A Multi-Flexible-Fingered Roller Pineapple Harvesting Mechanism

Abstract

:1. Introduction

2. Materials and Methods

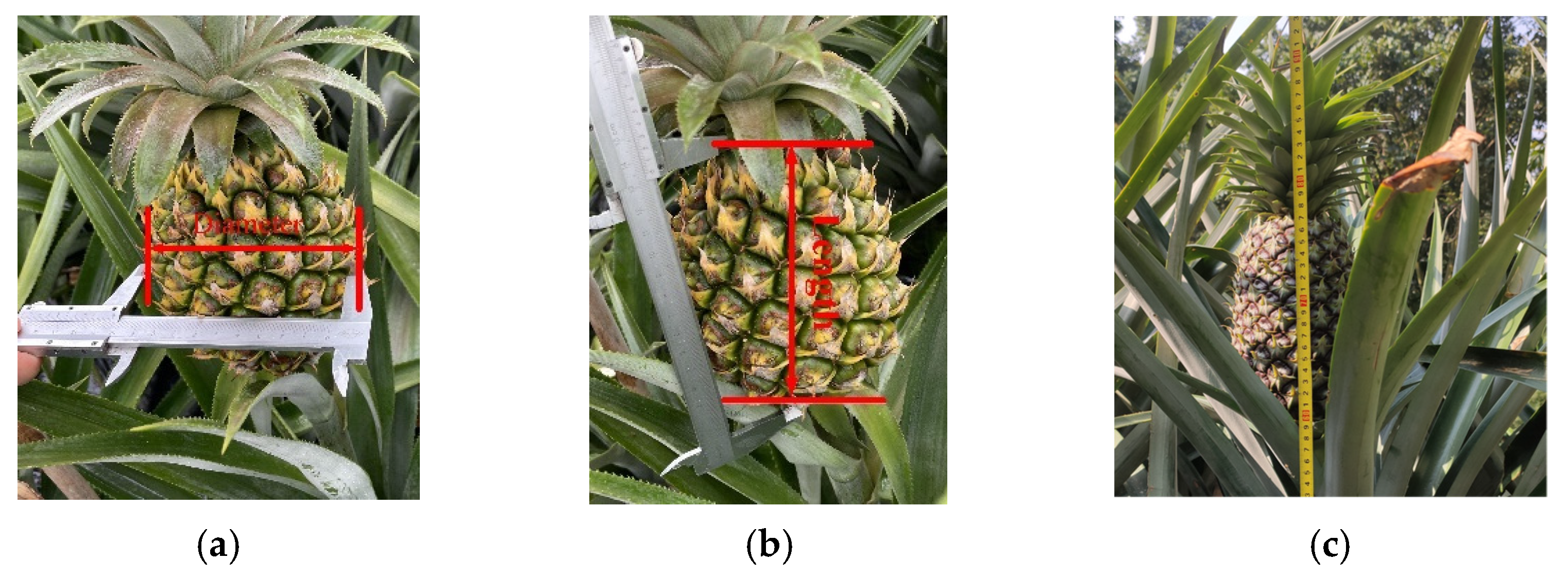

2.1. The Physical and Mechanical Properties of Pineapples and Their Stems

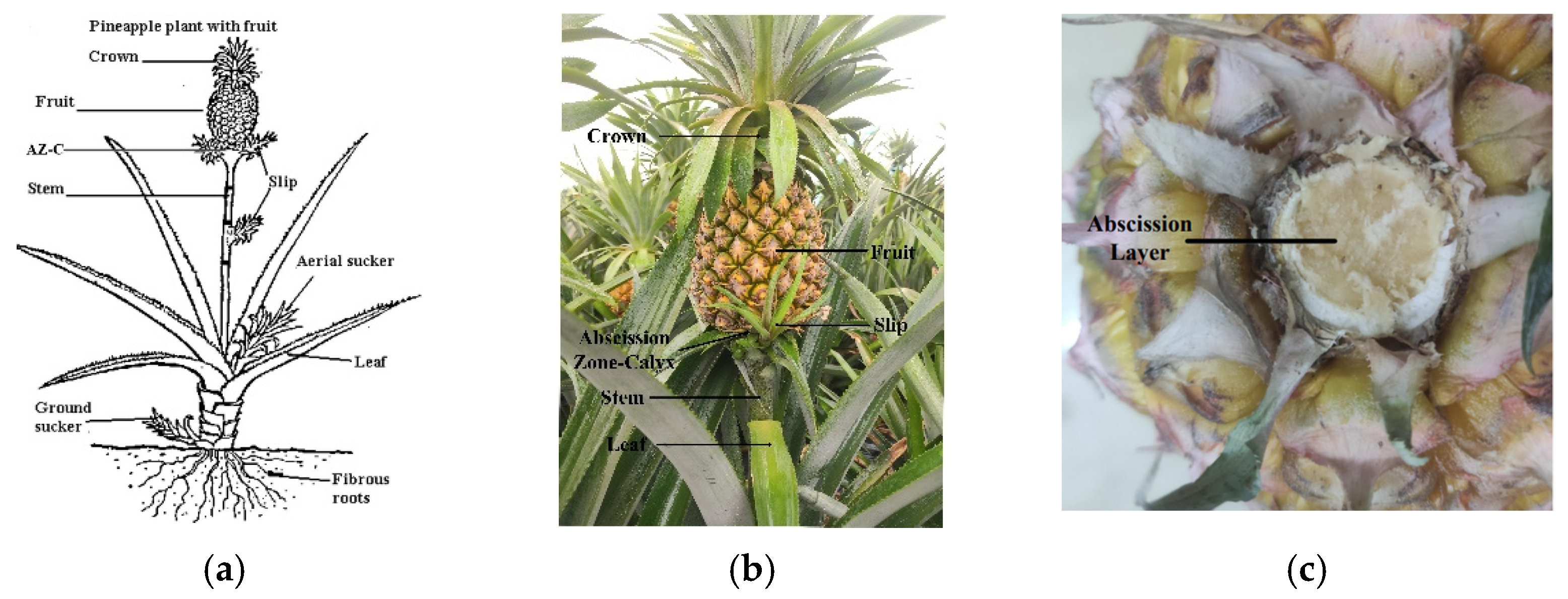

2.1.1. Physical Characteristics of Pineapple Fruit and Plant

2.1.2. Pineapple Separation Mode from Plant

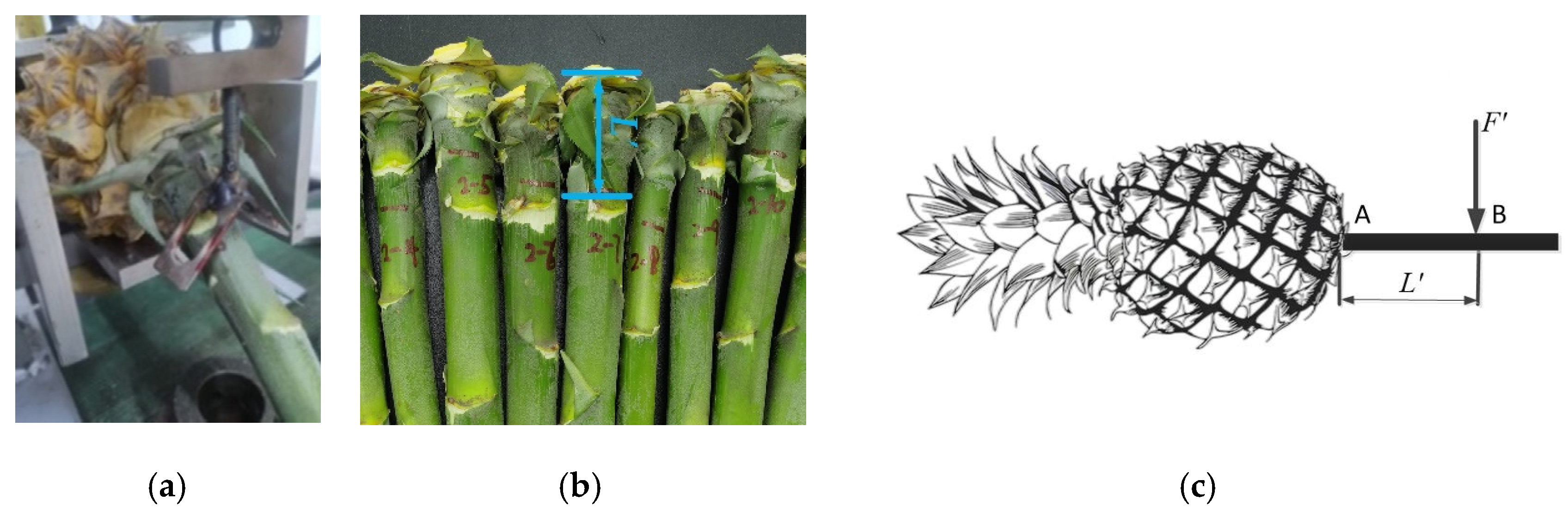

2.1.3. Mechanical Properties of the Abscission Layer at the Calyx of the Pineapple

2.1.4. Analysis of Experimental Results

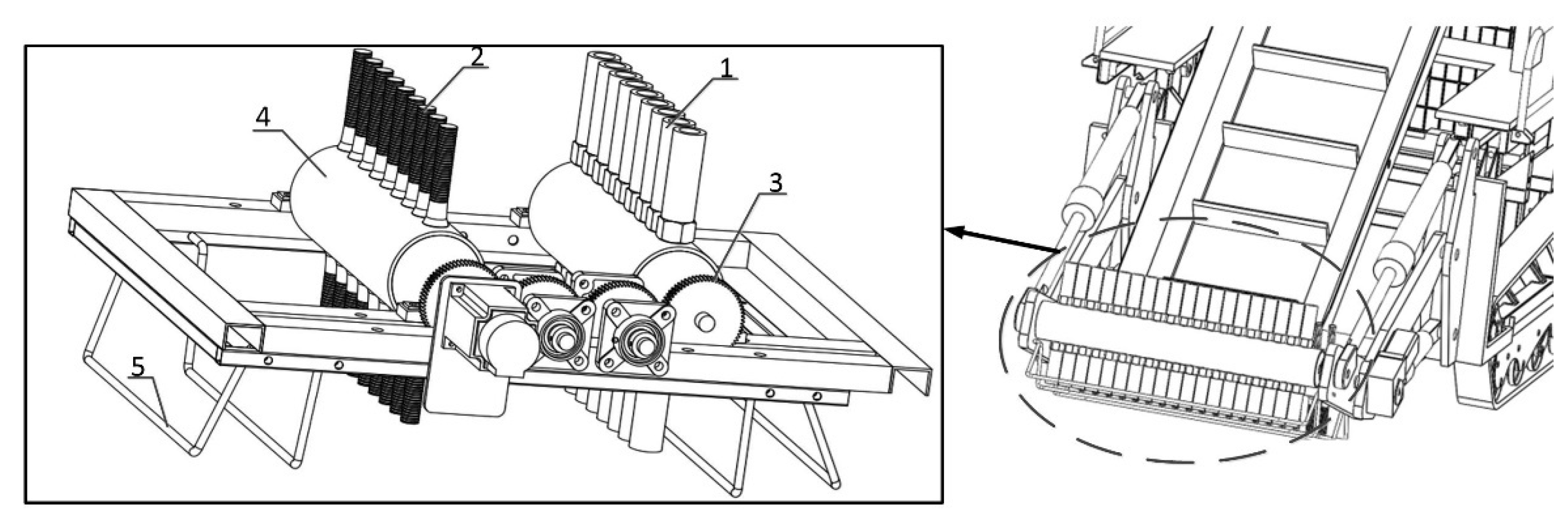

2.2. Pineapple Batch Harvesting Mechanism Design

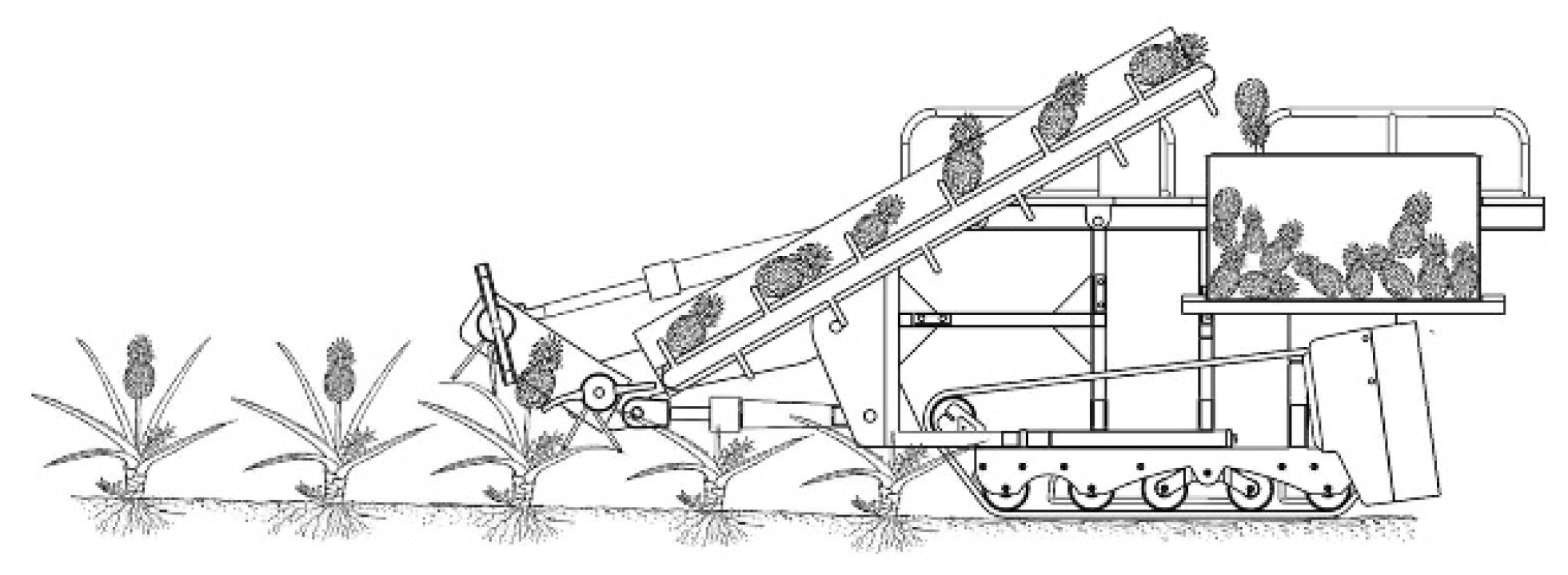

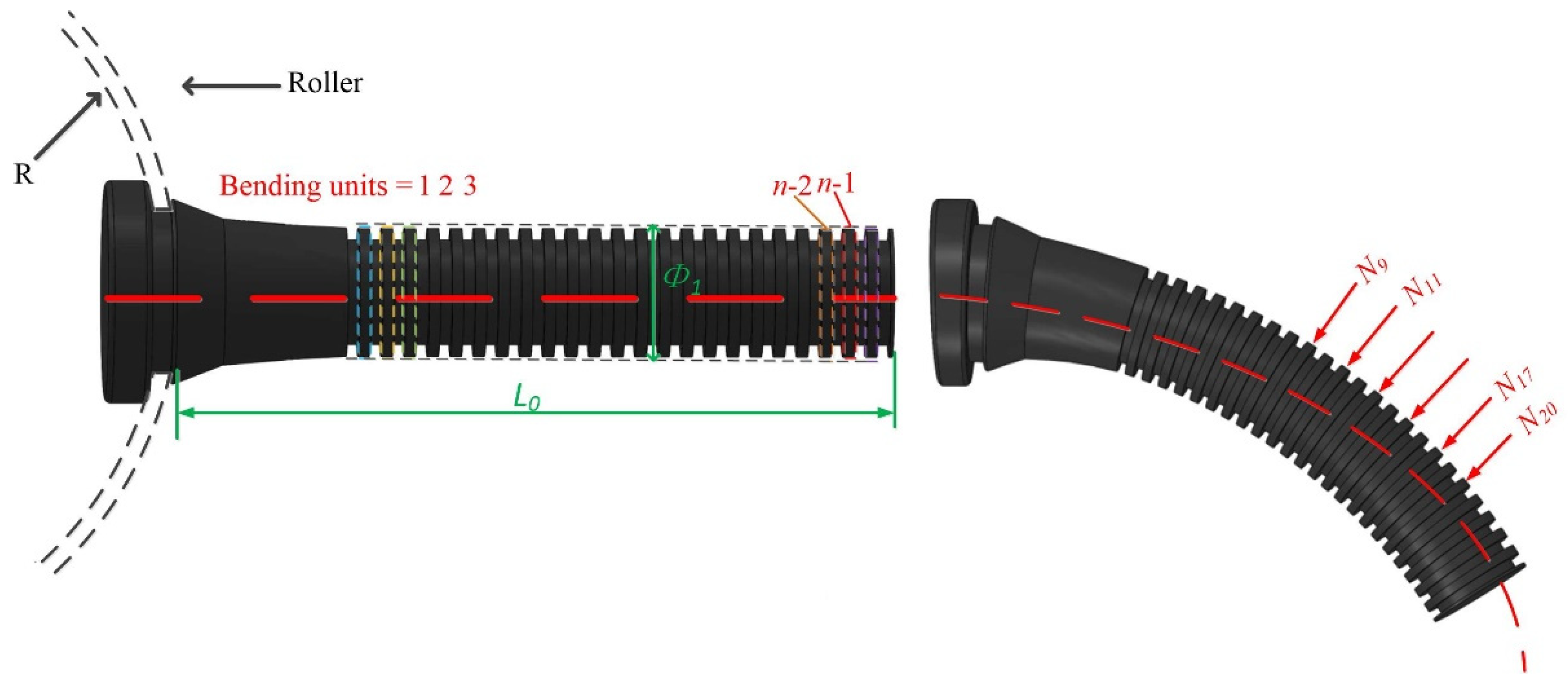

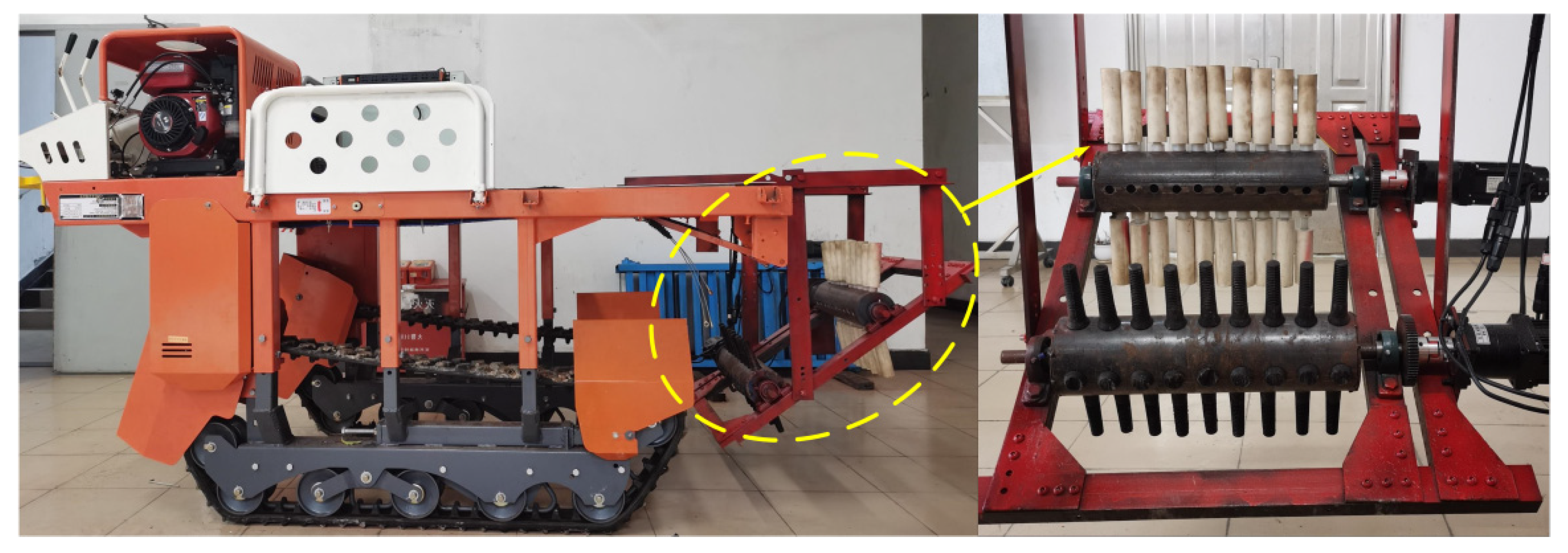

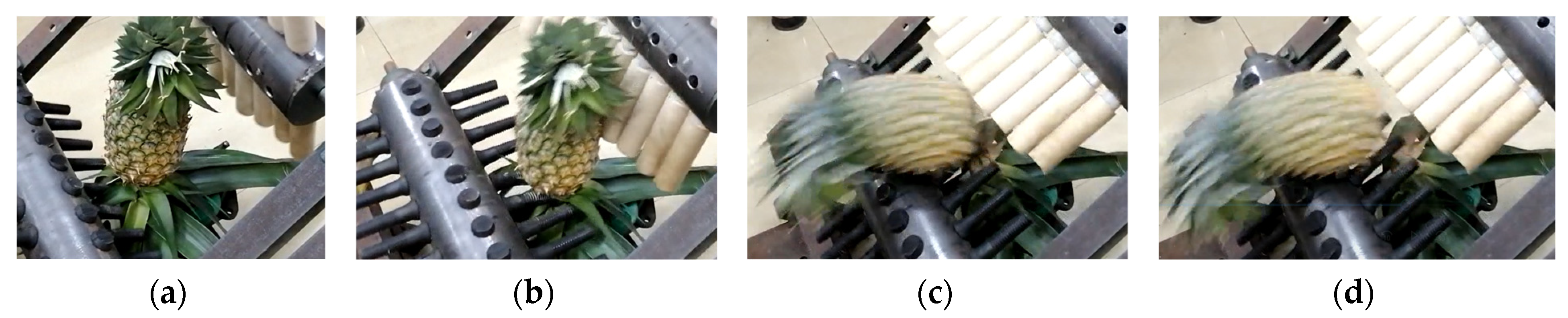

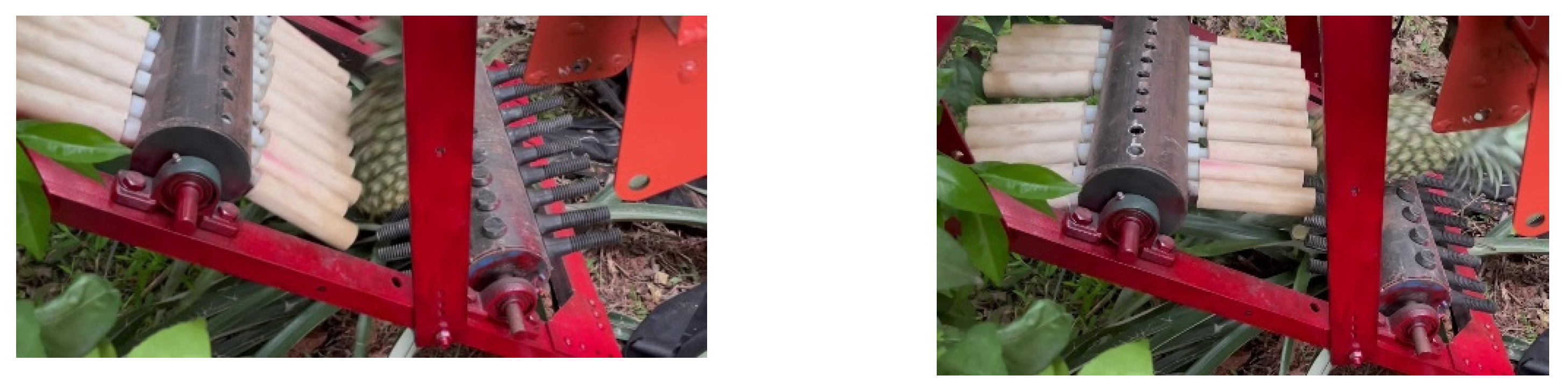

2.2.1. Multi-Flexible-Fingered Roller Pineapple Harvesting Mechanism

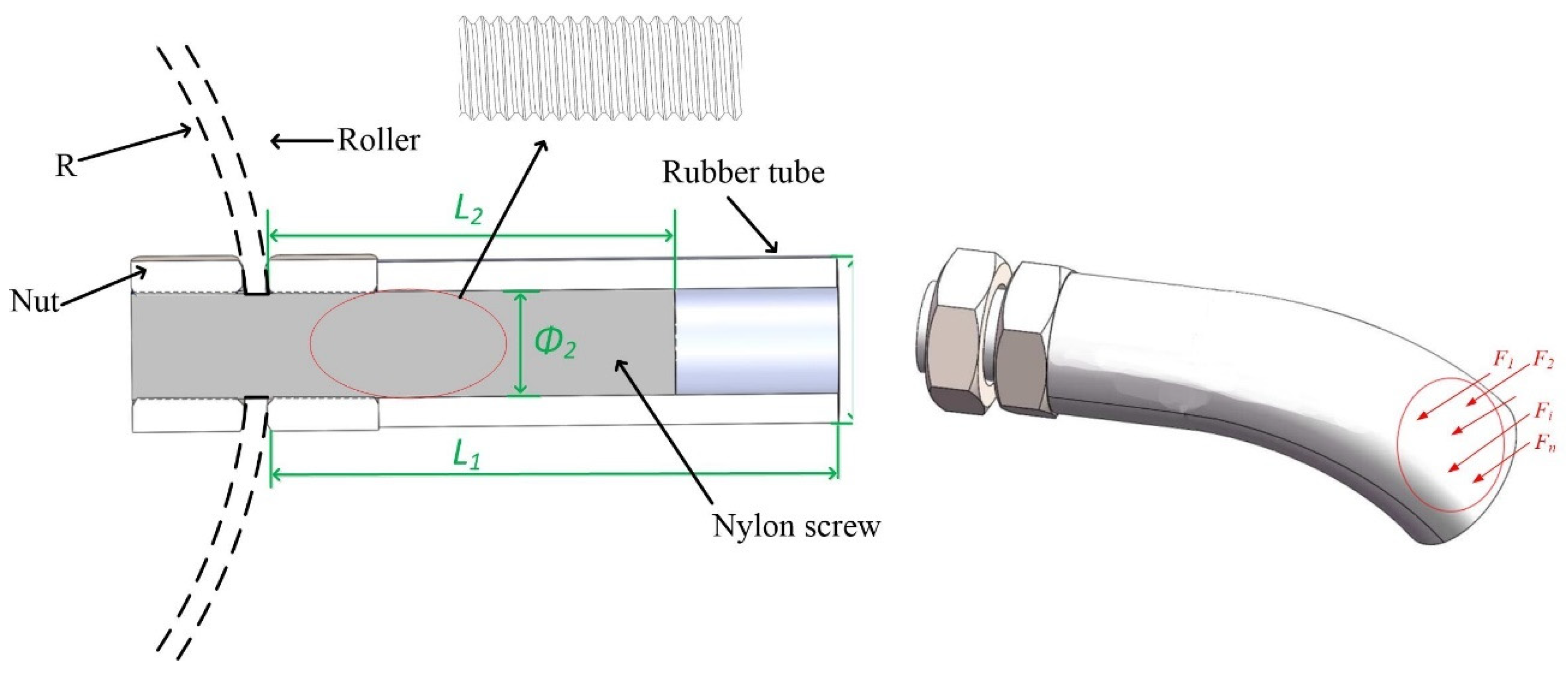

2.2.2. Flexible Fingers Design and Force Deformation Analysis

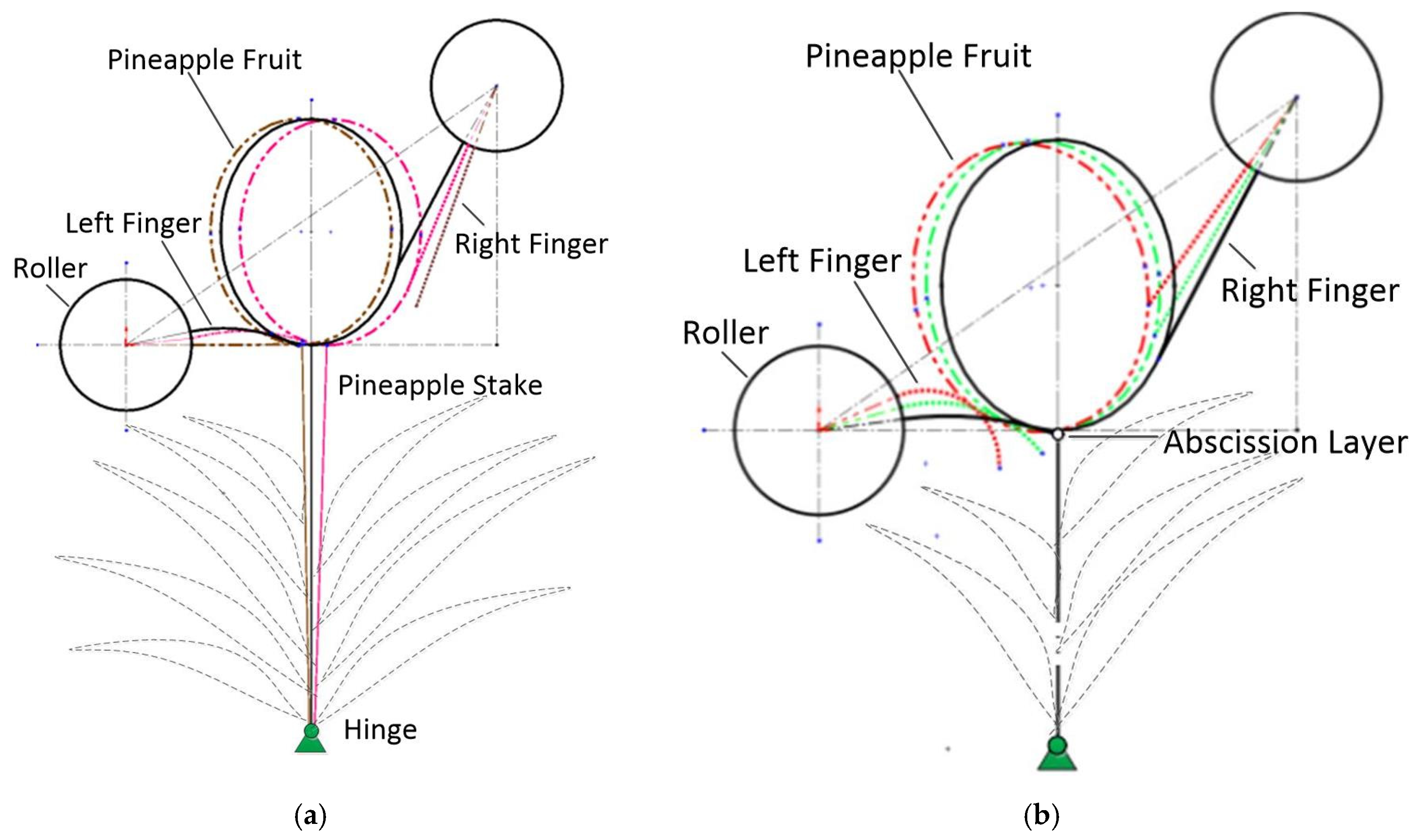

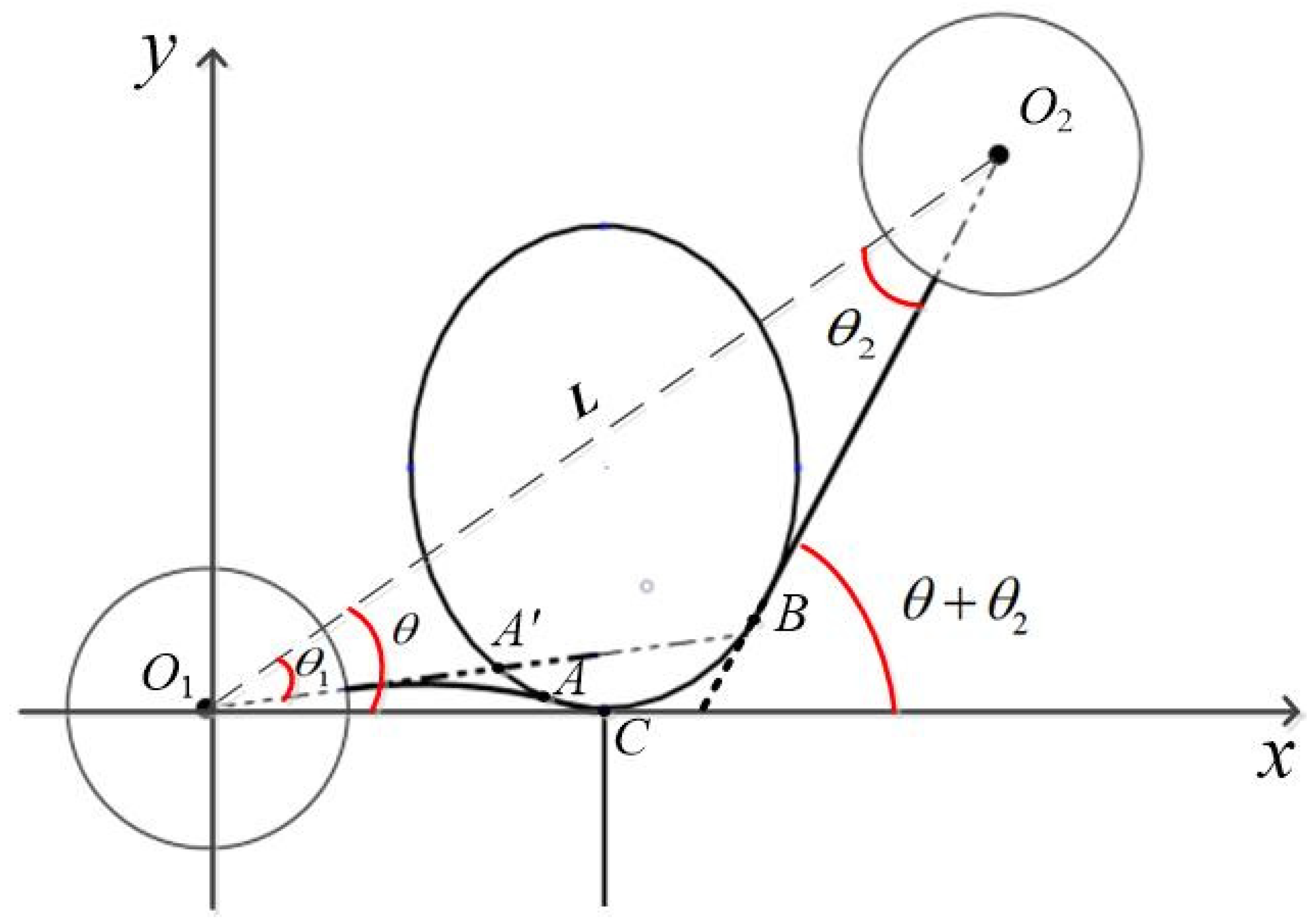

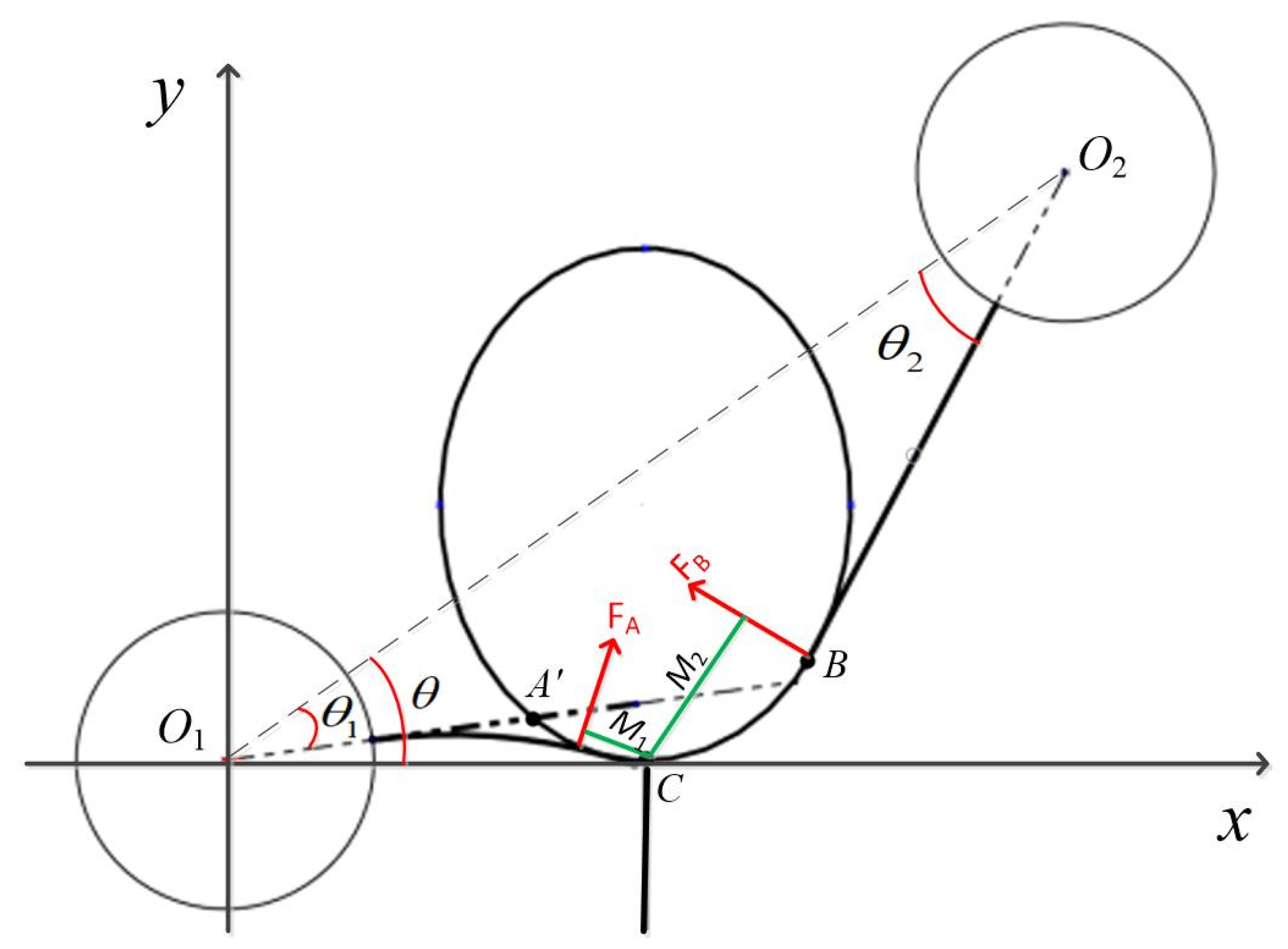

2.2.3. Mechanical Analysis of the Critical Fracture State of the Abscission Layer under the Action of a Flexible Finger

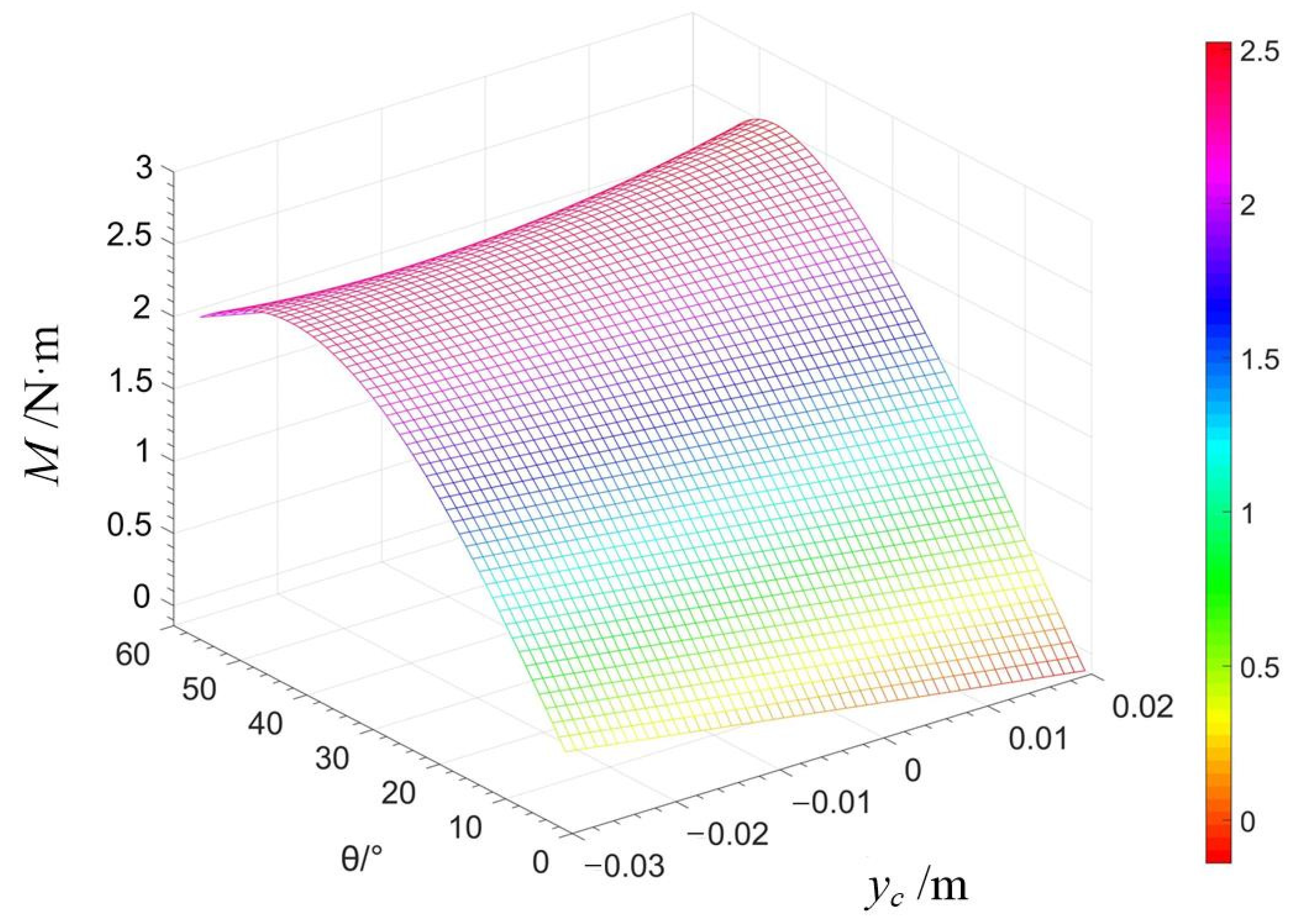

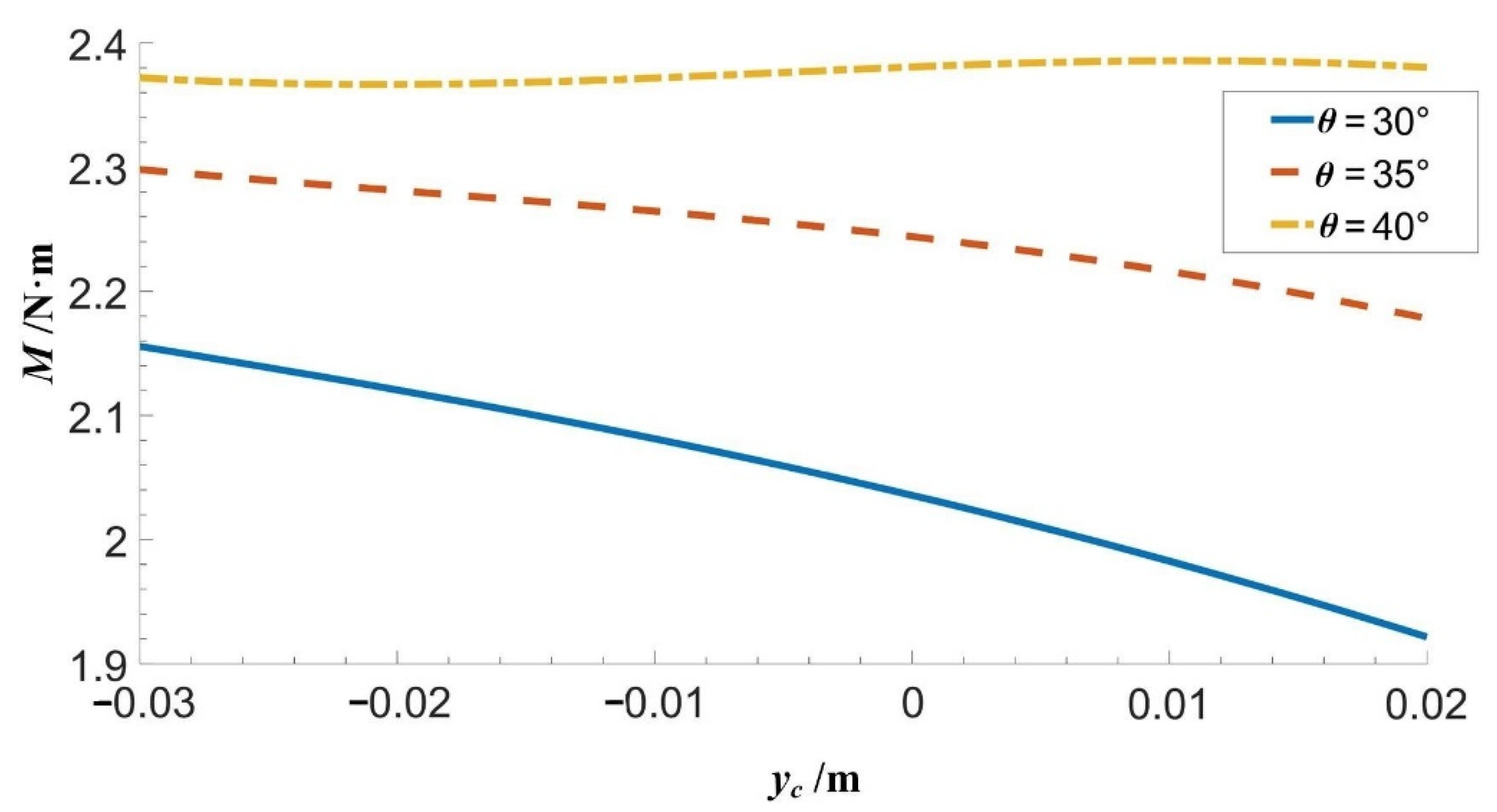

2.2.4. Key Parameters of the Harvesting Mechanism

2.3. Experiment Method

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- CIGR Handbook of Agricultural Engineering, Volume III Plant Production Engineering, Chapter 1 Machines for Crop Production, Parts 1.1.1–1.1.4 Human-Powered Tools and Machines. pp. 1–22. Available online: https://elibrary.asabe.org/abstract.asp?aid=36337 (accessed on 1 May 2022).

- Liu, T.H.; Ehsani, R.; Toudeshki, A.; Zou, X.J.; Wang, H.J. Experimental study of vibrational acceleration spread and comparison using three citrus canopy shaker shaking tines. Shock. Vib. 2017, 2017, 9827926. [Google Scholar] [CrossRef] [Green Version]

- Kearsley M, W. Principles and practices for harvesting and handling fruits and nuts. Food Chem. 1984, 14, 234–235. [Google Scholar]

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de-Santos, P. Soft grippers for automatic crop harvesting: A review. Sensors 2021, 21, 2689. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Igathinathane, C.; Li, J.; Cen, H.; Lu, Y.; Flores, P. Technology progress in mechanical harvest of fresh market apples. Comput. Electron. Agric. 2020, 175, 105606. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Li, P. History and Present Situations of Robotic Harvesting Technology: A Review. In Rapid Damage-Free Robotic Harvesting of Tomatoes; Springer: Singapore, 2021; pp. 1–106. [Google Scholar]

- Shi, Y.; Wang, Y.; Zhang, Z. Design, Test, and Improvement of a Low-Cost Fresh Market Apple Harvest-Assist Unit. In Mechanical Harvest of Fresh Market Apples; Springer: Singapore, 2022; pp. 23–37. [Google Scholar]

- Roshanianfard, A.; Noguchi, N. Pumpkin harvesting robotic end-effector. Comput. Electron. Agric. 2020, 174, 105503. [Google Scholar] [CrossRef]

- Sanders, K.F. Orange harvesting systems review. Biosyst. Eng. 2005, 90, 115–125. [Google Scholar] [CrossRef]

- Jianqiao, W.U.; Shengzhe, F.A.N.; Liang, G.O.N.G.; Jin, Y.U.A.N.; Qiang, Z.H.O.U.; Chengliang, L.I.U. Research status and development direction of design and control technology of fruit and vegetable picking robot system. Smart Agric. 2020, 2, 17. [Google Scholar]

- Jutras, P.J.; Coppock, G.E.; Patterson, J.M. Harvesting citrus fruit with an oscillating air blast. Trans. ASAE 1963, 6, 192–194. [Google Scholar]

- Sessiz, A.; Özcan, M.T. Olive removal with pneumatic branch shaker and abscission chemical. J. Food Eng. 2006, 76, 148–153. [Google Scholar] [CrossRef]

- Li, P.; Lee, S.H.; Hsu, H.Y. Review on fruit harvesting method for potential use of automatic fruit harvesting systems. Procedia Eng. 2011, 23, 351–366. [Google Scholar] [CrossRef] [Green Version]

- Ikram, M.M.M.; Mizuno, R.; Putri, S.P.; Fukusaki, E. Comparative metabolomics and sensory evaluation of pineapple (Ananas comosus) reveal the importance of ripening stage compared to cultivar. J. Biosci. Bioeng. 2021, 132, 592–598. [Google Scholar] [CrossRef] [PubMed]

- Bhat, K.; Chayalakshmi, C.L. Microcontroller-Based Semiautomated Pineapple Harvesting System. In International Conference on Mobile Computing and Sustainable Informatics; Springer: Cham, Switzerland, 2020; pp. 383–392. [Google Scholar]

- O’brien, M.; Kahl, W.H.; Moffett, L. Is mechanically harvesting pineapple practical? Agric. Eng. 1970, 51, 564–565. [Google Scholar]

- Li, B.; Ning, W.; Wang, M.; Li, L. In-field pineapple recognition based on monocular vision. Trans. Chin. Soc. Agric. Eng. 2010, 26, 345–349, (In Chinese with English Abstract). [Google Scholar]

- Dong-Jian, H.E.; Zhang, L.Z.; Xiang, L.I. Design of automatic pineapple harvesting machine based on binocular machine vision. J. Anhui Agric. Sci. 2019, 47, 207–210, (In Chinese with English Abstract). [Google Scholar]

- Jiang, T.; Guo, A.F.; Cheng, X.B.; Zhang, D.; Jin, L.I. Structural design and analysis of pineapple automatic picking-collecting machine. Chin. J. Eng. Des. 2019, 26, 577–586, (In Chinese with English Abstract). [Google Scholar]

- Kurbah, F.; Marwein, S.; Marngar, T.; Sarkar, B.K. Design and Development of the Pineapple Harvesting Robotic Gripper. In Communication and Control for Robotic Systems; Springer: Singapore, 2022; pp. 437–454. [Google Scholar]

- Joy, P.P.; Rashida, R.T. Harvesting and Post-Harvest Handling of Pineapple; Pineapple Research Station (Kerala Agricultural University): Vazhakulam, India, 2016; pp. 686–710. [Google Scholar]

- Goren, R. Anatomical, physiological, and hormonal aspects of abscission in citrus. Hortic. Rev. 2010, 15, 145–182. [Google Scholar]

- Jizhan, L.; Pingping, L.; Zhiguo, L.; Hanping, M. Experimental study on mechanical properties of tomatoes for robotic harvesting. Trans. Chin. Soc. Agric. Eng. 2008, 24, 64–70. [Google Scholar]

- Liu, J.; Peng, Y.; Faheem, M. Experimental and theoretical analysis of fruit plucking patterns for robotic tomato harvesting. Comput. Electron. Agric. 2020, 173, 105330. [Google Scholar] [CrossRef]

- Liu, T.H.; Nie, X.N.; Wu, J.M.; Zhang, D.; Liu, W.; Cheng, Y.; Zheng, Y.; Qiu, J.; Qi, L. Pineapple (Ananas comosus) fruit detection and localization in natural environment based on binocular stereo vision and improved YOLOv3 model. Precis. Agric. 2022, 23, 1–22. [Google Scholar]

- Liu, T.H.; Liu, W.; Zeng, T.J.; Qi, L.; Zhao, W.F.; Cheng, Y.F. Design and experiment of multi-flexible fingered roller pineapple harvesting mechanism. Trans. Chin. Soc. Agric. Eng. 2022, 24, 64–70, 38, 21–26. [Google Scholar]

- Burks, T.; Villegas, F.; Hannan, M.; Flood, S.; Sivaraman, B.; Subramanian, V.; Sikes, J. Engineering and horticultural aspects of robotic fruit harvesting: Opportunities and constraints. Hort Technol. 2005, 15, 79–87. [Google Scholar] [CrossRef]

- Thavamani, P.; Bhowmick, A.K. Wear of tank track pad rubber vulcanizates by various rocks. Rubber Chem. Technol. 1992, 65, 31–45. [Google Scholar] [CrossRef]

- Howell, L.L.; Midha, A.J. A method for the design of compliant mechanisms with small-length flexural pivots. J. Mech. Des. 1994, 116, 280–290. [Google Scholar] [CrossRef]

- Qi, H.J.; Joyce, K.; Boyce, M.C. Durometer hardness and the stress-strain behavior of elastomeric materials. Rubber Chem. Technol. 2003, 76, 419–435. [Google Scholar] [CrossRef]

- Du, X.; Yang, X.; Ji, J.; Jin, X.; Chen, L. Design and Test of a Pineapple Picking End-effector. Appl. Eng. Agric. 2019, 35, 1045–1055. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Li, P. Mathematical Modeling of Speedy Damage-Free Gripping of Fruit. In Rapid Damage-Free Robotic Harvesting of Tomatoes; Springer: Singapore, 2021; pp. 247–275. [Google Scholar]

- Guo, A.F.; Li, J.; Guo, L.Q.; Jiang, T.; Zhao, Y.P. Structural design and analysis of an automatic pineapple picking and collecting straddle machine. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; Volume 1777, p. 012029. [Google Scholar]

- Anh, N.P.T.; Hoang, S.; Van Tai, D.; Quoc, B.L.C. Developing robotic system for harvesting pineapples. In Proceedings of the 2020 International Conference on Advanced Mechatronic Systems (ICAMechS), Hanoi, Vietnam, 10–13 December 2020; pp. 39–44. [Google Scholar]

- Fu, M.; Li, C.X.; Zheng, Z.Q. Design and analysis of semi-automatic screw type pineapple picking-collecting machine. Chin. J. Eng. Des. 2020, 27, 487–497. [Google Scholar]

- Ma, X.Z.; Lian, H.S.; Gong, M.F.; Cheng, H.L.; Liao, G.X.; Deng, Z.X. Structural design and experiment of pineapple picking manipulator. J. Shandong Agric. Univ. (Nat. Sci. Ed.) 2020, 51, 727–732. [Google Scholar]

| Average Value/cm | Standard Error | |

|---|---|---|

| Height of plant | 70.56 | 9.19 |

| Diameter | 10.66 | 1.18 |

| Length | 13.23 | 0.59 |

| Maturity Levels | L’1/mm | L’2/mm | L’3/mm | L’4/mm | L’5/mm | L’6/mm | L’ 7/mm | L’8/mm | L’9/mm | L’10/mm |

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 33 | 30 | 31 | 33 | 32 | 34 | 38 | 46 | 63 | 59 |

| C2 | 36 | 43 | 51 | 47 | 37 | 35 | 45 | 42 | 37 | 60 |

| Maturity Levels | Average Bending Moment/(N·m) | Maximum Bending Moment/(N·m) |

|---|---|---|

| C1 | 3.67 | 4.96 |

| C2 | 2.41 | 3.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Liu, W.; Zeng, T.; Cheng, Y.; Zheng, Y.; Qiu, J. A Multi-Flexible-Fingered Roller Pineapple Harvesting Mechanism. Agriculture 2022, 12, 1175. https://doi.org/10.3390/agriculture12081175

Liu T, Liu W, Zeng T, Cheng Y, Zheng Y, Qiu J. A Multi-Flexible-Fingered Roller Pineapple Harvesting Mechanism. Agriculture. 2022; 12(8):1175. https://doi.org/10.3390/agriculture12081175

Chicago/Turabian StyleLiu, Tianhu, Wei Liu, Tingjun Zeng, Yifeng Cheng, Yan Zheng, and Jian Qiu. 2022. "A Multi-Flexible-Fingered Roller Pineapple Harvesting Mechanism" Agriculture 12, no. 8: 1175. https://doi.org/10.3390/agriculture12081175

APA StyleLiu, T., Liu, W., Zeng, T., Cheng, Y., Zheng, Y., & Qiu, J. (2022). A Multi-Flexible-Fingered Roller Pineapple Harvesting Mechanism. Agriculture, 12(8), 1175. https://doi.org/10.3390/agriculture12081175