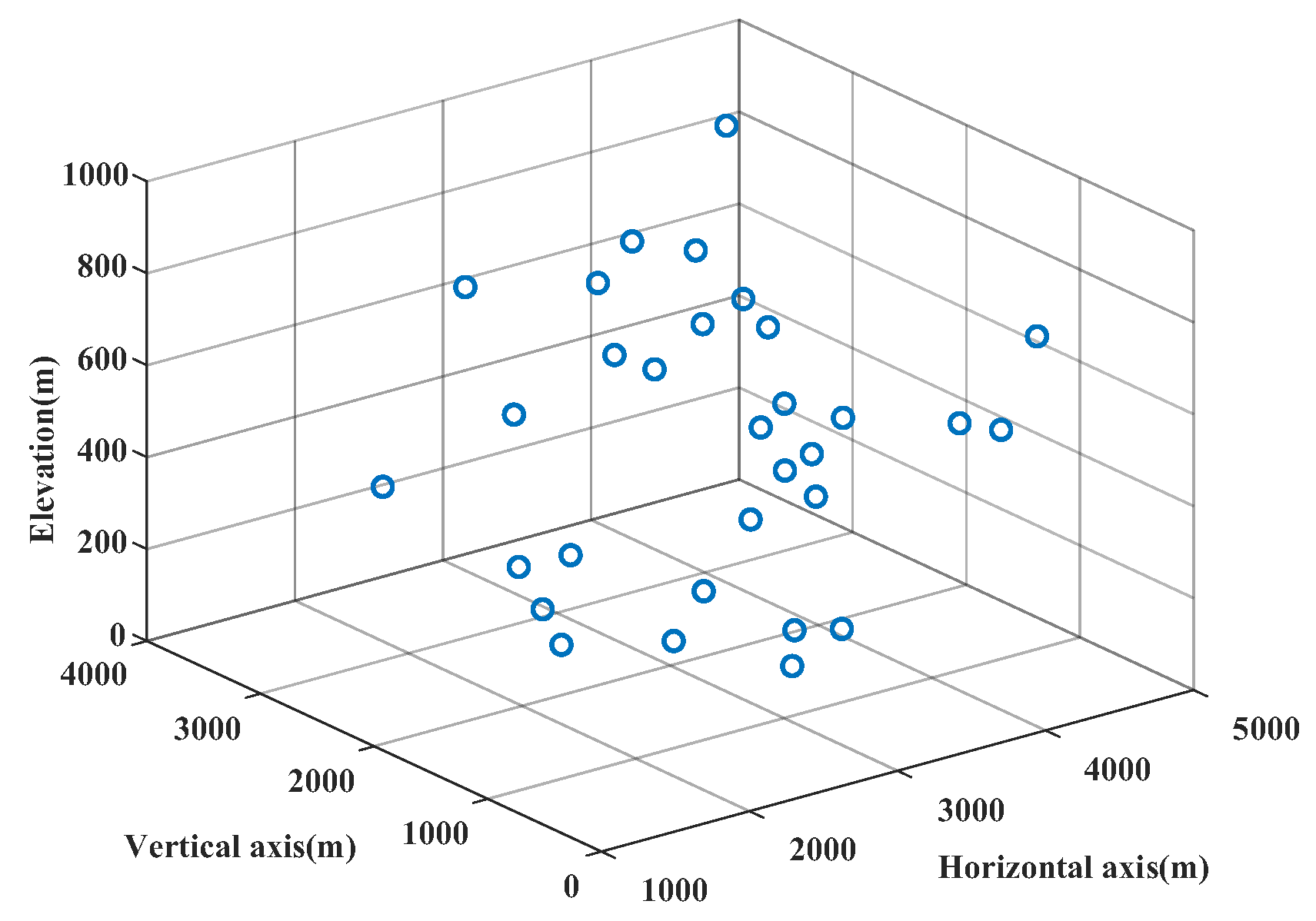

3.2. Simulation of Bump Environment

The cultivated land environment in Xinjiang is characterized by flat terrain [

28,

29]. Therefore, the node data in the cultivated area selected in this paper is approximately 2D. In order to further explore the adaptability of IWOA-ACO in the diversified cultivated land environment, we introduce the data of 31 nodes in the bump environment. The experimental steps and the parameters are set as shown in

Section 3.1, and this paper compares the simulation results of the three algorithms. The positions of 31 nodes in space are shown in

Figure 11.

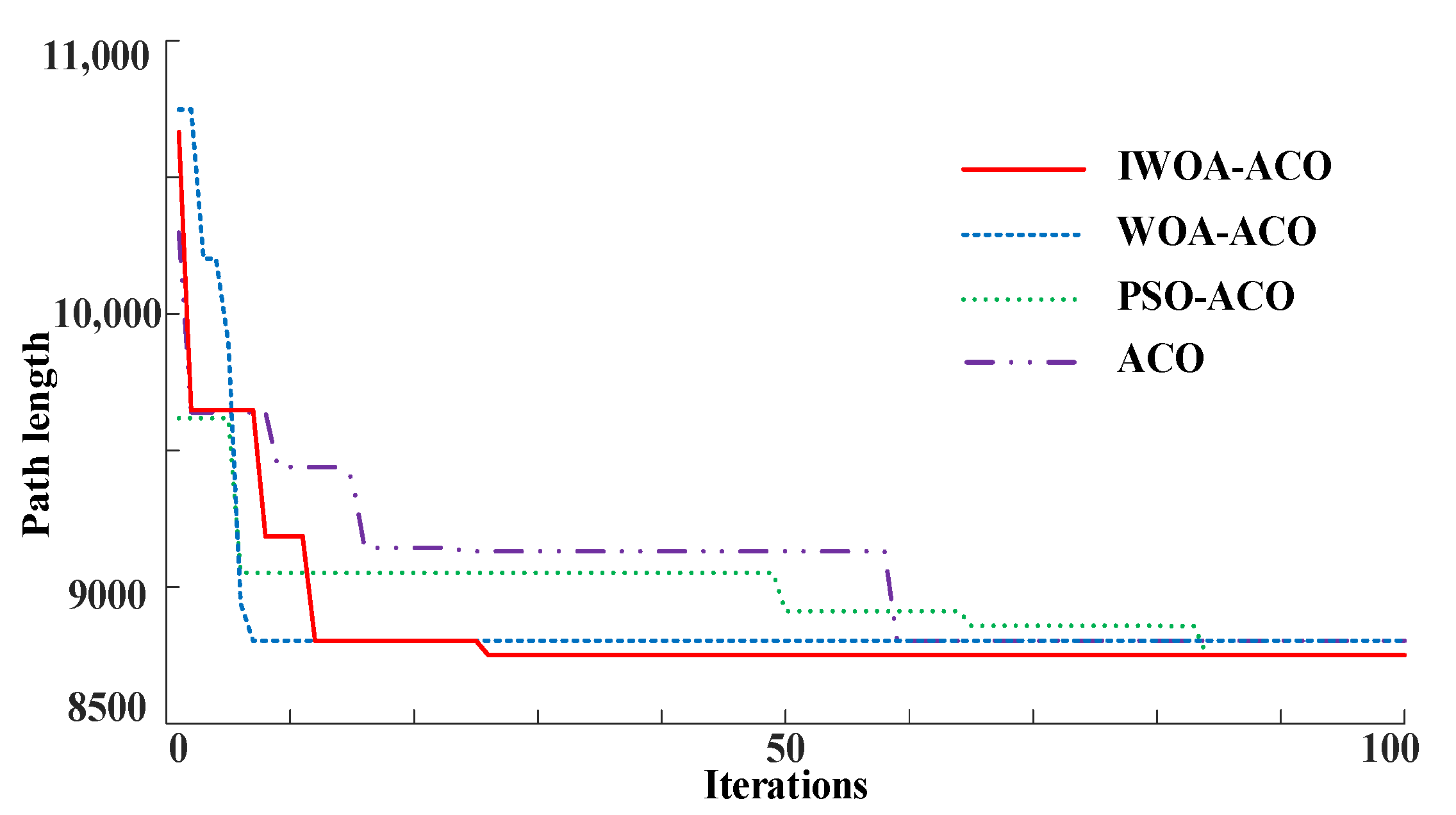

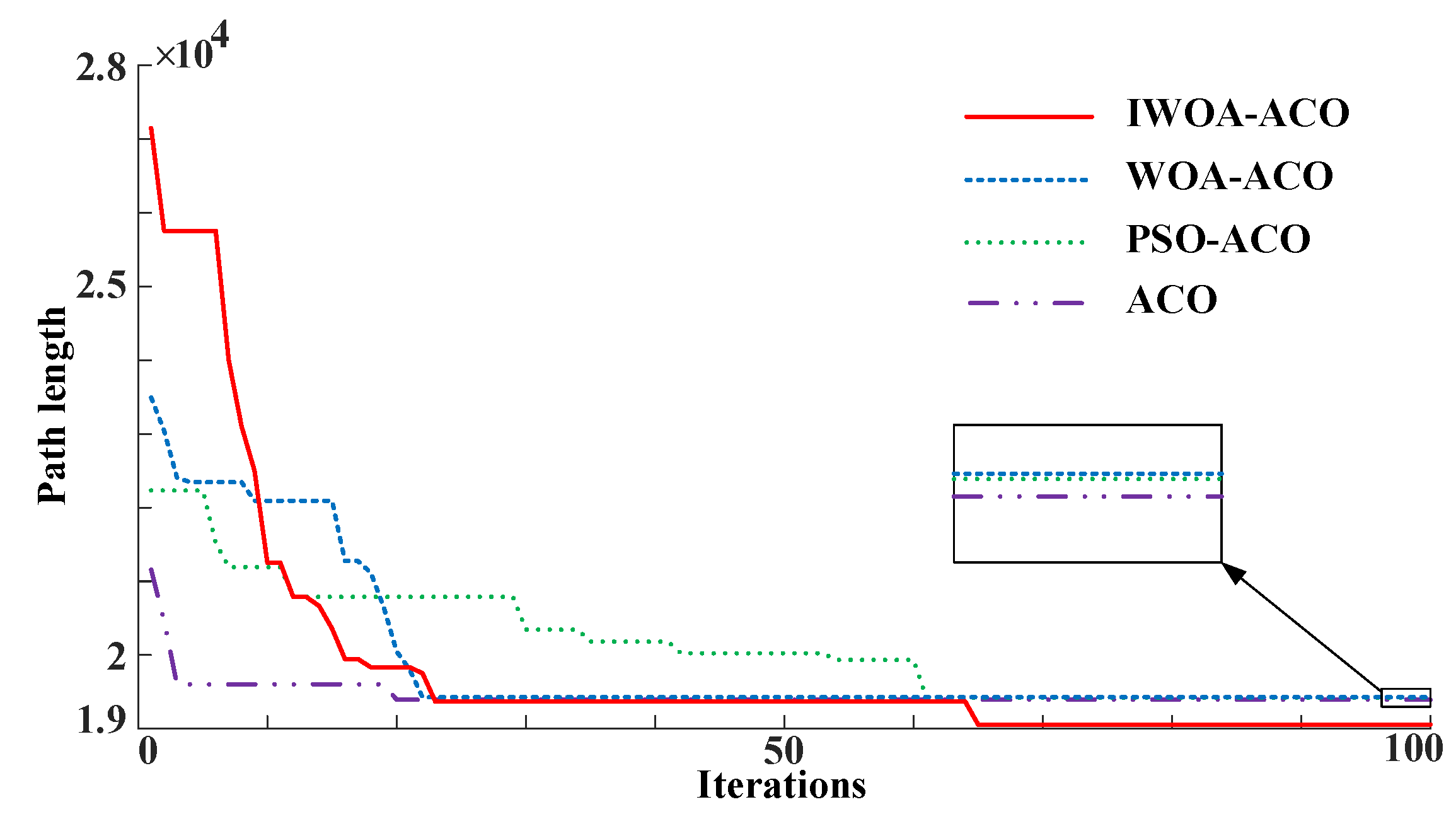

The convergence curve of the evaluation function corresponding to the three algorithms is shown in

Figure 12. The parameter values of ACO obtained by convergence of three functions are shown in

Table 4. The convergence value of the evaluation function of IWOA-ACO is better than that of WOA-ACO and PSO-ACO. Moreover, the evaluation function value of IWOA-ACO can converge to the optimal value after five iterations, while WOA-ACO requires 20 iterations and PSO-ACO requires 15 iterations. It can be seen that the convergence performance of IWOA-ACO is better than that of WOA-ACO and PSO-ACO in solving the multi-node path planning problem.

As in

Section 3.1, in order to better verify the convergence performance of the IWOA-ACO algorithm, we employ the optimization scheme of the standard ACO algorithm as the control group in the comparison simulation. The parameter values of the algorithm are

m = 50,

α = 1,

β = 7 and

rh = 0.3.

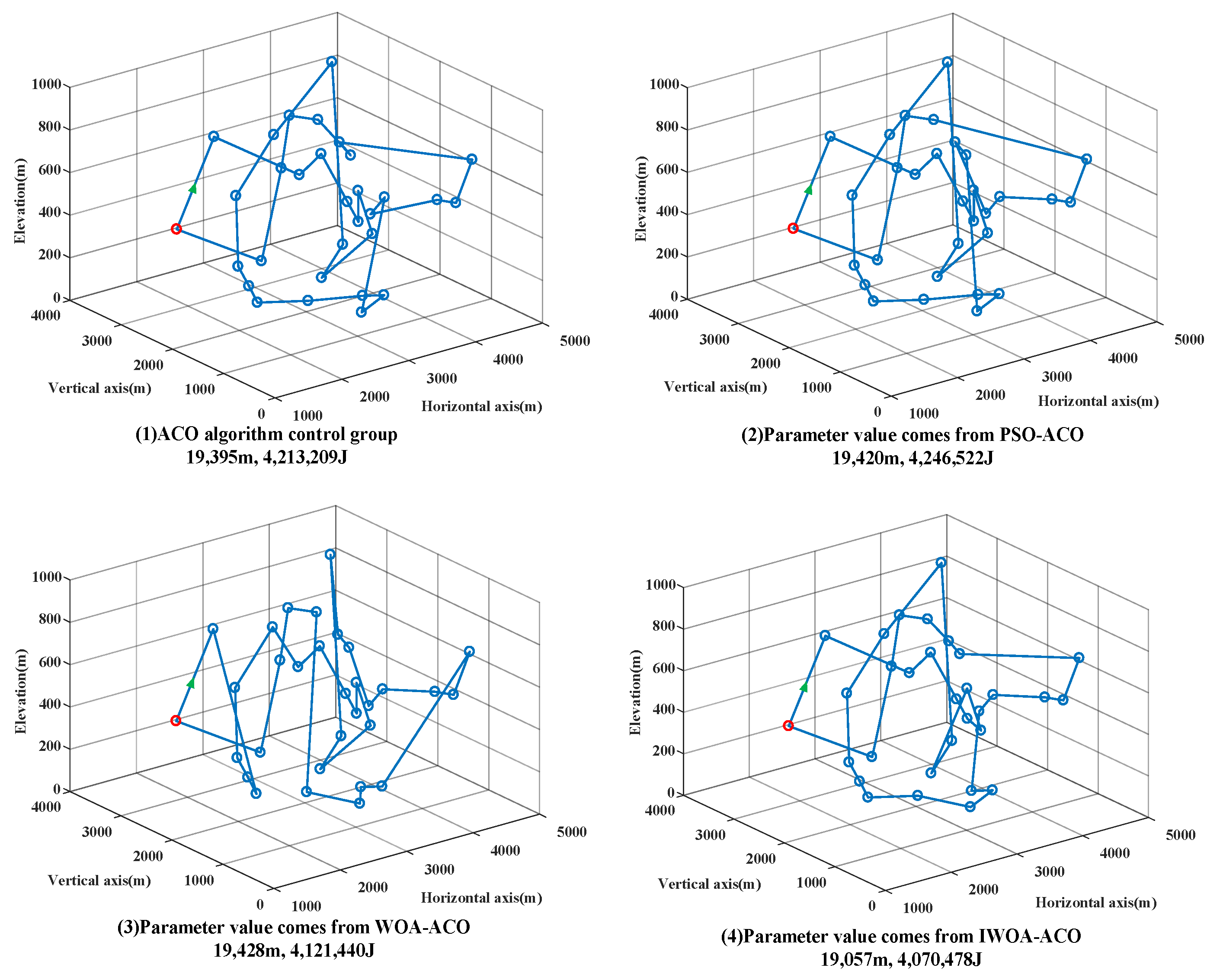

ACO plans the 31-node path of electric tractor based on the operating parameters obtained from the above three algorithms and experience parameters, and the resulting path planning diagram is shown in

Figure 13. This paper uses the iterative path length convergence curve to compare the convergence performance of ACO under different parameters, as shown in

Figure 14.

3.3. Discussion for Flat Environment Results

Based on

Figure 9 and

Figure 10, this paper analyzes the impact of ACO algorithm control group and the three parameter combinations shown in

Table 3 on the performance of ACO as follows:

On the one hand, as far as the convergence speed of ACO algorithm is concerned, IWOA-ACO is equivalent to WOA-ACO and faster than PSO-ACO.

On the other hand, the path length planned by PSO-ACO is 8750 (m), and the energy consumed by electric tractor is 2,141,837 (J). The length and energy consumption of IWOA-ACO planned path are the same as those of PSO-ACO, and are 0.61% less than those of WOA-ACO and ACO algorithm control group (the value of the path length is 8804 m, and the value of the energy is 2,154,892 J). In the simulation of flat environment, the path length and energy consumption data of electric tractor are shown in

Table 5. It is worth mentioning that since the nodes are approximately distributed in 2D space, the energy consumed by the electric tractor is proportional to the path length.

In general, the path planned by IWOA-ACO for the electric tractor has the advantages of fast convergence speed of WOA-ACO and strong convergence ability of PSO-ACO, which is helpful for efficient operation of the electric tractor.

3.4. Discussion for Bump Environment Results

In the simulation of bump environment, the path length and energy consumption data of electric tractor are shown in

Table 6.

Based on

Figure 13 and

Figure 14, this paper analyzes the impact of the three parameter combinations shown in

Table 4 on the performance of ACO as follows:

First of all, ACO, according to the parameters obtained from PSO-ACO, requires approximately 60 iterations to converge to the optimal value. The path length planned by the algorithm is 19,420 (m), and the energy consumed by electric tractor is 4,246,522 (J). The reason is that a small quantity of ants (the value is 47) leads to the slow convergence speed of the algorithm, and a small number of the pheromone concentration volatilization factor (the value is 0.2) leads to the local optimal solution of the algorithm.

In the second place, ACO, according to the parameters obtained from WOA-ACO, requires approximately 20 iterations to converge to the optimal value. The path length planned by the algorithm is 19,428 (m), and the energy consumed by electric tractor is 4,121,440 (J). The reason is that a large quantity of ants (the value is 76) leads to the fast convergence speed of the algorithm, but a small number of the pheromone concentration volatilization factor (the value is 0.32) leads to the local optimal solution of the algorithm.

Once more, ACO, according to the parameters obtained from IWOA-ACO, requires approximately 20 iterations to converge to the optimal value. The algorithm converges faster than the ACO algorithm with the parameters obtained from PSO-ACO, and approximates to the ACO algorithm with the parameters obtained from WOA-ACO. The path length planned by the algorithm is 19,057 (m), which is 1.91% less than that planned by the ACO algorithm with the parameters obtained from PSO-ACO and 1.95% less than that planned by the ACO algorithm with the parameters obtained from WOA-ACO. The energy consumed by electric tractor is 4,070,478 (J), which is 4.32% less than that optimized by the ACO algorithm with the parameters obtained from PSO-ACO and 1.25% less than that optimized by the ACO algorithm with the parameters obtained from WOA-ACO. In addition, the length and energy consumption of IWOA-ACO planned path are 1.74% and 3.39% less than those of ACO algorithm control group.

The reasons for the above results are as follows. On the one hand, a large quantity of ants (the value is 72) leads to the fast convergence speed of the algorithm and a large value of pheromone concentration volatilization factor (the value is 0.78) leads to good global convergence of the algorithm. On the other hand, the difference between the pheromone importance factor (the value is 0.83) and the heuristic function importance factor (the value is 2) is small, so that the algorithm can fully consider the pheromone concentration and heuristic function in the iterative process. Therefore, the algorithm can balance global and local searches.

However, IWOA-ACO has some limitations in practical application. On the one hand, IWOA-ACO can only obtain a set of set value parameters of ACO algorithm with good matching, but the ideal ACO parameter should be an adaptive function. On the other hand, affected by the fluctuation of ACO convergence results, the reliability of IWOA-ACO evaluation function has a negative correlation with the optimization time of the algorithm. We need to adjust the weight of evaluation function reliability and optimization time according to specific conditions.