Evaluation of the Use of Machine Learning to Predict Selected Mechanical Properties of Red Currant Fruit (Ribes rubrum L.) Ozonized during Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics of the Research Material

2.2. Ozonation Process

2.3. Determination of the Morphological and Physical Characteristics of Red Currant Fruit

2.4. Determination of the Mechanical Properties of Red Currant Fruit

2.5. Statistical Analysis

2.6. Machine Learning Methods

2.7. Sensitivity Analysis

2.8. Criteria of Accuracy Assessment of Models

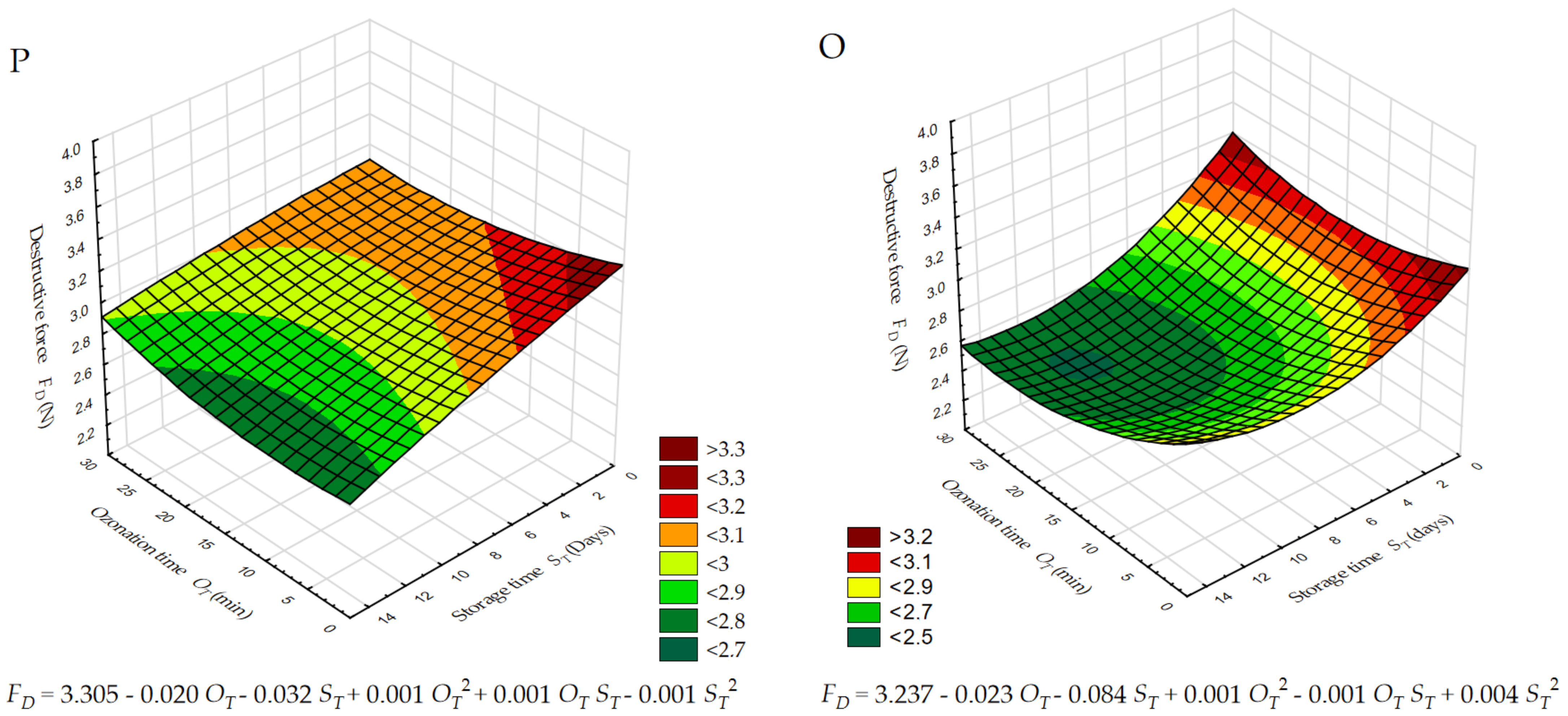

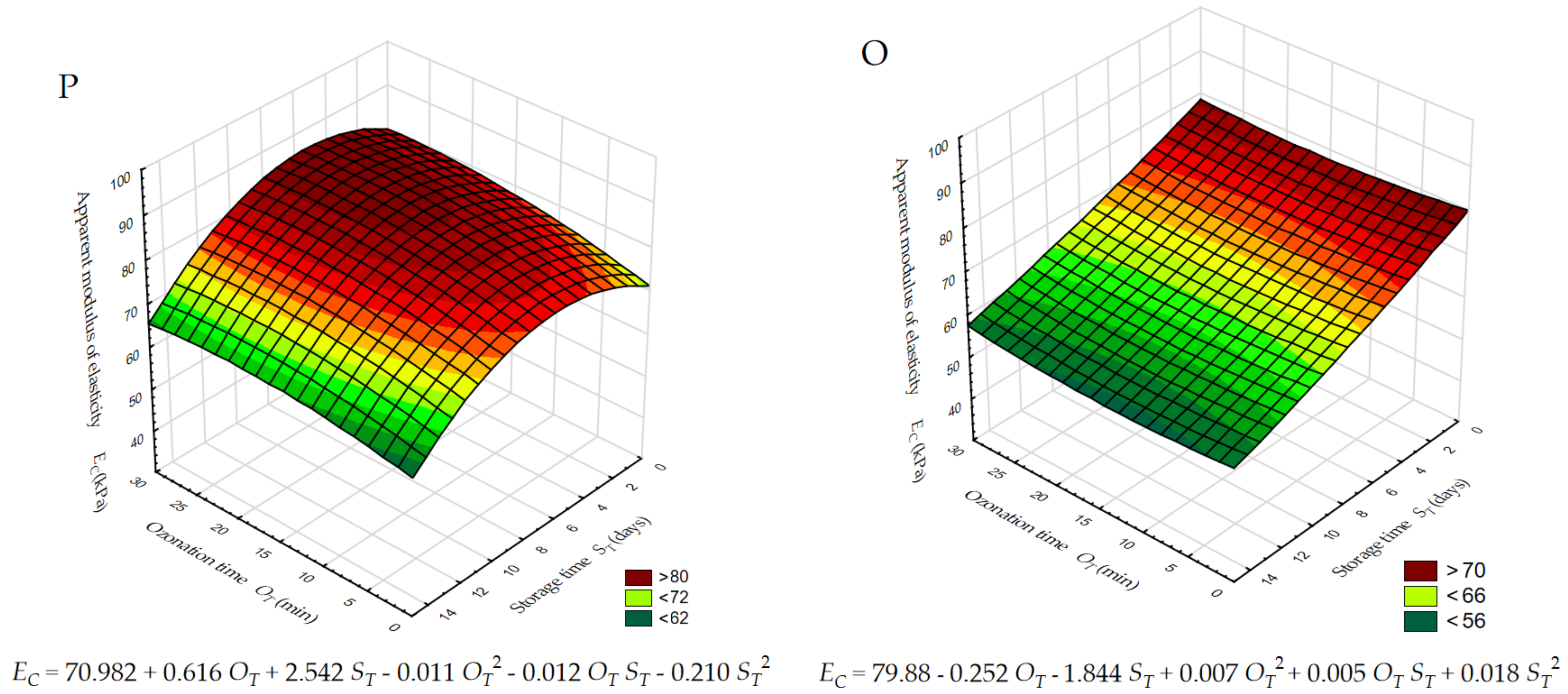

3. Results

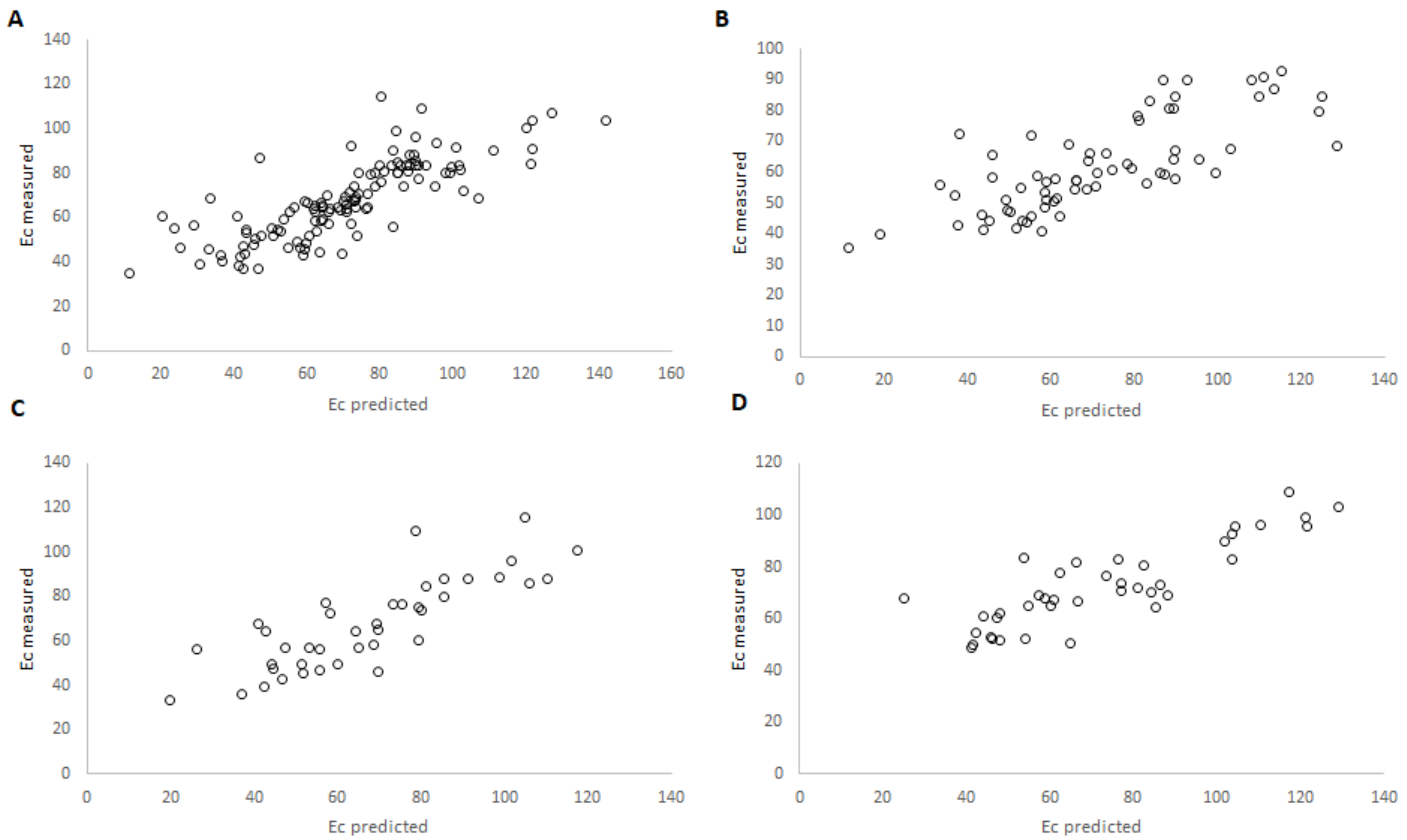

3.1. Machine Learning Models

3.1.1. Multilayer Perceptron

3.1.2. RBF Neural Networks

3.1.3. Support Vector Machines

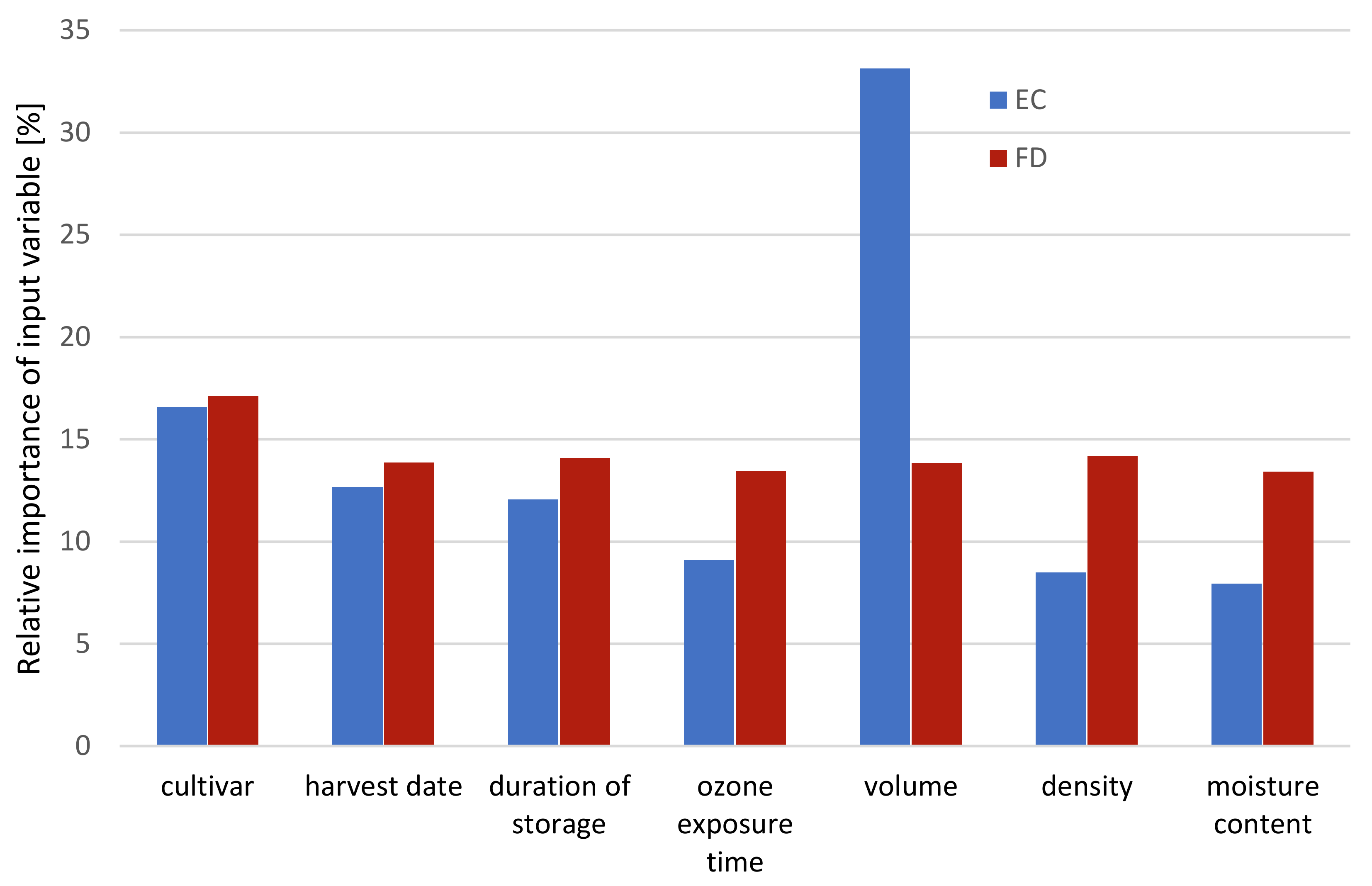

3.2. Sensitivity Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, Y.R.; Tahir, I.I.; Olsson, M.E. Effect of ozone application on bioactive compounds of apple fruit during short-term cold storage. Sci. Hortic. 2019, 253, 49–60. [Google Scholar] [CrossRef]

- Szmajda, G.; Nowakowski, T. Analysis of the harvesting quality of redcurrant with a trailed combine. Agric. Eng. 2020, 24, 91–102. [Google Scholar] [CrossRef]

- Panfilova, O.; Kalinina, O.; Golyaeva, O.; Knyazev, S.; Tsoy, M. Physical and mechanical properties of berries and biological features of red currant growth for mechanized harvesting. Res. Agric. Eng. 2020, 66, 156–163. [Google Scholar] [CrossRef]

- Li, Z.G.; Li, P.P.; Liu, J.Z. Effect of mechanical damage on mass loss and water content in tomato fruits. Int. Agrophys. 2011, 25, 77–83. [Google Scholar]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Harvest and Postharvest Factors Affecting Bruise Damage of Fresh Fruits. Hortic. Plant J. 2020, 6, 1–13. [Google Scholar] [CrossRef]

- ReFED. A Roadmap to Reduce U.S. Food Waste by 20 Percent; ReFED: Long Island City, NY, USA, 2016. [Google Scholar]

- 2021—Year of Vegetables and Fruits, 16 February 2021, 10–30. Available online: https://www.gazetaprawna.pl/wiadomosci/kraj/artykuly/8096722,2021-rok-warzyw-i-owocow.html (accessed on 30 October 2023).

- Gorzelany, J.; Belcar, J.; Kuzniar, P.; Niedbala, G.; Pentos, K. Modelling of Mechanical Properties of Fresh and Stored Fruit of Large Cranberry Using Multiple Linear Regression and Machine Learning. Agriculture 2022, 12, 200. [Google Scholar] [CrossRef]

- Thielen, M.; Speck, T.; Seidel, R. Viscoelasticity and compaction behaviour of the foam-like pomelo (Citrus maxima) peel. J. Mater. Sci. 2013, 48, 3469–3478. [Google Scholar] [CrossRef]

- Wang, J.X.; Zheng, D.C.; Cui, Q.L.; Xu, S.H.; Jiang, B.Y. Study on tensile mechanical property and microstructure of fruit and vegetable peels. Inmateh-Agric. Eng. 2019, 59, 227–236. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Pathare, P.; Opara, U.L. Susceptibility to impact damage of apples inside ventilated corrugated paperboard packages: Effects of package design. Postharvest Biol. Technol. 2016, 111, 286–296. [Google Scholar] [CrossRef]

- Kuzniar, P.; Belcar, J.; Zardzewialy, M.; Basara, O.; Gorzelany, J. Effect of Ozonation on the Mechanical, Chemical, and Microbiological Properties of Organically Grown Red Currant (Ribes rubrum L.) Fruit. Molecules 2022, 27, 8231. [Google Scholar] [CrossRef]

- Djordjevic, B.S.; Djurovic, D.B.; Zec, G.D.; Meland, M.O.; Aksic, M.M.F. Effects of shoot age on biological and chemical properties of red currant (Ribes rubrum L.) cultivars. Folia Hortic. 2020, 32, 291–305. [Google Scholar] [CrossRef]

- Heijerman, G.; van Gessel, G. Higher profits with planting hole treatment in red currant. In Xii International Rubus and Ribes Symposium: Innovative Rubus and Ribes Production for High Quality Berries in Changing Environments; International Society for Horticultural Science: Korbeek-Lo, Belgium, 2020; Volume 1277, pp. 239–243. [Google Scholar] [CrossRef]

- Ersoy, N.; Kupe, M.; Gundogdu, M.; Ilhan, G.; Ercisli, S. Phytochemical and Antioxidant Diversity in Fruits of Currant (Ribes spp.). Not. Bot. Horti Agrobot. Cluj-Napoca 2018, 46, 381–387. [Google Scholar] [CrossRef]

- Jurgiel-Małecka, G.; Buchwał, A. Characteristics of the chemical composition of currant fruit grown in the region of West Pomeran. Food Sci. Technol. Qual. 2016, 6, 90–101. [Google Scholar]

- Vakula, A.; Radojčin, M.; Pavkov, I.; Stamenković, Z.; Tepić Horecki, A.; Šumić, Z.; Pavlić, B. The impact of different drying methods on quality indicators of red currants (Ribes rubrum L.). J. Process. Energy Agric. 2015, 19, 249–254. [Google Scholar]

- Milivojevic, J.; Slatnar, A.; Mikulic-Petkovsek, M.; Stampar, F.; Nikolic, M.; Veberic, R. The Influence of Early Yield on the Accumulation of Major Taste and Health-Related Compounds in Black and Red Currant Cultivars (Ribes spp.). J. Agric. Food Chem. 2012, 60, 2682–2691. [Google Scholar] [CrossRef] [PubMed]

- Djordjevic, B.; Savikin, K.; Zdunic, G.; Jankovic, T.; Vulic, T.; Oparnica, C.; Radivojevic, D. Biochemical Properties of Red Currant Varieties in Relation to Storage. Plant Foods Hum. Nutr. 2010, 65, 326–332. [Google Scholar] [CrossRef]

- Jaramillo-Sanchez, G.; Contigiani, E.V.; Castro, M.A.; Hodara, K.; Alzamora, S.M.; Loredo, A.G.; Nieto, A.B. Freshness Maintenance of Blueberries (Vaccinium corymbosum L.) During Postharvest Using Ozone in Aqueous Phase: Microbiological, Structure, and Mechanical issues. Food Bioprocess Technol. 2019, 12, 2136–2147. [Google Scholar] [CrossRef]

- Piechowiak, T.; Antos, P.; Kosowski, P.; Skrobacz, K.; Jozefczyk, R.; Balawejder, M. Impact of ozonation process on the microbiological and antioxidant status of raspberries (Rubus ideaeus L.) during storage at room temperature. Agric. Food Sci. 2019, 28, 35–44. [Google Scholar] [CrossRef]

- Contigiani, E.V.; Jaramillo-Sanchez, G.; Castro, M.A.; Gomez, P.L.; Alzamora, S.M. Postharvest Quality of Strawberry Fruit (Fragaria x Ananassa Duch cv. Albion) as Affected by Ozone Washing: Fungal Spoilage, Mechanical Properties, and Structure. Food Bioprocess Technol. 2018, 11, 1639–1650. [Google Scholar] [CrossRef]

- Chwaszcz, B.; Józefczyk, R.; Bilek, M.; Balawejder, M. Ozonation as a method of extending the storage life of raspberry fruit under non-refrigerated conditions. In Technological Development of Food Quality; Wójciak, K.M., Dolatowski, Z.J., Eds.; Wydawnictwo Naukowe PTTŻ: Kraków, Poland, 2015; pp. 15–26. (In Polish) [Google Scholar]

- Szwedziak, K.; Polanczyk, E.; Grzywacz, Z.; Niedbala, G.; Wojtkiewicz, W. Neural Modeling of the Distribution of Protein, Water and Gluten in Wheat Grains during Storage. Sustainability 2020, 12, 5050. [Google Scholar] [CrossRef]

- Xia, A.L.; Zhang, Y.; Zhao, L.Z.; Qin, P. Simultaneous, Rapid and Nondestructive Determination of Moisture, Fat Content and Storage Time in Leisure Dried Tofu Using LF-NMR. Anal. Sci. 2021, 37, 301–307. [Google Scholar] [CrossRef] [PubMed]

- Mirzabe, A.H.; Khazaei, J.; Chegini, G.R.; Nejad, M.H.A.P.R. Determination of some physical properties of virgin olive fruits. Agric. Eng. Int. CIGR J. 2013, 15, 201–210. [Google Scholar]

- Sahithi Murakonda, S.; Patel, G.; Dwivedi, M. Characterization of engineering properties and modeling mass and fruit fraction of wood apple (Limonia acidissima) fruit for post-harvest processing. J. Saudi Soc. Agric. Sci. 2022, 21, 267–277. [Google Scholar] [CrossRef]

- Barbhuiya, R.I.; Nath, D.; Singh, S.K.; Dwivedi, M. Mass Modeling of Indian Coffee Plum (Flacourtia jangomas) Fruit with its Physicochemical Properties. Int. J. Fruit Sci. 2020, 20, S1110–S1133. [Google Scholar] [CrossRef]

- Vivek, K.; Mishra, S.; Pradhan, R.C. Physicochemical characterization and mass modelling of Sohiong (Prunus nepalensis L.) fruit. J. Food Meas. Charact. 2018, 12, 923–936. [Google Scholar] [CrossRef]

- Moradi, M.; Balanian, H.; Taherian, A.; Khaneghah, A.M. Physical and mechanical properties of three varieties of cucumber: A mathematical modeling. J. Food Process. Eng. 2020, 43, 13323. [Google Scholar] [CrossRef]

- Li, Z.G.; Andrews, J.; Wang, Y.Q. Mathematical modelling of mechanical damage to tomato fruits. Postharvest Biol. Technol. 2017, 126, 50–56. [Google Scholar] [CrossRef]

- Gao, Y.W.; Song, C.B.; Rao, X.Q.; Ying, Y.B. Image processing-aided FEA for monitoring dynamic response of potato tubers to impact loading. Comput. Electron. Agric. 2018, 151, 21–30. [Google Scholar] [CrossRef]

- Salarikia, A.; Miraei Ashtiani, S.-H.; Golzarian, M.R.; Mohammadinezhad, H. Finite element analysis of the dynamic behavior of pear under impact loading. Inform. Process. Agric. 2017, 4, 64–77. [Google Scholar] [CrossRef]

- Zulkifli, N.; Hashim, N.; Harith, H.H.; Shukery, M.F.M. Finite element modelling for fruit stress analysis—A review. Trends Food Sci. Technol. 2020, 97, 29–37. [Google Scholar] [CrossRef]

- Ropelewska, E. Assessment of the Influence of Storage Conditions and Time on Red Currants (Ribes rubrum L.) Using Image Processing and Traditional Machine Learning. Agriculture 2022, 12, 1730. [Google Scholar] [CrossRef]

- Hu, M.; Dong, Q.; Liu, B.; Opara, U.L. Prediction of mechanical properties of blueberry using hyperspectral interactance imaging. Postharvest Biol. Technol. 2016, 115, 122–131. [Google Scholar] [CrossRef]

- Huang, W.; Wang, X.; Zhang, J.; Xia, J.; Zhang, X. Improvement of blueberry freshness prediction based on machine learning and multi-source sensing in the cold chain logistics. Food Control 2023, 145, 109496. [Google Scholar] [CrossRef]

- PN-90/A-75101-03:1990; Fruit and Vegetable Preserves-Sample Preparation and Physicochemical Test Methods-Determination of dry Matter Content by Gravimetry. Polish Committee for Standardization: Warsaw, Poland, 1990.

- Vapnik, V.N.; Lerner, A. Pattern recognition using generalized portrait method. Autom. Remote Control 1963, 24, 774–780. [Google Scholar]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Yeh, I.C.; Cheng, W.-L. First and second order sensitivity analysis of MLP. Neurocomputing 2010, 73, 2225–2233. [Google Scholar] [CrossRef]

- Her, Q.L.; Wong, J. Significant correlation versus strength of correlation. Am. J. Health Syst. Pharm. 2019, 77, 73–75. [Google Scholar] [CrossRef]

- Yoon, H.; Jun, S.C.; Hyun, Y.; Bae, G.O.; Lee, K.K. A comparative study of artificial neural networks and support vector machines for predicting groundwater levels in a coastal aquifer. J. Hydrol. 2011, 396, 128–138. [Google Scholar] [CrossRef]

- El Bilali, A.; Moukhliss, M.; Taleb, A.; Nafii, A.; Alabjah, B.; Brouziyne, Y.; Mazigh, N.; Teznine, K.; Mhamed, M. Predicting daily pore water pressure in embankment dam: Empowering Machine Learning-based modeling. Environ. Sci. Pollut. Res. 2022, 29, 47382–47398. [Google Scholar] [CrossRef]

- Lara, I.; Belge, B.; Goulao, L.F. The fruit cuticle as a modulator of postharvest quality. Postharvest Biol. Technol. 2014, 87, 103–112. [Google Scholar] [CrossRef]

- Tzortzakis, N.; Borland, A.; Singleton, I.; Barnes, J. Impact of atmospheric ozone-enrichment on quality-related attributes of tomato fruit. Postharvest Biol. Technol. 2007, 45, 317–325. [Google Scholar] [CrossRef]

- Palou, L.; Crisosto, C.H.; Smilanick, J.L.; Adaskaveg, J.E.; Zoffoli, J.P. Effects of continuous 0.3 ppm ozone exposure on decay development and physiological responses of peaches and table grapes in cold storage. Postharvest Biol. Technol. 2002, 24, 39–48. [Google Scholar] [CrossRef]

- Crisosto, C.H.; Retzlaff, W.A.; Williams, L.E.; Dejong, T.M.; Zoffoli, J.P. Postharvest performance evaluation of plum (prunus-salicina lindel, casselman) fruit grown under 3 ozone concentrations. J. Am. Soc. Hortic. Sci. 1993, 118, 497–502. [Google Scholar] [CrossRef]

- Aday, M.S.; Caner, C. Individual and combined effects of ultrasound, ozone and chlorine dioxide on strawberry storage life. Lwt-Food Sci. Technol. 2014, 57, 344–351. [Google Scholar] [CrossRef]

- Cevher, E.Y.; Yildirim, D. Using Artificial Neural Network Application in Modeling the Mechanical Properties of Loading Position and Storage Duration of Pear Fruit. Processes 2022, 10, 2245. [Google Scholar] [CrossRef]

- Vasighi-Shojae, H.; Gholami-Parashkouhi, M.; Mohammadzamani, D.; Soheili, A. Predicting Mechanical Properties of Golden Delicious Apple Using Ultrasound Technique and Artificial Neural Network. Food Anal. Methods 2020, 13, 699–705. [Google Scholar] [CrossRef]

- Abasi, S.; Minaei, S.; Jamshidi, B.; Fathi, D.; Khoshtaghaza, M.H. Rapid measurement of apple quality parameters using wavelet de-noising transform with Vis/NIR analysis. Sci. Hortic. 2019, 252, 7–13. [Google Scholar] [CrossRef]

- Saiedirad, M.H.; Mirsalehi, M. Prediction of mechanical properties of cumin seed using artificial neural networks. J. Texture Stud. 2010, 41, 34–48. [Google Scholar] [CrossRef]

| Cultivar | Ozonation Time [min] | Harvest Date | Storage Time [Days] | Volume [cm3] | Density [g/cm3] | Moisture Content [%] | Destructive Force [N] | Apparent Modulus of Elasticity [kPa] |

|---|---|---|---|---|---|---|---|---|

| ‘Holenderska Czerwona’ | 0 | P | 1 | 0.48 b ± 0.10 | 1.075 a ± 0.041 | 85.74 b ± 1.98 | 2.99 a ± 0.93 | 70.80 a ± 22.34 |

| 0 | P | 8 | 0.42 a ± 0.15 | 1.066 a ± 0.056 | 86.54 b ± 1.45 | 2.73 a ± 0.84 | 68.58 a ± 22.58 | |

| 0 | P | 15 | 0.40 a ± 0.06 | 1.075 a ± 0.028 | 82.97 a ± 0.87 | 2.53 a ± 0.80 | 67.41 a ± 12.27 | |

| 0 | O | 1 | 0.46 a ± 0.11 | 1.046 a ± 0.027 | 84.10 a ± 1.27 | 3.24 b ± 0.63 | 81.84 b ± 18.05 | |

| 0 | O | 8 | 0.47 a ± 0.10 | 1.140 b ± 0.043 | 84.59 a ± 1.35 | 2.17 a ± 0.97 | 51.56 a ± 21.40 | |

| 0 | O | 15 | 0.45 a ± 0.08 | 1.109 b ± 0.045 | 83.92 a ± 2.57 | 2.73 ab ± 0.67 | 56.17 a ± 13.15 | |

| 15 | P | 1 | 0.36 a ± 0.09 | 1.044 a ± 0.026 | 85.43 b ± 1.18 | 2.94 ab ± 0.64 | 87.93 b ± 26.04 | |

| 15 | P | 8 | 0.34 a ± 0.12 | 1.097 b ± 0.049 | 85.56 b ± 1.72 | 3.46 b ± 0.78 | 95.43 b ± 28.67 | |

| 15 | P | 15 | 0.40 b ± 0.06 | 1.089 b ± 0.036 | 83.80 a ± 1.07 | 2.66 a ± 0.46 | 67.14 a ± 11.19 | |

| 15 | O | 1 | 0.45 b ± 0.07 | 1.089 a ± 0.070 | 83.51 a ± 0.95 | 2.50 a ± 0.76 | 70.97 b ± 20.00 | |

| 15 | O | 8 | 0.37 a ± 0.11 | 1.112 a ± 0.062 | 82.88 a ± 1.12 | 2.55 a ± 0.83 | 79.04 b ± 24.36 | |

| 15 | O | 15 | 0.47 b ± 0.08 | 1.097 a ± 0.047 | 83.86 a ± 1.65 | 2.77 a ± 0.52 | 56.14 a ± 12.04 | |

| 30 | P | 1 | 0.43 a ± 0.06 | 1.069 a ± 0.049 | 84.53 ab ± 1.50 | 3.07 a ± 0.71 | 78.15 a ± 19.04 | |

| 30 | P | 8 | 0.40 a ± 0.15 | 1.097 a ± 0.060 | 85.47 b ± 2.03 | 2.75 a ± 0.81 | 74.32 a ± 31.52 | |

| 30 | P | 15 | 0.40 a ± 0.06 | 1.096 a ± 0.046 | 83.68 a ± 1.24 | 2.72 a ± 0.78 | 65.32 a ± 12.01 | |

| 30 | O | 1 | 0.44 a ± 0.06 | 1.090 a ± 0.050 | 83.90 b ± 1.08 | 2.81 a ± 0.50 | 75.42 b ± 10.18 | |

| 30 | O | 8 | 0.47 a ± 0.11 | 1.110 a ± 0.052 | 82.64 a ± 1.19 | 2.72 a ± 0.95 | 59.17 a ± 22.64 | |

| 30 | O | 15 | 0.46 a ± 0.06 | 1.094 a ± 0.039 | 82.51 a ± 1.54 | 2.40 a ± 0.52 | 51.95 a ± 9.68 | |

| ‘Losan’ | 0 | P | 1 | 0.50 b ± 0.06 | 1.110 a ± 0.054 | 83.91 a ± 1.23 | 2.69 a ± 0.76 | 60.24 a ± 12.77 |

| 0 | P | 8 | 0.32 a ± 0.09 | 1.089 a ± 0.060 | 86.53 b ± 2.05 | 2.19 a ± 0.70 | 61.71 a ± 26.42 | |

| 0 | P | 15 | 0.36 a ± 0.06 | 1.103 a ± 0.047 | 85.84 b ± 1.47 | 2.38 a ± 0.68 | 54.98 a ± 9.25 | |

| 0 | O | 1 | 0.41 a ± 0.07 | 1.136 ab ± 0.052 | 86.51 b ± 1.84 | 3.15 b ± 0.93 | 75.77 c ± 12.51 | |

| 0 | O | 8 | 0.44 a ± 0.05 | 1.147 b ± 0.037 | 84.61 a ± 2.33 | 3.06 b ± 0.78 | 60.15 b ± 10.67 | |

| 0 | O | 15 | 0.40 a ± 0.10 | 1.099 a ± 0.075 | 84.40 a ± 1.27 | 1.69 a ± 0.89 | 37.65 a ± 16.70 | |

| 15 | P | 1 | 0.38 b ± 0.09 | 1.131 a ± 0.037 | 87.03 b ± 1.63 | 2.46 a ± 0.57 | 64.00 ab ± 17.25 | |

| 15 | P | 8 | 0.32 a ± 0.10 | 1.106 a ± 0.058 | 85.64 a ± 2.15 | 2.53 a ± 0.96 | 72.30 b ± 22.83 | |

| 15 | P | 15 | 0.36 ab ± 0.06 | 1.118 a ± 0.040 | 84.67 a ± 1.29 | 2.04 a ± 0.69 | 50.57 b ± 11.25 | |

| 15 | O | 1 | 0.31 a ± 0.12 | 1.132 b ± 0.054 | 86.29 b ± 2.43 | 1.72 a ± 0.71 | 52.43 ab ± 28.44 | |

| 15 | O | 8 | 0.36 a ± 0.06 | 1.110 b ± 0.040 | 84.93 a ± 0.91 | 2.49 b ± 0.79 | 65.73 b ± 9.96 | |

| 15 | O | 15 | 0.35 a ± 0.10 | 1.034 a ± 0.092 | 83.85 a ± 1.09 | 2.68 b ± 1.92 | 50.65 a ± 20.22 | |

| 30 | P | 1 | 0.40 b ± 0.08 | 1.095 a ± 0.050 | 84.90 a ± 1.76 | 2.79 a ± 1.38 | 59.88 a ± 17.98 | |

| 30 | P | 8 | 0.28 a ± 0.09 | 1.083 a ± 0.060 | 85.51 a ± 1.78 | 2.39 a ± 0.58 | 83.62 b ± 22.54 | |

| 30 | P | 15 | 0.36 b ± 0.06 | 1.117 a ± 0.043 | 85.18 a ± 1.27 | 2.40 a ± 1.26 | 52.67 a ± 11.48 | |

| 30 | O | 1 | 0.35 a ± 0.11 | 1.164 b ± 0.118 | 84.72 a ± 1.77 | 2.85 b ± 1.31 | 75.10 b ± 39.60 | |

| 30 | O | 8 | 0.37 a ± 0.04 | 1.132 ab ± 0.061 | 84.91 a ± 1.17 | 2.41 ab ± 1.02 | 59.56 a ± 10.41 | |

| 30 | O | 15 | 0.34 a ± 0.09 | 1.106 a ± 0.088 | 84.99 a ± 1.57 | 1.96 a ± 0.67 | 54.81 a ± 10.63 | |

| ‘Luna’ | 0 | P | 1 | 0.41 a ± 0.09 | 1.147 a ± 0.041 | 87.06 b ± 2.27 | 4.11 b ± 0.72 | 91.95 b ± 16.19 |

| 0 | P | 8 | 0.37 a ± 0.06 | 1.132 a ± 0.057 | 84.63 a ± 1.73 | 4.15 b ± 1.21 | 92.367 b ± 13.51 | |

| 0 | P | 15 | 0.35 a ± 0.06 | 1.129 a ± 0.040 | 84.90 a ± 1.54 | 3.29 a ± 0.95 | 71.28 a ± 18.30 | |

| 0 | O | 1 | 0.33 a ± 0.05 | 1.139 b ± 0.039 | 87.83 b ± 1.74 | 3.60 a ± 1.01 | 88.01 b ± 17.38 | |

| 0 | O | 8 | 0.34 a ± 0.12 | 1.136 b ± 0.050 | 86.97 b ± 1.26 | 3.52 a ± 1.94 | 80.81 ab ± 23.48 | |

| 0 | O | 15 | 0.39 a ± 0.06 | 1.078 a ± 0.050 | 83.57 a ± 1.49 | 3.80 a ± 1.62 | 70.00 a ± 14.46 | |

| 15 | P | 1 | 0.37 a ± 0.10 | 1.148 a ± 0.050 | 84.89 a ± 2.66 | 3.88 b ± 1.43 | 92.71 b ± 14.37 | |

| 15 | P | 8 | 0.35 a ± 0.08 | 1.143 a ± 0.043 | 85.06 a ± 3.06 | 2.87 a ± 0.99 | 82.39 ab ± 14.13 | |

| 15 | P | 15 | 0.33 a ± 0.03 | 1.145 a ± 0.059 | 83.95 a ± 1.22 | 3.37 ab ± 1.24 | 75.57 a ± 15.80 | |

| 15 | O | 1 | 0.41 a ± 0.13 | 1.129 b ± 0.067 | 84.72 a ± 1.91 | 3.58 b ± 1.49 | 81.47 b ± 24.33 | |

| 15 | O | 8 | 0.38 a ± 0.09 | 1.146 b ± 0.043 | 85.70 a ± 1.99 | 2.33 a ± 0.92 | 62.17 a ± 14.70 | |

| 15 | O | 15 | 0.37 a ± 0.07 | 1.056 a ± 0.055 | 84.81 a ± 2.01 | 3.79 b ± 1.17 | 69.22 ab ± 11.23 | |

| 30 | P | 1 | 0.33 a ± 0.07 | 1.150 a ± 0.079 | 85.74 b ± 1.57 | 3.43 a ± 1.23 | 99.27 b ± 30.66 | |

| 30 | P | 8 | 0.31 a ± 0.05 | 1.145 a ± 0.064 | 84.91 ab ± 2.24 | 3.83 a ± 0.78 | 104.41 b ± 17.02 | |

| 30 | P | 15 | 0.34 a ± 0.06 | 1.138 a ± 0.053 | 84.42 a ± 1.91 | 3.66 a ± 1.32 | 75.35 a ± 21.25 | |

| 30 | O | 1 | 0.36 a ± 0.09 | 1.163 b ± 0.054 | 85.41 b ± 1.42 | 4.17 b ± 1.15 | 91.81 b ± 20.21 | |

| 30 | O | 8 | 0.32 a ± 0.12 | 1.114 a ± 0.077 | 85.69 b ± 1.81 | 2.83 a ± 1.51 | 73.76 a ± 26.26 | |

| 30 | O | 15 | 0.36 a ± 0.06 | 1.129 ab ± 0.062 | 83.87 a ± 1.32 | 2.66 a ± 0.81 | 60.42 a ± 12.86 |

| Ozonation Time | Storage Time | Volume | Density | Moisture Content | Destructive Force | Apparent Modulus of Elasticity | |

|---|---|---|---|---|---|---|---|

| Ozonation time | 1.00 | 0.00 | −0.13 | 0.05 | −0.13 | −0.04 | 0.05 |

| Storage time | 0.00 | 1.00 | −0.07 | −0.09 | −0.24 | −0.13 | −0.30 |

| Volume | −0.13 | −0.07 | 1.00 | −0.12 | −0.32 | −0.07 | −0.55 |

| Density | 0.05 | −0.09 | −0.12 | 1.00 | 0.00 | 0.06 | 0.10 |

| Moisture content | −0.13 | −0.24 | −0.32 | 0.00 | 1.00 | −0.02 | 0.15 |

| Destructive force | −0.04 | −0.13 | −0.07 | 0.06 | −0.02 | 1.00 | 0.61 |

| Apparent modulus of elasticity | 0.05 | −0.30 | −0.55 | 0.10 | 0.15 | 0.61 | 1.00 |

| Output Parameter | Model Structure | Train | Validation | Test | GA | |||

|---|---|---|---|---|---|---|---|---|

| RMSE | R | RMSE | R | RMSE | R | |||

| modulus of elasticity EC | 7-8-1 | 12.92 | 0.83 | 12.53 | 0.88 | 14.68 | 0.80 | 1.14 |

| destructive force FD | 7-8-1 | 0.95 | 0.53 | 0.96 | 0.53 | 1.19 | 0.36 | 1.25 |

| Output Parameter | Model Structure | Train | Validation | Test | GA | |||

|---|---|---|---|---|---|---|---|---|

| RMSE | R | RMSE | R | RMSE | R | |||

| Control | ||||||||

| modulus of elasticity Ec | 6-21-1 | 13.03 | 0.80 | 11.92 | 0.86 | 14.86 | 0.77 | 1.14 |

| destructive force FD | 6-34-1 | 0.91 | 0.57 | 1.02 | 0.39 | 1.34 | 0.46 | 1.47 |

| Ozone exposure time 15 min | ||||||||

| modulus of elasticity EC | 6-18-1 | 13.79 | 0.79 | 13.16 | 0.82 | 13.98 | 0.82 | 1.01 |

| destructive force FD | 6-24-1 | 0.98 | 0.48 | 0.79 | 0.74 | 1.02 | 0.45 | 1.04 |

| Ozone exposure time 30 min | ||||||||

| modulus of elasticity Ec | 6-17-1 | 13.69 | 0.84 | 15.08 | 0.85 | 13.38 | 0.82 | 0.97 |

| destructive force FD | 6-31-1 | 0.70 | 0.76 | 1.09 | 0.56 | 0.93 | 0.60 | 1.33 |

| Output Parameter | Model Structure | Train | Validation | Test | GA | |||

|---|---|---|---|---|---|---|---|---|

| RMSE | R | RMSE | R | RMSE | R | |||

| modulus of elasticity EC | 7-37-1 | 15.77 | 0.73 | 15.74 | 0.75 | 17.52 | 0.75 | 1.11 |

| destructive force FD | 7-39-1 | 0.97 | 0.49 | 1.18 | 0.39 | 1.06 | 0.38 | 1.09 |

| Output Parameter | Model Structure | Train | Validation | Test | GA | |||

|---|---|---|---|---|---|---|---|---|

| RMSE | R | RMSE | R | RMSE | R | |||

| Control | ||||||||

| modulus of elasticity Ec | 6-46-1 | 13.45 | 0.79 | 14.88 | 0.80 | 14.71 | 0.78 | 1.09 |

| destructive force FD | 6-16-1 | 0.86 | 0.62 | 0.95 | 0.55 | 1.44 | 0.37 | 1.67 |

| Ozone exposure time 15 min | ||||||||

| modulus of elasticity EC | 6-36-1 | 14.44 | 0.77 | 15.81 | 0.77 | 17.36 | 0.70 | 1.20 |

| destructive force FD | 6-26-1 | 1.02 | 0.40 | 0.93 | 0.66 | 1.01 | 0.49 | 0.99 |

| Ozone exposure time 30 min | ||||||||

| modulus of elasticity Ec | 6-35-1 | 14.99 | 0.81 | 17.13 | 0.76 | 19.05 | 0.64 | 1.27 |

| destructive force FD | 6-35-1 | 0.89 | 0.56 | 1.08 | 0.54 | 1.11 | 0.33 | 1.25 |

| Output Parameter | Train | Test | GA | ||

|---|---|---|---|---|---|

| RMSE | R | RMSE | R | ||

| modulus of elasticity EC | 14.60 | 0.78 | 15.27 | 0.78 | 1.04 |

| destructive force FD | 1.13 | 0.36 | 1.16 | 0.28 | 1.03 |

| Output Parameter | Train | Test | GA | ||

|---|---|---|---|---|---|

| RMSE | R | RMSE | R | ||

| Control | |||||

| modulus of elasticity EC | 15.59 | 0.70 | 19.25 | 0.76 | 1.23 |

| destructive force FD | 1.03 | 0.52 | 1.04 | 0.43 | 1.01 |

| Ozone exposure time 15 min | |||||

| modulus of elasticity EC | 18.21 | 0.66 | 16.23 | 0.65 | 0.89 |

| destructive force FD | 1.25 | 0.42 | 1.20 | 0.30 | 0.96 |

| Ozone exposure time 30 min | |||||

| modulus of elasticity EC | 13.73 | 0.85 | 15.14 | 0.76 | 1.10 |

| destructive force FD | 1.05 | 0.51 | 0.93 | 0.37 | 0.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuźniar, P.; Pentoś, K.; Gorzelany, J. Evaluation of the Use of Machine Learning to Predict Selected Mechanical Properties of Red Currant Fruit (Ribes rubrum L.) Ozonized during Storage. Agriculture 2023, 13, 2125. https://doi.org/10.3390/agriculture13112125

Kuźniar P, Pentoś K, Gorzelany J. Evaluation of the Use of Machine Learning to Predict Selected Mechanical Properties of Red Currant Fruit (Ribes rubrum L.) Ozonized during Storage. Agriculture. 2023; 13(11):2125. https://doi.org/10.3390/agriculture13112125

Chicago/Turabian StyleKuźniar, Piotr, Katarzyna Pentoś, and Józef Gorzelany. 2023. "Evaluation of the Use of Machine Learning to Predict Selected Mechanical Properties of Red Currant Fruit (Ribes rubrum L.) Ozonized during Storage" Agriculture 13, no. 11: 2125. https://doi.org/10.3390/agriculture13112125

APA StyleKuźniar, P., Pentoś, K., & Gorzelany, J. (2023). Evaluation of the Use of Machine Learning to Predict Selected Mechanical Properties of Red Currant Fruit (Ribes rubrum L.) Ozonized during Storage. Agriculture, 13(11), 2125. https://doi.org/10.3390/agriculture13112125