Abstract

Rice is food consumed regularly and is vital for the food security of over half the world’s population. Rice production on a global scale is predicted to rise by 58 to 567 million tonnes (Mt) by 2030. Rice contains a significant number of calories and a wide variety of essential vitamins, minerals, and other nutritional values. Its nutrients are superior to those found in maize, wheat, and potatoes. It is also recognised as a great source of vitamin E and B5 as well as carbohydrates, thiamine, calcium, folate, and iron. Phytic acid and phenols are among the phenolic compounds found in rice, alongside sterols, flavonoids, terpenoids, anthocyanins, tocopherols, tocotrienols, and oryzanol. These compounds have been positively linked to antioxidant properties and have been shown to help prevent cardiovascular disease and diabetes. This review examines recent global rice production, selected varieties, consumption, ending stocks, and the composition of rice grains and their nutritional values. This review also includes a new method of paddy storage, drying, and grading of rice. Finally, the environmental impacts concerning rice cultivation are discussed, along with the obstacles that must be overcome and the current policy directions of rice-producing countries.

1. Introduction

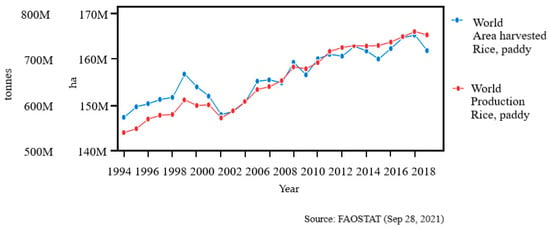

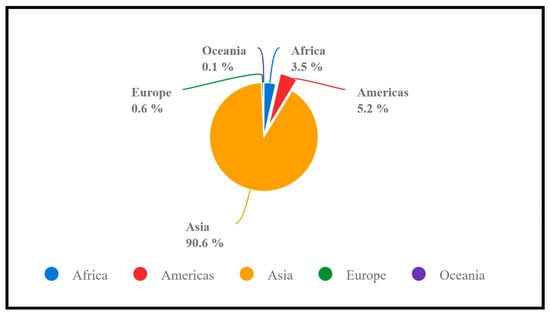

Rice is a crop that provides food for approximately half of the world’s population. Rice is a vital crop globally, accounting for over 21% of human caloric requirements and up to 76% of the calorific intake of Southeast Asian inhabitants [1]. Figure 1 shows that global paddy rice production increased from 1994 to 2019 [2]. According to the United States Department of Agriculture (USDA) [3], the primary rice production for 2020/2021 is 148.30 million tonnes (Mt) in China, followed by 120.00 Mt in India, 35.30 Mt in Bangladesh, 34.90 Mt in Indonesia, and 27.10 Mt in Vietnam. Furthermore, Thailand produced 18.6 Mt, the Philippines produced 12 Mt, Japan produced 7.62 Mt, Pakistan produced 7.60 Mt, Brazil produced 7.48 Mt, the United States produced 7.23 Mt, Nigeria produced 5.04 Mt, the European Union produced 1.96 Mt, Malaysia produced 1.83 Mt, and Turkey produced 0.59 Mt. Figure 2 illustrates rice and paddy production (average 1994–2019). Asia produces 90.6% of the global rice production, making it the world’s largest producer [2,4].

Figure 1.

Production/yield quantities of rice paddy in the world (1994–2019) [2].

Figure 2.

Production share of rice paddy by region (Average 1994–2019) [2].

According to OECD/FAO [5], rice is primarily a staple food in Asia, the Caribbean and Latin America, and is becoming progressively popular in Africa. In the decade ahead, global rice consumption is expected to expand by 0.9% per year, down from 1.1% per year in the previous decade. Asia is expected to account for up to 65% of the projected rise in world rice consumption; however, the growth rate will decrease by −0.15% per annum (Table 1). Rice consumption is predicted to increase significantly in Africa, while remaining stable or declining in all other regions. Future rice demand will be driven primarily by Africa, owing to a combination of population growth, dietary changes, and yield improvement on existing land (intensification) [6].

Table 1.

Rice per capita consumption (kg/person/year) [5].

The current review discusses recent global rice production, consumption, and ending stock, the composition of the rice grain, the nutritional values of rice, rice varieties, the milling process of rice, the environmental impacts of rice cultivation, and the challenges to overcoming obstacles and current policy directions.

2. Global Rice Production, Consumption, and Ending Stock

Table 2 shows the FAOSTAT data regarding rice production worldwide in 2019 [2]. In 2020/2021, the world’s rice consumption was 697.09 Mt. However, only 513.7 Mt (milled rice) was the world’s rice production for that year [7]. Although food consumption is expected to increase, food consumption growth is expected to account for the largest share of this annual increase, maintaining world per capita rice consumption at approximately 54 kg/person [8].

Table 2.

Production quantities of rice by country worldwide in 2019 [2].

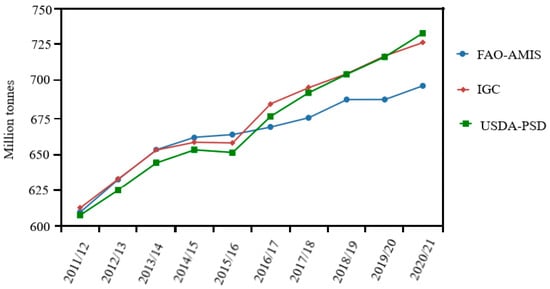

Rice consumption per capita is steadily declining in several Asian countries, due to changing dietary habits brought about by the influence of the Western diet, such as increased consumption of meat, dairy, and fast foods [9]. The rice consumption in China is 149,000 thousand metric tonnes (TMT), followed by India, Bangladesh, Indonesia, Vietnam, the Philippines, Thailand, Burma, Japan, and Brazil, which consume 106,500, 35,900, 35,800, 21,250, 14,400, 12,500, 10,400, 8250, and 7350 TMT of rice, respectively [10]. Even though rice production is declining, the current population projections show that Asia will need an extra 8 Mt of rice per year [11]. Due to the increasing number of Asian communities living in Western countries, the demand for rice in Western world has increased, as has the awareness and appreciation of the people for rice-based dishes [12]. Therefore, future rice production will need to significantly improve resource efficiency to meet notably increasing demand and discerning consumer demands. Figure 3 depicts the world’s total rice utilisation from 2011 to 2021.

Figure 3.

World rice total utilisation from 2011–2021 [7].

For the foreseeable future, rice is expected to remain a key component of Asian diets. Rice will also continue to play a significant role in African diets in the future. Africa will demand more rice due to growing consumer preferences and population increase. African women find rice to cook easier than coarse cereals, roots and tubers, which are major source of calorie supply in Africa [13,14].

As a result, it has always been of concern to ensure that an adequate rice supply is available to meet this growing demand. By 2030, the total cereal share is expected to reach 18%, primarily due to increased rice trade. However, rice will continue to be a scarce commodity. Asia has a more significant rice surplus. India, Vietnam, and Thailand will lead the global rice trade. Myanmar and Cambodia are forecast to expand in rice exports, while China’s exports will last beyond 2010–2016 [4].

3. Variety of Rice

In total, 110,000 different cultivated rice varieties are grown globally, but only the species of Oryza sativa and Oryza glaberrima are widely cultivated. Oryza sativa is also Asian rice, and Oryza glaberrima is African rice [15]. Oryza sativa is cultivated worldwide. However, Oryza glaberrima is cultivated exclusively in Africa. Oryza sativa is classified into subspecies, indica, which produces rice with long-grain, and japonica, rice with a round grain. Japonica rice is grown and consumed primarily in China, Korea, the European Union, Australia, Taiwan, Russia, Japan, Turkey, and the United States of America. Rice varieties of the genus indica are widely grown all across Asia [16]. Additionally, these varieties include fragrant types sold at a premium price. The leading fragrant varieties are Thai Hom Mali, Indian (Haryana and Punjab) and Pakistani Basmati (Punjab). Basmati, Jyothi, Joha, Pusa, Navara, Ponni, Jaya, Sona Masuri, Boli, Palakkad Matta, Kalajiri (aromatic) and others are widely cultivated in India. The coloured varieties include the following: Himalayan red rice; Jyothy, Matta rice, Kairali, Asha, Rakthashali, Bhadra from Kerala; Kaivara Samba, Red Kavuni, Mappillai Samba, Poongar, and Kuruvi Kar from Tamil Nadu [17]. In terms of length and shape (length and width), rice differs from one region to another. The variation in the length and shape of rice across regions is depicted. Certain regions prefer a variety of grain lengths and shapes [18].

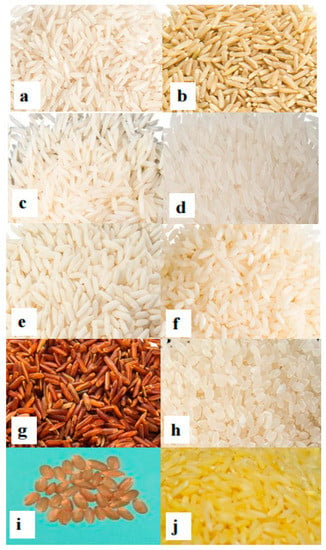

In rice markets, granulometric measurements of grain length and whiteness are highly regarded for grading and quality criteria. The palatability characteristics (e.g., appearance, cohesiveness, tenderness, and flavour) are considered when determining a food’s quality [19,20]. Figure 4 shows the regular white rice, brown rice, fragrant rice, basmati, glutinous or waxy rice, japonica rice, weedy rice and the genetically modified rice such as golden rice.

Figure 4.

The various varieties of rice: (a) white rice, (b) brown rice, (c) basmati, (d) fragrant rice (e) glutinous rice, (f) ponni rice (g), red rice, (h), japonica rice, (i) weedy or red rice, and (j) golden rice [11,21].

3.1. White Rice

White rice is grown with a moderate white kernel and a translucent endosperm. White rice has a long-grain length of greater than 7.0 mm, an average whole grain length of greater than 7.0 mm, and a length to width ratio greater than 3.0. After cooking, the grains are tender but firm, and there is no discernible aroma. It is adaptable to a wide variety of recipes [21].

3.2. Brown Rice

Brown rice is also referred to as hulled rice or unmilled rice. Brown rice is composed of bran layers and embryos, which contain biofunctional components and a variety of nutritional aspects such as dietary fibre, oryzanol, vitamins, and minerals. Brown rice is consumed at a lower rate than white rice, due to its inferior texture when cooked. The rice retains its mild nutty flavour and chewiness. The cooked rice is fluffy and light with a distinct texture. Brown rice is excellent in making fried rice and pairs well with various healthy side dishes, such as vegetables or beans. The rice takes longer to prepare because the bran layer prevents water absorption [22].

3.3. Fragrant Rice

Fragrant rice is famously known for its aromatic characteristics. The crucial ingredient in fragrant rice that makes it smell good is 2-acetyl-1-pyrroline (2AP). The nithine or proline, glutamate, 1-pyrroline-5-carboxylic acid (P5C), 1-pyrroline,-aminobutyraldehyde, and acetyl groups are all essential precursors in the synthesis of 2AP. On the other hand, enzymes such as 1-pyrroline-5-carboxylate synthase (P5CS, EC 2.7.2.11/1.2.1.41), diamine oxidase (DAO, EC 1.4.3.22), ornithine aminotransferase (OAT, EC 2.6.1.13), and proline dehydrogenase (PDH, EC 1.5.99.8) have been reported to be critical enzymes in 2AP bio [23].

3.4. Basmati Rice

Basmati rice is a popular dish with an intoxicating aroma that makes it a popular choice for cooking [24]. Rice of the Basmati and Jasmine varieties is traded at a premium in domestic and international markets. It is a long, thin grain of rice with a long, slim shape originated in India and Pakistan and is now grown worldwide [25]. Although it is white, the blade shape has a slight curve. When baked, it nearly doubles in size and emits a faint aroma, but it retains its separation and light texture while keeping separate, and it has a shiny texture [26].

3.5. Ponni Rice

Compared to other rice varieties, Ponni rice has a plump, shorter and nearly circular kernel [27]. While still firm, cooked grains have a slight springiness to the bite. This rice, which has its origins in India, is an excellent choice for everyday cooking [28]. When it comes to the Indian population, it is well known for being served alongside delicious meals and spicy curries [27].

3.6. Glutinous or Waxy Rice

Many countries, including the Lao People’s Democratic Republic, Japan, China, Thailand, Vietnam, Myanmar, Bangladesh, Cambodia, Malaysia and India, grow glutinous rice varieties. The Laotians eat glutinous rice as their main meal. It has always been usually served as a breakfast cereal, dessert, or steamed glutinous rice folded in banana leaves that is served for breakfast. Owing to the unique starch composition of glutinous rice, the rice exhibits unique processing properties. The productivity of rice milling and grain quality can be enhanced through various pretreatments such as tempering during the post-harvest tempering process and parboiling, which reduces internal slits and increases head rice output [29,30].

3.7. Red Rice

Red rice is versatile and frequently found in Asian cuisine. In the case of red rice, it can either be hulled wholly or partially hulled. Its nutritional profile is similar to that of brown rice. In comparison with white rice, red rice has a high antioxidant content. This rice is nuttier, chewier, and sweeter than white rice, making it an excellent substitute. Since red rice takes longer to cook than other types of rice, soaking it for 30 min prior helps soften the rice texture and speeds up the cooking time [31].

3.8. Japonica Rice

Japonica is a staple food in Japan. Its shorter, plumper presence recognises it compared to other plant family members. When grains are uncooked, their appearance is slightly glassy and translucent. It is tender and moist, and it has quite a sticky texture. Japonica has lower amylose content than indica [32]. While the rice is excellent at absorbing flavours, it possesses the characteristics of Japanese Koshihikari and thus is less expensive. This ingredient significantly enhances the flavour of sushi and other Japanese dishes.

3.9. Weedy or Red Rice

Weedy rice is an undesirable plant in the genus Oryza that exhibits some undesirable cultivation characteristics and poses a significant menace to the global rice industry’s sustainability. Unluckily, it is now one of the most prevalent weeds worldwide, infesting rice fields. Weedy rice, also known as red rice, is nearly identical to cultivated rice (Oryza sativa) appearance [33]. The characteristics are nearly similar to those of cultivated rice. However, it can be differentiated from cultivated rice by its long and powerless culm, diverse grain shapes, red pericarp, higher level of seed torpidity, and shattering seed [34].

3.10. Golden Rice

Golden rice is slated to become the first genetically modified biofortified crop commercially available with enhanced quality and micronutrients, particularly vitamin A in rice [35]. The colour of golden rice is yellow, as is the beta-carotene contained in the rice. It is believed to be the most cost-effective way to tackle vitamin A deficiency in millions of people, particularly in developing countries where poorer people eat rice as their primary food [36,37]. Generic engineers have developed a solution by expressing the provitamin A precursor in its grain [38,39]. It exhibits comparable resistance to pests and yields performance to cultivated rice. A study by Mallikarjuna Swamy et al. [40] described the characterisation of GR2E Golden rice introgression lines in grain golden rice. It was reported that the best-performing lines found in each genetic background had unique carotenoids in the milled grains. These lines meet approximately 30–50% of the average vitamin A need.

4. Composition of Rice Grain

4.1. Rice Anatomy

Rough rice in its mature state (complete grains with intact husks) is composed of a brown kernel surrounded by a husk. The husk, also known as the hull, is the most visible element of a rough rice grain. The hull is the outer layer that surrounds the caryopsis and, while it is inedible, it accounts for approximately 20% to 25% of the total grain weight [29]. The hull acts as a barrier against invasion and environmental changes. Sterile lemmas, palea, rachilla and lemma comprise the hull. The lemma covers two-thirds of the seed, with the edges of the palea fitting snugly inside to form a tight seal around the seed. The embryo and starchy endosperm are contained within the caryopsis, enclosed by the pericarp and seed coat [41].

4.2. Starch

Approximately 90% of the dry weight of milled rice is starch [42]. Starch is a polymer composed of D-glucose linked α-(1–4) and typically consists of two fractions: an essentially linear fraction called amylose and a branched fraction called amylopectin. The ratio of amylose to amylopectin is vital for the structure, appearance, and eating quality of rice grains. The normal amylose content percentage in rice endosperm is classified as waxy (0% to 2%), very low (2% to 10%), low (10% to 20%), intermediate (20% to 25%), or high (25% to 33%) [43]. Table 3 summarises the various physicochemical properties of starch fractions. Branches are connected via α-(1–6) linkages. Rice amylose has two to four chains, a number-average degree of polymerisation (DPn) of 900 to glucose units, and a β-amylolysis limit of 73% to 87%. It is a mixture of branched and linear molecules with DPn values ranging from 1100 to 1700 and 700 to 900 [44].

Table 3.

Properties of starch fractions in rice endosperm [29].

Amylose comprises branched fractions that account for 25% to 50% of the total number and 30% to 60% of the total weight. Rice amyloses have a 20% to 21% iodine affinity by weight. Rice amylopectin has a 56% to 59% β-amylolysis limit, chain lengths of 19 to 22 glucose units, a DPn of 5000 to 15,000 glucose units, and a chain count of 220 to 700 chains per molecule. Rice amylopectin has an iodine affinity of 0.4% to 0.90% in low- and intermediate-amylose rice, but only 2% to 3% in high-amylose rice. Isoamylase-debranched amylopectin has longer chain fractions (DPn > 100) (9–14%) in high-amylose samples and a higher iodine affinity than low- and intermediate-amylose samples (2–5%) and waxy rice amylopectin (0%) [29,45]. Milled rice is classified as waxy (1–2%), very low amylose (2–12%), low amylose (12–20%), intermediate (20–25%), or high (25–33%) based on colourimetric starch–iodine colour absorption standards at 590–620 nm [46,47].

The waxy endosperm is transparent and contains air spaces between the starch granules, resulting in a lower density than the non-waxy endosperm [48]. Although the starch granule structure remains unknown, crystallinity and staling are ascribed to the amylopectin fraction [49]. It is widely accepted that amylopectin molecules are composed of short amylose chains containing 6100 glucosyl residues, and elucidating the fine structure assembled by these chains is extremely difficult due to their high molecular weight [50].

4.3. Protein

The physicochemical properties of rice are influenced by its protein content [51]. As depicted in Table 4, rice typically has low protein content compared to most cereals. Additionally, it contains little fibre and lipids. However, rice has the highest net protein usage and digestible energy compared to all cereals such as wheat, corn, barley, millet, sorghum, rye, and oat [41].

Table 4.

Protein and fibre content of cereal [29].

Brown rice has a protein content ranging from 6.6% to 7.3%, milled rice has a protein content ranging from 6.2% to 6.9%, and milled basmati rice has a protein content ranging from 8.2 to 8.4%. Certain wild rice varieties found in China and North America contain a significant protein. These varieties may contain between 12.0 and 15.0% protein. The proportion of protein and fat in food reduces proportionally as the degree of polish increases. This component is primarily found in the outer layers of the kernel [29].

Endosperm (milled rice) contains several protein fractions, including 5.0–8.0% prolamin, 15% albumin plus globulin, and the remaining portion of glutelin [52]. Rice bran proteins contain more albumin than endosperm proteins and are found in the aleurone layer and germ as distinct protein bodies called globoids [53]. The shapes differ from endosperm protein bodies [54]. A recent study discovered that purple rice bran included anthocyanins and proanthocyanins. Anthocyanins are antioxidants that are used to modulate immune responses. They may help prevent Type 2 diabetes, cardiovascular disease, and even some cancers [15,55].

The endosperm protein is found primarily in sizeable spherical protein bodies in the endosperm (PB). Proteins are typically estimated to be between 0.5 and 4 microns in size. The glutelin-rich crystalline protein bodies (PB-II) and the prolamin-rich large spherical protein bodies (PB-I) are found in abundance in the crystalline protein bodies [56]. Using immunofluorescence microscopy, the PB-I in rice endosperm comprises a core region containing 10 kDa prolamin, an inner layer containing 13 kDa prolamin, two middle layers containing 13 and 16 kDa prolamin, and an outermost layer containing 13 kDa prolamin. It was discovered that the 13 kDa prolamins were a large group of prolamins found in rice [57].

4.4. Lipids

Indica and japonica rice varieties contain a diverse range of lipid groups in nearly identical proportions [58]. However, they are not distributed uniformly across the rice. Additionally, endosperm lipids contained a significantly higher amount of polar lipids. Rice contains the majority of its lipid or fat content in the bran fraction (20% on a dry basis), specifically as lipid bodies or spherosomes (0.1–1 m) in the aleurone layer and bran; however, about 1.5–1.7% is present in milled rice, primarily as non-starch lipids extracted with ether, chloroform-methanol, and cold water-saturated butanol [59,60].

Additionally, the protein bodies, particularly the core, contain a high concentration of lipids. These lipids are primarily composed of linoleic, oleic, and palmitic acids [61]. Rice oil contains between 29 and 42% linoleic acid and between 0.8 and 1% linolenic acid as essential fatty acids [62]. While grains’ essential fatty acid content is likely to increase with temperature, the total oil content will likely decrease. Palmitic and linoleic acids are the primary fatty acids in starch lipids, with a trace of oleic acid [63]. The majority of starch lipids are monoacyl lipids [64]. The starch–lipid content of waxy starch granules is the lowest (0.2%) [65]. It is highest for rice with a moderate amount of amylose (1.0%) and might be slightly less for rice with a high amount of amylose. Waxy milled rice contains a higher concentration of non-starch lipids than non-waxy milled rice. However, starch lipids contribute only small energy to the rice grain.

4.5. Non-Starch Polysaccharides

Non-starch polysaccharides contain both insoluble and soluble and dietary fibre [66]. They may form a complex with starch and exert hypocholesterolemic properties. The endosperm contains less dietary fibre than the rest of the brown rice [67]. The values obtained for neutral detergent fibre range from 0.7 to 2.3%. Additionally, the endosperm or milled rice cell wall contains a small amount of lignin but a high amount of pectic substances or pectin. Endosperm pectin contains more uronic acid than other grain tissues but has a lower arabinose-to-xylose ratio. Additionally, endosperm’s hemicellulose has a lower arabinose-to-xylose ratio than the other three grain tissues [68].

Non-starch polysaccharides are typically long polymeric carbohydrate chains containing thousands of monomeric units [69,70]. They are primarily composed of celluloses, hemicelluloses, and pectins, while fructans, glucomannans, and galactomannans are less abundant in the plant [71]. Mucilages, alginates, exudates, gums, and b-glucans are all classified as non-starch polysaccharide constituents [72]. Non-starch polysaccharides are used as a marker in dietary guidelines to provide useful information about food labelling to consumers [73]. In terms of health benefits, non-starch polysaccharides are effective at softening stool and are believed to help prevent diabetes, atherosclerosis, and high cholesterol levels. Non-starch polysaccharides are used as functional ingredients in the food industry, particularly in bakery products, to alter the rheological properties and dough characteristics [74].

4.6. Phenolic Compound

Rice grains contain various chemical compounds, including anthocyanins, oryzanol, flavonoids, terpenoids, sterols, phenols, phytic acid, tocopherols, and tocotrienols. Rice grain total phenolic content is positively correlated to antioxidant properties [75]. Additionally, the total phenolic content is used to regulate blood lipid levels, which aids in preventing the spread of cardiovascular disease and diabetes [76].

Numerous studies have demonstrated the antioxidant properties of phenolic compounds [77]. Antioxidants help prevent and mitigate damage caused by reactive oxygen species (ROS) in foods by delaying the oxidation process, thus further extending the quality and shelf-life of functional foods [78]. Additionally, phenolic compounds, ascorbic acid, and beta-carotene all play critical roles in inflammation reduction, human ageing, and the prevention of certain cancers [79]. Unfortunately, these compounds, including anthocyanins, phenolic acids, and proanthocyanidins, are the most abundant secondary metabolites in rice grains. They are found in pigmented grains and are widely regarded as the most potent antioxidants found in nature [80]. The most common phenolic components are described further below.

4.6.1. Phenolic Acids

Phenolic acids are found in both insoluble and soluble forms in rice grains [81]. The insoluble form, referred to as bound phenolics, adheres to the cell walls [82]. However, the soluble form, which includes the conjugated and free forms, can be extracted using solvents such as ethanol, acetone or aqueous methanol, while the conjugated form can be hydrolysed from soluble phenolics using alkali. The most abundant phenolic fraction is insoluble bound phenolic acids, followed by soluble conjugated phenolic acids, and finally, soluble free phenolic acids, which are the least abundant [83]. Furthermore, phenolic acids are found primarily in ice bran and trace amounts in the endosperm of various rice genotypes. Phenolic acids are classified into two subclasses: hydrobenzoic acids and their derivatives, and hydroxycinnamic acids and their derivatives [84]. Protocatechuic, p-hydroxybenzoic, syringic, and gallic acids are all derivatives of hydroxybenzoic acid [85].

4.6.2. Flavonoids

Flavonoids are secondary plant metabolites with a polyphenolic structure similar to that of phenolic acids that have been shown to have a variety of health-promoting properties and to contribute to a decreased risk of chronic disease [79]. Rice phenolic compounds, particularly those belonging to the flavonoid subgroup, are secondary metabolites believed to be the protective response of plants to these biotic and abiotic stressors. Flavonoids are the most diverse compounds in the plant kingdom, with a 15-carbon skeleton organised by a 3-carbon chain (C6–C3–C6 structure). Flavonoids are classified into various subclasses, including flavones, flavanols, anthocyanins, and isoflavones. The most abundant flavonoids in rice are flavanols, flavones, flavonols, anthocyanins, and flavanons [86].

4.6.3. Proanthocyanidins and Anthocyanins

Proanthocyanidins and anthocyanins are bioactive compounds found in several rice varieties [87]. These vibrant bioactive pigments are found in the aleurone layer of the rice grain. Pigmented rice has a wide range of colours, owing primarily to the high anthocyanin content of the grain [88]. Numerous pigmented rice varieties have been reported, such as brown, dark brown, red-grain rice, black, and dark purple, the colour determined by the type of pigment used [89].

Proanthocyanidins

Proanthocyanidins are a class of polymeric flavan-3-ol compounds that include afzelechin, catechin, epiafzelechin, gallocatechin, epicatechin and epigallocatechin. The tannins are a group of more complex proanthocyanidins that share this very same polymeric building block. Proanthocyanidins can be classified as A-type or B-type, with flavan-3-ol units doubly linked via C2-O7 and C4-C6 or C2-O7 and C4-C8 for the former primarily via C4-C6 or C4-C8 for the latter. B-type proanthocyanidins are incredibly abundant in nature. Catechin and epicatechin form the proanthocyanidin block unit in red rice. In plants, proanthocyanidins are synthesised via anthocyanidins as critical intermediates. Additionally, these pigmented substances are responsible for rice’s red and purple hues [90].

Anthocyanins

Anthocyanins are a class of water-soluble flavonoids found in pigmented rice and other cereal grains [91]. Anthocyanidins, or aglycons, are the basic structural units of anthocyanins. They are composed of an aromatic C6 (A ring) bonded to a heterocyclic C3 (C ring) containing oxygen, which is bonded to a third aromatic C6 (A ring) via a carbon–carbon bond (B ring). When anthocyanidins are glycosidically linked to a sugar moiety, they are referred to as anthocyanins. They are found in plants as mono, di, or tri-glycosides of O-glycosides and acylglycosides of anthocyanidins [92]. Individual anthocyanidins differ in terms of their hydroxyl group count, the type, number, and position of sugars attached to the molecule, and the presence of aliphatic or aromatic acids attached to the sugar molecule. Anthocyanins are composed of the six most abundant anthocyanidins (aglycones), delphinidin, cyanidin, peonidin, petunidin, pelargonidin, and malvidin. Numerous anthocyanins have been isolated and identified from pigmented rice, such as cyaniding 3-galactoside, cyaniding 3-glucoside, malvidin 3-galactoside, cyaniding 3, 5-diglucoside, cyaniding 3-rutinoside, pelargonidin 3, 5-diglucoside, and peonidin 3-glucoside [93]. The primary chemical structures of the significant anthocyanidin Cyanidin-3-O-glucoside have been defined as having a significantly higher concentration in black rice than in other rice varieties [94].

4.7. Volatile Components

The volatile components of rice are of interest for the study of flavour constituents because they travel to the nose during eating and stimulate the olfactory receptors in the nasal cavity [95,96]. As a result, the primary sensory qualities of rice are its flavour volatiles, aroma, and texture [97,98]. Rice volatile materials are considered to fall into various classes, including aldehydes, alcohols, terpenes, benzenoids, and derivatives of amino acids and fatty acids [76]. The major volatile compounds responsible for the aroma of traditional varieties have been identified, including hexanal, octanal, non-anal, (E)-2-octenal, 1-octen-3-ol, guaiacol, and vanillin [99]. Aromatic rice contains a volatile aroma component with a popcorn-like flavour. 2-acetyl-1-pyrroline [100]. Volatiles found in cooked rice include ammonia, hydrogen sulphide, and acetaldehyde. After cooking, all aromatic rice contains the primary aromatic principle of 2-acetyl-1-pyrroline [101].

Hexanal, pentanal, non-anal, 2-heptene aldehyde, heptanal, octanal, benzene formaldehyde, and decyl aldehyde have been found in both indica and japonica [102]. Hexanal was the most abundant aldehyde, accounting for an average of 13.31% of total aldehydes (14.69% for indica and 1.93% for japonica), followed by non-anal at 7.93%. Benzene formaldehyde, decyl aldehyde, hexanal, pentanal, non-anal, and heptanal were detected at relatively high concentrations. Some twenty-three different volatile ketones were identified, with 19 being found in indica rice and 13 in japonica rice [29]. The ketones were significantly less abundant than the aldehydes [103].

Additionally, Lin et al. [104] examined the volatile compounds present in various indica and japonica rice varieties. The most abundant volatile alcohols in indica rice were n-octanol, 2-hexyl-1-octanol, and 3,7,11-trimethyl-1-12 alcohol; n-octanol, 2-hexyl-1-octanol, and 3,7,11-trimethyl-1-12 alcohol were the most abundant volatile alcohols in japonica rice. In other literatures Ashokkumar et al. [76] determined the total phenolic content (TPC) and profiled all the volatile organic compounds (VOCs) in eight popular traditional rice varieties cultivated in South India, namely Seeraga samba, Kaiviral samba, Kichili samba, Mappilai samba, Karuppu kavuni, Kuzhiyadichan, and Kattuyanam, as well as two modern rice varieties such as CO 45 and CR 1009 cultivated in South India. The majority of the predominant components identified were not identical, indicating variation among rice varieties. There were significant differences between rice varieties in terms of total terpenes (12.6 to 30.7%), total aliphatic alcohols (0.8 to 5.9%), total phenols (0.9 to 10.0%), total alkanes (0.5 to 5.1%), total alkenes (1.0 to 4.9%), and total fatty acids (46.9 to 76.2%). Palmitic acid, elaidic acid, linoleic acid, and oleic acid were all found in concentrations ranging from 11.1 to 33.7%, 6.1 to 31.1%, 6.0 to 28.0%, and 0.7 to 15.1%, respectively. Palmitic acid content was higher in modern varieties (26.7 to 33.7%) than in traditional varieties (11.1 to 20.6%). However, all traditional varieties contained a higher percentage of linoleic acid (10.0 to 28.0%) than modern varieties (6.0 to 8.5%). Traditional varieties contained significant amounts of phenolic compounds such as butyric acid, stearic acid, and glycidyl oleate, which were lacking in modern varieties.

5. Nutritional Value of Rice

Rice is regarded as an energising and reviving food, similar to other cereals [105]. While white rice is a significant source of calories, it also contains various essential minerals [1,39,40]. Table 5 shows the chemical composition of white and brown rice. Carbohydrates, mainly starch, account for approximately 80% of the dry matter of the grain, while proteins account for approximately 7%. The amino acid profile of rice reveals a high aspartic acid and glutamic content, with lysine being the limiting amino acid [106]. Brown rice contains polyunsaturated fatty acids such as oleic acid (18:1), linoleic acid (18:2), linolenic acid (18:3), and Eicosenoic (20:1). Polyunsaturated fatty acids can help prevent osteoarthritis, cancer and autoimmune disorders [107]. Additionally, brown rice is higher in dietary fibre, vitamins and minerals, particularly the B group such as Thiamine (B1), Ribofavin (B2), Niacin (B3), Pantothenic acid (B5), Pyridoxine (B6) and Biotin (B7). Another recent finding illustrates that B vitamins’ anti-inflammatory properties prevents from tau hyperphosphorylation and cognitive impairment caused by 1,2 diacetyl benzene [108]. The higher fibre content of brown rice compared to the white rice may help with appetite control and weight loss, as well as contribute to the reduction in LDL cholesterol [109].

Table 5.

Nutritional composition of rice. Modified from [1,29].

The reduction in the nutritional components including antioxidant activity, dietary fibre, and other chemical components were found after various milling processes [110]. According to Paul et al. [111], the degree of rice milling has an effect on the loss of zinc content as well as lower the yield of head rice. Kim et al. [112] suggested that as the degree of rice milling increased, the phenolic contents in organic, the fatty acid, pesticide-free grains Vitamin E homolog, and conventional rice grains decreased significantly. 2,2-diphenyl-1-picrylhydrazyl demonstrated a significant reduction in radical scavenging activity as a function of degree of milling. Another recent study found that the microstructures of cooked rice were altered by the degree of milling, which in turn affected the starch digestibility of cooked rice in vitro [113].

A diet high in wholegrain cereals, such as rice, is healthier than one high in refined cereals [114]. Consumption of whole grains has been shown in recent epidemiological studies to reduce obesity and the risk of metabolic disorders, particularly Type 2 diabetes mellitus [115], cardiovascular disease [116], and certain types of cancer [117].

6. Rice Processing

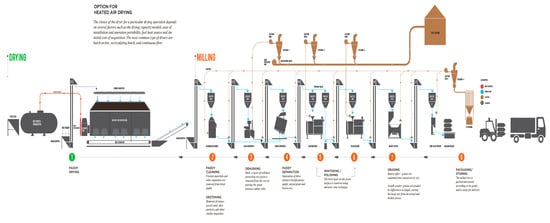

After harvesting and processing, rice can be classified as either white or brown, depending on the milling characteristics obtained [118]. As aforementioned, the paddy is composed of three layers: the husk on the outside, rice bran in the annular portion, and white rice in the centre [119]. Although there are a wide variety of rice processing methods available, each of which produces a different rice quality, it has been observed that the fundamentals of rice production remain the same [120,121]. Rice processing entails a series of steps that must be completed correctly, using various methods and equipment [122]. Figure 5 depicts the general steps of paddy drying, paddy cleaning, paddy destoning, husk separation, paddy separation, whitening, grading, packing, and storage in the rice milling process.

Figure 5.

Rice milling process [21].

6.1. Storage of Paddy

There are several aspects that affect rice grain storage strategies: (a) oxygen, temperature, moisture content as well as relative humidity of the storage condition; (b) must be protected from insect such as Sitophilus oryzae (Rice weevil) and rats/mice activity, as well as mould growth; (c) socioeconomic factors such as farmers’ family size, grain storage duration, route efficiency, grain market price, off-farm income, and grain safety during storage all need to be considered [123]. Traditional methods of preserving and storing rice grains include the use of Silo, Nahu, Camphor, Dole, Motka, jute bags, Obeh and polypropylene bag [124]. The new method of storing rice grain, which includes hermetic bags such as the GrainPro, AgroZ, and Purdue Improved Crop Storage (PICS), have been reported [125,126,127]. The interest of farmers in hermetic bags has been sparked by the aim to cut rice grain storage losses due to insect pests and the difficulties (inefficacy) associated with current storage methods [128,129]. The hermetic bag is made of plastic, which has a low permeability to O2, CO2 and other atmospheric gases. Inside the hermetic bag, respiration by grain, insects, and fungi leads to a reduction in oxygen and an increment in carbon dioxide [130]. Fungal and insect growth become hampered in a short period of time. Kanta (2016) studied the use of GrainPro bag for paddy storage. Due to the hermetic nature of the GrainPro bag, the moisture content of stored paddy remained nearly unchanged. Owing to the absence of insect attack and the high moisture content of the GrainPro bag containing seeds, the germination rate was enhanced.

6.2. Paddy Drying

Drying and storage techniques are critical components of post-harvest technology for improving paddy quality and reducing paddy loss, thereby facilitating nations in achieving socioeconomic empowerment and food security [131,132,133]. Oikeh et al. [134] reported the conventional paddy drying process in rice milling. Paddy is automatically conveyed into the dryer via a belt conveyor. The paddy is recirculated, and cross-flow hot air passes through the drier. A heat exchanger is used to heat the ambient air. The most suitable dryer for a particular drying operation is determined by several factors, including the required drying capacity, ease of installation and operation, fuel heat cost, and initial acquisition cost. The most common types are batch-in-bin, recirculating batch, and continuous-flow dyers.

To date, numerous cost-effective drying techniques have been developed, including solar, infrared, convective, desiccant, fluidised, and spouted bed dryers [135]. Solar dryers appear to be a promising alternative for small farmers, due to low energy consumption, as well as reasonable investment and operating costs when compared to commercial dryers that heat the air with petrol fuels [136]. The infrared drying is believed to extend the shelf life of brown and white rice by inactivating the lipase enzyme and thus minimising lipid oxidation by using infrared heating. High drying rates, good milling quality, effective disinfestation and disinfection of rough rice, an increase in shelf life rice and improved storage stability of rice bran were achieved through infrared drying [137]. A modified convective dryer incorporating ultrasound intervention resulted in a significant reduction in niacin and TPC losses over a shorter drying time [138]. A comparison of fluidised bed and spouted bed drying for seeds revealed that a fluidised bed dryer had a faster drying rate, whereas a spouted bed dryer was superior in terms of lower specific energy consumption [139]. A hybrid drying system combining a heat pump dryer and a fluidised bed dryer resulted in a significant increase in head rice yield and a decrease in the number of fissured grains [140].

6.3. Cleaning and Destoning

When paddy enters the mill, it may be contaminated with foreign materials such as weed seeds, straw and soil. If these items are not removed prior to hulling, the huller’s efficiency and milling recovery will be reduced [141]. The pre-cleaning procedure is divided into two stages: cleaning and de-stoning. The paddy cleaner is the most critical piece of equipment in a rice mill because it removes all impurities such as clay, straw, dust, sand, and large particles of any size from the paddy [142]. Cleaning removes foreign materials from the paddy, such as sand, stones, straw, and seeds. The input paddy is highly impure. These impurities are removed before entering the soaking chamber using a two-stage sieve and air blasting. The first stage involves the removal of light impurities such as chaff and dust. Heavier impurities such as stone and brick are removed [143]. Adetola and Akindahunsi [144] reported the performance of rice de-stoning machines. The de-stoning efficiency ranged from 40.8 to 99.75%, the capacity ranged from 1.8 to 7500 kg/h, and the operating speed ranged from 200 to 2980 rpm.

6.4. Dehusking and Separation of Husk

The husks, brown rice, and unhusked rice were separated using a tray-type paddy separator. The paddy separator separates it from the brown rice by dehusking the paddy [145]. Rice dehusking is the process of removing the husk and bran from paddy rice to produce head-sized white rice grains that are sufficiently milled, impurity free, and contain as few broken grains as possible [146]. It is the process of removing the husk from the paddy and then separating the husk from the paddy with the least amount of damage to the grain. Husking is carried out with the aid of a rubber-roll huller. The rice is then reintroduced unhusked to the huller [147].

6.5. Whitening and Polishing

White rice results from rice milling process by machines that involve removing of husk and bran layers. Abrasion and friction are the two processes used to remove the bran from the grain. This abrasion removes the bran layers, exposing the rice to be white or polished [41,148]. On the other hand, polishing refers to removing small bran particles that adhere to the rice surface following whitening and imparting a shiny appearance to the rice grains. Brown rice is polished using an abrasive polisher [118,134]. A novel rice whitening method uses enzymes such as xylanase and cellulase to degrade the rice grain’s surface structure [149]. According to Xu et al. [150], the rate and duration of rice polishing affected the rice’s physicochemical and rheological properties. Compared to unpolished rice starches, the swelling power and solubility index of low- and high-amylose rice starches elevated with milling speed and duration.

6.6. Rice Grading

The process of classifying and grading rice is vital in determining the quality of the rice and the subsequent market price [151]. When determining rice grades, two critical factors must be considered: (a) the grading technique and (b) the grading determinants used [152]. Numerous advanced approaches have been used to ascertain the characteristics of rice for grading [153,154,155]. These include image processing in conjunction with support vector machines [156], neural networks [153], wavelet packets [157], contact angle analysis (for separating contacting rice grains), image processing in conjunction with an adaptive network-based fuzzy inference system (ANFIS) [158], a multi-threshold method based on maximum entropy (chalkiness) [159], image processing in conjunction with computer vision and a minimum rectangle (MER) (length and width) [160], and image processing in conjunction with neural networks [161]. Another recent study discovered that MATLAB’s Image Processing Toolbox can be used to grade rice grains, as it aids in extracting the grains’ morphological characteristics [155].

7. Environmental Impacts of Rice Cultivation

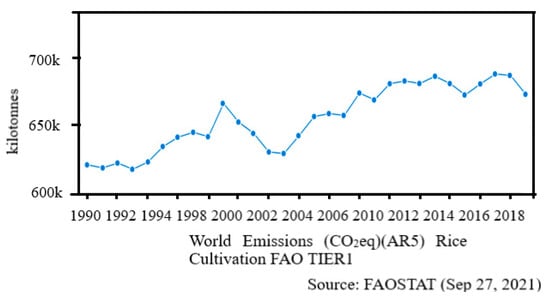

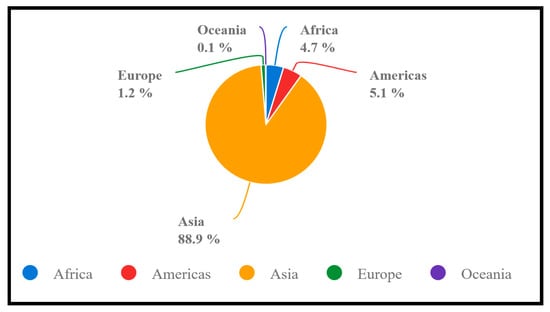

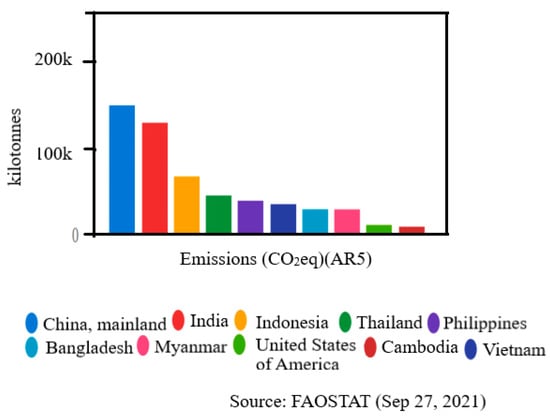

According to FAOSTAT [162], the total emissions (CO2eq) including CO2, methane, nitrous oxide and other anthropogenic greenhouse emissions from rice cultivation were 674,367.27 kilotonnes (kt) (AR5) in 2019, compared to 620,852.75 kt in 1990 (Figure 6). For almost two decades, it has been an increase of approximately 8%. Figure 7 shows the total emissions caused by rice cultivation on earth from 1990 to 2019. Figure 8 depicts the top 10 emitters (emissions CO2eq (AR5)) from rice cultivation (average 1990 to 2019). China is the world’s largest emitter at 148,343.14 kt, followed by India at 128,314.06 kt, Indonesia at 67,670.17 kt, Thailand at 45,545.03 kt, the Philippines at 38,694.92 kt, Vietnam at 36,084.7 kt, Bangladesh at 30,034.81 kt, and Myanmar at 28,837.39 kt, the United States of America at 11,803.87 kt, and Cambodia at 10,310.73 kt of total emissions (COeq), respectively. Asia accounts for the largest share of global emissions (CO2eq (AR5)) caused by rice cultivation, accounting for 88.9% of total emissions.

Figure 6.

Total emissions from rice cultivation on a global scale (1990–2019) [162].

Figure 7.

Share of emissions (CO2eq (AR5)) by continent, rice cultivation in 2019 [162].

Figure 8.

Top 10 emitters (emissions CO2eq (AR5)) from rice cultivation (average 1990–2019) [162].

Methane is among the most significant greenhouse gases after CO2, accounting for approximately 15 to 20% of global warming. Globally, rice cultivation is one of the largest sources of agricultural methane emissions [163]. Flooded rice fields contribute significantly to methane emissions, which account for 48% of agricultural greenhouse gas emissions [164,165]. Methane emission from paddy is primarily influenced by water management practices and soil conditions [166]. The water from flooded rice restricts oxygen from permeating the soil, creating ideal conditions for bacteria that emit methane. The longer flooding persists, the greater the accumulation of methanogenic bacteria. The methane emission is the net result of two contrasting bacterial processes, production in anaerobic microenvironments and consumption and oxidation in aerobic microenvironments, which occur simultaneously in flooded rice soils [167]. Alternate wetting and drying (AWD) have been identified as one of the most promising techniques for reducing methane emissions from rice cultivation. Using the methodologies outlined by the Intergovernmental Panel on Climate Change, the AWD scenario could reduce annual methane emissions by 32% compared to the continuously flooded scenario [168]. Other strategies for reducing methane emissions from paddy rice fields include the addition of sulphates and the preference of rice varieties [169].

Climate change is expected to affect rice production and trade. Koizumi et al. [170] established Rice Economy Climate Change (RECC) model to account for the effects of climate change on rice production in 24 countries. Climate change is expected to affect japonica and indica rice, based on RECC baseline projections and scenario simulations. In particular, the international price of japonica rice is expected to be more volatile compared to the price of indica rice. Additionally, Firdaus et al. [171] investigated the effects of climate change, focusing on Malaysia. The analysis demonstrated that the minimum (Tmin) and maximum (Tmax) temperatures in the granary areas increased by 0.3 °C to 0.5 °C and 0.2 °C to 0.3 °C, respectively, in each decade, using Mann–Kendall and Sen’s slope. Simultaneously, precipitation has increased, ranging from 133 mm to 200 mm. The findings indicated that climate change poses a significant threat to paddy production, which will eventually affect food security, same as reported by other literatures [172,173,174,175].

In rice milling, rice husk is an abundant agricultural waste in rice production [176,177,178,179]. When rice husk ash is dumped directly into the environment, it contributes significantly to water and land pollution [180], resulting in various health problems [120]. Environmental pollution has been linked to rice milling factors producing large amounts of effluent high in nutrients, solid wastes, and organic matter [181,182]. According to Kumar et al. [183], rice mill effluent contains a sufficient amount of pesticides and nutrients to result in groundwater pollution and eutrophication.

8. Challenges to Overcoming Barriers and Current Policy Directions

According to FAO [184], 45 countries, 34 of which are in Africa, continue to require food aid from outside sources. The COVID-19 pandemic’s impact, mainly in terms of income losses, is a significant driver of global food insecurity, worsening and exacerbating already uncertain conditions. Conflicts, weather events, and pests continue to be major contributors to the high levels of intense food insecurity [185,186]. Table 6 shows the challenges to the sustainability of the food production system, with a focus on rice production, as well as strategies for overcoming those challenges.

Table 6.

Challenges to the sustainability of the rice production system and suggested proposed solutions [187,188].

Table 7 summaries current government policies designed to increase rice production and quality by global rice producers. In terms of Malaysia, Che Omar et al. [189] stated that in the future, agricultural policies relating to food in Malaysia should no longer be driven solely by production targets. The recommendations include giving farmers and farm-related organisations equal credit for adopting Malaysia’s Good Agricultural Practices (MyGAP), efficient water use, and soil management in order to increase paddy production. At the midstream level, it is advised to recognise stakeholders who follow Good Manufacturing Practices (GMPs), conduct Hazard Analysis Critical Control Point (HACCP) analyses, and promote manufacturing and marketing transparency, such as the use of Blockchain technology.

Table 7.

Current policies development [190].

9. Conclusions

Although the COVID-19 pandemic and some natural disasters, such as floods, have posed numerous challenges to global rice production, 513.7 Mt of milled rice have been produced worldwide in 2020. Rice is such a vital crop that it is a source of high-energy or high-calorie foods with a high nutritional value. Starch accounts for approximately 90% of the dry weight in milled rice, along with lipid, protein, non-starch polysaccharide and numerous volatile components. Furthermore, rice contains phenolic compounds that have anti-inflammatory, anticancer, and anti-diabetic properties. It contributes significantly to health benefits and disease prevention for humankind.

The rice milling process includes the process of paddy drying, paddy cleaning, paddy destoning, husk separation, paddy separation, whitening, grading, packing, and storage. In order to ensure food security, a substantial persistent quality improvement has been made in the rice’s quality, post-harvest handling, and the milling process. In 2019, global emissions due to rice cultivation were 674,367.27 kt (CO2eq (AR5). For almost two decades, there has been an increase of approximately 8%. Asia accounts for the most significant global emissions (CO2eq (AR5)), accounting for 88.9%.

The rise in the global population and the effects of climate change in the region influence the need to boost rice production and improve its quality. The recent food crisis has also spurred a revisiting of self-sufficiency goals of rice. For sustainability of agriculture, rice-producing countries have created rice policies that emphasise productivity and quality growth to ensure adequate food supplies for the people.

Author Contributions

N.A.M. designed and writing the manuscript. Writing and editing by N.A.M. and N.H. Both R.S. and H.C.M. contributed to the final version of the manuscript. N.H. supervised the project. All authors have read and agreed to the published version of the manuscript.

Funding

The authors wish to acknowledge the Ministry of Higher Education, Malaysia for financial support via the Transdisciplinary Research Grant Scheme project TRGS/1/2020/UPM/02/7.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

There is no conflict of interest.

References

- Zhao, M.; Lin, Y.; Chen, H. Improving nutritional quality of rice for human health. Theor. Appl. Genet. 2020, 133, 1397–1413. [Google Scholar] [CrossRef] [PubMed]

- FAOSTAT. Production/Yield Quantities of Rice, Paddy in World + (Total). Food and Agriculture Organization of the United Nations, 2021. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 1 September 2021).

- USDA. World Rice Production 2021/2022. 2022. Available online: http://www.worldagriculturalproduction.com/crops/rice.aspx/ (accessed on 1 September 2021).

- Bandumula, N. Rice Production in Asia: Key to Global Food Security. Proc. Natl. Acad. Sci. India Sect. B Biol. Sci. 2018, 88, 1323–1328. [Google Scholar] [CrossRef]

- OECD/FAO. OECD-FAO Agricultural Outlook 2021–2030; OECD Publishing: Paris, France, 2021; pp. 7–8. [Google Scholar] [CrossRef]

- Van Oort, P.A.J.; Saito, K.; Tanaka, A.; Amovin-Assagba, E.; Van Bussel, L.G.J.; Van Wart, J.; de Groot, H.; van Ittersum, M.K.; Cassman, K.G.; Wopereis, M.C.S. Assessment of rice self-sufficiency in 2025 in eight African countries. Glob. Food Secur. 2015, 5, 39–49. [Google Scholar] [CrossRef]

- AMIS. AMIS MARKET MONITOR No. 94—December 2021. 2021. Available online: http://www.amis-outlook.org/fileadmin/user_upload/amis/docs/Market_monitor/AMIS_Market_Monitor_Issue_94.pdf (accessed on 1 October 2021).

- FAO. Crop Prospects and Food Situation—Quarterly Global Report No. 2, July 2021. Rome. 2021. Available online: https://doi.org/10.4060/cb5603en (accessed on 1 September 2021).

- von Goh, E.; Azam-Ali, S.; McCullough, F.; Mitra, S.R. The nutrition transition in Malaysia; Key drivers and recommendations for improved health outcomes. BMC Nutr. 2020, 6, 32. [Google Scholar] [CrossRef]

- Statista. Rice Consumption Worldwide in 2021/2022, by Country (in 1000 metric tons). 2021. Available online: https://www.statista.com/statistics/255971/top-countries-based-on-rice-consumption-2012-2013/ (accessed on 1 September 2021).

- International Rice Research Institute. Rice Consumption with Center Pivots and Linears; International Rice Research Institute: Los Baños, Philippines, 2013; Volume 12. [Google Scholar]

- Schreinemachers, P.; Simmons, E.B.; Wopereis, M.C.S. Tapping the economic and nutritional power of vegetables. Glob. Food Secur. 2018, 16, 36–45. [Google Scholar] [CrossRef]

- Samal, P.; Babu, S. The shape of rice agriculture towards 2050. In Proceedings of the 30th International Conference of Agricultural Economists, Vancouver, BC, Canada, 28 July–2 August 2018. [Google Scholar]

- Reardon, T.; Tschirley, D.; Liverpool-Tasie, L.S.O.; Awokuse, T.; Fanzo, J.; Minten, B.; Vos, R.; Dolislager, M.; Sauer, C.; Dhar, R.; et al. The processed food revolution in African food systems and the double burden of malnutrition. Glob. Food Secur. 2021, 28, 100466. [Google Scholar] [CrossRef]

- Fukagawa, N.K.; Ziska, L.H. Rice: Importance for global nutrition. J. Nutr. Sci. Vitaminol. 2019, 65, S2–S3. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Jabran, K.; Mahajan, G. Rice Production Worldwide; Springer: Cham, Switzerland, 2017; pp. 1–563. [Google Scholar] [CrossRef]

- Priya, T.S.R.; Nelson, A.R.L.E.; Ravichandran, K.; Antony, U. Nutritional and functional properties of coloured rice varieties of South India: A review. J. Ethn. Foods 2019, 6, 11. [Google Scholar] [CrossRef]

- Calingacion, M.; Laborte, A.; Nelson, A.; Resurreccion, A.; Concepcion, J.C.; Daygon, V.D.; Mumm, R.; Reinke, R.; Dipti, S.; Bassinello, P.Z.; et al. Diversity of global rice markets and the science required for consumer-targeted rice breeding. PLoS ONE 2014, 9, e85106. [Google Scholar] [CrossRef]

- Qiu, X.; Pang, Y.; Yuan, Z.; Xing, D.; Xu, J.; Dingkuhn, M.; Li, Z.; Ye, G. Genome-wide association study of grain appearance and milling quality in a worldwide collection of Indica rice germplasm. PLoS ONE 2015, 10, e145577. [Google Scholar] [CrossRef]

- Weerawatanakorn, M.; Wu, J.C.; Pan, M.H.; Ho, C.T. Reactivity and stability of selected flavor compounds. J. Food Drug Anal. 2015, 23, 176–190. [Google Scholar] [CrossRef] [PubMed]

- BERNAS. Rice Type in Malaysia. 2022. Available online: https://www.bernas.com.my/bernas/index.php/ricepedia/rice-type-in-malaysia (accessed on 1 January 2022).

- Cho, D.H.; Lim, S.T. Germinated brown rice and its bio-functional compounds. Food Chem. 2016, 196, 259–271. [Google Scholar] [CrossRef] [PubMed]

- Xie, W.; Li, Y.; Li, Y.; Ma, L.; Ashraf, U.; Tang, X.; Pan, S.; Tian, H.; Mo, Z. Application of γ-aminobutyric acid under low light conditions: Effects on yield, aroma, element status, and physiological attributes of fragrant rice. Ecotoxicol. Environ. Saf. 2021, 213, 111941. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.; Singh, A.K.; Mohapatra, T.; Krishnan, S.G.; Ellur, R.K. Pusa Basmati 1121—A rice variety with exceptional kernel elongation and volume expansion after cooking. Rice 2018, 11, 19. [Google Scholar] [CrossRef]

- Bera, A. Basmati rice: A new hope for farmers. Agric. Food e-Newslett. 2020, 2, 819–821. [Google Scholar] [CrossRef]

- Prodhan, Z.H.; Qingyao, S. Rice Aroma: A Natural Gift Comes with Price and the Way Forward. Rice Sci. 2020, 27, 86–100. [Google Scholar] [CrossRef]

- Ramasamy, S.; Robin, S.I.; Muthurajan, R. Developing improved versions of a popular rice variety (Improved White Ponni) through marker assisted backcross breeding. Green Farming 2020, 8, 506–511. [Google Scholar]

- Ramchander, S.; Ushakumari, R.; Arumugam, M.P. Quality characteristics of rice mutants generated through gamma radiation in white ponni quality characteristics of rice mutants generated through gamma radiation in white ponni. Int. J. Agric. Sci. 2015, 7, 719–723. [Google Scholar]

- Nawaz, M.A. Processing and Quality of Glutinous Rice; The University of Queensland: St. Lucia, QLD, Australia, 2018. [Google Scholar]

- Qiu, S.; Abbaspourrad, A.; Padilla-Zakour, O.I. Changes in the Glutinous Rice Grain and Physicochemical Electric Field. Foods 2021, 10, 395. [Google Scholar] [CrossRef]

- Agustin, A.T.; Safitri, A.; Fatchiyah, F. Java red rice (Oryza sativa L.) nutritional value and anthocyanin profiles and its potential role as antioxidant and anti-diabetic. Indones. J. Chem. 2021, 21, 968–978. [Google Scholar] [CrossRef]

- Gong, M.; Zhou, Z.; Liu, S.; Zhu, S.; Li, G.; Zhong, F.; Mao, J. Dynamic changes in physico-chemical attributes and volatile compounds during fermentation of Zhenjiang vinegars made with glutinous and non-glutinous japonica rice. J. Cereal Sci. 2021, 100, 103246. [Google Scholar] [CrossRef]

- Ratnasekera, D. Weedy rice: A threat to rice production in Sri Lanka. J. Univ. Ruhuna 2015, 3, 2. [Google Scholar] [CrossRef][Green Version]

- Dimitrovski, T.; Andreevska, D.; Andov, D. Morphological and grain characterisation of Macedonian weedy rice (Oryza sativa L.). Maced. J. Ecol. Environ. 2018, 20, 5–17. [Google Scholar]

- de Steur, H.; Stein, A.J.; Demont, M. From Golden Rice to Golden Diets: How to turn its recent approval into practice. Glob. Food Secur. 2022, 32, 100596. [Google Scholar] [CrossRef] [PubMed]

- Dubock, A. The present status of Golden Rice. J. Huazhong Agric. 2014, 33, 69–84. [Google Scholar]

- Rodríguez, A.V.; Rodríguez-Oramas, C.; Velázquez, E.S.; de la Torre, A.H.; Armendáriz, C.R.; Iruzubieta, C.C. Myths and Realities about Genetically Modified Food: A Risk-Benefit Analysis. Appl. Sci. 2022, 12, 2861. [Google Scholar] [CrossRef]

- Zhu, Q.; Zeng, D.; Yu, S.; Cui, C.; Li, J.; Li, H.; Chen, J.; Zhang, R.; Zhao, X.; Chen, L.; et al. From Golden Rice to aSTARice: Bioengineering Astaxanthin Biosynthesis in Rice Endosperm. Mol. Plant 2018, 11, 1440–1448. [Google Scholar] [CrossRef]

- Swamy, B.M.; Samia, M.; Boncodin, R.; Marundan, S.; Rebong, D.B.; Ordonio, R.L.; Miranda, R.T.; Rebong, A.T.O.; Alibuyog, A.Y.; Adeva, C.C.; et al. Compositional Analysis of Genetically Engineered GR2E ‘golden Rice’ in Comparison to That of Conventional Rice. J. Agric. Food Chem. 2019, 67, 7986–7994. [Google Scholar] [CrossRef]

- Mallikarjuna Swamy, B.P.; Marundan, S.; Samia, M.; Ordonio, R.L.; Rebong, D.B.; Miranda, R.; Alibuyog, A.; Rebong, A.T.; Tabil, M.A.; Suralta, R.R.; et al. Development and characterization of GR2E Golden rice introgression lines. Sci. Rep. 2021, 11, 2496. [Google Scholar] [CrossRef]

- Hoogenkamp, H.; Kumagai, H.; Wanasundara, J.P.D. Rice Protein and Rice Protein Products; Elsevier Inc.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Cornejo-Ramírez, Y.I.; Martínez-Cruz, O.; del Toro-Sánchez, C.L.; Wong-Corral, F.J.; Borboa-Flores, J.; Cinco-Moroyoqui, F.J. The structural characteristics of starches and their functional properties. CYTA-J. Food 2018, 16, 1003–1017. [Google Scholar] [CrossRef]

- Zhang, H.; Jang, S.G.; Lar, S.M.; Lee, A.R.; Cao, F.Y.; Seo, J.; Kwon, S.W. Genome-Wide Identification and Genetic Variations of the Starch Synthase Gene Family in Rice. Plants 2021, 10, 1154. [Google Scholar] [CrossRef] [PubMed]

- Belitz, H.-D.; Rosch, W.; Schieberle, P. Food Chemistry; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar] [CrossRef]

- Bertoft, E. Understanding starch structure: Recent progress. Agronomy 2017, 7, 56. [Google Scholar] [CrossRef]

- Maung, T.Z.; Yoo, J.M.; Chu, S.H.; Kim, K.W.; Chung, I.M.; Park, Y.J. Haplotype Variations and Evolutionary Analysis of the Granule-Bound Starch Synthase I Gene in the Korean World Rice Collection. Front. Plant Sci. 2021, 12, 707237. [Google Scholar] [CrossRef] [PubMed]

- Madhusankha, G.D.M.; Thilakarathna, R.C. Meat tenderization mechanism and the impact of plant exogenous proteases: A review. Arab. J. Chem. 2020, 14, 102967. [Google Scholar] [CrossRef]

- Alcázar-Alay, S.C.; Meireles, M.A.A. Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci. Technol. 2015, 35, 215–236. [Google Scholar] [CrossRef]

- Vlad-Oros, B.; Preda, G.; Dudas, Z.; Dragomirescu, M.; Chiriac, A. Entrapment of glucoamylase by sol-gel technique in PhTES/TEOS hybrid matrixes. Process. Appl. Ceram. 2007, 1, 63–67. [Google Scholar] [CrossRef]

- Peng, X. Advanced Characterization of Glucan Particulates: Small-Granule Starches, Retention of Small Molecules and Local … no. December. 2018. Available online: http://pstorage-purdue-258596361474.s3.amazonaws.com/13701095/XingyunPengsDissertation_1201182.pdf (accessed on 1 September 2021).

- Cornejo, F.; Rosell, C.M. Physicochemical properties of long rice grain varieties in relation to gluten free bread quality. LWT-Food Sci. Technol. 2015, 62, 1203–1210. [Google Scholar] [CrossRef]

- Uraipong, C. Investigation into the Biological Functions of Rice Bran Protein Hydrolysates. Ph.D. Thesis, The University of New South Wales, Sydney, NSW, Australia, 2016; pp. 1–219. [Google Scholar]

- Pedrazzini, E.; Mainieri, D.; Marrano, C.A.; Vitale, A. Where do protein bodies of cereal seeds come from? Front. Plant Sci. 2016, 7, 1139. [Google Scholar] [CrossRef][Green Version]

- Roustan, V.; Hilscher, J.; Weidinger, M.; Reipert, S.; Shabrangy, A.; Gebert, C.; Dietrich, B.; Dermendjiev, G.; Schnurer, M.; Roustan, P.-J.; et al. Protein sorting into protein bodies during barley endosperm development is putatively regulated by cytoskeleton members, MVBs and the HvSNF7s. Sci. Rep. 2020, 10, 1864. [Google Scholar] [CrossRef]

- Mohd Fairulnizal, M.N.; Norhayati, M.K.; Zaiton, A.; Norliza, A.H.; Rusidah, S.; Aswir, A.R.; Suraiami, M.; Mohd Naeem, M.N.; Jo-Lyn, A.; Mohd Azerulazree, J.; et al. Nutrient content in selected commercial rice in Malaysia: An update of Malaysian food composition database. Int. Food Res. J. 2015, 22, 768–776. [Google Scholar]

- Masumura, T.; Shigemitsu, T.; Morita, S.; Satoh, S. Identification of the region of rice 13 KDa prolamin essential for the formation of ER-derived protein bodies using a heterologous expression system. Biosci. Biotechnol. Biochem. 2015, 79, 566–573. [Google Scholar] [CrossRef] [PubMed]

- Saito, Y.; Shigemitsu, T.; Yamasaki, R.; Sasou, A.; Goto, F.; Kishida, K.; Kuroda, M.; Tanaka, K.; Morita, S.; Satoh, S.; et al. Formation mechanism of the internal structure of type I protein bodies in rice endosperm: Relationship between the localization of prolamin species and the expression of individual genes. Plant J. 2012, 70, 1043–1055. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.-Y.; Kim, J.-H.; Rico, C.-W.; Nam, S.-H. A comparative study on the physicochemical characteristics of black rice varieties. Int. J. Food Prop. 2011, 14, 1241–1254. [Google Scholar] [CrossRef][Green Version]

- Yoon, M.R.; Rico, C.W.; Koh, H.J.; Kang, M.Y. A study on the lipid components of rice in relation to palatability and storage. J. Korean Soc. Appl. Biol. Chem. 2012, 55, 515–521. [Google Scholar] [CrossRef]

- Zhang, X.; Yi, S.; Ning, Z.; Jinsong, B.; Wu, D.; Xiaoli, S. The effects of internal endosperm lipids on starch properties: Evidence from rice mutant starches. J. Cereal Sci. 2019, 89, 102804. [Google Scholar] [CrossRef]

- Lu, H.; Jiang, H.; Chen, Q. Determination of fatty acid content of rice during storage based on feature fusion of olfactory visualization sensor data and near-infrared spectra. Sensors 2021, 21, 3266. [Google Scholar] [CrossRef]

- Orsavova, J.; Misurcova, L.; Ambrozova, J.V.; Vicha, R.; Mlcek, J. Fatty acids composition of vegetable oils and its contribution to dietary energy intake and dependence of cardiovascular mortality on dietary intake of fatty acids. Int. J. Mol. Sci. 2015, 16, 12871–12890. [Google Scholar] [CrossRef]

- Devi, A.; Khatkar, B.S. Effects of fatty acids composition and microstructure properties of fats and oils on textural properties of dough and cookie quality. J. Food Sci. Technol. 2018, 55, 321–330. [Google Scholar] [CrossRef]

- Mohamed, I.O. Effects of processing and additives on starch physicochemical and digestibility properties. Carbohydr. Polym. Technol. Appl. 2021, 2, 100039. [Google Scholar] [CrossRef]

- Bao, J. Rice Starch; Elsevier Inc. in Cooperation with AACC International: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Wattanavanitchakorn, S.; Wansuksri, R.; Chaichoompu, E. Biochemical and molecular assessment of cooking quality and nutritional value of pigmented and non-pigmented whole grain rice. Preprints 2021. [Google Scholar] [CrossRef]

- Chawla, R.; Patil, G.R. Fiber. Compr. Rev. Food Sci. Food Safe 2010, 9, 178–196. [Google Scholar] [CrossRef]

- Sethy, K.; Mishra, S.K.; Mohanty, P.P.; Agarawal, J.; Meher, P.; Satapathy, D.; Sahoo, J.K.; Panda, S.; Nayak, S.M. An overview of Non Starch Polysaccharide. J. Anim. Nutr. Physiol. 2015, 1, 17–22. [Google Scholar]

- Sinha, A.K.; Kumar, V.; Makkar, H.P.S.; de Boeck, G.; Becker, K. Non-starch polysaccharides and their role in fish nutrition—A review. Food Chem. 2011, 127, 1409–1426. [Google Scholar] [CrossRef]

- Hartini, S.; Choct, M. The effects of diets containing different level of non-starch polysaccharides on performance and cannibalism in laying hens. J. Indones. Trop. Anim. Agric. 2010, 35, 145–150. [Google Scholar] [CrossRef][Green Version]

- Harholt, J.; Suttangkakul, A.; Scheller, H.V. Biosynthesis of pectin. Plant Physiol. 2010, 153, 384–395. [Google Scholar] [CrossRef]

- van Dam, J.E.G.; van den Broek, L.A.M.; Boeriu, C.G. Polysaccharides in human health care. Nat. Prod. Commun. 2017, 12, 821–830. [Google Scholar] [CrossRef]

- WCRF/AICR. Recommendations and public health and policy implications. In Continous Update Project; WCRF/AICR: London, UK, 2018. [Google Scholar]

- Uthumporn, U.; Nadiah, I.; Izzuddin, I.; Cheng, L.H.; Aida, H. Physicochemical characteristics of non-starch polysaccharides extracted from cassava tubers. Sains Malays. 2017, 46, 223–229. [Google Scholar] [CrossRef]

- Krishnanunni, K.; Senthilvel, P.; Ramaiah, S.; Anbarasu, A. Study of chemical composition and volatile compounds along with in-vitro assay of antioxidant activity of two medicinal rice varieties: Karungkuravai and Mappilai samba. J. Food Sci. Technol. 2015, 52, 2572–2584. [Google Scholar] [CrossRef]

- Ashokkumar, K.; Govindaraj, M.; Vellaikumar, S.; Shobhana, V.G.; Karthikeyan, A.; Akilan, M.; Sathishkumar, J. Comparative Profiling of Volatile Compounds in Popular South Indian Traditional and Modern Rice Varieties by Gas Chromatography–Mass Spectrometry Analysis. Front. Nutr. 2020, 7, 260. [Google Scholar] [CrossRef]

- Cory, H.; Passarelli, S.; Szeto, J.; Tamez, M.; Mattei, J. The Role of Polyphenols in Human Health and Food Systems: A Mini-Review. Front. Nutr. 2018, 5, 87. [Google Scholar] [CrossRef]

- Altemimi, A.; Lakhssassi, N.; Baharlouei, A.; Watson, D.G.; Lightfoot, D.A. Phytochemicals: Extraction, isolation, and identification of bioactive compounds from plant extracts. Plants 2017, 6, 42. [Google Scholar] [CrossRef]

- Ciulu, M.; de la Luz Cádiz-Gurrea, M.; Segura-Carretero, A. Extraction and analysis of phenolic compounds in rice: A review. Molecules 2018, 23, 2890. [Google Scholar] [CrossRef]

- Shao, Y.; Hu, Z.; Yu, Y.; Mou, R.; Zhu, Z.; Beta, T. Phenolic acids, anthocyanins, proanthocyanidins, antioxidant activity, minerals and their correlations in non-pigmented, red, and black rice. Food Chem. 2018, 239, 733–741. [Google Scholar] [CrossRef]

- Wisetkomolmat, J.; Arjin, C.; Satsook, A.; Seel-Audom, M.; Ruksiriwanich, W.; Prom-u-Thai, C.; Sringarm, K. Comparative Analysis of Nutritional Components and Phytochemical Attributes of Selected Thai Rice Bran. Front. Nutr. 2022, 9, 833730. [Google Scholar] [CrossRef]

- Podgórska, A.; Burian, M.; Gieczewska, K. Altered Cell Wall Plasticity Can Restrict Plant Growth under Ammonium Nutrition. Front. Plant Sci. 2017, 8, 1344. [Google Scholar] [CrossRef]

- Speranza, S.; Knechtl, R.; Witlaczil, R.; Schönlechner, R. Reversed-Phase HPLC Characterization and Quantification and Antioxidant Capacity of the Phenolic Acids and Flavonoids Extracted from Eight Varieties of Sorghum Grown in Austria. Front. Plant Sci. 2021, 12, 769151. [Google Scholar] [CrossRef]

- Singla, R.K.; Dubey, A.K.; Garg, A.; Sharma, R.K.; Fiorino, M.; Ameen, S.M.; Haddad, M.A.; Al-Hiary, M. Natural Polyphenols: Chemical Classification, Definition of Classes, Subcategories, and Structures. J. AOAC Int. 2019, 102, 1397–1400. [Google Scholar] [CrossRef]

- Kumar, N.; Goel, N. Phenolic acids: Natural versatile molecules with promising therapeutic applications. Biotechnol. Rep. 2019, 24, e00370. [Google Scholar] [CrossRef]

- Ansari, M.-U.-R. Recent Advances in Rice Research; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Bhat, F.M.; Sommano, S.R.; Riar, C.S.; Seesuriyachan, P.; Chaiyaso, T.; Prom-U-thai, C. Status of bioactive compounds from bran of pigmented traditional rice varieties and their scope in production of medicinal food with nutraceutical importance. Agronomy 2020, 10, 1817. [Google Scholar] [CrossRef]

- Huang, Y.P.; Lai, H.M. Bioactive compounds and antioxidative activity of colored rice bran. J. Food Drug Anal. 2016, 24, 564–574. [Google Scholar] [CrossRef]

- Verma, D.K.; Srivastav, P.P. Bioactive compounds of rice (Oryza sativa L.): Review on paradigm and its potential benefit in human health. Trends Food Sci. Technol. 2020, 97, 355–365. [Google Scholar] [CrossRef]

- Rauf, A.; Imran, M.; Abu-izneid, T.; Patel, S. Proanthocyanidins: A comprehensive review. Biomed. Pharmacother. 2019, 116, 108999. [Google Scholar] [CrossRef]

- Gunaratne, A.; Wu, K.; Li, D.; Bentota, A.; Corke, H.; Cai, Y.Z. Antioxidant activity and nutritional quality of traditional red-grained rice varieties containing proanthocyanidins. Food Chem. 2013, 138, 1153–1161. [Google Scholar] [CrossRef]

- Panche, A.N.; Diwan, A.D.; Chandra, S.R. Flavonoids: An overview. J. Nutr. Sci. 2016, 5, e47. [Google Scholar] [CrossRef]

- Khoo, H.E. Anthocyanidins and anthocyanins: Colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr. Res. 2017, 61, 1361779. [Google Scholar] [CrossRef]

- Daiponmak, W.; Theerakulpisut, P.; Thanonkeo, P.; Vanavichit, A. Changes of anthocyanin cyanidin-3-glucoside content and antioxidant activity in Thai rice varieties under salinity stress. Sci. Asia 2010, 36, 286–291. [Google Scholar] [CrossRef]

- Bharti, S.; Anand, S. Fragrance and Aroma in Rice. Food Sci. Rep. 2020, 1. [Google Scholar] [CrossRef]

- Hinge, V.R.; Patil, H.B.; Nadaf, A.B. Aroma volatile analyses and 2AP characterization at various developmental stages in Basmati and Non-Basmati scented rice (Oryza sativa L.) cultivars. Rice 2016, 9, 38. [Google Scholar] [CrossRef]

- Verma, S.; Srivastava, S.; Tiwari, N. Comparative study on nutritional and sensory quality of barnyard and foxtail millet food products with traditional rice products. J. Food Sci. Technol. 2015, 52, 5147–5155. [Google Scholar] [CrossRef]

- Yin, W.; Hewson, L.; Linforth, R.; Taylor, M.; Fisk, I.D. Effects of aroma and taste, independently or in combination, on appetite sensation and subsequent food intake. Appetite 2017, 114, 265–274. [Google Scholar] [CrossRef]

- Liyanaarachchi, G.D.; Kottearachchi, N.S.; Samarasekera, R. Volatile profiles of traditional aromatic rice varieties in Sri Lanka. J. Natl. Sci. Found. Sri Lanka 2014, 42, 87–93. [Google Scholar] [CrossRef]

- Ramtekey, V.; Cherukuri, S.; Modha, K.G.; Kumar, A.; Kethineni, U.B.; Pal, G.; Singh, A.N.; Kumar, S. Extraction, characterization, quantification, and application of volatile aromatic compounds from Asian rice cultivars. Rev. Anal. Chem. 2021, 40, 272–292. [Google Scholar] [CrossRef]

- Kasote, D.; Singh, V.K.; Bollinedi, H.; Singh, A.K.; Sreenivasulu, N. Profiling of 2-Acetyl-1-Pyrroline and Other Volatile Compounds in Raw and Cooked Rice of Traditional and Improved Varieties. Foods 2021, 10, 1917. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Hui, T.; Fang, F.; Ma, Q.; Li, S.; Zhang, D. Characterization and Discrimination of Key Aroma Compounds in Pre- and Postrigor Roasted Mutton by GC-O-MS, GC E-Nose and Aroma Recombination Experiments. Foods 2021, 10, 2387. [Google Scholar] [CrossRef]

- Müller-Wirtz, L.M.; Kiefer, D.; Ruffing, S.; Brausch, T.; Hüppe, T.; Sessler, D.I.; Volk, T.; Fink, T.; Kreuer, S.; Maurer, F. Quantification of Volatile Aldehydes Deriving from In Vitro Lipid Peroxidation in the Breath of Ventilated Patients. Molecules 2021, 26, 3089. [Google Scholar] [CrossRef]

- Lin, J.-Y.; Fan, W.; Gao, Y.-N.; Wu, S.-F.; Wang, S.-X. Study on volatile compounds in rice by HS-SPME and GC-MS. In Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, 27 June–2 July 2010; pp. 125–134. [Google Scholar] [CrossRef]

- Rasane, P.; Jha, A.; Sabikhi, L.; Kumar, A.; Unnikrishnan, V.S. Nutritional advantages of oats and opportunities for its processing as value added foods—A review. J. Food Sci. Technol. 2015, 52, 662–675. [Google Scholar] [CrossRef]

- Carcea, M. Value of wholegrain rice in a healthy human nutrition. Agriculture 2021, 11, 720. [Google Scholar] [CrossRef]

- Kapoor, B.; Kapoor, D.; Gautam, S.; Singh, R.; Bhardwaj, S. Dietary Polyunsaturated Fatty Acids (PUFAs): Uses and Potential Health Benefits. Curr. Nutr. Rep. 2021, 10, 232–242. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Jo, W.H.; Hong, N.; Hoang, M.; Kim, M. International Immunopharmacology Anti-inflammatory effects of B vitamins protect against tau hyperphosphorylation and cognitive impairment induced by 1, 2 diacetyl benzene: An in vitro and in silico study. Int. Immunopharmacol. 2022, 108, 108736. [Google Scholar] [CrossRef]

- Lattimer, J.M.; Haub, M.D. Effects of dietary fiber and its components on metabolic health. Nutrients 2010, 2, 1266–1289. [Google Scholar] [CrossRef]

- Ma, Z.-Q.; Yi, C.-P.; Wu, N.-N.; Ban, T. Reduction of phenolic profiles, dietary fiber, and antioxidant activities of rice after treatment with different milling processes. Cereal Chem. 2020, 97, 1158–1171. [Google Scholar] [CrossRef]

- Paul, H.; Nath, B.C.; Bhuiyan, M.G.K.; Paul, S. Effect of Degree of Milling on Rice Grain Quality. J. Agric. Eng. 2020, 42, 69–76. [Google Scholar]

- Kim, S.H.; Yang, Y.J.; Chung, I.M. The effect of degree of milling on the nutraceutical content in ecofriendly and conventional rice (Oryza sativa L.). Foods 2020, 9, 1297. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Guan, X.; Li, C. Effects of degree of milling on the starch digestibility of cooked rice during (in vitro) small intestine digestion. Int. J. Biol. Macromol. 2021, 188, 774–782. [Google Scholar] [CrossRef] [PubMed]

- van der Kamp, J.W.; Poutanen, K.; Seal, C.J.; Richardson, D.P. The HEALTHGRAIN definition of ‘whole grain’. Food Nutr. Res. 2014, 58, 1–8. [Google Scholar] [CrossRef]

- Develaraja, S.; Reddy, A.; Yadav, M.; Jain, S.; Yadav, H. Whole Grains in Amelioration of Metabolic Derangements. J. Nutr. Health Food Sci. 2016, 4, 1–11. [Google Scholar]

- Hollænder, P.L.B.; Ross, A.B.; Kristensen, M. Whole-grain and blood lipid changes in apparently healthy adults: A systematic review and meta-analysis of randomized controlled studies1-3. Am. J. Clin. Nutr. 2015, 102, 556–572. [Google Scholar] [CrossRef]

- Aune, D.; Keum, N.; Giovannucci, E.; Fadnes, L.T.; Boffetta, P.; Greenwood, D.C.; Tonstad, S.; Vatten, L.J.; Riboli, E.; Norat, T. Whole grain consumption and risk of cardiovascular disease, cancer, and all cause and cause specific mortality: Systematic review and dose-response meta-analysis of prospective studies. BMJ 2016, 353, i2716. [Google Scholar] [CrossRef]

- Nokkoul, R. Organic upland rice seed production. Adv. J. Food Sci. Technol. 2014, 6, 1313–1317. [Google Scholar] [CrossRef]

- Gul, K.; Yousuf, B.; Singh, A.K.; Singh, P.; Wani, A.A. Rice bran: Nutritional values and its emerging potential for development of functional food—A review. Bioact. Carbohydr. Diet. Fibre 2015, 6, 24–30. [Google Scholar] [CrossRef]

- Kumar, A.; Priyadarshinee, R.; Roy, A.; Dasgupta, D.; Mandal, T. Current techniques in rice mill effluent treatment: Emerging opportunities for waste reuse and waste-to-energy conversion. Chemosphere 2016, 164, 404–412. [Google Scholar] [CrossRef] [PubMed]